Splayed lattice type truss steel supporting structure

A steel support, lattice technology, applied in infrastructure engineering, construction, excavation, etc., can solve the problems of large steel consumption, small effective space, slow construction speed, etc., to reduce steel consumption, high assembly efficiency, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

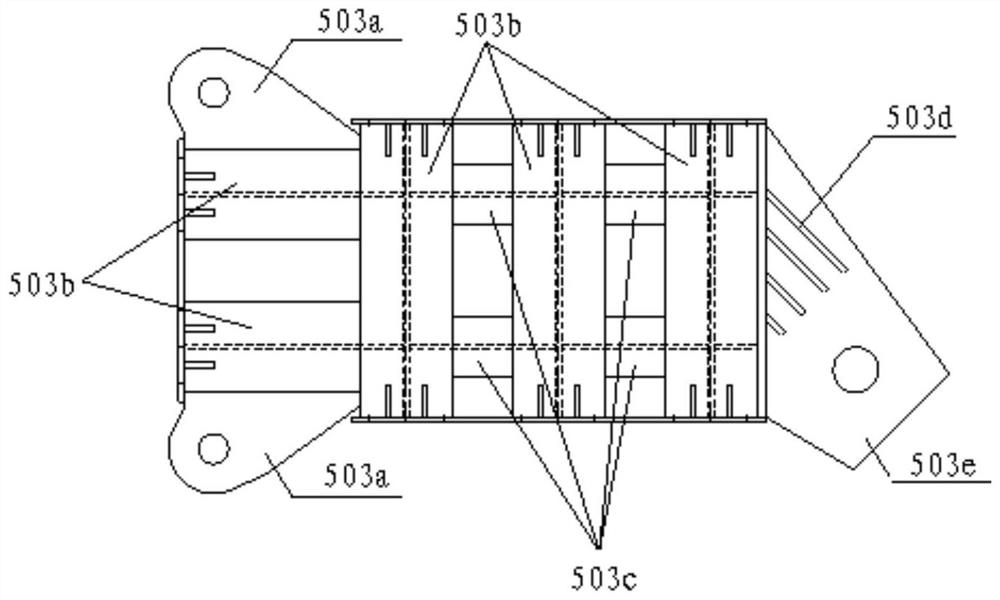

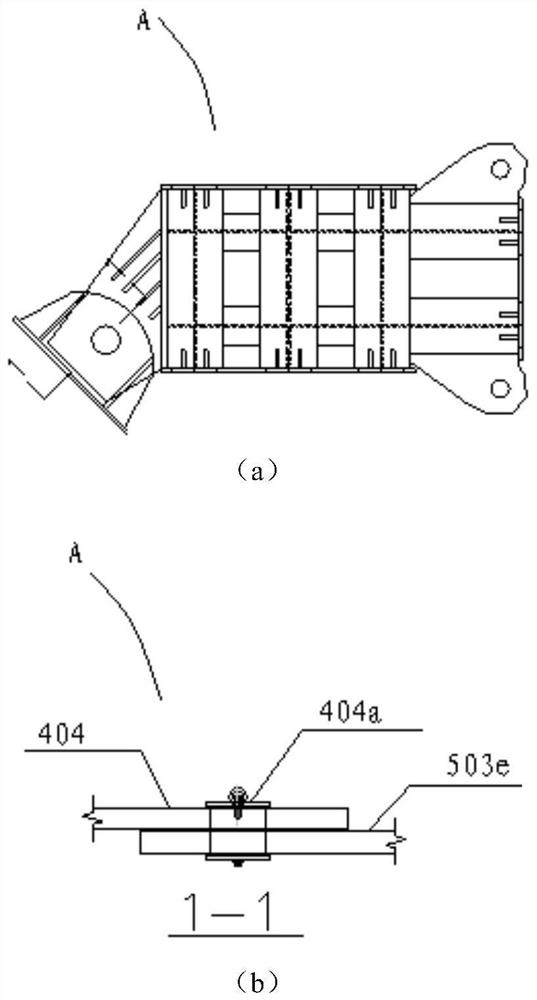

[0029] see Figure 1-6 , Eight-shaped lattice truss steel support structure, composed of reinforced concrete crown / waist beam 1, secondary pouring structure 2, reinforced concrete corbel 3, diagonal bracing structure 4, end truss steel support 5, middle truss steel support 6 The reinforced concrete corbel 3 provides the installation plane and angle for the steel support, so that the force of the steel support is simple and clear, and the secondary pouring structure 2 has the function of adjustment and leveling, which can minimize the impact of the construction errors of the surrounding structures on the steel support.

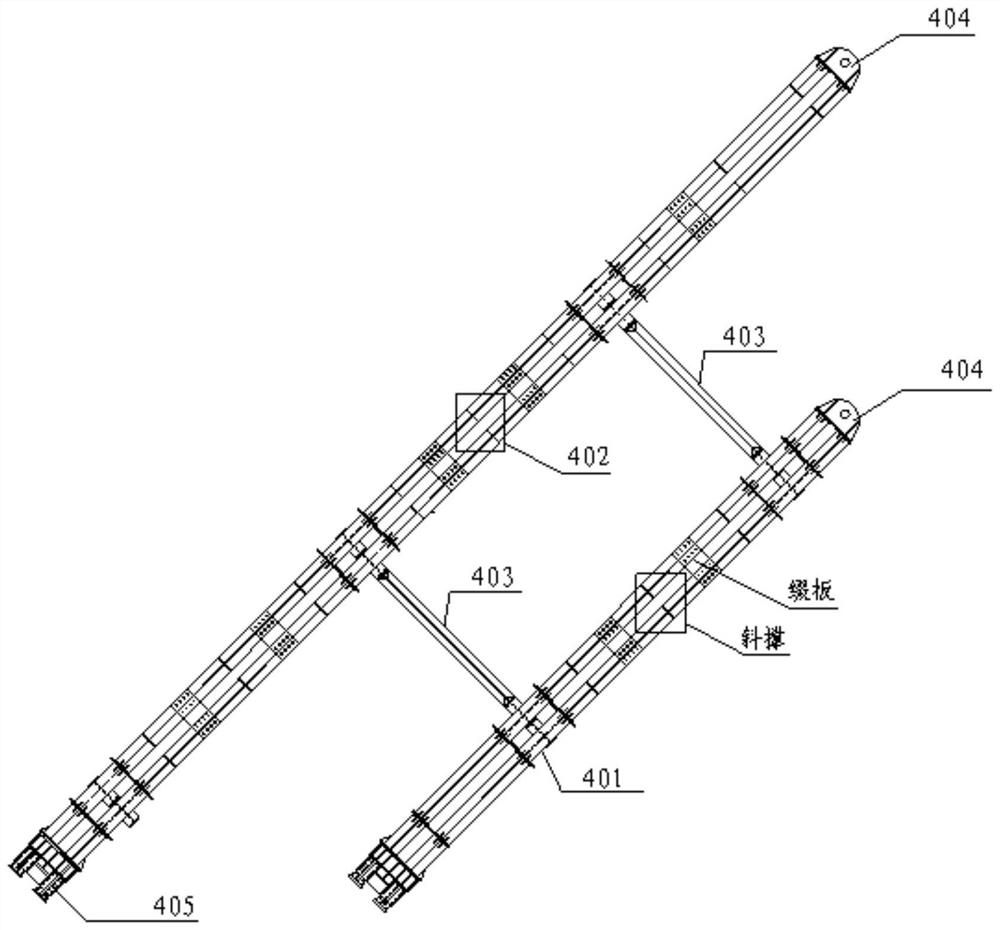

[0030] see figure 1 , the diagonal brace structure 4 is composed of expanded nodes 401, diagonal braces 402, cross-web rods 403, lug plate connectors 404, and prestressing device 405. The number is expanded, the diagonal brace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com