Making method of red mud modified asphalt

A technology for modifying asphalt and red mud, which is applied in building components, building insulation materials, buildings, etc. It can solve problems such as high cost, affecting strength and appearance, and frosting, and achieves improved resistance to deformation, high temperature performance, and Thickness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

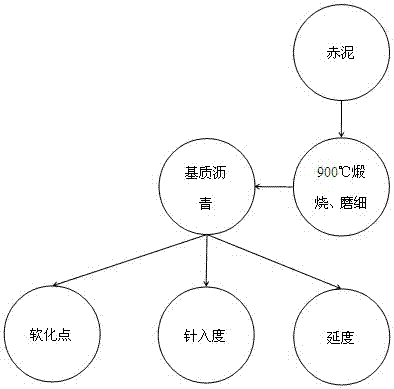

[0013] 1. Preparation of red mud modified asphalt

[0014] (1) The red mud is calcined and ground at 900°C.

[0015] (2) Mix 13 parts by weight of the red mud obtained in step (1) with 100 parts by weight of petroleum asphalt to obtain a red mud modified asphalt.

[0016] 2. Take 0-20 parts of the red mud obtained in step (1) (take every two parts and take ten parts for analysis), (take 25℃ as an example for analysis): ①At the same temperature, different blends The penetration of the red mud modified asphalt is lower than that of the base asphalt, and the penetration is the smallest when the red mud content is 13%. It shows that the incorporation of red mud increases the consistency of the base asphalt and improves the resistance of the asphalt to deformation. ②After mixing with red mud, the softening point of asphalt has also been significantly improved, and reaches the maximum when the mixing amount is 13%, and its value is 65.2℃. ③The incorporation of red mud greatly reduces th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com