Variable-damping variable-rigidity viscoelasticity-friction composite damping device

A technology of friction damper and compound damping, which is applied in the field of damper, variable damping and variable stiffness viscoelasticity-friction compound damper, to achieve the effect of increasing resistance to deformation, good energy dissipation capacity and improved dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

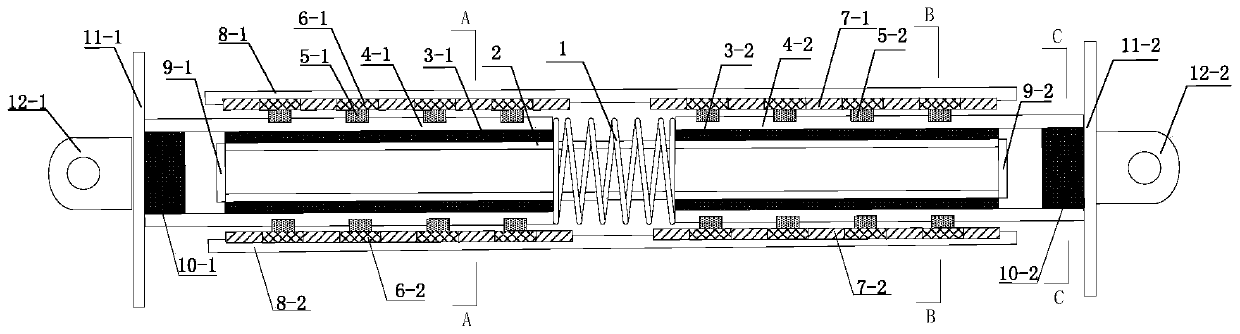

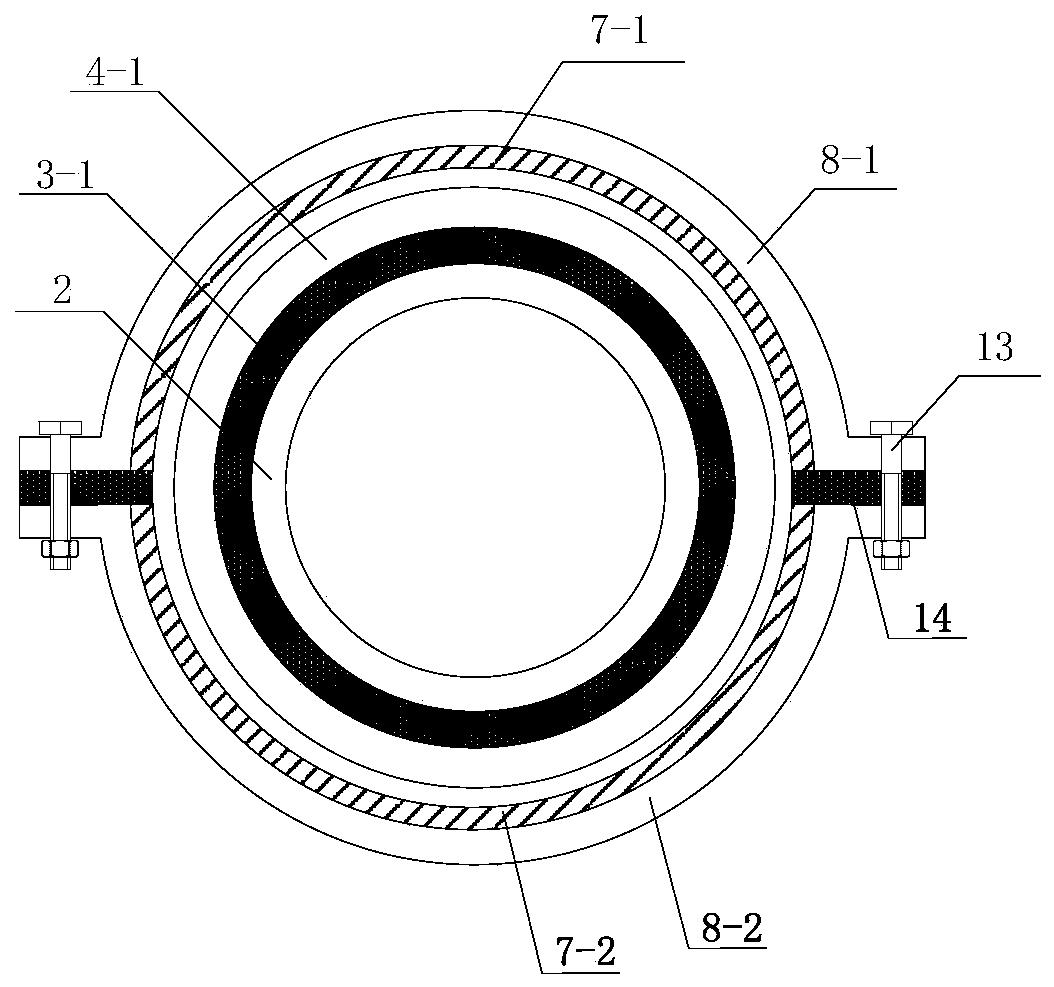

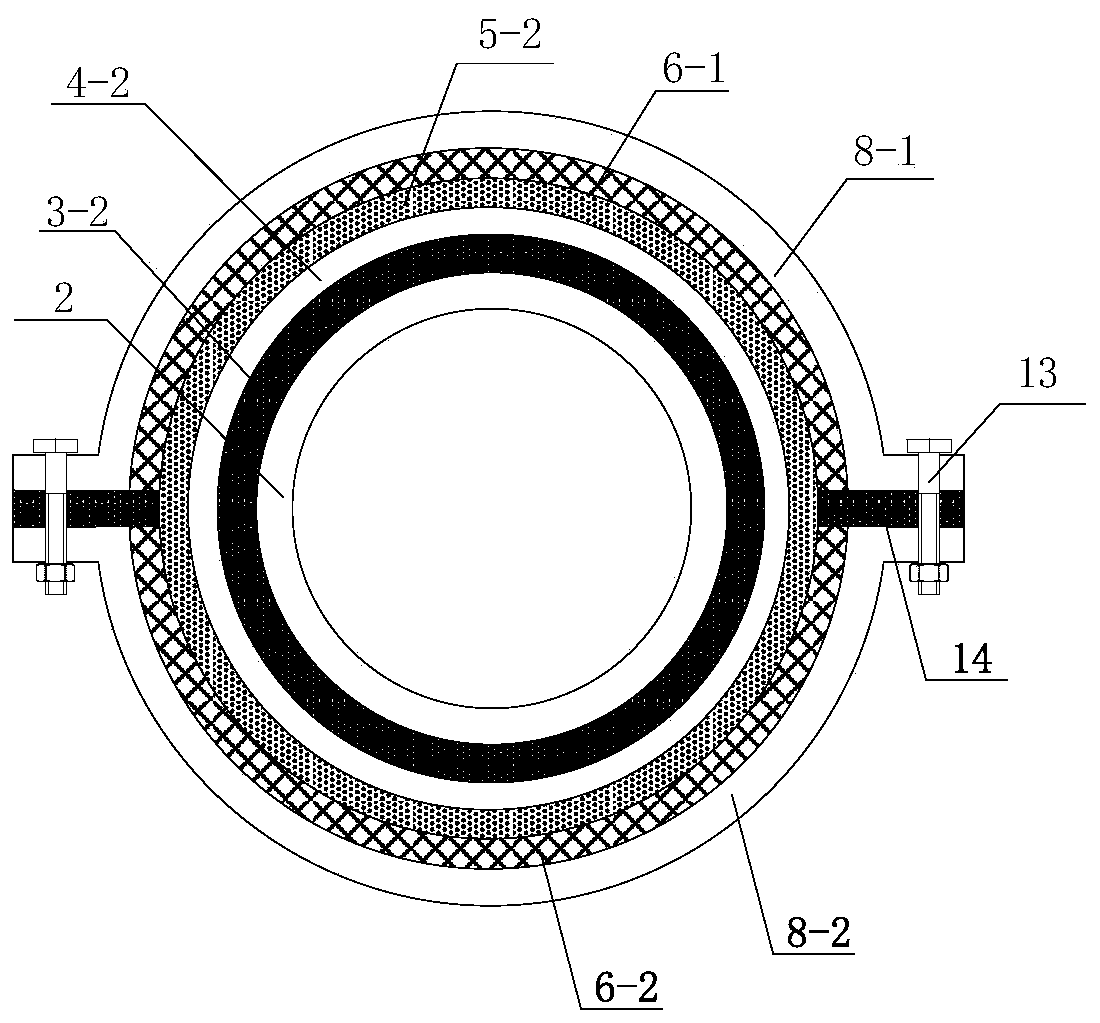

[0027] Examples, please refer to Figure 1-5 :

[0028] The variable damping and variable stiffness viscoelasticity-friction composite damper of the present invention has a symmetrical structure as a whole, including two cylindrical viscoelastic damper units and two cylindrical friction damper units. The viscoelastic damper units are symmetrically connected to each other, and the two friction damper units are respectively sleeved on the outside of the two cylindrical viscoelastic damper units, wherein,

[0029]The components of the cylindrical viscoelastic damper unit are arranged coaxially. From the inside to the outside, there are annular inner steel cylinder 2, annular viscoelastic material layer 3, and annular middle steel cylinder 4. The annular inner steel cylinder 2 is divided into left and right sides. , middle and right three sections, the annular middle steel cylinder 4 is divided into a left annular middle steel cylinder 4-1 and a right annular middle steel cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com