Sodium ion battery cathode material based on MXene and pseudocapacitance transition metal oxide nano composite structure, and synthetic method

A sodium-ion battery and transition metal technology, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of poor conductivity and low electrochemical active surface area, and achieve easy scale production, The effect of simple process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 The preparation method of the nanocomposite electrode material based on MXene and molybdenum oxide nanoparticles

[0033] 1) Dissolve 40mg MXene, 40mg dopamine, 150mg ammonium molybdate tetrahydrate in 30mL water, add 60mL absolute ethanol and 0.4mL ammonia water to prepare a suspension. The reaction temperature was 25°C. After stirring for 4 hours, the mixture was separated and washed to obtain a black powder.

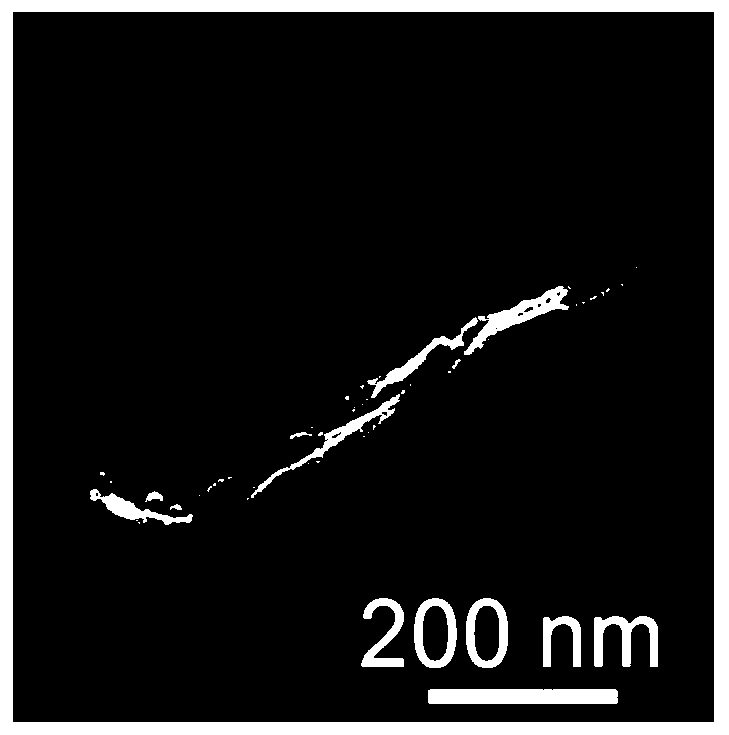

[0034] 2) The composite structure obtained in step 1) is calcined in argon, the calcining temperature is 550° C., and the calcining time is 3 h. The obtained product is a carbon-coated MXene two-dimensional nanosheet with an average size of about 250-400 nm and uniformly loaded molybdenum oxide nanoparticles on the surface, wherein the size of the molybdenum oxide nanoparticles is about several nanometers.

Embodiment 2

[0035] Embodiment 2 Preparation method of nanocomposite electrode material based on MXene and manganese oxide nanoparticles

[0036] 1) Dissolve 50mg of MXene, 70mg of dopamine, and 250mg of manganese sulfate tetrahydrate in 40mL of water, add 70mL of absolute ethanol and 0.6mL of ammonia water to prepare a suspension. The reaction temperature was 40°C. After stirring for 5 hours, the mixture was separated and washed to obtain a black powder.

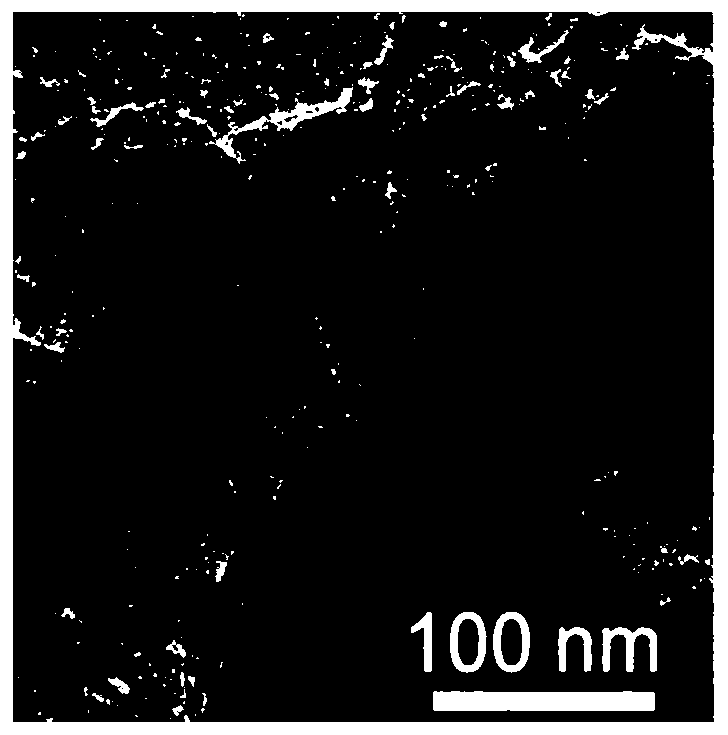

[0037] 2) Calcining the composite structure obtained in step 1) in nitrogen, the calcination temperature is 600° C., and the calcination time is 3 h. The obtained product is a carbon-coated MXene two-dimensional nanosheet with an average size of about 200-400 nm and uniformly loaded manganese oxide nanoparticles on the surface, wherein the size of the manganese oxide nanoparticles is about several nanometers.

Embodiment 3

[0038] Example 3 Preparation method of nanocomposite electrode material based on MXene and tungsten molybdenum oxide nanoparticles

[0039] 1) Dissolve 20mg MXene, 30mg dopamine, 90mg ammonium tungstate tetrahydrate and 50mg ammonium molybdate tetrahydrate in 20mL water, add 30mL absolute ethanol and 0.3mL ammonia water to prepare a suspension. The reaction temperature was 20°C. After stirring for 5 hours, the mixture was separated and washed to obtain a black powder.

[0040] 2) Calcining the composite structure obtained in step 1) in argon, the calcination temperature is 900° C., and the calcination time is 3 h. The obtained product is a carbon-coated MXene two-dimensional nanosheet with an average size of about 300-600nm and uniformly loaded tungsten-molybdenum oxide nanoparticles on the surface, wherein the size of the tungsten-molybdenum oxide nanoparticles is about several nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com