A test device for 15t-level planetary roller screw

A planetary roller and testing device technology, which is applied to measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of complicated loading process, low bearing range, waste of time, etc., to ensure relative accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the examples.

[0030] The invention provides a testing device for a 15t-level planetary roller screw, which can be adapted to various types and specifications of planetary roller screws, and meets the test requirements of large load and high precision; maintain platform accuracy.

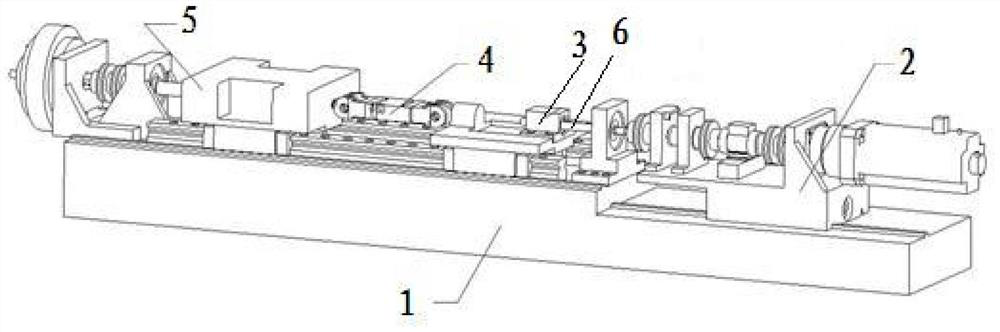

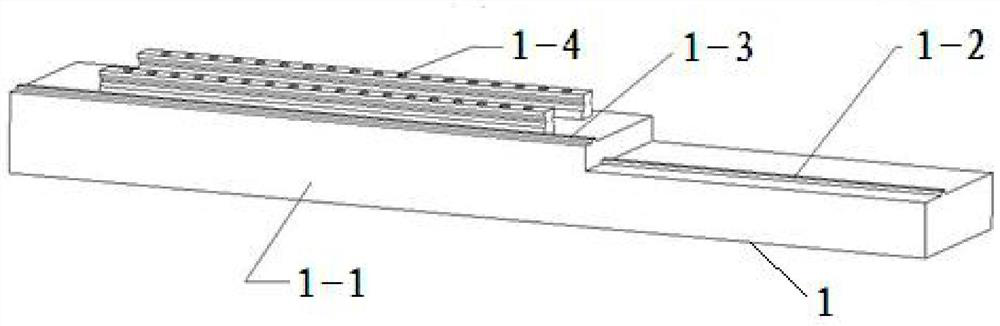

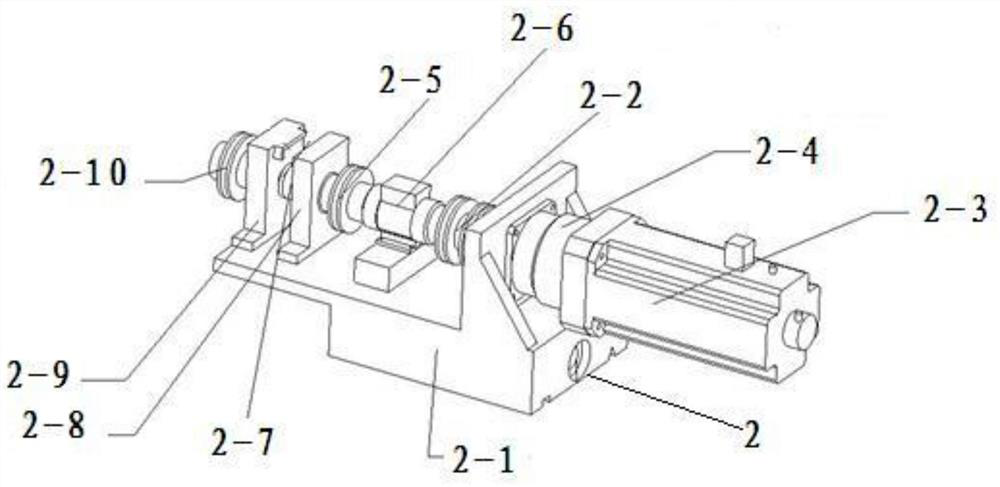

[0031] Test device for 15t class planetary roller screw, such as figure 1 As shown, it includes a base 1, a movable sliding table 2, a clamping device 3, a tension and pressure sensor group 4, a braking device 5 and a lead screw 6 to be measured; wherein, the base 1 is a horizontally placed cuboid platform; the movable sliding table 2, The clamping device 3, the tension and pressure sensor group 4, and the braking device 5 are all arranged on the upper surface of the base 1; the lead screw 6 to be measured is axially and horizontally arranged in the clamping device 3; The movable sliding table 2, the clamping device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com