Method for reinforcing roadway floor by grouting

A technology of grouting reinforcement and bottom plate, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of slow advancement of the excavation face, influence and restrict the progress of the excavation construction, etc. The effect of increasing the bearing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

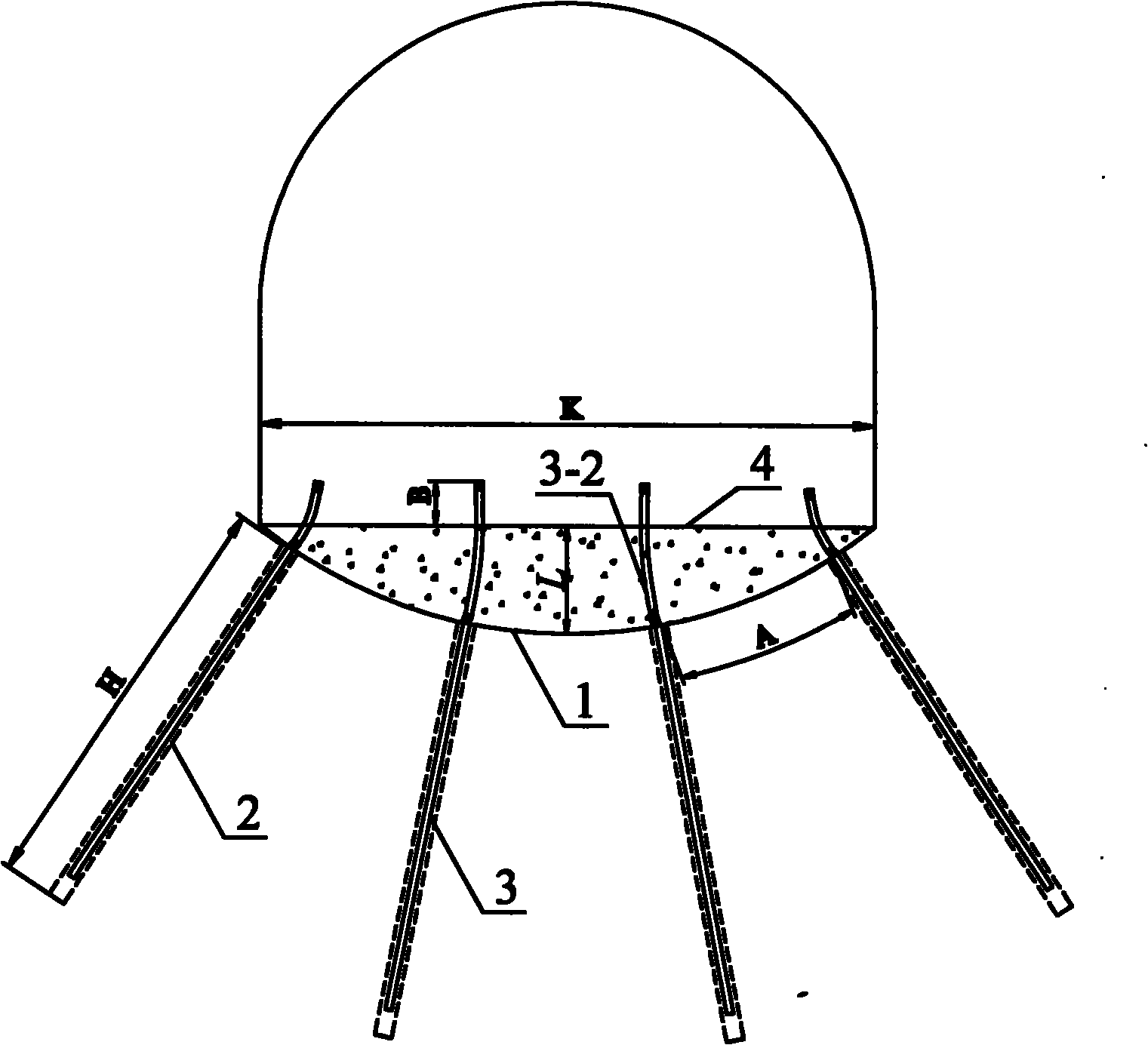

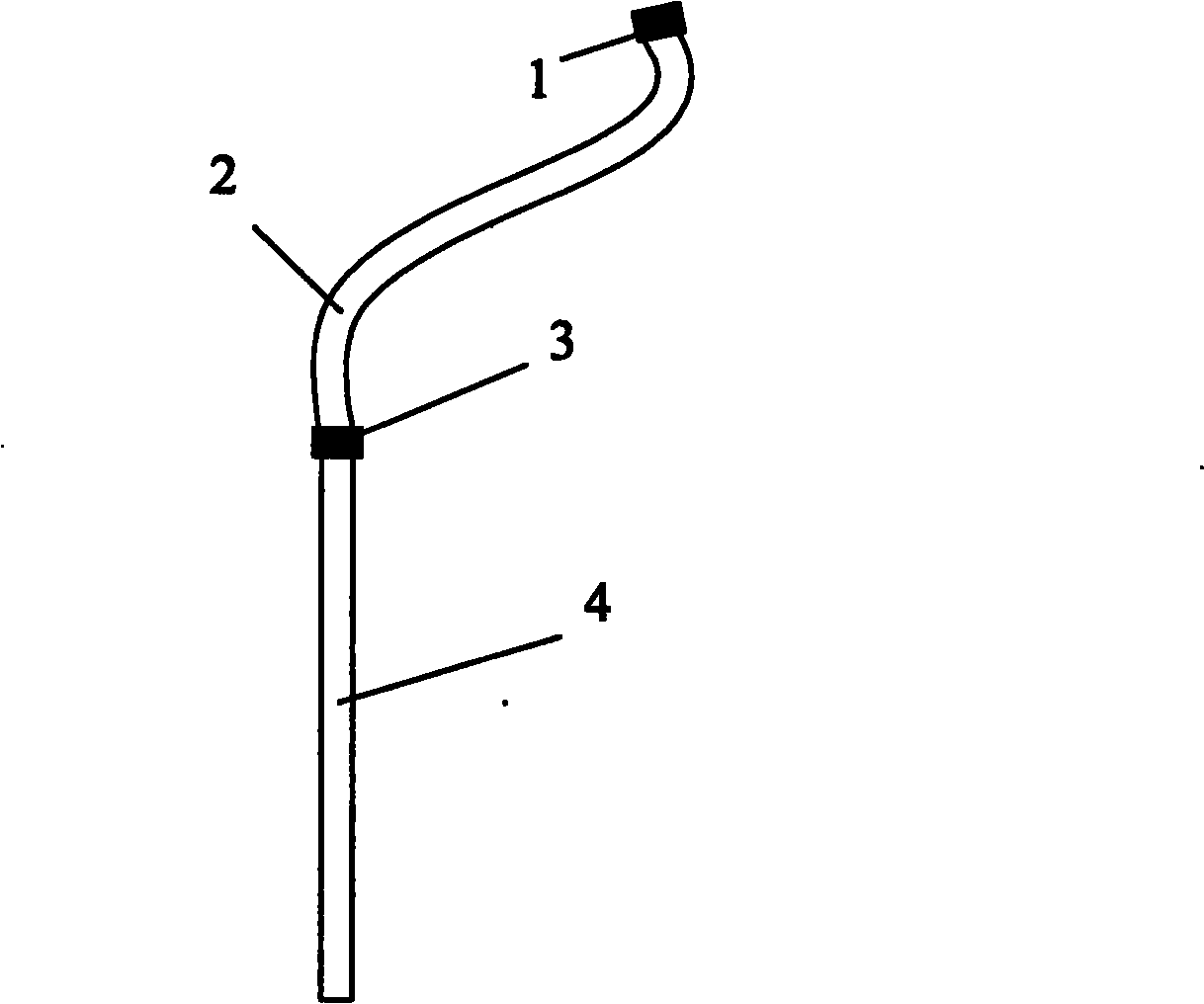

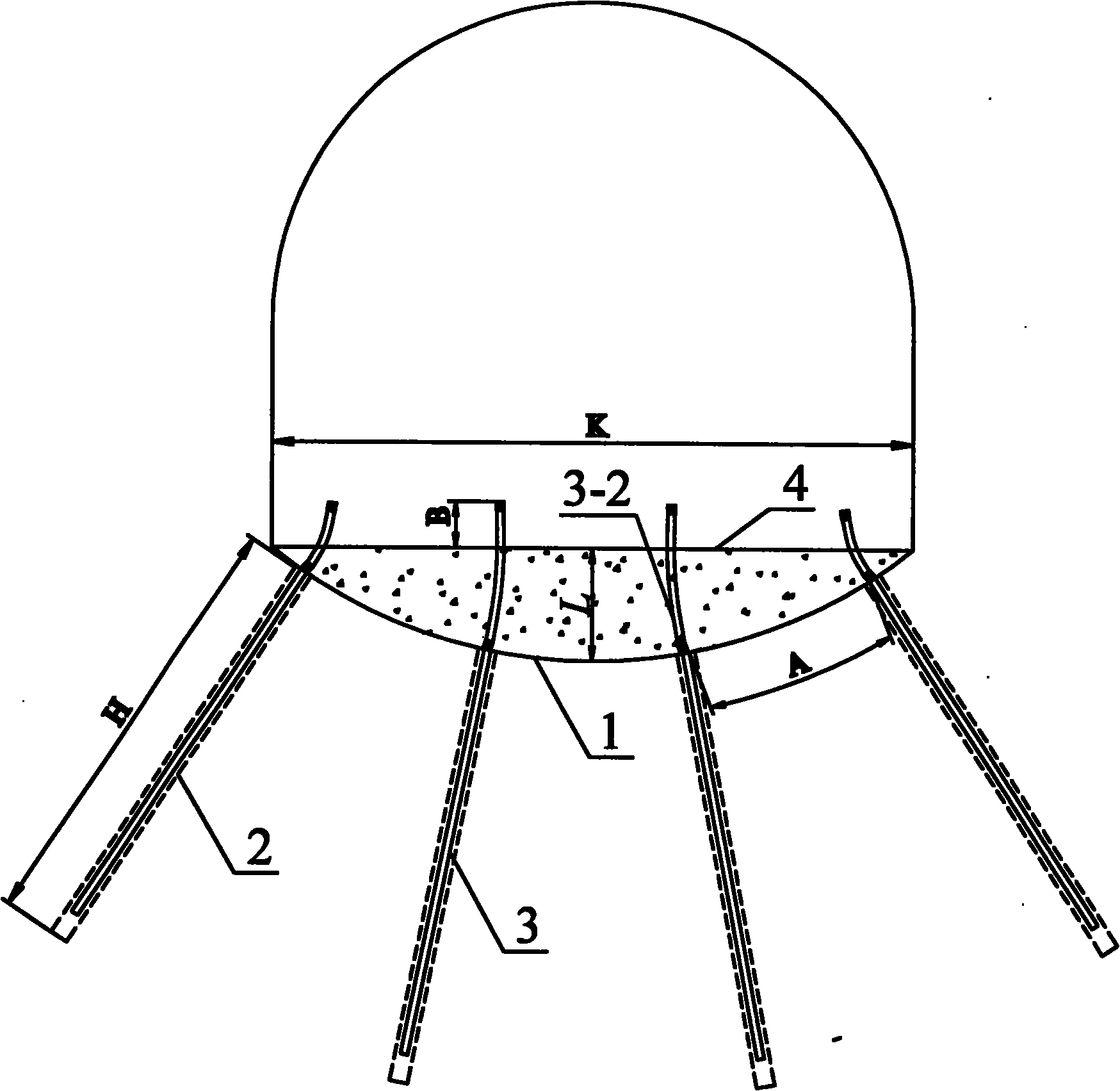

[0020] figure 1 As shown, in the grouting reinforcement method of the first-buried-then-injection roadway floor of the present invention, firstly, when the roadway is excavated, the roadway floor is excavated to form an anti-arch 1; Construct a plurality of grouting drilling holes 2; install the special grouting pipe 3 for the bottom plate; fill the arch bottom with crushed gangue or cement; wait for the excavation working face to advance a certain distance and then seal the bottom plate with grouting, and use a grouting pump to Grouting pipe for grouting. Specific steps are as follows:

[0021] (1) When the roadway is excavated, the bottom plate of the roadway is made into a reverse arch 1, and the arch height L of the reverse arch 1 is 1000-1500mm;

[0022] (2) Construct a plurality of grouting boreholes 2 at equal intervals along the anti-arch sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com