Automatic ink color blending equipment

A technology of ink and equipment, which is applied in the field of ink color automatic blending equipment, can solve the problems of cumbersome and time-consuming, semi-solidified ink, waste of production time, etc., and achieve the effect of avoiding cumbersome manual operation, convenient and quick color testing process, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0046]The embodiment of the present invention relates to the provided automatic ink color adjustment equipment, which can realize automatic ink color adjustment and matching with target color.

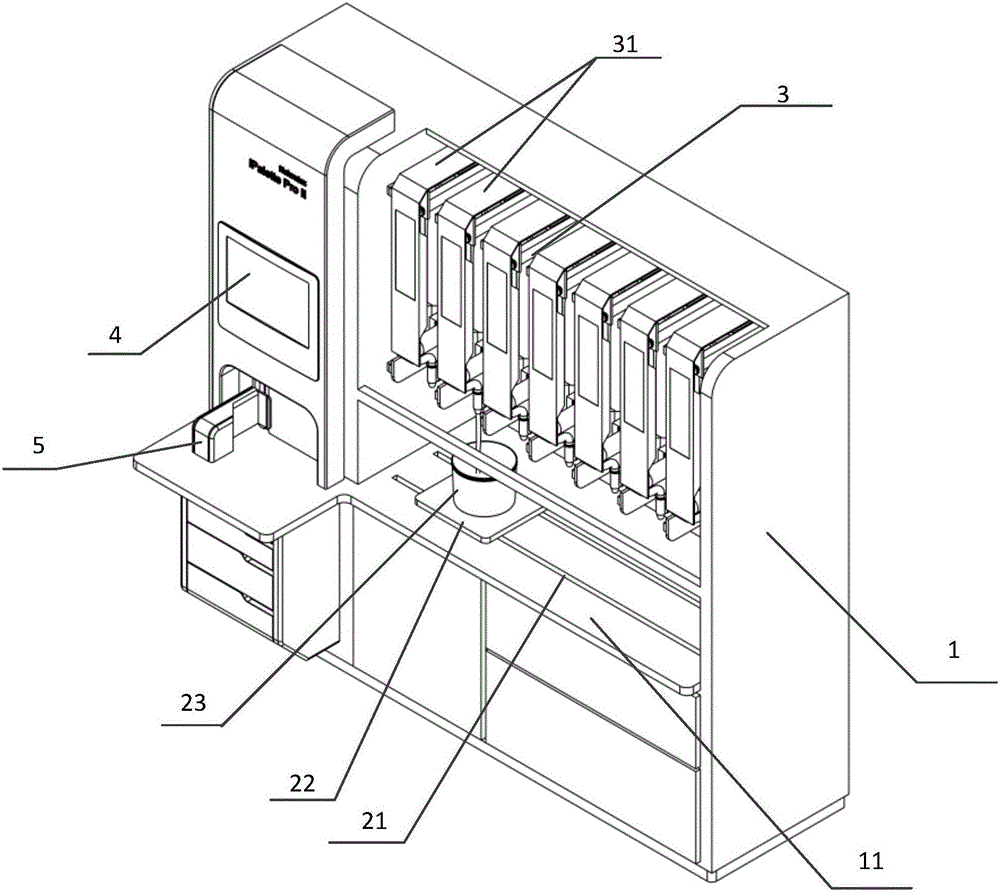

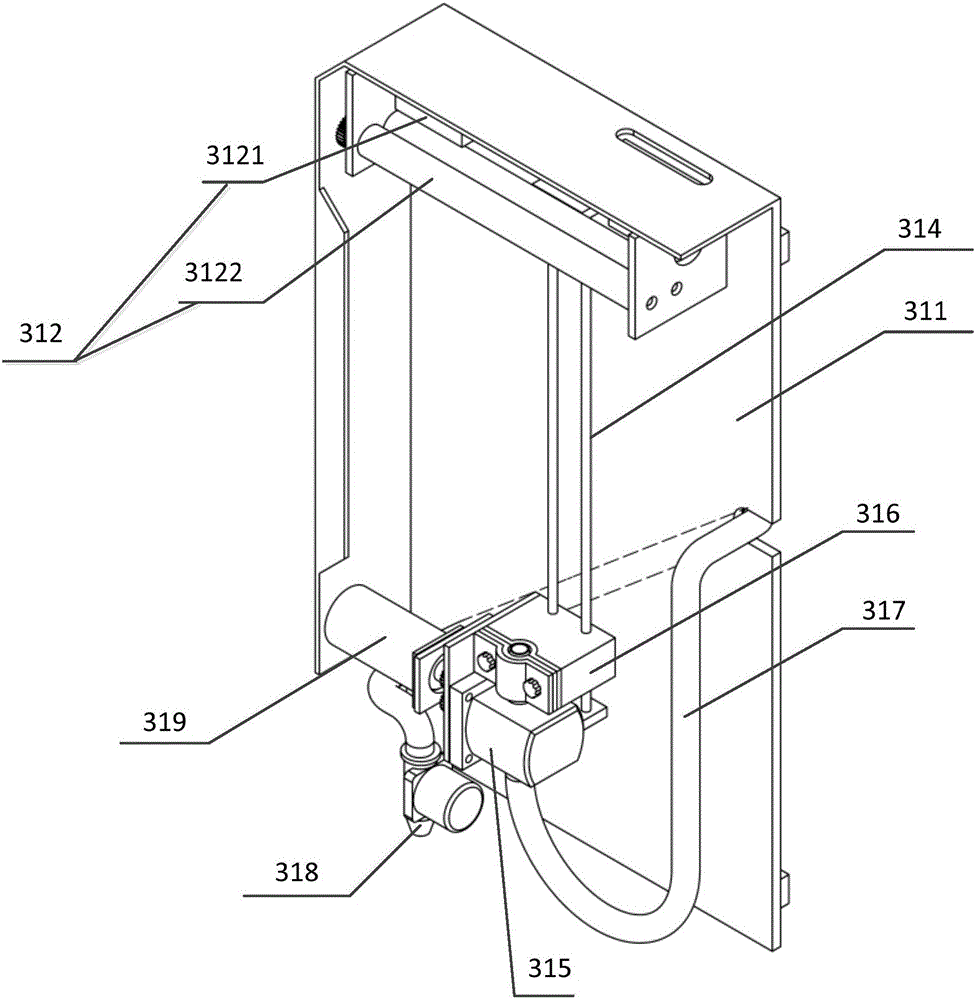

[0047] figure 1 Shown is a schematic diagram of the appearance and structure of the ink color automatic blending equipment. Such as figure 1 As shown, the ink color automatic blending equipment provided in this embodiment includes:

[0048] The equipment cabinet 1 has a bearing platform 11 on it; the lower part of the cabinet 1 can be set as a storage space for storing printing samples and the like.

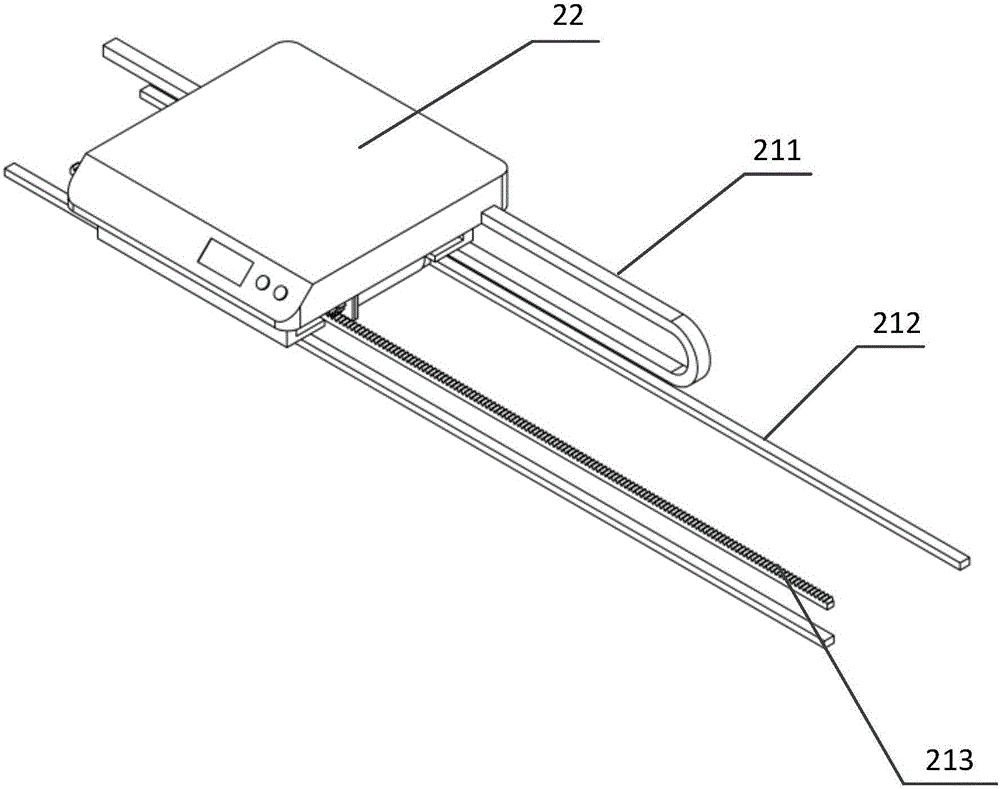

[0049] The ink barrel moving platform 2 is arranged on the carrying platform 11; the ink barrel moving platform 2 includes a moving guide rail 21, a weighing device 22 and an ink barrel 23; the ink barrel 23 is placed on a weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com