Patents

Literature

447results about How to "Easy injection molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly heat-conducting insulation engineering plastic and preparation method thereof

InactiveCN102174254AIncrease China UnicomImprove thermal conductivityPlastic/resin/waxes insulatorsHeat-exchange elementsFiberAntioxidant

The invention discloses highly heat-conducting insulation engineering plastic, which consists of the following components in part by weight: 100 parts of plastic substrate, 100 to 900 parts of heat-conducting filler, 1 to 45 parts of compatibilizer, 1 to 90 parts of toughening agent, 1 to 45 parts of reinforcing agent, 1 to 36 parts of lubricating agent and 0.3 to 5.4 parts of antioxidant. The invention also discloses a preparation method of the engineering plastic, which comprises the following steps of: drying the plastic substrate and the heat-conducting filler in a 60 to 100 DEG C air dry oven for 4 to 8 hours; putting the components into a high-speed mixer and mixing for 3 to 5 minutes; performing internal mixing on the mixture in an internal mixer for 10 to 30 minutes; and uniformly grinding the mixture in a grinder, transferring to a charging hopper of a double-screw extruder, feeding fiber fillers through a fiber inlet of the double-screw extruder, melting, mixing, extruding, cooling, drying, and pelletizing. The prepared material has high heat-conducting property and mechanical property, and is easily subjected to injection molding.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Heat-conducting plastic and preparation method thereof

ActiveCN102746560AImprove thermal conductivityEasy injection moldingHeat conductingDegrees of freedom

The invention discloses a heat-conducting plastic and a preparation method thereof, wherein the heat-conducting plastic comprises, by weight, 25% to 80% of matrix resins, 5% to 40% of heat-conducting fillers, 5% to 10% of coupling agents and 5% to 30% of halogen-free flame retardants. According to the heat-conducting plastic, the coefficient of heat conductivity is high, the injection molding is convenient, the cost is low, heat dissipation is even, hot spots can be avoided, local deformation of parts caused by the high temperature is reduced, the weight is light and lighter than the weight of aluminum materials by 40% to 50%, the molding processing is convenient, secondary processing is not needed, and the product design degree of freedom is high.

Owner:SHENZHEN FRD SCI & TECH

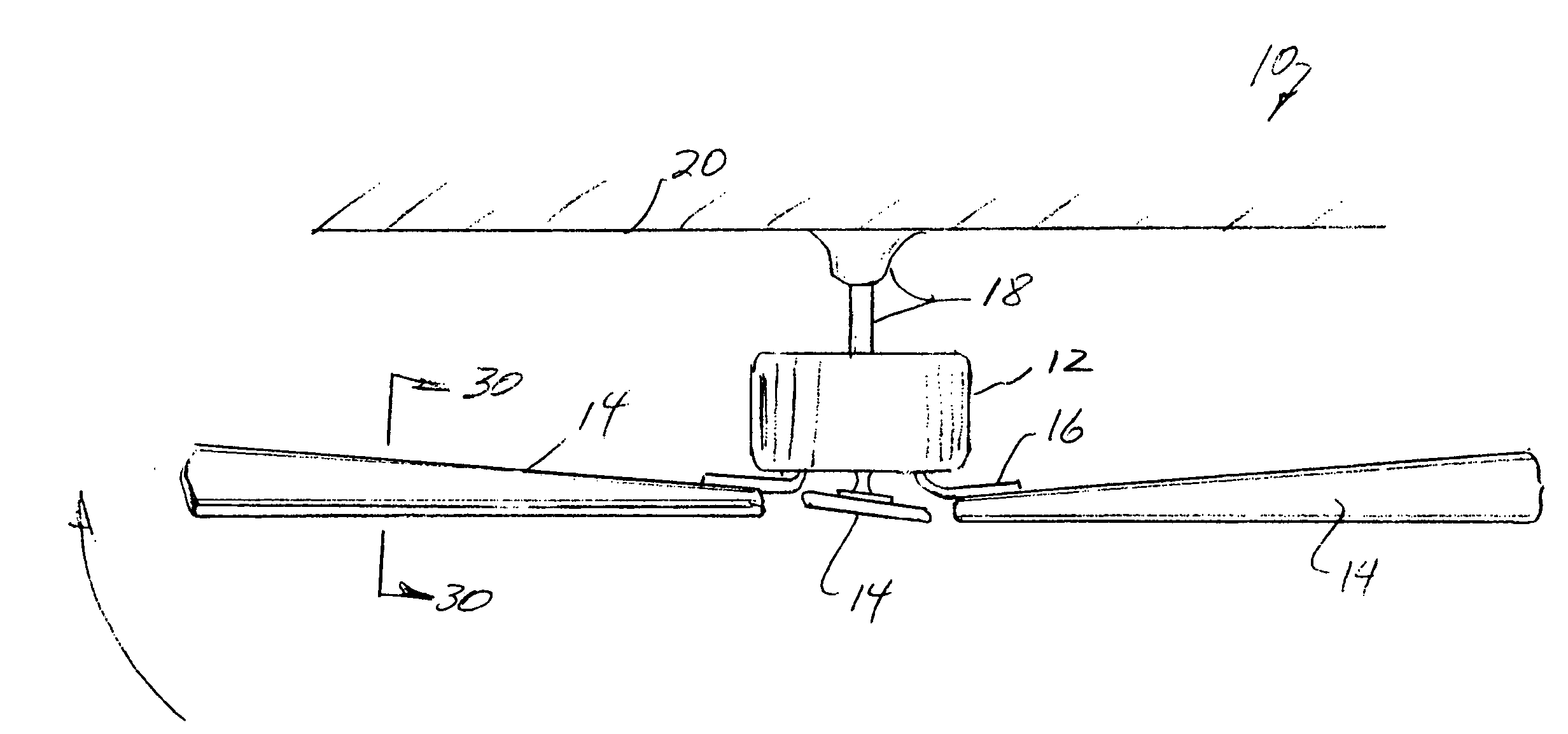

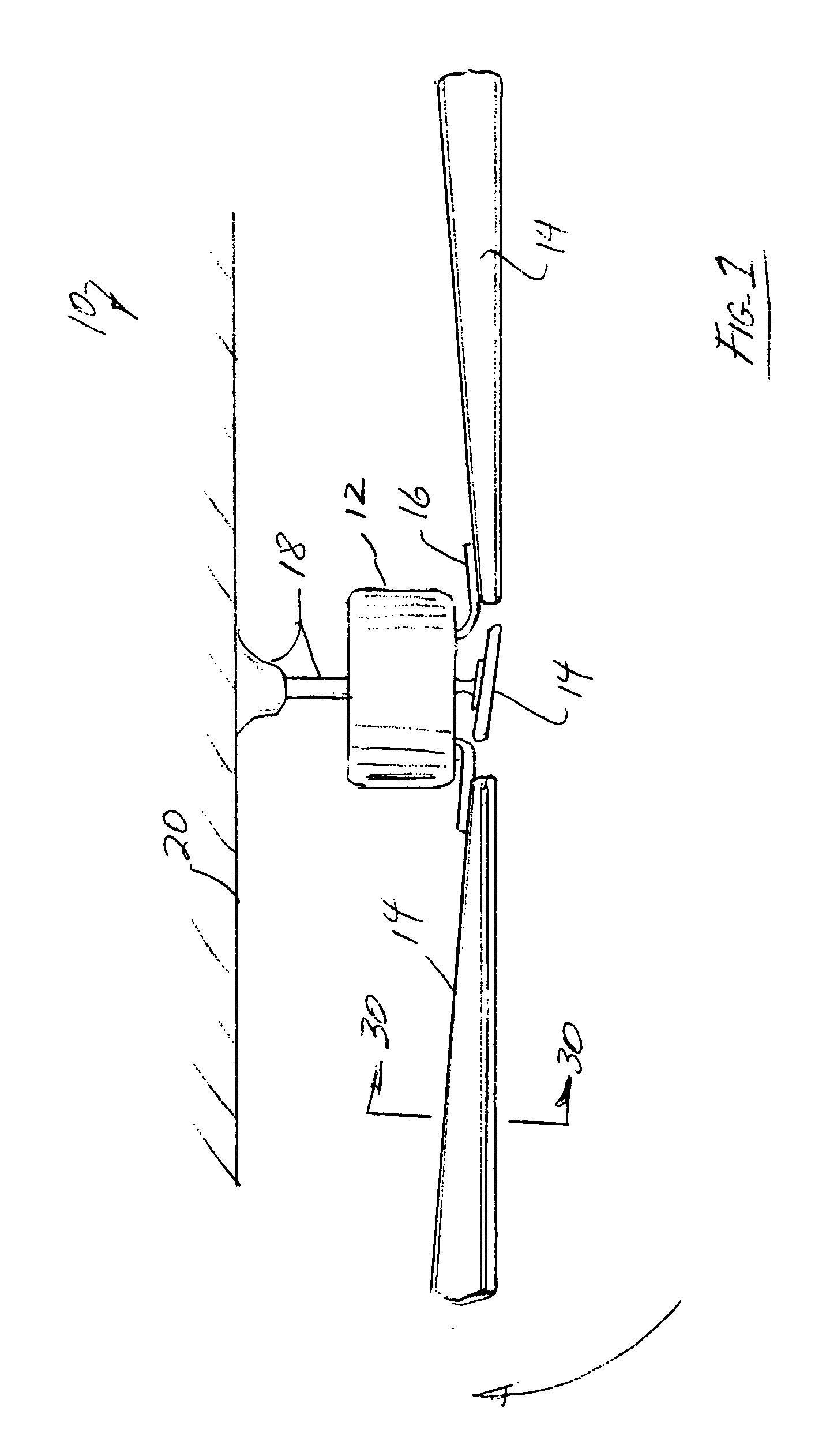

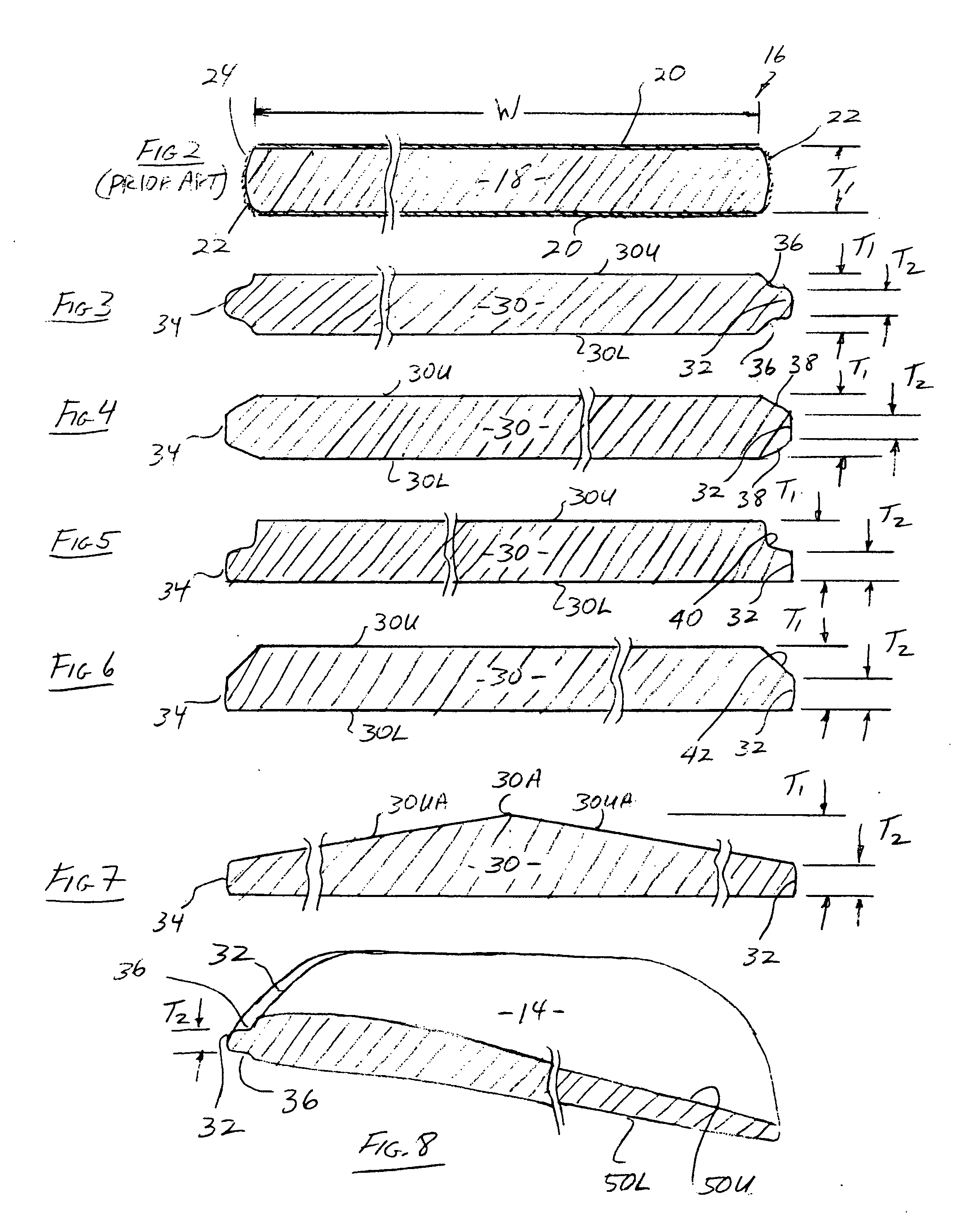

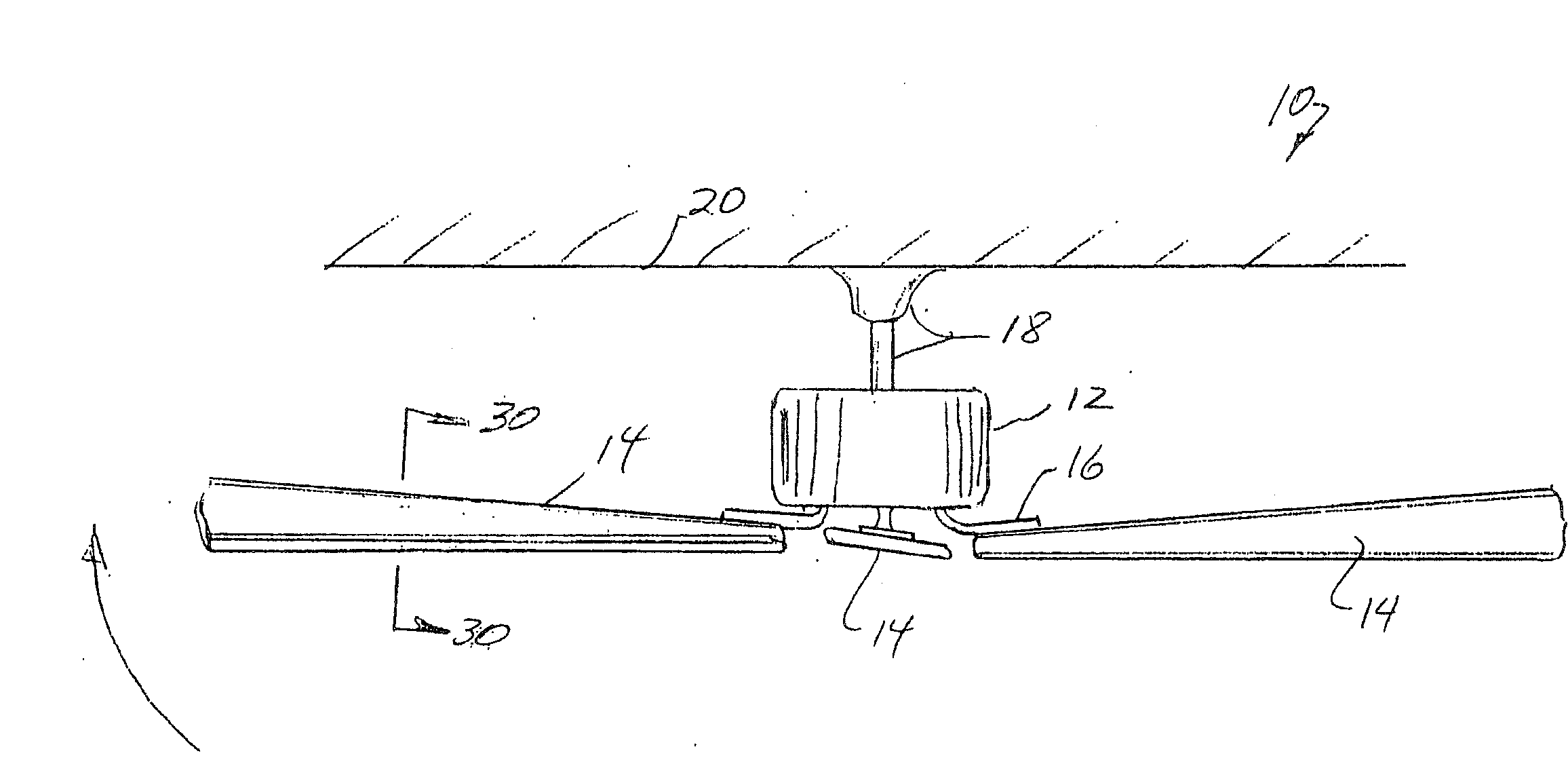

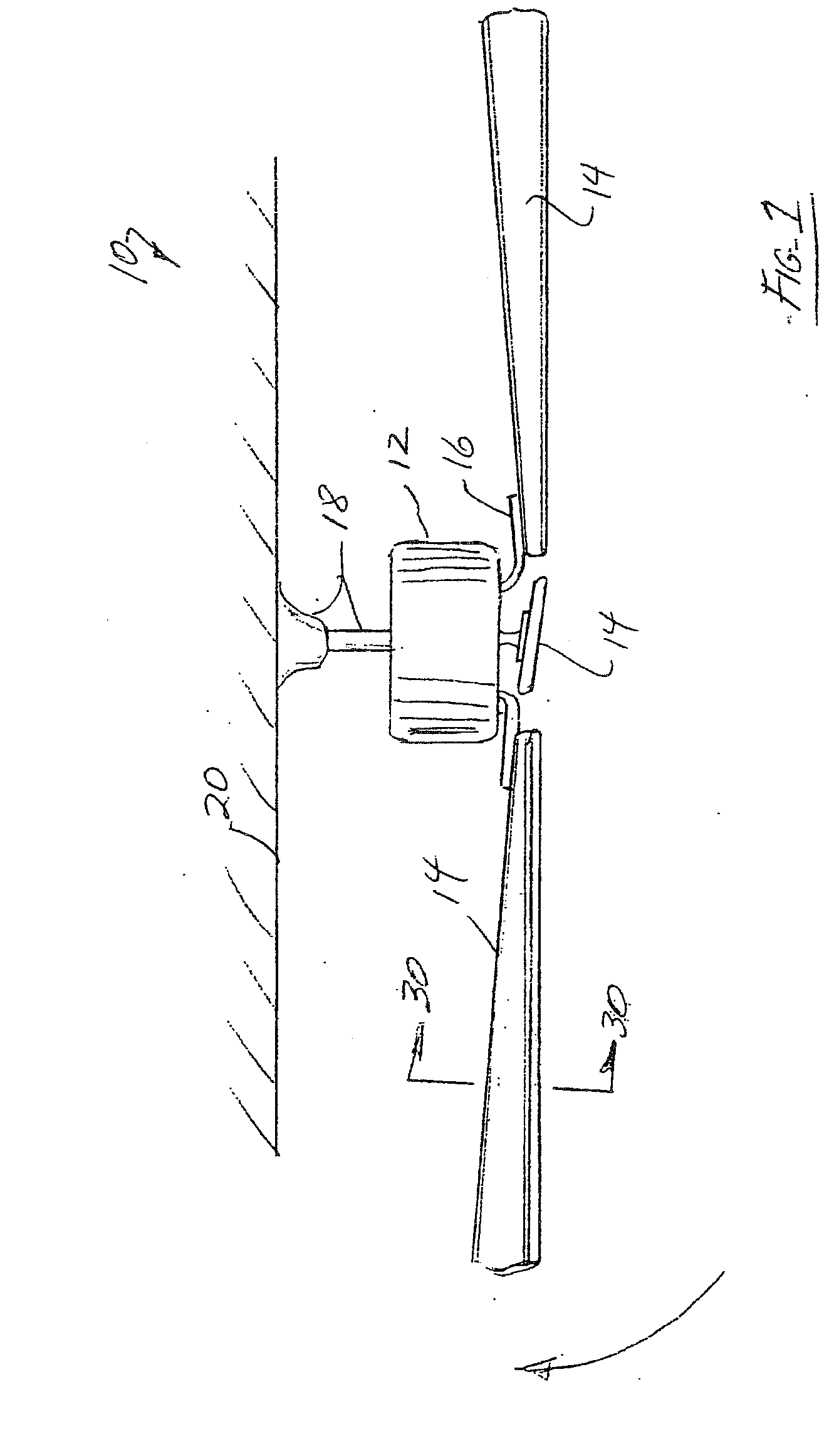

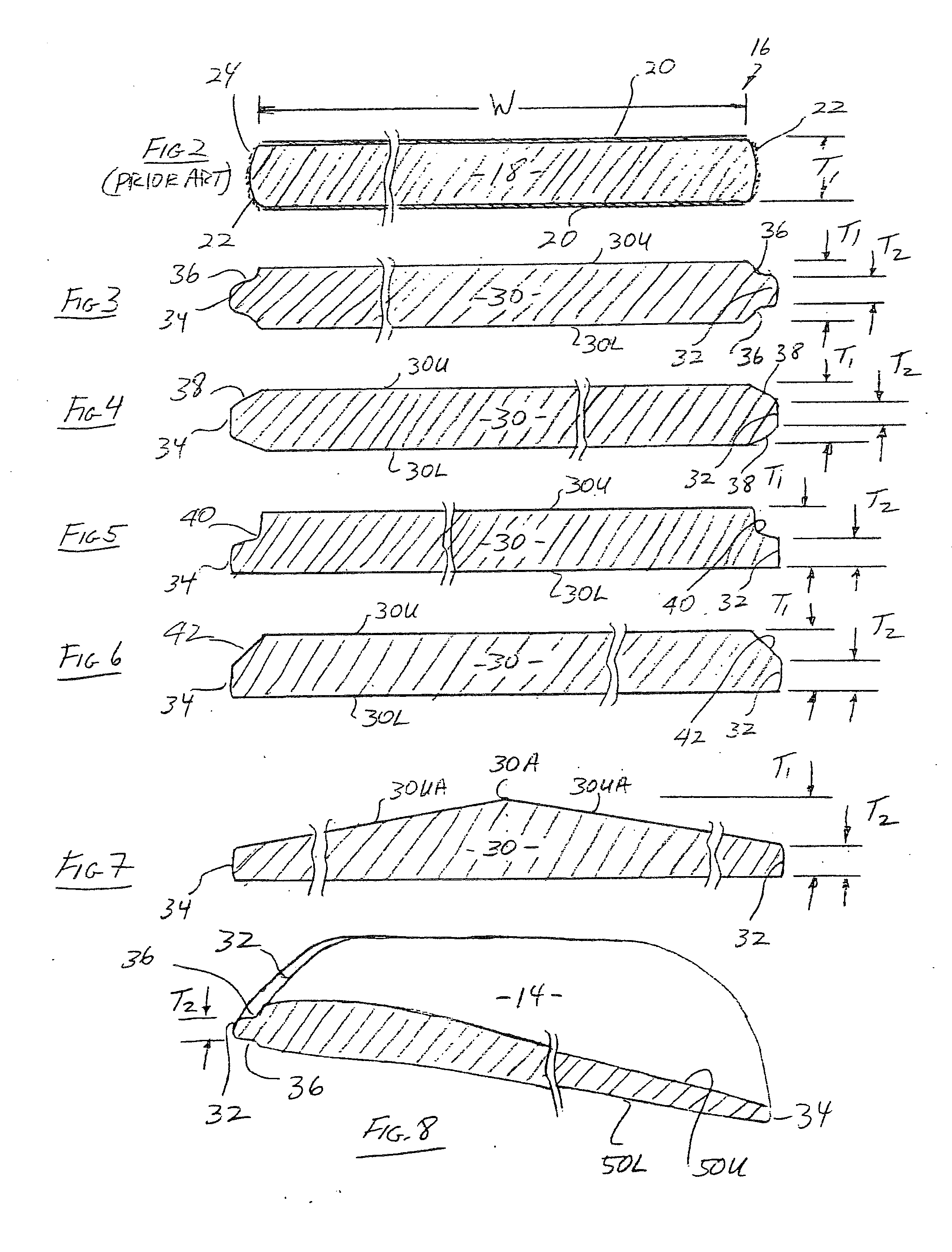

Ceiling fan with high efficiency ceiling fan blades

InactiveUS20070154315A1High efficiency fan bladeReduce edge thicknessPump componentsRotary propellersLeading edgeCeiling fan

A ceiling fan including a motor having a rotatable rotor, a plurality of ceiling fans blades having a thickness, the blades connected to the rotor to rotate therewith and each of the ceiling fan blades comprising a thin edge along its leading edge that is thinner than the thickness of the ceiling fan blade to present less resistance and produce less turbulence and achieve high efficiencies.

Owner:BUCHER JOHN C

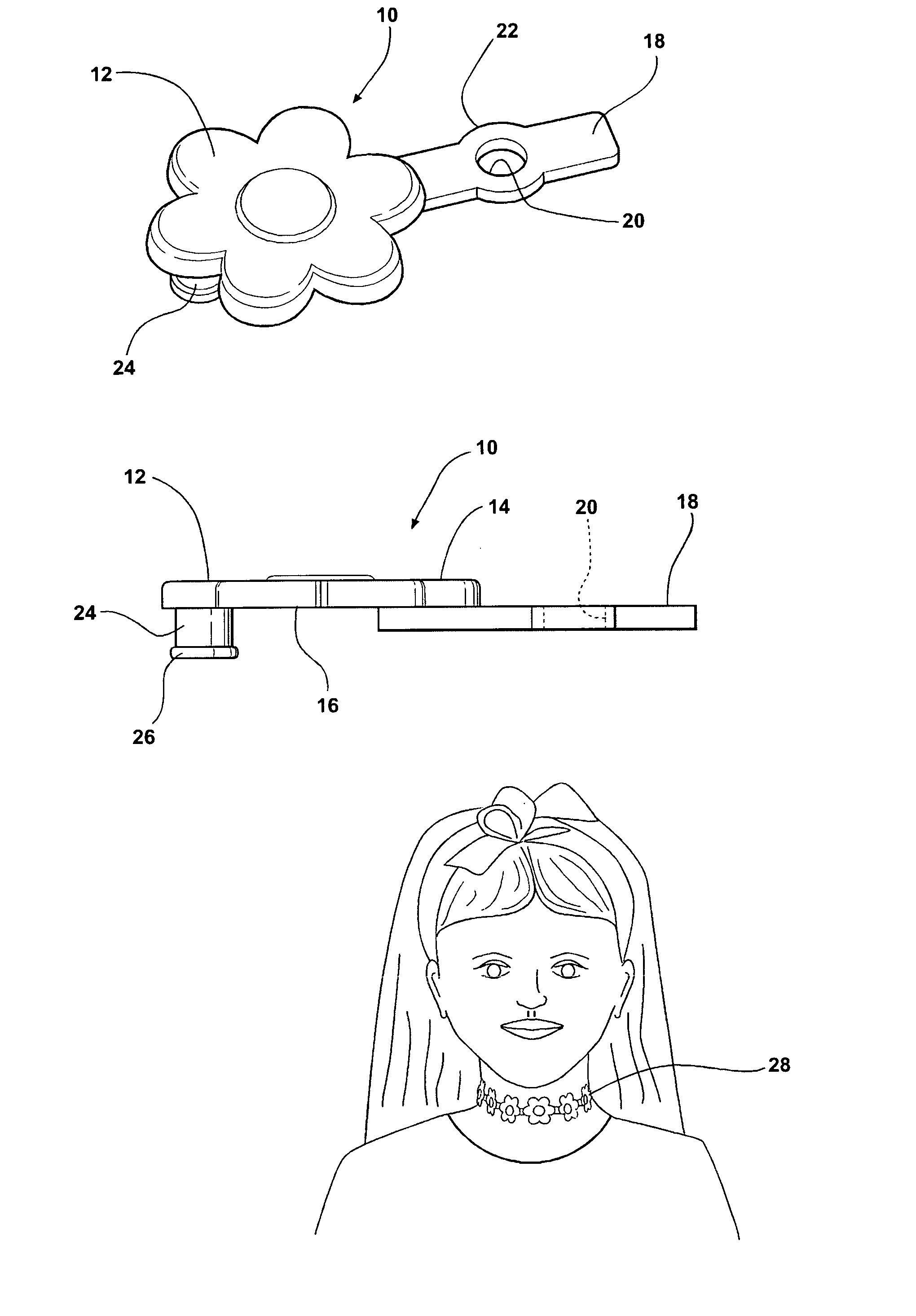

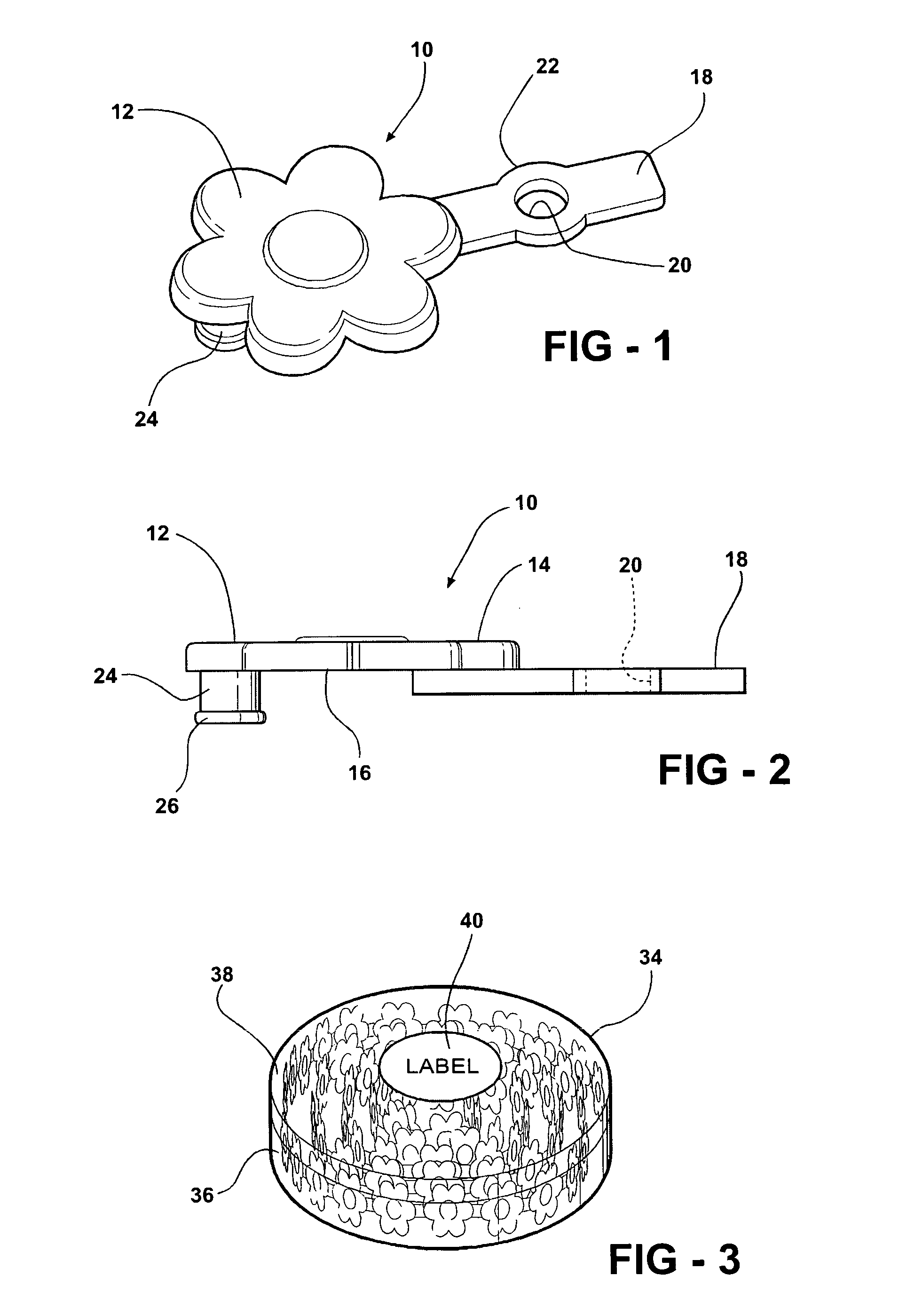

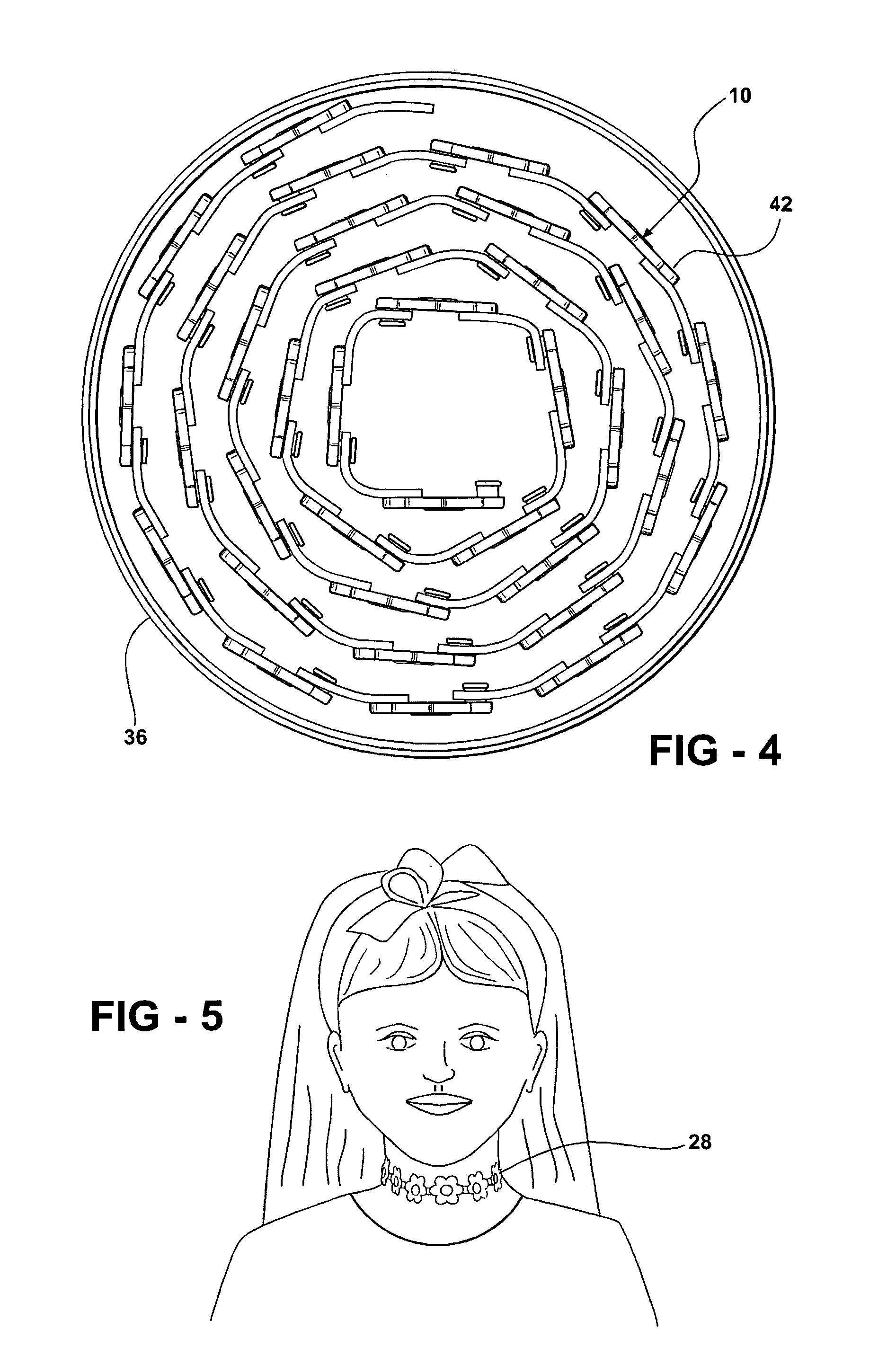

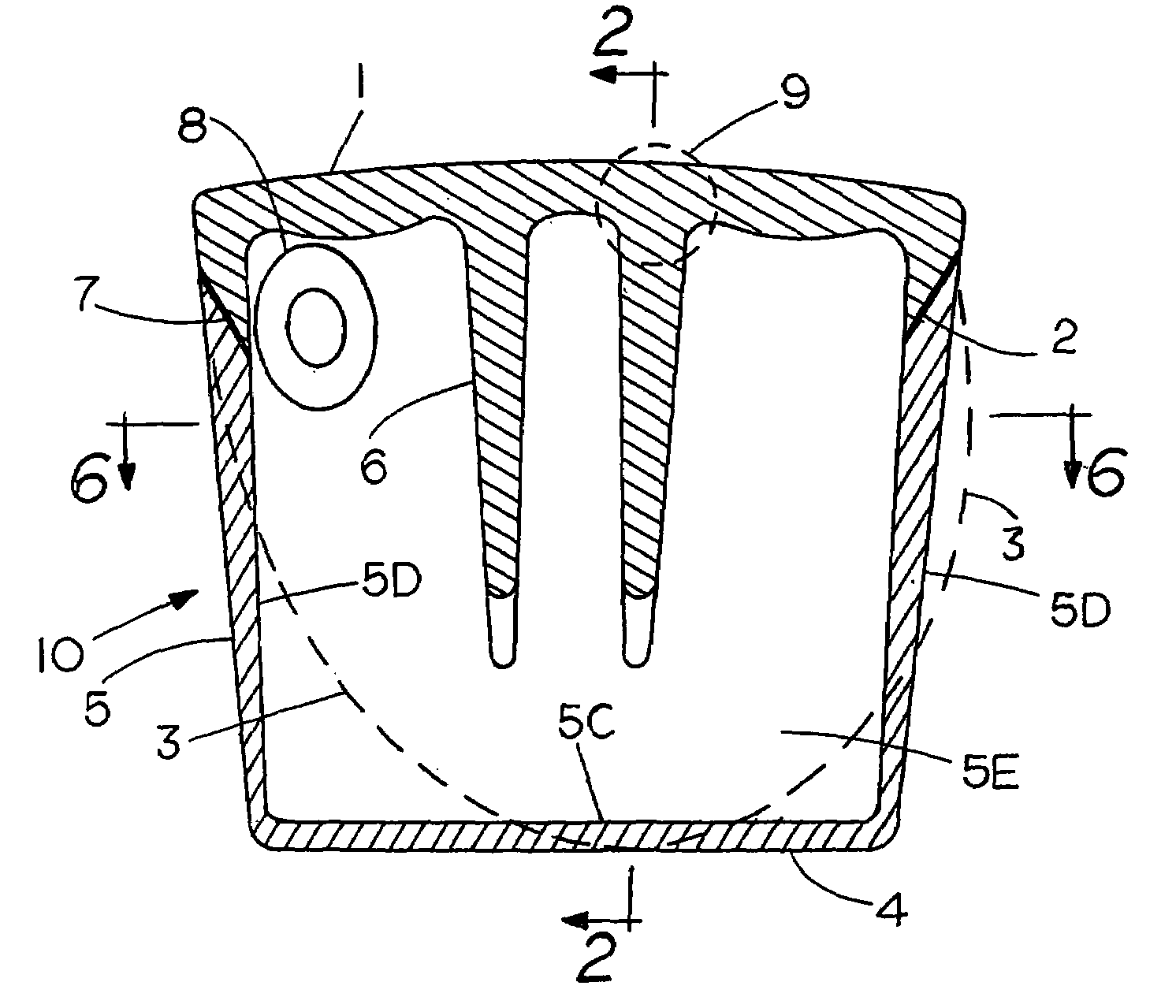

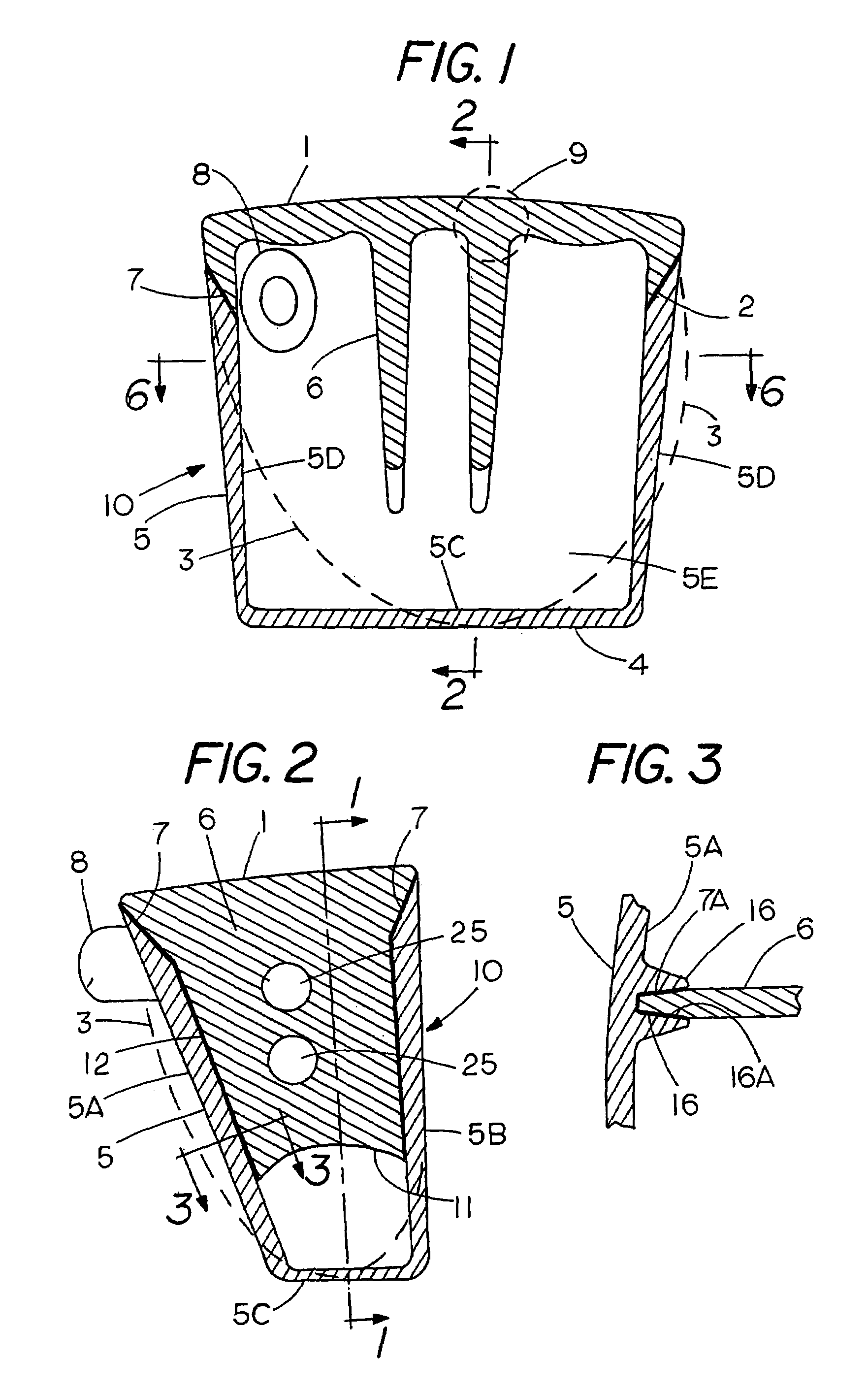

Personal adornment

InactiveUS7178364B2Simple and inexpensive to manufactureEasy injection moldingBraceletsChain elementsEngineeringMechanical engineering

Owner:SHAPIRO KRISTEN M +1

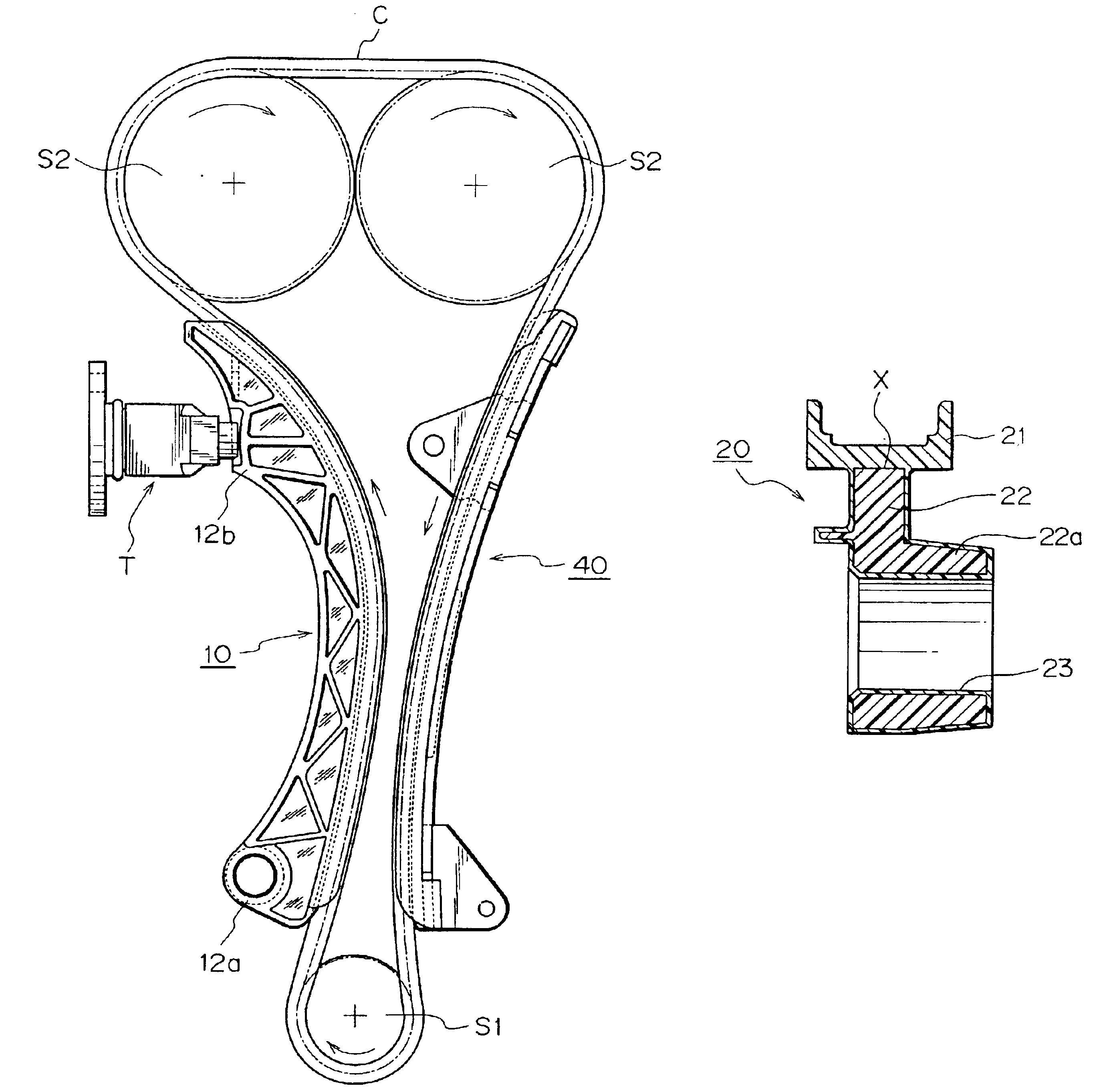

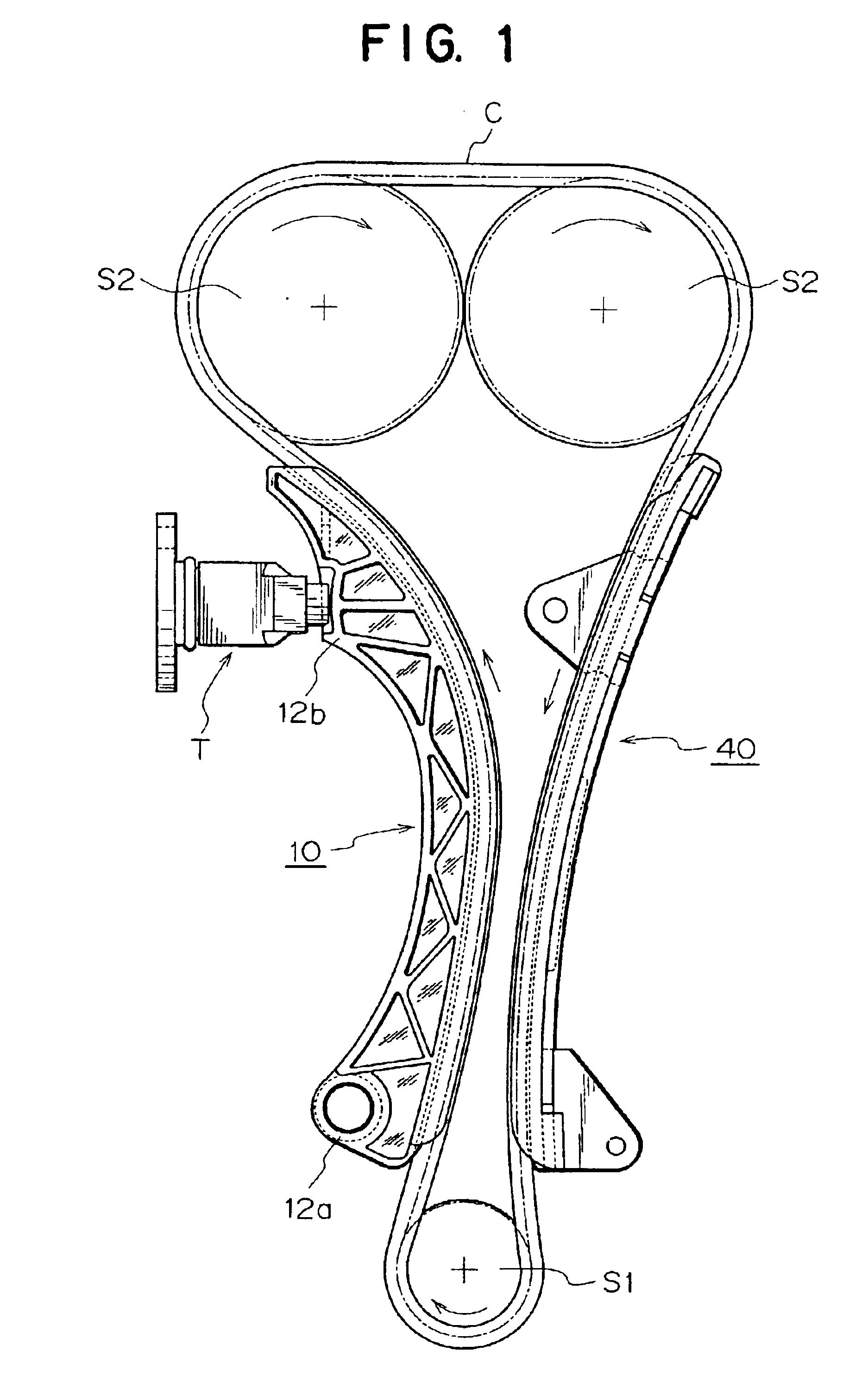

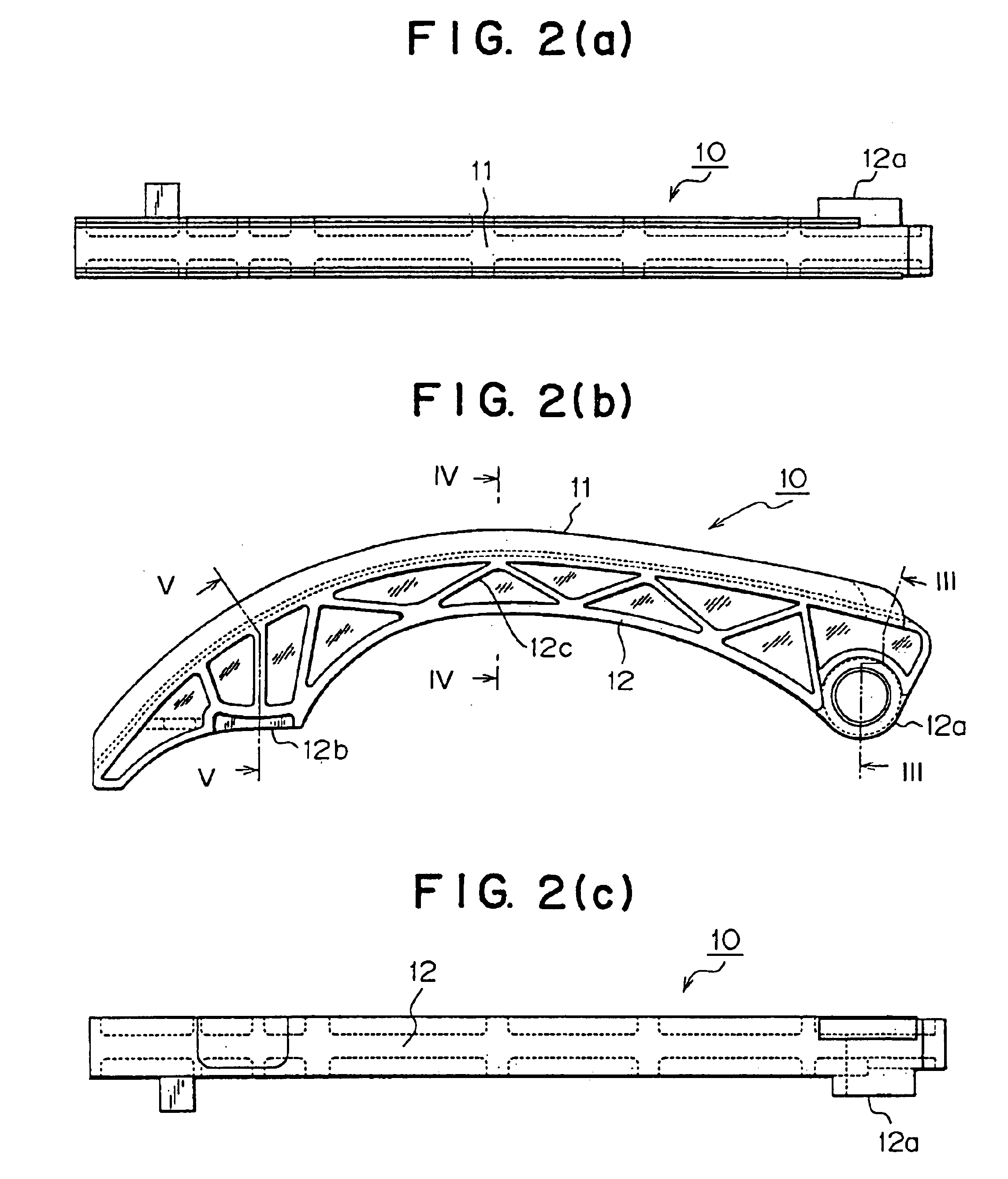

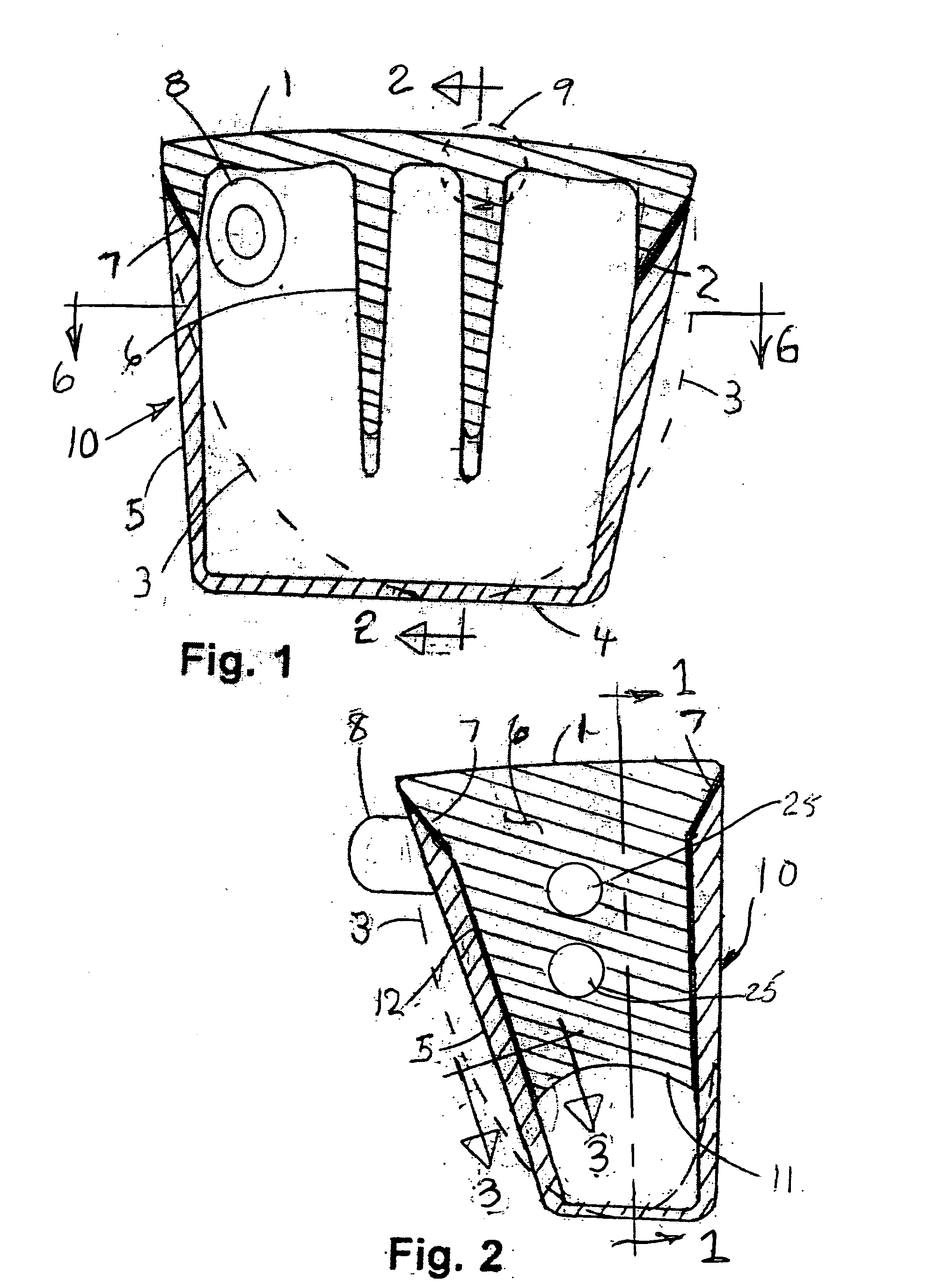

Sandwich-molded guide for transmission device

A guide for as transmission device such as a chain or belt, is injection molded using a sandwich-molding process. The sandwhich-molded guide comprises a slide rail on which a chain or belt slides, and a rail supporting member intergrally provided along with the slide rail. The slide rail is composed of a material the principle component of which is first polymeric material having wear resistance and heat resistance, and the rail supporting member is composed of a material the principle component of which is a second polymeric material having higher strength than the material having the first polymeric material as its principle component. The slide rail and the rail supporting member are intimately joined to each other by injection molding using the sandwhich molding process.

Owner:TSUBAKIMOTO CHAIN CO +2

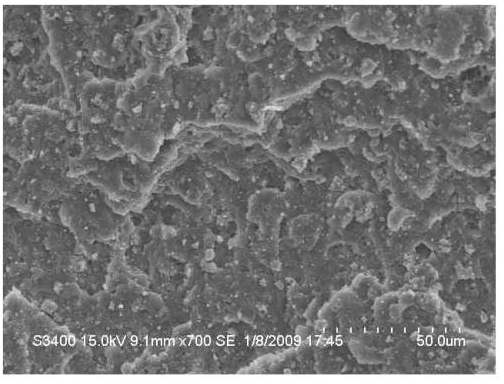

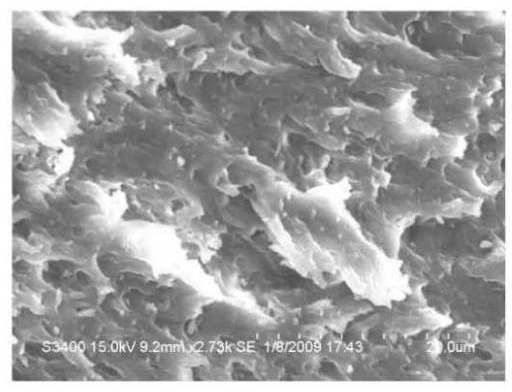

Preparation method of metal resin complex and metal resin complex prepared thereby

ActiveCN103448202AEasy accessSize has little effectAnodisationLaminationAlloy substrateWater soluble

The invention provides a preparation method of a metal resin complex and the metal resin complex prepared thereby. The preparation method of the metal resin complex comprises the following steps: S1, micropores are formed on the surface of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, the metal substrate having the micropores on the surface thereof and obtained by the step S1 is soaked in a water-soluble polymer solution for modification; and S3, the surface of the treated metal substrate modified by soaking in the step S2 is coated with a resin composition, and after molding the metal resin complex is obtained. In the metal resin complex, the binding force between metal and resin is strong, and the process is simple, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

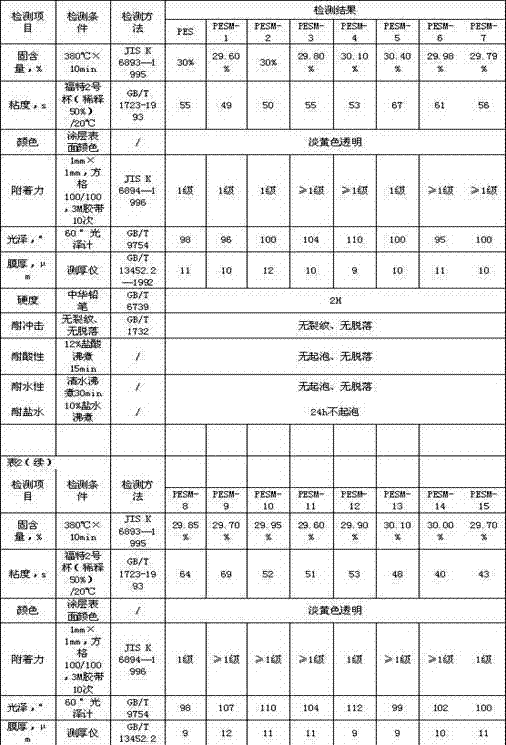

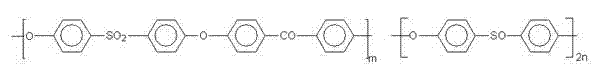

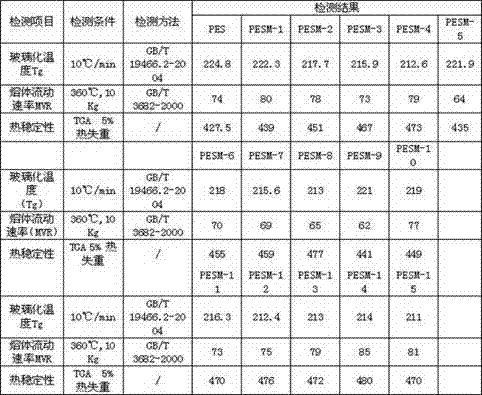

Ketone group-containing polyethersulfone resin and synthetic method thereof

The invention belongs to the technical field of polymer materials and provides ketone group-containing polyethersulfone resin which is high in thermal stability, low in processing temperature and is easier for injection-molding and extrusion-molding. The ketone group-containing polyethersulfone resin is a product synthetized through nucleophilic polycondensation reaction of the following polymerization monomers: 4,4-dihydroxyl dihydroxydiphenylsulfone, 4,4'-dichlorobenzophenone and 4,4-dichlorodiphenyl sulfone. The ketone group is introduced onto the molecular chain of polyethersulfone, so as to improve the thermal stability of the polymer, reduce the processing temperature of the polymer and ensure that the polymer is more convenient for injection-molding and extrusion-molding. The invention also provides a synthetic method of the ketone group-containing polyethersulfone resin. The method is easy to operate, and the reaction process and the viscosity of materials are easily controlled.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

Ceiling Fan With High Efficiency Ceiling Fan Blades

InactiveUS20090263254A1High efficiencyReduce thicknessPump componentsMetal-working apparatusCeiling fanLeading-edge slats

A ceiling fan including a motor having a rotatable rotor, a plurality of ceiling fans blades having a thickness, the blades connected to the rotor to rotate therewith and each of the ceiling fan blades comprising a thin edge along its leading edge that is thinner than the thickness of the ceiling fan blade to present less resistance and produce less turbulence and achieve high efficiencies.

Owner:KING OF FANS

Plastic golf club head

A method of assembly of construction and assembly of golf club head parts used to manufacture golf club heads primarily composed of strong plastic materials that can be formed by injection plastic molding processes in a minimum of two parts. Draft is practical for both molded parts to simplify mold making. A preferred plastic is polycarbonate. Internal reinforcement elements are designed and arranged to provide structural features to facilitate assembly and improve strength of bonds. Internal reinforcement elements may be molded as separate parts to join with the face and shell structure. A hosel, which is not considered part of the shell and which may be made of plastic or metal, is bonded into the golf club head parts described.

Owner:ORIGIN INC

High-impact water-supply pipe granular material and preparation method thereof

InactiveCN101948594AReduce manufacturing costAuxiliary role in thermal stabilizationFlexible pipesWhole bodyPolyvinyl chloride

The invention discloses a high-impact water-supply pipe granular material and a preparation method thereof, wherein the high-impact water-supply pipe granular material is a blending system comprising PVC (Polyvinyl Chloride) resin and additives blended in the PVC resin; the additives comprise a toughening agent, stabilizing agents, a lubricant, a filling agent, a processing aid and titanium pigment; the stabilizing agents include an organic tin stabilizing agent and epoxidized soybean oil; and the contents of all the components in parts by weight are as follows: 100 parts of the PVC resin, 3.5-11 parts of the toughening agent, 2-4 parts of whole body of the two stabilizing agents, 1.5-3.5 parts of the lubricant, 4-12 parts of the filling agent, 1.5-6 parts of the processing aid and 0-0.5 part of the titanium pigment. A water-supply pipe produced by the granular material has good appearance and good toughness, the anti-impact strength is higher than 68kJ / m<2>, the Vicat heat deformation temperature is higher than 72 DEG C, and after being frozen for 60 minutes at the temperature of 0 DEG C, a cracking phenomenon can not occur when the water-supply pipe freely falls from a 10m high position.

Owner:JIANGSU UNIV OF TECH

Polyphenylene sulfide/polyamide composite material and method for making same

The present invention discloses one kind of polyphenyl thioether / polyamide composite material and its preparation process. The polyphenyl thioether / polyamide composite material is prepared with polyphenyl thioether 23-69.3 wt%, polyamide 10-30 wt%, glass fiber 20-40 wt%, heat stabilizer 0.2-2 wt%, silane coupler 0.1-2 wt%, processing lubricant 0.2-2 wt% and crystallization promoter 0.1-1 wt%. The polyphenyl thioether / polyamide composite material has high shock toughness, simple preparation process and low cost.

Owner:ANHUI KEJU NEW MATERIALS

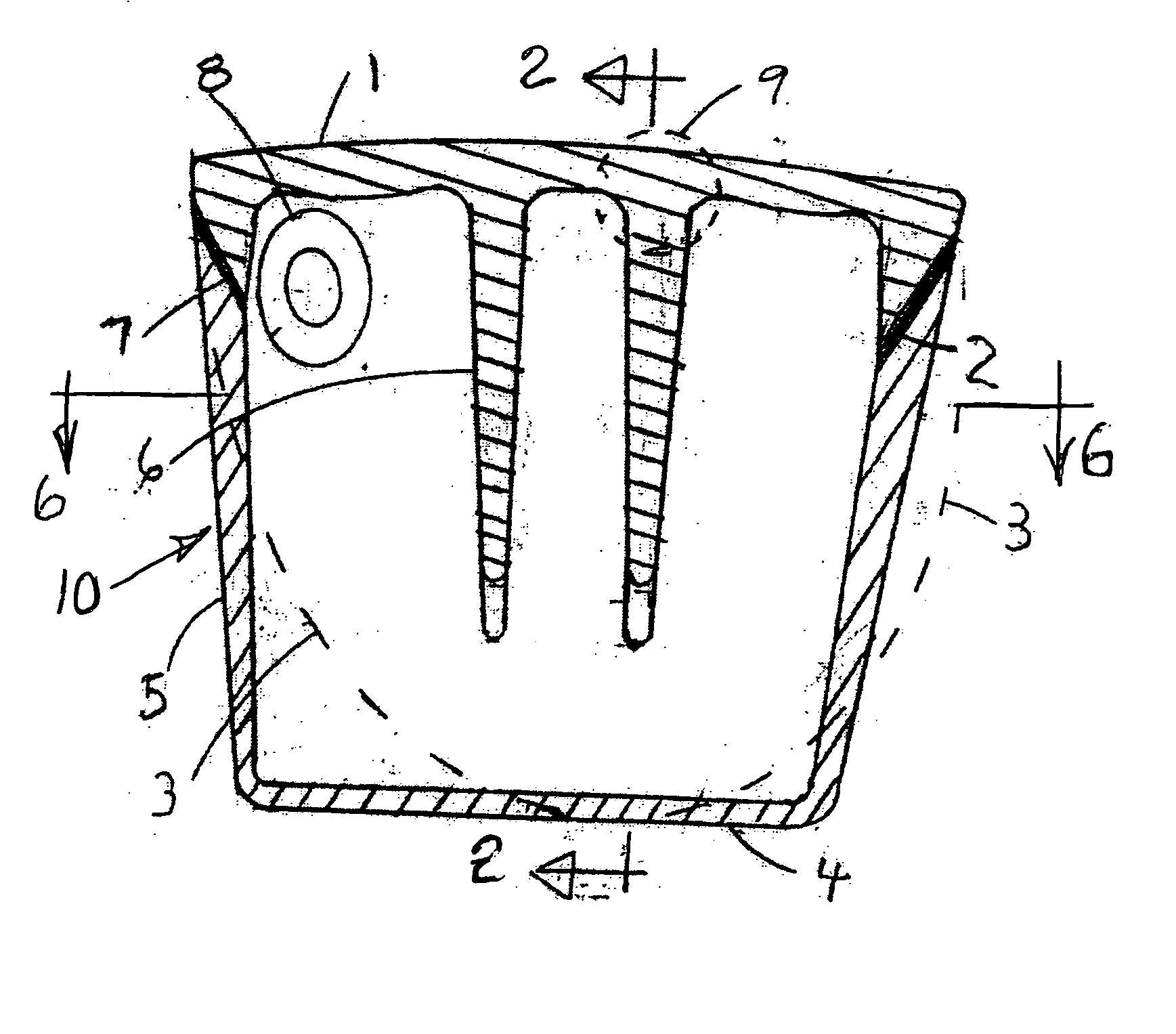

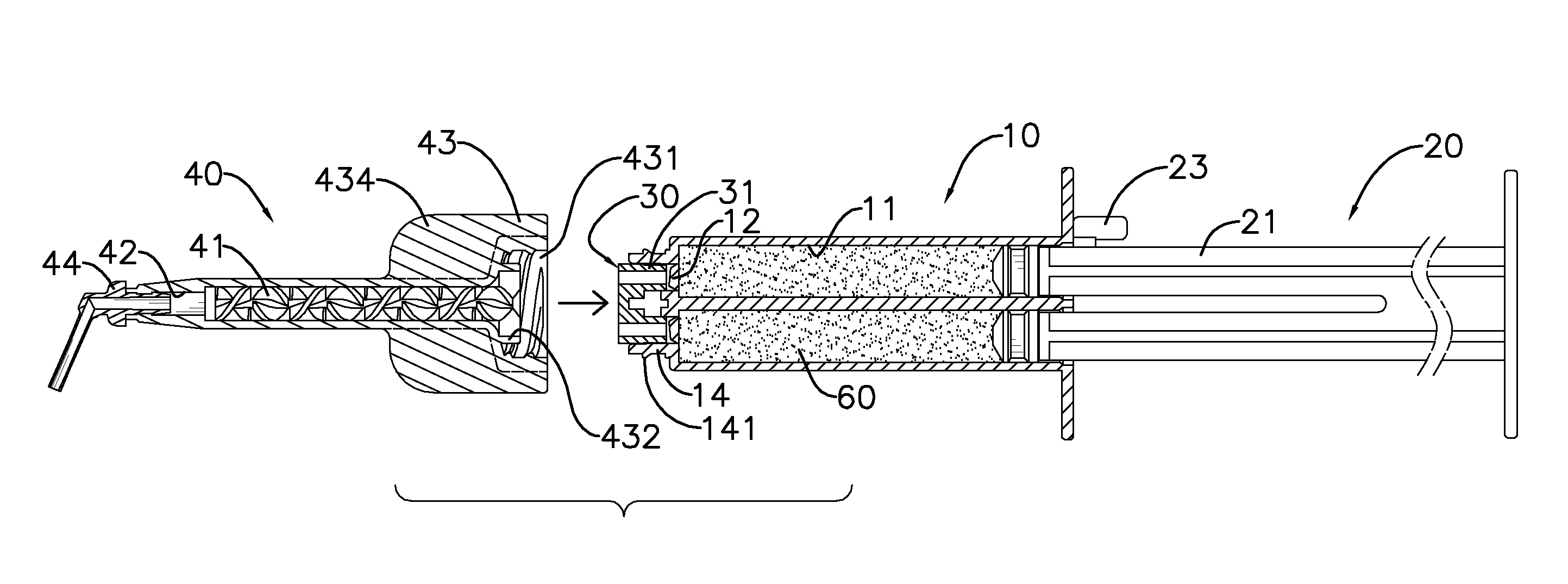

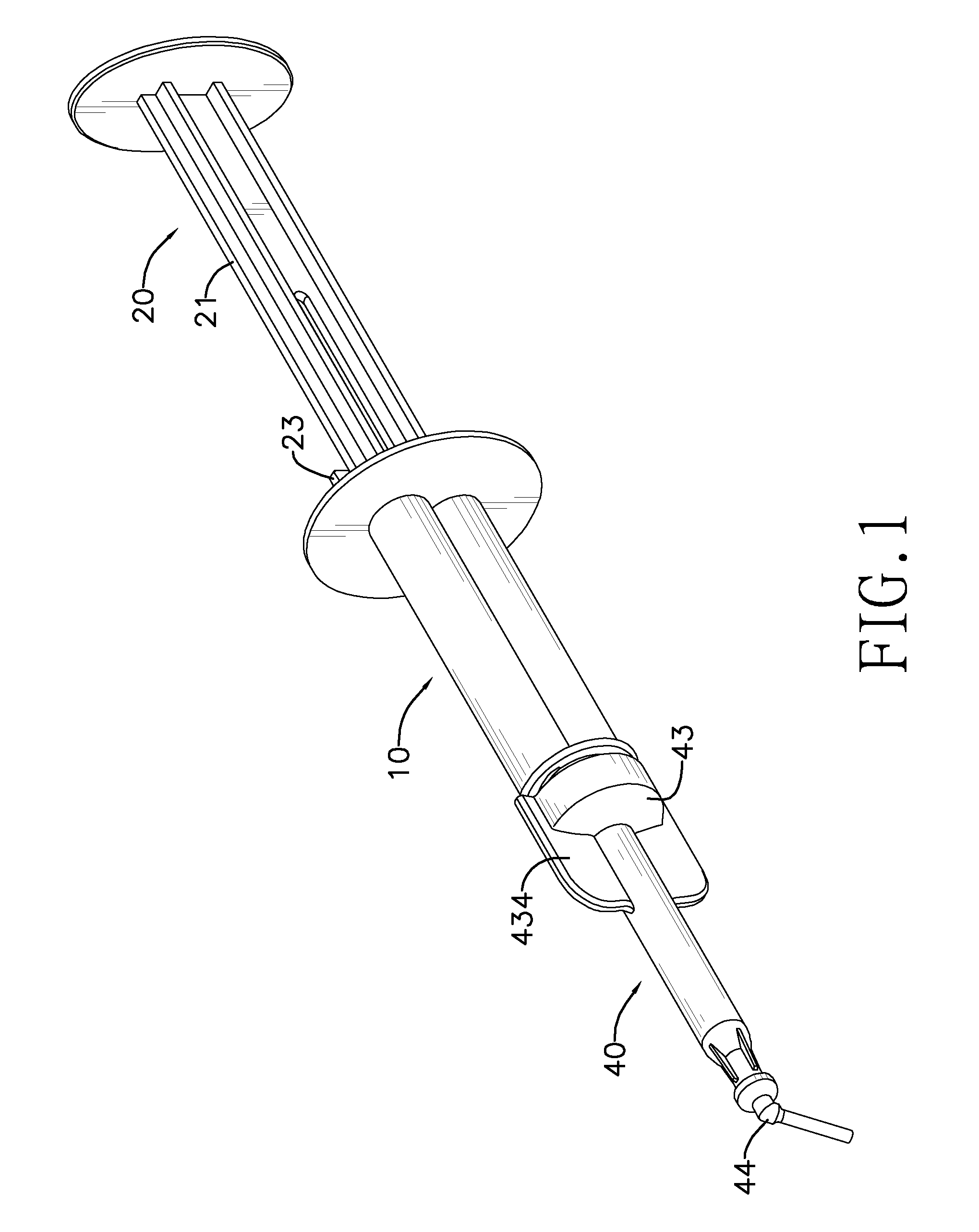

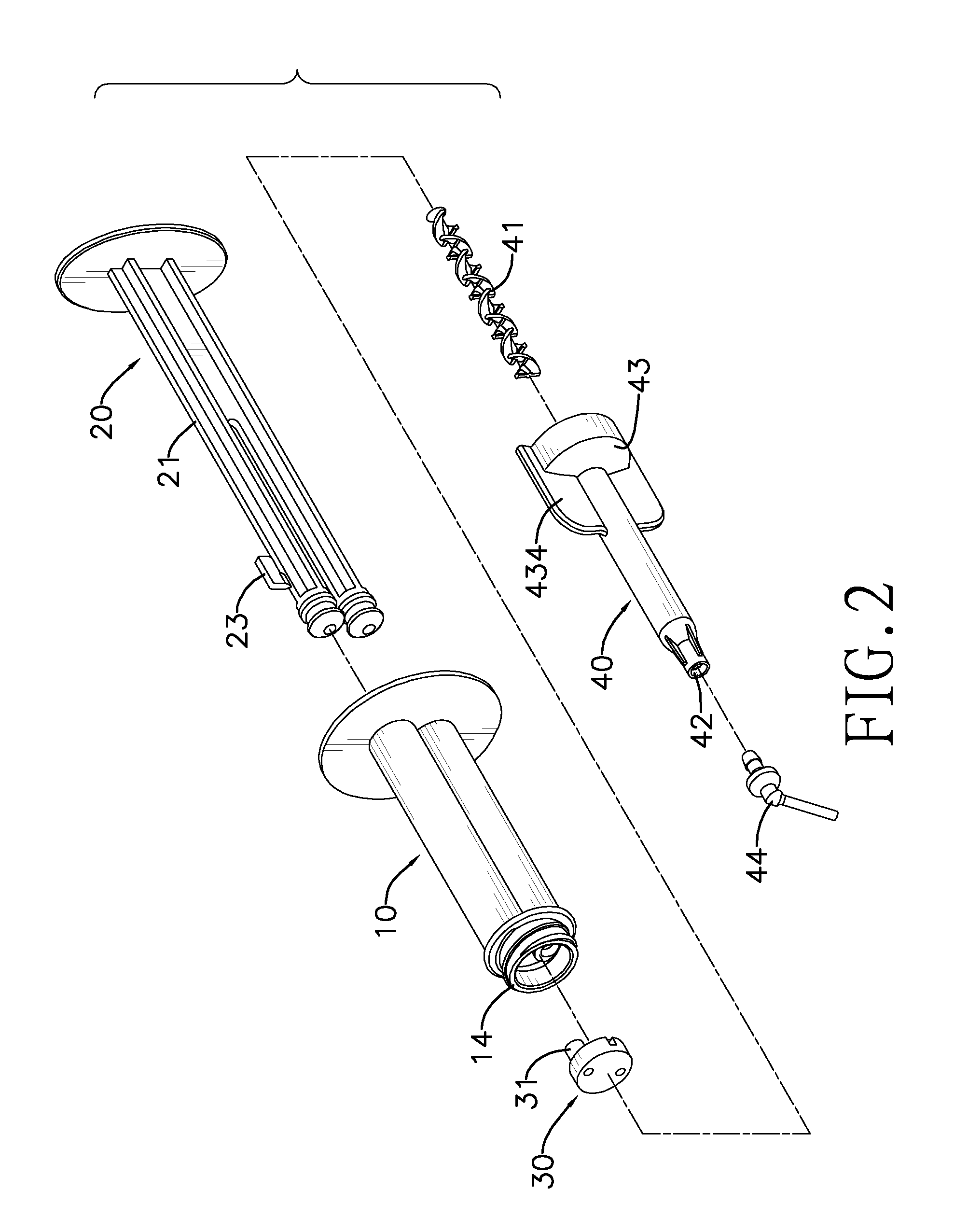

Mixing device

InactiveUS20100256591A1Combination is reliableGuaranteed uptimeDiagnosticsSurgeryEngineeringInjection moulding

Owner:HO PHILLIP PHUNG I

Anti-cracking polyphenyl thioether composite material and preparation method thereof

ActiveCN101967280AImprove melt fluidityGuaranteed mechanical propertiesGlass fiberStrength of materials

The invention provides an anti-cracking polyphenyl thioether composite material comprising the following components in percentage by weight: 50-70 percent of polyphenylene sulfide, 25-45 percent of fibre glass, 3-7 percent of toughener, 0.3-1.5 percent of coupling agent, 0.2-1.0 percent of lubricant and 0.2-1 percent of antioxidant. The invention also provides a preparation method of the composite material. The invention has the advantages that by a specific toughening system and a composite technology, the invention better maintains the mechanical property of the polyphenyl thioether composite material and greatly increases the anti-cracking toughness of the composite material at the same time, and otherwise, the anti-cracking polyphenyl thioether composite material has good melt liquidity and is easy to inject and mold.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Preparation method of antibacterial flame-retardant ABS material

The invention discloses an antibacterial flame-retardant ABS material and a preparation method thereof. The antibacterial flame-retardant ABS material is prepared from ABS resin, a flame-retarding agent, a coordinative flame-retarding agent, an auxiliary flame-retarding agent, a thermal stabilizer, an antibacterial master batch, a compatilizer, an antioxidant and a lubricating agent in parts by weight, wherein the antibacterial master batch is prepared from ABS and at least one of a silver ion type antibacterial agent, zinc oxide and copper oxide by a mass ratio of 10 to 1. According to the ABS material disclosed by the invention, the silver ion type antibacterial agent or the zinc oxide or the copper oxide and the ABS are used for preparing the antibacterial master batch by the mass ratio of 10 to 1, so that the silver ion type antibacterial agent or the zinc oxide or the copper oxide is effectively uniformly dispersed in the ABS resin in order to improve the antibacterial efficiency and achieve a better antibacterial effect than an antibacterial agent which is used independently; and color changes of antibacterial ABS plastic can be effectively prevented, and the antibacterial properties of the antibacterial ABS plastic can be improved.

Owner:ORINKO NEW MATERIAL CO LTD

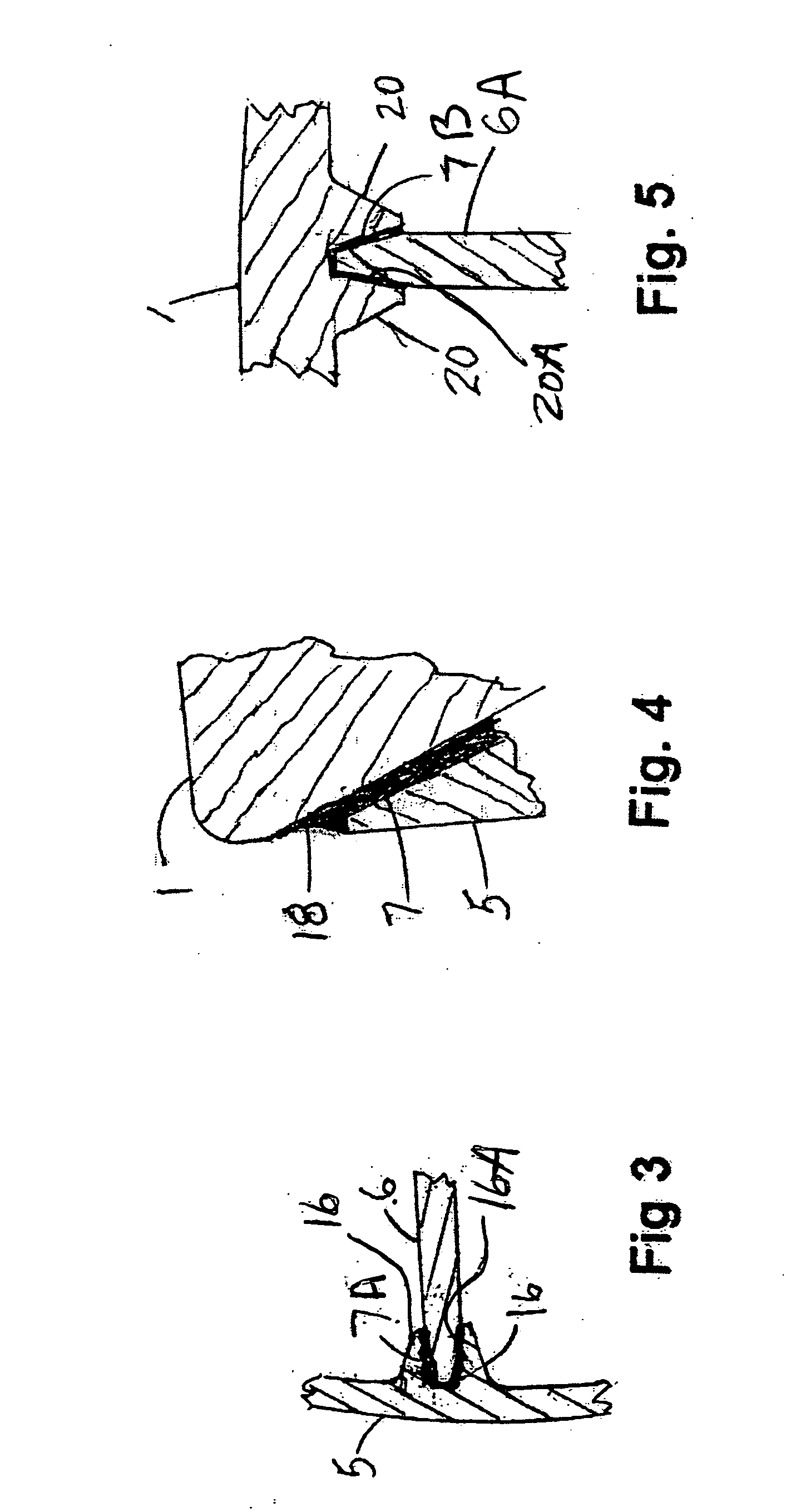

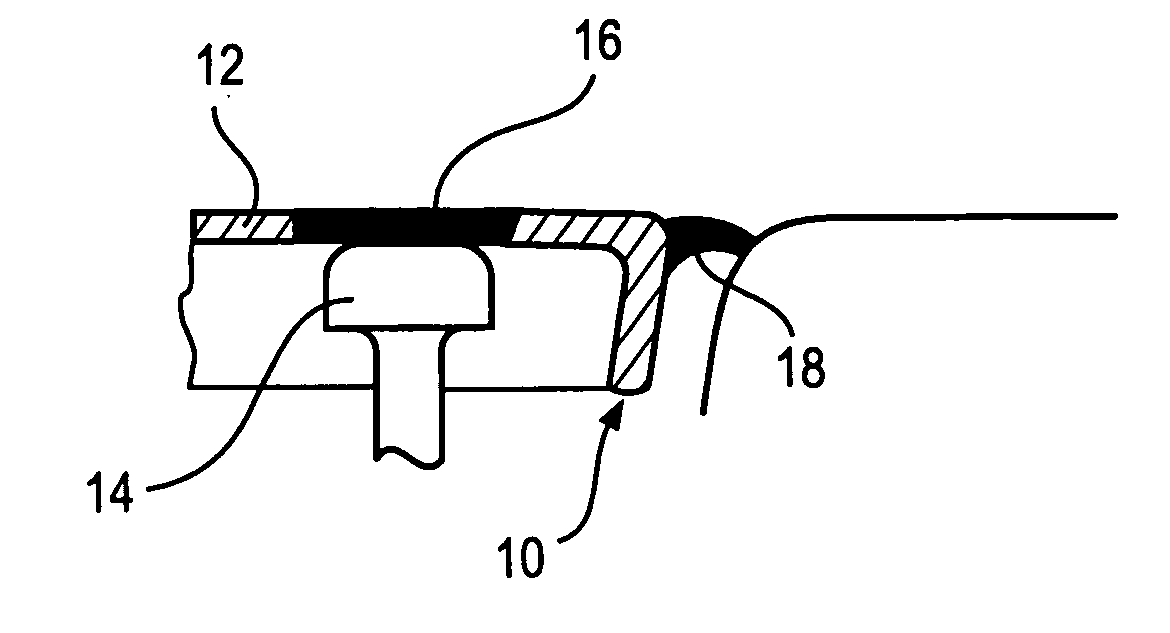

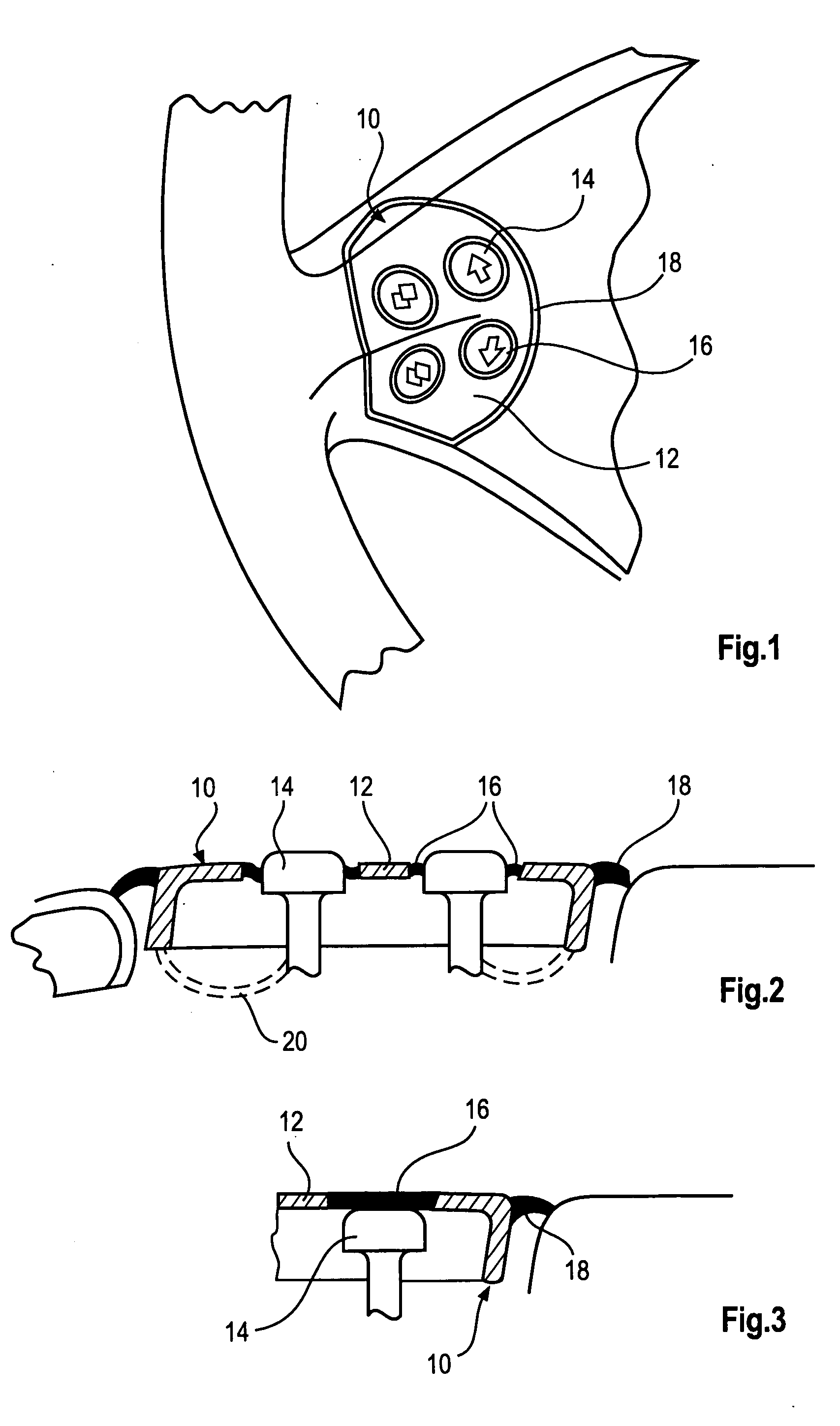

Partly chrome-plateable device and method of manufacturing the same

InactiveUS20090117398A1Easy and less-expensive to performEasy injection moldingSynthetic resin layered productsDomestic articlesElectroplatingMechanical engineering

A device, in particular a vehicle interior component, includes a base body (10) made of a first plastic material which is suitable for injection molding and for coating with chromium. The device furthermore includes at least one elastic partial body (16, 18) molded to the base body (10), which is made of a second plastic material which is suitable for injection molding, but not for coating with chromium. A method for manufacturing such a device with a base body (10) coated with chromium comprises the following steps:injection molding a base body (10) of the first plastic material;injection molding the partial body (16, 18) of the second plastic material to the base body (10);electroplating a chromium coating onto the base body (10), wherein the base body (10) passes through a chrome-plating bath together with the integrally molded partial body (16, 18).

Owner:TRW AUTOMOTIVE SAFETY SYST

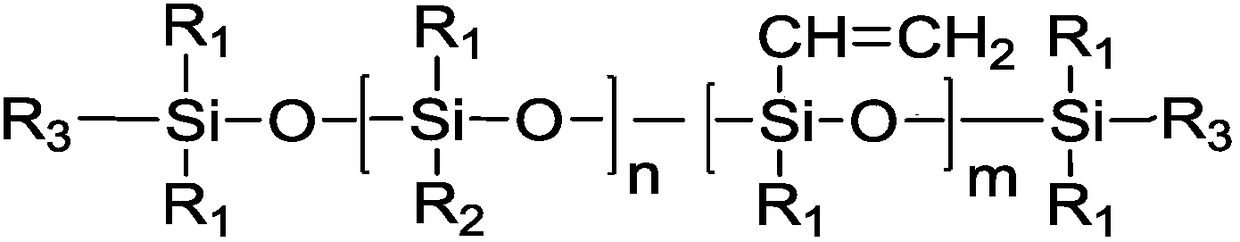

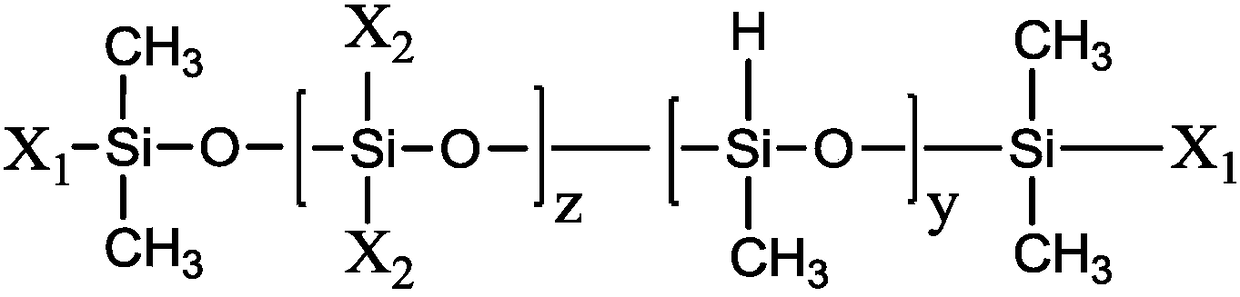

Dynamic vulcanized silicone rubber/thermoplastic polyurethane elastomer and preparation method thereof

The invention provides a dynamic vulcanized silicone rubber / thermoplastic polyurethane elastomer material and a preparation method thereof. The material is prepared, by weight, the following components: vinyl polysiloxane: 100 parts, thermoplastic polyurethane elastomer: 10-500 parts, compatibilizer: 3-30 parts, hydrogen-containing silicone oil: 0.1-15 parts, platinum-based catalyst: 0.1-100 ppm (content of platinum atom in the vinyl polysiloxane and hydrogen-containing silicone oil), anti-poison agent: 0.1-20 parts. In the preparation process, no hydrogen is generated, and the process is simple and safe. The product integrates the advantages of two materials of silicon rubber and TPU, has excellent surface hand feeling, has excellent adhesion with PC, PC / ABS, ABS and the like, is easy toextrude and formed through injection molding, the additive amount of the platinum-based catalyst is low in the preparation process, the product has excellent endurance performance and low cost, and can be widely applied to the fields of intelligent wearable products and electronic and appliance products and the like with relatively high requirements.

Owner:WANHUA CHEM GRP CO LTD

Plastic golf club head

A method of assembly of construction and assembly of golf club head parts used to manufacture golf club heads primarily composed of strong plastic materials that can be formed by injection plastic molding processes in a minimum of two parts. Draft is practical for both molded parts to simplify mold making. A preferred plastic is polycarbonate. Internal reinforcement elements are designed and arranged to provide structural features to facilitate assembly and improve strength of bonds. Internal reinforcement elements may be molded as separate parts to join with the face and shell structure. A hosel, which is not considered part of the shell and which may be made of plastic or metal, is bonded into the golf club head parts described.

Owner:ORIGIN INC

Surface functionalized carbon fiber reinforced polyether-ether-ketone dental composite material and preparation method thereof

PendingCN110201224ATightly boundChanging the composition of surface functional groupsPharmaceutical delivery mechanismTissue regenerationCarbon fibersBiocompatibility Testing

The invention provides a surface functionalized carbon fiber reinforced polyether-ether-ketone dental composite material. The surface treatment of the carbon fiber reinforced polyether-ether-ketone composite material is carried out by sulfonation and functionalization of graphene oxide to obtain a surface functionalized carbon fiber reinforced polyether-ether-ketone composite material coated witha graphene oxide functional layer, the functional layer has strong binding force to a substrate, is not easy to fall off, and can effectively change the surface geometry and surface functional group composition of the carbon fiber reinforced polyether-ether-ketone composite material, the carbon fiber reinforced polyether-ether-ketone composite material is given with a new surface topography and surface properties, the biocompatibility and osteogenicity are increased, the application in medical materials is increased, the operation method of the invention is simple and easy, the surface treatment condition is mild, and the method is suitable for large-scale promotion and application, and has high medical value.

Owner:FIRST HOSPITAL OF SHANXI MEDICAL UNIV

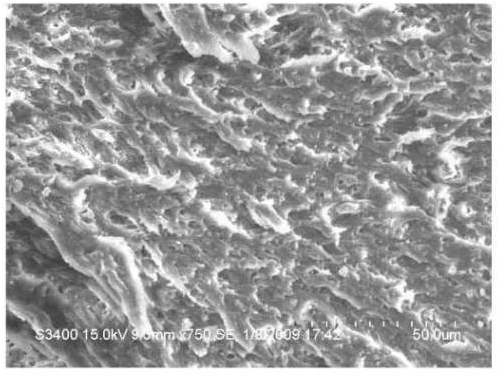

Preparation method of stainless steel-resin composite and stainless steel-resin composite prepared by same

ActiveCN103895151AGood corrosion resistanceEasy to corrodeMetal layered productsPolymer chemistryResin composite

The invention relates to a preparation method of a stainless steel-resin composite and a stainless steel-resin composite prepared by the same. The preparation method comprises the following steps: S1. coating an ink on the surface of a pretreated stainless steel substrate in need of combining resin to obtain a stainless steel substrate of which part of surface is coated with an ink layer; S2. carrying out oxidization and passivation on the stainless steel substrate of which part of surface is coated with an ink layer, which is obtained in the step S1; S3. removing the ink layer coated on the surface of the stainless steel substrate obtained in the step S2; S4. putting the stainless steel substrate obtained in the step S3 into an acid and / or salt solution containing 2-30 wt% of A<-> to perform electrochemical corrosion, wherein A is halogen; and S5. carrying out injection molding on a resin composition onto the surface of the stainless steel substrate obtained in the step S4, and forming to obtain the stainless steel-resin composite. The prepared product has the advantages of strong binding force between stainless steel and resin, simple technique, no pollution and low cost, can easily implement large-scale production, and can not cause corrosion of the non-injection molding region of the stainless steel.

Owner:BYD CO LTD

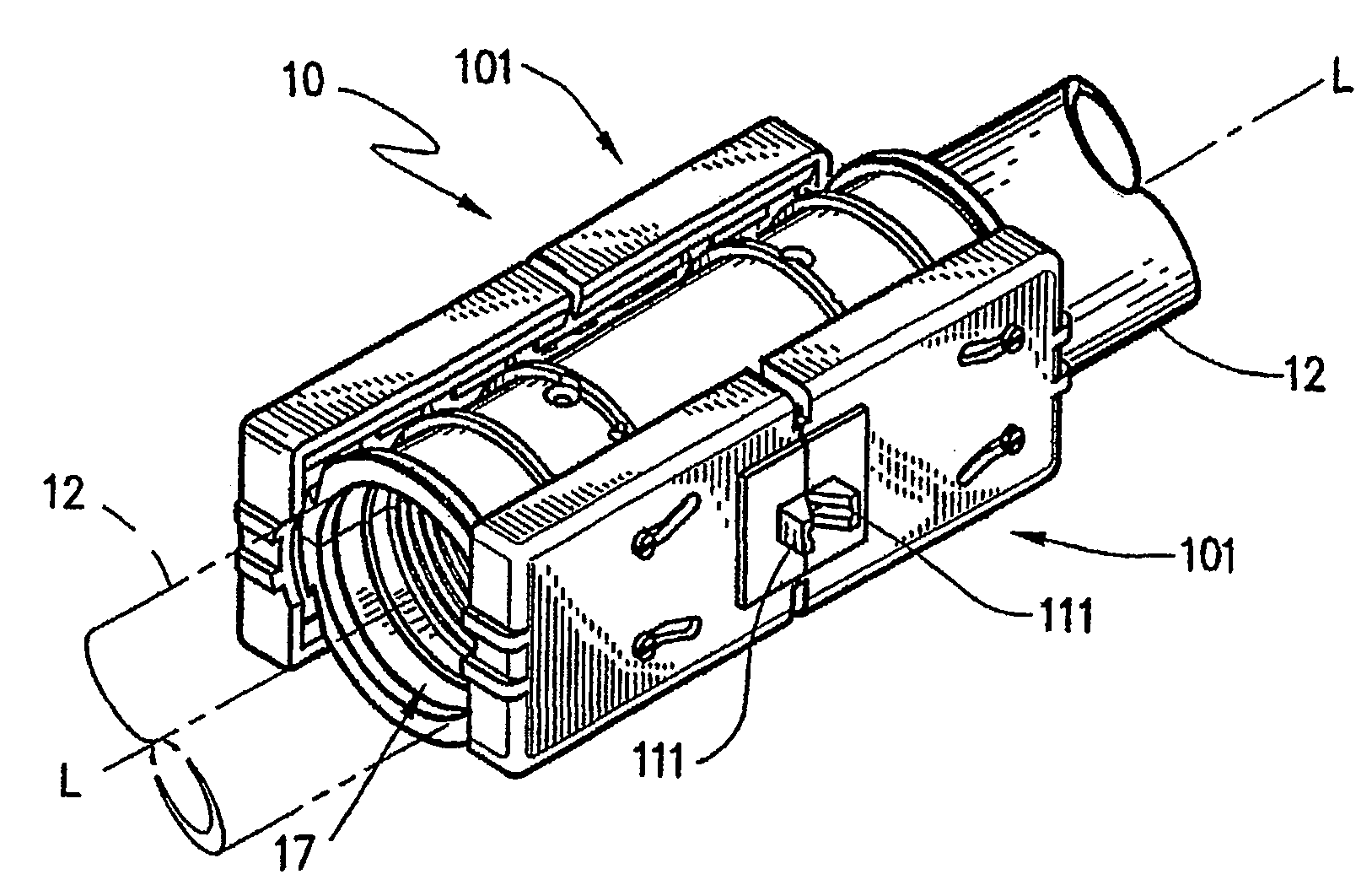

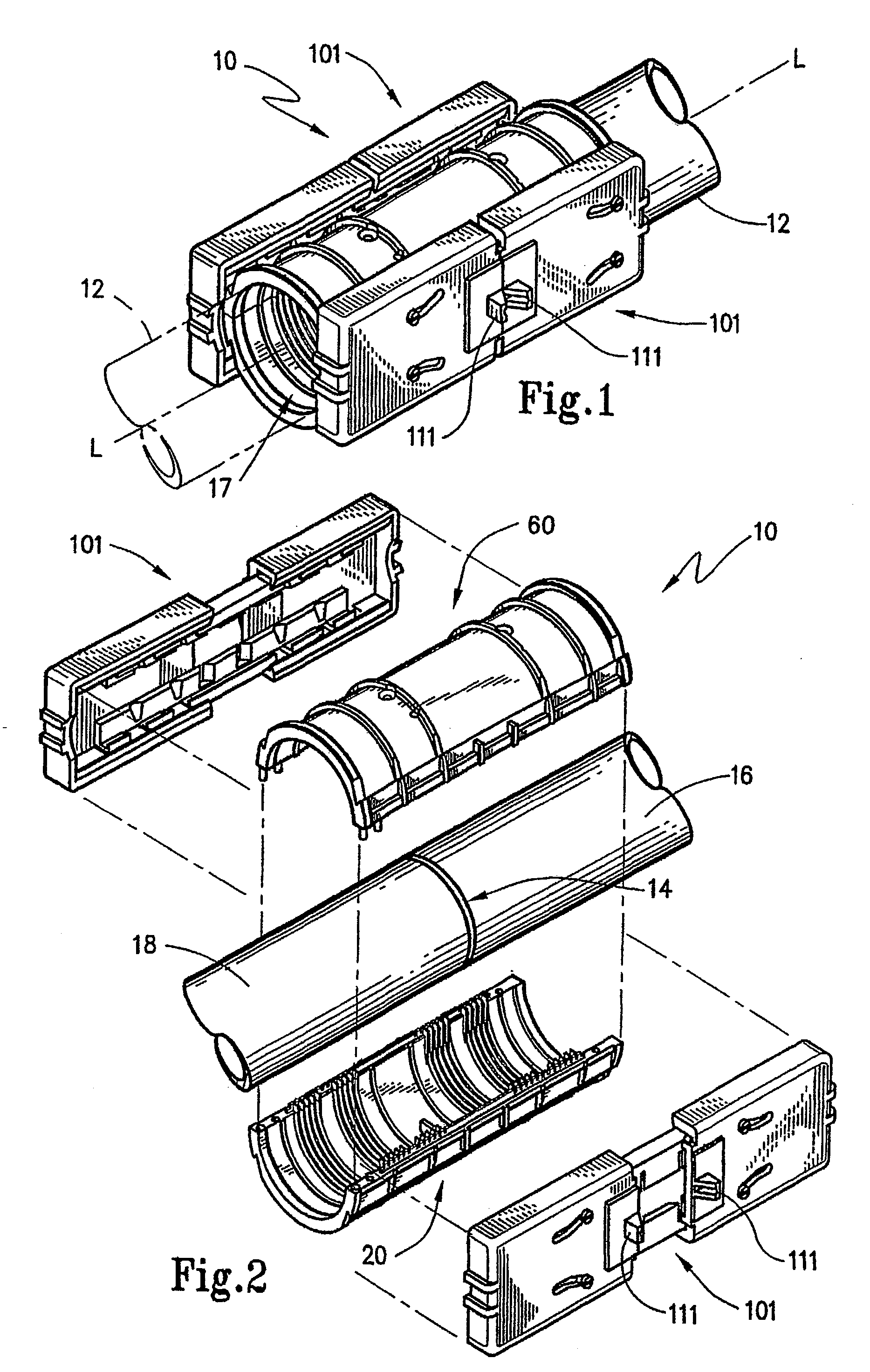

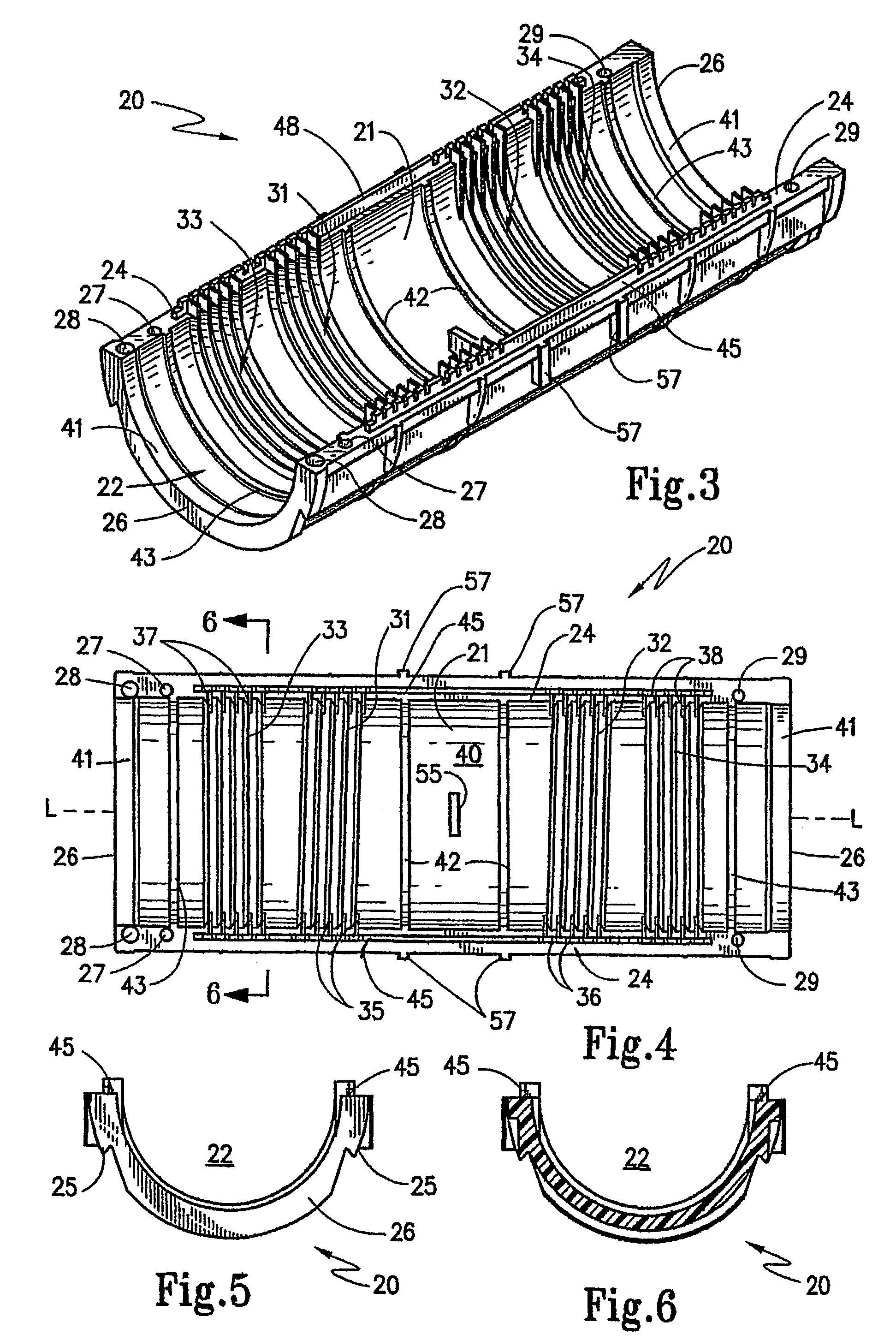

Splicing Device and Method for Sealing Conduit Spaces

InactiveUS20060255592A1Easy injection moldingLow costSleeve/socket jointsFluid pressure sealed jointsEngineeringMechanical advantage

A splicing device (10) is provided for sealing a conduit space (14) between two pipe sections (16,18). The splicing device includes a first body (20) and a second body (60) that are formed as an integral one-piece. A pair of clasp members (101) are mounted on the first and second body sections to secure them in an assembled state. To allow for mechanical advantage in closing the clasp members, each member is provided with an outwardly oriented ear (111) that can be engaged to a tool to force the members towards one another.

Owner:MINEMYER JOHN T +3

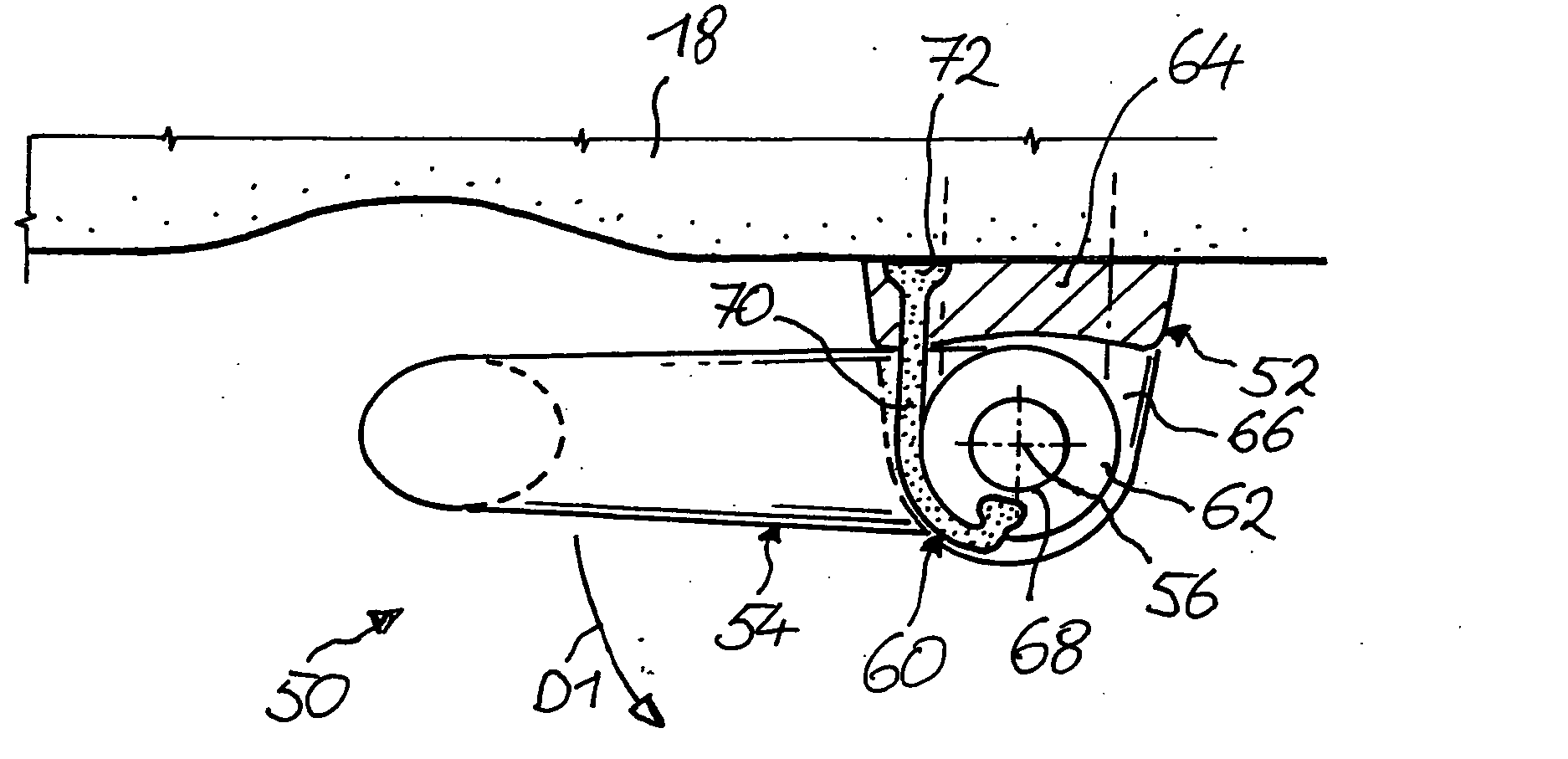

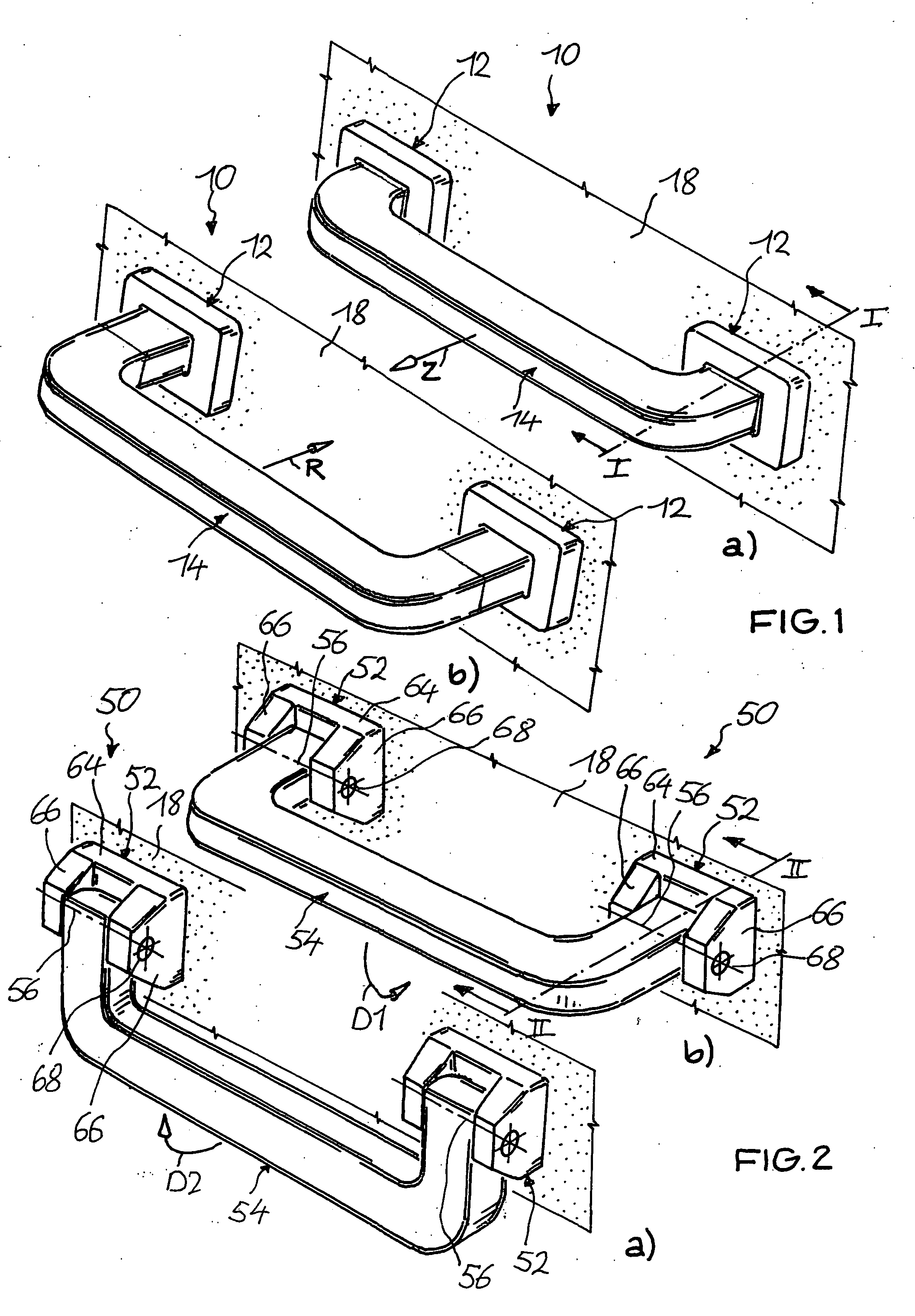

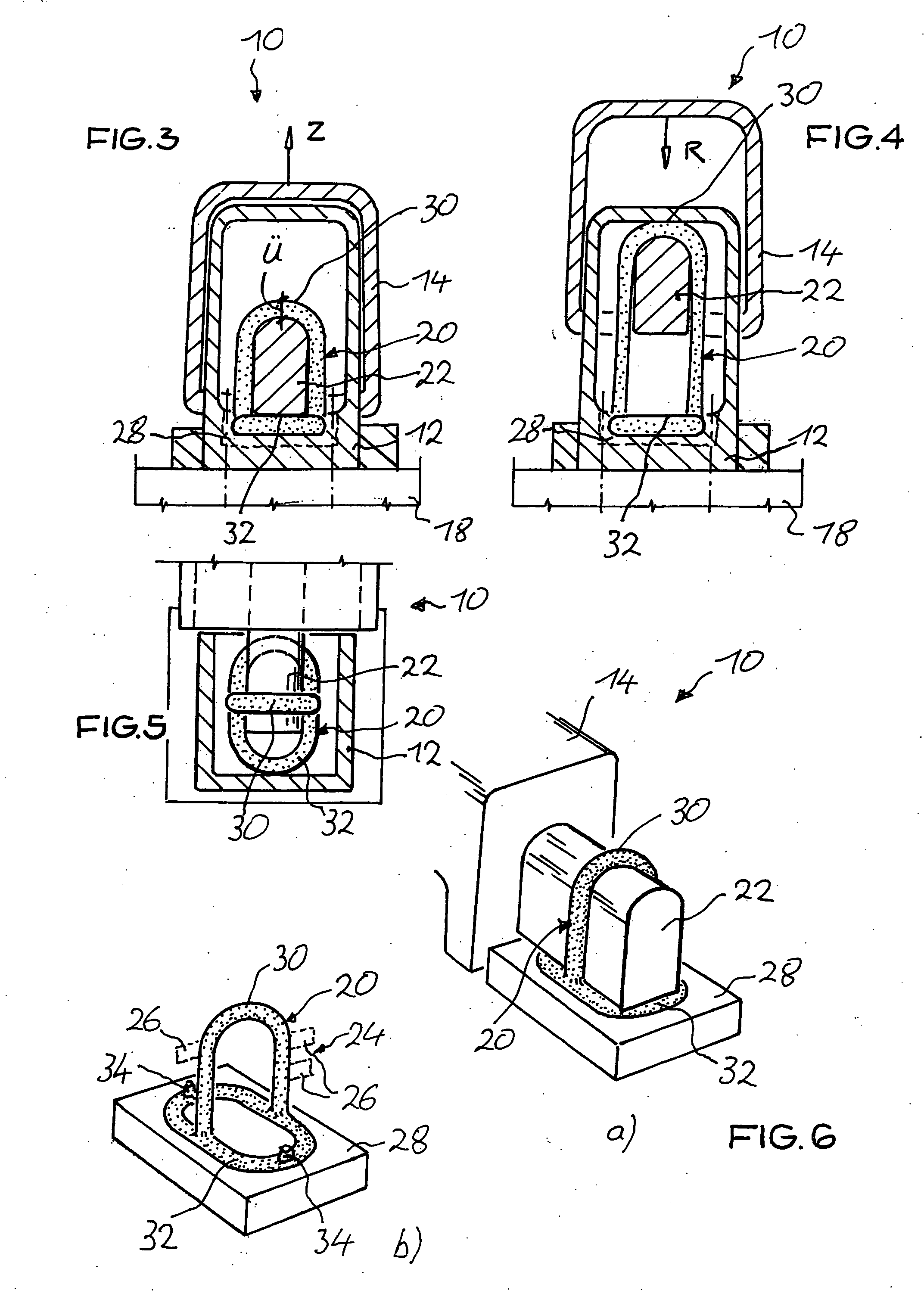

Component for vehicle interiors, in particular roof handle

InactiveUS20060143868A1Outstanding mechanical characteristicEasy injection moldingVehicle arrangementsTravelling carriersThumb oppositionRest position

A component (10) for vehicle interiors comprising a first fixed assembly (12) that can be mounted on the wall (18) of the vehicle interior and a second assembly (14) that is displaceably attached to the first assembly (12), the second assembly (14) being displaceable in opposition to the action of elastic elements (20) from a resting position into a position of use and vice versa and the second assembly (14) being displaced from the position of use into the resting position, or being maintained in the resting position by the sole action of the elastic elements (20), has the distinguishing feature that the elastic elements (20) take the form of at least one elastically extensible strap or cable or an elastically extensible cord.

Owner:OLHO SINSHEIM

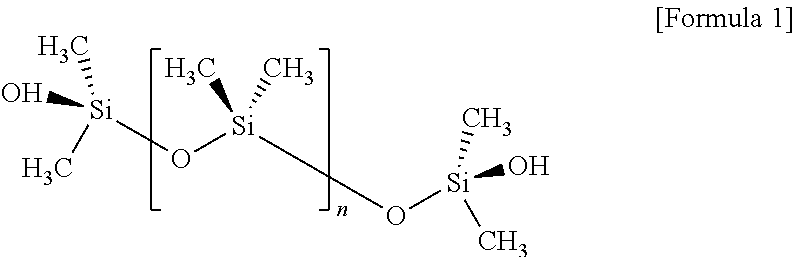

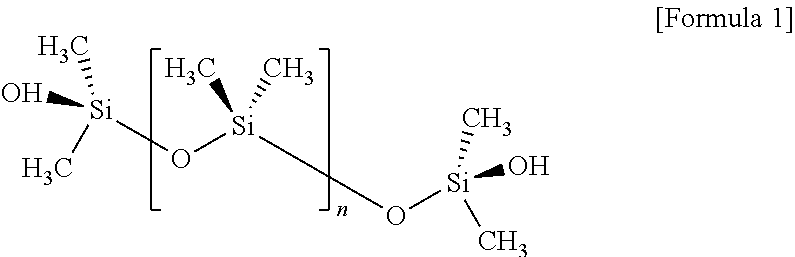

Thermoplastic polyurethane composition for injection molding and method of manufacturing the same

ActiveUS20170029554A1Easy injection moldingExcellent molded article qualityManufacturing cost reductionPolyester

The present invention provides a thermoplastic polyurethane composition for injection molding and a method of manufacturing the same. The thermoplastic polyurethane composition for injection molding can be easily injection-molded since a slip property is imparted to a soft segment, and can possess excellent durability properties such as heat-aging resistance, photoaging resistance, and wear resistance, and stability properties such as airbag deployment performance and anti-fogging property, as well as excellent tactile sensation and embossing quality, when a chain extender and a multifunctional polydimethylsiloxane-based compound are mixed with an isocyanate- and ether-containing polyester polyol, and can be useful in simplifying processes, reducing manufacturing costs, and simplifying facilities due to a decrease in the number of parts when molded articles are manufactured using the composition.

Owner:HYUNDAI MOTOR CO LTD +3

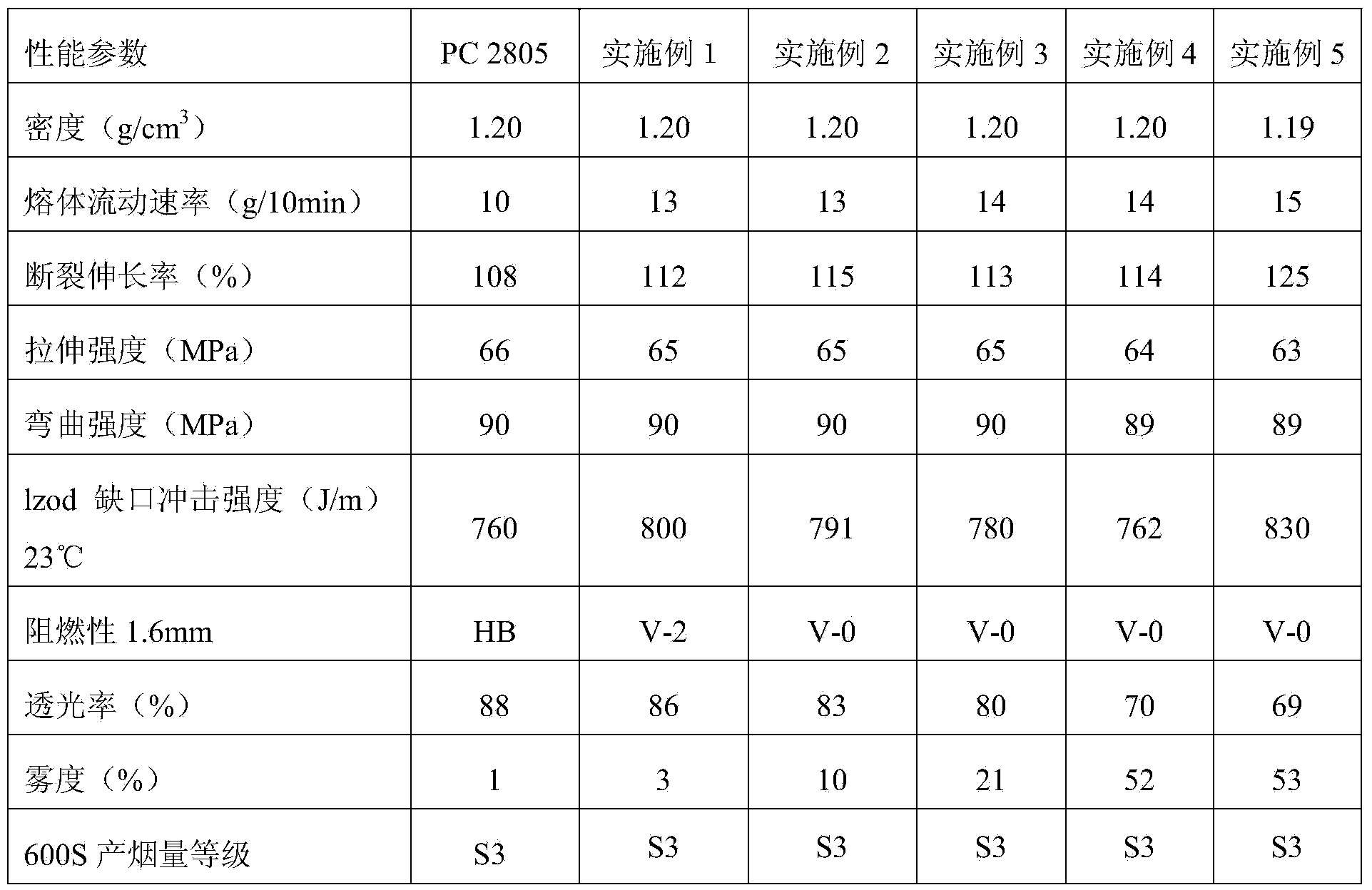

Transparent halogen-free low smoke antiflaming polycarbonate composite material and preparation method thereof

The invention discloses a transparent halogen-free low smoke antiflaming polycarbonate composite material and a preparation method thereof. The polycarbonate composite material comprises the following components in parts by weight: 900-980 parts of polycarbonate resin, 5-50 parts of polysiloxane fire retardant, 1-10 parts of sulfonate fire retardant, and 5-50 parts of additive. The preparation method comprises the following steps of mixing the polycarbonate resin, polysiloxane fire retardant, sulfonate fire retardant and additive in a highly mixing machine, then pelletizing through twin screw extrusion, drying and injection molding so as to obtain the transparent halogen-free low smoke antiflaming polycarbonate composite material. On one hand, the hazard that bromine antiflaming polycarbonate material generates carcinogen such as 4-bromo-dibenzdioxan and 4-bromo-dibenzofuran is avoided; on the other hand, the transparent halogen-free low smoke antiflaming polycarbonate composite material has excellent antiflaming performance, reaches the US standard of UL94V-0, also has high grade of transparency and excellent mechanical property, thermal property, low temperature performance and low smoke performance, and remarkably improves the processibility of the material.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

Novel production method for edible injection bone for pet

The invention relates to a production method for an extrusion injection bone for a pet. According to the production method, cowhide, pigskin, fish skin crushed particles, meat and bone meal, muddy flesh, glycerol and natural perfume are served as principal raw materials; the cowhide, the pigskin and the fish skin particles are soaked in water; or fresh skin of cattle, pigs and fish are ground into skin particles with the size of 10 to 12 meshes through a meat grinder; the skin particles are ground into skin mud through a bone mud machine; the skin mud is stirred into skin glue in a kneading machine with a high temperature and is continued to be stirred after the meat and bone meal, animal protein powder and the glycerol are added into the kneading machine; materials are took out from the kneading machine to perform air drying and cut into small blocks; the small blocks are extruded and granulated into particles through a granulating machine; and injection molding is performed on the particles through an injection molding machine after being dried. Compared with the common pet teeth cleaning bone, the edible injection bone for the pet has the advantages of being rich in nutrition, having special aroma of the skin, the meat and the bone, taking functions of food tempting, dental caring and oral cavity cleaning and being high in tenacity, easy to digest, free of starch adding, high in compactness, low in moisture and capable of being performed as snacks for the pet to clean the teeth and chew.

Owner:高鸿立

Special material for forming halogen-free high-flowability anti-yellowing wire rod and preparation method of material

The invention discloses a special material for forming a halogen-free high-flowability anti-yellowing wire rod. The material is prepared from the following raw materials: SEBS (Styrene-Ethylene-Butylene-Styrene) rubber resin, a softening plasticizer, a polyolefin elastomer, functional resin, polypropylene resin, an antioxidant, a light stabilizer and a processing agent. The invention further discloses a preparation method of the special material for forming the wire rod. The special material for forming the wire rod has the advantages of no halogens, anti-yellowing property, good adhesiveness, high tensile strength, high flowability and easiness in injection molding, processing and forming and the like. As no halogens are available, the condition that harmful substances in the combusting and heating process are released to threat the physical health of human and environment is effectively avoided. The preparation method provided by the invention is concise in technical step and easy to realize, and can quickly prepare the special material product for forming the halogen-free high-flowability anti-yellowing wire rod. The product can be widely applied to other wire rod products such as external membranes of plugs of top grade earphone lines and external membranes of plugs of data lines, and is wide in application range.

Owner:DONGGUAN JISU PLASTIC TECH

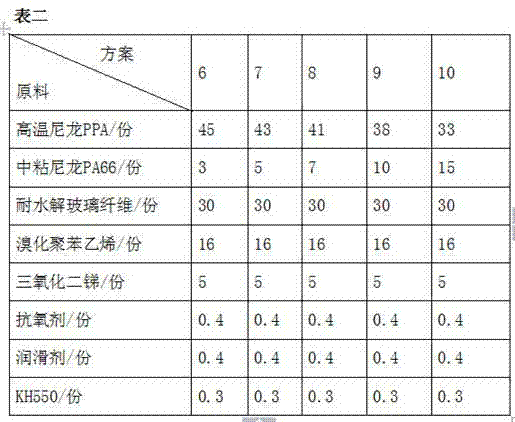

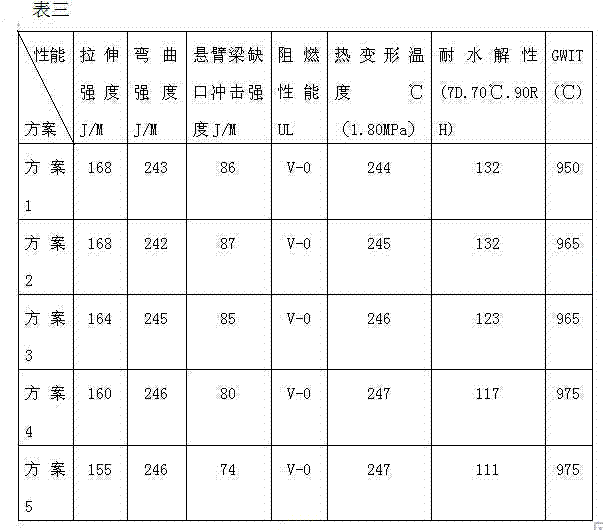

Flame-retardant reinforced high temperature nylon composite material and its preparation method

The invention discloses a flame-retardant reinforced high temperature nylon composite material. The composite material is prepared by blending the following raw materials, by weight, 25-65 parts of PPA, 3-15 parts of PA66, 15-50 parts of glass fiber, 15-22 parts of a bromine family flame retardant, 4-10 parts of a metal oxide flame retardant, 0.4-1 part of an antioxidant, 0.1-1 part of a lubricant and 0.1-1 part of a coupling agent. The invention also discloses a preparation method of the composite material. The method comprises the following steps: uniformly mixing the above raw materials except the glass fiber in a mixer, pouring the obtained mixture into a storage hopper under a feeding speed of 16-20hz, adding the mixture to an extruder, carrying out shearing blending, adding the glass fiber, carrying out melt extrusion, and granulating to obtain the composite material, wherein the extrusion speed is 320-400rpm, and the processing temperature is 280-310DEG C. The composite material has the advantages of high temperature resistance, high strength, good fluidity, good processing performance, good flame retardation property, and hydrolysis resistance.

Owner:DONGGUAN ZHONGYI NEW MATERIAL TECH CO LTD

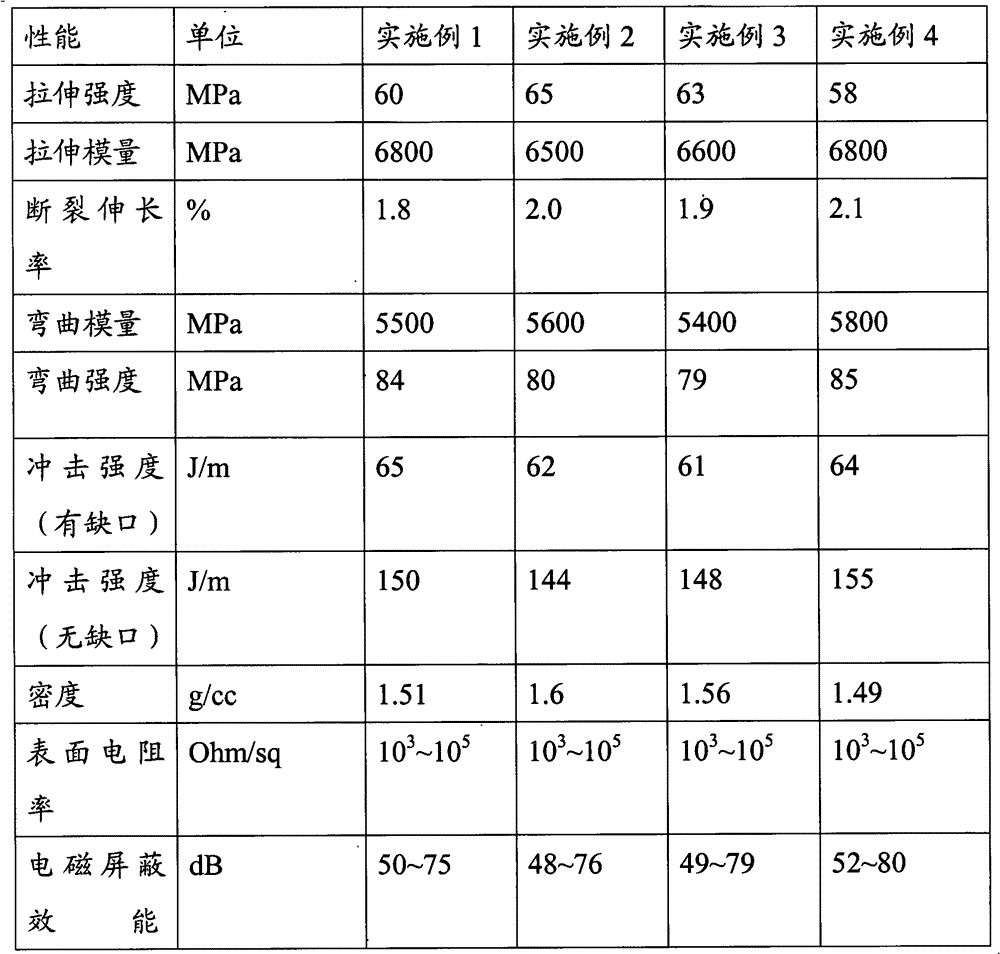

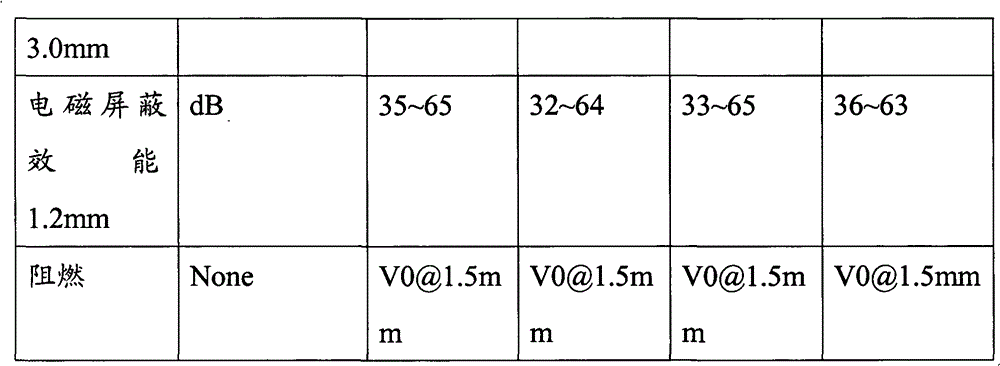

Shielding plastic and preparation method thereof

The invention discloses a shielding plastic and a preparation method of the shielding plastic. The shielding plastic comprises the following components in percentage by weight: 5-40% of conductive fiber, 25-80% of plastic, 5-10% of modifying agent, and 5-30% of halogen-free flame retardant. The conductive fiber and the modifying agent are mixed for a modification treatment through a coupling method. The conductive fiber is coated with the plastic through a melting solution of the plastic and the halogen-free flame retardant. The diameter of the conductive fiber is 1-10mum and the length of the conductive fiber is 1-10mm. The shielding plastic disclosed by the invention has good properties, which are particularly shown as follows: the volume resistivity is less than 1000 ohm.cm, the screening effectiveness (30MHz-18GHz) is more than10dB, the fire rating is UL 94-V0, UL 94-V1, UL 94-V2, UL 94-HB, and no halogen is generated.

Owner:SHENZHEN FRD SCI & TECH

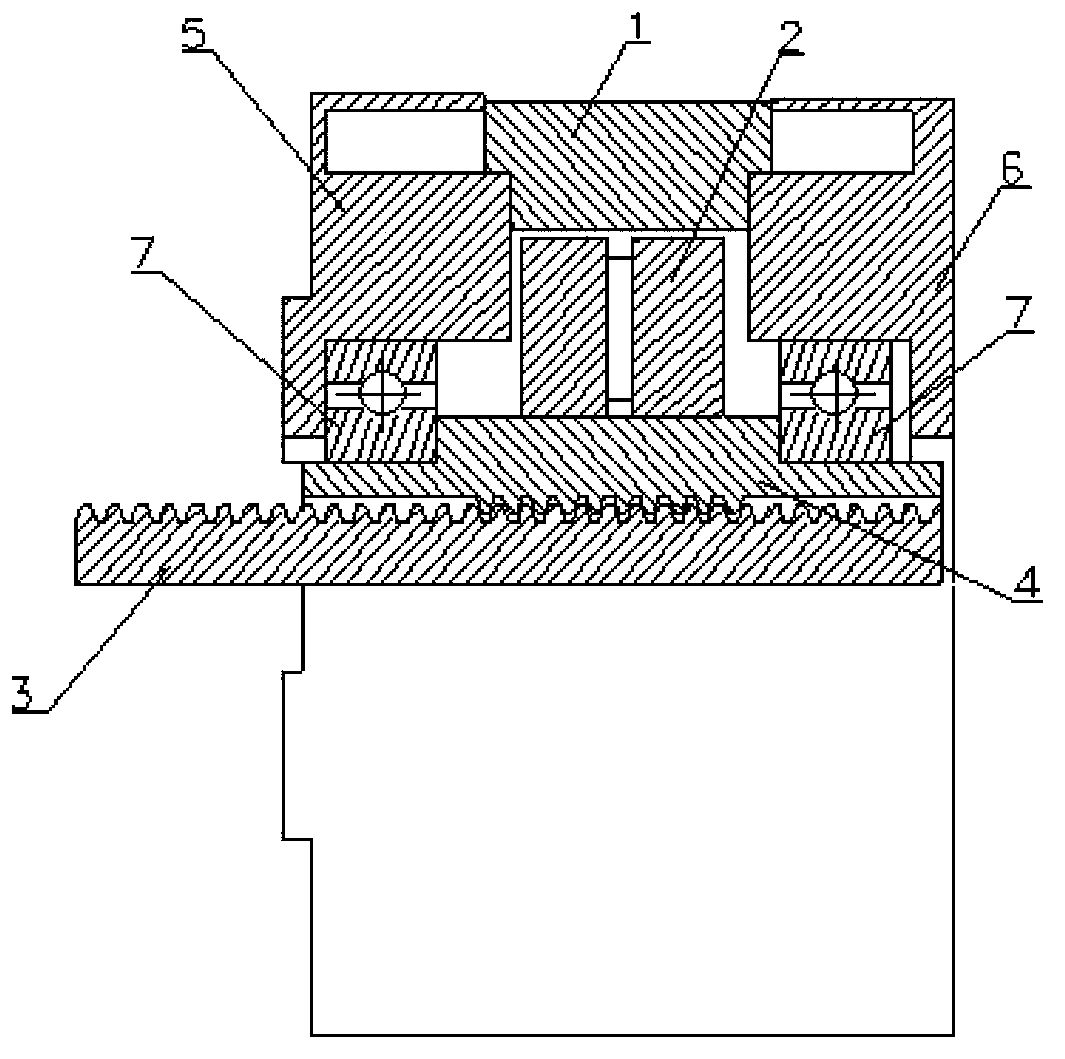

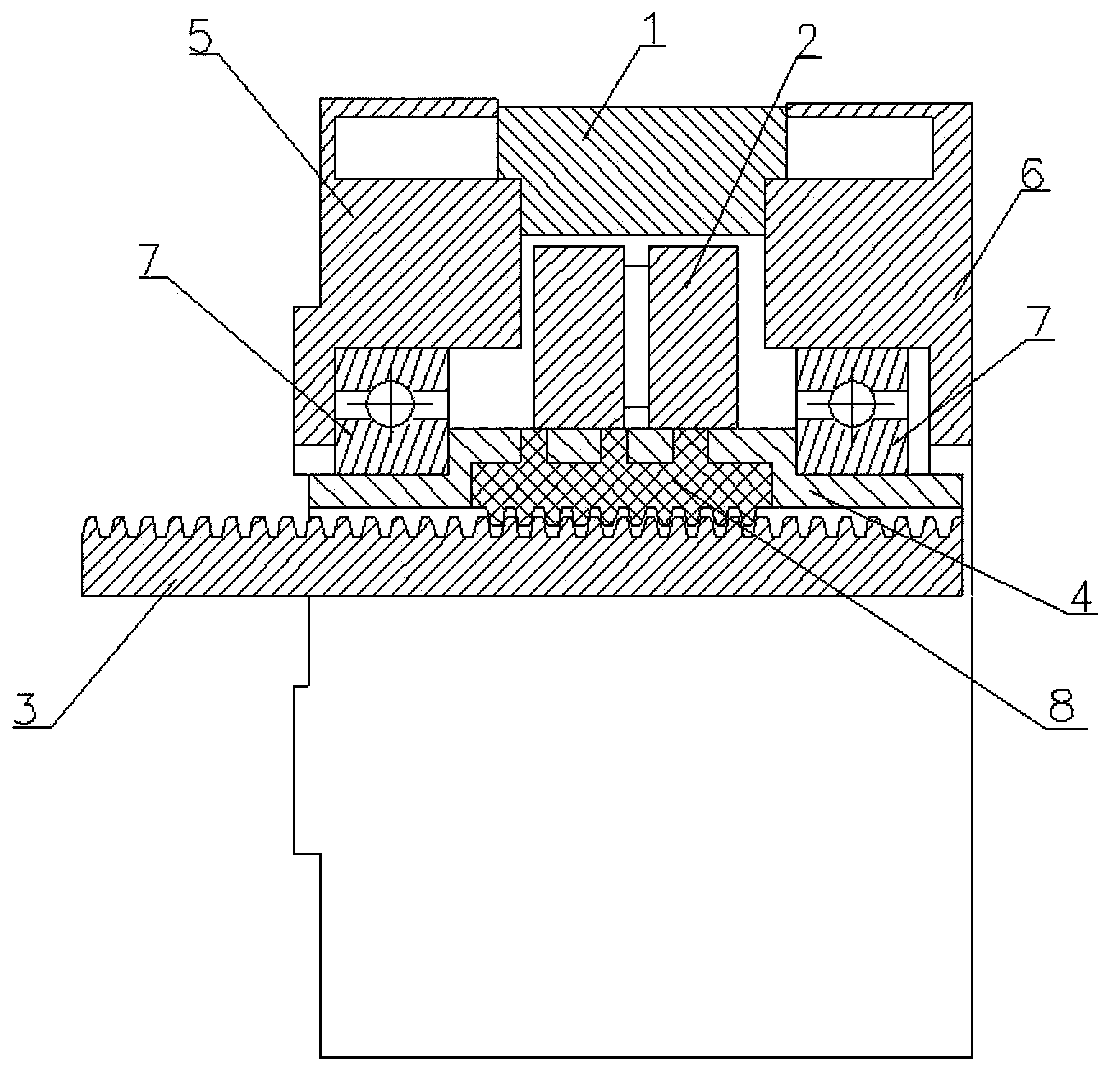

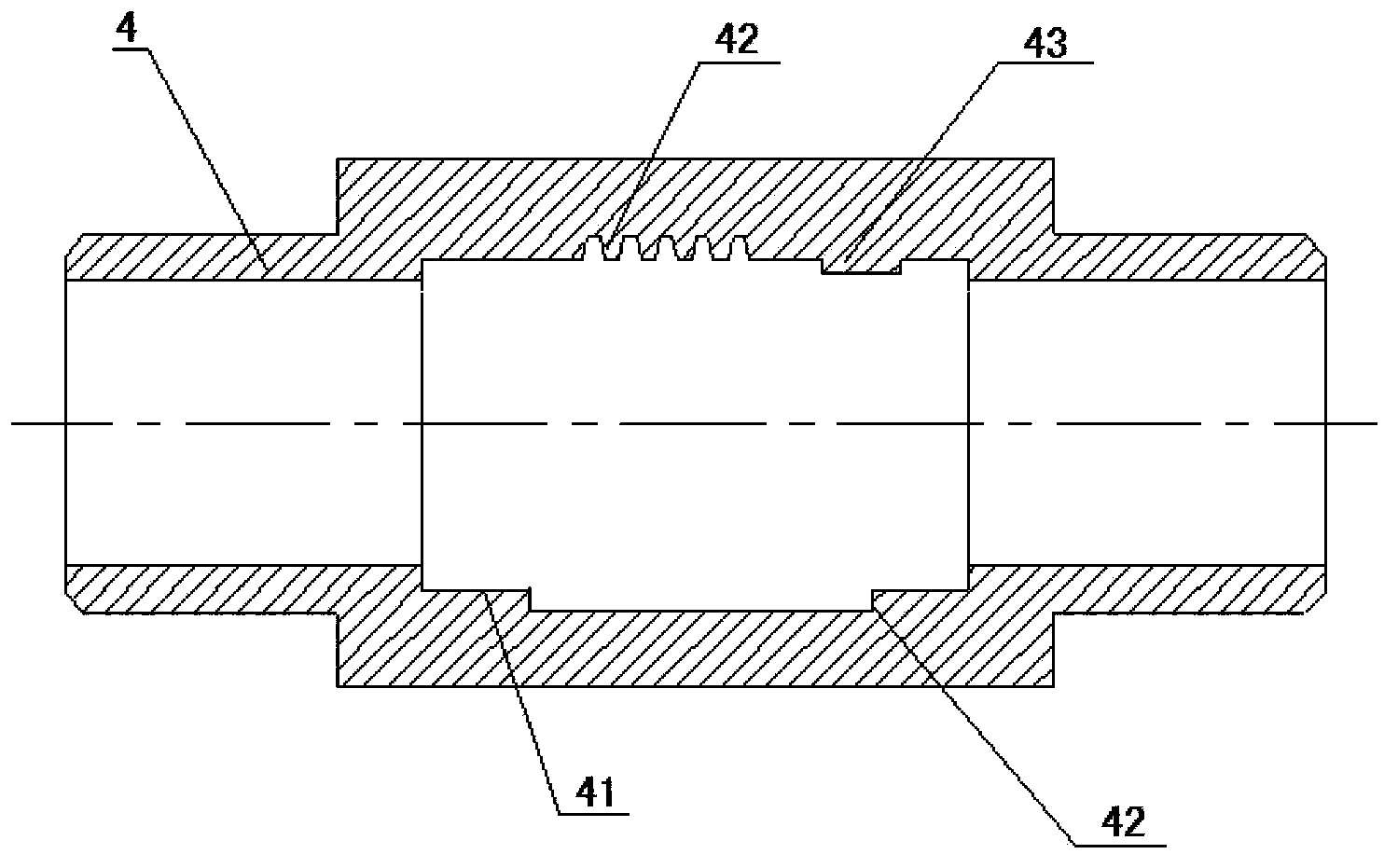

Stepping linear motor

ActiveCN103580370AExtended service lifeHigh strengthMechanical energy handlingPropulsion systemsConvex structureInjection moulding

Provided is a stepping linear motor which comprises a stator, a rotor, a rotor shaft and a screw rod. The rotor shaft is internally provided with a plastic internal nut which is used for being connected with the screw rod in a transmission way. The rotor shaft is a metal hollow shaft. The internal wall of the metal hollow shaft is provided with a ring groove which is used for embedding the plastic internal nut. The wall of the ring groove is provided with a concave-convex structure which is used for preventing the plastic internal nut from radial rotation and axial movement. The plastic internal nut is embedded inside the ring groove and engaged with the concave-convex structure. According to the stepping linear motor, the rotor is relatively high in the service life, great in anti-rotating and stopping performance, high in injection molding nut intensity, relatively high in transmission efficiency, relatively low in heat radiation, great in injection molding degree, relatively high in transmission accuracy, etc.

Owner:SHANGHAI MOONS ELECTRICAL APPLIANCE

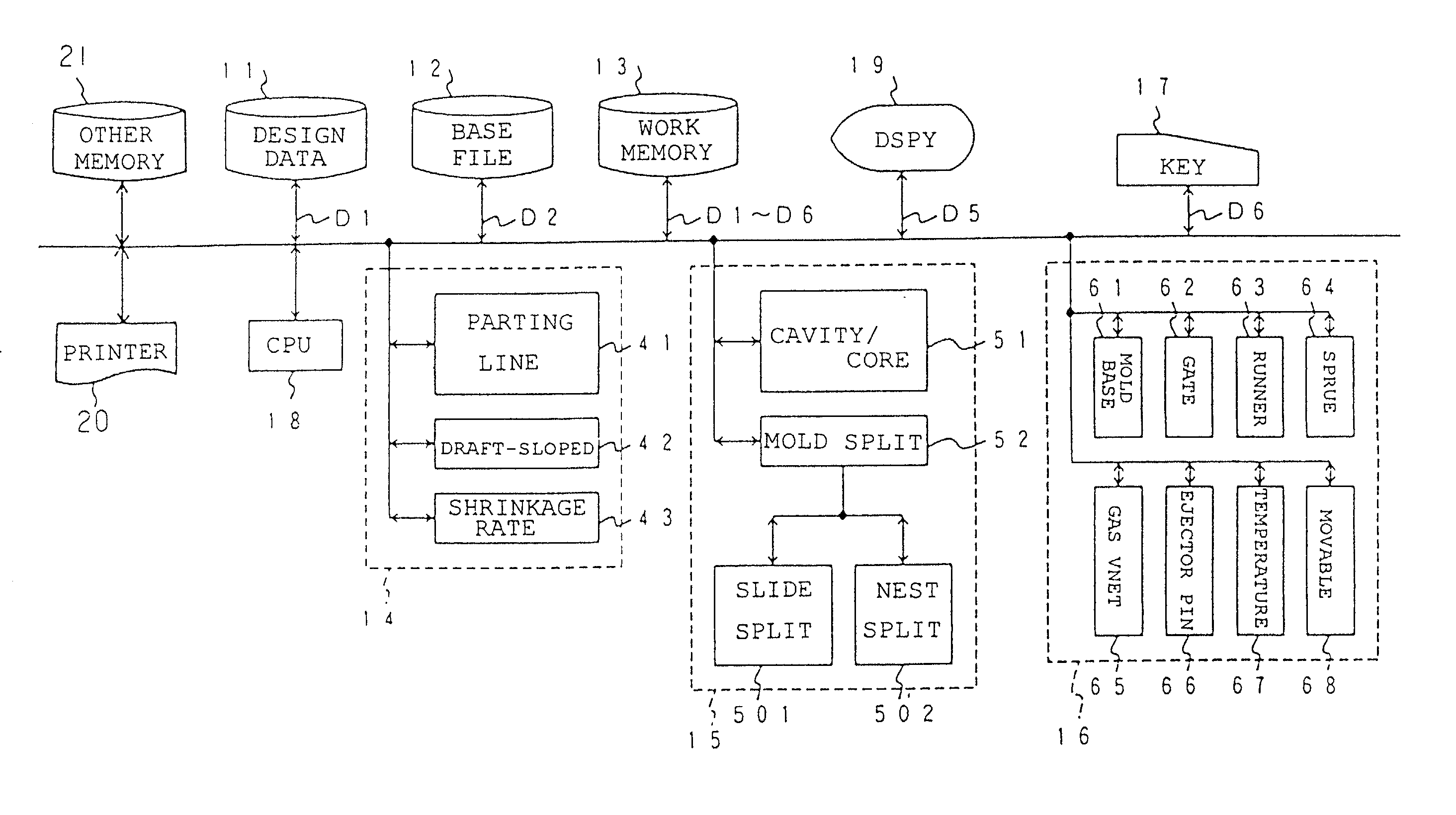

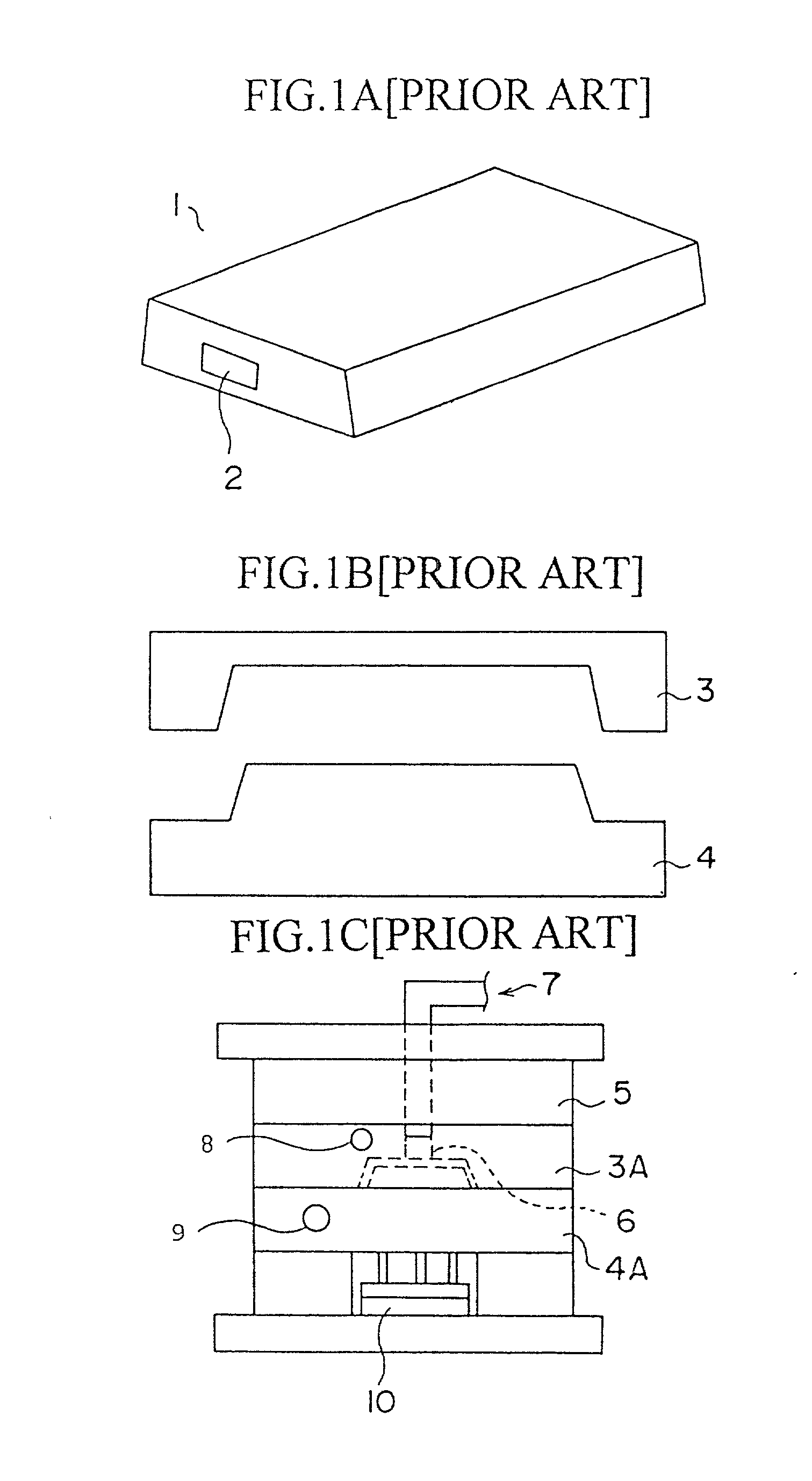

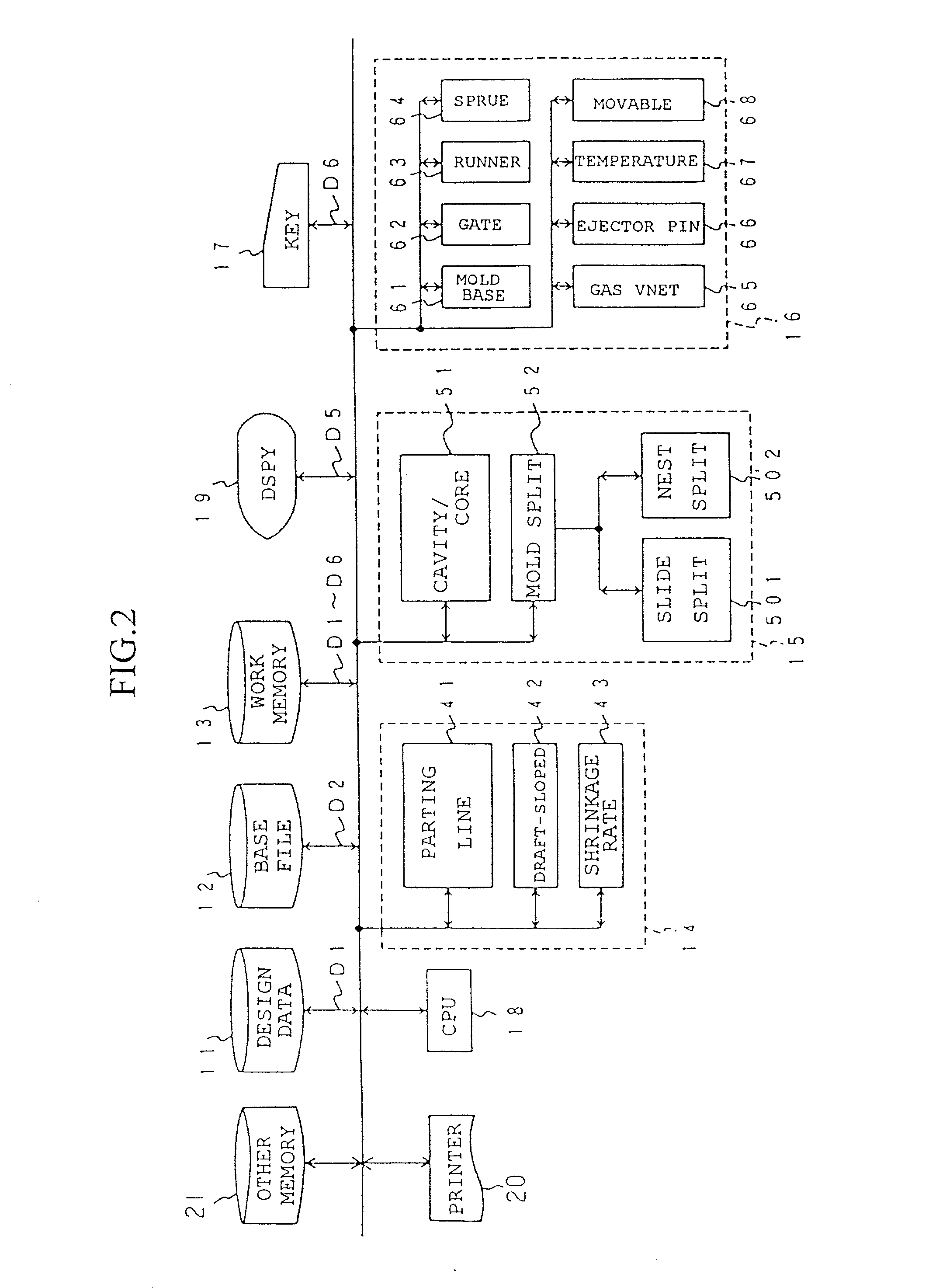

Injection mold design system and injection mold design method

InactiveUS20020128744A1Easy injection moldingShort methodProgramme controlComputer controlDisplay deviceBiomedical engineering

An injection mold design method for correcting a profile of a product to be fabricated into a releasable profile from a mold to design an injection mold based on a corrected product shape, utilizing a storage device for storing information of the product shape and mold profile, a display device for displaying the product shape or the mold profile on a screen based on the information read from the storage device, an input device for inputting designation information necessary for correction of the product shape or the mold profile, and a controlling device for unloading information of lines or planes being obstructive to correction of the product shape and the mold profile in the storage device in response to the designation information input by the input device. The method comprises removing lines or planes from the screen, and replotting the lines or the planes on the screen in terms of the information of lines or planes unloaded into the storage device after the correction operation of the product shape or the mold profile is completed.

Owner:FUJITSU LTD

Preparation method of stainless steel-resin composite and stainless steel-resin composite prepared by same

ActiveCN103895160ADoes not affect appearanceAppearance has no effectMolten spray coatingLamination ancillary operationsAl powderPolymer science

Provided are stainless steel-resin composite and method of preparing the same. The method comprises steps of: providing a stainless steel substrate; spraying aluminum particles onto a first surface of the stainless steel substrate via thermal spraying to form an aluminum layer on the first surface of the stainless steel substrate; removing the aluminum layer via dipping the stainless steel substrate into an alkaline solution with a p H value greater than or equal to 10 so as to form a porous surface; and injecting a resin composition onto the porous surface of the stainless steel substrate so as to form a resin layer.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com