Stratified aluminum boron carbide compound material and preparation method thereof

A composite material, boron carbide technology, applied in the field of layered composite materials, can solve problems such as easy fracture or even broken, user loss, and affecting material application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step S110, selecting aluminum powder with an average particle size of 50-60 μm and boron carbide powder with an average particle size of 1-30 μm. The aluminum powder and boron carbide powder were weighed and mixed according to the following 5 groups of volume ratios to obtain 5 groups of mixed powders. Group 1: 95vol% aluminum powder and 5vol% boron carbide powder; Group 2, 90vol% aluminum powder and 10vol% boron carbide powder; Group 3, 85vol% aluminum powder and 15vol% boron carbide powder; Group 4, 80vol % aluminum powder and 20vol% boron carbide powder; Group 5, 75vol% aluminum powder and 25vol% boron carbide powder.

[0023] In step S120, the mixed powders in step S110 are respectively put into a planetary ball mill by wet mixing method, and after ball milling, put into a blast drying oven for drying, and respectively make 5 groups of aluminum boron carbide powders correspondingly. Specifically, the following steps are included:

[0024] In step S121, each group ...

Embodiment 2

[0031] Example 2 Except that the sintering conditions in the vacuum hot-press furnace are inconsistent with Example 1, other steps are consistent with Example 1, see Example 1

[0032] In the first stage of the vacuum hot pressing furnace in Example 2, the temperature rises from normal temperature to 500°C, and the heating rate is 10°C / min; Insulate at 680°C for 90 minutes. Start the pressurization program before the temperature rises to 530°C, pressurize to a sintering pressure of 30MPa, and hold the pressure for 90min.

[0033] The mechanical properties of the layered aluminum boron carbide composite material obtained in Example 2 are measured by testing: density 98.43%, bending strength 629.63±27.24MPa, toughness 12.45±2.12MPa m 1 / 2 , hardness 151.11±18.65Hv.

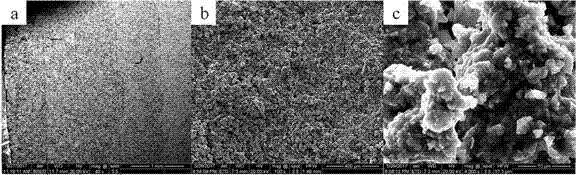

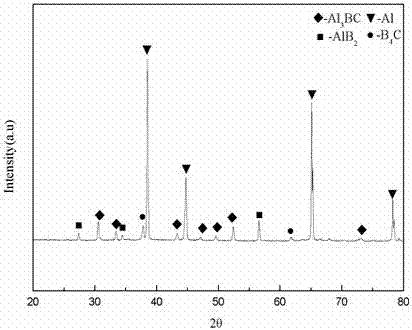

[0034] figure 1 The scanning electron micrograph of the layered aluminum boron carbide composite material prepared for the second embodiment can be obtained by figure 1 a It can be seen that the layered aluminum ...

Embodiment 3

[0036] Example 3 Except that the sintering conditions in the vacuum hot-press furnace are inconsistent with Example 1, other steps are consistent with Example 1, see Example 1

[0037] In the first stage of the vacuum hot pressing furnace in Example 3, the temperature was raised from normal temperature to 500°C, and the heating rate was 10°C / min; Insulate at 700°C for 120 minutes. Start the pressurization program before the temperature rises to 550°C, pressurize to a sintering pressure of 20MPa, and hold the pressure for 120min.

[0038] The mechanical properties of the layered aluminum boron carbide composite material obtained in Example 3 are measured by testing: density 99.01%, bending strength 685.12±32.18 MPa, toughness 12.87±2.23MPa m 1 / 2 , hardness 156.89±20.45Hv.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com