Patents

Literature

1178results about How to "Easy extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of porous fiber non-woven fabric

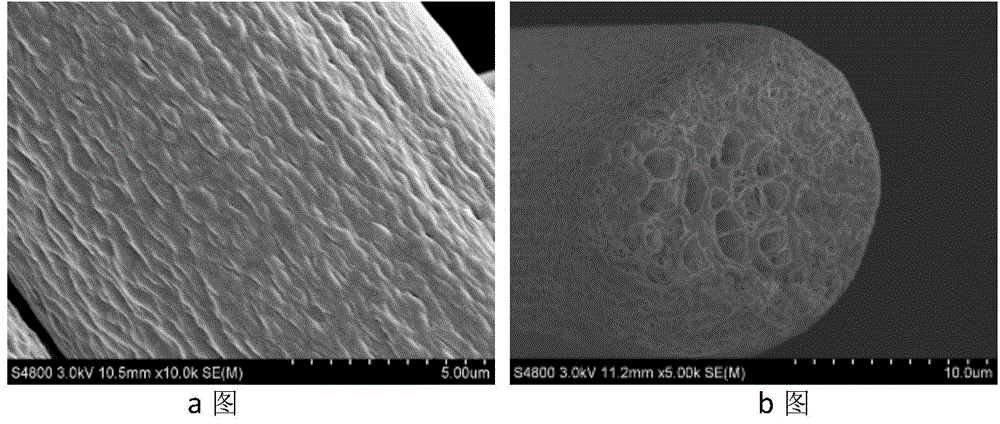

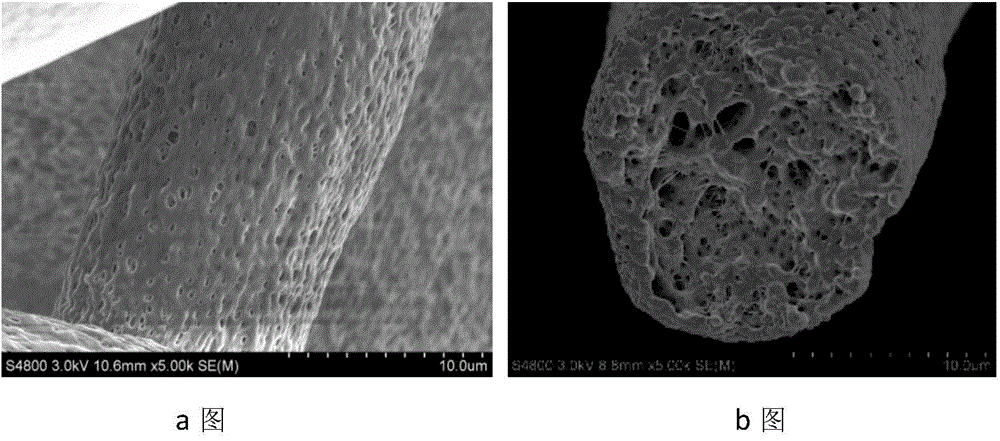

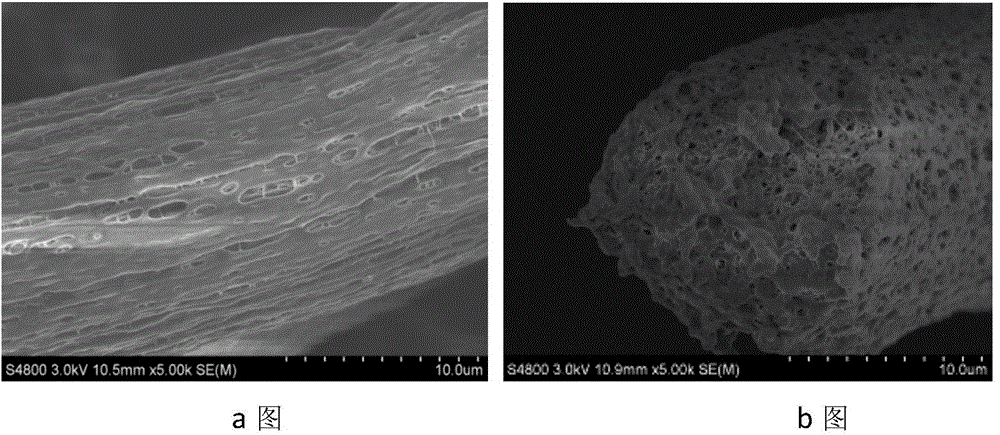

ActiveCN103981635AReduce melt viscosityReduce degradationFilament forming substance formingMelt spinning methodsDiluentNonwoven fabric

The invention relates to a preparation method of a porous fiber non-woven fabric. The aim of the preparation method is to improve the product performance of the conventional non-woven fabric, so that the non-woven fabric meets the requirements on high-precision and high-performance filter. The technical scheme is that the preparation method of the porous fiber non-woven fabric comprises the following steps in sequence: (1) uniformly mixing a polymer and a diluent to obtain a blend with 10 to 60 percent of polymer; (2) melting and extruding the blend in the step (1) by adopting a screw extruder granulator, and directly cooling and granulating in air; (3) producing master batches in the step (2) by melt-down equipment to obtain a primary non-woven fabric; (4) extracting to remove the diluent from the primary non-woven fabric in the step (3), performing pore-forming on fibers in the non-woven fabric, and drying to obtain the porous fiber non-wave fabric; (5) recovering mixed waste liquid of the diluent and an extraction agent for reuse.

Owner:浙江省轻工业品质量检验研究院

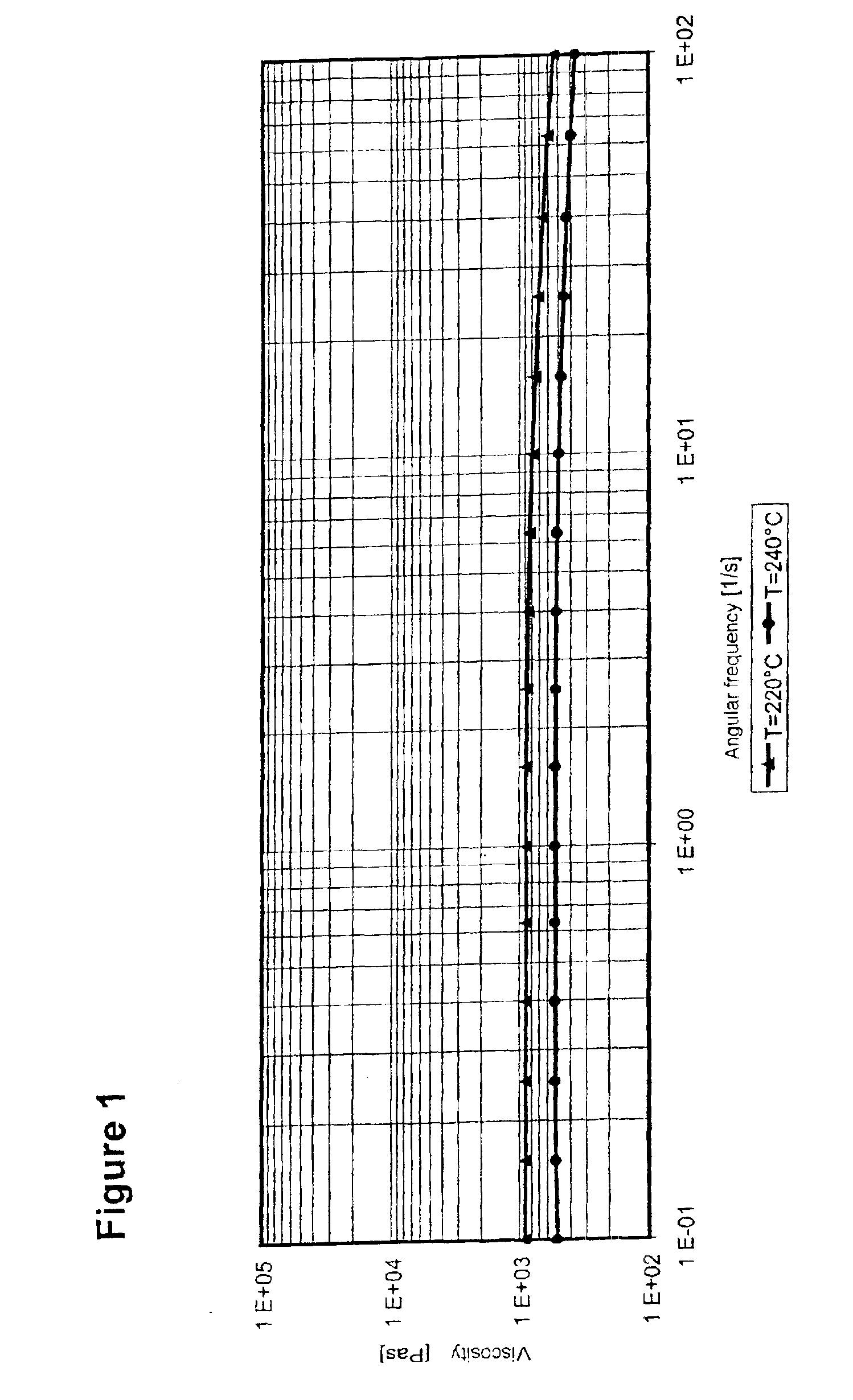

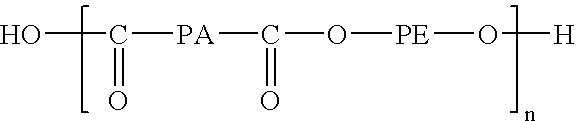

Molding composition based on polyetheramides

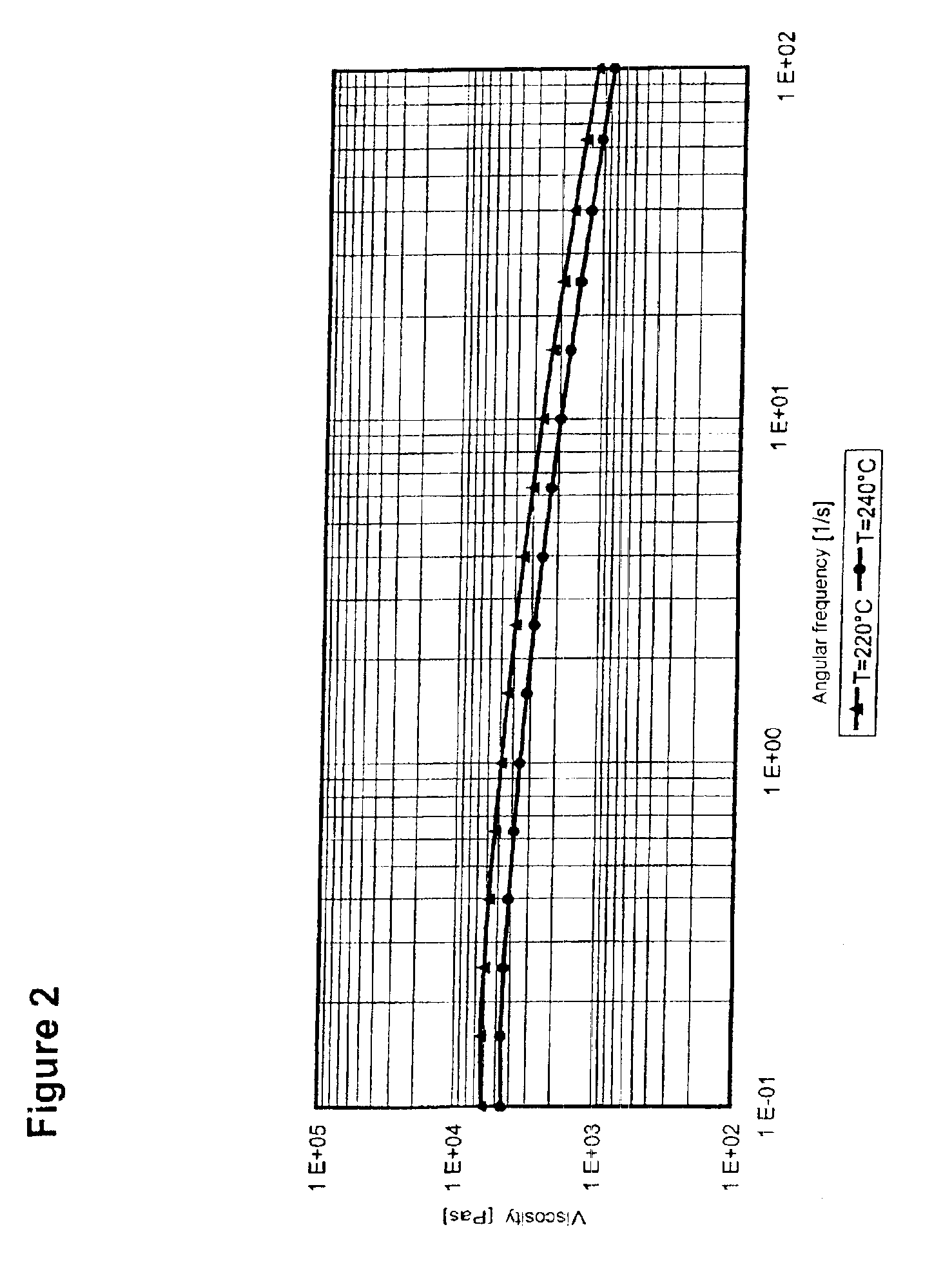

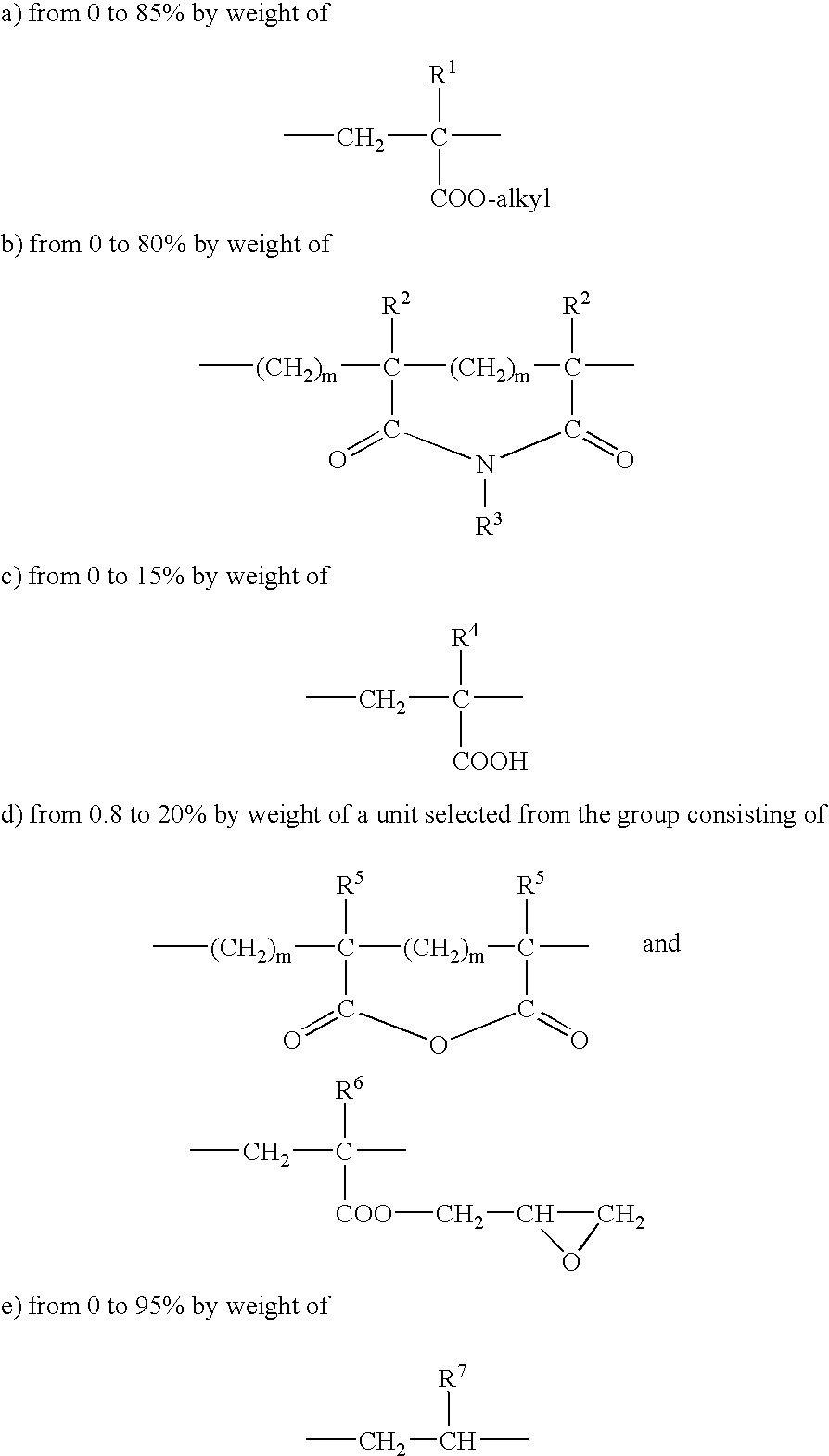

InactiveUS6884485B2Increase melt viscosityEasy extrusionEnvelopes/bags making machineryBottlesPolymer scienceDicarboxylic acid

A molding composition containing the following components:I. from 99.9 to 95 parts by weight of a polyetheramide obtained from 1) a linear aliphatic diamine having from 6 to 12 carbon atoms, 2) a linear aliphatic or aromatic dicarboxylic acid having from 6 to 12 carbon atoms, and 3) a polyetherdiamine having at least 3 carbon atoms per ethereal oxygen atom and having a primary amino group at an end of the chain, andII. from 0.1 to 5 parts by weight of a copolymer which contains from 0.8 to 20% by weight of an anhydride or an epoxide in copolymerized form,wherein the total amount of I. and II. is 100 parts by weight, is suitable for the extrusion of flexible pipes, and also for the production of flexible blow-molded articles.

Owner:EVONIK DEGUSSA GMBH

Low smoke halogen-free flame retardant ethylene-propylene-diene rubber and preparation method by extrusion molding thereof

ActiveCN101704976AGood mechanical propertiesEasy extrusionEngine sealsVehicle sealing arrangementsPolymer scienceMechanical property

The invention relates to a low smoke halogen-free flame retardant ethylene-propylene-diene rubber and a preparation method by extrusion molding thereof; the preparation method comprises the following steps: firstly, raw rubber matrix is evenly mixed at 80-100 DEG C by an open mill or a banbury mixer, and then cooled down to the room temperature; carbon black, modified nanometer / micrometer hydroxide, plasticizer, flame retardant synergist, vulcanization accelerator and vulcanizing agent are added in sequence according to the proportion and evenly mixed. Mixed rubber is added into a single screw extrusion machine; the temperature of a machine body, a screw and a machine head is controlled to be 50-90 DEG C; the rotating speed of the screw is within 15-40 r / min to cause that glue stock is continuously squeezed out; and hot air (175-200 DEG C) or microwave (915-2450 MHz) is adopted to cause that the glue stock is continuously vulcanized and molded. The flame retardant ethylene-propylene-diene rubber has excellent mechanical property, low smoke halogen-free flame retardant performance and good extrusion performance, and is applicable to manufacturing of flame retardant gland strips used in doors and windows for building and vehicles.

Owner:BEIJING UNIV OF CHEM TECH +1

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

Conductive fluoropolymers

InactiveUS6533955B1Improve conductivityEasy to processNon-metal conductorsConductive materialConductive polymerFluoropolymer

The invention provides a melt-processable conductive fluorothermoplastic composition comprising three components. The first component is at least one melt-processable, thermoplastic fluoropolymer component having its interpolymerized units derived from (i) at least 50 wt % of TFE, and (ii) one or more ethylenically-unsaturated monomers represented by the formulas (a) CF2=CF-Rf, (b) CF2=CF-O-Rf', and (c) CH2=CR2, wherein Rf is a perfluoroalkyl of 1 to 8 carbon atoms, Rf' is Rf or a perfluoroalkoxy of 1 to 8 carbon atoms, and R is selected from H, F, Cl, or an aliphatic group having from 1 to 8 carbon atoms which may have F or Cl substituents. The thermoplastic fluoropolymer component is substantially free of interpolymerized units derived from VDF. The second component is from about 0.1 to about 10 weight percent of a hydrocarbon polymer, and the third component is from about 1 to about 20 weight percent of conductive filler. The invention also provides a method for making fluorothermoplastic compositions and shaped articles comprising a conductive fluorothermoplastic composition.

Owner:3M INNOVATIVE PROPERTIES CO

Aluminum alloy of excellent machinability and manufacturing method thereof

An aluminum alloy containing Si: 1.5-12% (mass % here and hereinafter), Mg: 0.5-6% and, optionally, at least one of Mn: 0.5-2%, Cu: 0.15-3% and Cr: 0.04-0.35% and, further, containing Ti: 0.01-0.1% and the balance of Al and inevitable impurities, in which the average grain size of crystallized grains of Si system compounds is from 2 to 20 mu m and an area ratio thereof is from 2 to 12%. The alloy is melted to obtain a cast ingot having DAS (Dendrite Arm Spacing) of 10 to 50 mu m, which is then put to a soaking treatment at 450 to 520 DEG C. and then to extrusion molding. The aluminum alloy has excellent machinability with no addition of low melting metals.

Owner:KOBE STEEL LTD

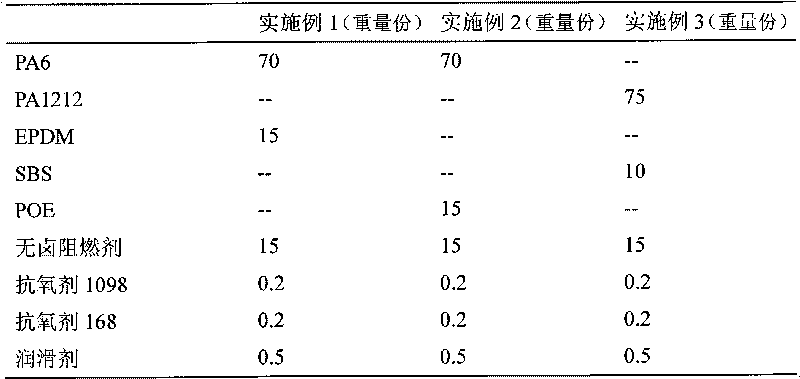

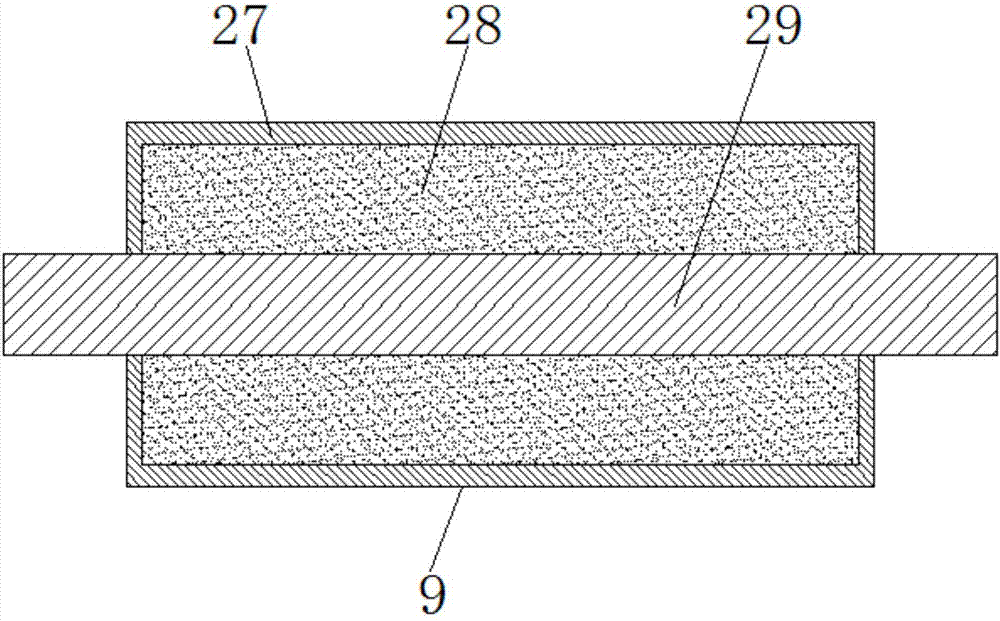

High-viscosity halogen-free flame-retardant polyamide composition

The invention relates to a high-viscosity halogen-free flame-retardant polyamide composition which comprises the following components in parts by weight: 60-92 of polyamide, 3-20 of plasticizer, 5-20 of halogen-free flame retardant and 0.1-2 of other assistants. After the polyamide composition prepared by the invention is formed and processed, a product has good flexibility, twisting resistance and good bending property and can bear a heavier load; the product has acid resistance and friction resistance, has resistance to lubricating oil and cooling liquid and has luster at the surface; the product can bear the stress of foot tread, has no rupture and no deformation, can be quickly restored and has no any damage per se; and the appearance of the product is smooth, black and bright, and the product has no broken fragments and has uniform color. The invention can be used for the finished pieces of a corrugated pipe and the like of a high-grade automobile.

Owner:HEFEI GENIUS NEW MATERIALS

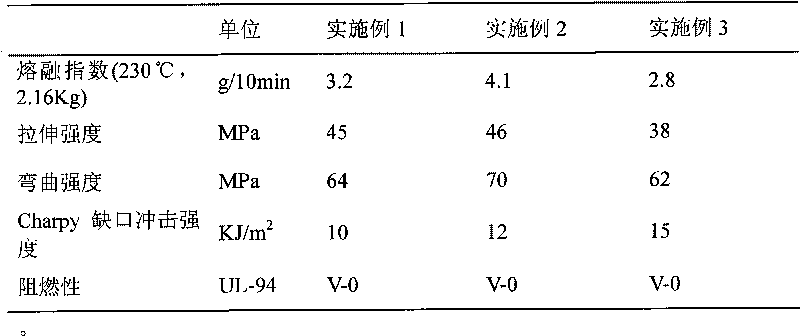

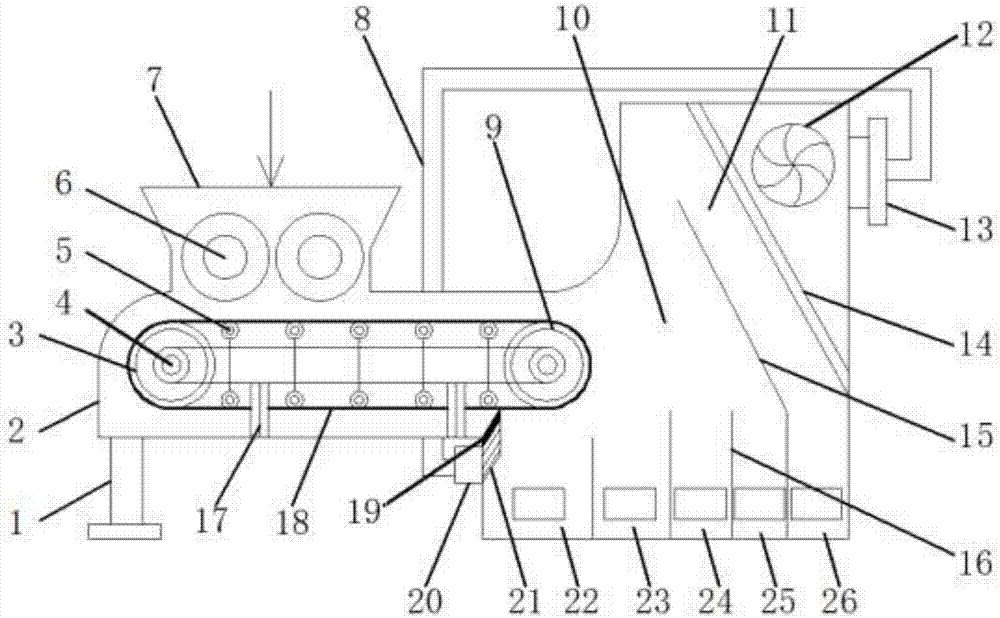

Transportation magnetic separation equipment for crushing and processing construction waste

InactiveCN107282175APromote fragmentationAchieve brokenGas current separationMagnetic separationSlagArchitectural engineering

The invention discloses a transportation magnetic separation equipment for crushing and processing construction waste, which comprises a frame, a transmission box, a magnetic separation roller and a conveyor belt. The transmission box is installed on the upper end of the frame, and a conveyor frame is installed inside the transmission box , a driving roller and a magnetic separation roller are installed on the conveyor frame, and a conveyor belt is set between the driving roller and the magnetic separation roller; the upper left end of the transmission box is welded with a construction waste adding bucket, and the bottom of the construction waste adding bucket is A crushing roller is installed inside; the right end of the conveyor belt is provided with a winnowing chamber, and the bottom side of the right end of the conveyor belt is installed in sequence from left to right with an iron collection box, a heavy material box, a light material box, a slag collection box and Dust settling box; it is convenient to add construction waste into the hopper and crush it through the two crushing rollers; the magnetic separation roller absorbs and screens the construction waste containing ferromagnetism to realize the crushing and transportation of construction waste , Removal of ferromagnetism, screening, separation and dust removal, the operation is convenient and quick.

Owner:寿涵红

High strength Al-Mg-Zn-Si alloy for welded structures and brazing application

InactiveUS6302973B1Improve corrosion resistanceHigh strengthWelding/cutting media/materialsSoldering mediaMagnesiumZinc

Aluminium-magnesium-zinc-silicon alloy, preferably in the form of a plate or a sheet or an extrusion, having the following composition in weight percent: Mg 0.5-1.5; Zn 0.1-3.8; Si 0.05-1.5; Mn 0.2-0.8; Zr 0.05-0.25; Cr 0.3 max.; Cu<0.3; Fe 0.5 max.; Ag 0.4 max.; Ti 0.2 max.; balance Al and inevitable impurities.

Owner:HOOGOVENS ALUMINIUM PROFILTECHNIK GMBH +1

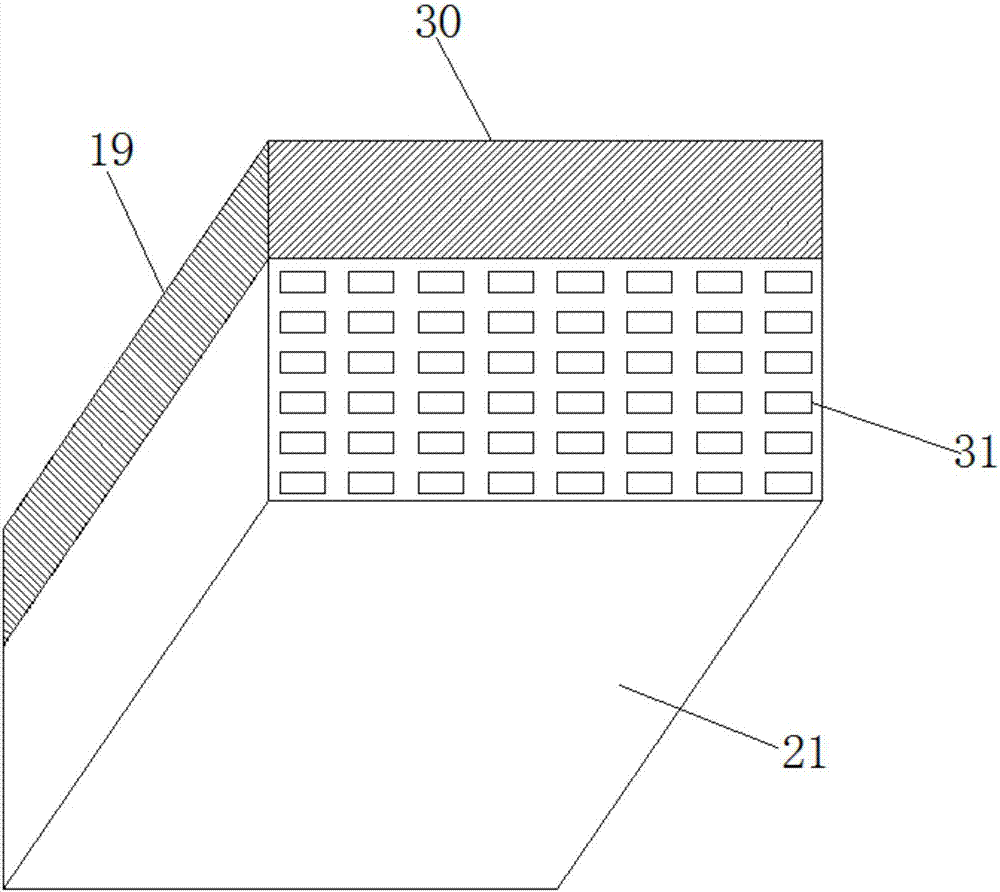

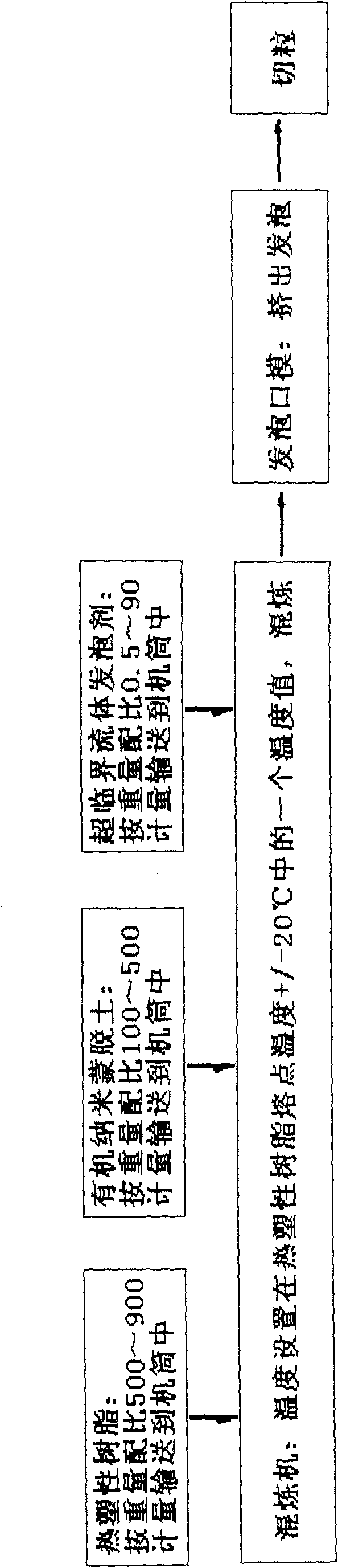

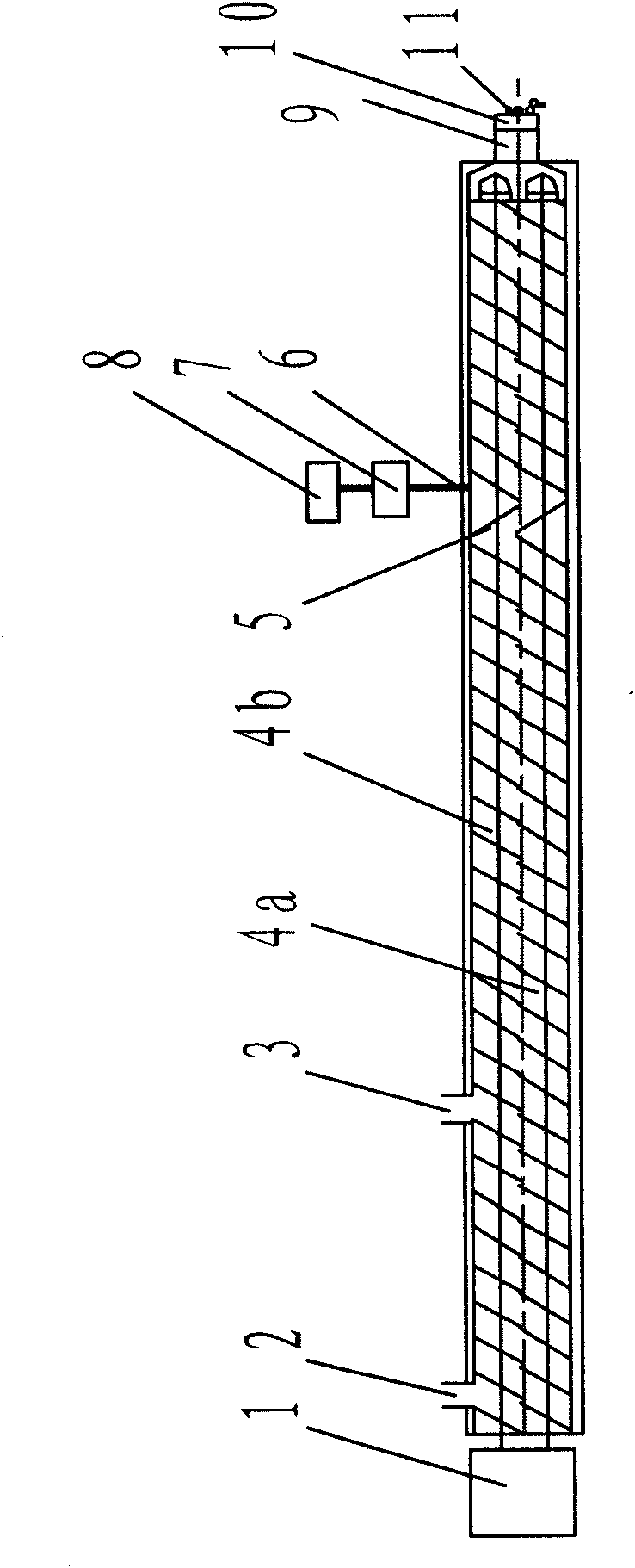

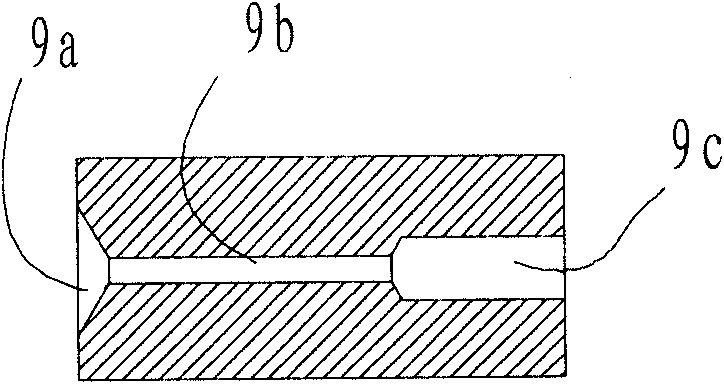

Nucleating agent master batches used for foaming of thermoplastic resin

ActiveCN101565550AConvenient injection foam moldingEasy extrusionVolumetric Mass DensityNitrogen gas

The invention relates to a nucleating agent and a method for preparing the nucleating agent, wherein the nucleating agent is used for reducing the dimension of the foaming hole and improving the density of the foaming hole when a supercritical fluid foaming agent (such as carbon dioxide or nitrogen) is used for producing thermoplastic foaming products. The raw materials of the nucleating agent mainly consists of an organic montmorillonite, a thermoplastic resin and a supercritical fluid foaming agent; the specific weight of the nucleating agent master batches is controlled within 100+ / -5% of that of the thermoplastic resin. The method has the advantages that a supercritical fluid foaming method is adopted to prepare the nucleating agent master batches which have approximate specific weights to the resin material adopted by the subsequent foam forming, thus facilitating the subsequent injection foam forming and extrusion foam forming; and the carbon dioxide or nitrogen in supercritical state is used for reducing the viscosity of the carrier resin during the mixing process, the dispersion uniformity of the peeled sandwich montmorillonite in the carrier resin is reinforced, the process temperature is reduced, the layer spacing of the sandwich nano-montmorillonite which may be not peeled is increased and the sufficient peeling is realized.

Owner:BEIJING CHN TOP MACHINERY

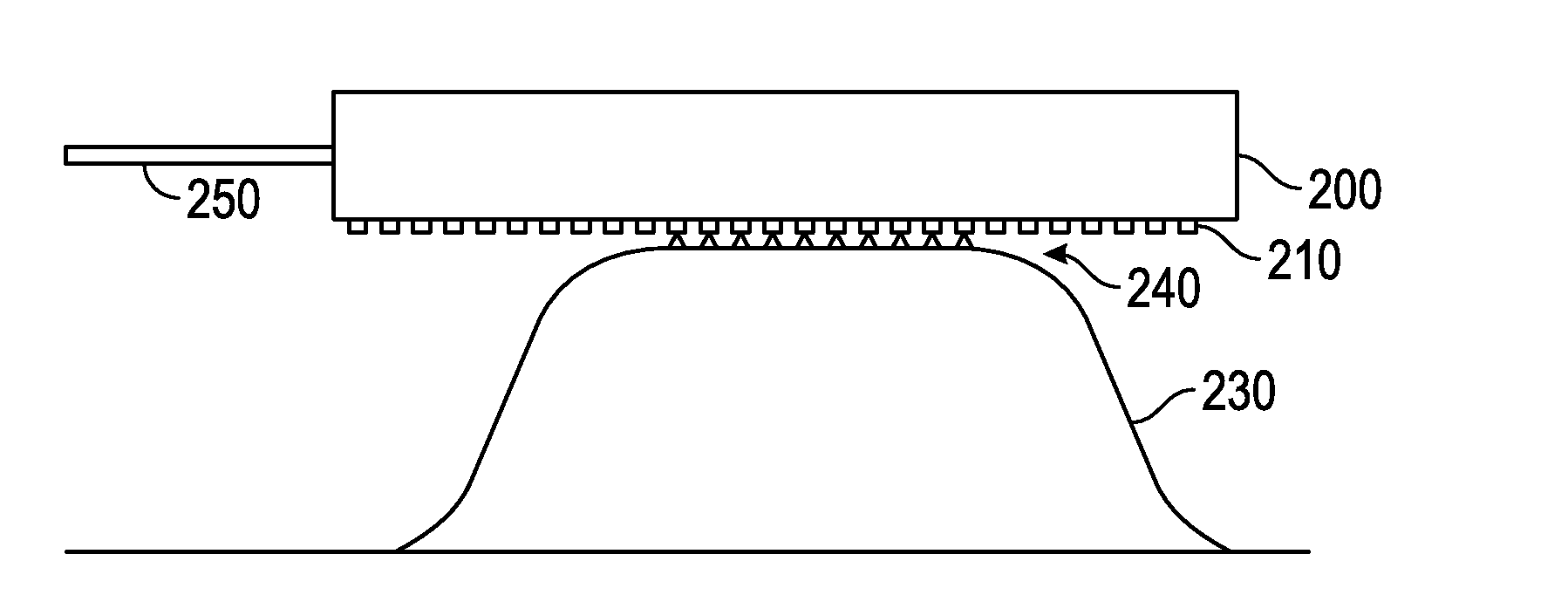

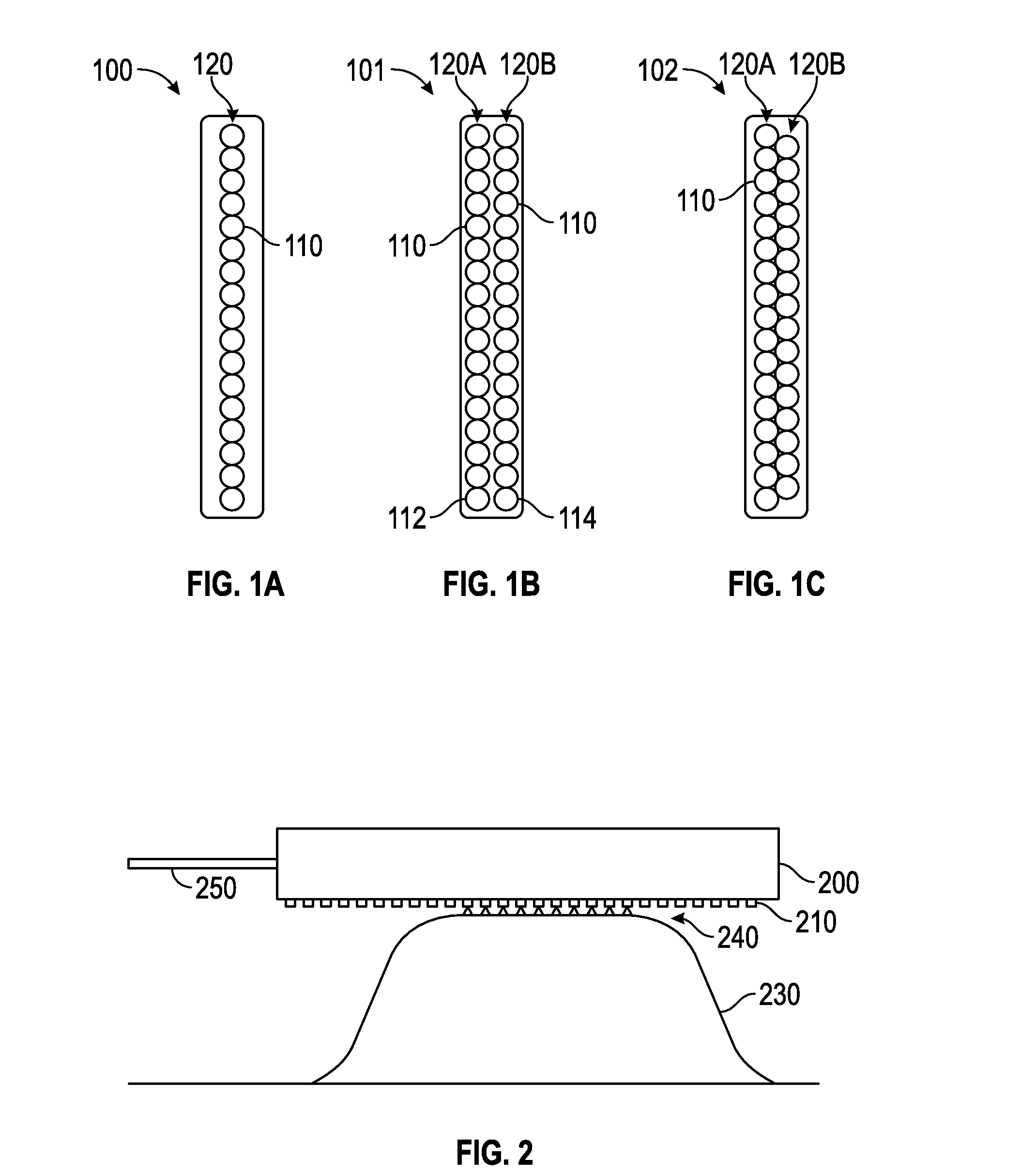

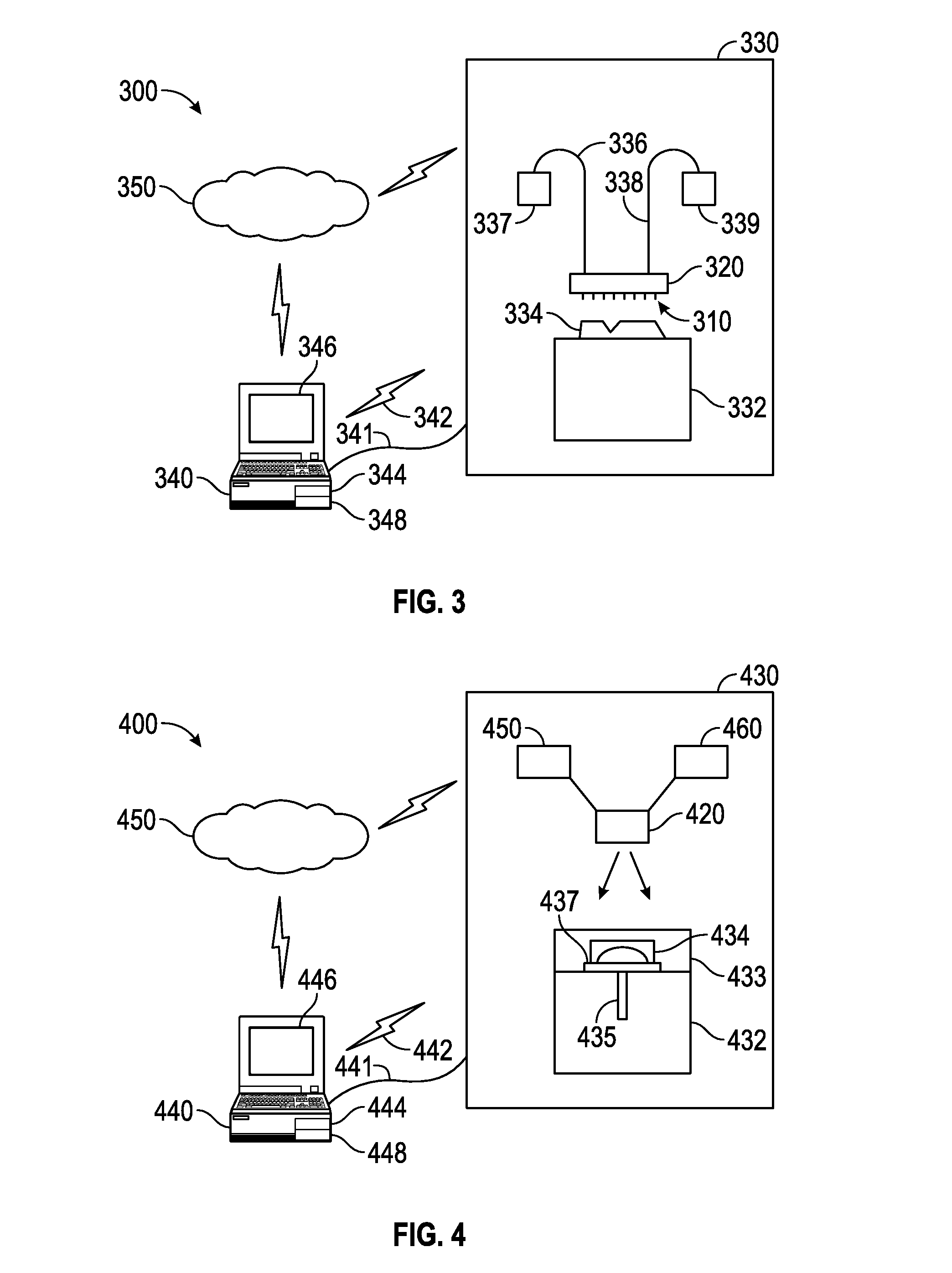

System, method and apparatus for 3D printing

InactiveUS20150273769A1Increase depositionEasy extrusionAdditive manufacturing apparatusElectric discharge heatingOne passSpray nozzle

The present invention is directed to three-dimensional printing techniques, methodologies, systems and apparatus to facilitate increased print speed. Through the use of multiple nozzles on a print head printing line by line, more material is deposited. By including nozzles sufficient for a line dimensional (or portion) of a page or planar element of an object design, the material deposition for an entire plane or layer is done line by line in one pass of the print head. Likewise, through the inclusion of multiple lasers, beams or energy sources more material can be cured, such as all along a contour line, instead of point by point.

Owner:KORN STANLEY

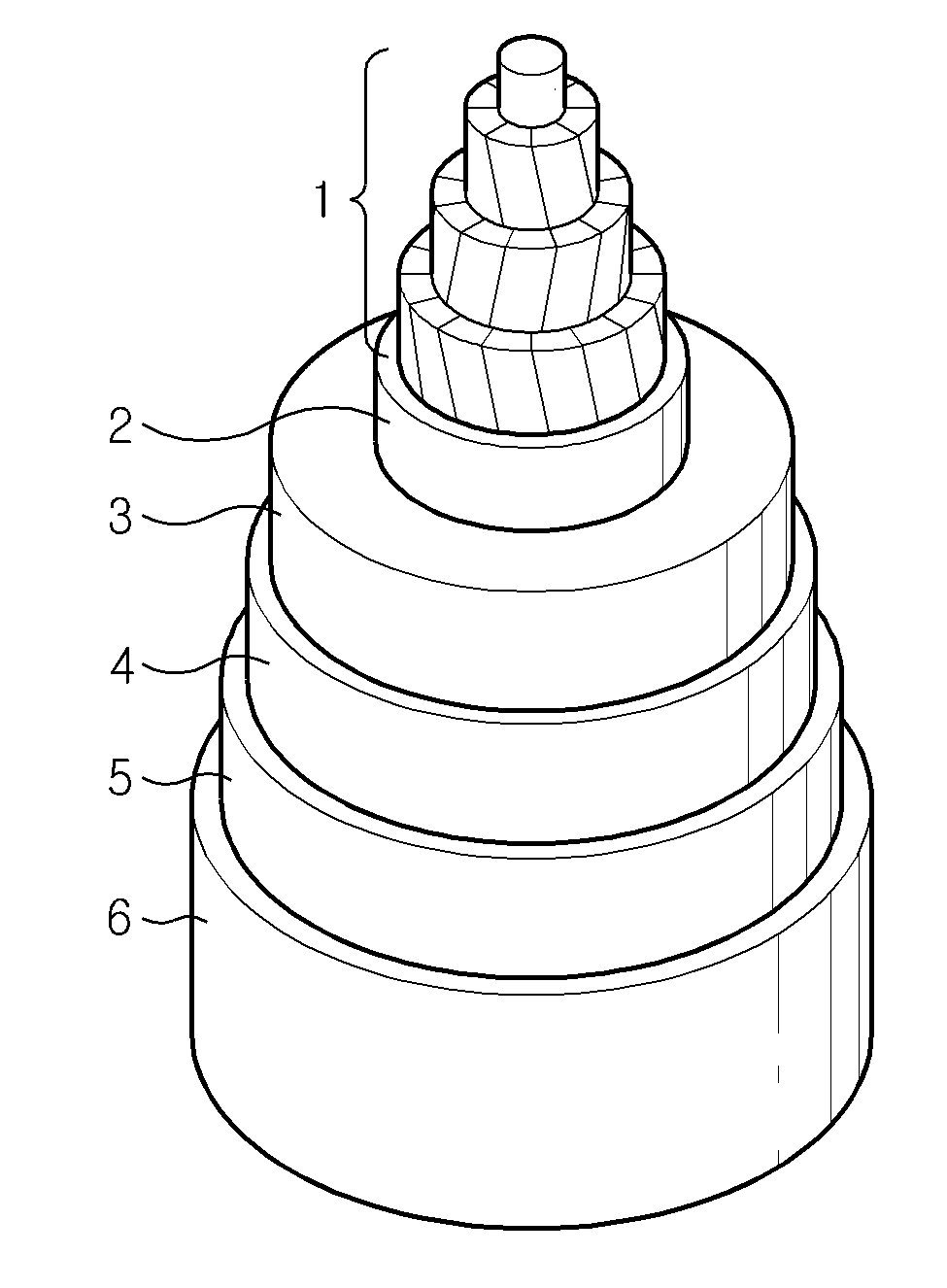

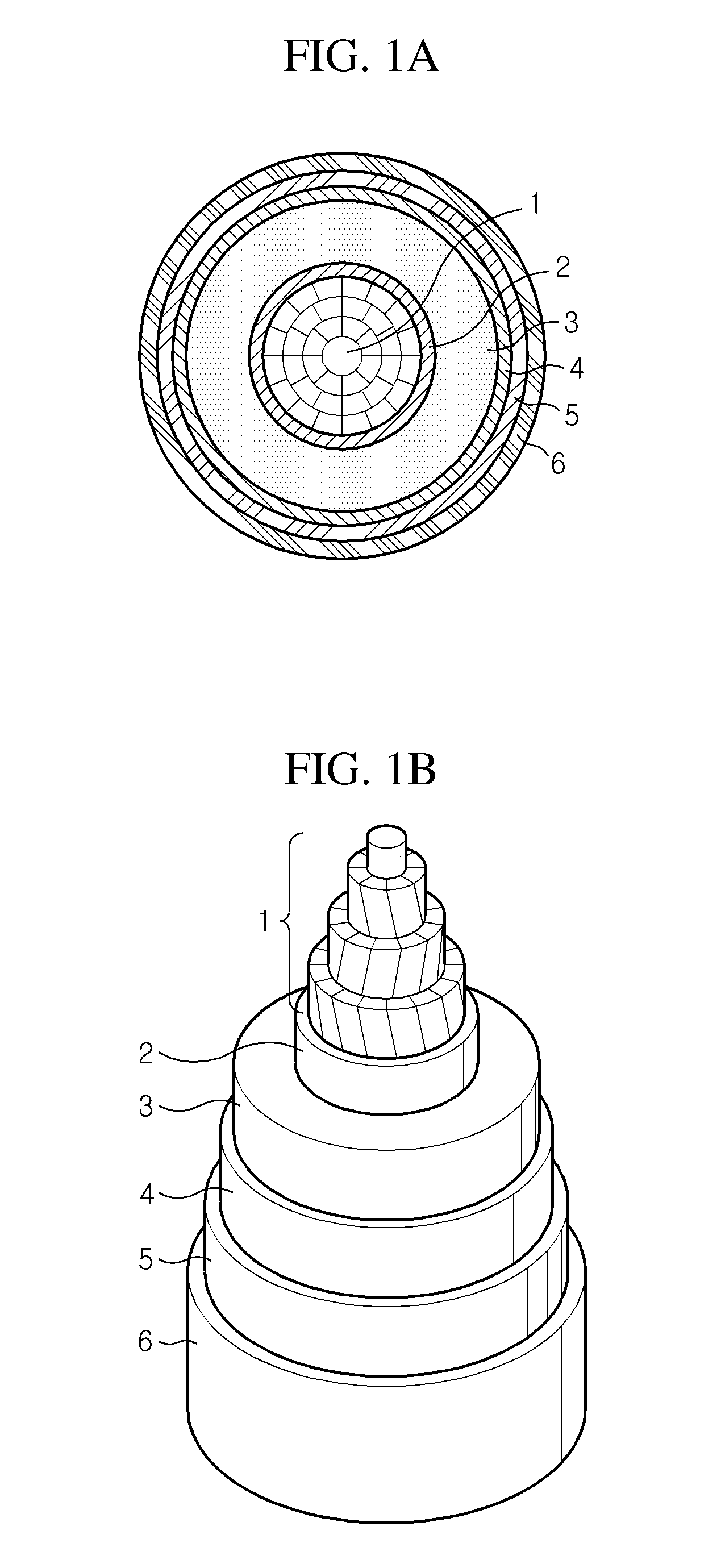

DC power cable with space charge reducing effect

ActiveUS20120012362A1Easy extrusionExcellent space charge suppression effectInsulated cablesPower cablesLow-density polyethylenePower cable

Provided is a DC power cable including a conductor, an inner semiconductive layer, an insulation and an outer semiconductive layer. In particular, the inner semiconductive layer or the outer semiconductive layer may be formed from a semiconductive composition containing a polypropylene base resin or a low-density polyethylene base resin and carbon nano tubes; and the insulation may be formed from an insulation composition containing a polypropylene base resin or a low-density polyethylene base resin and inorganic nano particles. The resulting power cable may have improved properties such as volume resistivity, hot set, and so on, and excellent space charge reducing effect.

Owner:LG CABLE LTD (KR)

Polyolefine sheathing compound for coaxial cable and preparation method thereof

ActiveCN102153812AShorten the manufacturing cycleHarm reductionPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePolyolefin

The invention discloses a polyolefine sheathing compound for a coaxial cable and a preparation method thereof. The sheathing compound consists of the following components in parts by weight: 60-90 parts of ethylene-propylene-diene rubber, 5-25 parts of high-density polyethylene, 5-15 parts of functional polyolefin resin, 180-200 parts of flame retardant, 1-3 parts of surface modifier, 0.01-0.05 part of crosslinking agent, 0.5-2 parts of antioxidant and 1.5-9 parts of processing aid. The preparation method comprises the following steps of: putting the flame retardant into a high-speed stirrer for stirring at a high speed at the temperature of not lower than 80 DEG C; adding organosilane and stirring for 3-5 minutes; putting the remaining materials into the high-speed stirrer for continually stirring for 3-5 minutes; adding into a double-screw mixing extruder set by using a feeder for pelletizing; and drying. The sheathing compound has the advantages of flame retardance, low smoke, freeness from halogen, low toxicity, freeness from harmful heavy metals such as lead, cadmium and the like, freeness from phosphorus, difficulty in burning and small smog harm in case of fire, environmental friendliness, high temperature resistance level of 105 DEG C, high extruding performance, excellent electric performance, no need of subsequent crosslinking after stranding, saving in a large amount of manpower and materials and great reduction in the manufacturing period of the cable.

Owner:KINGFA SCI & TECH CO LTD +2

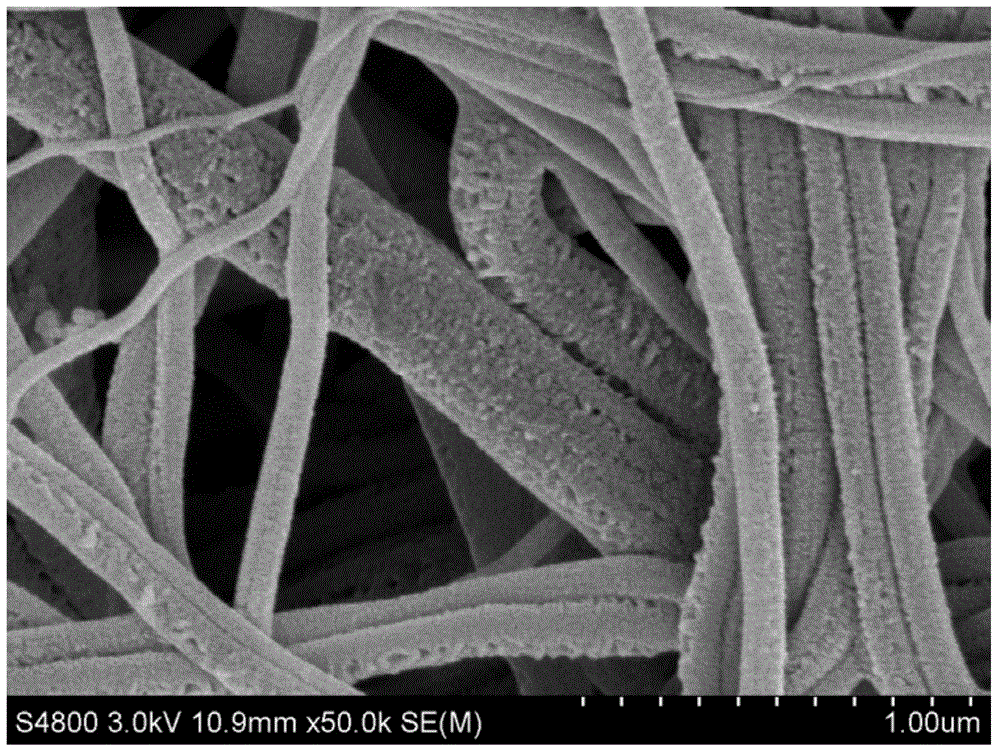

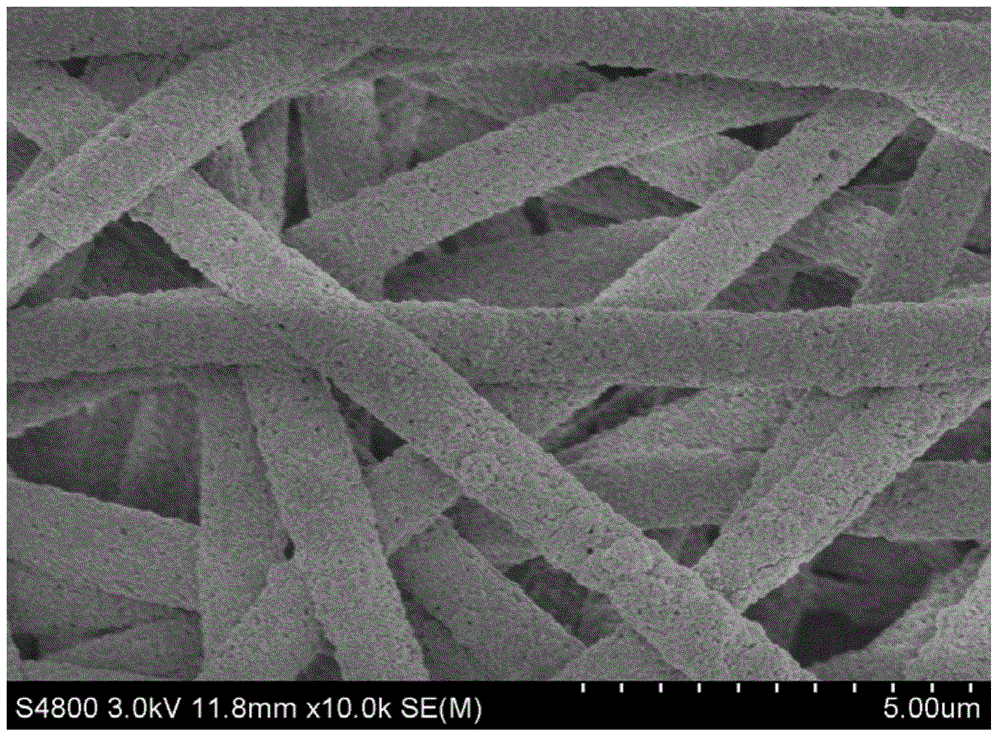

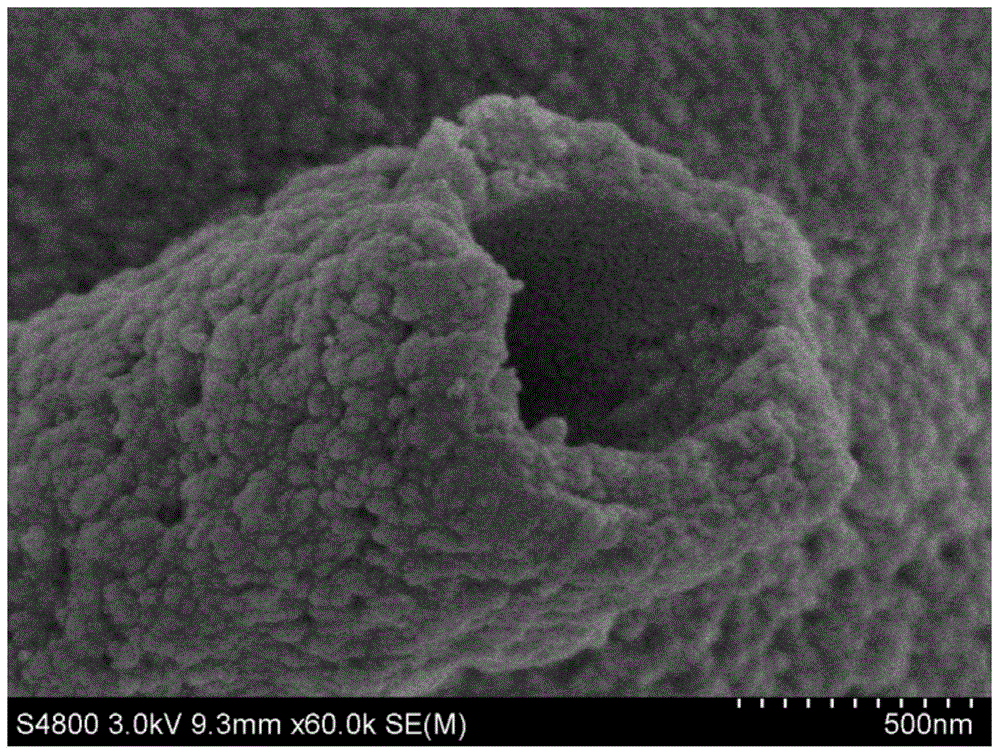

Preparation method of porous nanofiber non-woven fabric

InactiveCN103981633ALower melting temperatureImprove stabilityFilament/thread formingFiltration separationBoiling pointNanofiber

The invention relates to a preparation method of porous nanofiber non-woven fabric, and aims to provide a method capable of realizing large-scale preparation for porous nanofiber non-woven fabric. According to the technical scheme, the preparation method of the porous nanofiber non-woven fabric comprises the following steps in sequence: (1) stirring and dissolving polymers and a combined thinning agent uniformly in a reaction kettle at the temperature of 25-150 DEG C to prepare a polymer solution with the percent concentration of 10-60%, wherein the combined thinning agent is a mixture of a good solvent and a bad solvent, the mass ratio of the good solvent to the bad solvent is between 9: 1 and 1: 9, and the boiling point of the good solvent is lower than that of the bad solvent; (2) producing the polymer solution in the first step with melting blowing equipment to obtain primary non-woven fabric; (3) extracting and removing the combined thinning agent in the primary non-woven fabric in the second step and forming pores on fibers of the primary non-woven fabric, and drying to obtain the porous nanofiber non-woven fabric.

Owner:浙江省轻工业品质量检验研究院

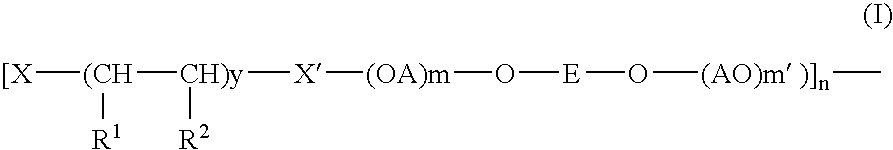

Extruded ink-receiving layer for use in inkjet recording

InactiveUS20060222789A1Overcome limitationsImprove performanceLamination ancillary operationsLayered product treatmentPolyamidePolyolefin

An inkjet recording element comprising a support coated with an immiscible polymer blend to overcome limitations of existing hydrophilic materials for extrusion coating. The two phases correspond, respectively to a first composition comprising a hydrophobic thermoplastic polymer such as a polyolefin, which does not absorb water, and a second composition comprising a hydrophilic thermoplastic polymer, for example, polyvinyl alcohol, modified ethyl vinyl alcohol, polyether block polyamide, or the like. The characteristics of the polymers are such that hydrophilic thermoplastic polymer encapsulates the polyethylene layer during extrusion and produces a swellable inkjet receiver layer. Also disclosed are methods for making and a method of printing on such inkjet recording elements.

Owner:EASTMAN KODAK CO

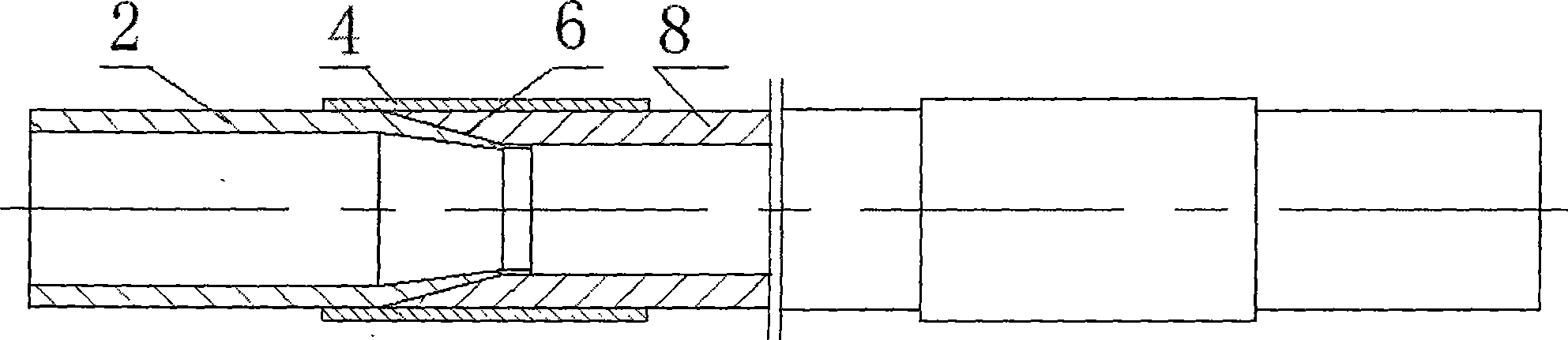

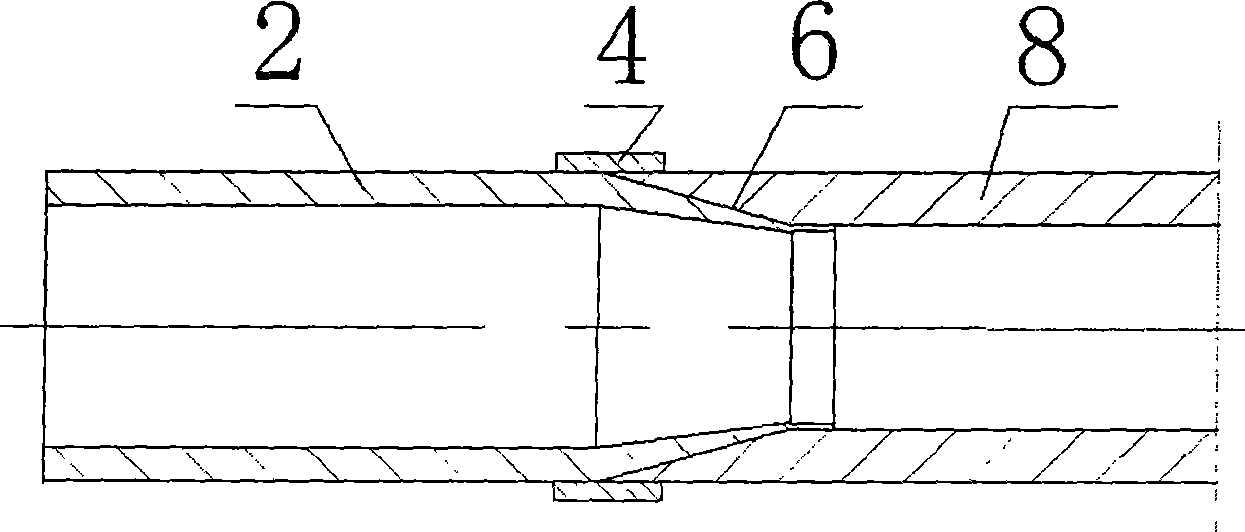

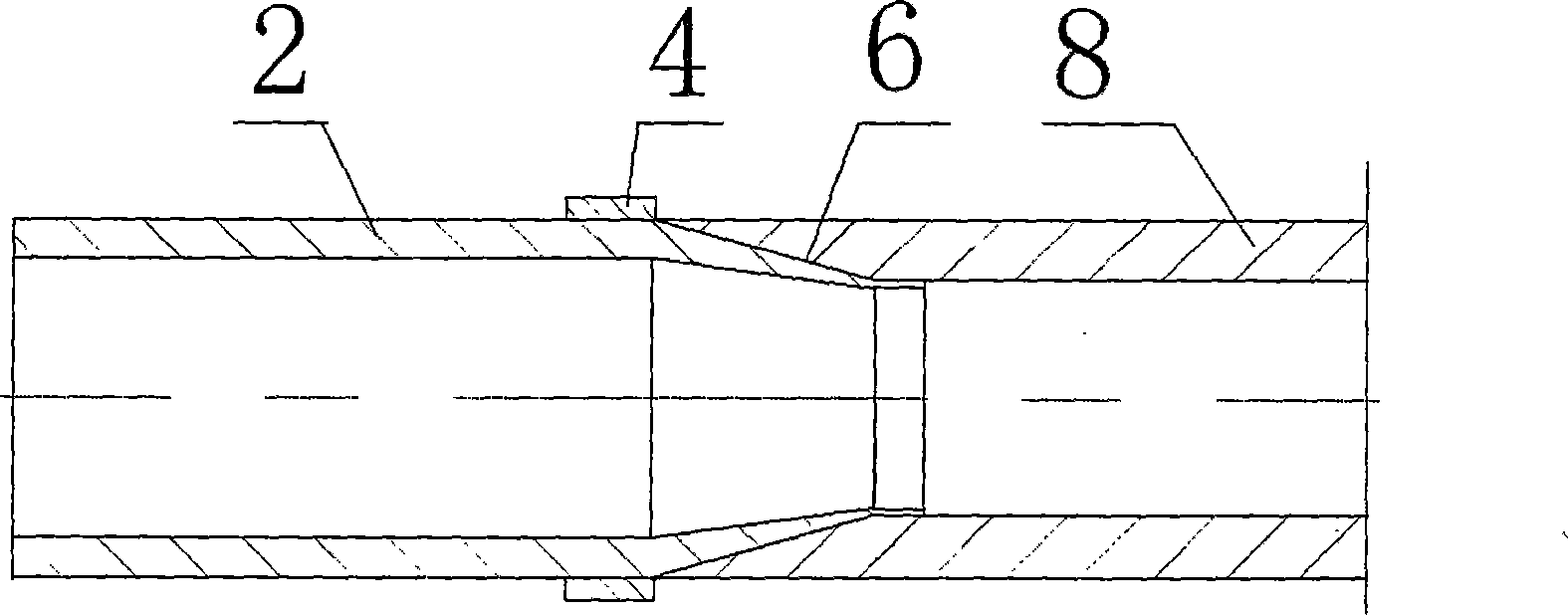

Copper and aluminium connecting tubes with hard sleeve and method for making same

InactiveCN101382215APut an end to sheddingAvoid spatterNon-disconnectible pipe-jointsResistance welding apparatusWeld seamThin walled

The invention relates to a Cu-Al connecting pipe provided with a rigid sleeve and a preparation method thereof. The welding head of a Cu pipe is provided with a conical solder side provided with a straight tubular guiding part; the external diameter of the guiding part is slightly less than the internal diameter of an Al pipe; the conical solder side of the Cu pipe and the internal wall of the Al pipe form direct chemical bond connection; the external sleeve of the Cu-Al connecting pipe is sleeved by a small section of a rigid sleeve; when in use, the rigid sleeve can prevent the cracking of the Al pipe caused by the bending of a butt joint and prevent the breaking of welding joint of the Al pipe or the Cu pipe in the sleeve. The rigid sleeve can avoid severe accidents such as the desquamating of welding joint and cracking of Al pipe near the joint and the like, prevents the generation of external splashing matter outside the welding joint, simplifies the process, relieves the destabilized deformation generated when the thin walled Cu pipe bears high pressure in the axial direction, increases the length of no-eutectic tissue welding seam, and is especially applicable to the welding of thin walled Al pipe and thin walled Au pipe.

Owner:左铁军 +1

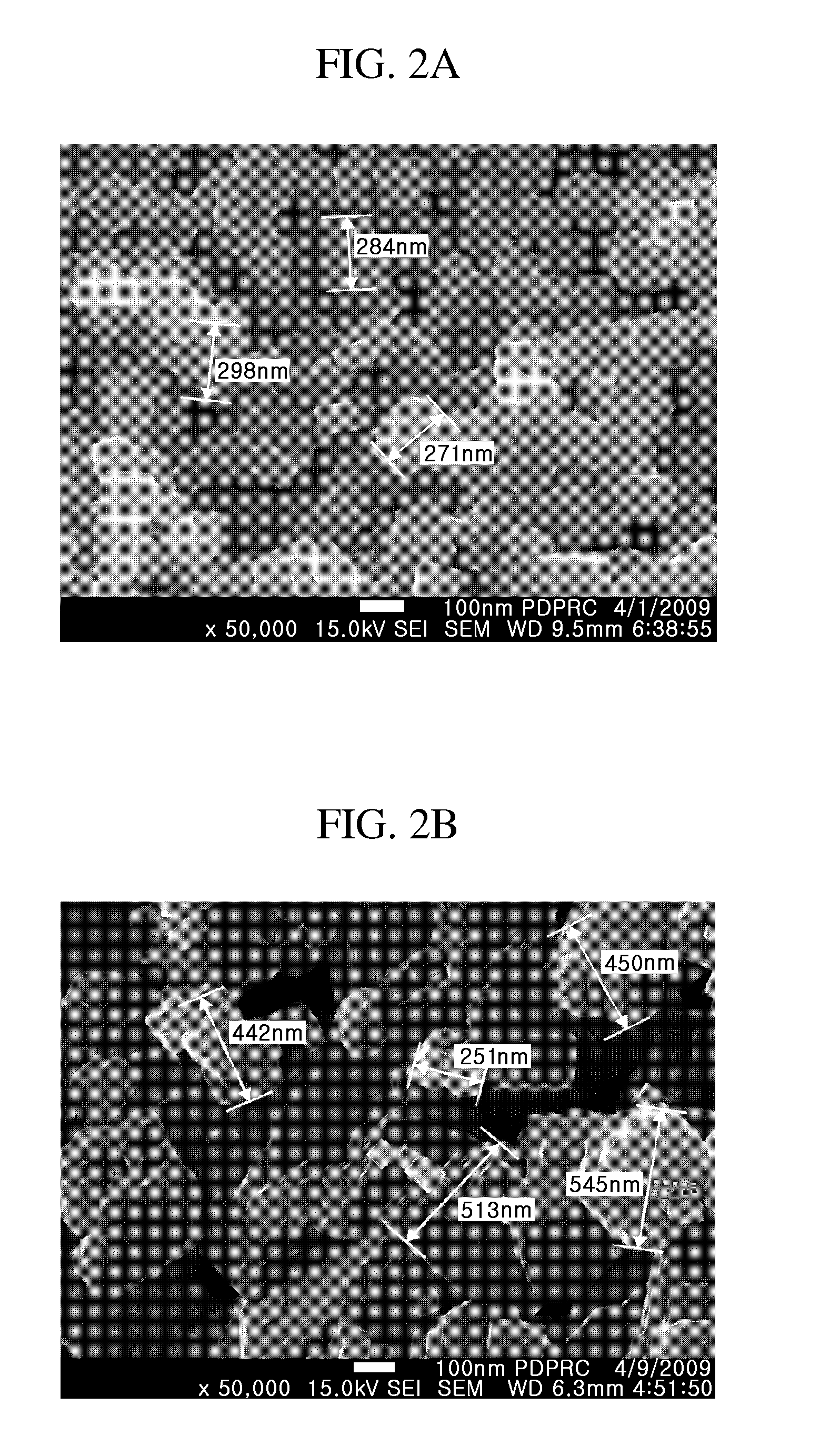

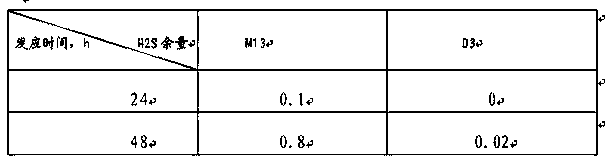

Normal-temperature dearsenic agent as well as preparation method thereof

ActiveCN103566947AGuaranteed arsenic removal activityHigh arsenic removal efficiencyRefining with metal oxidesMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureCopper oxide

The invention relates to a normal-temperature dearsenic agent as well as a preparation method thereof, belonging to the technical field of dearsenic purifying. The normal-temperature dearsenic agent consists of active ingredients and auxiliaries, wherein the auxiliaries are one or more of a binder, a pore-forming agent and an extruding aid; the active ingredients comprise the following components: 40wt%-60wt% of manganese dioxide, 5wt%-15wt% of copper oxide and 5wt%-15wt% of zinc oxide; and content of the auxiliaries is 15wt%-20wt%. In the normal-temperature dearsenic agent disclosed by the invention, the manganese dioxide, the copper oxide and the zinc oxide with proper component content are matched, so that competing reaction of H2S and the copper oxide is restrained, and therefore, a using range of copper-series dearsenic agents is broadened, the copper-series dearsenic agents are enabled to be capable of being suitable for an H2S-contaning substance with arsenic to be removed, dearsenic activity of the dearsenic agent is ensured, dearsenic efficiency is improved, and cost of the dearsenic agent is lowered.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Feed raw material rich in energy and protein of omega-3 fatty acid and preparation method thereof

InactiveCN101473889AChange ingredientsChange natureAnimal feeding stuffAdditive ingredientAnti nutritional

The invention discloses a prescription for preparing an energy and protein feeding stuff raw material full of omega-3 fatty acid by using rubber seeds and a method thereof. The weight percentages of the omega-3 energy and protein feeding stuff raw materials are as follows: rubber seeds 20-80%, bean pulp, corn, rapeseed cake (pulp), cottonseed cake (pulp), rice bran and wheat bran or any combination thereof 20-80%. The preparation method is as follows: the exuviated and dried rubber seeds are mixed with various ingredients evenly and puffed, and then finished product is gained. By the invention, the nutrient components such as omega-3 fatty acid, energy and protein and the like contained in the rubber seeds can be used fully, meanwhile, anti-nutritional components such as hydrocyanic acid and the like contained in the rubber seeds are removed, the energy and protein raw materials full of omega-3 fatty acid widely accepted by the feeding stuff industry and applicable to various birds, livestock and fish feeding stuff are processed. The price of the energy and protein raw material is low.

Owner:云南三环生物技术有限公司

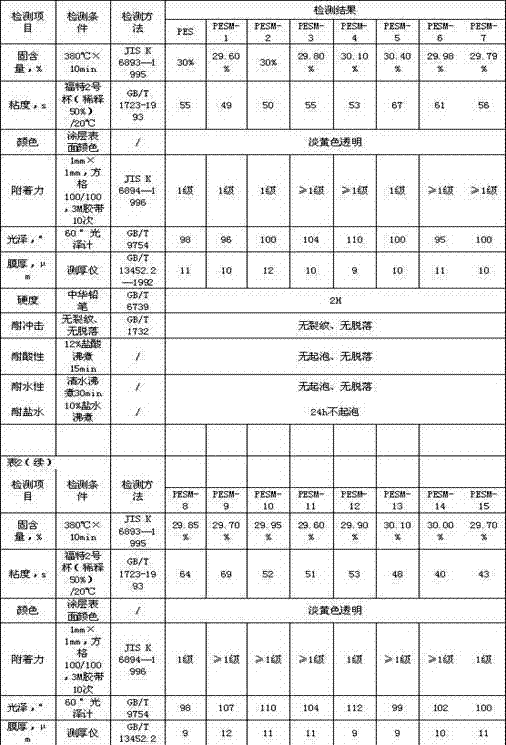

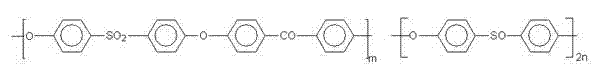

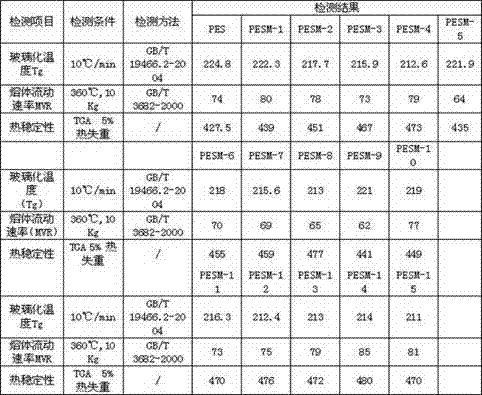

Ketone group-containing polyethersulfone resin and synthetic method thereof

The invention belongs to the technical field of polymer materials and provides ketone group-containing polyethersulfone resin which is high in thermal stability, low in processing temperature and is easier for injection-molding and extrusion-molding. The ketone group-containing polyethersulfone resin is a product synthetized through nucleophilic polycondensation reaction of the following polymerization monomers: 4,4-dihydroxyl dihydroxydiphenylsulfone, 4,4'-dichlorobenzophenone and 4,4-dichlorodiphenyl sulfone. The ketone group is introduced onto the molecular chain of polyethersulfone, so as to improve the thermal stability of the polymer, reduce the processing temperature of the polymer and ensure that the polymer is more convenient for injection-molding and extrusion-molding. The invention also provides a synthetic method of the ketone group-containing polyethersulfone resin. The method is easy to operate, and the reaction process and the viscosity of materials are easily controlled.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

Low-temperature fine desulfurizer and its preparation method

ActiveCN102512942AGuaranteed desulfurization efficiencyGuaranteed accuracyDispersed particle separationFlareCopper carbonate

The invention relates to a low-temperature fine desulfurizer and its preparation method. Raw materials for preparing the fine desulfurizer are consisting of, by weight, 40-60% of basic zinc carbonate, 15-25% of copper carbonate and at least one component selected from 0-10% of a pore forming agent, 0-10% of a binder and 5-10% of an extrusion aid. The fine desulfurizer is characterized by containing 20-30 wt% of a waste agent which can enhance catalyst strength and simplify the preparation technology. In addition, the preparation raw materials also contain 0-10 wt% of a lubricant which can raise binding performance of the materials. The method comprises the following steps of: uniformly mixing the above materials, adding 5-10 wt% of the extrusion aid, kneading for molding, and drying at 100-120 DEG C for 3-4 hours to obtain the fine desulfurizer used at low temperature. The low-temperature fine desulfurizer is applicable to fine desulphurization of industrial gases such as natural gas, oil-associated gas, refinery flares, coal gas and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

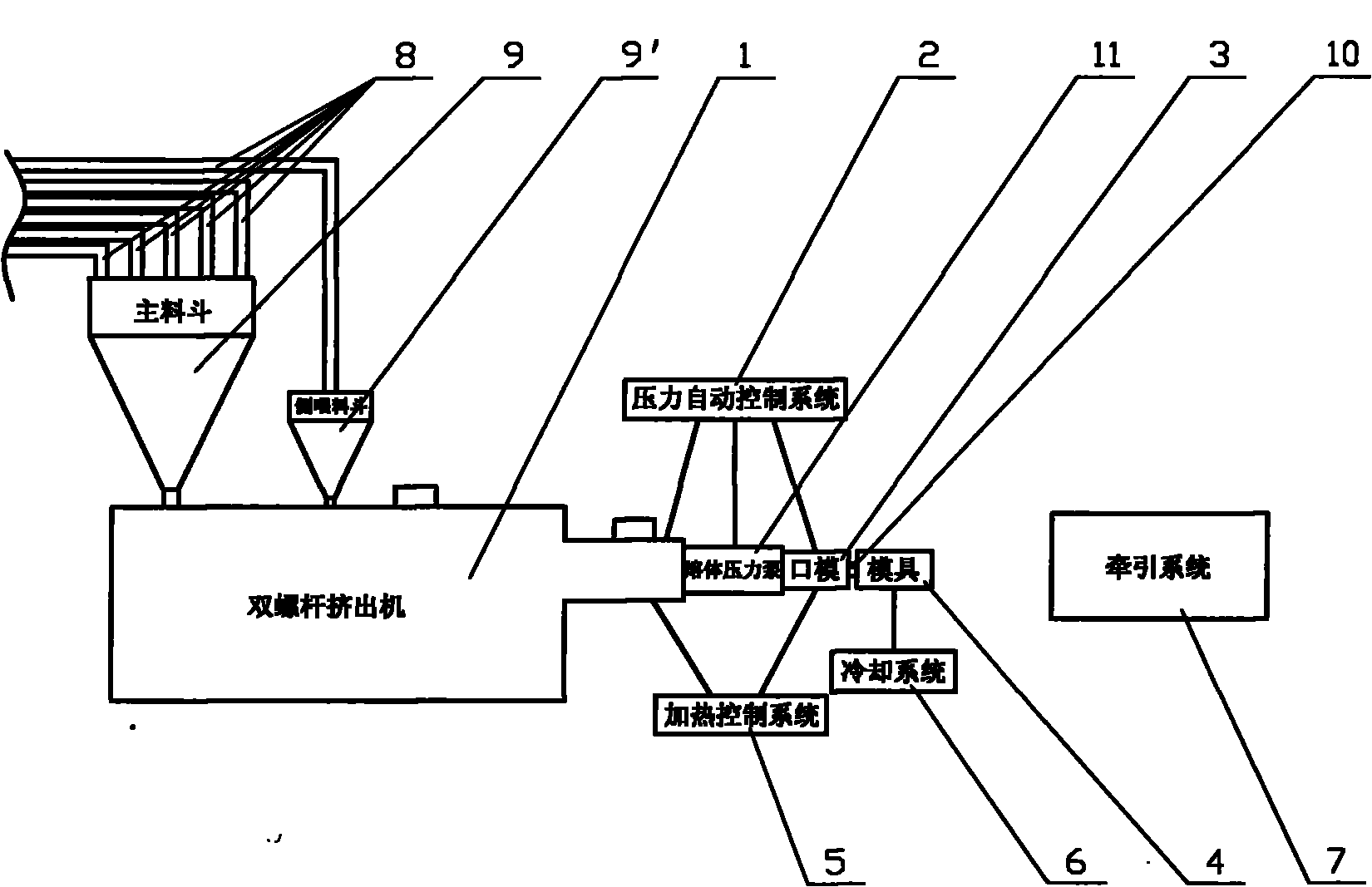

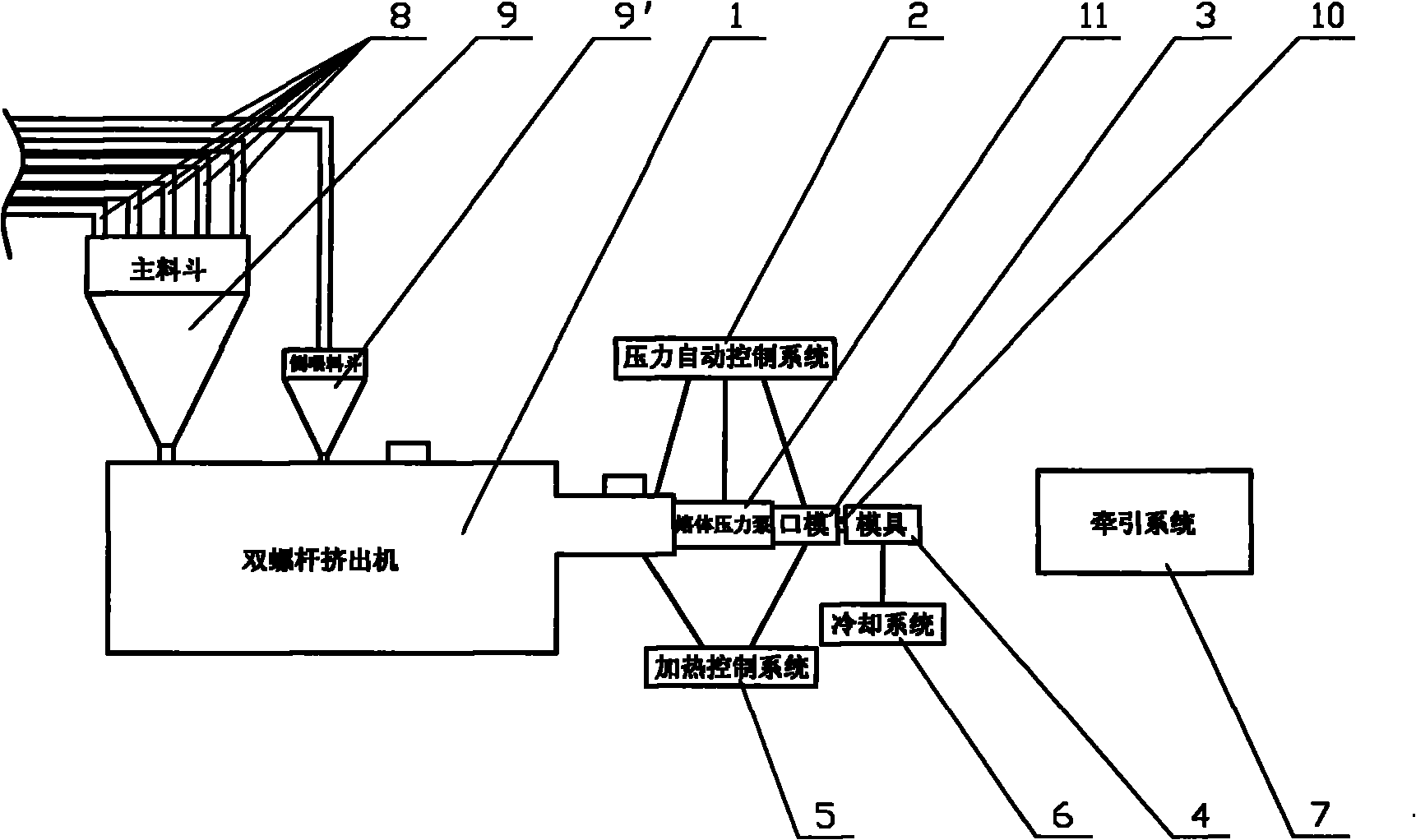

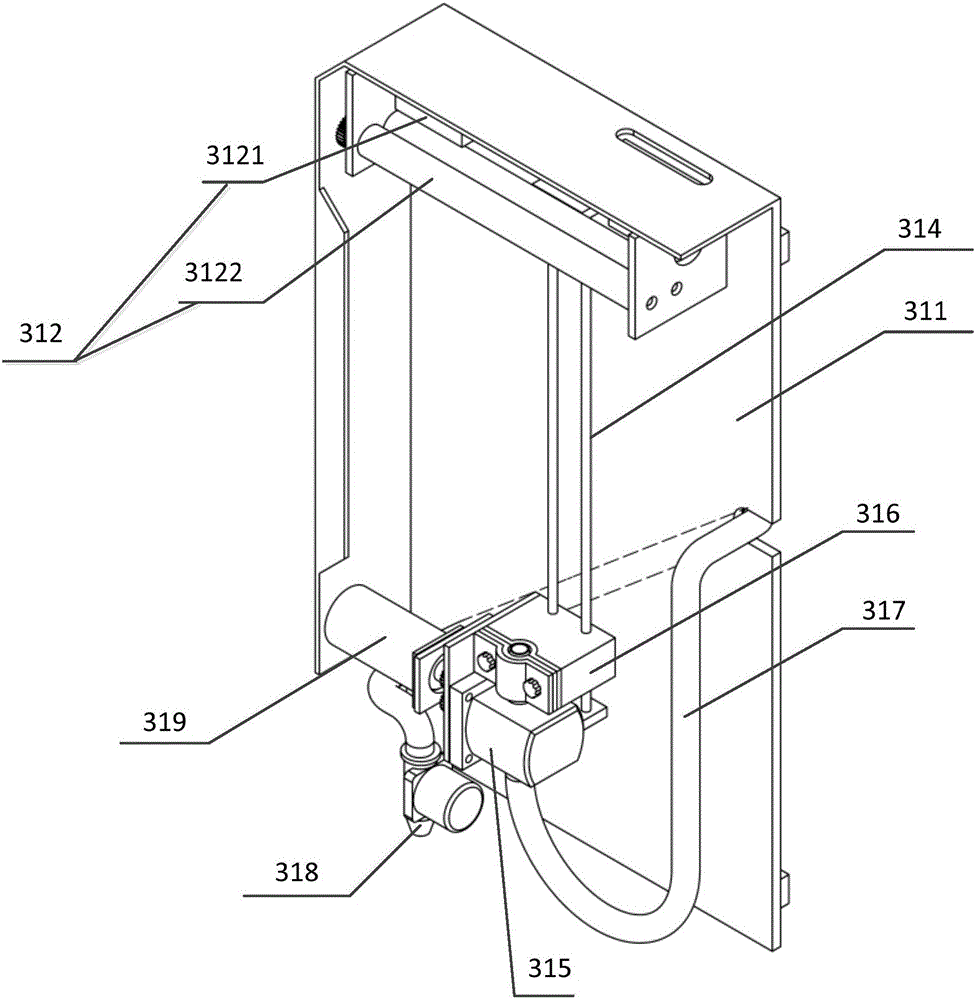

Device and method for manufacturing glass fibre reinforced nylon 66 heat-insulating strips

InactiveCN101791844AImprove product performanceEasy to recrystallizeNylon 66Manufacturing engineering

The invention discloses a device for manufacturing glass fibre reinforced nylon 66 heat-insulating strips, which comprises a feeding system, an extruder, a pressure control system, a die, a shaping die, a heating control system, a cooling system and a pull system. The feeding system comprises conveying pipelines and a hopper and each conveying pipeline conveys a single component of raw materials to the hopper and then feeds the material to the extruder; and the extruder is a double-screw extruder. The invention also discloses a method for manufacturing the glass fibre reinforced nylon 66 heat-insulating strips on the basis of the manufacturing device. In the device and the method, each component of the raw materials does not need to be mixed for pelletizing in advance, and a mode of conveying the single component of the raw materials with each conveying pipeline is adopted, so a pelletizing process and a melting and plasticizing process of the materials are reduced; the heat-insulating strip product with high performance and stable quality can be obtained to meet using requirements; and the application and development of the heat-insulating strip product and the manufacturing process technology are promoted.

Owner:FOSHAN NANHAI YILE ENG PLASTICS

Regeneration high-density polyethylene (HDPE) particle used for tubings and manufacture method thereof

The invention discloses a regeneration high-density polyethylene (HDPE) particle used for tubings and a manufacture method thereof. The method comprises the following steps: firstly, drying a cross-linking agent, an antioxidant and a color masterbatch; then evenly stirring 0.1 to 2 percent of cross-linking agent, 0.1 to 1 percent of antioxidant and 0.1 to 0.2 percent of color masterbatch; then adding to the charging opening of a plastic extruder together with 96.8 to 99.7 percent of dried and recovered HDPE; then extruding materials by the extruder at the speed of 80 to 150rpm, and cutting the materials into particles by a cutting machine and then drying to obtain the regeneration HDPE particle. In the invention, the parameter of the melt index and the like of the recovered HDPE is changed by crosslinking to enable the HDPE to be beneficial to extrusion molding, and the mechanical properties of toughness, tensile strength and the like of the recovered HDPE are improved so that the regeneration HDPE particle can be used for tubing manufacture, thereby reducing the material costs of the HDPE tubes and being beneficial to the environmental protection.

Owner:马鞍山支点高分子材料研究院有限公司

Heat-resistant silane crosslinked resin molded body and method of producing the same, heat-resistant silane crosslinkable resin composition and method of producing the same, silane master batch, and heat-resistant product using heat-resistant silane crosslinked resin molded body

ActiveUS20160208060A1Increase elasticityImprove extrusion appearanceRubber insulatorsPlastic/resin/waxes insulatorsMasterbatchPolymer science

A method comprising at least (a) a step of preparing a silane master batch by melt-kneading, to 100 parts by mass of a base resin (RB) containing a non-aromatic organic oil and ethylene rubber, an organic peroxide of from 0.01 to 0.6 parts by mass, an inorganic filler of from 10 to 400 parts by mass, and a silane coupling agent of from 1 to 15.0 parts by mass, at a temperature equal to or higher than the decomposition temperature of the organic peroxide; a heat-resistant silane crosslinked resin molded body and a heat-resistant silane crosslinkable resin composition prepared by the method, and a silane master batch and a heat-resistant product.

Owner:FURUKAWA ELECTRIC CO LTD

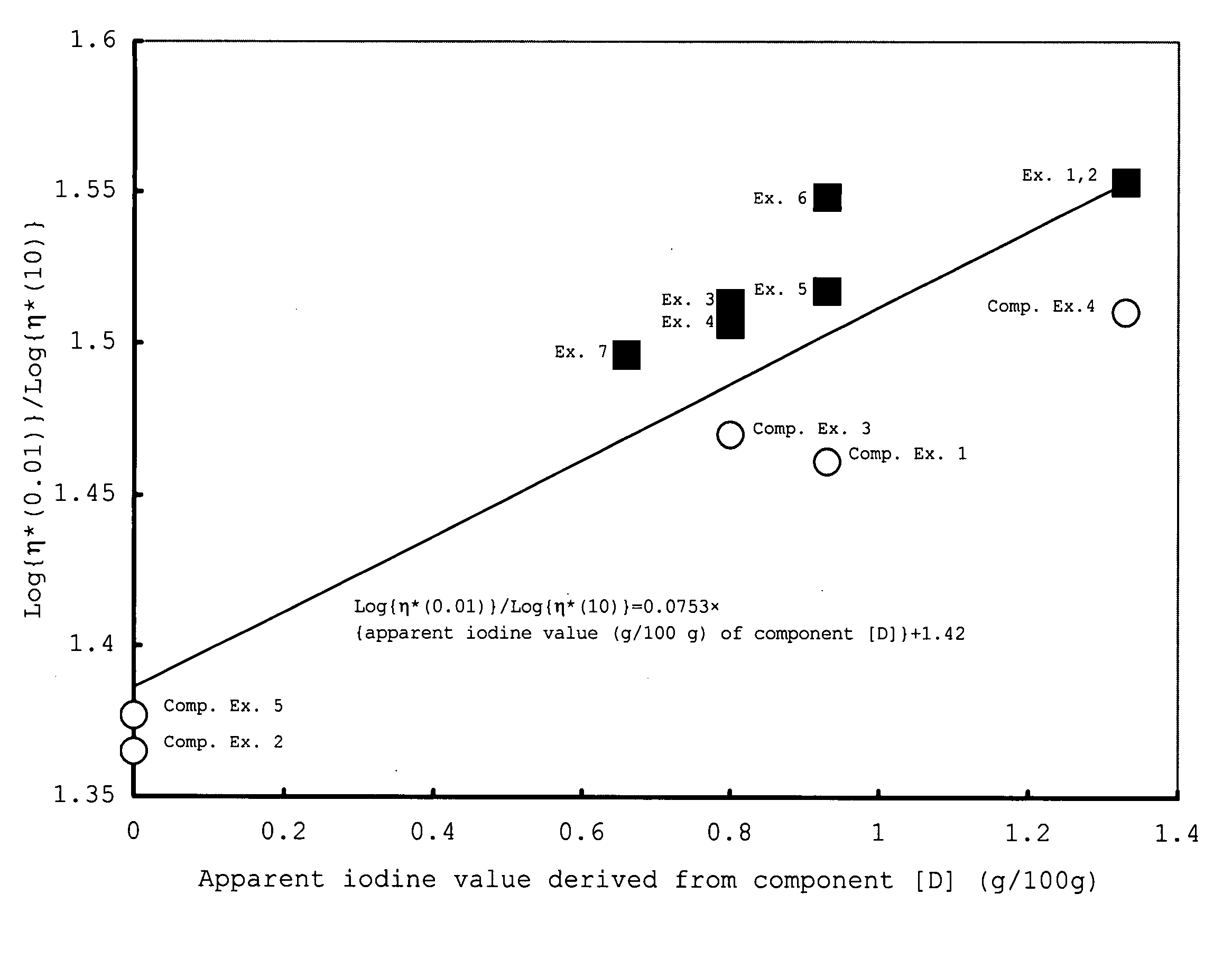

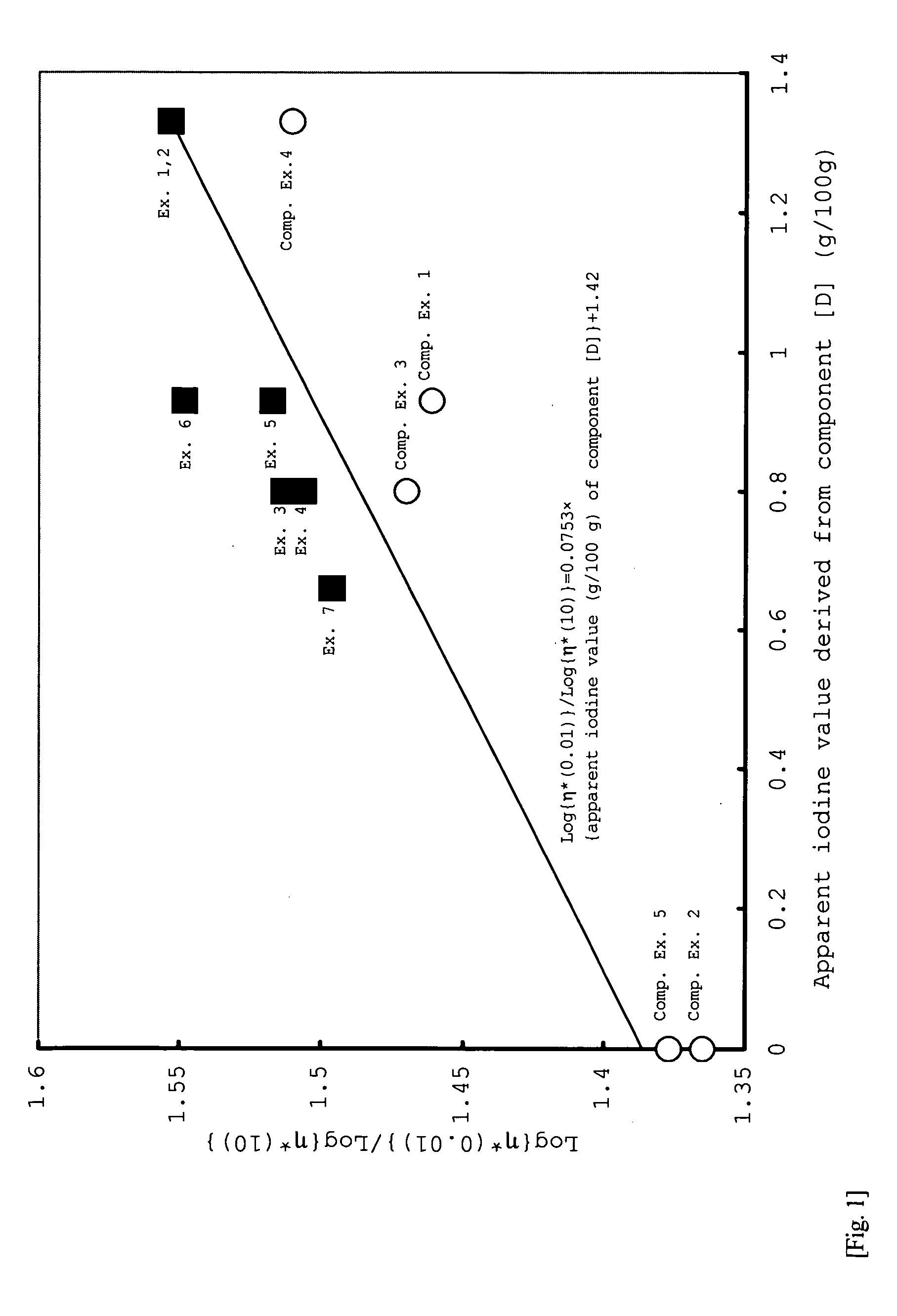

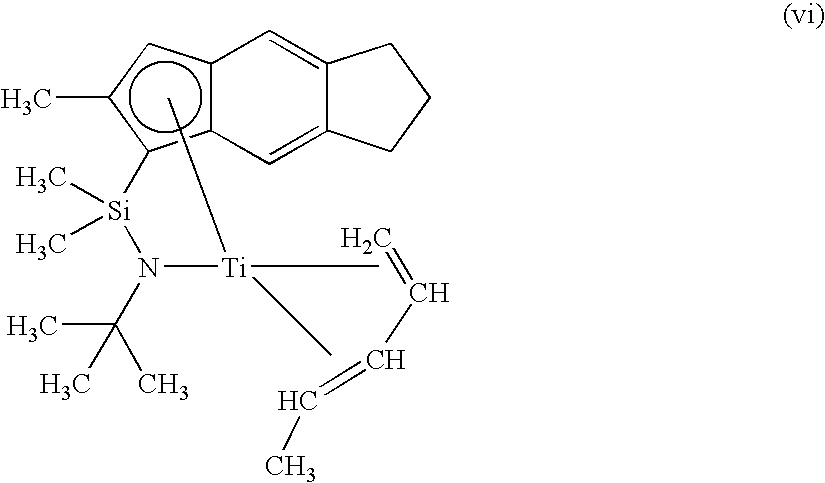

Copolymer rubber, rubber composition and rubber molding

The present invention provides a copolymer rubber which contains only small amounts of impurities and is excellent in kneading processability, extrusion processability and retention of shape and a rubber composition containing the copolymer rubber, and further provides a rubber molded product which is obtained from the rubber composition, is excellent in surface appearance, strength properties, heat aging resistance and weathering resistance and has a low compression set. The copolymer rubber of the present invention comprises structural units derived from [A]ethylene, [B] an α-olefin of 3 to 20 carbon atoms, [C] a non-conjugated polyene having one double bond between adjacent carbon atoms in one molecule, said double bond being capable of polymerization by a metallocene catalyst, and [D] a non-conjugated polyene having two of the above double bonds in one molecule, and the copolymer rubber satisfies specific requirements (1) to (5).

Owner:MITSUI CHEM INC

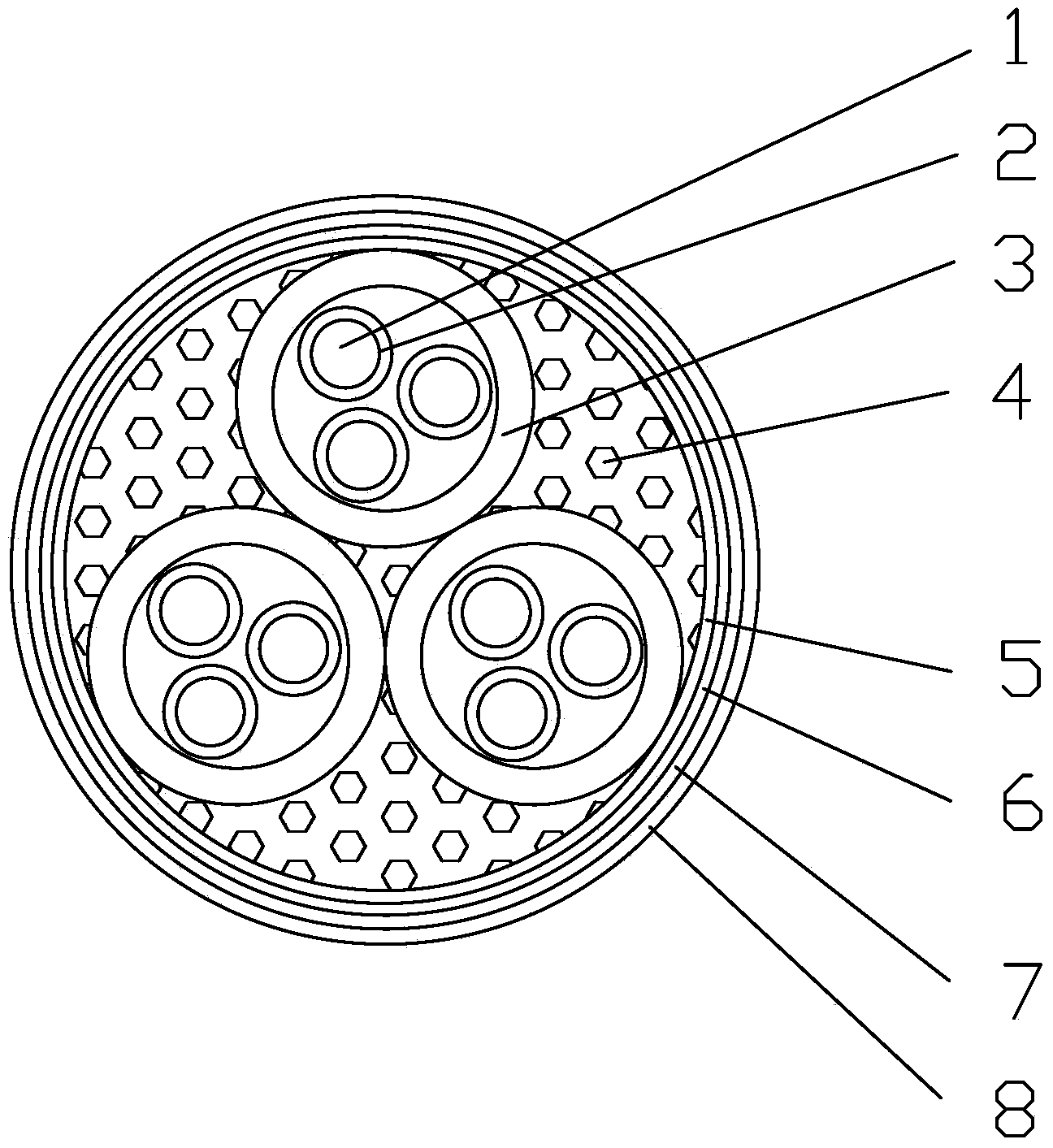

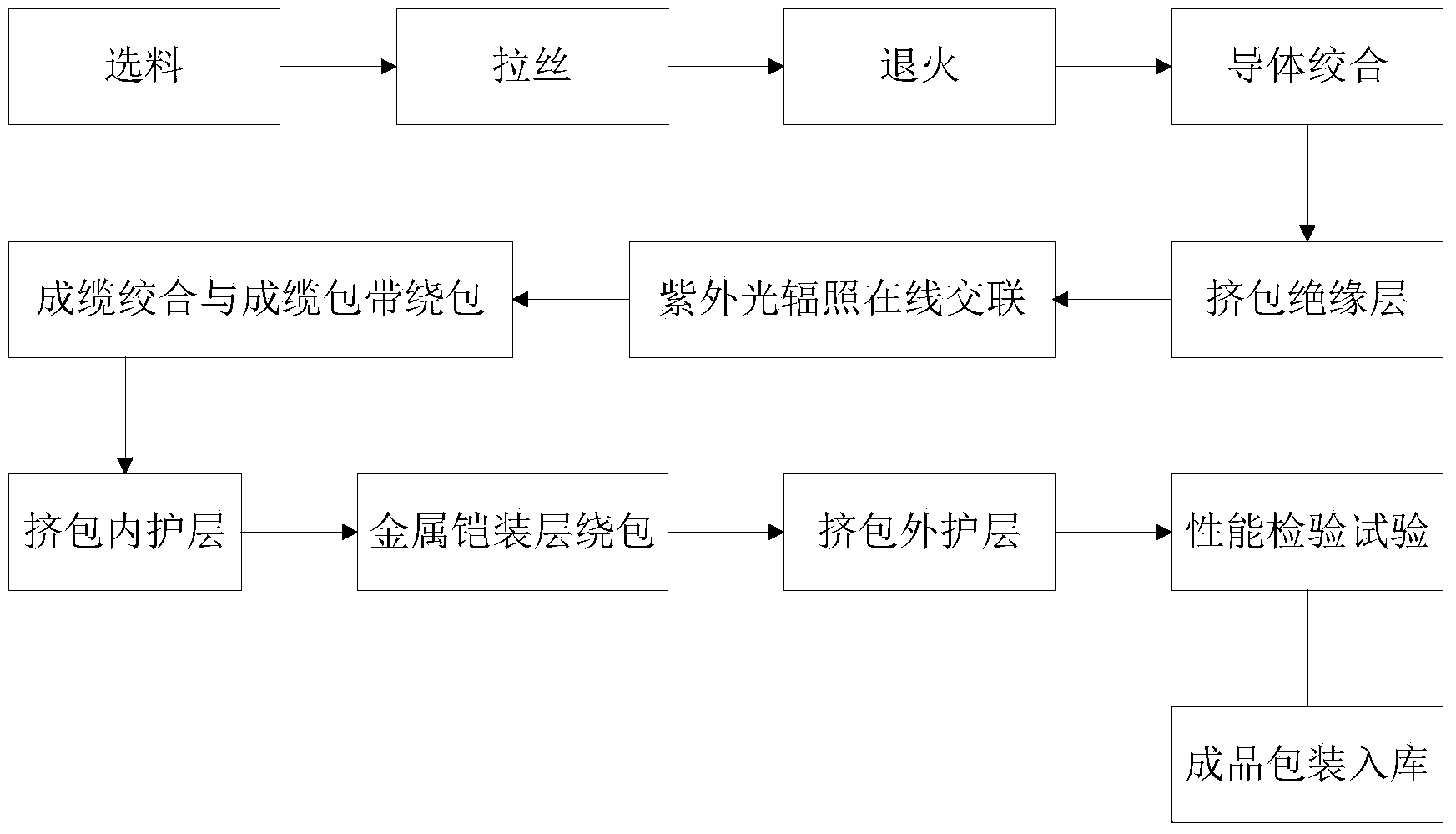

Irradiation cross-linking polyethylene insulated low-voltage power cable preparing method

InactiveCN104319015AImprove physical mechanicsImprove electrical performanceInsulating conductors/cablesElectrical conductorInsulation layer

The invention discloses an irradiation cross-linking polyethylene insulated low-voltage power cable preparing method and belongs to the technical field of cable manufacturing. A cable comprises a conductor, an insulation wire core which is formed in an insulation mode and is extruded on the outer edge of the conductor, a cable core formed by the insulation wire core, filling materials at a gap of the cable core, a cable forming wrapping belt layer wrapped outside the cable core, an inner protecting layer extruded outside the cable forming wrapping belt, a wrapped metal armoring layer and an extruded outer protecting sleeve from inside to outside. The cable is prepared through the following steps of material selecting, wire drawing, annealing, conductor intertwisting, insulation layer extruding and irradiation, cable forming intertwisting and cable forming wrapping belt wrapping, inner protecting layer extruding, metal armoring layer wrapping and outer protecting sleeve layer extruding in sequence. According to the novel irradiation cross-linking polyethylene insulated low-voltage power cable preparing method, energy loss can be lowered, and production cost can be lowered.

Owner:SICHUAN MINGXING CABLE

Cement-based composite material suitable for 3D printing rapid-forming process

ActiveCN106830843AControllable clotting time3D printing is goodAdditive manufacturing apparatusPortland cementUltimate tensile strength

The invention relates to a cement-based composite material suitable for making a building structure and components through a 3D printing rapid-forming process. The cement-based composite material is characterized in that an extrudable property is good, a stacking property is good, printing time is controllable, and mechanical properties and durability are excellent. Regarding detailed properties, the material has good thixotropy, controllable condensing and hardening time and good adhesion, hour strength development is rapid, and strength growth is stable at the later stage, requirements for the 3D printing process and rapid construction can be met, and actual application of the 3D printing technology in the building industry is promoted easily. The cement-based composite material includes 100 parts of ordinary Portland cement, 100-300 parts of fine aggregate, 5-20 parts of strength-promoting shrinkage reducing agent, 30-60 parts of mixing water, 0.1-2.0 parts of water reducing agent, 0.5-15 parts of interface reinforcing agent, 0.05-0.2 part of thixotropic agent and 0.5-3.5 parts of liquid coagulating components.

Owner:BEIJING UNIV OF TECH

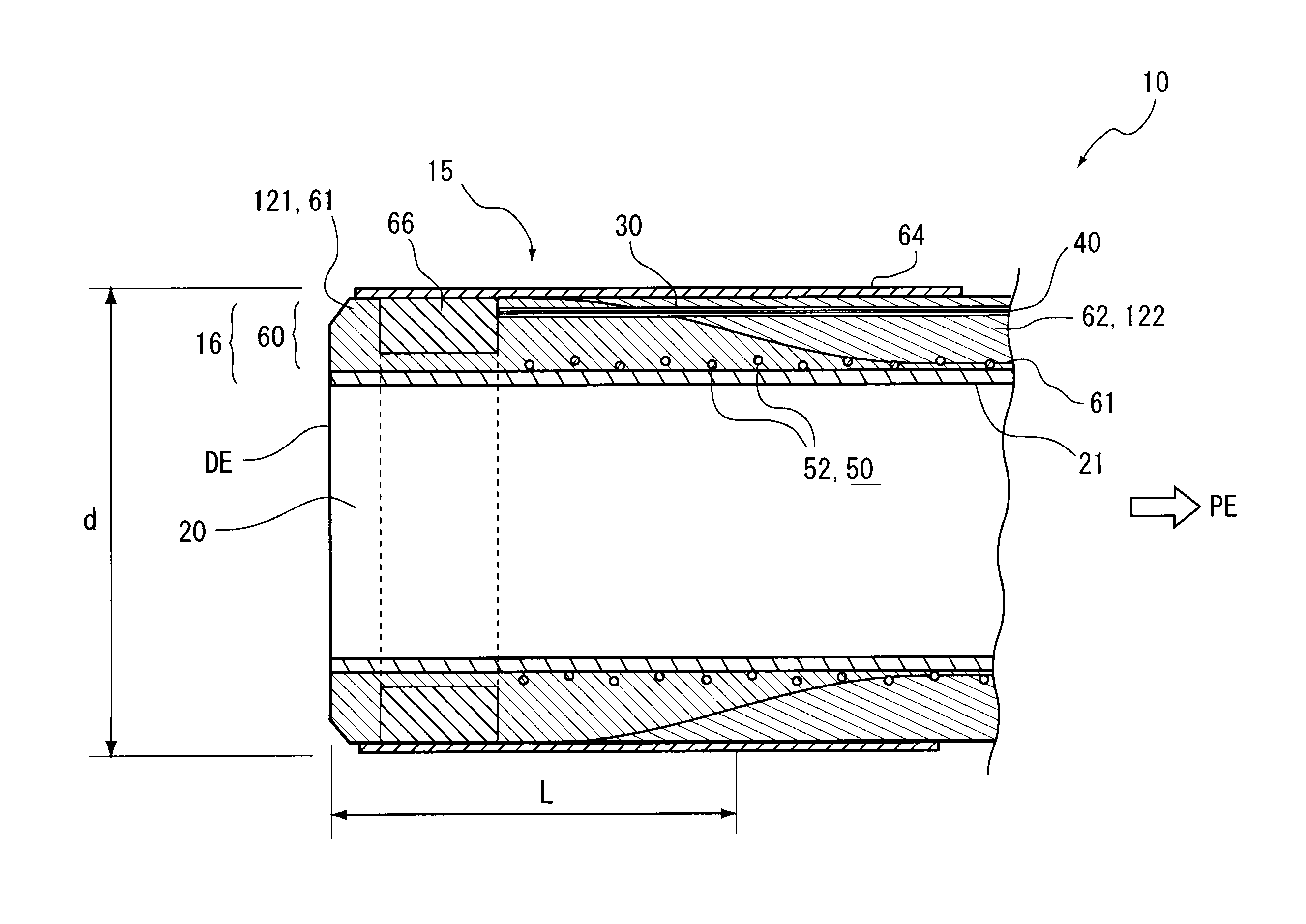

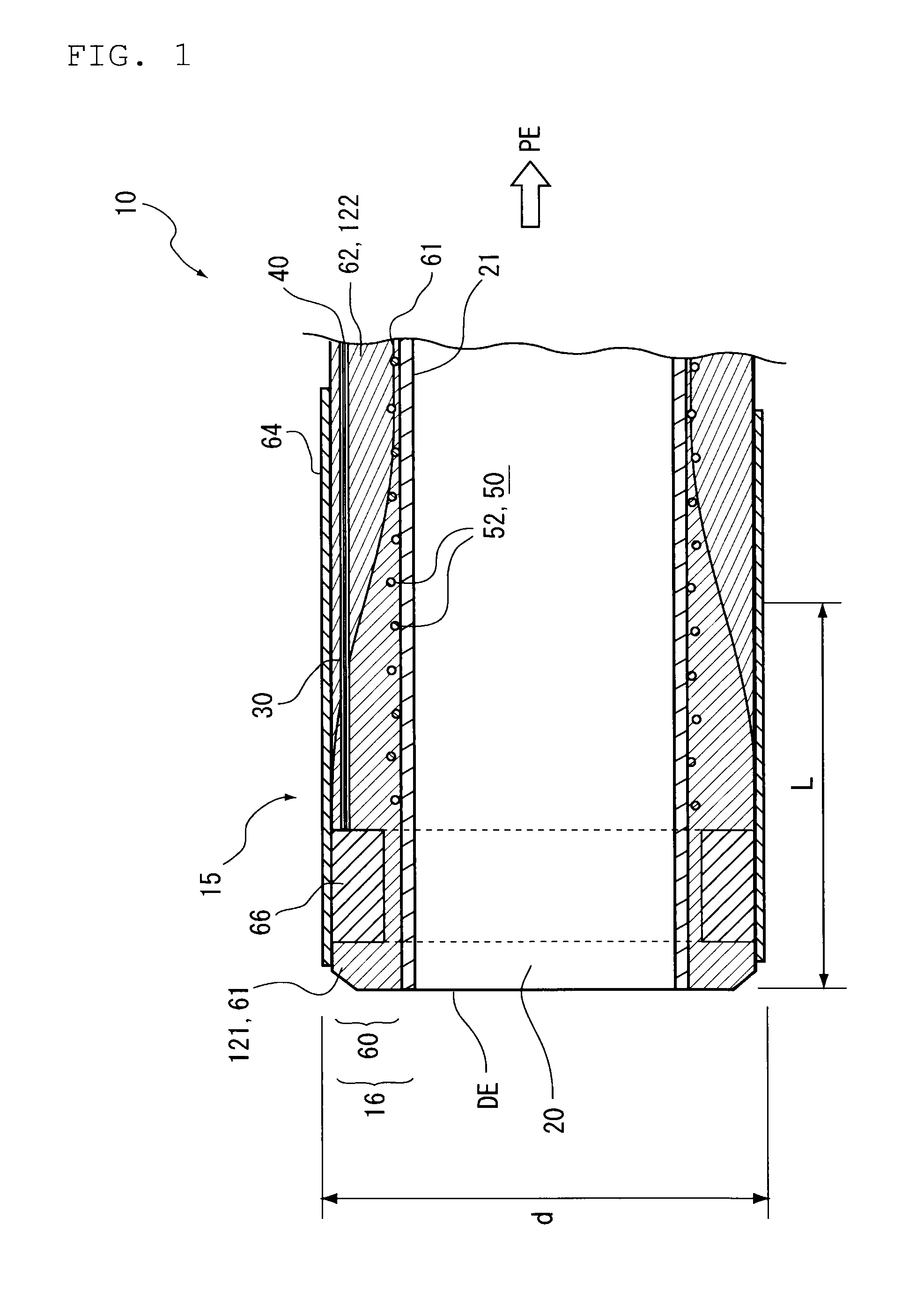

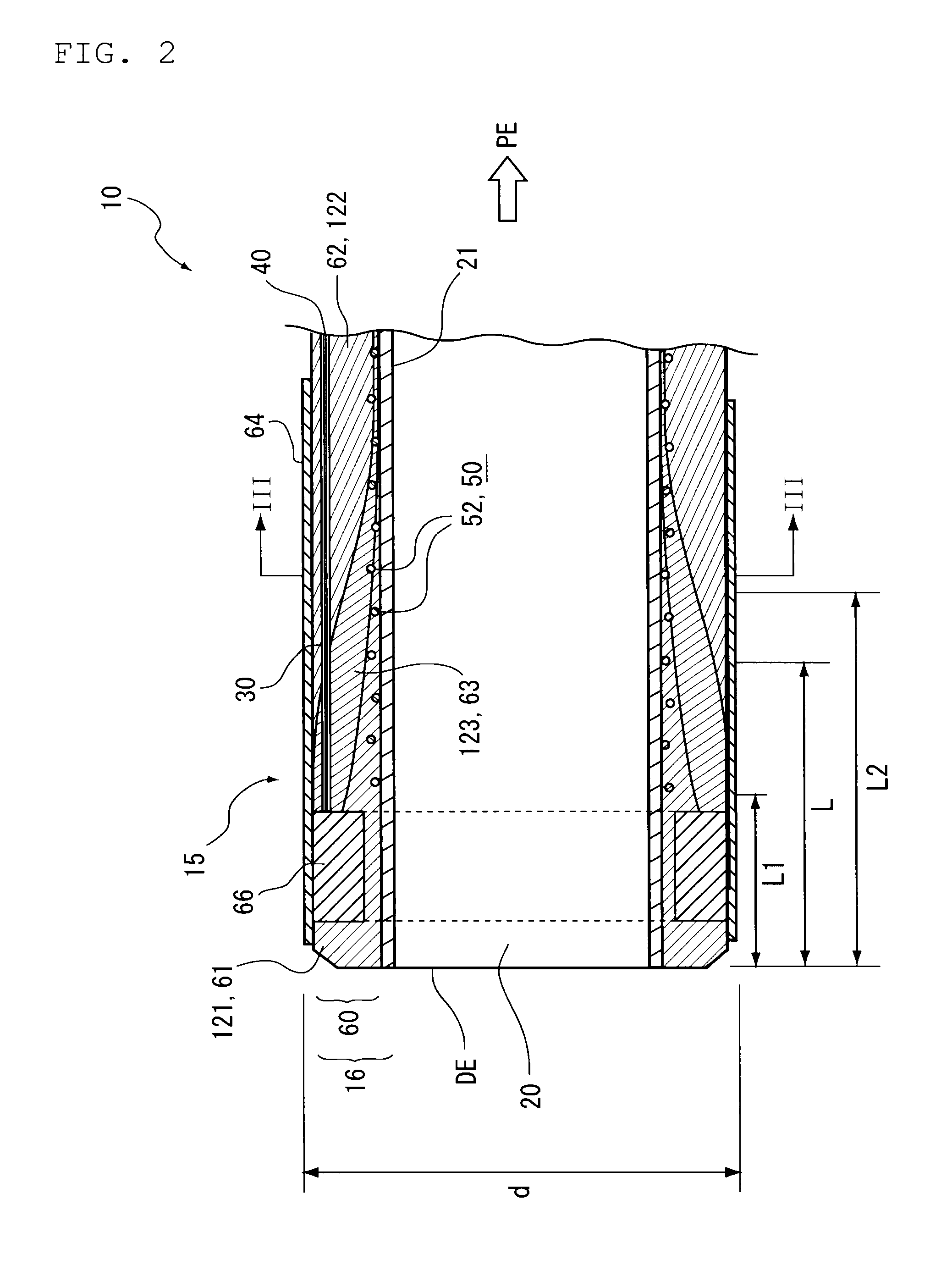

Catheter and method of manufacturing catheter

InactiveUS20110295217A1Large resilienceImprove bending performanceHollow filament manufactureEndoscopesBiomedical engineeringCatheter device

A main lumen (20) and sub-lumens (30) having a diameter smaller than that of the main lumen (20) are respectively formed in a sheath (16) of a catheter (10) in the longitudinal direction thereof so as to extend therethrough. An operating wire (40) is laid through each sub-lumen (30) in a slidable manner, with the end thereof fixed to the distal end section (15) of the sheath (16). The sheath (16) is configured a first resin layer (61) and a second resin layer (62) having a hardness higher than that of the first resin layer (61), stacked in the thickness-wise direction, each of which being composed of a resin material. In the sheath (16), the thickness of the second resin layer (62) increases from the distal end side towards the proximal end side.

Owner:SUMITOMO BAKELITE CO LTD

Dried bean curd cutting device beneficial to flavor infusing

The invention relates to a food cutting device, in particular to a dried bean curd cutting device beneficial to flavor infusing. The dried bean curd cutting device comprises a pressing plate and a handle arranged on the pressing plate, and is characterized in that the pressing plate is in polygon shape, criss-cross blades are perpendicularly arranged on the lower portion of the pressing plate, cutting pieces are connected to the side faces of the pressing plate through bolts, strip-shaped adjustment holes connected with the bolts are vertically formed in the cutting pieces, the pressing plate and the handle are of an integrally-formed hollow structure, an air bag is arranged below the handle and communicated with the hollow structure, and vent holes communicated with one sides of the blades are formed in the portion, above the pressing plate, of the hollow structure. By means of the scheme, the dried bean curd cutting device is high in cutting speed and capable of conveniently conducting cutting.

Owner:CHONGQING HEDELONG FOOD

Aluminum alloy extruded product for heat exchangers and method of manufacturing the same

InactiveUS20050189047A1Reduce resistanceReduce the amount requiredHeat exchange apparatusSiluminHigh intensity

A high-strength aluminum alloy extruded product for heat exchangers which excels in extrudability, allows a thin flat multi-cavity tube to be extruded at a high critical extrusion rate, and excel in intergranular corrosion resistance at a high temperature, and a method of manufacturing the same. The aluminum alloy extruded product includes an aluminum alloy including 0.2 to 1.8% of Mn and 0.1 to 1.2% of Si, having a ratio of Mn content to Si content (Mn % / Si %) of 0.7 to 2.5, and having a content of Cu as an impurity of 0.05% or less, with the balance being Al and impurities, the aluminum alloy extruded product having an electric conductivity of 50% IACS or more and an average particle size of intermetallic compounds precipitating in a matrix of 1 μm or less.

Owner:FURUKAWA SKY ALUMINUM CORP +2

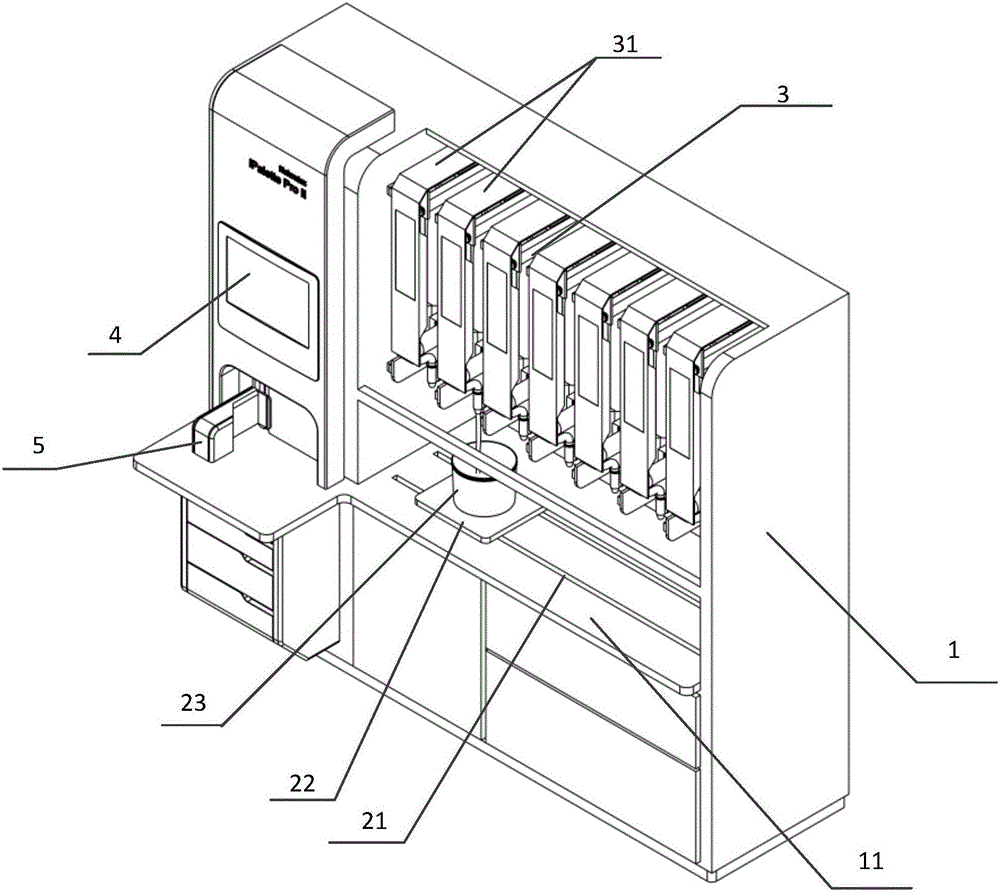

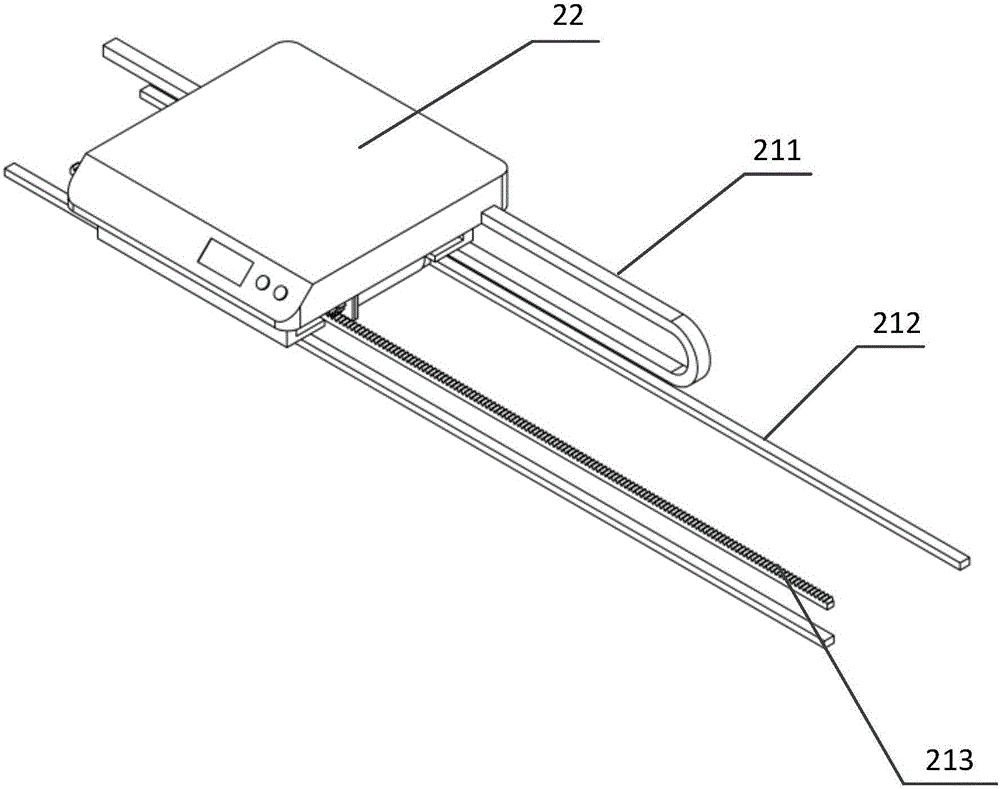

Automatic ink color blending equipment

InactiveCN105882140AResidue reductionEasy extrusionTransportation and packagingMixer accessoriesColor ScaleEngineering

The embodiment of the invention relates to automatic ink color blending equipment. The automatic ink color blending equipment comprises an equipment cabinet with a carrying platform, wherein an ink barrel moving platform is arranged on the carrying platform. The ink barrel moving platform comprises a moving guide rail, weighing equipment and an ink barrel. The ink barrel is arranged on the weighing equipment, and the weighing equipment is arranged on the moving guide rail and moves along the moving guide rail. An ink supply bin is erected above the ink barrel moving platform and comprises multiple sets of ink supply devices, wherein the ink supply devices are used for providing ink in different color scales. A control terminal is arranged on the carrying platform and electrically connected with the ink supply bin, the moving guide rail and the weighing equipment. The control terminal obtains target color scale information, generates ink selection and control information according to the target color scale information and controls and selects one or more sets of ink supply devices to inject ink of the corresponding weight into the ink barrel, wherein the ink selection and control information comprises ink device selection information and needed injection ink amount information.

Owner:桑春龙 +6

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com