High-strength steel bar and production method thereof

A technology of high-strength steel bars and production methods, applied in heat treatment equipment, furnaces, manufacturing tools, etc., can solve the problems of increased steel consumption, resource and energy consumption, low strength, etc., to improve the ability to resist external disturbances and improve resistance to damage. , the effect of improving the ability to resist deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

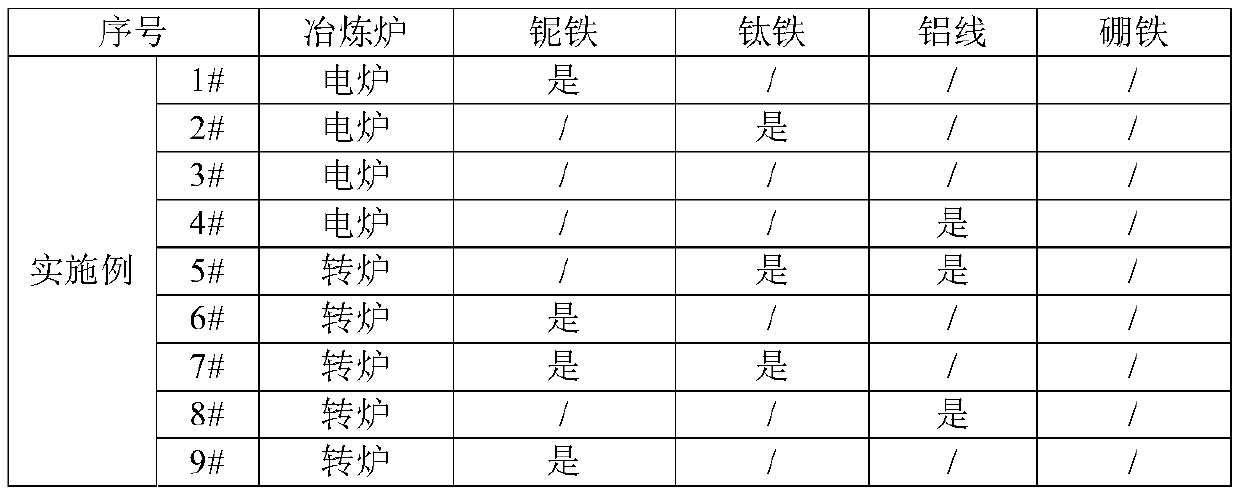

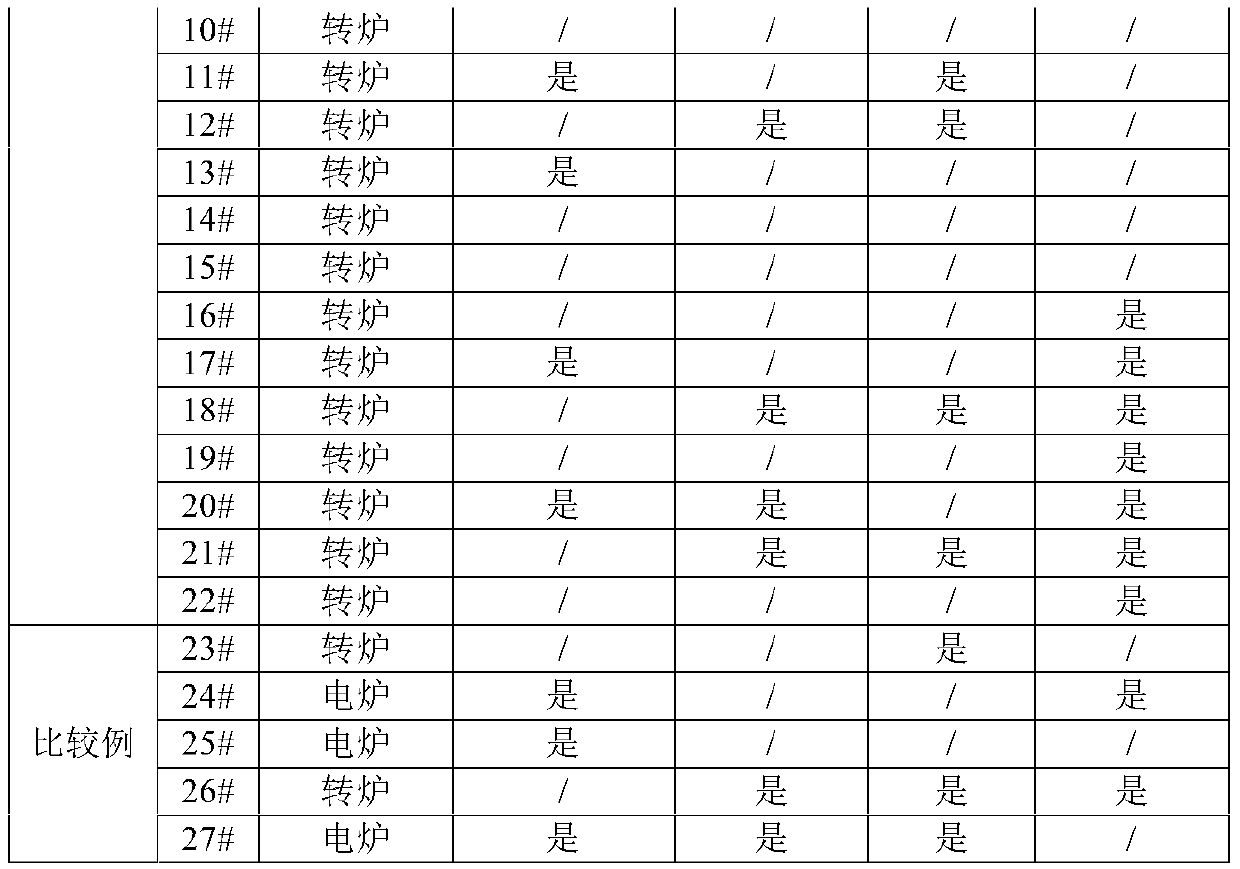

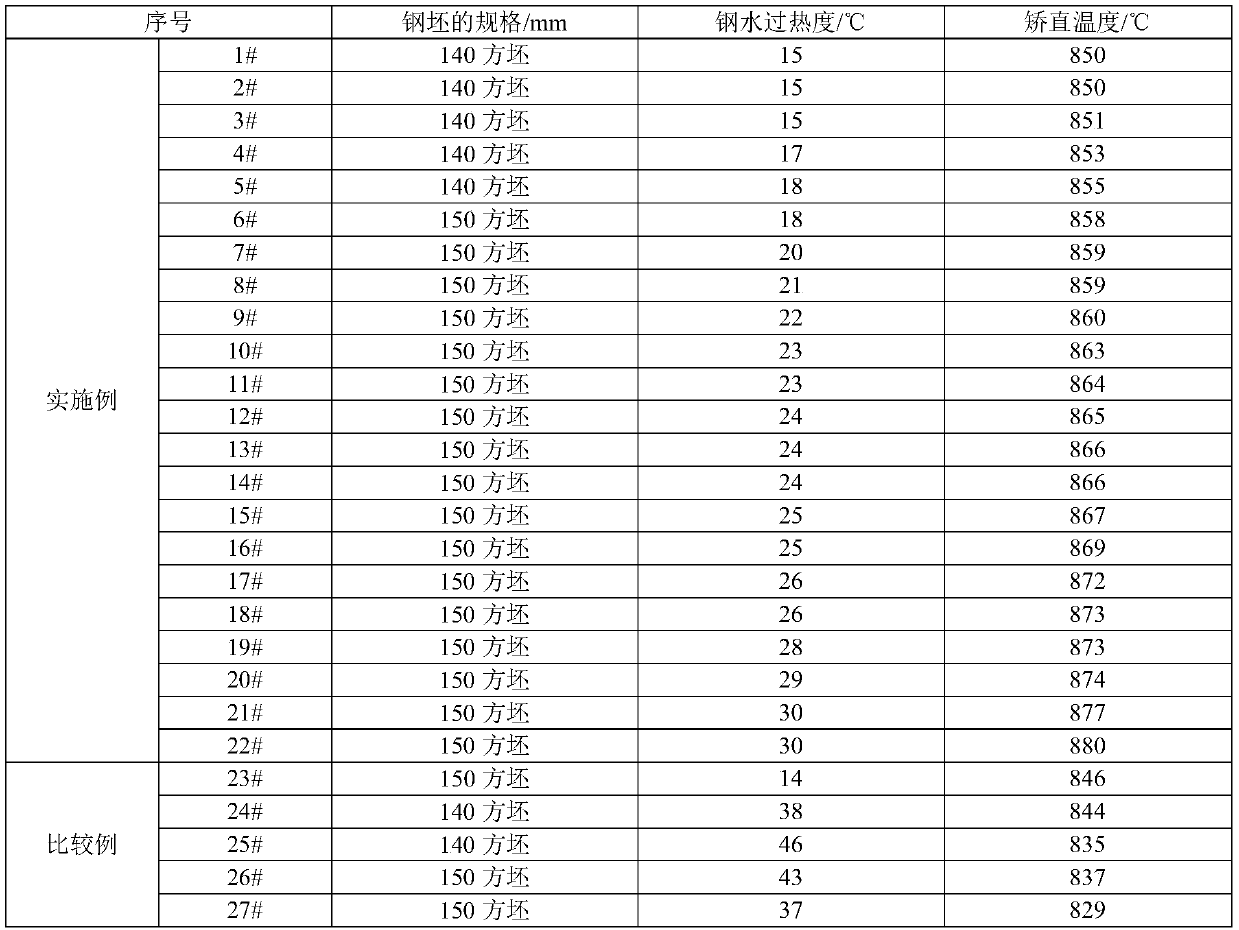

Examples

Embodiment Construction

[0027] As described in the background technology, there are problems such as obvious yield platform and low strength in low-grade steel bars (including common steel bars and even some anti-seismic steel bars), which do not meet the increasing safety level requirements, and the inventor provides based on this A high-strength steel bar with no obvious yield platform and good comprehensive strength performance and a production method thereof, based on its excellent performance, the high-strength steel bar can also be called a large deformation-resistant steel bar.

[0028] Specifically, in one embodiment of the present invention, the chemical composition of the high-strength steel bars includes: C: 0.15-0.32%, Si+Mn: 0.5-1.9%, Mn+Cr+Mo+Ni: 1.1-2.1% by mass percentage %, V:0.02-0.8%, at least one of Nb, Ti and Al: 0.01-0.3%, the balance is Fe and unavoidable impurities; wherein, Mn=(2.5-3.5)Si, carbon equivalent Ceq= C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15≤0.56%.

[0029] Based on a large ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com