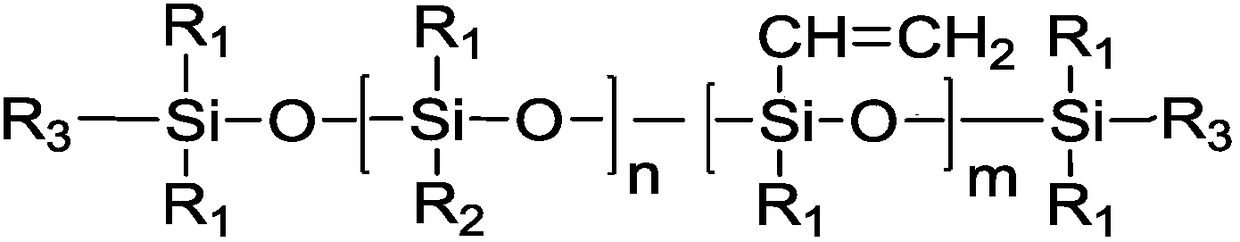

Dynamic vulcanized silicone rubber/thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane, dynamic vulcanization technology, applied in the field of thermoplastic elastomer material production, can solve the problems of easy to produce safety, high price, affecting the surface feel of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below we further illustrate the present invention in conjunction with specific examples, but the scope of the present invention is not limited to these examples.

[0056] The preparation steps of embodiment are:

[0057](1) High-temperature kneading: put TPU, compatibilizer, vinyl silicone polysiloxane, optional inert filler, optional antioxidant, platinum catalyst, and anti-poisoning agent at a temperature of 150-200°C Add the X(S)N-20x30 kneader of Dalian Huahan Rubber and Plastic Machinery Co., Ltd. to knead for 5-10 minutes, and then extrude and granulate through the SJ-45 single-screw extruder of Zhangjiagang Huaming Machinery Co., Ltd.;

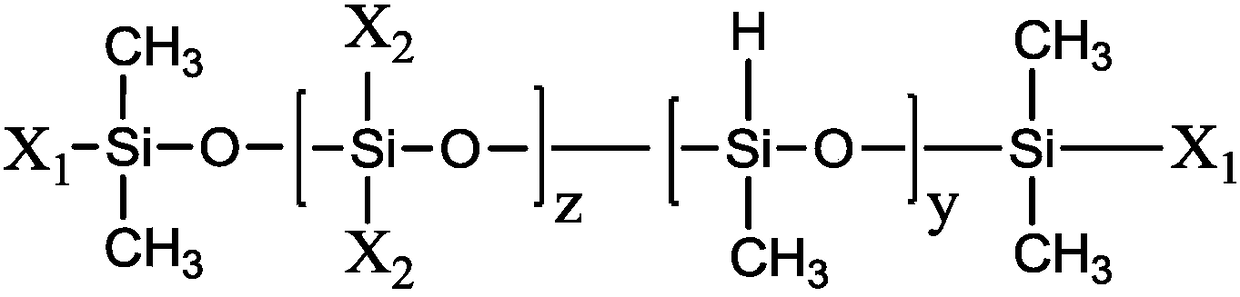

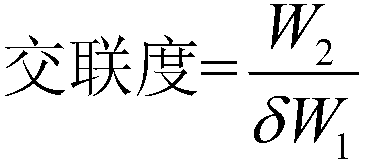

[0058] (2) Dynamic vulcanization: the above-mentioned particles are fed into Nanjing Jieya through the NX-S50L weight loss feeding scale of Kubota, Japan, and the hydrogen-containing silicone oil is fed into Nanjing Jieya through the HF-L-1 liquid weight loss feeding scale of Wuxi Haifei Machinery Equipment Co., Ltd. In the SHJ-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com