Patents

Literature

209results about How to "Increased resistance to deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

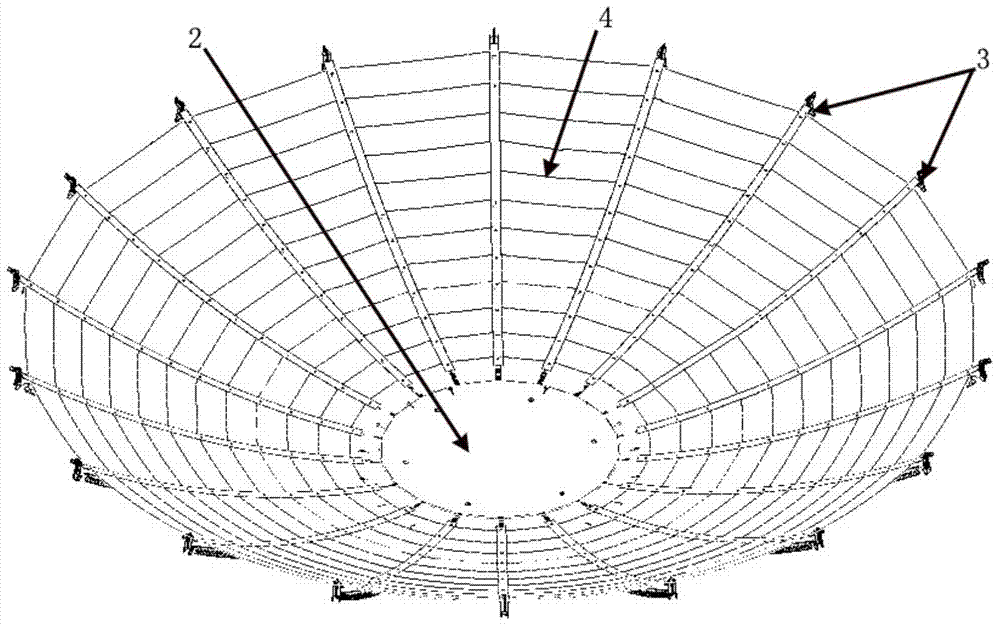

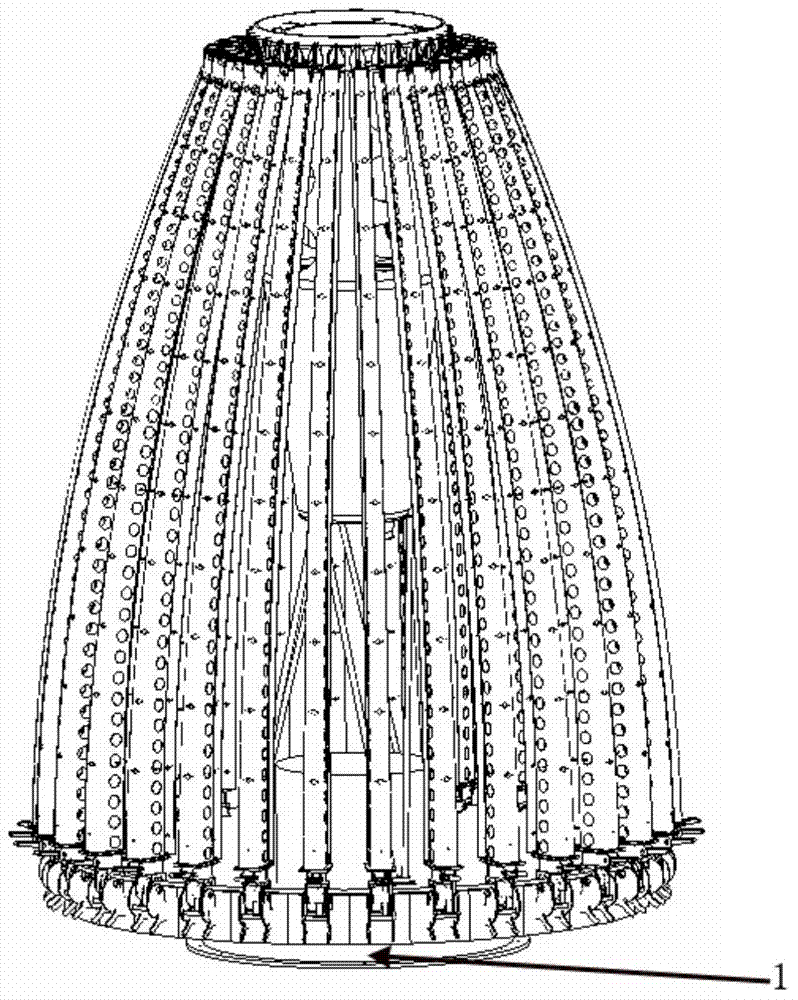

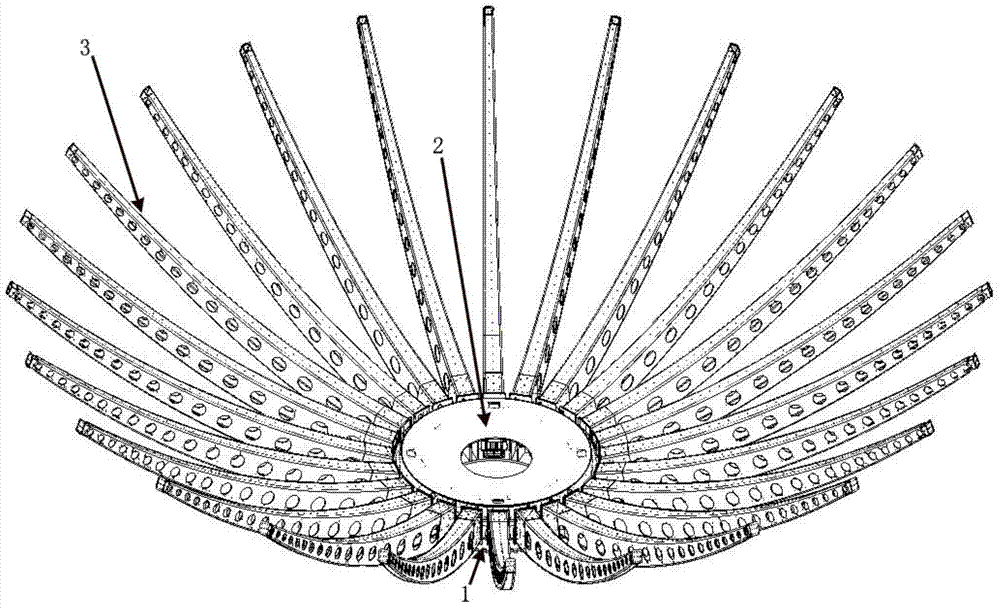

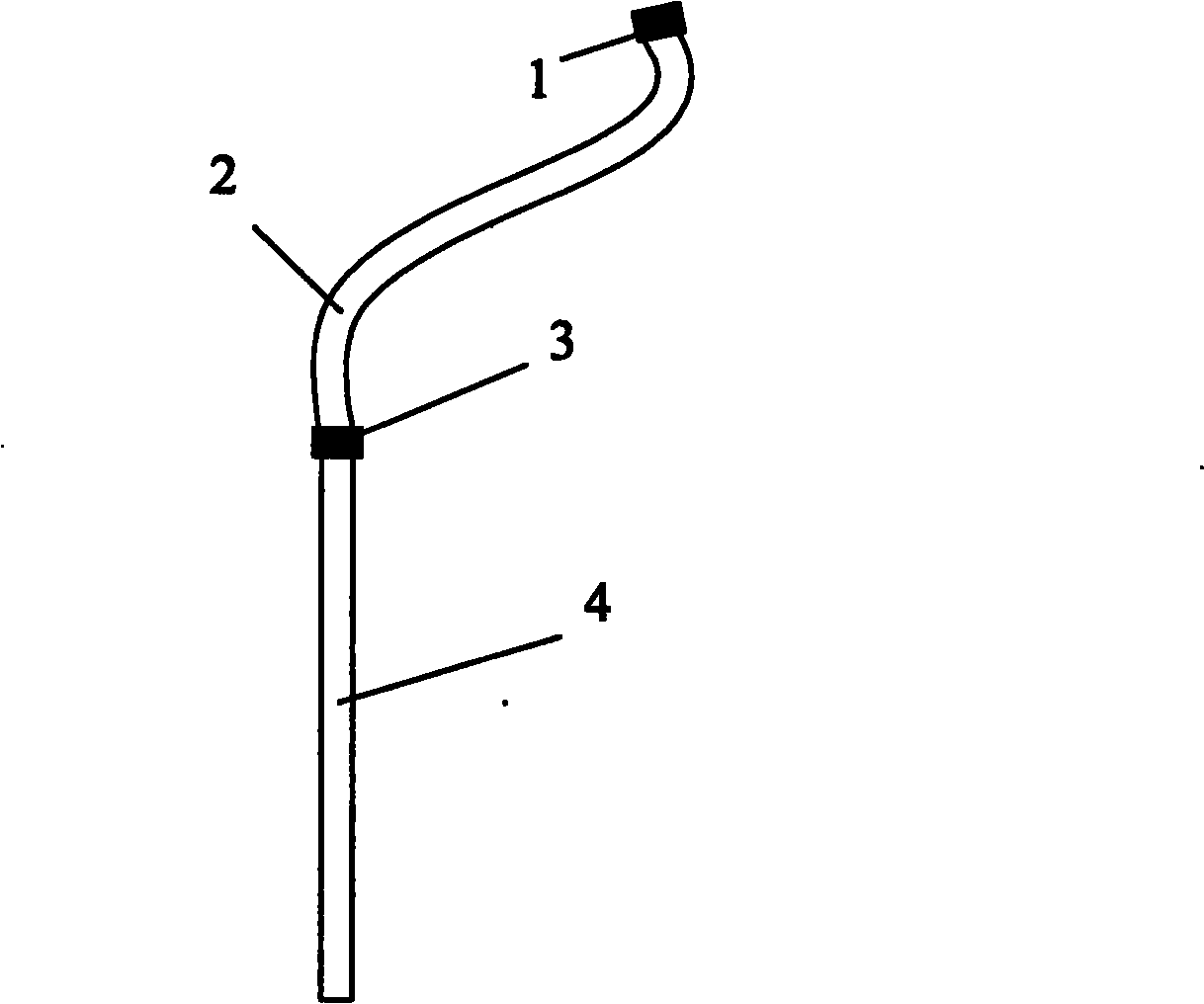

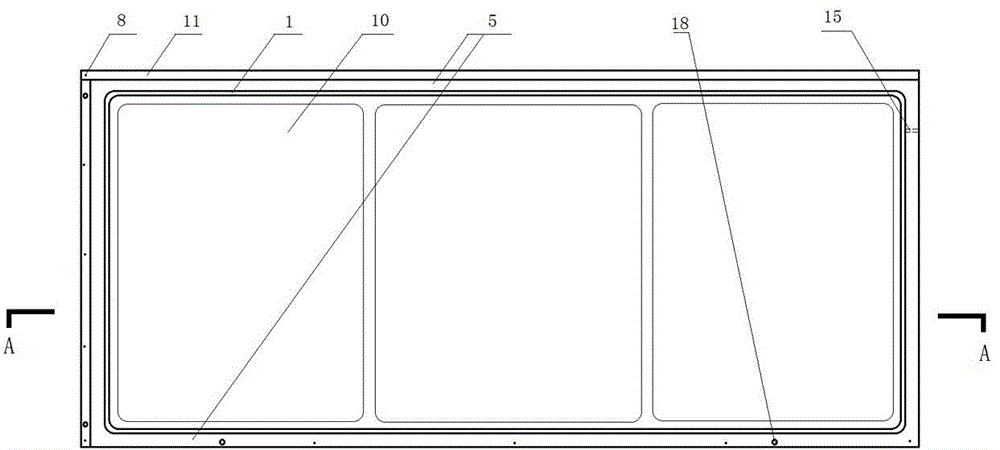

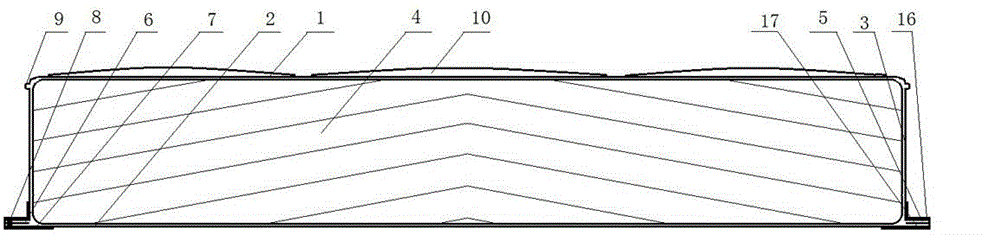

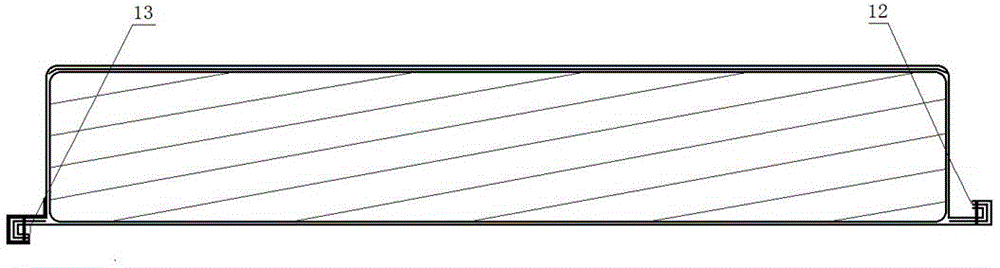

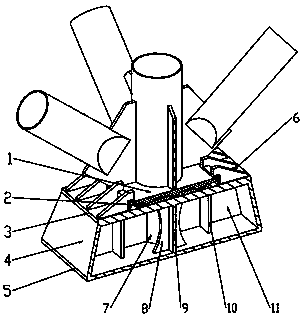

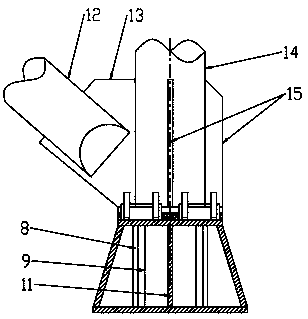

Umbrella-shaped antenna reflector

ActiveCN104269657ASuccessful implementationDoes not affect effective areaAntennasEngineeringMechanical engineering

The invention provides an umbrella-shaped antenna reflector which comprises a base, a fixing face part, a foldable part, a mesh face part and a driving assembly. The fixing face part is a fixing face reflector body. The foldable part comprises a plurality of unfolding ribs. The mesh face part comprises a front tension mesh and a rear tension mesh. The driving assembly comprises a motor and a power rope. The fixing face part is fixedly connected with the base. The foldable part is connected with the base in a hinged mode. The mesh face is arranged on the foldable part. The umbrella-shaped antenna reflector can be unfolded smoothly through the driving assembly. The umbrella-shaped antenna reflector is provided with a large diameter and high in accuracy, has the advantages of being high in molded surface accuracy, high in molded surface keeping capacity, high in stability and high in reflection efficiency and can be applied to the outer space, and the unfolding ribs are large in rigidity.

Owner:SHANGHAI YS INFORMATION TECH

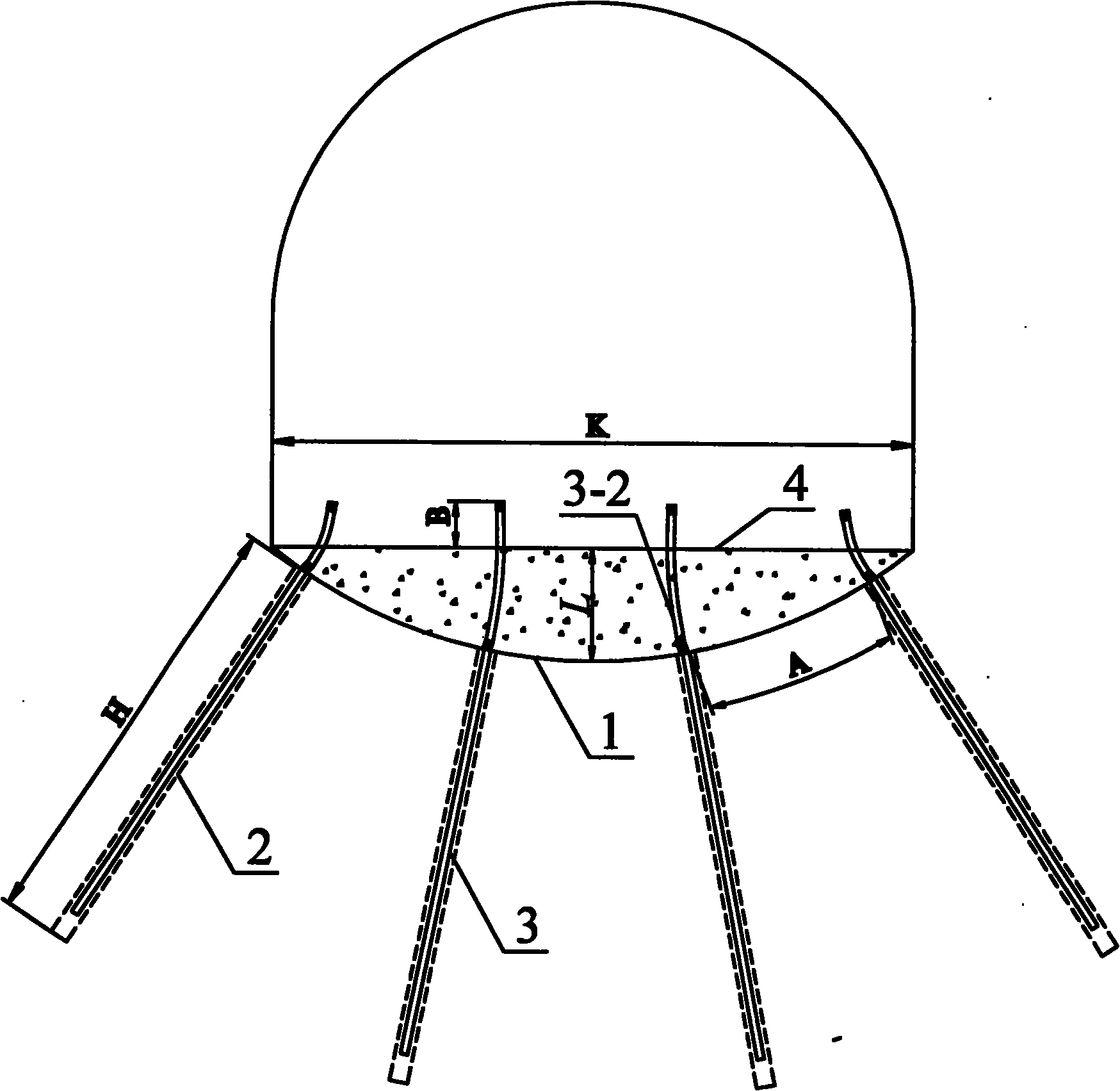

Method for reinforcing roadway floor by grouting

ActiveCN101839140ALarge carrying rangeIncreased resistance to deformationUnderground chambersTunnel liningCoalDrill hole

The invention discloses a method for reinforcing a roadway floor by grouting in the way that the roadway floor is buried before the grouting, which is suitable for supporting projects of roadways in coal mines. The method comprises the following steps of: excavating the roadway floor during the excavation of a roadway to form a reverse arch; constructing a plurality of grouting drill holes at equal intervals along the section of the reverse arch perpendicular to the camber lines of the reverse arch respectively; arranging a special grouting tube with a hose for the floor in the grouting drill hole; filling the bottom of the arch with crushed waste rocks or cement and ensuring that the outer end head of the grouting hose is exposed from the plane of the floor; after the excavated working surface moves forwards for a certain distance, guniting and sealing the floor; and performing grouting operation on each pre-buried grouting tube through the grouting hose by connecting the exposed grouting hose with a grouting pump. The method not only avoids the reverse arch during secondary excavation of the floor, but also solves the problem that the grouting construction is interactional with the construction of the excavation working surface; the pre-buried grouting tube is easy to protect and the exposed part of the grouting tube after the grouting is easy to process; and the method can obviously improve the grouting depth, increase the bearing range for the loose and crushed rock stratum of the floor and improve the deformation resistance capacity of the floor .

Owner:CHINA UNIV OF MINING & TECH

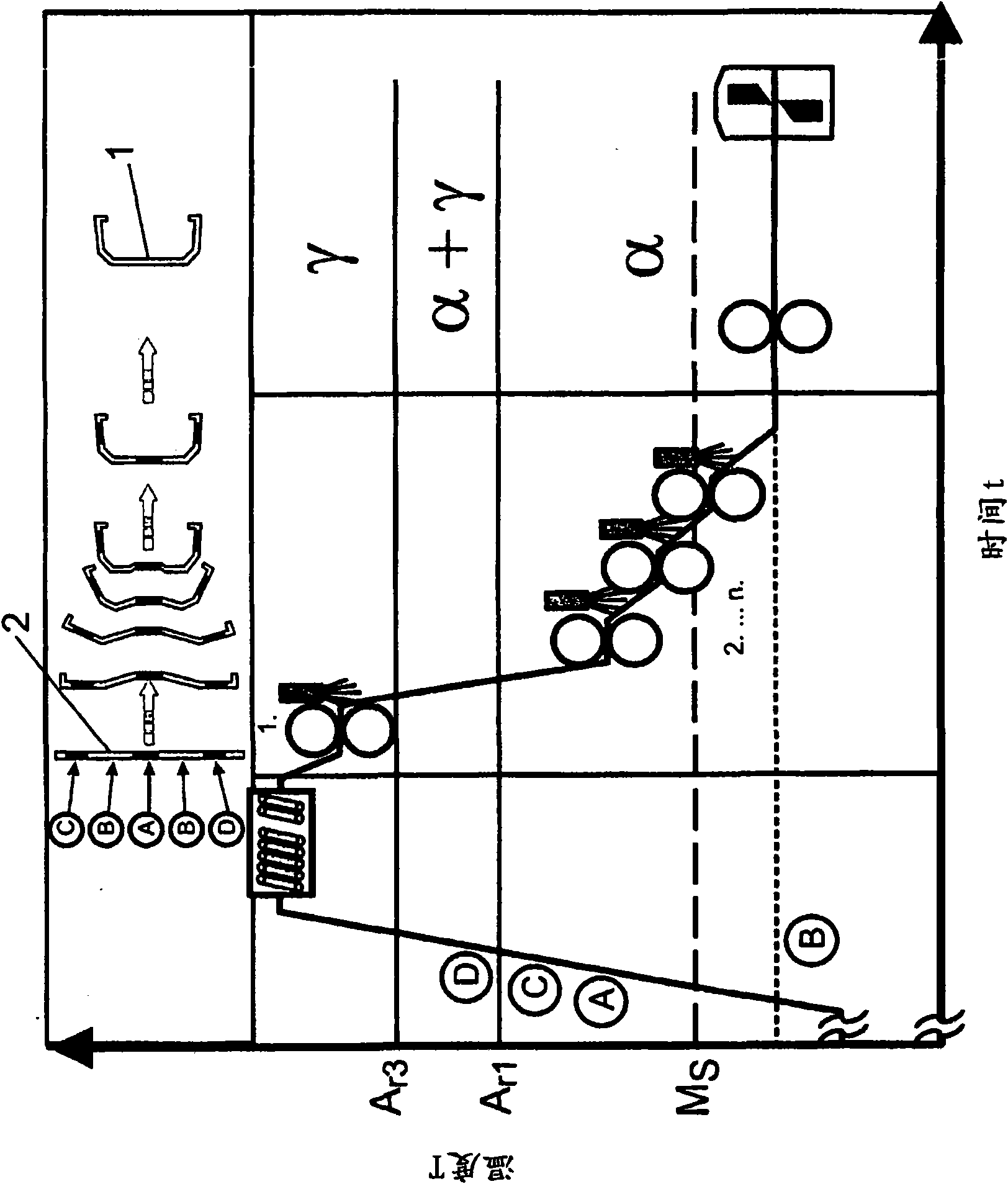

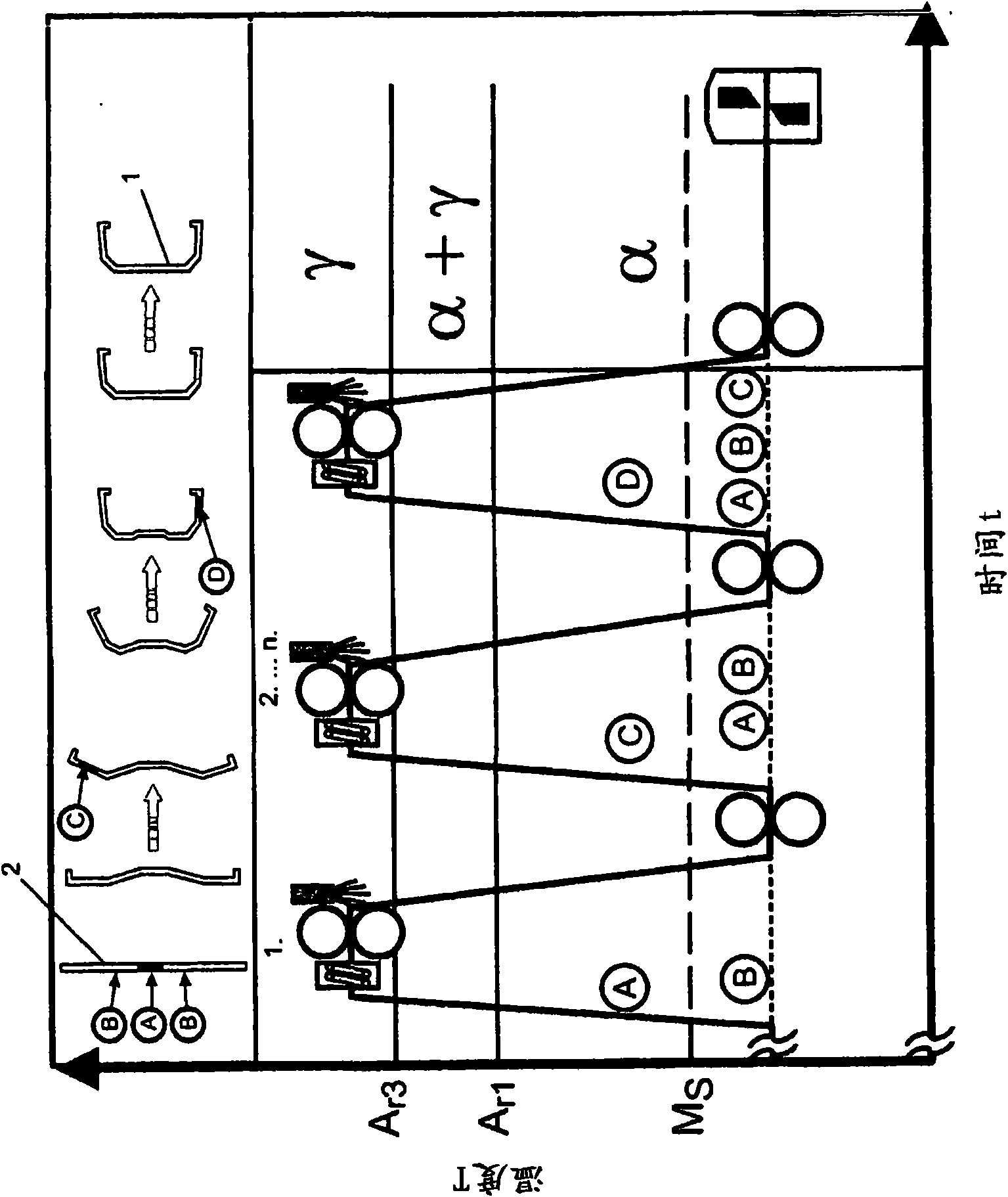

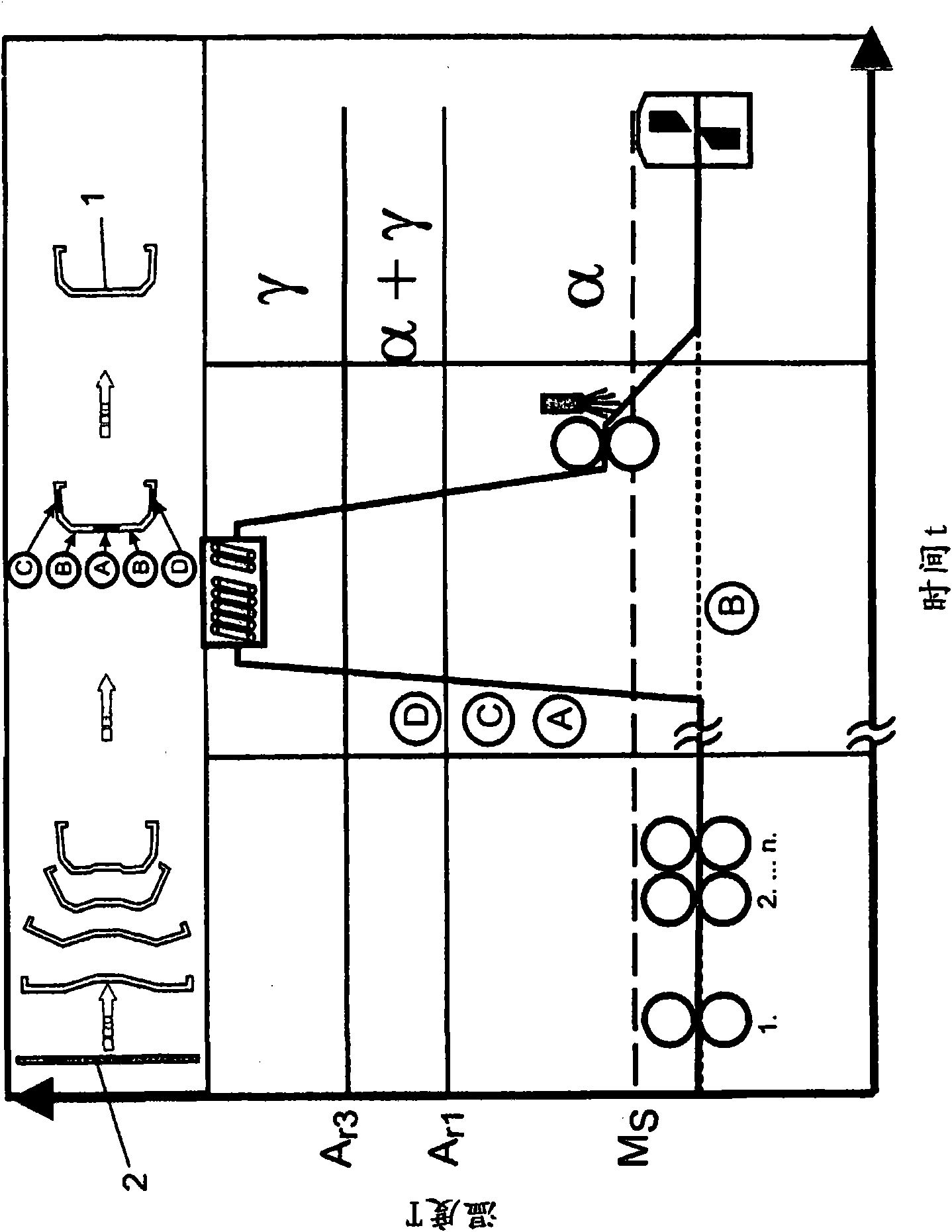

Process for producing a locally hardened profile component, locally hardened profile component and use of a locally hardened profile component

ActiveCN101688264ARealize heat dissipationImprove functional propertiesFurnace typesVehicle componentsMetallurgyWork in process

The present invention relates to a process for producing a profile component (i) which at least in sections has a structurally increased strength from a semifinished sheet metal part (2), in which thesemi-finished sheet metal part (2) is formed in an at least one-stage bending process and the bending process and also subsequent parting and cutting operations on the semifinished sheet metal part (2) are combined with a thermal treatment of at least one geometrically delineated region (A, C, D) of the semifinished sheet metal part (2), which comprises at least one heating step and a subsequentcooling step, in such a way that the at least one geometrically delineated region (A, C, D) has a structurally increased strength after cooling. Bending can be effected by means of roller profiling orswage bending. The rollers are preferably cooled.

Owner:乌尔里希·朔夫

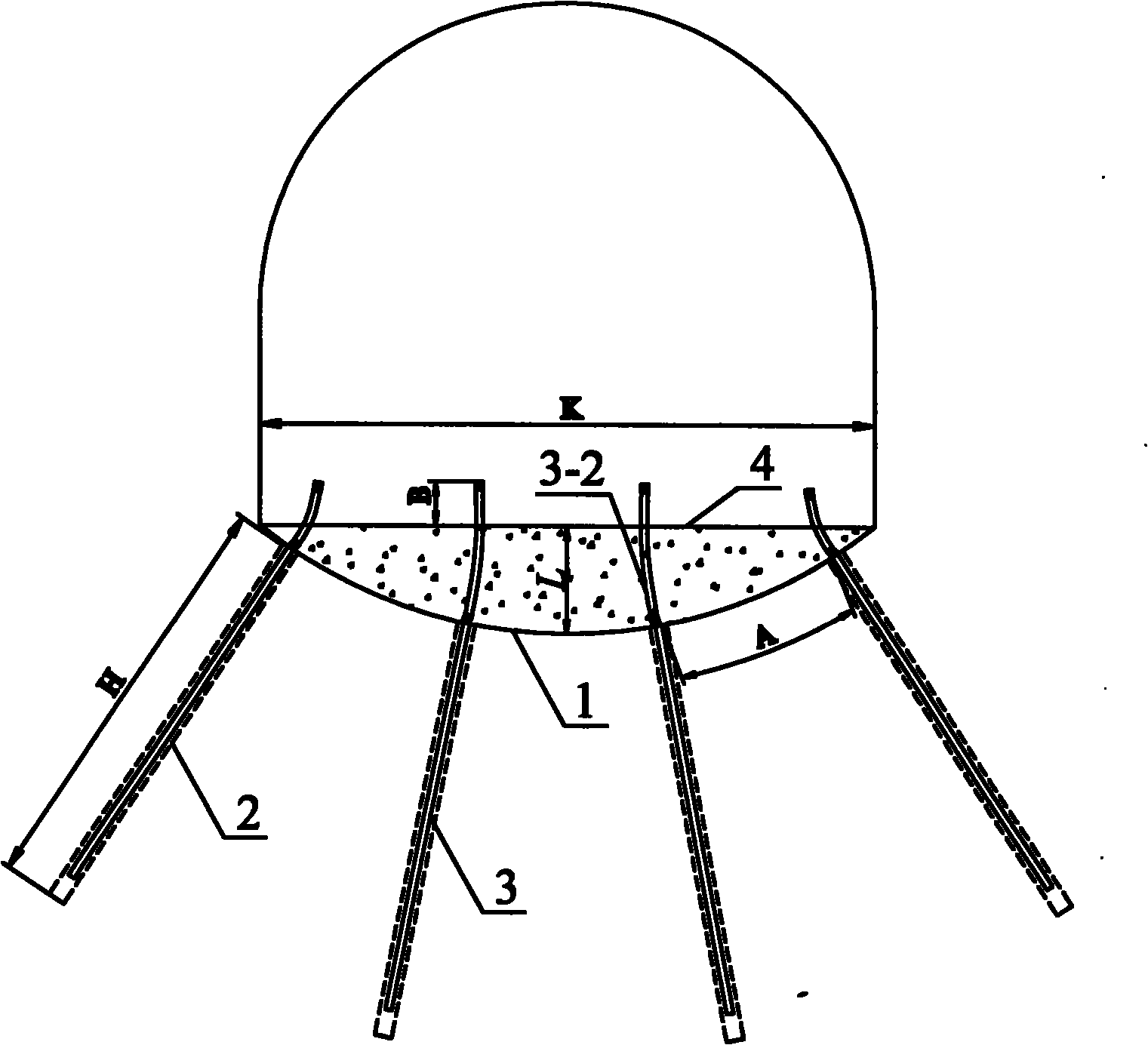

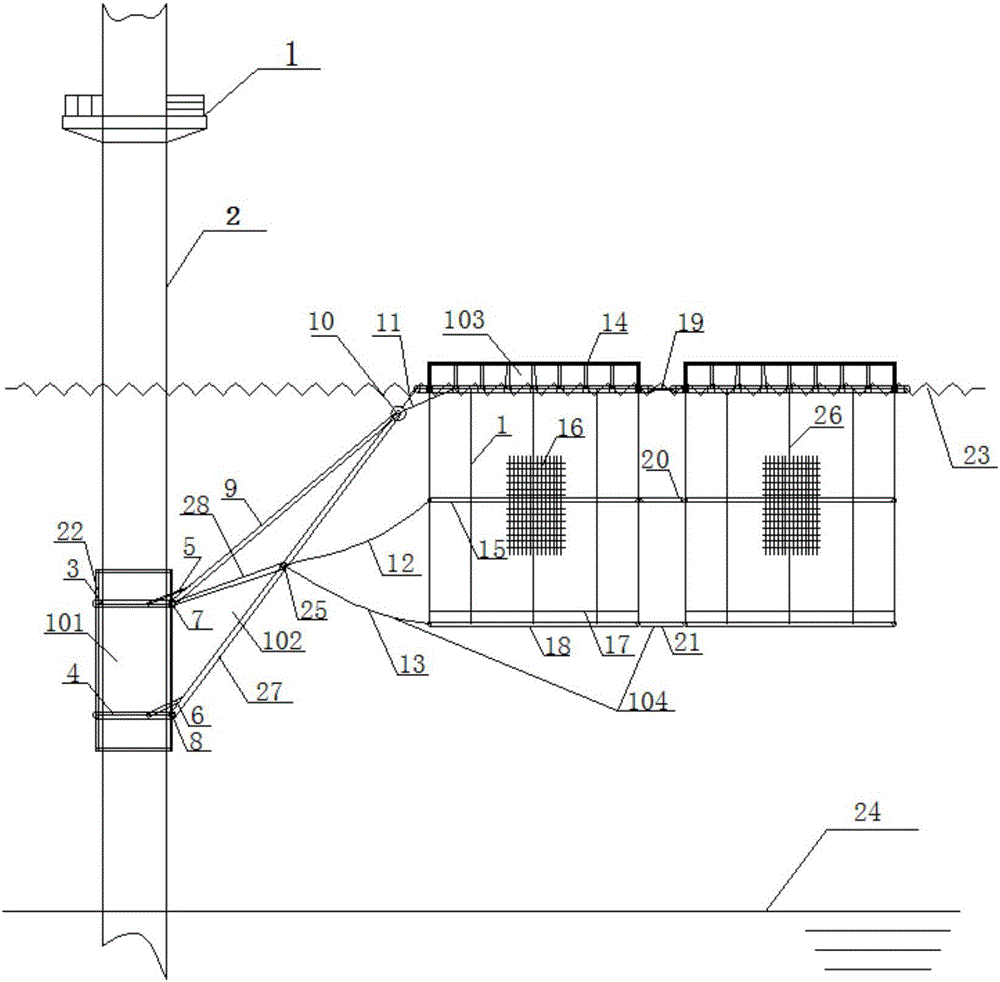

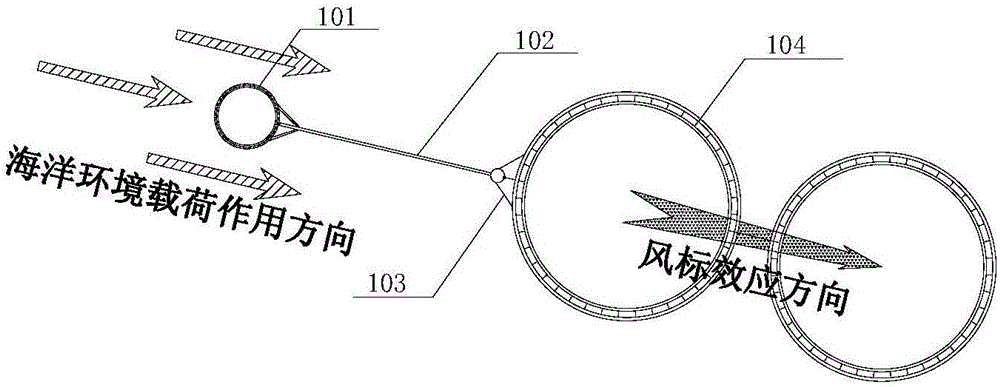

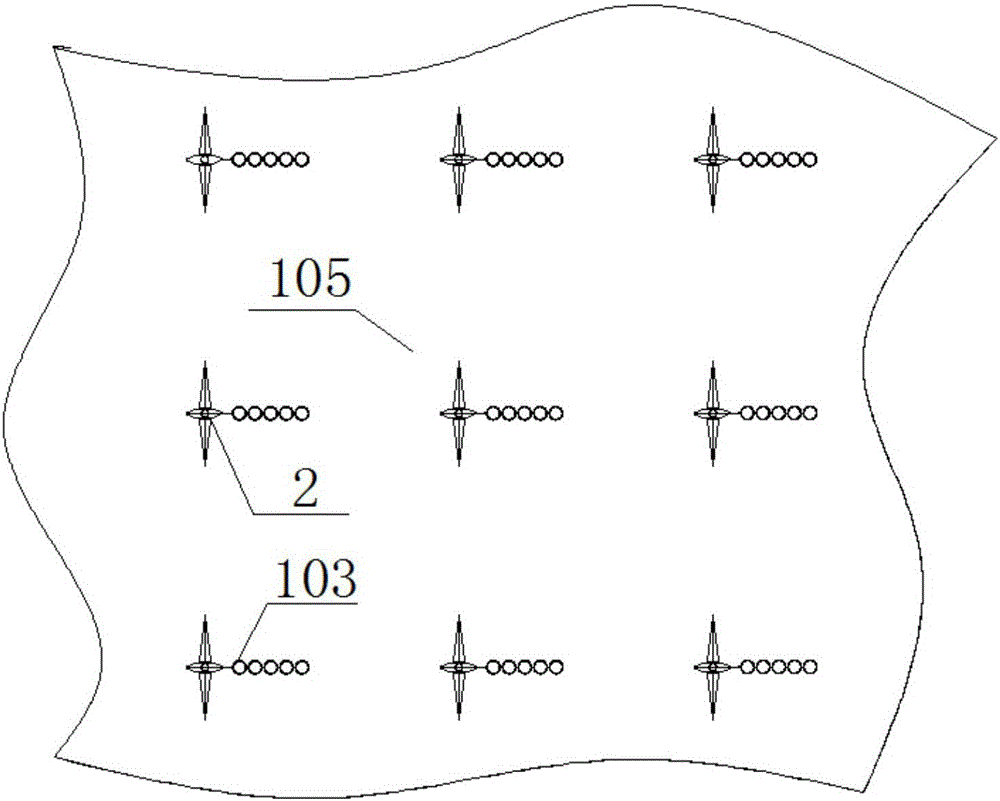

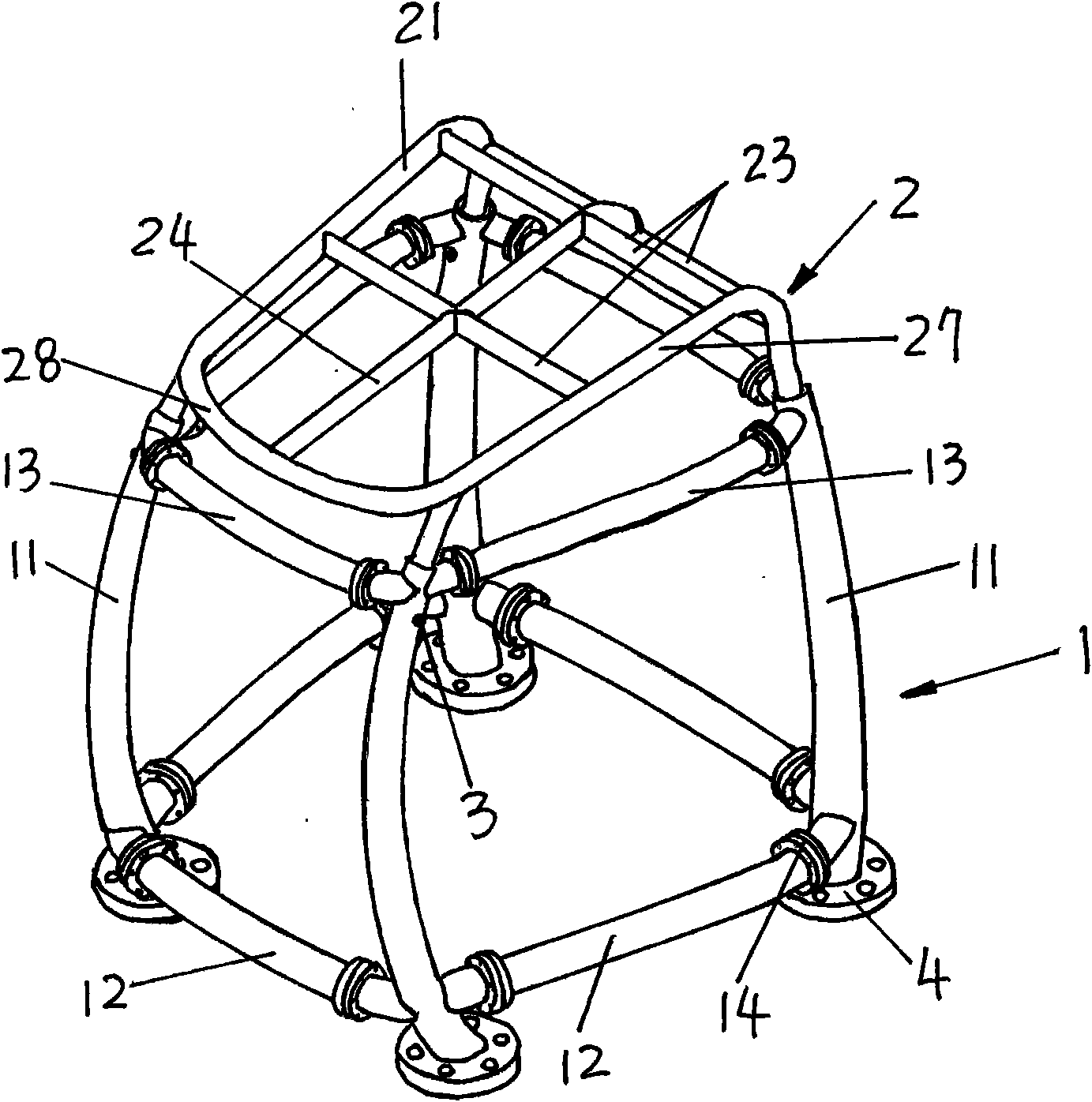

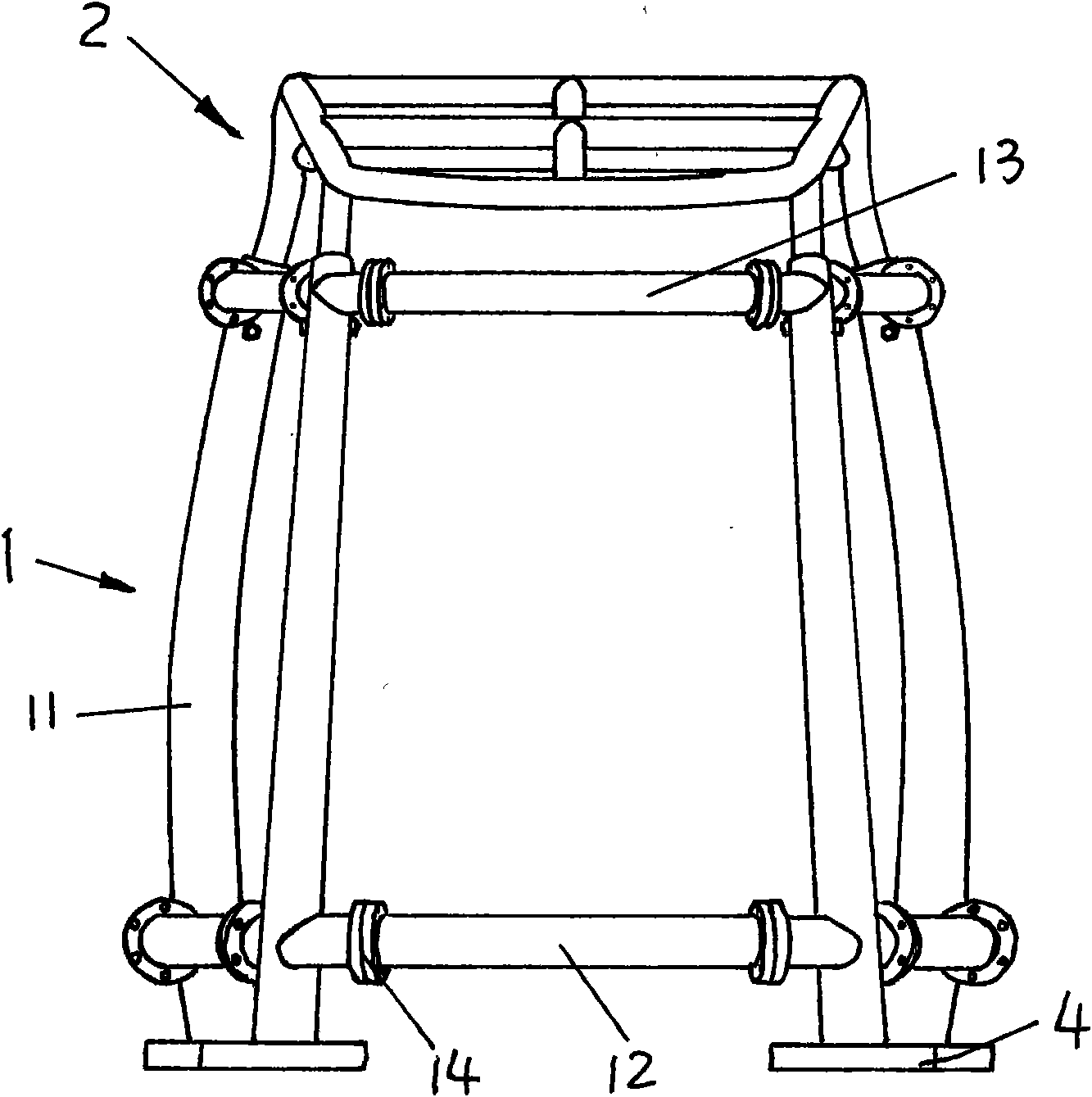

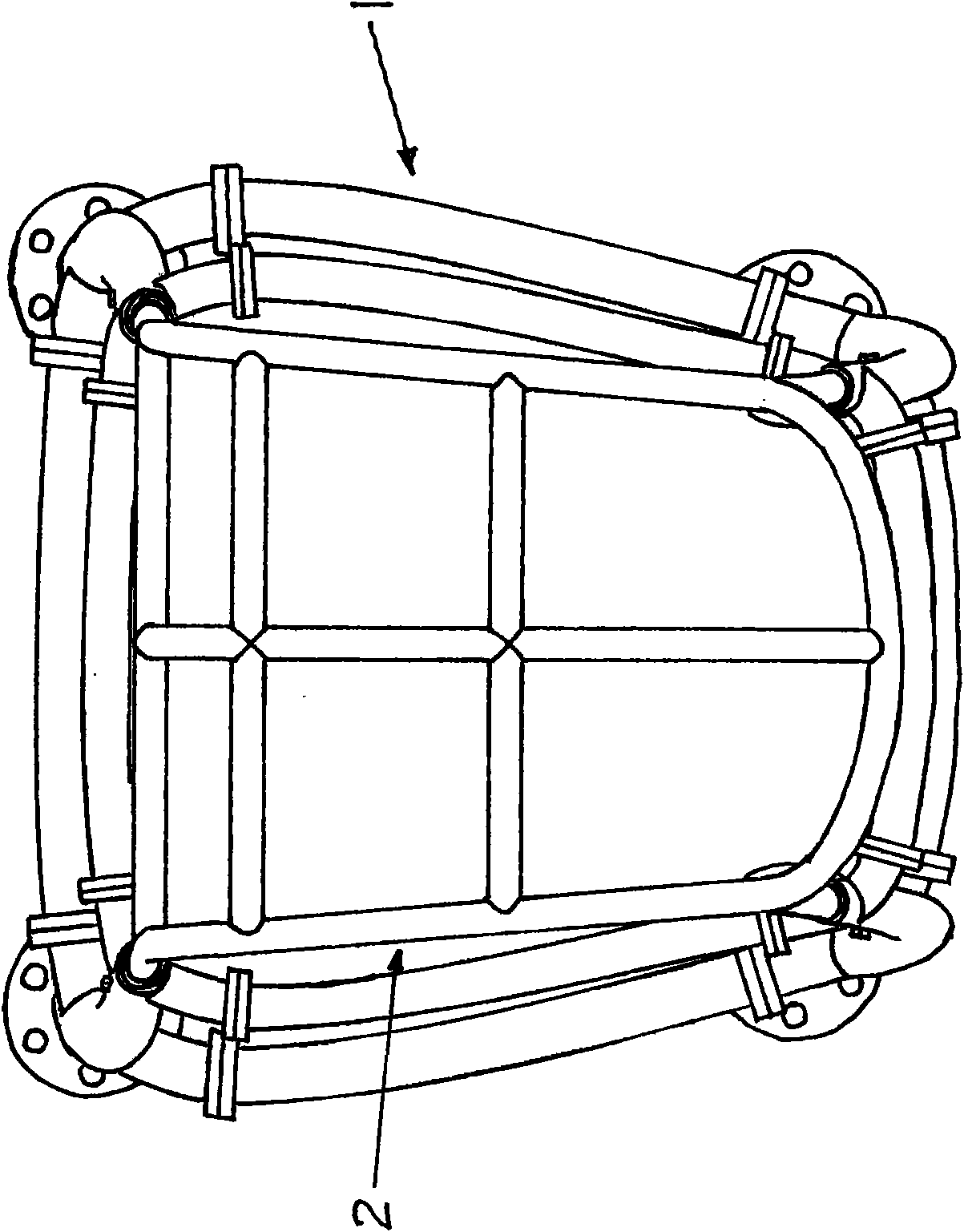

Deep sea net box cultivating apparatus for offshore wind field

ActiveCN105104271AReduces the effects of oxidation and corrosionIncrease stiffnessClimate change adaptationAgricultural fishingWind forceElectric energy

The invention discloses a deep sea net box cultivating apparatus for offshore wind field, which comprises an offshore wind turbine foundation, wherein an operation platform is mounted on the top portion of the offshore wind turbine foundation; a rotary sleeve ring fixing system is mounted on a lower end of the offshore wind turbine foundation; the rotary sleeve ring fixing system is connected to a rotary arm mechanism; the rotary arm mechanism is connected to an offshore net box module through a cable connecting rod component; the rotary sleeve ring fixing system comprises a reinforced cylinder sleeve; an upper rotary sleeve ring and a lower rotary sleeve ring are respectively mounted on an upper end and a lower end of the reinforced cylinder sleeve; and the upper rotary sleeve ring and the lower rotary sleeve ring are respectively connected to the rotary arm mechanism through an upper connecting buckle and a lower connecting buckle. According to the utility model, by adopting the apparatus provided herein, the offshore wind field can be applied with various purposes; organic combination between the offshore wind power generation and the offshore net box cultivation is realized; the space of the offshore wind field and the offshore wind power are fully utilized, thus improving the overall economy benefits.

Owner:佛山市榕岸海洋工程装备有限公司

Method for preparing single-crystal high-temperature alloy from seed crystal subjected to solid-solution treatment

ActiveCN108624959AOvercome the need to set up a spiral crystal selector to suppress the formation of miscellaneous crystals below the remelting interface inside the seed crystalOvercoming the problem of stray crystal formation below the remelt interfacePolycrystalline material growthFrom frozen solutionsSolution treatmentSingle crystal superalloy

The invention discloses a method for preparing single-crystal high-temperature alloy from seed crystal subjected to solid-solution treatment. The method is characterized in that the original structurestate of seed crystal is converted into a uniform structure from a thick seed crystal structure through a solid-solution thermal treatment way, so that a structure on the upper part of a mushy zone under a melting-back interface forms a complex network shaped structure in a seed crystal single-crystal preparation process; un-melted solid phases are connected with each other to improve ability ofresisting deformation, so that flow speed when melt is poured to the upper end of the seed crystal does not need to limit, and therefore, the purpose of removing a spiral crystal selector structure ina mould shell is achieved. In a process of preparing the single-crystal high-temperature alloy, the seed crystal re-melting region is completely inhibited to form mixed crystal, so that the structureof the corresponding mould shell is simplified, mechanical degree and assembly precision of shell making are improved, and cost is reduced, and therefore, the defect of using a spiral crystal selecting section in the mould shell in a process of producing single-crystal high-temperature alloy by repeatedly using seed crystal is avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

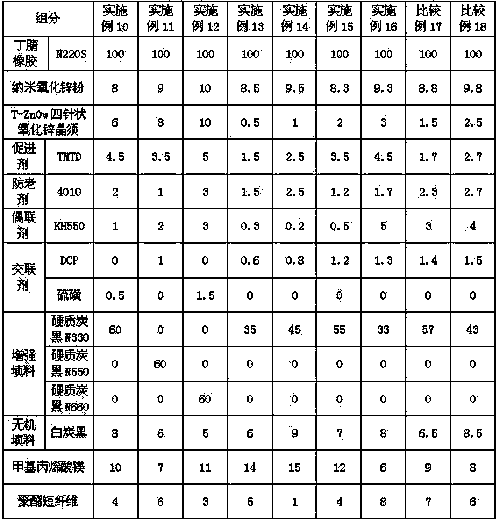

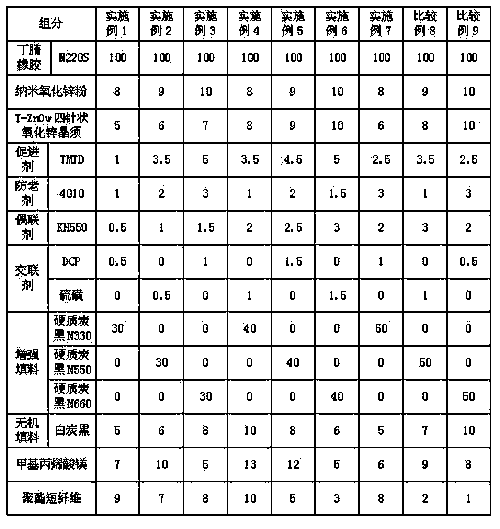

Nitrile rubber composite capable of improving mechanical property

The invention discloses a nitrile rubber composite capable of improving mechanical property. With the adoption of the composite, the nitrile rubber composite with better mechanical property can be obtained, and can be used for a blowout preventer rubber seal product. The composite adopts the technical scheme that the composite takes nitrile rubber as a main material. The composite adopts a T-ZnOw tetrapod-like zinc oxide whisker and utilizes high strength and high modulus of a complete structure of the composite to improve a high molecule; a three-dimensional crystal form structure of the composite is dispersed in a matrix, so that a skeleton effect is exerted; a unique three-dimensional space structure allows a gripping force between the composite and the matrix to be greater, so that an improvement effect is more significant, and the tensile strength is improved significantly; and transverse and longitudinal tensile strength values are basically same, so that the mechanical property of a matrix material is improved isotropically, and the strength and the processability of the matrix are improved significantly.

Owner:HEBEI BOLU TIANBAO PETROLEUM EQUIP MFG CO LTD

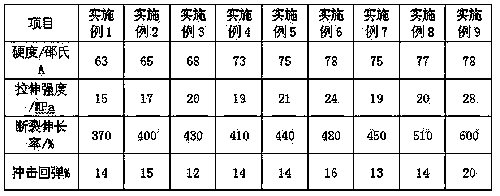

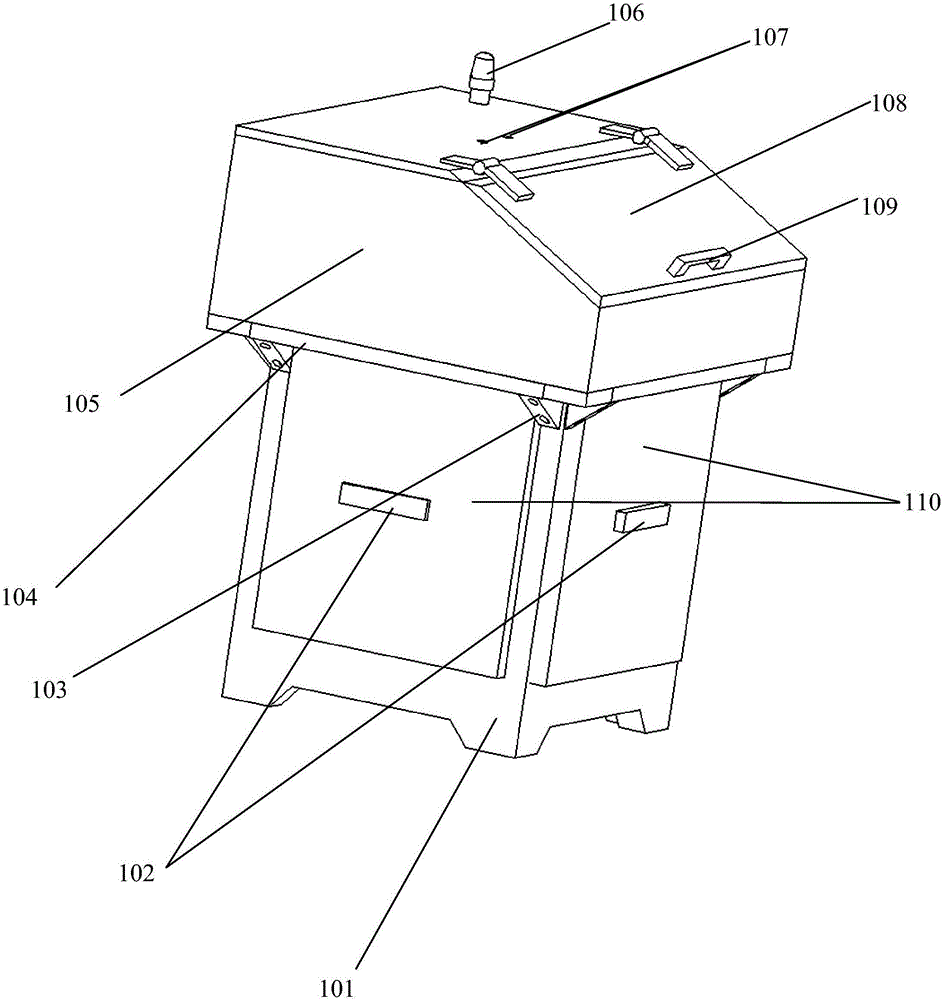

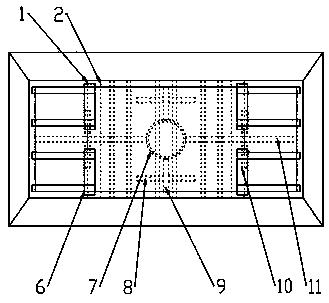

Sealed multi-material special engineering plastic additive manufacturing method and apparatus

ActiveCN106553337AImprove support strengthIncreased resistance to deformationManufacturing heating elementsManufacturing material handlingSelective laser sinteringManufacturing technology

The invention relates to sealed multi-material special engineering plastic additive manufacturing method and apparatus and belongs to the technical field of additive manufacturing of special engineering plastic. A three-axis movement platform assembly is installed inside a thermal insulation chamber assembly. A special engineering plastic filament delivery roll assembly is installed in a back surface plate of the thermal insulation chamber assembly. A spray nozzle assembly is disposed on the top of interior of the thermal insulation chamber assembly. The method and the apparatus achieve low temperature difference and low deformation in 3D printing of special engineering plastic, so that parts in complex structures, which have high crystalline degree, high mechanical strength and low surface roughness, can be formed from a high-melt-point special engineering plastic. Defects of large deformation, poor mechanical strength of a moulded part, and low size precision in a conventional high-temperature special engineering material printing process are overcome, and a defect of warping deformation during a powder moulding process in a selective laser sintering 3D printing technology is avoid. The method and the apparatus solve the problems such as high surface roughness in artificial bone 3D printing in the medical field, and have excellent medical and industrial application prospect.

Owner:JILIN UNIV

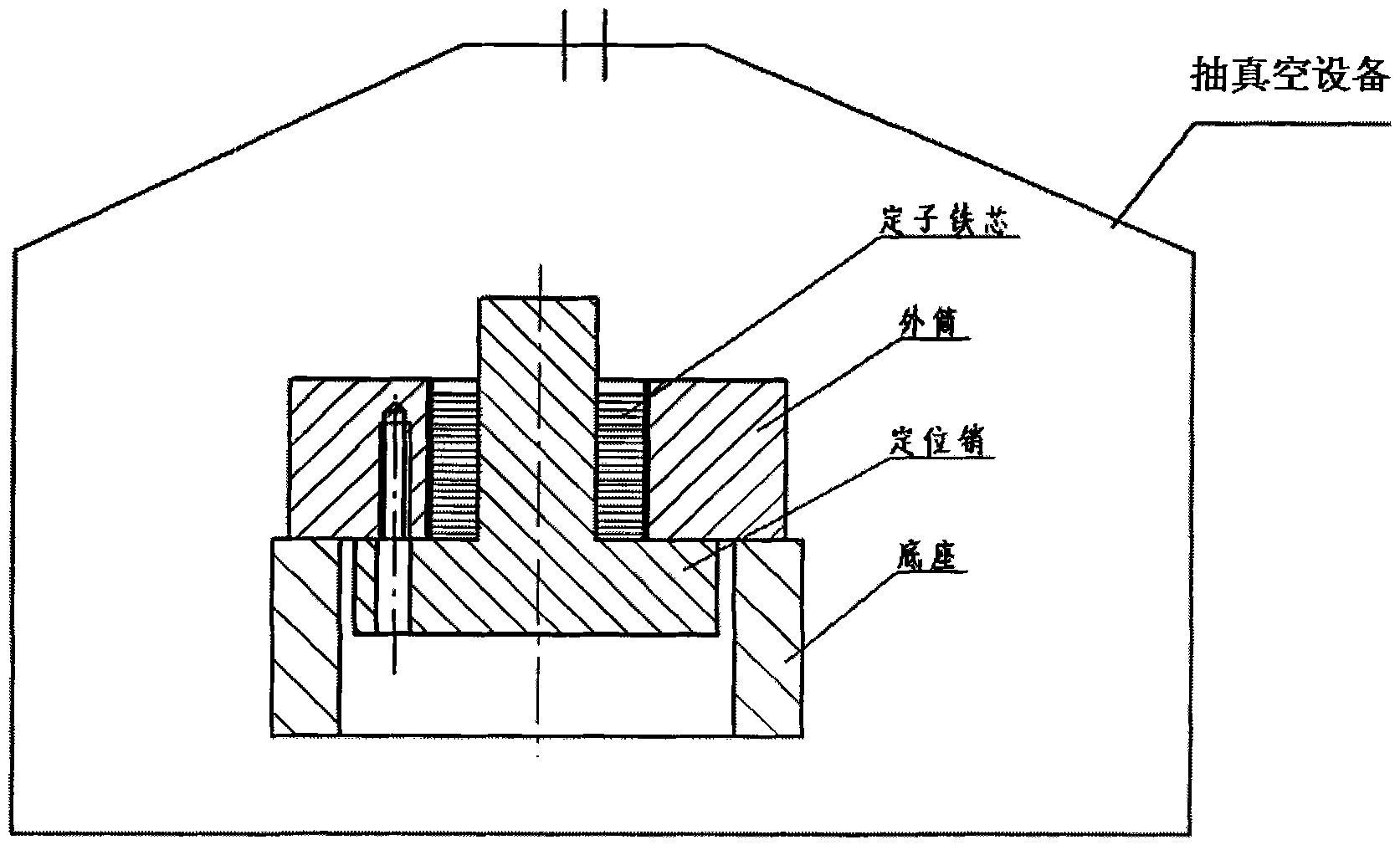

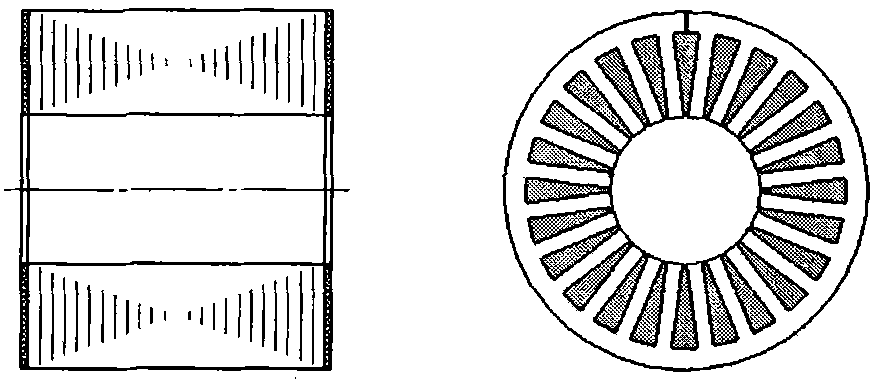

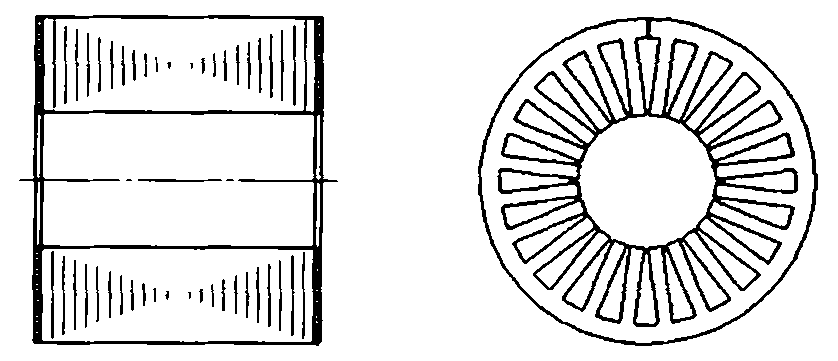

Adhesive filling and grinding processing method for stator-rotor iron core component of motor

InactiveCN101895176ASolve the problem of inner and outer conicityIncreased resistance to deformationManufacturing stator/rotor bodiesAdhesiveRoom temperature

The invention discloses an adhesive filling and grinding method for a stator-rotor iron core component of a motor. The method comprises the processes of gluing the iron core component through lamination, grinding an iron core by a benchwork, filling an adhesive, removing adhesive layers on two end faces by the benchwork, grinding an inner hole and an excircle of the iron core by a grinder, removing a potting adhesive and the like. The method is characterized in that: when the adhesive is filled, the potting adhesive is placed into a container, stirred and heated to a temperature of between 120 and 130 DEG C; the potting adhesive is poured into an pre-heated iron core groove immediately; a die is vacuumized in a vacuum chamber, so that bubbles are removed from the die, wherein the vacuum degree is 10 to 300Pa and the time is 5 to 20 minutes; and the die is taken out and cooled at the room temperature, so that the potting adhesive is solidified. Compared with the prior art, a profiled groove part of the stator-rotor iron core component forms an entity through the adhesive filling process so that deformation resistance of the stator-rotor iron core component is enhanced and interrupted cut is avoided; and at the same time, the grinding process solves the problems of crack, swelling, poor coaxiality and the like caused by internal and external conicity of the stator-rotor iron core component and temperature distortion of the adhesive layers of the iron core component.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

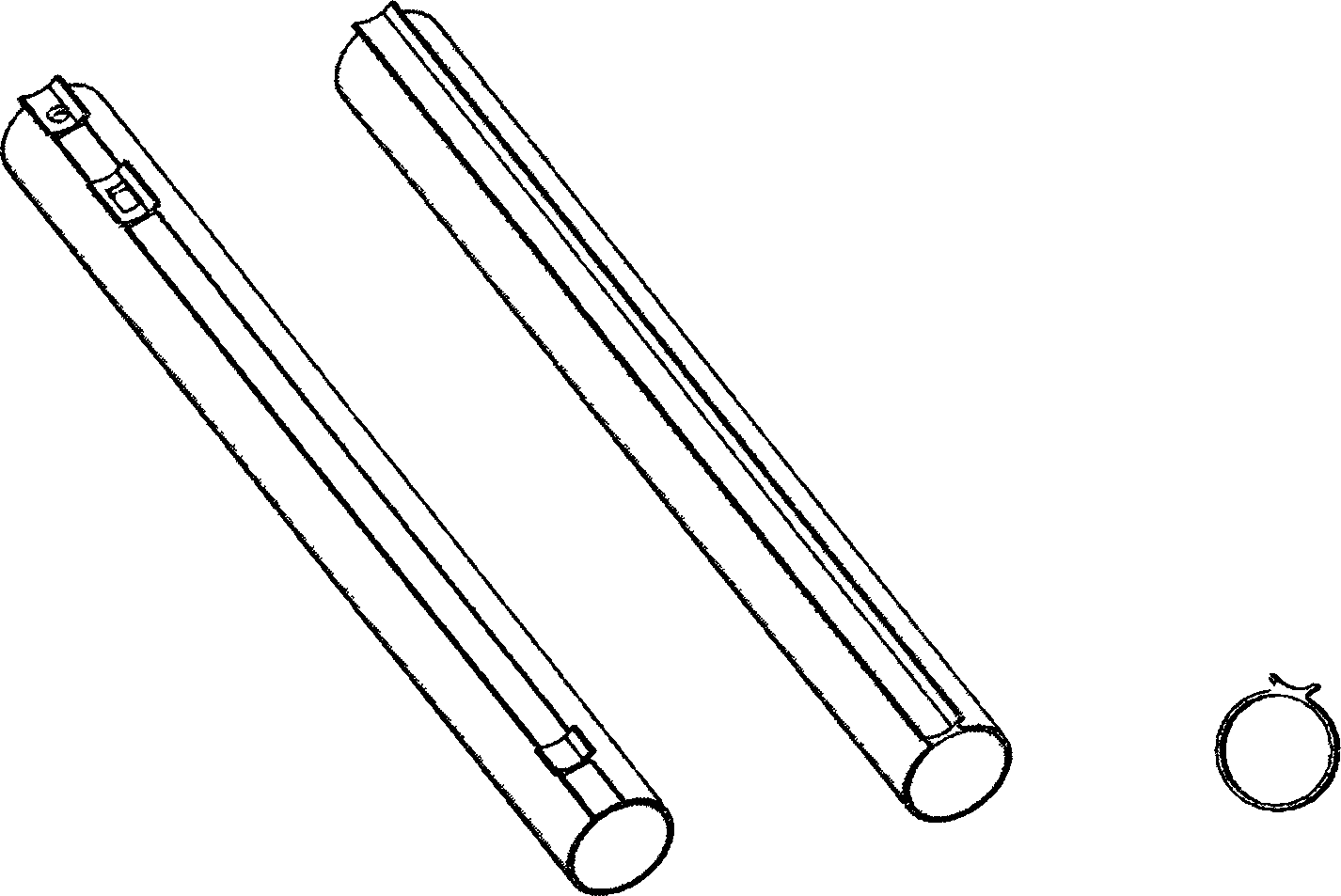

Quick clamp for milling thin-walled tube type workpiece

InactiveCN104043977AIncrease stiffnessAvoid vibrationPositioning apparatusMetal-working holdersThin walledEvaporator

The invention provides a quick clamp for milling a thin-walled tube type workpiece by using a method for combining a core shaft, a piston ring and an O-shaped rubber sealing ring and aims to solve the problem that a thin-walled aluminum tube commonly used for manufacturing an air-conditioning evaporator and a condenser is greatly deformed often during milling. When a fixture clamps the machined thin-walled aluminum tube, the O-shaped rubber sealing ring is deformed to a certain extent and is tightly pressed against the inner wall of the thin-walled aluminum tube, so that the rigidity of the thin-walled aluminum tube is improved, the deformation resisting capacity is improved, and the thin-walled tube type workpiece is prevented from being vibrated and deformed when being milled.

Owner:天津硕智机电贸易有限公司 +1

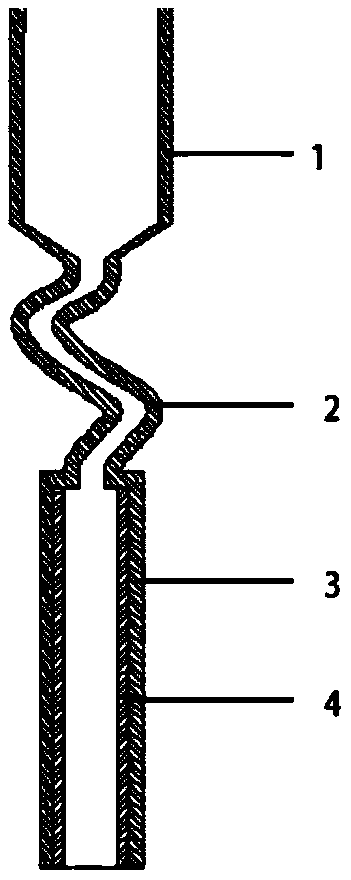

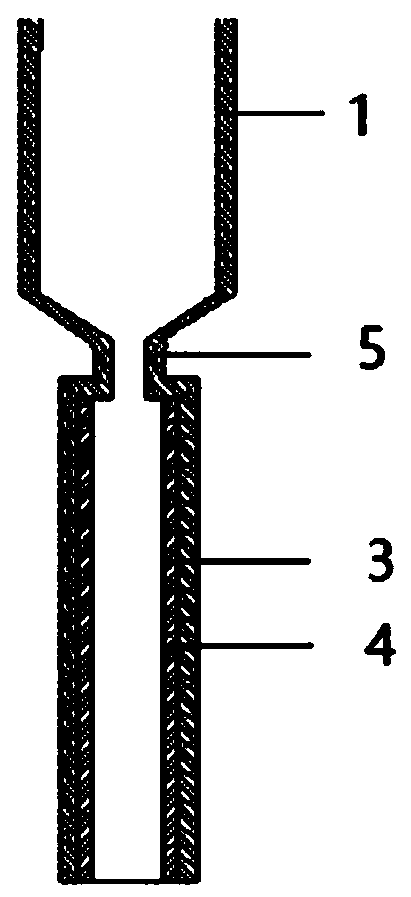

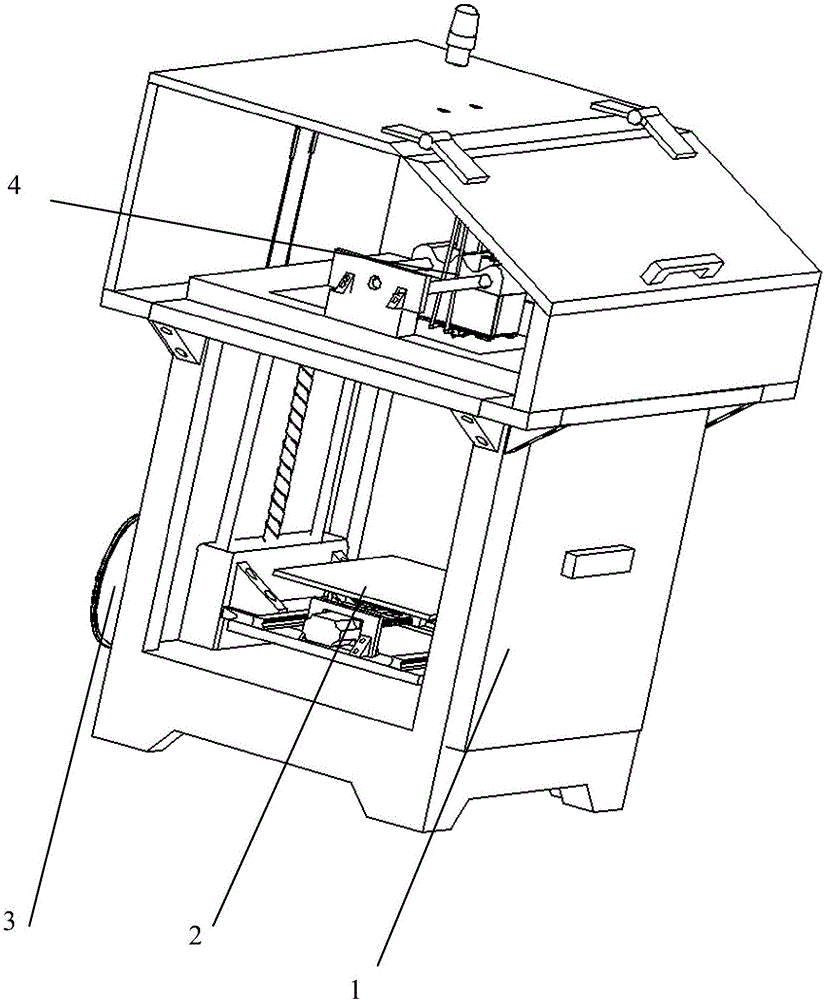

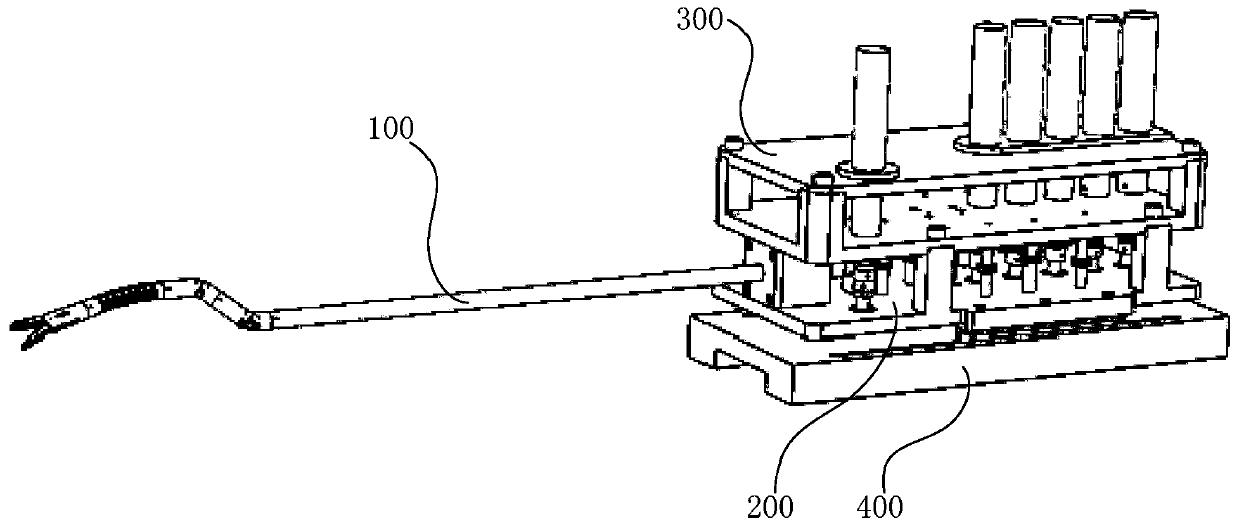

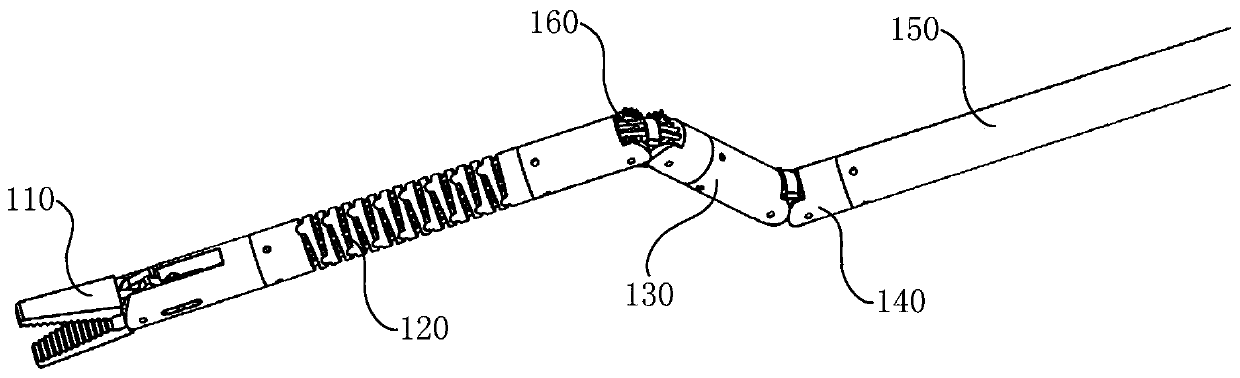

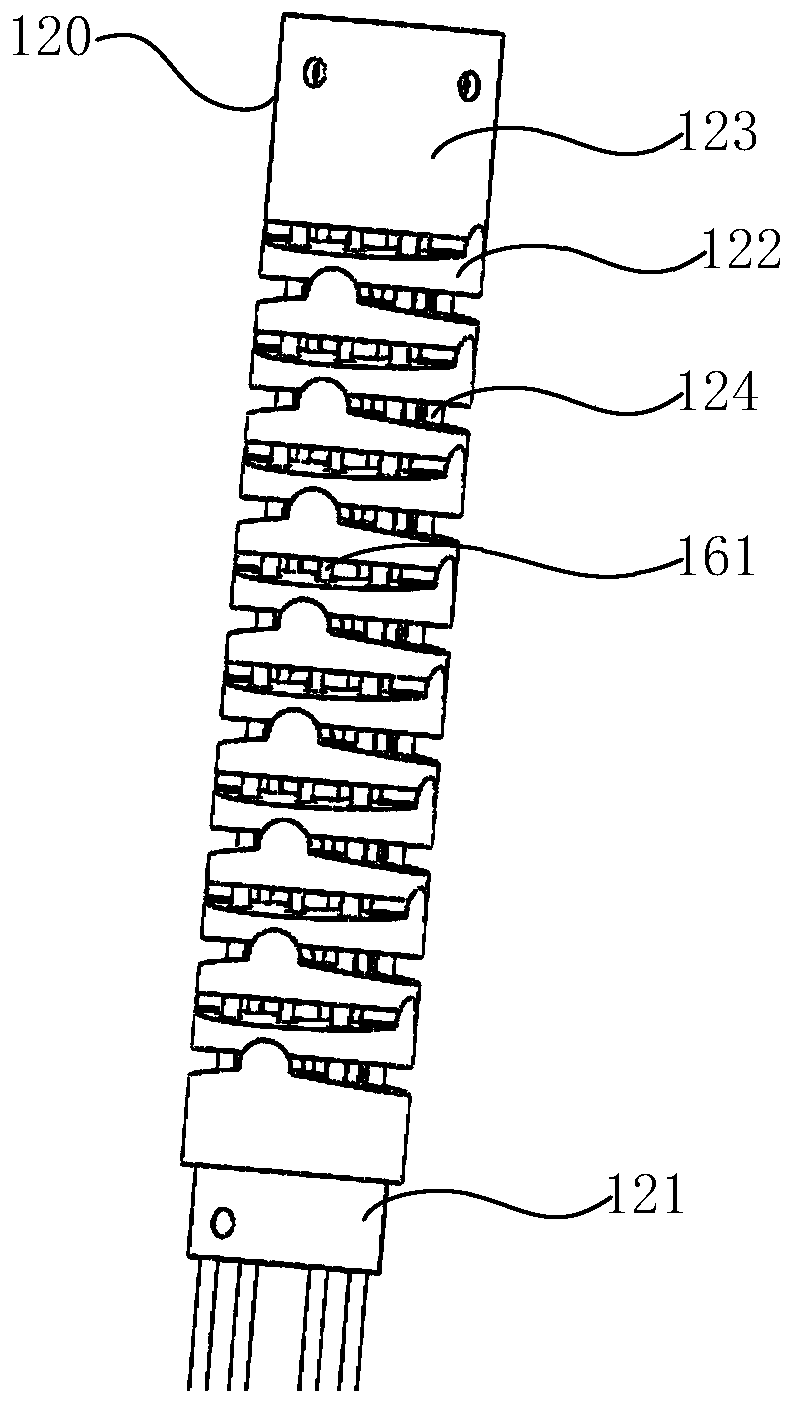

Snake-shaped surgical robot applied to minimally invasive surgery

ActiveCN111437036AEasy to operateGood resistance to deformationSurgical robotsPhysical medicine and rehabilitationMinimally invasive procedures

The invention provides a snake-shaped surgical robot applied to minimally invasive surgery. The snake-shaped surgical robot comprises a sliding table module, a pulley module connected to the sliding table module in a sliding manner, a driving module arranged on the pulley module and a mechanical arm connected with the pulley module, wherein the driving module provides power for the mechanical armthrough the pulley module; the mechanical arm comprises an operation actuator, a first joint which is connected with the operation actuator and can do bending motion, and a second joint which is connected with the first joint and can do swinging motion, wherein the first joint is of a continuum structure, and the second joint is of a gear meshing structure. The mechanical arm is formed by matchingthe continuum structure and the gear meshing structure; the rigidity of the mechanical arm is effectively improved in the premise that the flexible movement and the deformation capability of the tailend of the mechanical arm can be ensured; and moreover, the coupling effect of the mechanical arm of an existing surgical robot can be achieved or improved, and the motion control precision of the mechanical arm is improved. Compared with the existing surgical robot, the snake-shaped surgical robot is high in operability.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

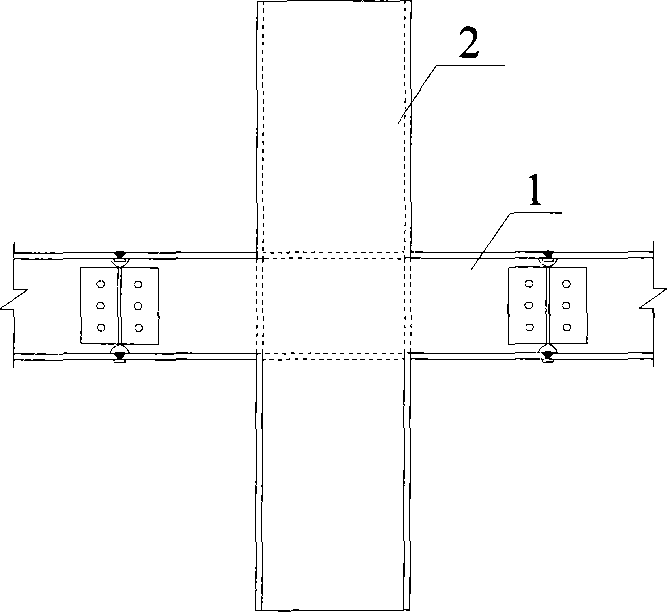

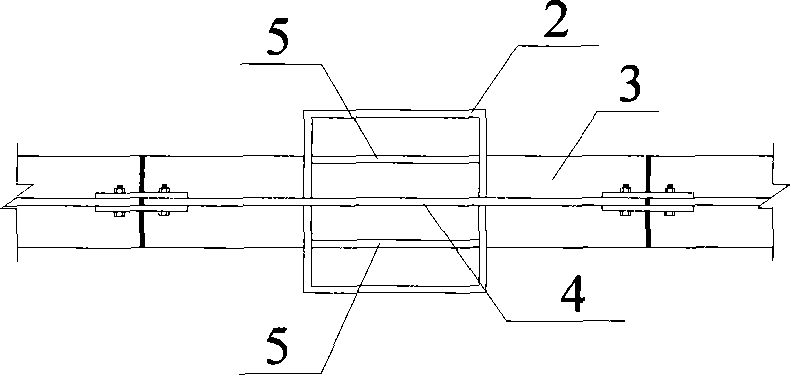

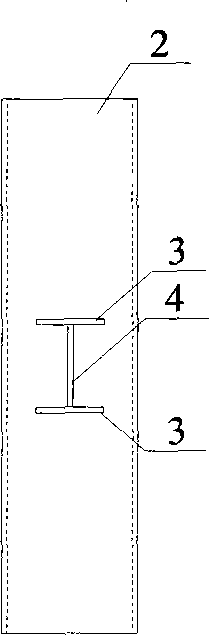

Square steel pipe concrete and H-shaped steel beam nod connection structure

The present invention relates to a structure for connecting the square steel tube concrete column with the node of the axle I-beam in the construction engineering technique field, comprising a square steel tube concrete column, an axle I-beam and a built-in steel plate. The position of the axle I-beam web plate on the wallboard of the square steel tube concrete column is arranged with a vertical groove with dimension same to the girder steel web plate and the groove is taken as the channel that the axle I-beam web plate passes through the wallboard of the square steel tube concrete column. The axle I-beam web plate runs through the wallboard of the square steel tube concrete column, the wing rim of the axle I-beam is directly welded on the external wall of the square steel tube concrete column. The placing mode of the build-in steel plate in the square steel tube concrete column is vertical and is parallel with the web plate of the axle I-beam, and the edge is accordant with the wing rim of the axle I-beam. The invention increases the whole shearing resistance and bending-resisting bearing ability of the node, and guarantees the coordinate operation of the square steel tube concrete column and the axle I-beam.

Owner:SHANGHAI JIAO TONG UNIV

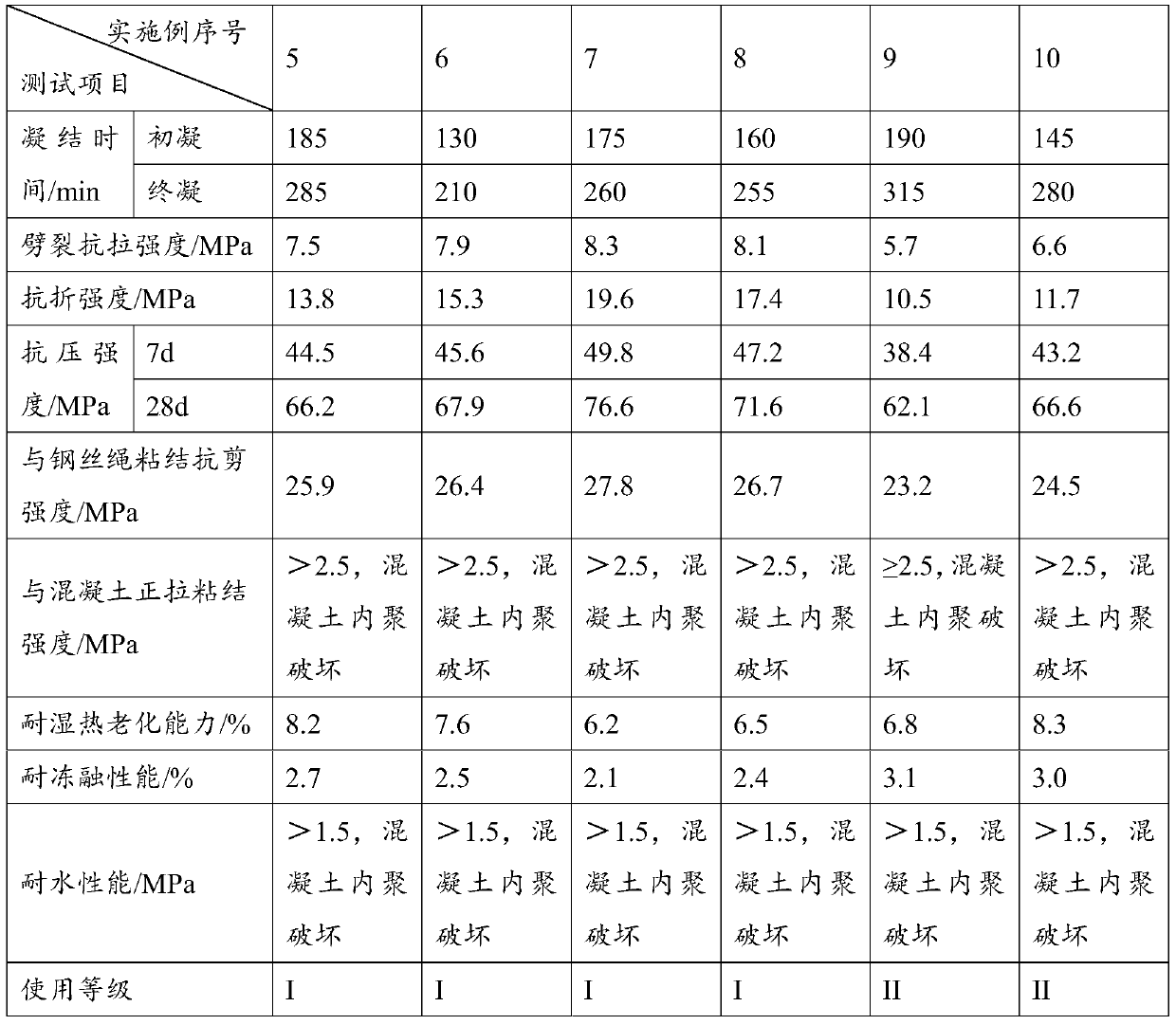

Water-borne epoxy resin-modified cement mortar used for structure reinforcement and production method thereof

InactiveCN109970407AIncreased splitting tensile strengthImprove flexural strengthEmulsionReactive diluent

The invention provides water-borne epoxy resin-modified cement mortar used for structure reinforcement and a production method thereof. The cement mortar is composed of A, B and C components and additional water with a mass ratio of 1 to (1.0 to 2.5) to (10 to 45) to (1.0 to 7.0), wherein the A component is composed of 100 parts of epoxy resin, 0-25 parts of epoxy reactive diluent, 8-20 parts of epoxy flexibilizer and 0.1-0.5 part of defoaming agent, the B component is composed of 100 parts of curing agent, 3-10 parts of curing accelerator and 0.8-2.5 parts of coupling agent, and the C component is composed of 100 parts of silicate cement, 100-300 parts of aggregate, 5-30 parts of silica fume and 0.1-0.5 part of water reducer. The invention further provides an emulsion-type water-borne epoxy resin curing agent ZB-804. The produced water-borne epoxy resin-modified cement mortar is used for repair and reinforcement of concrete buildings and structures, the durability of cement concrete is improved, the service lives of the structures are prolonged, and safe use of the buildings is guaranteed.

Owner:SUZHOU CONCRETE CEMENT PROD RES INST +1

Composite bulletproof armor plate and preparation method thereof

ActiveCN109855473AHigh compressive strengthIncrease elasticitySynthetic resin layered productsLaminationInterference fitCeramic composite

The invention discloses a composite bulletproof armor plate and a preparation method thereof. The composite bulletproof armor plate comprises a protective cover plate, ceramic plates, metal restraining plates, a fiber metal laminated plate and a porous metal sandwich plate; and the ceramic plates and the metal restraining plates are assembled and connected in an interference fit mode, the ceramicplates are supported through the fiber metal laminated plate and the porous metal sandwich plate, and the bullet resistance of a bulletproof armor plate is improved. The preparation technology is simple, the cost is low, compared with a traditional ceramic composite armor plate, the composite bulletproof armor plate is higher in impact resistance at a time and has the multi-time impact resistance,and the composite bulletproof armor plate has the wide application prospects in the bulletproof fields of armed helicopters, armored cars, vessels and the like.

Owner:XI AN JIAOTONG UNIV

PTB (Phenacyl Thiazolium Bromide) waterproof ventilated type aerated concrete block surfactant and use method thereof

InactiveCN101823861AReduce the possibilityHave the ability to deformSolid waste managementCeramicwareEconomic benefitsSURFACTANT BLEND

The invention relates to a waterproof ventilated type aerated concrete block surfactant which simultaneously has better adhesive property, moisture retention property, waterproof property, weather resisting property and air permeability, can solve the difficult problem bothering people for a long time in the application of aerated concrete blocks, is suitable for large-scale popularization and application and has remarkable economic benefit.

Owner:福建康波力特阳光建材有限公司

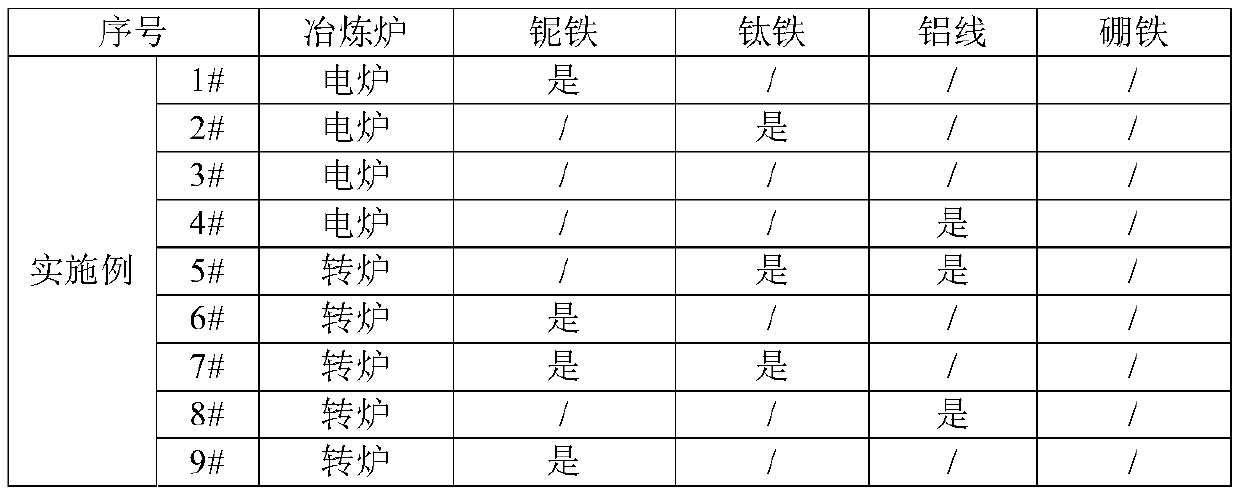

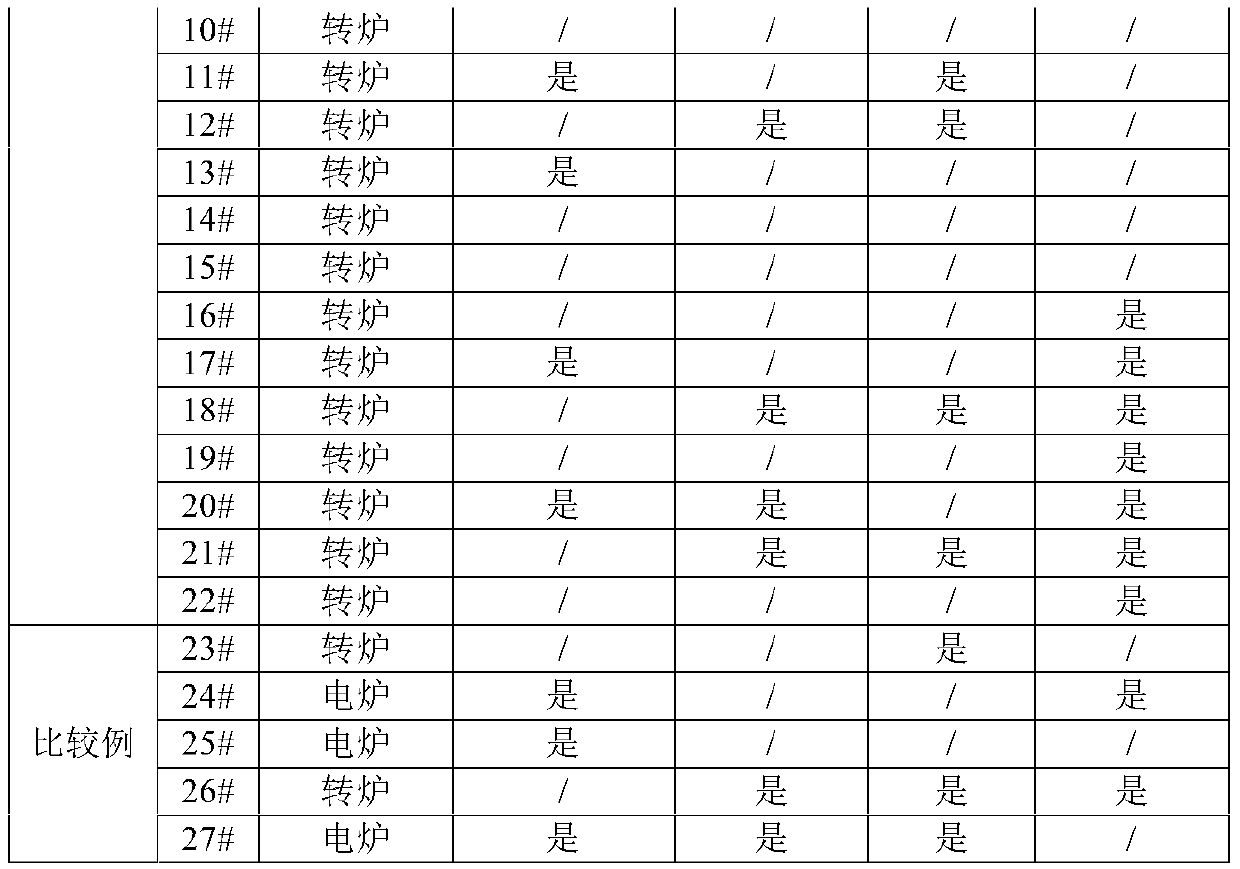

High-strength steel bar and production method thereof

ActiveCN110129675ARealize fine controlImproved resistance to external disturbancesFurnace typesHeat treatment furnacesTemperature controlChemical composition

The invention discloses a high-strength steel bar and a production method thereof. The high-strength steel bar comprises the chemical components of 0.15-0.32% of C, 0.5-1.9% of Si+Mn, 1.1-2.1% of Mn+Cr+Mo+Ni, 0.02-0.8% of V, 0.01-0.3% of at least one of Nb, Ti and Al and the balance Fe and inevitable impurities; and Mn=(2.5-3.5)Si, Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15<=0.56%. The production method ofthe high-strength steel bar comprises the steps of smelting, continuous casting, temperature control rolling and temperature control cooling, wherein the superheat temperature of molten steel subjected to continuous casting is 15-30 DEG C, the heating temperature is 1200-1250 DEG C, in addition, the molten steel stays in a furnace for 60-120 min, the rolling start temperature is 1000-1150 DEG C,the finish rolling temperature is 850-950 DEG C, and the temperature of the steel when the steel is fed onto a cooling bed is 800-920 DEG C.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Metal vacuum warming plate and manufacturing method for same

InactiveCN104975661AImprove rigidityIncreased resistance to deformationCovering/liningsClimate change adaptationAlloyCavity wall

The invention discloses a metal vacuum warming plate. A vacuum cavity is formed by sealed cooperative connection between an upper metal plate and a lower metal plate; a supporting core is disposed in the vacuum cavity; a vacuumizing hole is formed in the cavity wall of the vacuum cavity; metal with melting point ranging from 90 to 350 DEG C or related alloy sealing bars are arranged between sealing sides for the sealed cooperative connection between the upper metal plate and the lower metal plate; and the sealing bars are bonded with the upper metal plate and the lower metal plate and sealed with the same. The metal vacuum warming plate is advantaged by high vacuum degree durableness in bad natural environments, excellent sealing property, strong anti-deformation capabilities, great corrosion and rust resisting performance and long service life as long as buildings; fireproof performance is A-level; the metal vacuum warming plate is integrated functions of warming, decoration and construction; the construction period can be obviously shortened; installation cost can be reduced; various shapes can be formed; special demands for building outer wall surface corners and arcs can be met; and the metal vacuum warming plate is suitable for various building outer wall warming and roof insulation.

Owner:许浒

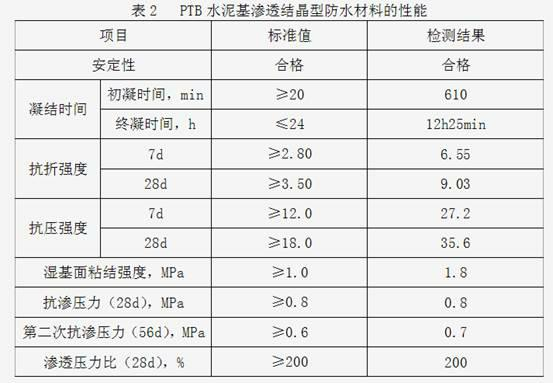

PTB cementitious capillary crystalline waterproofing material and use method thereof

InactiveCN101928124AHigh bonding strengthImprove waterproof performanceSocial benefitsEconomic benefits

The invention provides a PTB cementitious capillary crystalline waterproofing material and a use method thereof, belonging to the technical field of building materials. The PTB cementitious capillary crystalline waterproofing material comprises a PTB water solution and PTB special powder. The use method comprises the steps of: cleaning a base layer, and spraying water for wetting; preparing the PTB cementitious capillary crystalline waterproofing material; constructing the PTB cementitious capillary crystalline waterproofing material; and maintaining. The invention solves the leakage difficulty puzzled for a long time by people and the problem of poor property of the traditional waterproofing coating. The waterproofing material has better bonding, waterproofing and ventilating properties, can overcome the defect of the traditional cementitious capillary crystalline waterproofing material, is suitable for massive popularization and application, and has remarkable economic benefit and social benefit.

Owner:福建康波力特阳光建材有限公司

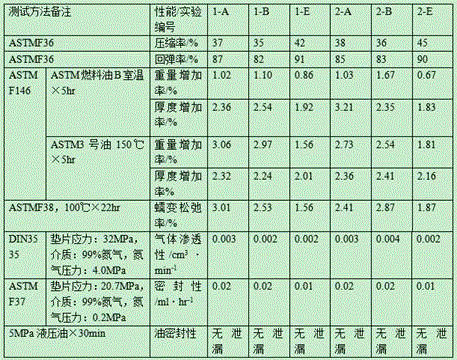

Foaming nitrile rubber metal composite plate and preparation method thereof

ActiveCN106752403AImprove performanceImprove sealingOther chemical processesConjugated diene hydrocarbon coatingsFoam rubberComposite plate

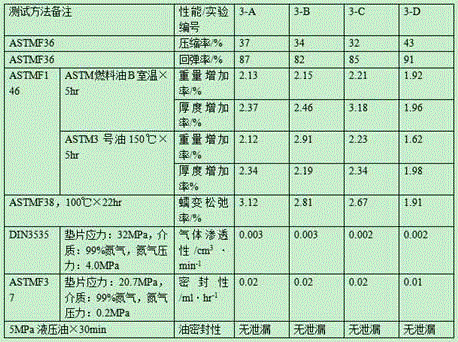

The invention provides a foaming nitrile rubber metal composite plate and a preparation method thereof, and relates to a sealing material. The foaming nitrile rubber metal composite plate comprises a metal base plate, wherein a foaming rubber layer is arranged at the surface of the metal base plate; the foaming rubber layer is prepared from the following raw materials in parts by mass: 100 parts of nitrile rubber, 1 to 10 parts of zinc oxide, 2 to 10 parts of accelerant, 0.5 to 5 parts of sulfur, 20 to 40 parts of carbon black, 1 to 5 parts of foaming agent, and 1 to 10 parts of additive. The foaming nitrile rubber metal composite plate has the advantages that the compression rate is 32 to 47%, the resilience rate is more than 80%, the creepage relaxation rate is less than 4%, the sealing property ml / hr is equal to or less than 0.02, and the oil sealing and non-leakage properties are realized; for resistant fuel B at room temperature after 5h, the weight increase is less than 2%, and the thickness increase is less than 4%; for resistant ASTM No.3 fuel at the temperature of 150 DEG C after 5h, the weight increase is less than 4%, and the thickness increase is less than 3%; the excellent compression rate, resilience rate, anti-creepage property, temperature and oil-resistant property and the like are realized.

Owner:南阳天一密封股份有限公司

Thermal insulation mortar using rubber powder of waste tire

InactiveCN101643347AIncreased resistance to deformationImprove crack resistanceSolid waste managementFiberPolymer science

The invention aims to provide a thermal insulation mortar using large amount of waste tire, comprising tire rubber, cement, emulsion powder, fiber and cellulose ether and the like; the main proportionof cement to emulsion powder to tire rubber is 1:0.2:0.6; the particle size of tire rubber particle is in the range of 0.1-5 mm; thus, high flexible thermal insulation mortar of rubber powder is doped; by researching and testing the performances of flexible mortar, the intensity of mortar can be reduced by rubber powder to improve compression strength of mortar, thereby increasing resistance to deformation of the thermal insulation mortar, and improving the anti-cracking performance of the thermal insulation mortar. The invention has the characteristics of fine chemical resistance, no water absorption, great toughness, fine anti-cracking performance and fine thermal insulation performance, and is used for preparing thermal insulation mortar, thereby not only showing thermal insulation andenergy saving of buildings, but also having fine environmental effect.

Owner:苏州同济材料科技股份有限公司

Waterproof ventilating type old wall ceramic tile retreading interface agent and using method thereof

InactiveCN101898905AImprove breathabilityImprove waterproof performanceOXALIC ACID DIHYDRATEPortland cement

The invention discloses a waterproof ventilating type old wall ceramic tile retreading interface agent. The waterproof ventilating type old wall ceramic tile retreading interface agent consists of copolymer solution, 42.5 ordinary portland cement and fine sand, and a small amount of fly ash, water reducing agent, cellulose ether and PVA are added at the same time; a using method of the interface agent comprises the following steps of: (1) cleaning a base layer: cleaning floating dust, residues, oil stains and the like on a base surface of the well, preferably by using oxalic acid; (2) preparing the interface agent: mixing and preparing the interface agent according to the formula; (3) constructing the interface agent: constructing the prepared interface agent by using a spray gun or a roller, wherein the thickness of the constructed interface agent is 0.8 to 1.2 mm, and the construction is not carried out in rainy days; and (4) maintaining: after the completion of the construction, maintaining the interface agent for 12 to 24 hours and performing plastering construction.

Owner:江其东

High temperature oxidation resistant grid section and preparation method thereof

The invention provides a high temperature oxidation resistant grid section, comprising the following components by weight percent: 0.3-0.6% of C, 0.2-0.4% of N, 22-25% of Cr, 0.3-0.5% of Si, 3-4% of Mn, 6-8% of Ni, 0.001-0.002% of B, less than 0.01% of Zr, the balance Fe. The grid section of the invention is prepared by adopting melting, refining, alloying and casting stages. The grid section of the invention has high rigidity and better impact property, distortion resistance capacity at high temperature is improved, and meanwhile corrosion resistance is also improved, and the oxidation film of the grid section of the invention contains no Mn3O4, so that the oxidation film thereof is stable at high temperature and has better compactness and continuity, bonding degree with base material is higher, and the grid section has excellent oxidation resistance and is superior to the existing grid section.

Owner:北京力拓科技有限公司

Novel high-toughness fiber reinforced cement-based composite material and preparation method thereof

The invention discloses a novel high-toughness fiber reinforced cement-based composite material and a preparation method thereof. The composite material is prepared from, by weight, 10-20 parts of composite reinforcing fiber, 30-50 parts of portland cement, 15-25 parts of fly ash, 4-10 parts of fine sand, 1-5 parts of dispersing agent, 2-5 parts of water reducing agent, 0.5-3.5 parts of tougheningagent and 12-18 parts of water. According to the composite material, the toughness and crack resistance of the material are improved, the composite reinforcing fiber is uniformly distributed by the dispersing agent, the mechanical properties are changed, the ability of the material to resist deformation is greatly improved, and the probability of occurrence of cracking and fracture of concrete isreduced.

Owner:合肥市闵葵电力工程有限公司

Buffer-induced independent combined-type roll-over protection structure

InactiveCN101559788AIncreased resistance to deformationLight weightPedestrian/occupant safety arrangementSuperstructure subunitsVehicle frameEngineering

The invention discloses a buffer-induced independent combined-type roll-over protection structure, which consists of a main-body bearing structure and a buffer-induced structure, wherein the main-body bearing structure is formed by connecting four upright columns with an upper beam and a lower beam through flanges; the main-body bearing structure is in a curved-edge trapezoidal shape in the left-right, front-back and upper-lower surfaces; the buffer-induced structure is in a trapezoidal shape; the buffer-induced structure is in the curved-edge trapezoidal shape in the left-right, front-back and upper surfaces; the upright column of the buffer-induced structure and the upright column of the main-body bearing structure are connected with bolts though transition fit; the lower end of the upright column of the buffer-induced structure is welded with a curved pipe; the curved pipe is inserted into the upright column of the main-body bearing structure and is fixed through the bolt throughout the two; and the main-body bearing structure and the buffer-induced structure are arranged outside a cab and are connected with a vehicle frame through the flanges. The protection structure has the advantages of taking the flanges for connection to ensure convenient replacement and maintenance, short maintenance cycle and lower maintenance cost, along with strong capability of resisting deformation and absorbing the kinetic energy of roll-over.

Owner:JILIN UNIV +1

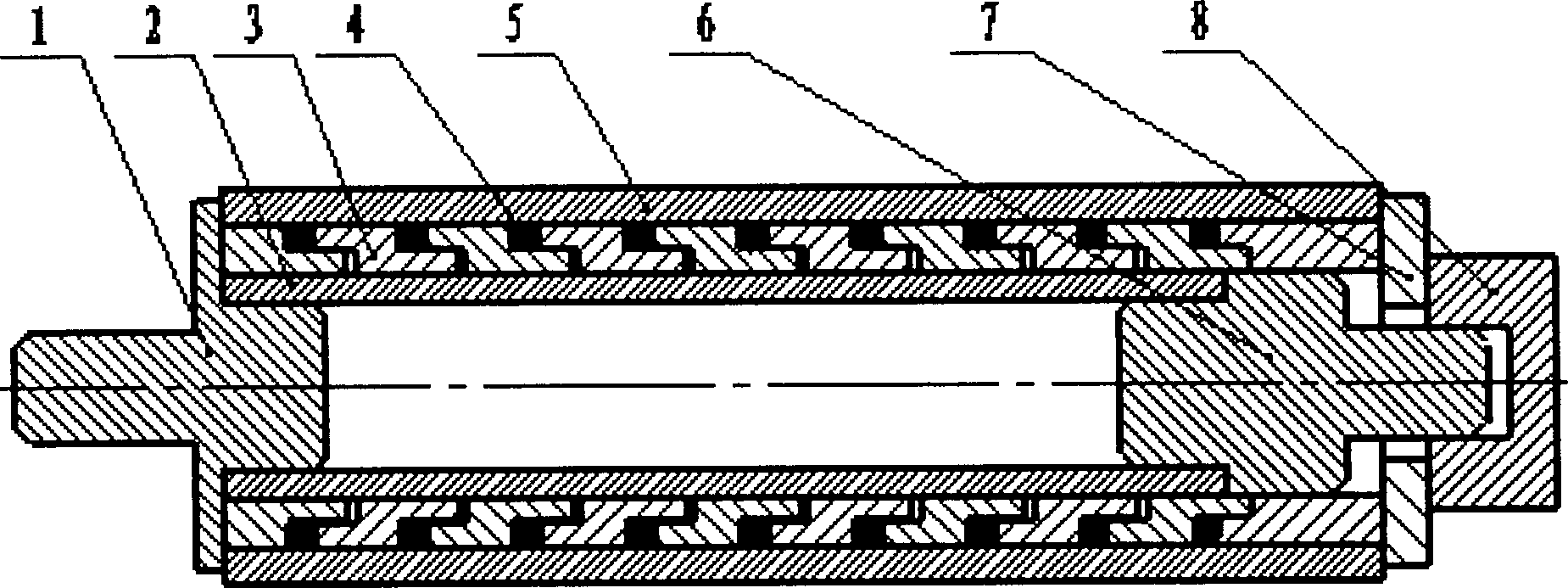

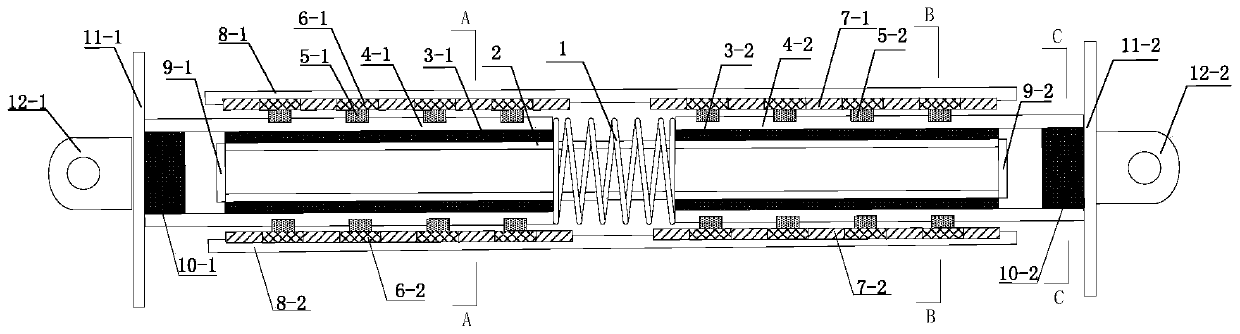

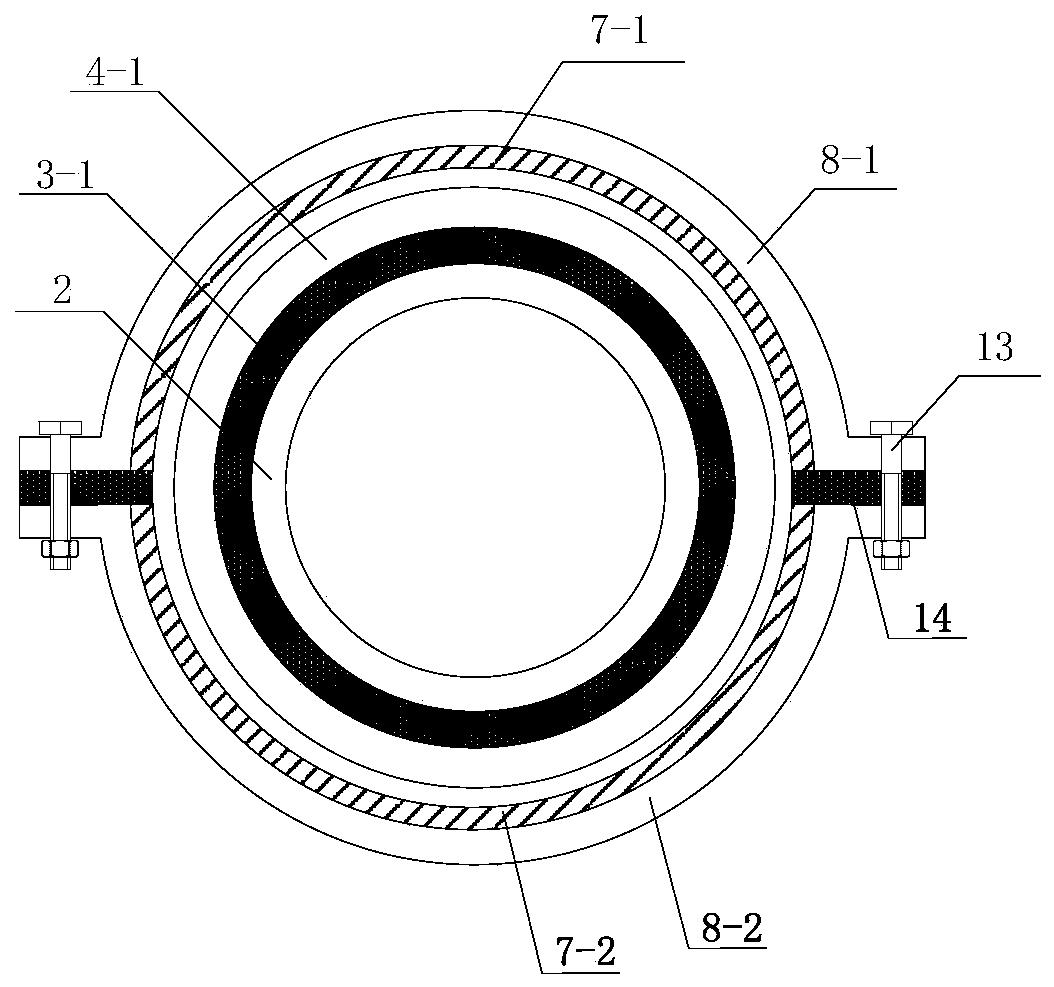

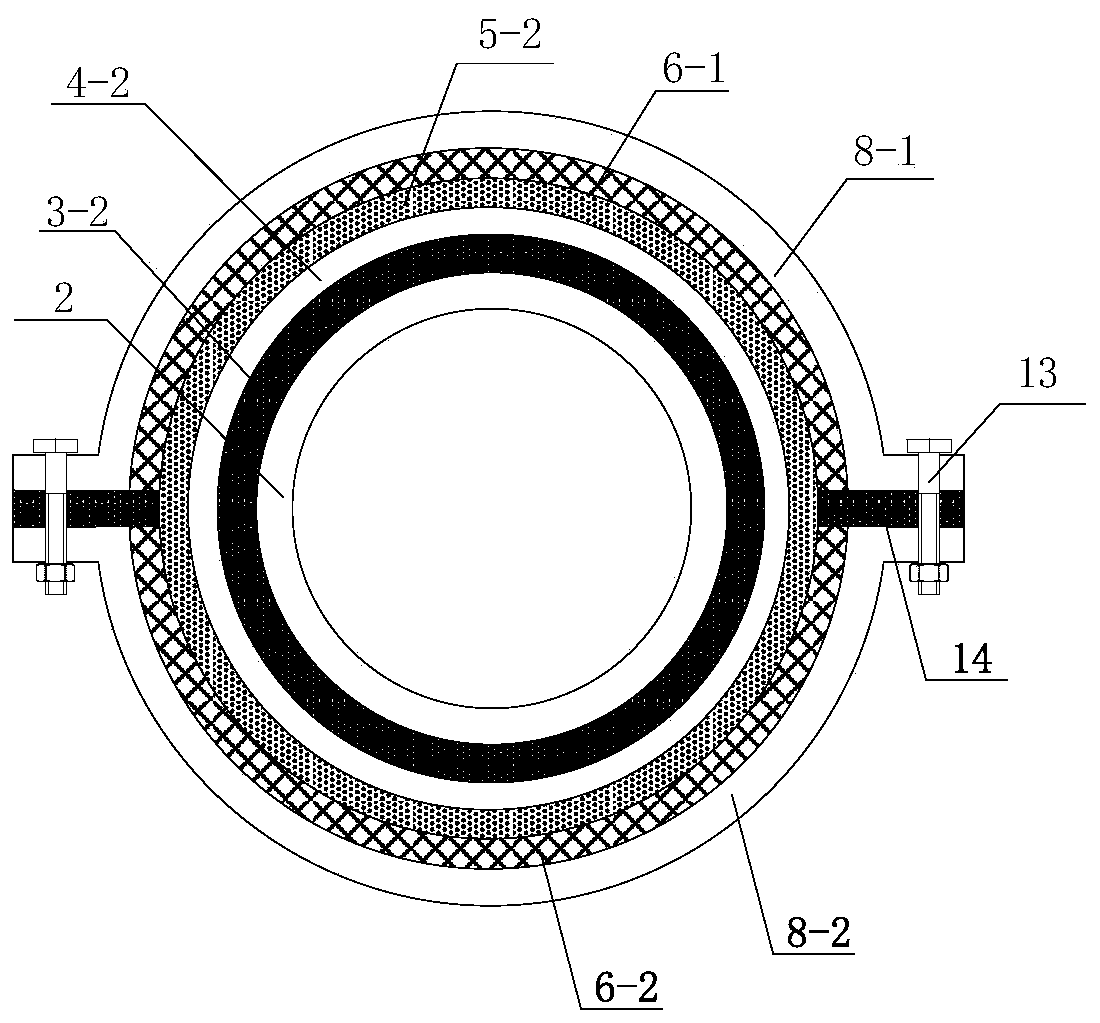

Variable-damping variable-rigidity viscoelasticity-friction composite damping device

ActiveCN111350291AImproved dissipation capacityReduce vibration responseProtective buildings/sheltersShock proofingViscoelastic dampingShock absorber

The invention discloses a variable-damping variable-rigidity viscoelasticity-friction composite damping device. The variable-damping variable-rigidity viscoelasticity-friction composite damping devicecomprises two symmetric cylinder type viscoelasticity damping device units and two cylinder type friction damping device units, the friction damping device units sleeve the outer sides of the cylinder type viscoelasticity damping device units, the cylinder type viscoelasticity damping device units sequentially comprise annular inner steel cylinders, annular viscoelasticity material layers and annular middle steel cylinders from inside to outside, elastic elements are sleeved with the middles of the annular inner steel cylinders, closed steel plates are mounted on two ends of the annular innersteel cylinders, cylinder viscoelasticity materials are mounted on inner sides of two ends of the annular middle steel cylinders, connecting anchorage steel plates are mounted on two ends of the annular middle steel cylinders, the friction damping device units sequentially comprise annular middle steel cylinders, annular friction pieces, annular friction plates and annular outer steel cylinders from inside to outside, the annular friction plates comprise first annular friction plates and second annular friction plates, and each annular outer steel cylinder is formed through connecting of an upper half annular outer steel cylinder and a lower half annular outer steel cylinder through bolt assembling.

Owner:HUBEI UNIV OF ARTS & SCI

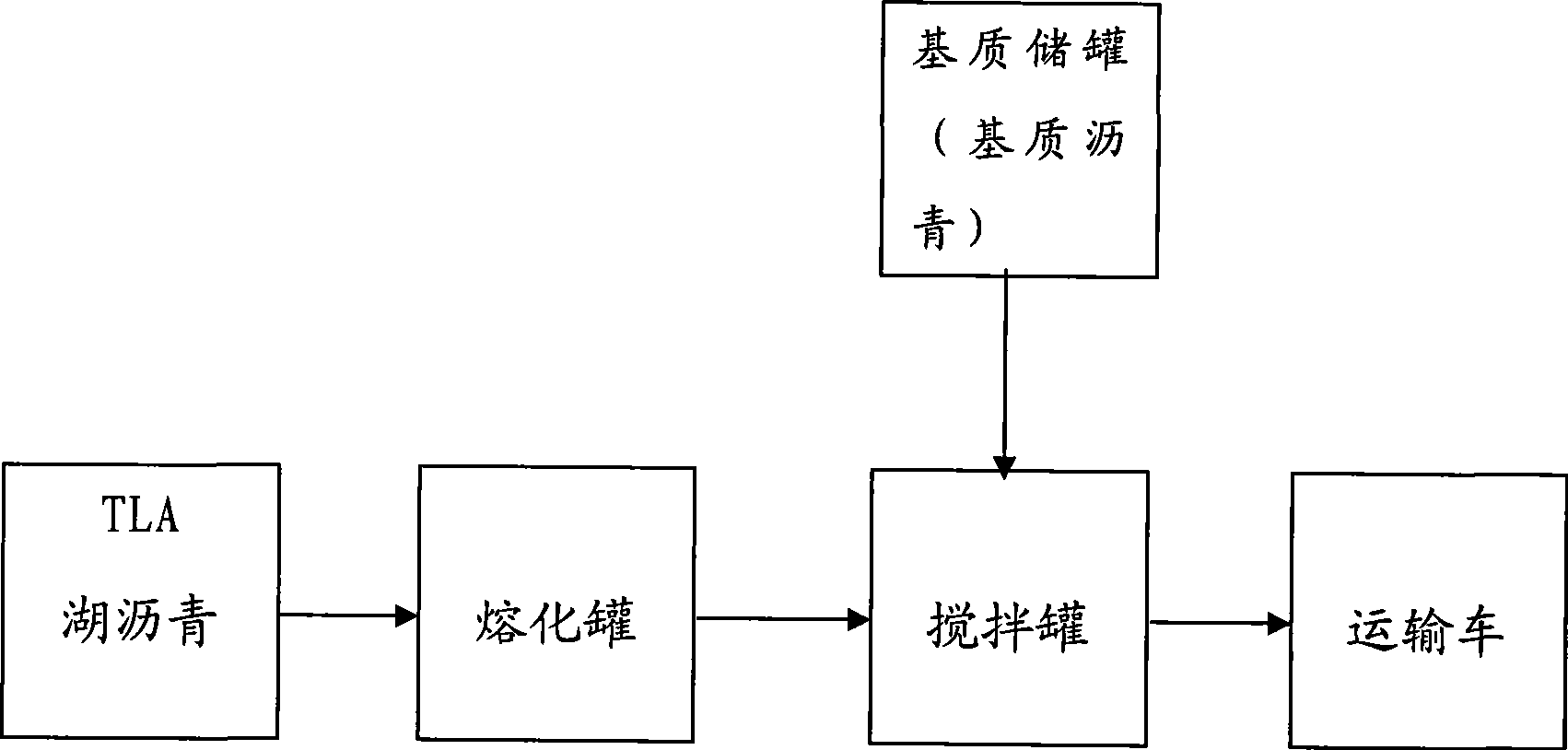

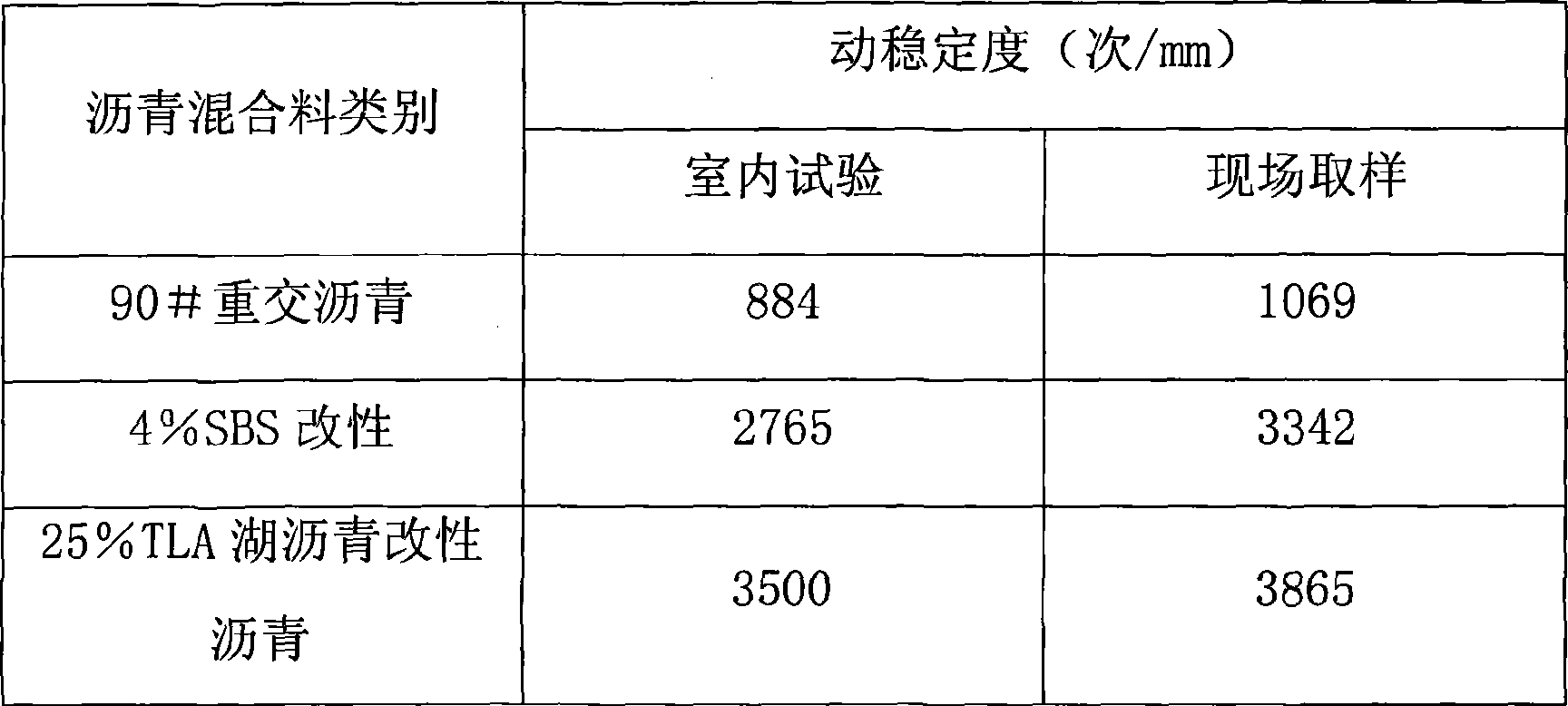

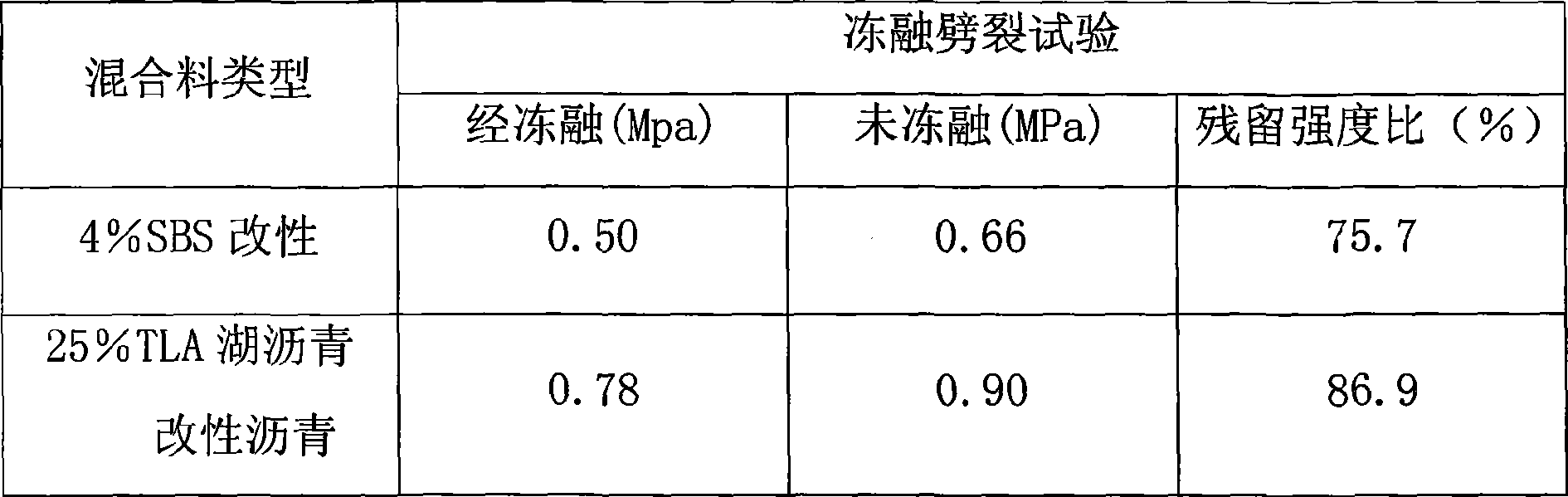

Modified asphalt applying lake asphalt and preparation method thereof

ActiveCN101445659ALong-lasting consistency propertiesHigh viscosityBuilding insulationsSoil sciencePhysical chemistry

The invention discloses modified asphalt applying lake asphalt and a preparation method thereof. The modified asphalt is prepared by the following materials according to the following weight percentage: 20 percent to 95 percent of basic asphalt and 5 percent to 80 percent of Trinidad lake asphalt. The method comprises the following technique processes of: melting the basic asphalt at a temperature of 120 DEG C to 140 DEG C; melting the Trinidad lake asphalt at a temperature of 165 DEG C to 195 DEG C; and mixing the melted basic asphalt and the melted Trinidad lake asphalt and stirring the mixture of the basic asphalt and the Trinidad lake asphalt for 10 min to 50 min at a temperature of 165 DEG C to 195 DEG C, and the obtained mixture with even mixing is the finished product. The modified asphalt has the property of durable thickness (aging resistance), can improve the stability and bearing capacity under the condition of high temperature, improves the deformation resistance under heavy load and cracking resistance under heavy load in cold regions, has long life cycle which can reach 20 to 50 years, has excellent environment-friendly performance and can reduce pollution generated during the production of a polymer modifier.

Owner:国润通工程集团有限公司

High toughness cement-based material and preparation method thereof

The invention discloses a high toughness cement-based material and a preparation method thereof. The high toughness cement-based material is prepared from the following raw materials in parts by weight: 10 to 20 parts of styrene-butadiene emulsion, 30 to 50 parts of portland cement, 15 to 25 parts of coal ash, 7 to 15 parts of composite reinforced fiber, 6 to 14 parts of silica fume, 4 to 10 partsof mica powder, 1 to 5 parts of dispersing agent, 2 to 5 parts of water reducing agent, 0.5 to 3.5 parts of thickening agent and 12 to 18 parts of water. According to the high toughness cement-basedmaterial disclosed by the invention, through compound mixing of the styrene-butadiene emulsion and the composite reinforced fiber, meanwhile, the flexibility of concrete matrix and the bonding strength of the composite reinforced fiber and concrete after concrete cracking are increased so that the purpose of reinforcing the toughness of the concrete is achieved, the styrene-butadiene emulsion canbe dehydration hardened into a three-dimensional continuous film-like structure in the concrete so that the concrete can show high tension, good plasticity and high impact toughness, and the compositereinforced fiber is tightly bonded with cement by the styrene-butadiene emulsion so as to improve the crack resistance of the material.

Owner:合肥金云新材料有限公司

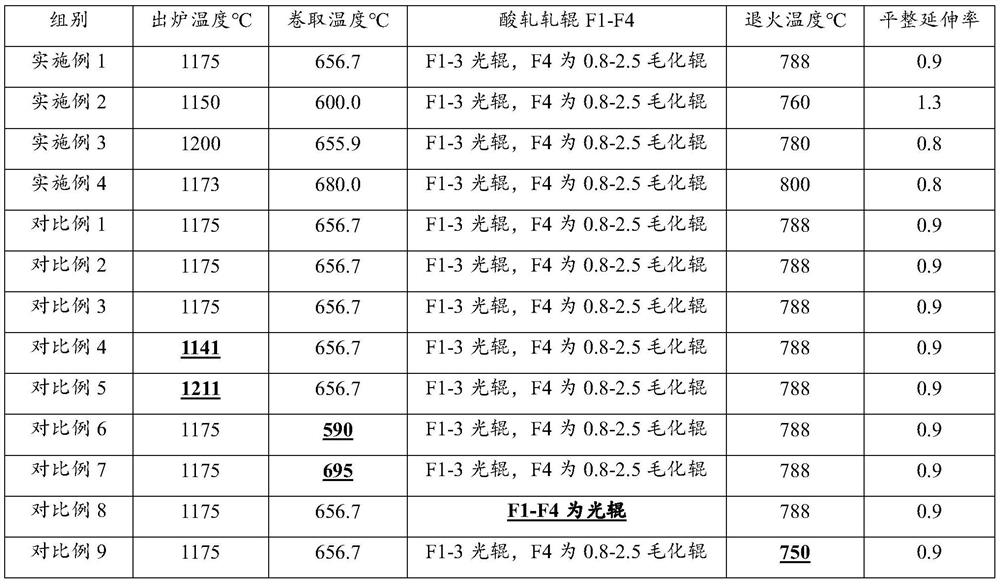

Continuous annealing cold-rolled carbon steel for stamping and preparation method thereof

The invention discloses continuous annealing cold-rolled carbon steel for stamping. The continuous annealing cold-rolled carbon steel comprises the following chemical components in percentage by mass:less than or equal to 0.0060% of C, less than or equal to 0.05% of Si, 0.15%-0.3% of Mn, 0.015-0.025% of P, less than or equal to 0.018% of S, 0.035%-0.065% of Al, 0.035%-0.09% of Ti and the balanceFe and inevitable impurities. The invention further discloses a method. The method comprises the following steps: casting a blank, heating before rolling, hot rolling, cooling after rolling, coiling,pickling, cold rolling, annealing and flattening, wherein the heating temperature before rolling is 1150-1200 DEG C, the coiling temperature is 600-680 DEG C, a F1-F3 grinding smooth roll is subjectedto pickling rolling, a 0.8-2.5 microns roughening roll is used for F4, the annealing temperature is 760-800 DEG C, and the flattening elongation is 0.8-1.3%. According to the continuous annealing cold-rolled carbon steel for stamping, the surface of strip steel is free of stamping roughness defects after more than 4% of strip steel is subjected to stamping forming.

Owner:首钢股份公司迁安钢铁公司 +1

Semi-sliding box-type buttress of floating production storage and offloading (FPSO) upper module

The invention relates to a semi-sliding box-type buttress of a floating production storage and offloading (FPSO) upper module. The semi-sliding box-type buttress of the FPSO upper module mainly consists of a supporting circular stand column, side wing support plates, concave arc wrist plates, rectangular wrist plates, a box body, a sliding trapezoidal groove base plate, baffle plates, a sliding trapezoidal tooth base plate, a fixed end metal gasket and a fixed end stand pipe base plate, wherein the supporting circular stand column is a supporting body connected with an upper plate and a lowerplate of the box body; an internal supporting body of the box body is formed by welding the side wing support plates, the concave arc wrist plates and the rectangular wrist plates; the metal gasket iswelded on a fixed end box body cover plate for reinforcing and balancing, so that a fixed end buttress is formed; the baffle plates are welded on a sliding end box body cover plate along the bow andstern direction for limiting the cross sliding and vertical fluctuating of the sliding trapezoidal groove base plate; furthermore, the base plate is welded on the box body cover plates, and the sliding trapezoidal tooth base plate is in lap joint with the upper part of the base plate, so that a sliding end buttress is formed; support legs for a frame platform are fixedly welded with a module buttress part in a form of simply supported beams, and are in partial sliding contact. The semi-sliding box-type buttress of the FPSO upper module is reasonable in stress, high in adaptability of sea conditions and wide in applicable sea areas.

Owner:SOUTHWEST PETROLEUM UNIV

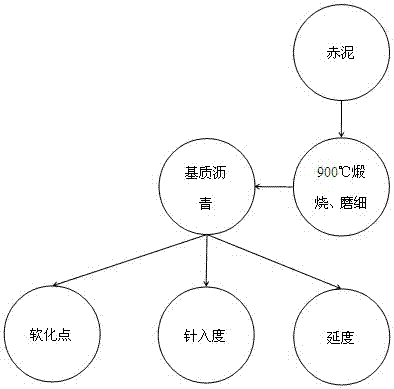

Making method of red mud modified asphalt

The invention discloses a making method of red mud modified asphalt. The method comprises the following steps: 1, calcining red mud at 900 DEG C, and grinding the calcined red mud; and 2, mixing 13 parts by weight of the red mud obtained in step 1 with 100 parts by weight of asphalt to obtain the red mud modified asphalt. The red mud is industrial waste residues generated in the alumina extraction process in the aluminum making industry. A result of test researches shows that the 900 DEG C calcined red mud has good activity. The red mud is added to reduce the penetration and the 15 DEG C ductility of the asphalt and rise the softening point, and the red mud and matrix asphalt form a uniform and stable blend system, so the temperature sensitivity and the high temperature stability of the asphalt are improved; and the red mud is used as a modifying material, so a new way is provided for solving the problem of waste residues in the aluminum ore industry, recycling and extension of the industry chain, and the problem of pollution of the red mud to environment is effectively solved in the invention.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

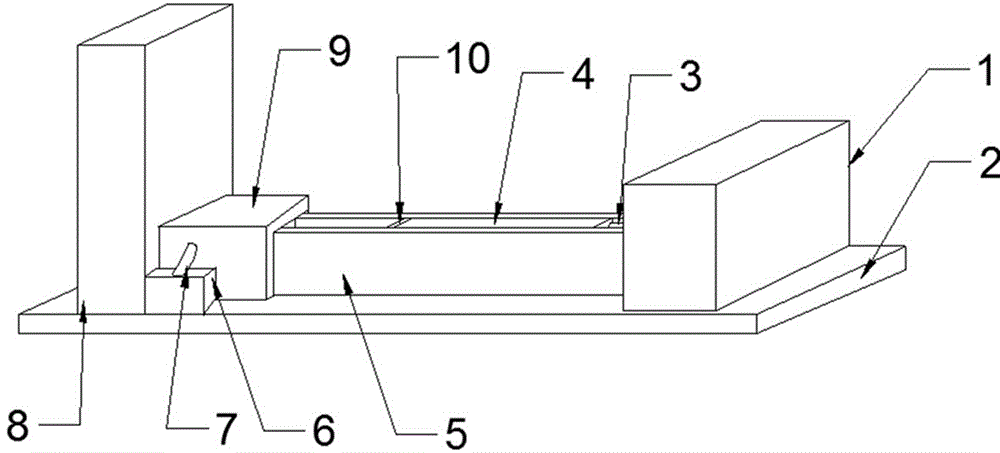

Aluminum material extruding machine

The invention discloses an aluminum material extruding machine in the technical field of equipment manufacturing. The aluminum material extruding machine comprises a platform fixed to the ground. The platform is sequentially provided with a die base, an extruding cylinder, an extruding beam and an air cylinder from left to right. The die base is provided with a die. The extruding beam and a piston rod of the air cylinder are fixed. The die is fixedly connected into the extruding cylinder. The die base, the die, the extruding beam and the extruding cylinder are located on the same axis. The extruding cylinder comprises an inner layer and an outer layer. The outer layer of the extruding cylinder is connected with a vacuum pump through a flexible pipe. One end of the flexible pipe extends into an interlayer formed by the inner layer and the outer layer of the extruding cylinder. The vacuum pump is arranged on the platform. By the adoption of the extruding machine in the scheme, after the vacuum pump is started, air in the interlayer is pumped out to make the interlayer vacuum, the extruding cylinder does not dissipate heat easily, the cooling speed of aluminum materials is low, and the aluminum materials can be formed beneficially.

Owner:ZUNYI HENG JIA ALUMINUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com