Exhaust pipe with effective noise reducing function and compressor

An exhaust pipe and compressor technology, which is applied in the field of compressors, can solve the problems of high transmission noise and small air flow noise in the pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

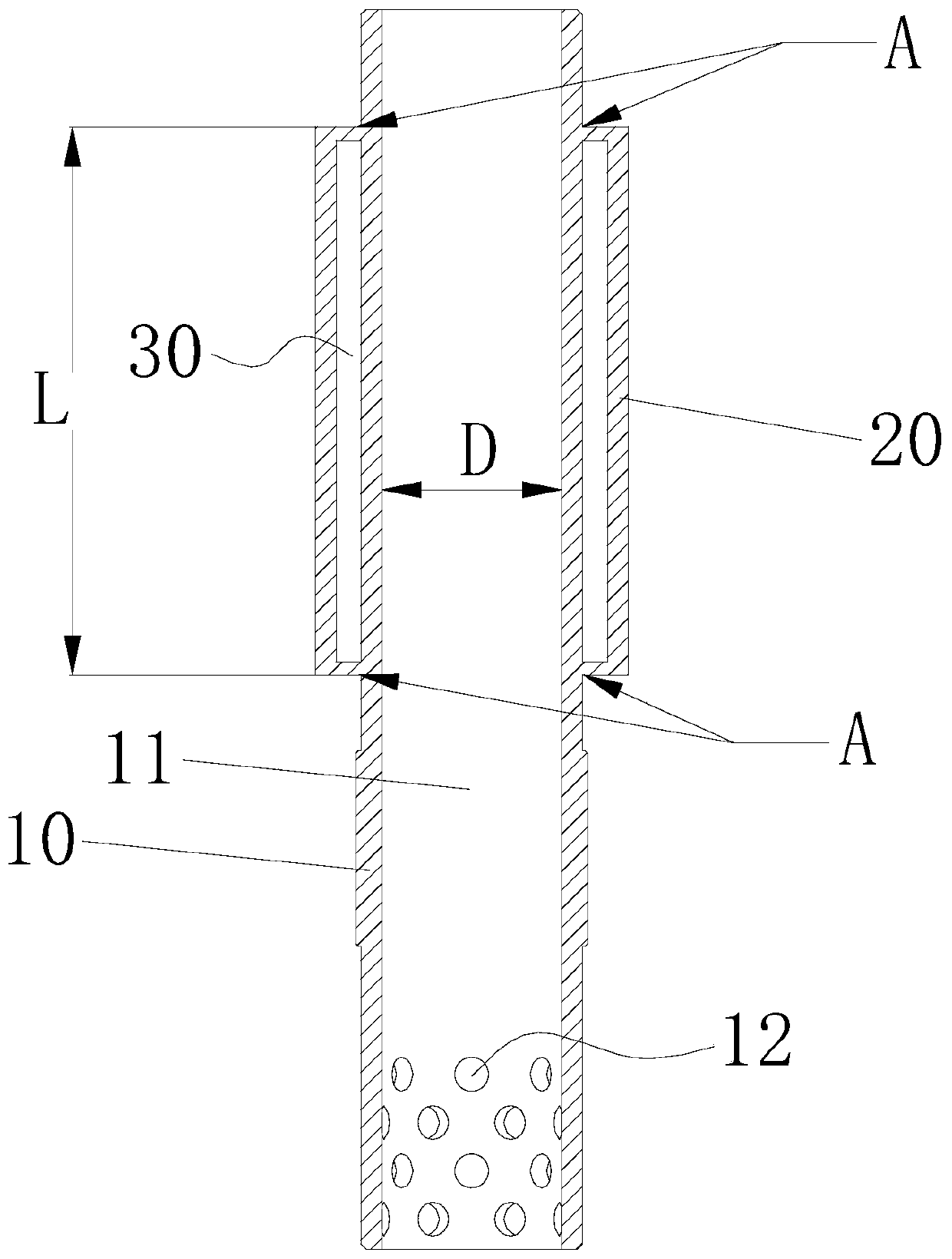

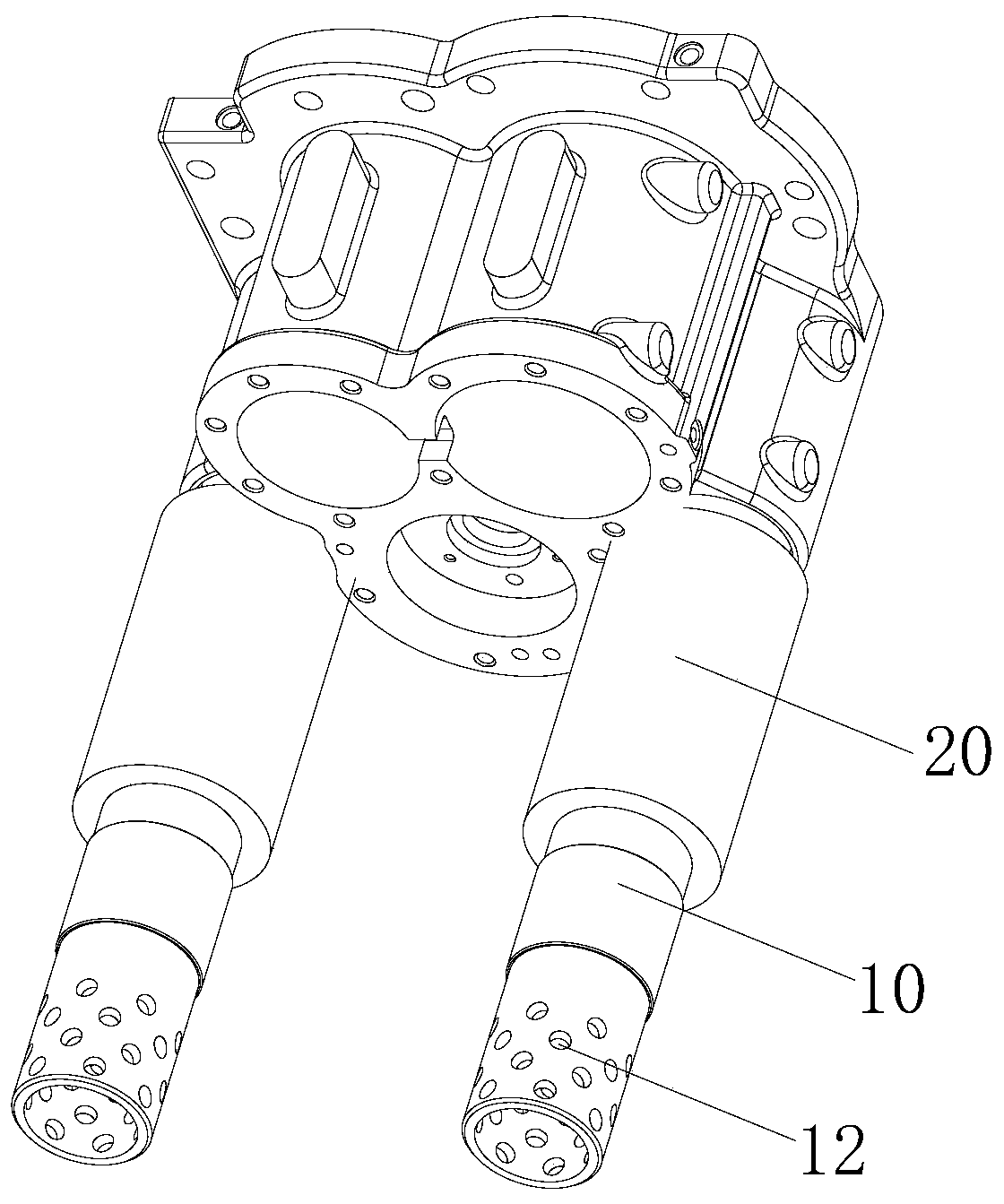

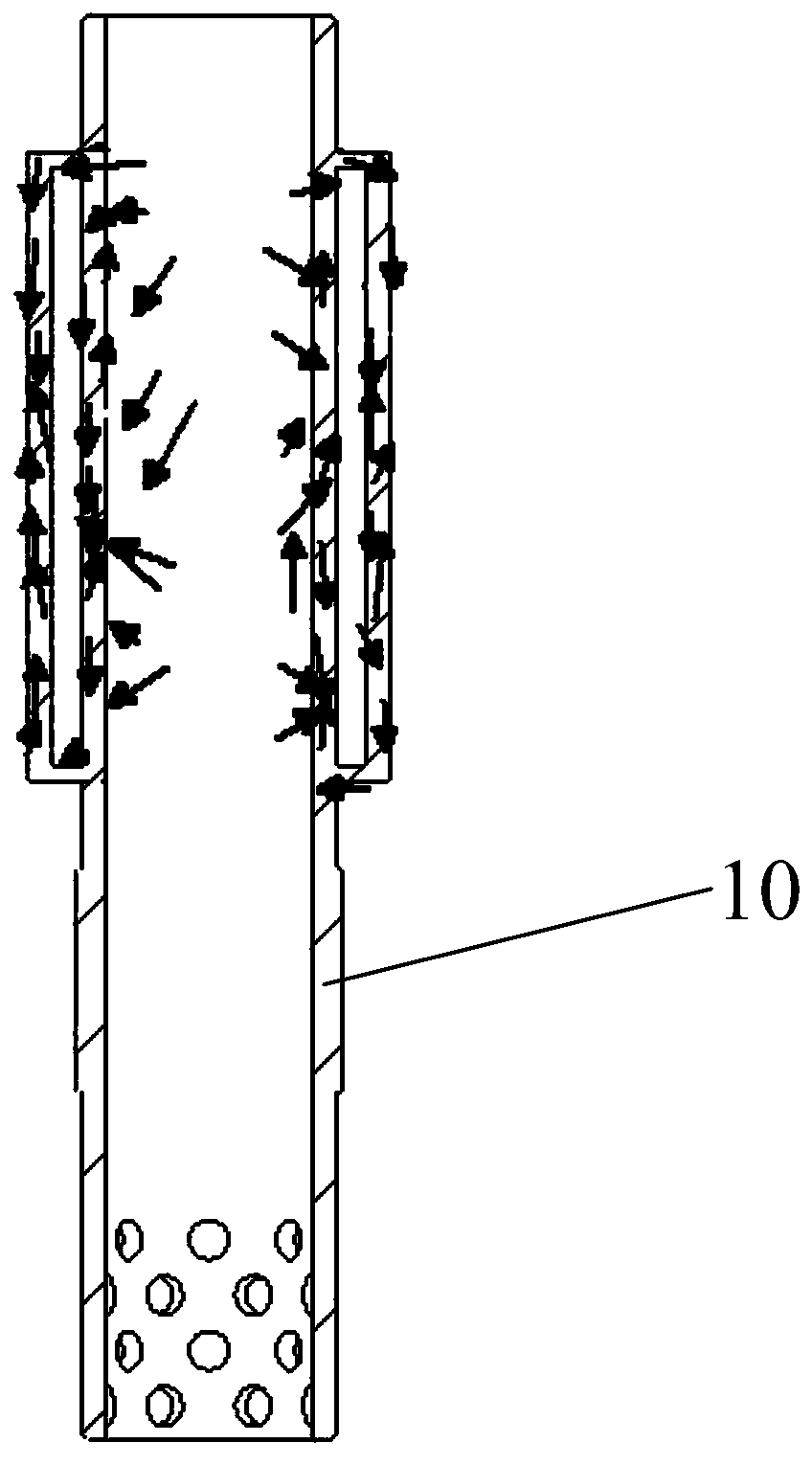

[0020] In the screw compressor, the exhaust pipe structure is used in the exhaust oil separation stage. The airflow in the exhaust pipe is high-temperature, high-pressure and high-speed flow, which produces a large airflow noise, which is transmitted through the exhaust pipe wall. The exhaust flow rate is constant. Under normal circumstances, the inner diameter of the exhaust pipe can be determined, and in the common selection of exhaust pipes, the wall thickness of the seamless steel pipe is almost a fixed value, and the wall thickness of the seamless steel pipe material that is often forced to be used is only sufficient for strength, but for Blocking exhaust noise isn't enough.

[0021] Aiming at the above-mentioned objective technical difficulty and technical problems that cannot be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com