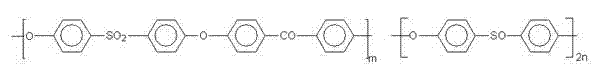

Ketone group-containing polyethersulfone resin and synthetic method thereof

A synthesis method and polyethersulfone technology are applied in the field of ketone group-containing polyethersulfone resin and its synthesis, which can solve the problems of high glass transition temperature, unfavorable molecular motion, difficulty in molding and processing, etc. Ease of route, effect of improved thermal stability and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

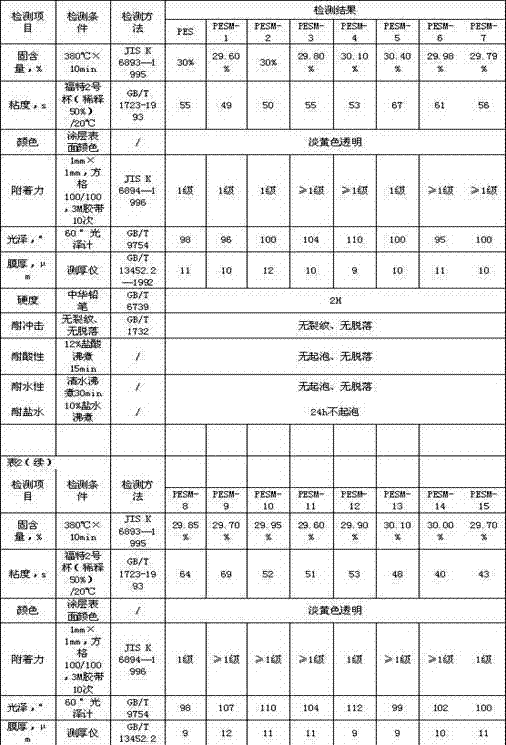

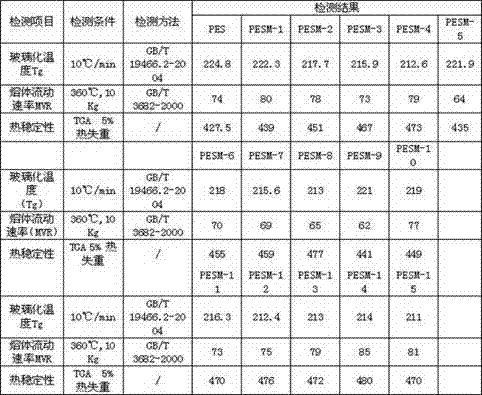

Examples

Embodiment 1

[0029] Into a 1000ml four-necked reaction flask equipped with a thermometer, an air inlet pipe, a reflux liquid separator, and a stirrer with a torque display to remove oxygen, and then add 137.7g (0.55mol) 4,4-dihydroxydiphenylsulfone successively and 13.8g (0.0551mol) of 4,4-dichlorobenzophenone, then add 600g of distilled sulfolane, start the agitator to stir, and start to heat up, when the temperature reaches 85°C, observe the material in the reactor Dissolution situation, when the material is completely dissolved in the solvent, slowly add 308.6g concentration of 20% potassium hydroxide solution and 90g toluene, continue heating, when toluene and water azeotrope are steamed out, pass through the reflux separator Reflux the toluene into the reactor, release the water and weigh it, when the temperature reaches 145°C, stop heating, and control the temperature of the material in the reactor at 130-160°C, keep the temperature for 70--80 minutes, when the reactor is steamed Whe...

Embodiment 2

[0032] According to the same method as in Example 1, except that the feeding weight of 4,4-dichlorobenzophenone is changed to 41.4g (0.165mol), and the weight of 4,4-dichlorodiphenylsulfone is changed to 110.6g (0.385mol) , at 230°C, keep the temperature constant for 40-60 minutes to obtain a ketone-containing polyethersulfone resin product, coded as PESM-2.

Embodiment 3

[0034]According to the same method as in Example 1, except that the feeding weight of 4,4-dichlorobenzophenone is changed to 55.2g (0.22mol), and the weight of 4,4-dichlorodiphenylsulfone is changed to 94.8g (0.33mol) , at 230°C, keep the temperature constant for 50-70 minutes to obtain a ketone-containing polyethersulfone resin product, coded as PESM-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com