Aluminum material extruding machine

A technology of aluminum extrusion machine and extrusion cylinder, which is applied in the field of aluminum extrusion machine, can solve the problem of fast heat dissipation of extrusion cylinder, and achieve the effect of simple structure, large output power and small deformation resistance

Inactive Publication Date: 2017-02-01

ZUNYI HENG JIA ALUMINUM CO LTD

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention aims at the above-mentioned existing technical problems, and provides an extruder to solve the problem of fast heat dissipation of the extruding cylinder in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] Below in conjunction with embodiment technical solution of the present invention is further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

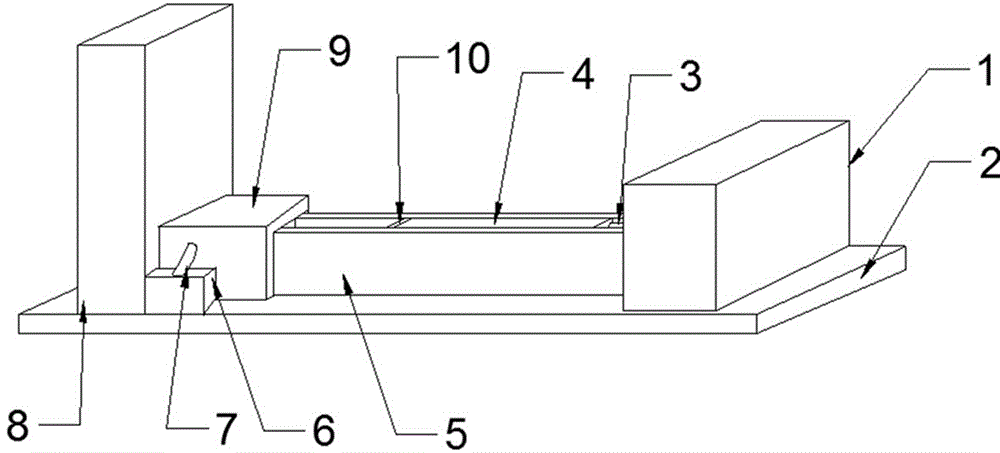

The invention discloses an aluminum material extruding machine in the technical field of equipment manufacturing. The aluminum material extruding machine comprises a platform fixed to the ground. The platform is sequentially provided with a die base, an extruding cylinder, an extruding beam and an air cylinder from left to right. The die base is provided with a die. The extruding beam and a piston rod of the air cylinder are fixed. The die is fixedly connected into the extruding cylinder. The die base, the die, the extruding beam and the extruding cylinder are located on the same axis. The extruding cylinder comprises an inner layer and an outer layer. The outer layer of the extruding cylinder is connected with a vacuum pump through a flexible pipe. One end of the flexible pipe extends into an interlayer formed by the inner layer and the outer layer of the extruding cylinder. The vacuum pump is arranged on the platform. By the adoption of the extruding machine in the scheme, after the vacuum pump is started, air in the interlayer is pumped out to make the interlayer vacuum, the extruding cylinder does not dissipate heat easily, the cooling speed of aluminum materials is low, and the aluminum materials can be formed beneficially.

Description

technical field [0001] The invention relates to the technical field of equipment manufacturing, in particular to an aluminum extrusion machine. Background technique [0002] In recent years, due to the miniaturization and lightweight requirements of automotive air-conditioning equipment, the proportion of aluminum extruded products in heat exchanger tubes and hollow profiles has increased rapidly, and aluminum and aluminum alloy products account for more than 70% of extruded products. The development of aluminum alloy profile extrusion technology has therefore led to the development of modern extrusion technology. [0003] The extrusion process of aluminum alloy profiles is to put the aluminum alloy blank into the extrusion cylinder installed on the plastic forming equipment. The hole is extruded to obtain the required cross-sectional shape and size; during the extrusion process, the aluminum alloy is in a state of strong three-dimensional compressive stress in the extrusio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21C29/04B21C23/21

CPCB21C29/04B21C23/211B21C29/006

Inventor 蒋继明蒋丰产陈智斌

Owner ZUNYI HENG JIA ALUMINUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com