Patents

Literature

261results about How to "Easy to squeeze out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

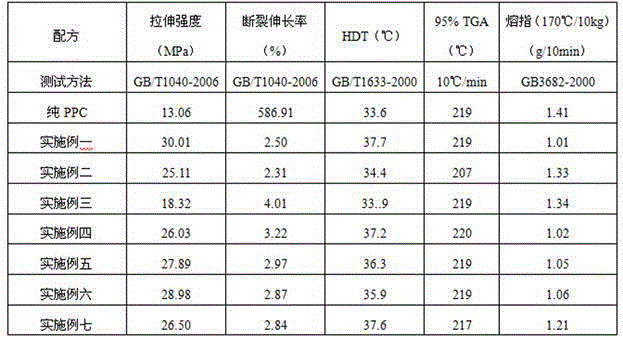

Application of hyperbranched polyester to plastic processing

The invention discloses an application of hyperbranched polyester to plastic processing, and belongs to the technical field of plastic processing assistants. The application of the hyperbranched polyester to plastic processing includes the steps that by mass, 0.1% to 5% of the hydroxyl-terminated hyperbranched polyester is added into plastic; the mixture is mixed to be even, extruded, prilled and dried, and a modified plastic product is obtained. According to the application, the plastic such as PPC and the hyperbranched polyester are melted and blended, and the plastic such PPC is modified through a double-screw extruder; after the hyperbranched polyester is added into a base material of the plastic such as PPC, the effective melt viscosity of the plastic such as PPC can be remarkably reduced; in other words, processing temperature and thermal degradation are reduced; in addition, melting fluidity improved in this way can also be achieved through the small adding amount,, and extruding film forming can be more easily achieved; the tensile strength of the modified plastic such as PPC is up to 30 MPa, and the strength can be higher than the strength of thin-film-level LLDPE and the strength of thin-film-level PVC.

Owner:WEIHAI CY DENDRIMER TECH

High temperature resistance non halogen flame retardant cable sheath material and preparation method thereof

ActiveCN101613506AImprove temperature resistanceOvercome the problem of not being able to prepare high temperature resistant halogen-free flame retardant cable sheathing materialsRubber insulatorsPolymer scienceVulcanization

The invention discloses a high temperature resistance non halogen flame retardant cable sheath material and a preparation method thereof. The high temperature resistance non halogen flame retardant cable sheath material comprises the following components with the following parts by weight: 100 parts of ethylene-propylene-diene monomer (EPDM), 1.5-6 parts of vulcanizing agent, 1.5-6 parts of co-vulcanization agent, 0.5-5 parts of coupling agent, 4-20 parts of antiager, 4-30 parts of softener and 80-250 parts of inflaming retarding filling agent. In the invention, the halogen-free material is adopted, thick smoke, corrosive halogenide gas and other harmful substances are not generated in the process of burning; the cable sheath of the invention features excellent elasticity and tenacity, not only has obvious inflaming retarding effect, but also improves heat-resisting and anti-aging properties, can resist high temperature, and has high mechanical strength and wide application range; in addition, the production process is easy and is convenient for rubber-producing enterprises to achieve self-sufficiency.

Owner:SICHUAN MINGXING CABLE

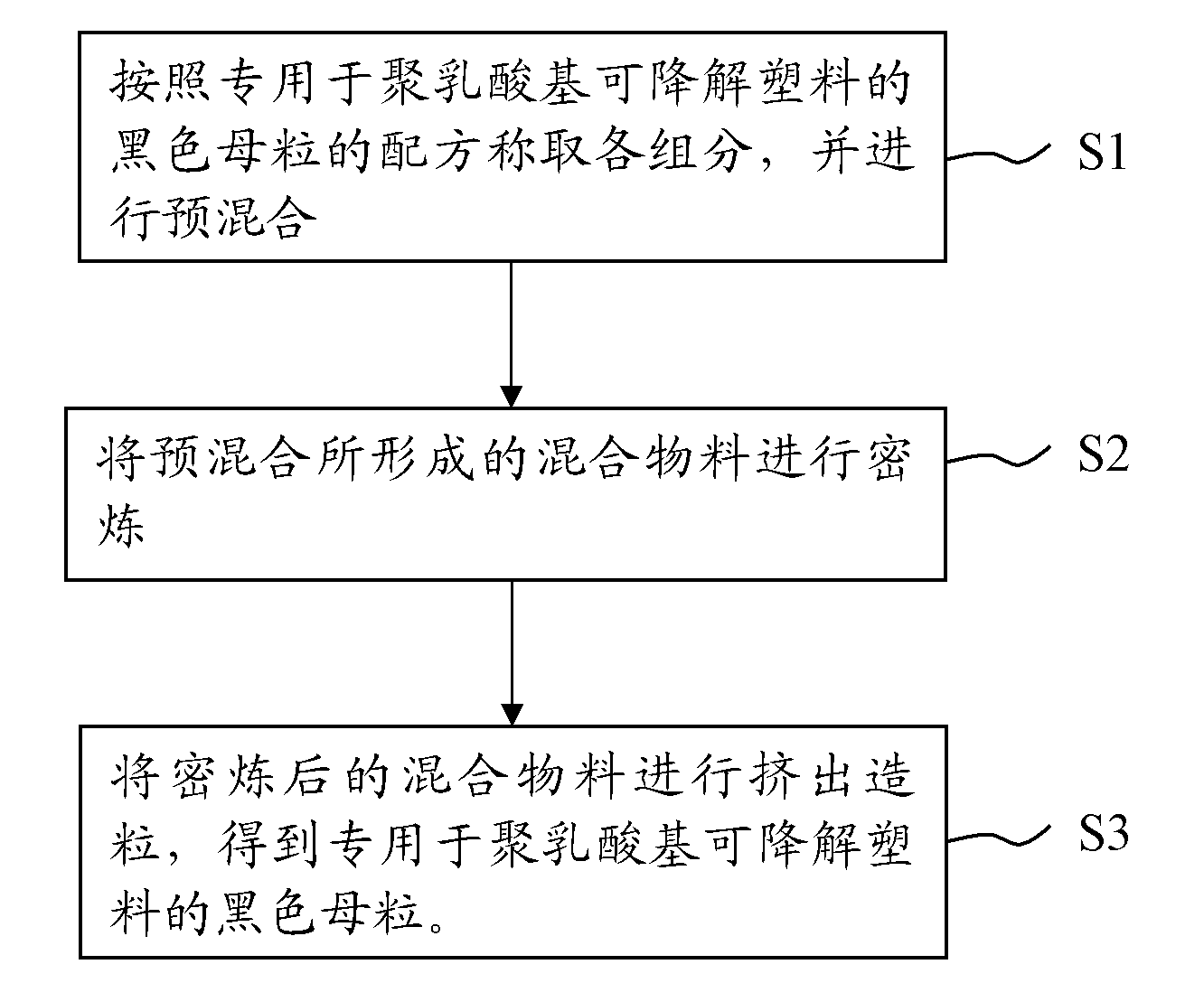

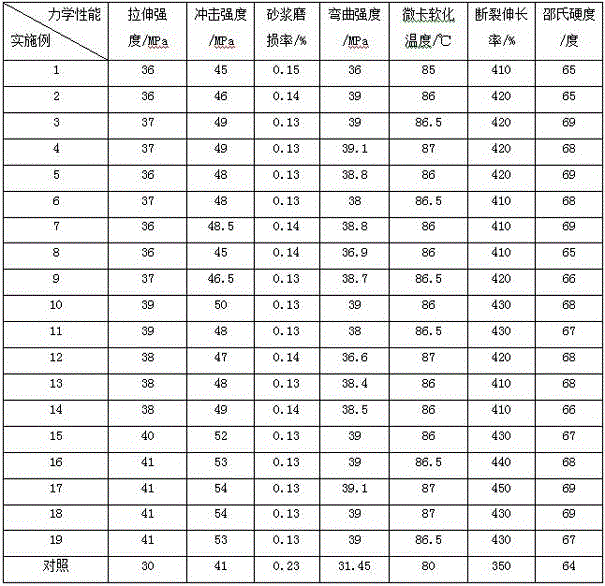

Special black master batch for polylactic acid based degradable plastics and preparation method thereof

The invention discloses a special black master batch for polylactic acid based degradable plastics and a preparation method thereof. The special black master batch for polylactic acid based degradable plastics comprises the following components in percentage by weight: 20-40% of pigment carbon black, 15-30% of dispersing lubricant and 40-65% of carrier resin, wherein the carrier resin adopts polylactic acid. In the special black master batch for polylactic acid based degradable plastics, the polylactic acid carrier resin is taken as a basic component, and interacted with the pigment carbon black, the dispersing lubricant and the like in the extrusion process, thus special black master batch for polylactic acid based degradable plastics has the advantages of good compatibility and easy dispersing. In the process of preparing the plastics by using the special black master batch for polylactic acid based degradable plastics, the black master batch is used a little, the prepared plastic is good in mechanical behaviors, easy in degradation, and economic and environmentally friendly. In the preparation method, the process is simple, and the cost is low; and the preparation method is suitable for industrialized production.

Owner:SHENZHEN KEJU NEW MATERIAL

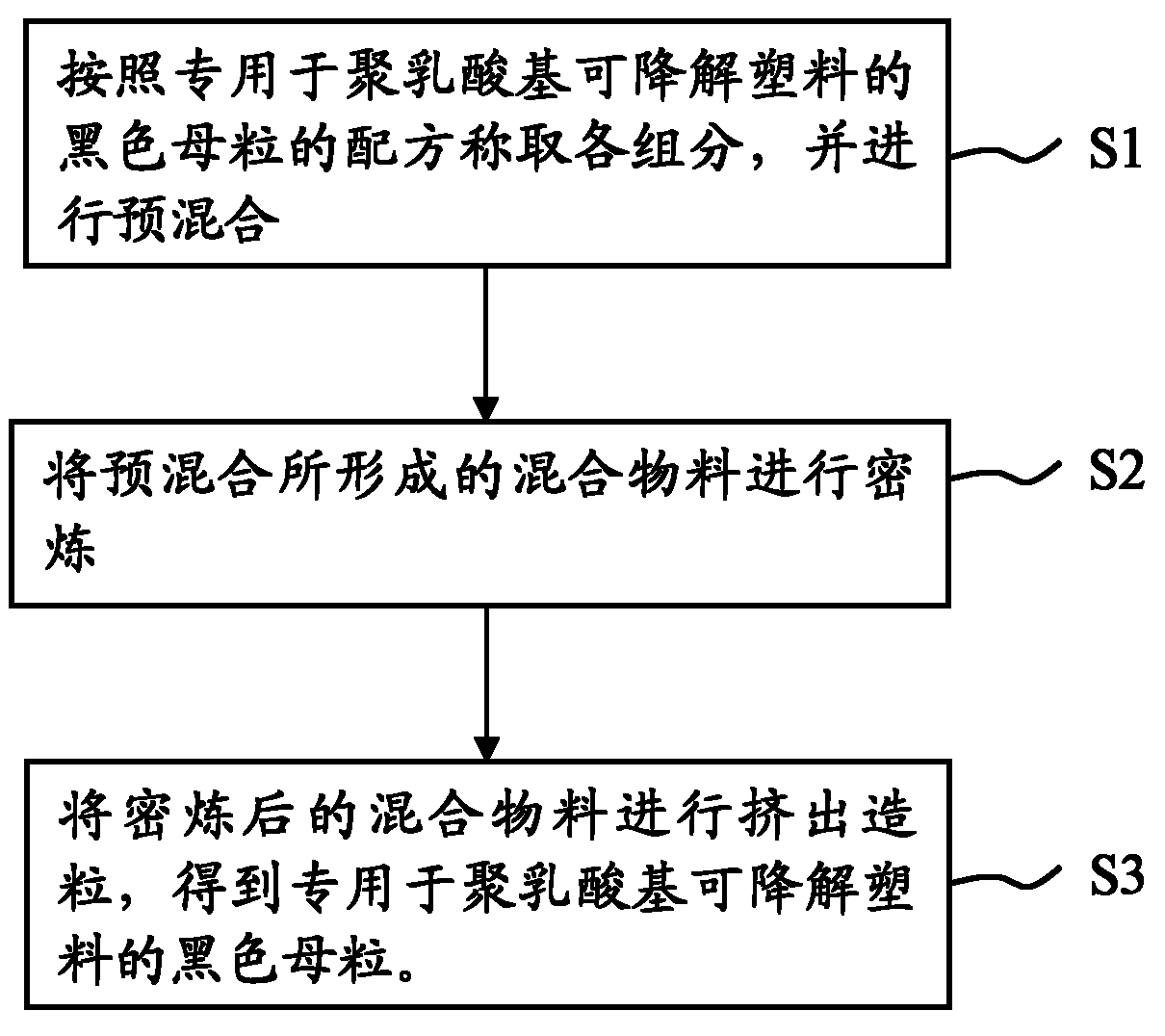

High-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material

The invention relates to a high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material. The blend material comprises the following raw materials by weight: 60 to 100 parts of UHMWPE, 5 to 12 parts of HDPE, 6 to 16 parts of LLDPE, 0.1 to 3 parts of a high-molecular-weight polymer nucleating agent and 1.5 to 3 parts of a flow modifier. The high-molecular-weight polymer nucleating agent has the advantages of no odor, good dispersibility, good compatibility, capacity of realizing heterogeneous crystallization, a high degree of crystallization and a small application amount; the high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material retains original characteristics of polyethylene UHMWPE and has obviously improved tensile strength, impact strength, bending strength, Vicat softening temperature, elongation at break and Shore hardness and a reduced mortar wear rate.

Owner:漯河科莱堡科技有限公司

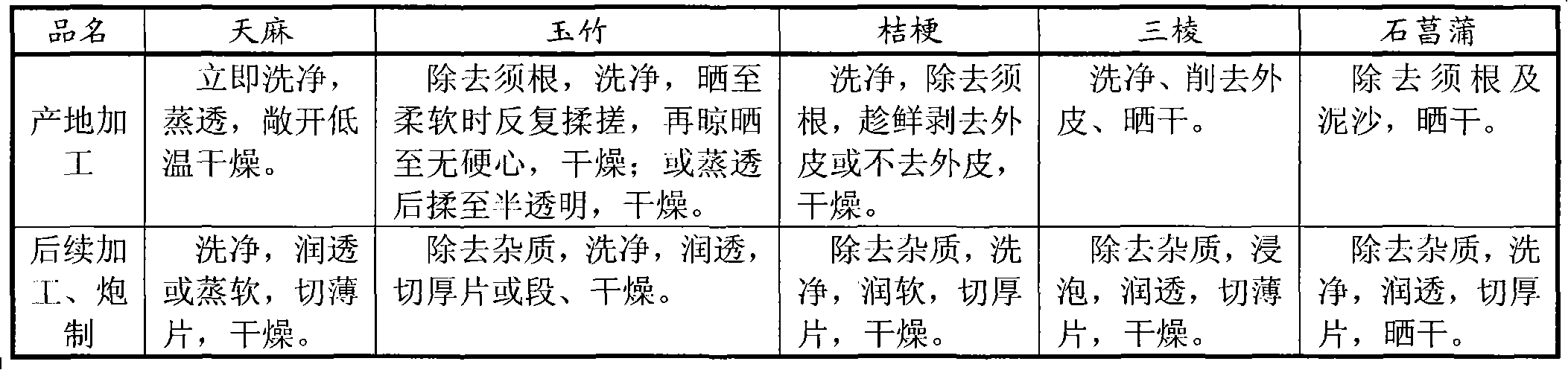

Fresh processing technology of traditional Chinese plant medicine at producing site

InactiveCN102000119AQuality improvementGuaranteed curative effectPlant ingredientsSocial benefitsBiology

The invention relates to the filed of traditional Chinese plant medicine processing technologies at the producing site, in particular to a fresh processing technology of a traditional Chinese plant medicine at the producing site. The technology comprises the following steps of: harvesting, cleaning, cutting, inactivating and drying the medicinal material, or harvesting, cleaning, cutting and drying the medicinal material. The multiple and repeated procedures of cleaning and drying the medicinal material at the producing site and cleaning, softening, cutting and drying the medicinal material at a medicine piece plant of the prior art are directly changed into the process of cleaning, cutting and drying at the producing site. Thus, the invention achieves the purposes of simplifying the processing, subsequent processing and preparing procedures of the traditional Chinese medicinal material at the producing site, saving energy consumption, reducing comprehensive production cost, ensuring medicinal material quality and increasing peasant incomes and has obvious economical and social benefits.

Owner:HANGZHOU HAISHAN PHARMA EQUIP

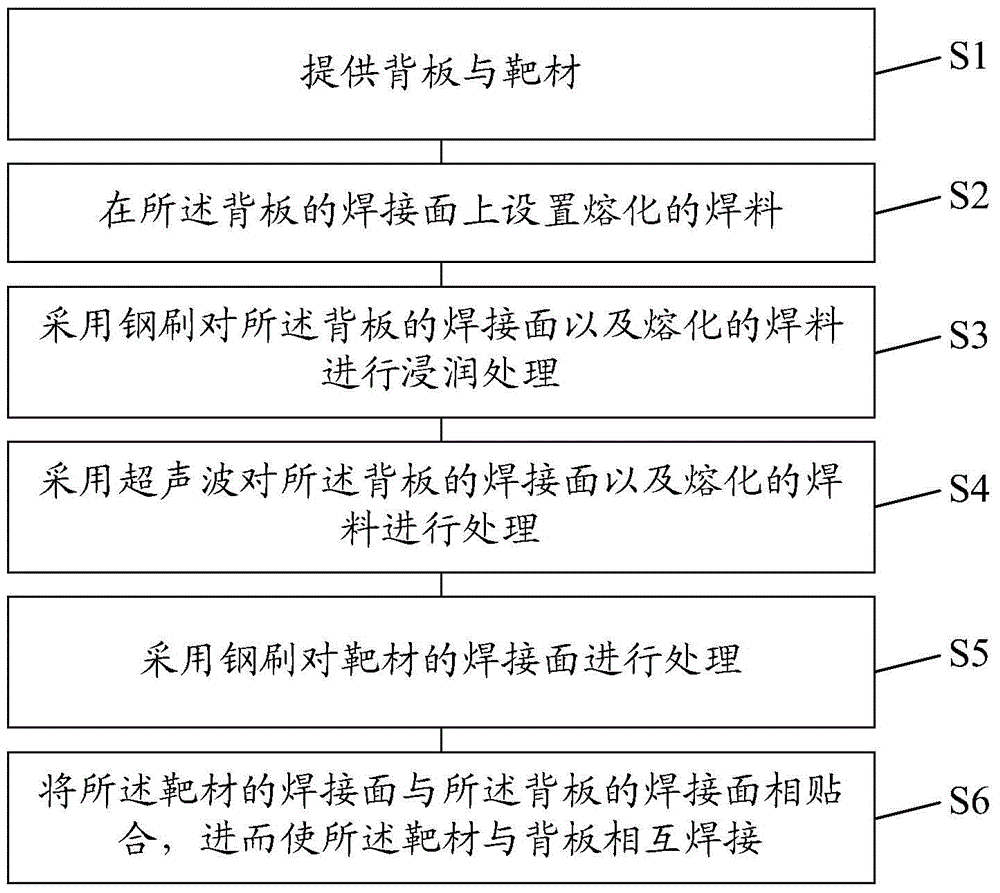

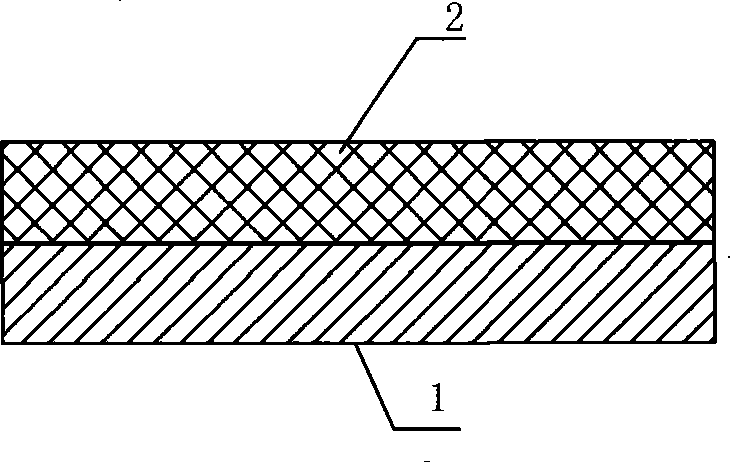

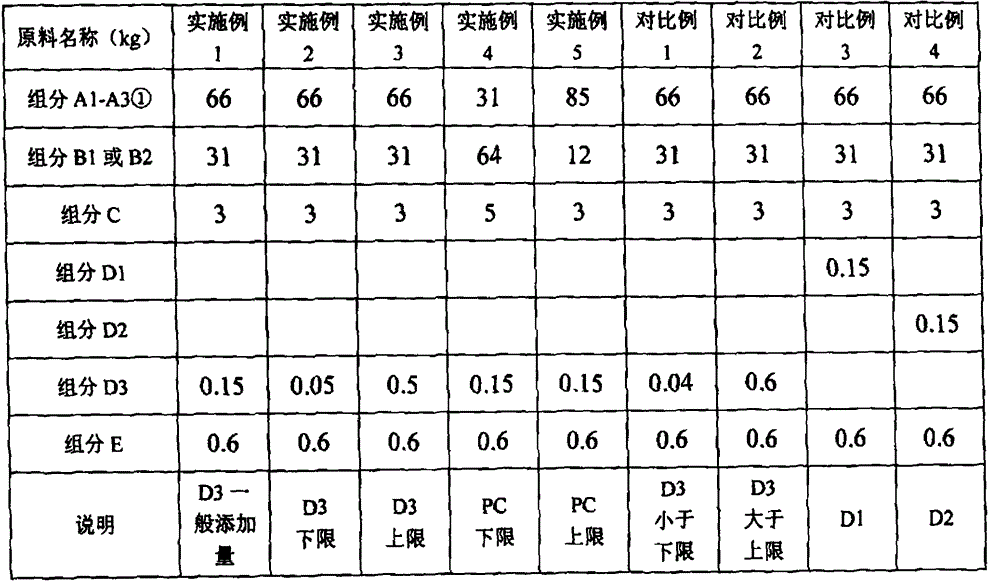

Welding method for target assembly

The invention provides a welding method for a target assembly. The welding method is used for welding a target and a back plate to form the target assembly. The method includes the steps that the back plate and the target are provided; molten solder is arranged on a welding face of the back plate; a steel brush is used for wetting the welding face of the back plate and the molten solder, and ultrasonic waves are used for processing the welding face of the back plate and the molten solder; the steel brush is used for processing a welding face of the target; and the welding face of the target and the welding face of the back plate are attached so as to weld the target and the back plate. The welding method has the beneficial effects that the contact area between the molten solder and the welding face of the back plate is enlarged, atoms of the solder can be conveniently and more quickly dispersed onto the welding face of the back plate, and therefore the molten solder can conveniently wet the surface of the welding face of the back plate, and the welding quality of the target and the back plate is higher.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Waterless stemming for blast furnace

InactiveCN1523120AImprove workabilityEasy to squeeze outBlast furnace componentsBlast furnace detailsAnthraceneContraction rate

The present invention provides an anhydrous stemming for blast furnace. Its composition includes (wt%) coarse brown corundun 1-4%, fine brown corundum 2-5%, coarse mullite 7-15%, fine mullite 9-20%, coke powder 15-20%, clay 10-19%, silicon carbide 7-11%, sericite 5-8%, bitumen 2-4% and anthracene oil 15-25%. It has good working property, stable high temperature resistance, excellent caking property, quick agglutinating property, low ton-iron stemming consumption, low contraction rate and high strength, it can raise tap up-to-standard rate to 100% from original 61.5%, can raise production safety of blast furnace, and can raise smelting strength.

Owner:WUKUN STEEL

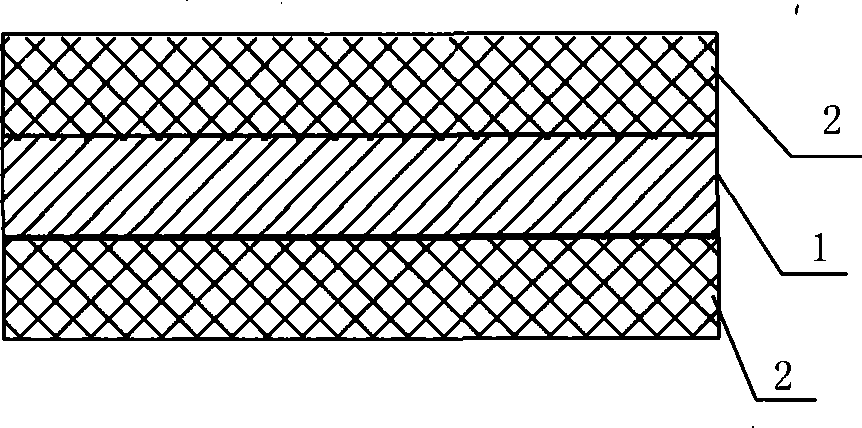

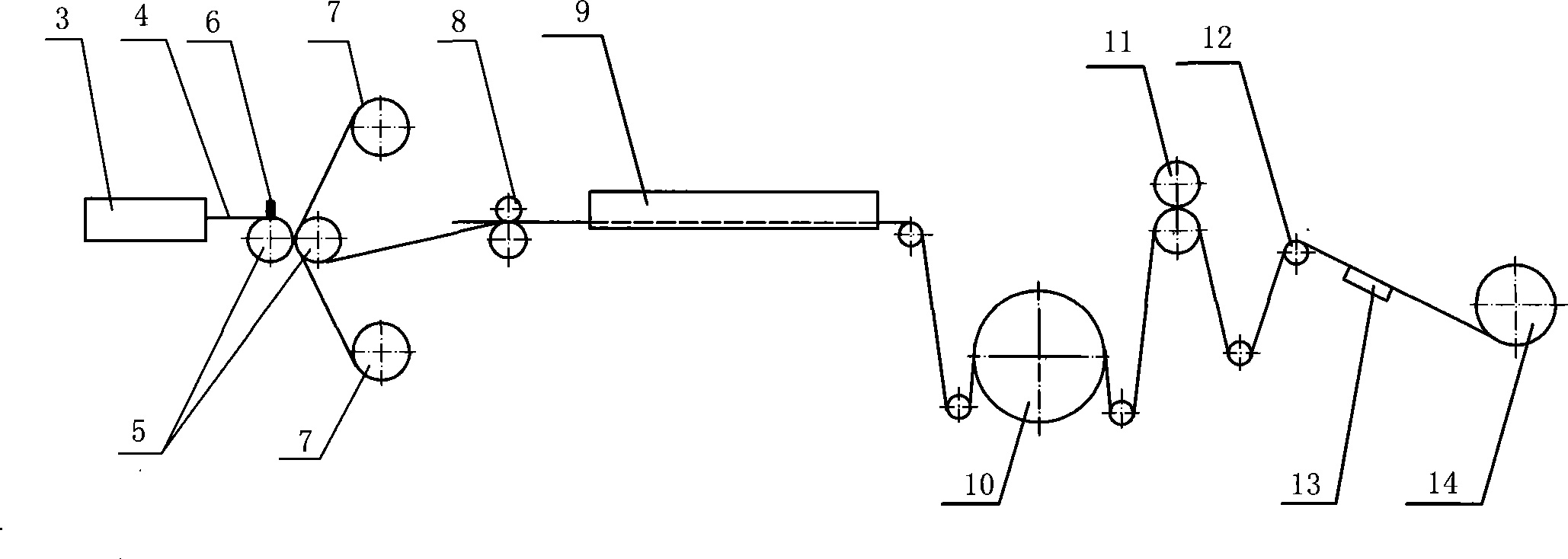

Composite water-proof coil stock of rubber and producing method thereof

ActiveCN101245237AHigh strengthImprove waterproof performanceOther chemical processesRoof covering using flexible materialsFiberPolymer science

The invention relates to a rubber composite waterproofing membrane and a producing method, which is compositely composed of a base course and a surface course in staggered superposition, the base course is a rubber waterproof layer, the surface course is chemical fiber non-woven fabric or chemical fiber woven fabric, the main materials of the rubber of the base course are ethylene propylene diene monomer rubber, calculated according to parts by weight, 100 parts of ethylene propylene diene monomer rubber are regarded as the reference, the content of other components is as follows: 5 to 10 parts of zinc oxide, 1 to 3 parts of stearic acid, 0.5 to 3 parts of polyethylene glycol, 1 to 4 parts of paraffin, 40 to 80 parts of fast extruding carbon black, 10 to 50 parts of calcium carbonate, 40 to 80 parts of plasticizer, 0.5 to 1.5 parts of accelerator BZ, 0.5 to 3 parts of accelerator CZ, 0.5 to 1.5 parts of accelerator TMTD and 1 to 3 parts of sulfur. The membrane provided by the invention has the advantages of the good performance, the good aging resistance, the long life span, protecting environment, no pollution, the simple processes and the high producing efficiency.

Owner:大庆深润化工科技有限公司

Halogen-free flame retardant PVC elastic material and preparation method thereof

ActiveCN102443226AGood environmental protection and flame retardancyGood thermal stabilityPlasticizerStabilizing Agents

The invention provides a halogen-free flame retardant PVC elastic material and a preparation method thereof, relating to a preparation method of a polymer composite material. The preparation method comprises the following steps of: mixing PVC resin in a kneader till the temperature is 70-80 DEG C; then adding a stabilizing agent, a plasticizer, a lubricant, pigments and a halogen-free flame retardant and continuing mixing till the temperature of the mixture is 85-95 DEG C and discharging the mixed material; cooling the mixed material in a cooling stirrer to 40-50 DEG C; and adding the cooled mixed material in a twin-screw extruder, and extruding strip-shaped halogen-free flame retardant PVC elastic material under the condition that the temperature of an extrusion die head is 130-150 DEG C. An elevator balance compensation chain sheath prepared from the special material provided by the invention has beautiful appearance, good toughness, good aging resistance, high thermal stability andgood fire retardant effect.

Owner:JIANGSU XINGHUA RUBBER BELT

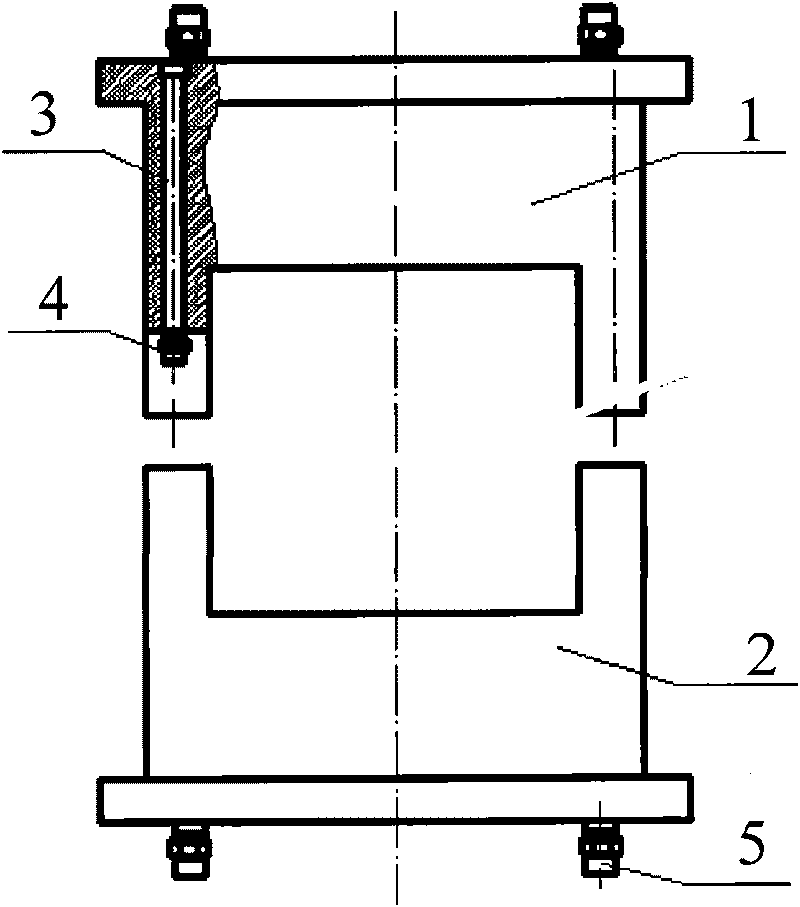

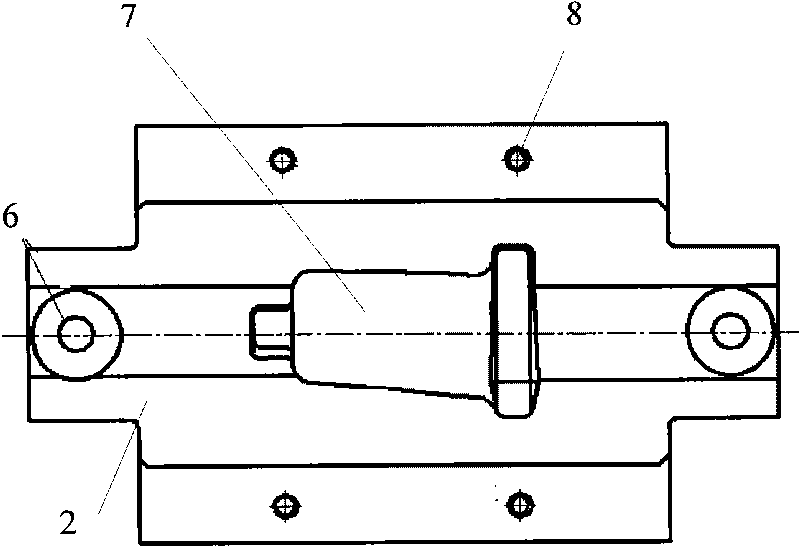

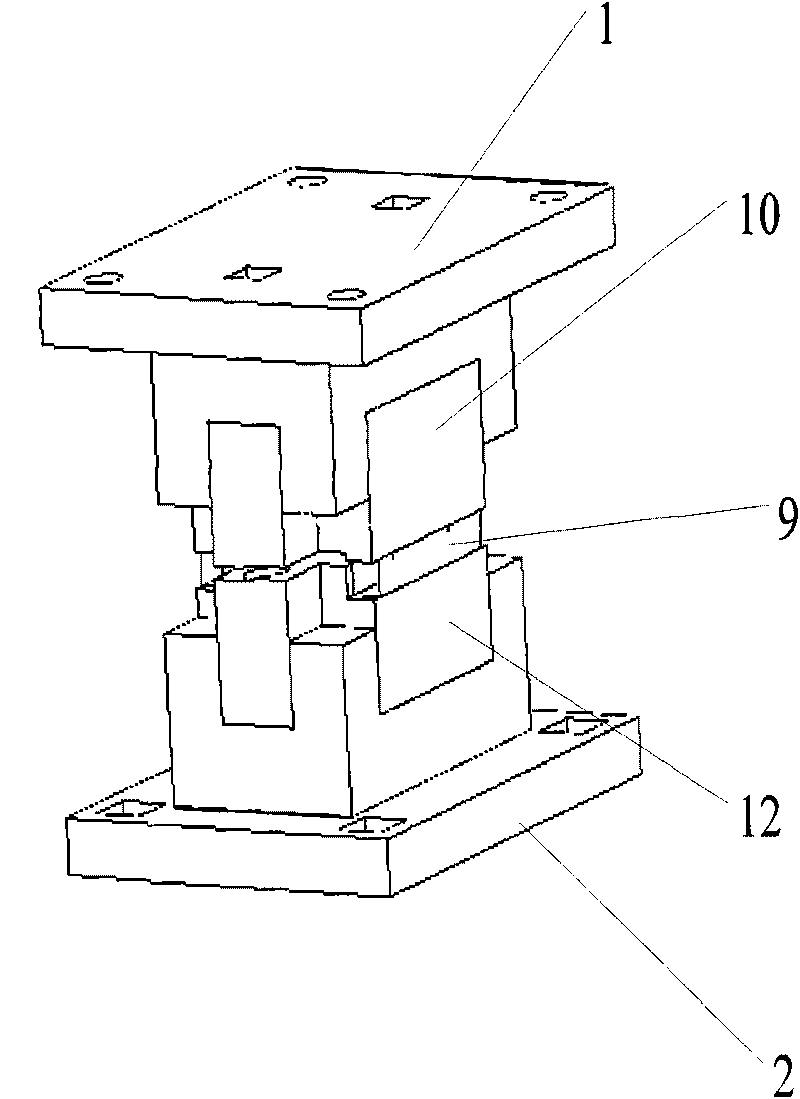

Isothermal forging method for titanium alloy blade

InactiveCN101733348ALower deformation temperatureImprove surface qualityForging/hammering/pressing machinesTitanium alloyMechanical property

The invention discloses an isothermal forging method for titanium alloy blade, which is implemented by the following steps: (1) coating lubricant on the surface of pre-forged titanium alloy blade blank; pre-heating with an electrothermal furnace to the deformation temperature of the blade blank; (2) fixing a lower die holder in an isothermal molding heater, and respectively fixing the upper die and the lower die on the upper die holder and lower die holder; (3) fixing the isothermal molding heater on a hydraulic press, heating to 900-930 DEG C and maintaining the temperature for at least 3h; (4) taking the blade blank out of the electrothermal furnace, putting into the upper die and the lower die in the isothermal molding heater, forging by the hydraulic press, and controlling the hydraulic press to perform return stroke operation when the dimension of the blade blank satisfies the requirement. The titanium alloy blade blank obtained by the inventive method has a preciseness satisfying technical requirement and obviously improved mechanical property.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

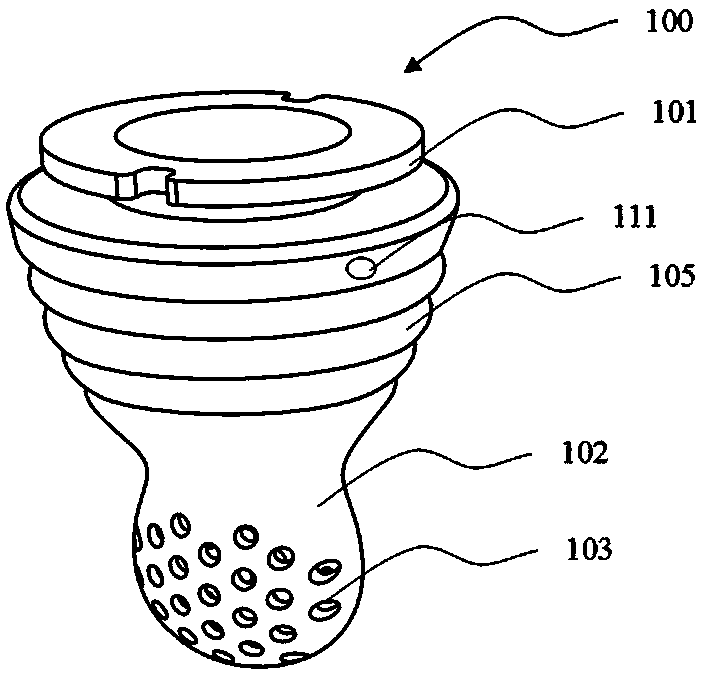

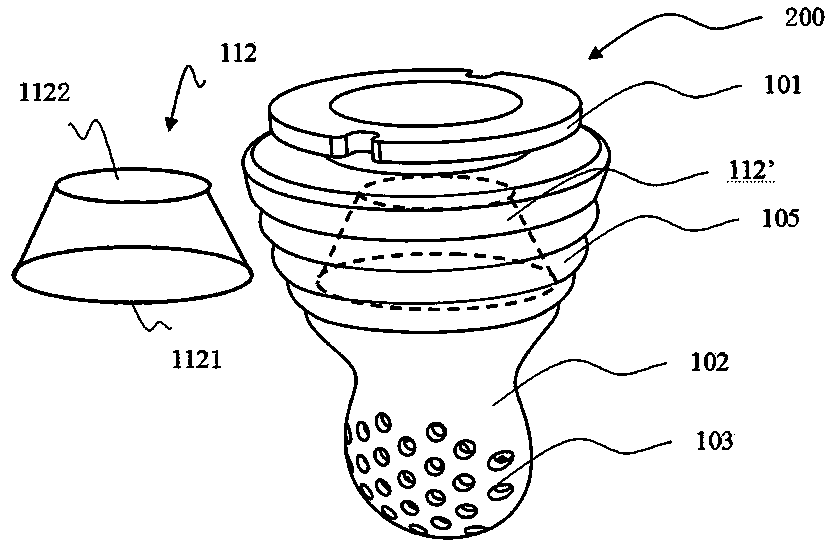

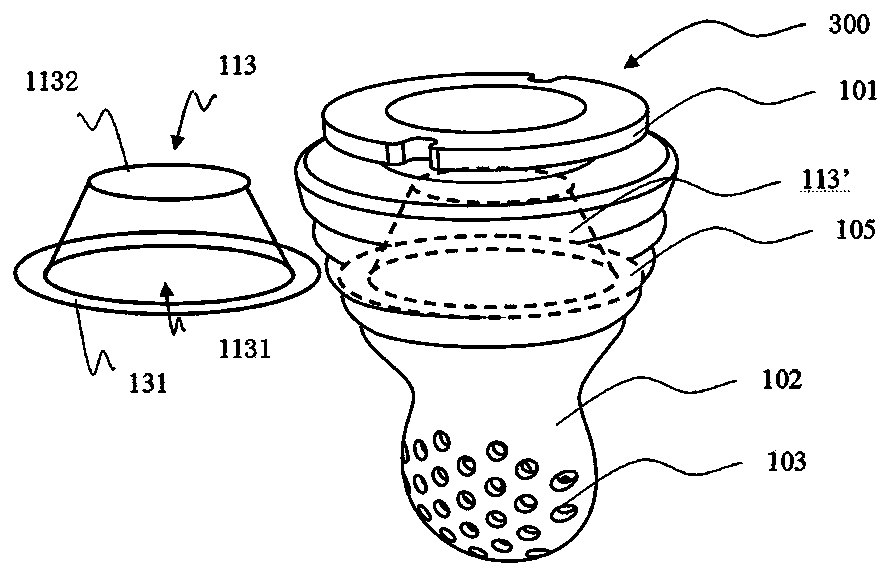

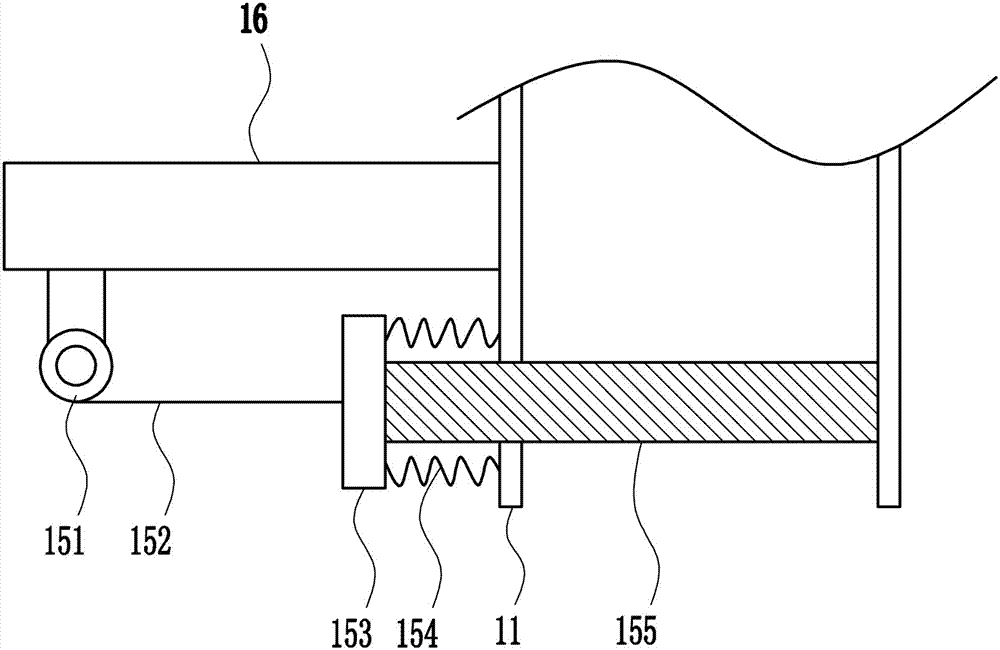

Feeder and feed device

ActiveCN103690375AIncreased food capacityImprove usabilityFeeding-bottlesMechanical engineeringFood grade

The invention relates to a feeder and a feeding device with the feeder. The feeder is made of a food-grade elastic material, and comprises an annular base part and a bag formed by downward extension of the annular base part, wherein one or more through holes are formed in the tail end of the bag; the bag is provided with an annular folding part. The feed device comprises the feeder. According to the feeder, due to the existence of the annular folding part arranged on the bag of the feeder, on the one hand, the volume of the bag can be increased, and the bag can be used for accommodating more foods, and on the other hand, the folding part plays the effect of a pump, and a user can extrude foods from the bag more easily, and can be fed more conveniently; furthermore, the folding part can be bent at a certain angle to increase the usability and practicality of the feeder, and a user can extrude foods in the feeder more easily due to the arranged vent holes and / or sliding parts and / or elastic parts.

Owner:DONGGUAN KIDSME IND LTD

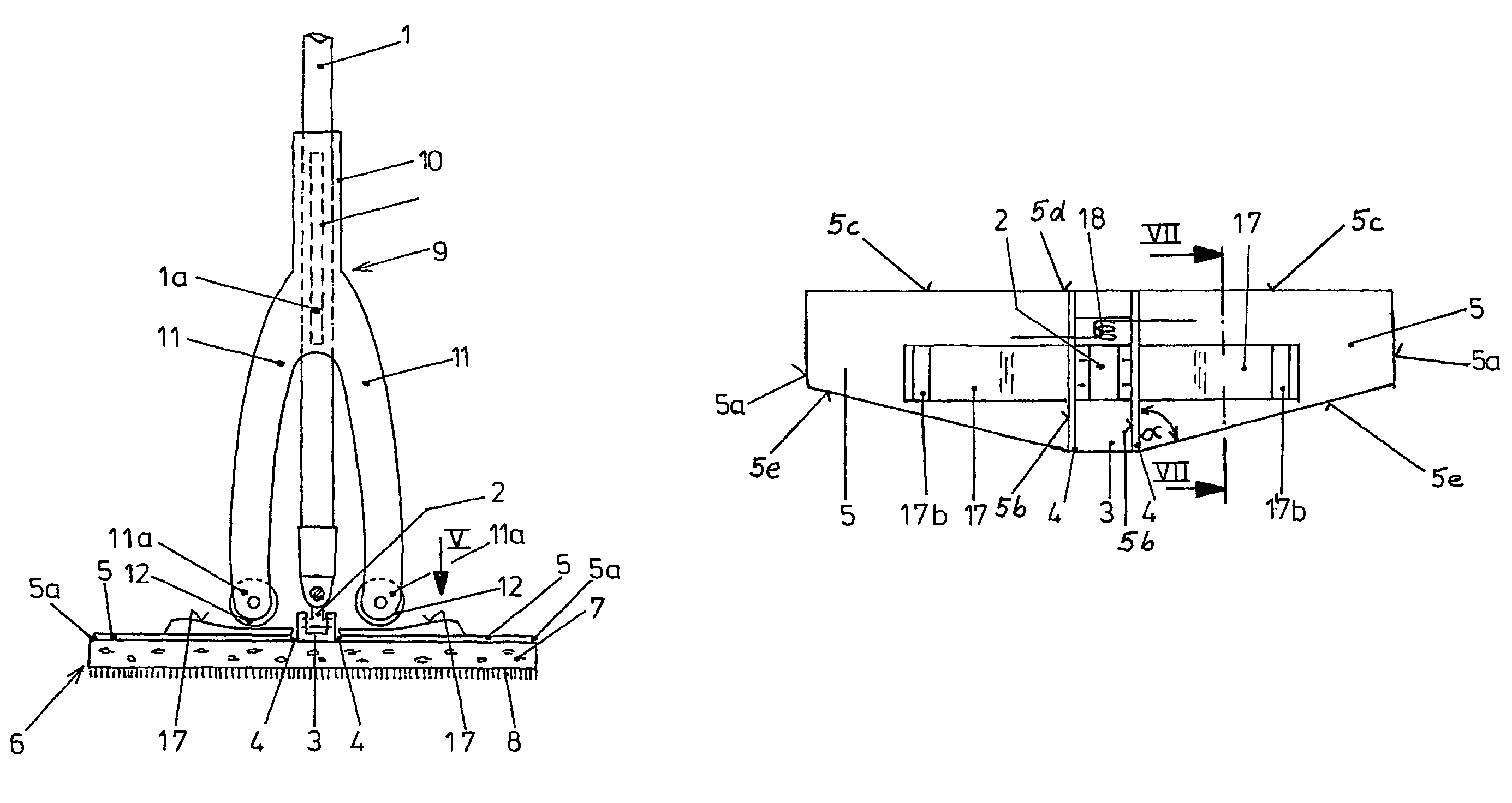

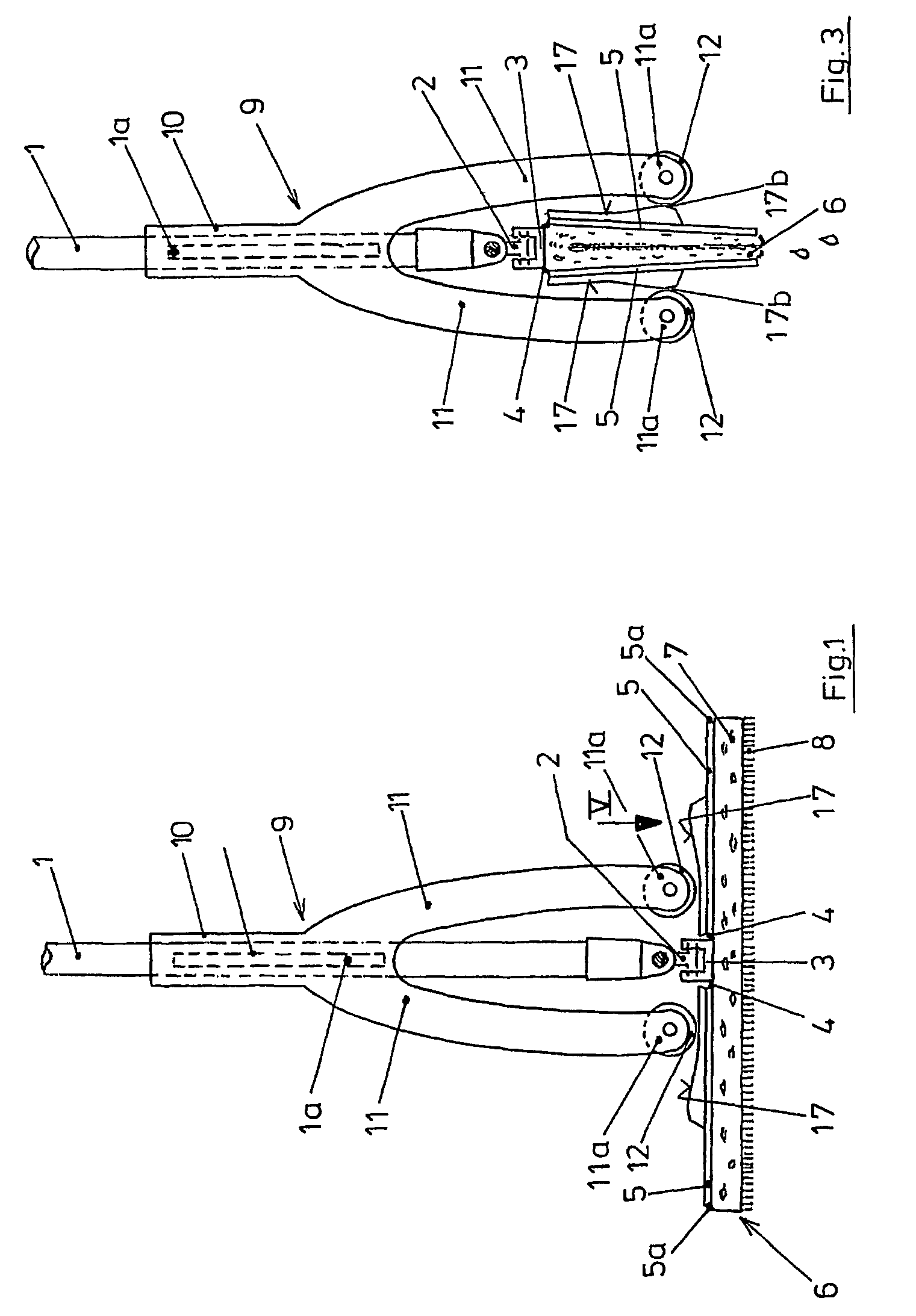

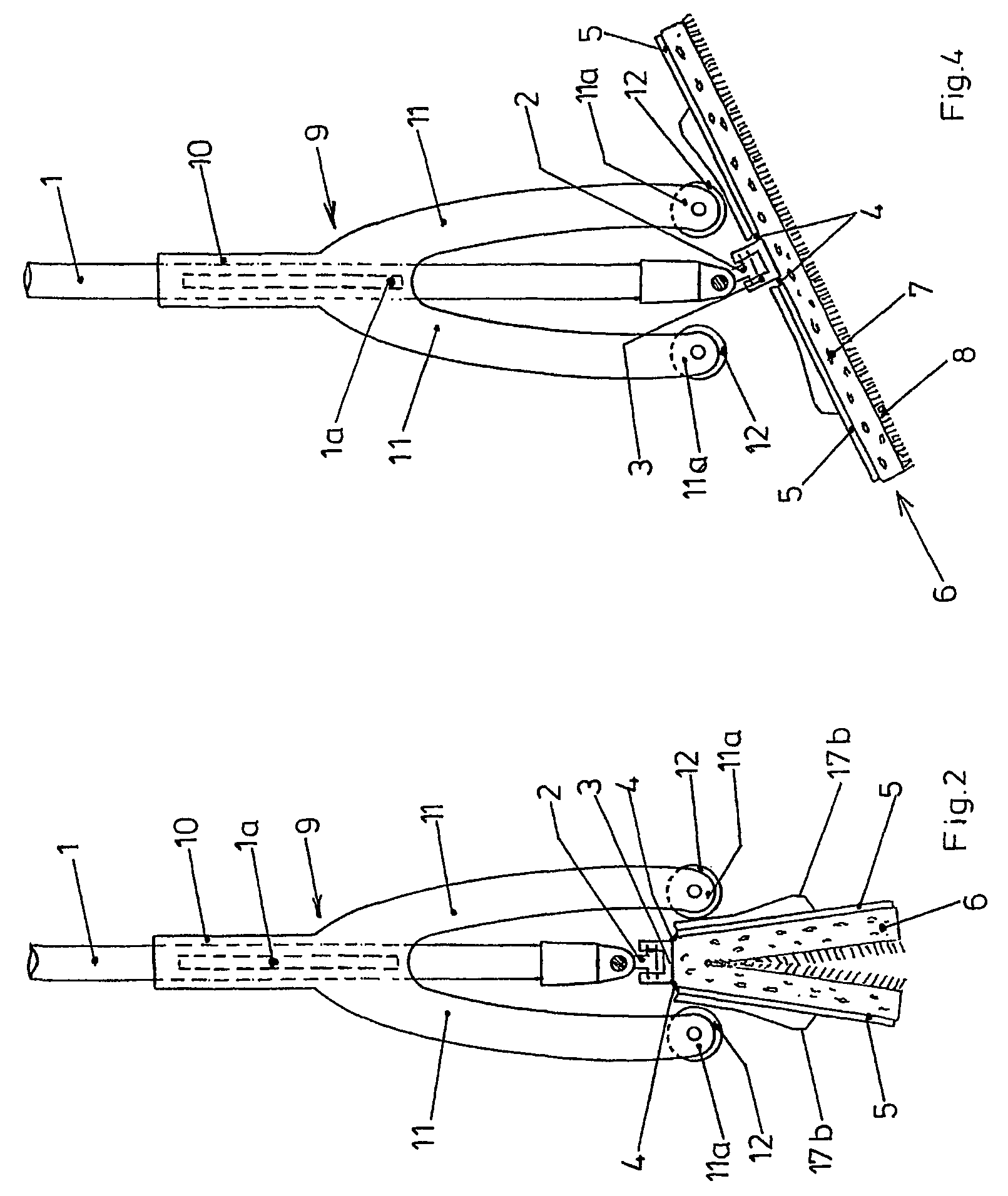

Floor mop

A floor mop has two mop supporting wings, which carry an absorbent mop layer and are hinge-connected to a common supporting centerpiece. A mop handle is hinge-mounted to the supporting centerpiece via a Cardan joint. A squeezing slider, which is displaceable along the mop handle and is guided non-rotatably, has two rigid squeezing arms whose ends can each be brought into engagement with a guide surface on the upper side of the respectively assigned mop supporting wings via rollers. Each mop supporting wing forms a rectangular trapezium or triangle. The edges running at right angles to the hinge edge of each mop supporting wing form a common straight continuous front edge.

Owner:CARL FREUDENBERG KG

Dynamic vulcanized silicone rubber/thermoplastic polyurethane elastomer and preparation method thereof

The invention provides a dynamic vulcanized silicone rubber / thermoplastic polyurethane elastomer material and a preparation method thereof. The material is prepared, by weight, the following components: vinyl polysiloxane: 100 parts, thermoplastic polyurethane elastomer: 10-500 parts, compatibilizer: 3-30 parts, hydrogen-containing silicone oil: 0.1-15 parts, platinum-based catalyst: 0.1-100 ppm (content of platinum atom in the vinyl polysiloxane and hydrogen-containing silicone oil), anti-poison agent: 0.1-20 parts. In the preparation process, no hydrogen is generated, and the process is simple and safe. The product integrates the advantages of two materials of silicon rubber and TPU, has excellent surface hand feeling, has excellent adhesion with PC, PC / ABS, ABS and the like, is easy toextrude and formed through injection molding, the additive amount of the platinum-based catalyst is low in the preparation process, the product has excellent endurance performance and low cost, and can be widely applied to the fields of intelligent wearable products and electronic and appliance products and the like with relatively high requirements.

Owner:WANHUA CHEM GRP CO LTD

Cyclic heating high efficiency 3D printer nozzle device

InactiveCN106426912ANot easy to cureSolve obstaclesManufacturing heating elements3D object support structuresHeat conductingThermal insulation

The invention relates to a cyclic heating high efficiency 3D printer nozzle device, including a base plate, the middle of the base plate is provided with a feeding tube, the main body of the feeding tube is located below the base plate, the lowermost of the feeding tube is a nozzle, the upper outer side of the feeding tube is provided with a heat dissemination component, the outside of the lower part of the feeding tube is a heating component, the outer wall of the nozzle is constructed from multiple layered structures, the inner layer is a main heat conducting layer, which is touched and fixed with an elastic thermal preservation layer outside the main heat conducting layer, the outer side of the elastic thermal insulation layer is an outer wall, the top of the elastic thermal preservation layer is provided with a compression rod, the inside of the feeding tube is provided with a rotating shaft, the rotation of which is driven by a motor, the heat dissemination component includes a heat dissemination tube and a liquid heat dissemination device connected with the heat dissemination tube, the liquid heat dissemination device is connected with a control device, the control device through controlling a temperature sensor provided on the heat dissemination tube performs a heat disseminating control to the materials in the feeding tube. The device has good performance on heating and disseminating heat, and has obvious effect on anti clogging.

Owner:HUNAN RUIDU TECH

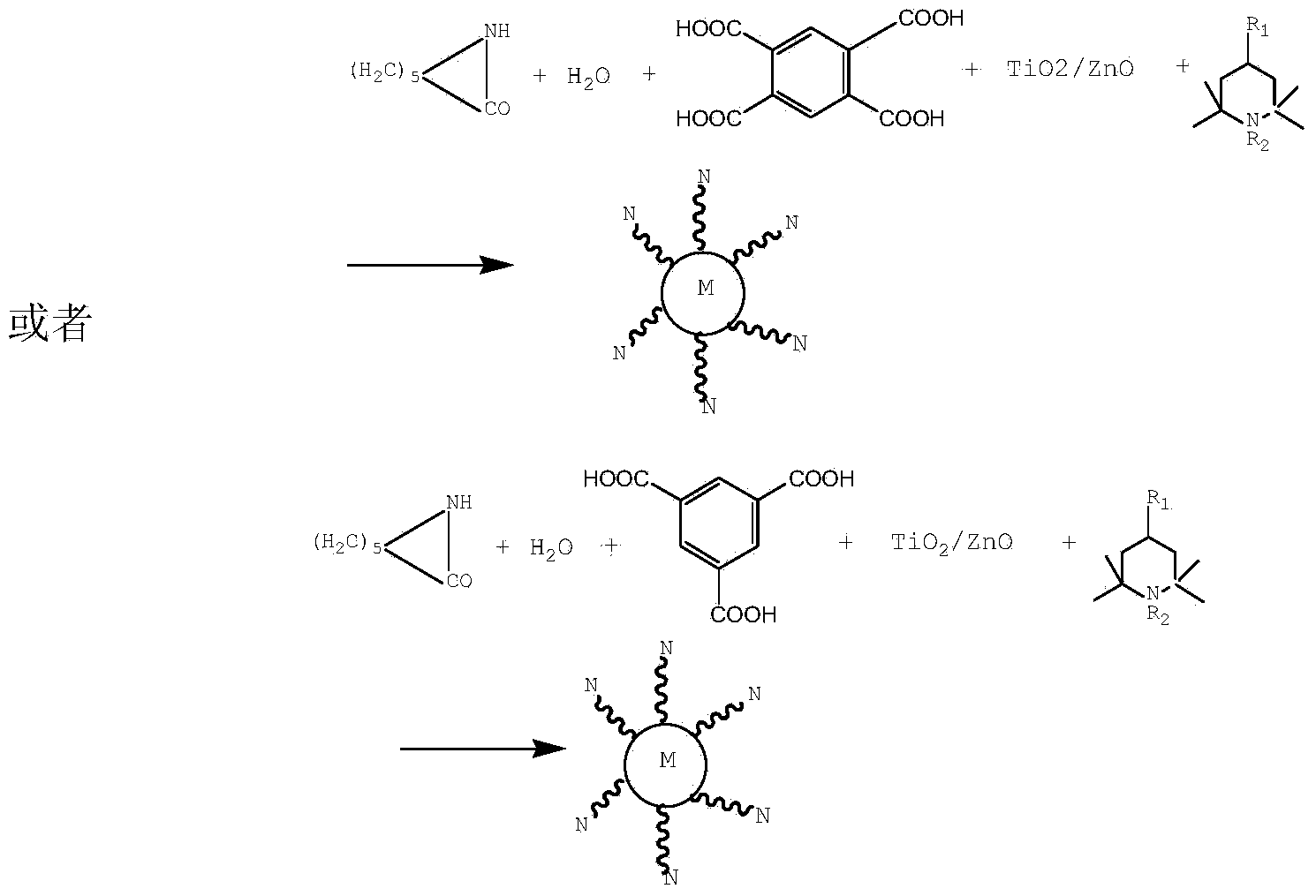

Application of hyperbranched poly(amide amine)s in plastic processing

The invention discloses application of hyperbranched poly(amide amine)s in plastic processing, and belongs to the technical field of plastic processing agents. The application provided by the invention comprises the steps of uniformly mixing 0.1 to 5 parts by weight of amino-terminated hyperbranched poly(amide amine)s and 100 parts by weight of plastic, performing extrusion pelletization, and drying to obtain a modified plastic product. According to the application provided by the invention, the hyperbranched poly(amide amine)s is taken as a processing agent of the plastic of PPC, PP, PE, PA and the like, the outer layer of a hyperbranched poly(amide amine)s molecule contains a large number of active functional groups, and is low in melt viscosity, by adding the hyperbranched poly(amide amine)s into plastic substrates of PPC, PP, PE, PA and the like, the effective melt viscosity of a plastic system can be significantly reduced, namely the processing temperature and thermal degradation are decreased; in addition, such enhanced melt fluidity can still be realized through a lower additive amount, a finished film can be more easily extruded out, and the tensile strength and the processing performance of the plastic of PPC, PP, PE, PA and the like are greatly increased.

Owner:WEIHAI CY DENDRIMER TECH +1

Machining process for pet urinal pad with deodorizing function

InactiveCN103477997AImprove adsorption capacityStable hygroscopicityAnimal housingFerrous saltsMass ratio

The invention discloses a machining process for a pet urinal pad with a deodorizing function. The method comprises the following steps of A, selecting the raw materials according to the following parts by mass ratio: 0.5-1 part of metal aluminum salt, 0.5-1 part of metal ferrous salt and 1-2 parts of adsorbents, and grinding and mixing the three components to obtain a deodorant; adding 0.5-1.3 parts of the deodorant into the 100 parts of super adsorbent resin and fully mixing; B, attaching the mixture formed in the last step with wood pulp paper to form an adsorbing layer; C, paving a PE (poly ethylene ) film (bottom cloth) and non-woven cloth (face coating layer) on the adsorbing layer to form the pet urinal pad with the deodorizing function.

Owner:JIANGSU ZHONGHENG PET ARTICLES JOINT CO LTD

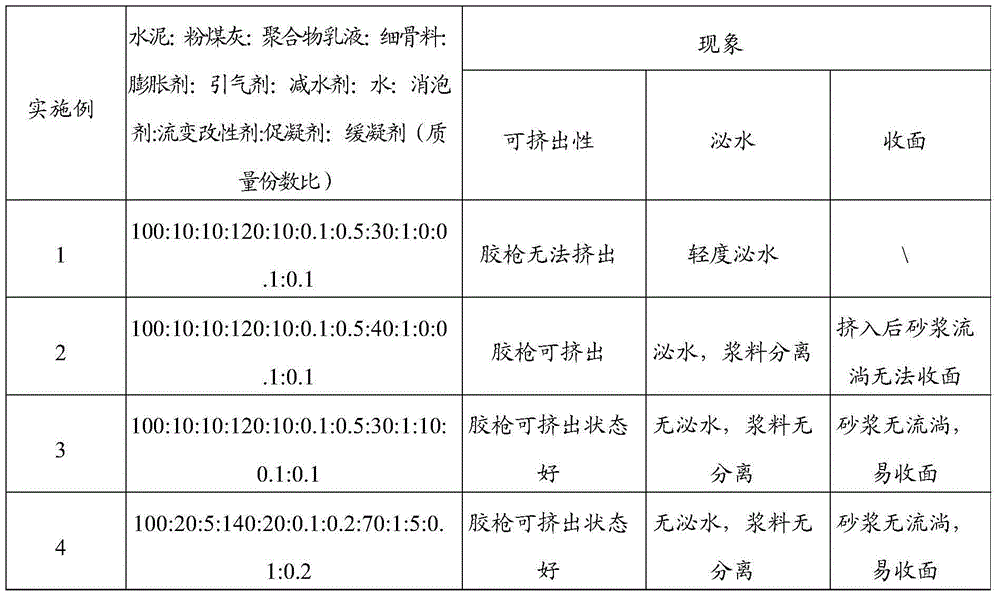

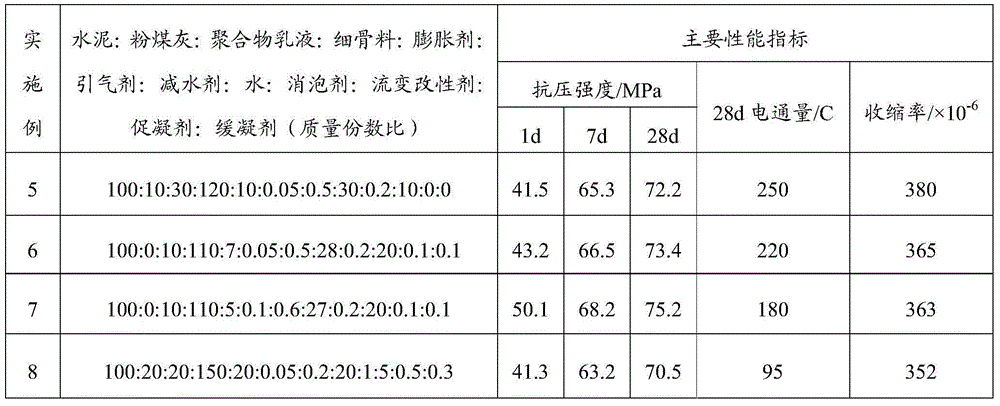

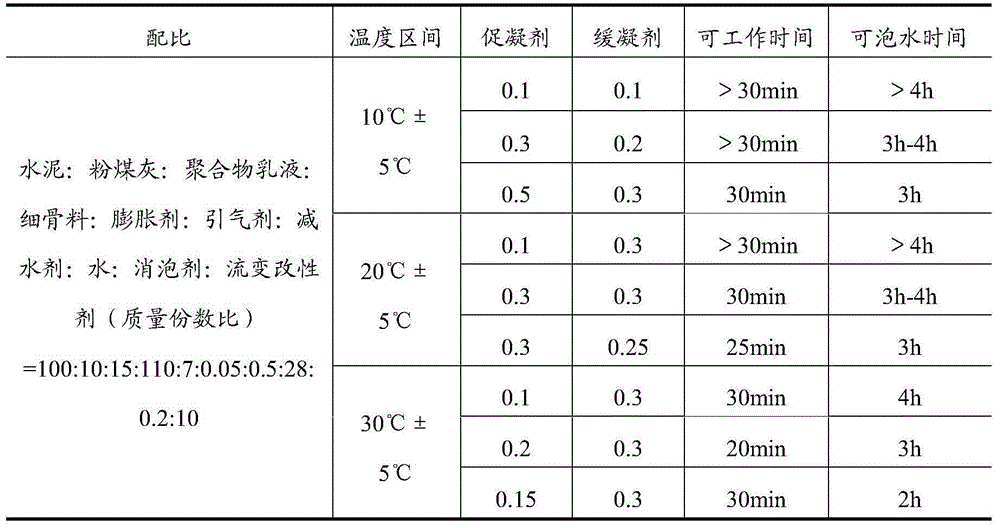

Track board sealing anchor mortar and preparation method thereof

The invention provides track board sealing anchor mortar and a preparation method thereof. The track board sealing anchor mortar comprises the following components in parts by weight: 100 parts of cement, 0-20 parts of coal ashes, 5-30 parts of polymer emulsion, 50-150 parts of fine aggregates, 1-20 parts of expanding agent, 0.05-0.5 part of air entraining agent, 0.2-3 parts of water reducing agent, 10-70 parts of water, 0.05-1 part of antifoaming agent, 5-20 parts of rheology modifier, 0-1 part of coagulant and 0-1 part of retarder. The mortar has excellent characteristics of extrudability, easiness in surface finishing, high construction efficiency, compaction, permeability resistance, durability and freezing resistance.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

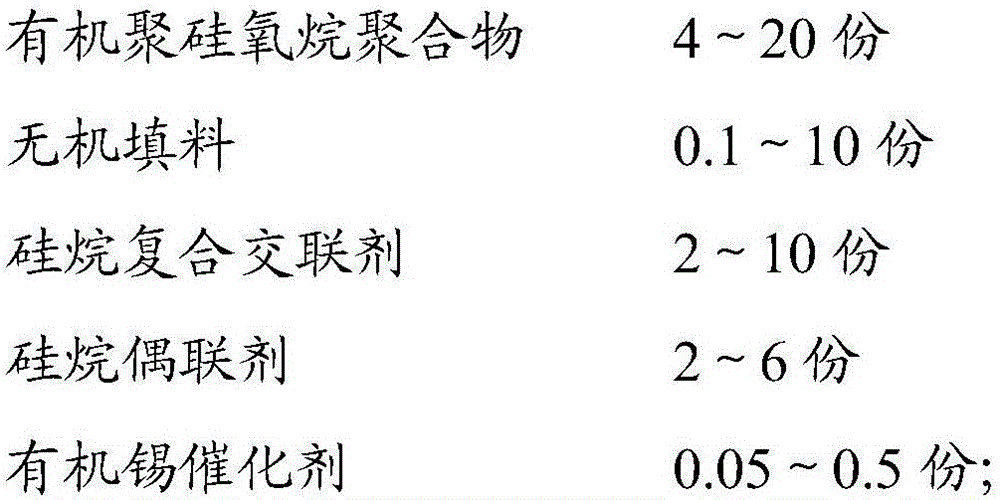

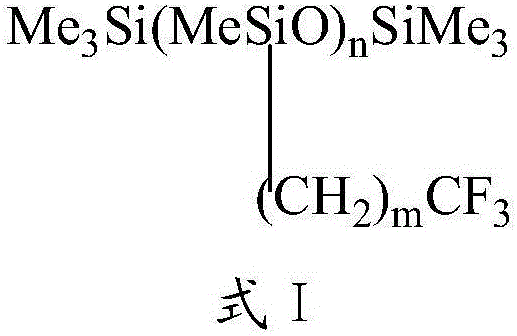

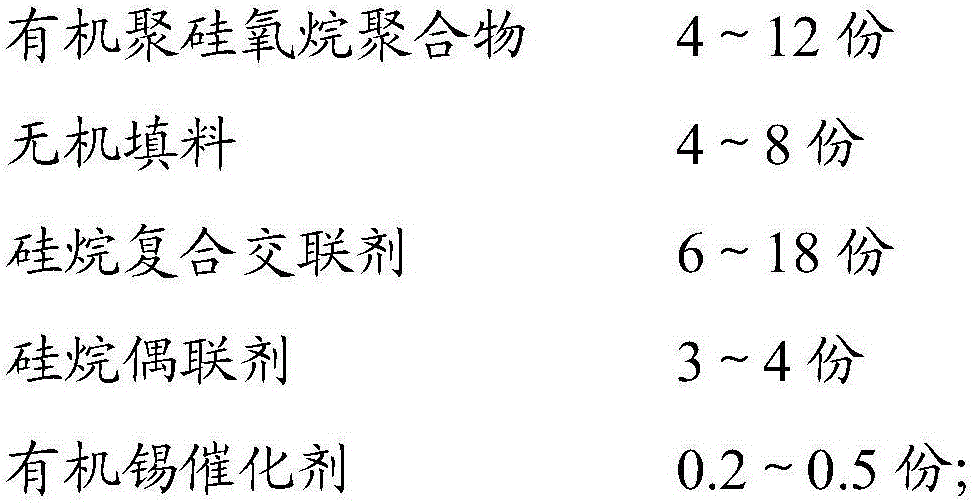

Multi-component silicone sealant and preparation method thereof

InactiveCN106833507ANot affected by humidityImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesMechanical propertyPolymer

The invention relates to a multi-component silicone sealant for door and window sealing and a preparation method thereof. The multi-component silicone sealant comprises a component A, a component B and a component C, the weight ratio of the component A and the component B is (7:1)-(15:1), the weight ratio of the component A and the component C is (10:1)-(30:1); the component A is prepared from an organic polysiloxane polymer, an inorganic filler and a thixotropic agent, the component B is prepared from an organic polysiloxane polymer, an inorganic filler, a silane composite crosslinker, a silane coupling agent and an organic tin catalys, and the component C is prepared from an organic polysiloxane polymer, an organosilicon defoamer, and a toner. The multi-component silicone sealant has the advantages that the curing is fast and is not affected by the environmental humidity, and can be adjusted in a certain ranged; the multi-component silicone sealant has good adhesion for door and window materials, is simple in color blending and convenient for being adjusted to a desired color of a user, and has good mechanical properties.

Owner:GUANGZHOU BAIYUN CHEM IND

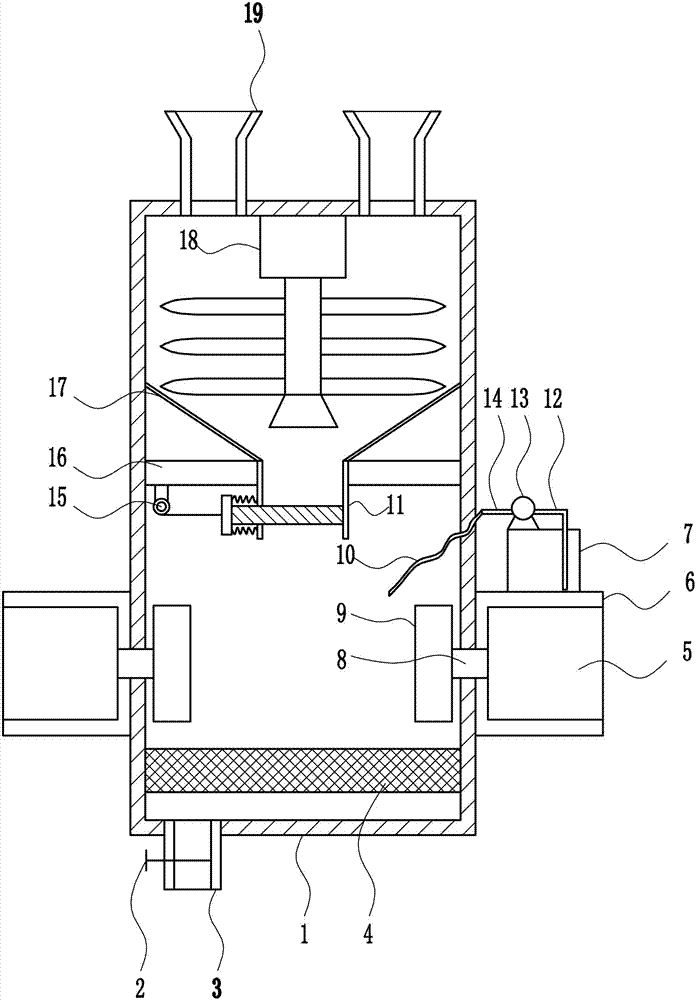

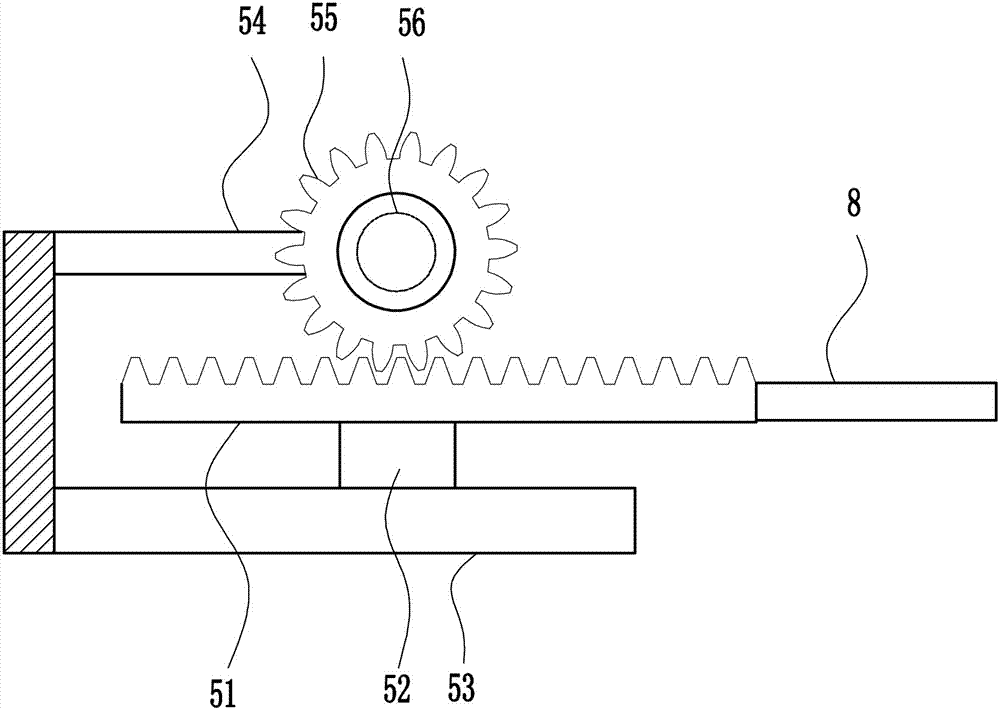

Pulping device for papermaking factory

ActiveCN107012706AReduce workloadImprove the efficiency of squeezingRaw material divisionPulp and paper industryRaw material

The invention relates to a pulping device, in particular to a pulping device for a papermaking factory. According to the technical aim, the pulping device for the papermaking factory is abundant in extruding force and high in production efficiency. In order to achieve the technical aim, the pulping device for the papermaking factory comprises a box, a valve, a pulp outlet pipe, a filtering screen, movable mechanisms, mounting boxes, a water tank, first supporting rods, pulp pressing plates, a liquid outlet hose, a discharging opening, a water drawing pipe and the like. The pulp outlet pipe is arranged on the left side of the bottom of the box, the filtering screen is arranged on the pulp outlet pipe, and the mounting boxes are symmetrically arranged on the left side and the right side of the box. The movable mechanisms are arranged in the mounting boxes, the first supporting rods are arranged on the movable mechanisms and penetrate through the box, and the pulp pressing plates are arranged on the first supporting rods. The effects of being abundant in extruding force and high in production efficiency are achieved, a smashing cutter and a smashing scraper blade of the device rotate, then raw materials are smashed fully and evenly, and the smashing efficiency is improved.

Owner:JIANGSU COLLEGE OF INFORMATION TECH

Cross-linking process of polyethylene-silane

A process for preparing cross-linked polyvinyl silane includes mixing polyethylene, diisoproplbenzene peroxide, vinyl triethoxyl silane, zinc stearate, tert [beta-(3,5-di-tert-butyl-4-hydroxyl-phenyl) propanoic] pentaerythritol ester and tri(2,4-tert-butyl phenyl) phosphite, stirring, extruding out, and immersing in water at 80 + / -5 deg. for 9-11 hrs. Its advantages are less consumption of trigger and cross-linking agent (decreased by 50%) and smooth surface of product.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Halogen-free charging pile electric cable material and preparation method thereof

The present invention discloses a halogen-free charging pile electric cable material, which comprises the following raw materials: a TPEE thermoplastic elastomer, a TPU thermoplastic elastomer, a flame retardant agent, a compatibilizer, an antioxidant, a light stabilizer and a processing aid. The invention further discloses a preparation method of the halogen-free charging pile electric cable material. According to the present invention, the halogen-free charging pile electric cable material has characteristics of reasonable formula, no halogen, good flame retardant property, good adhesion, high fluidity, gasoline resistance, extremely easy extrusion processing molding and the like, wherein the material has the characteristics of no halogen and flame retardant property so as to effective eliminate the harmful substance release during the heating process, such that the phenomenon that the human body health and the environment are threatened can not be generated; and the preparation method has characteristics of simple process, easy achieving and high production efficiency, and can rapidly produce the halogen-free charging pile electric cable material product, and the product can be widely used for the charging pile electric cable material and other products requiring flame-retardant and gasoline-resistant wire materials.

Owner:DONGGUAN JISU PLASTIC TECH

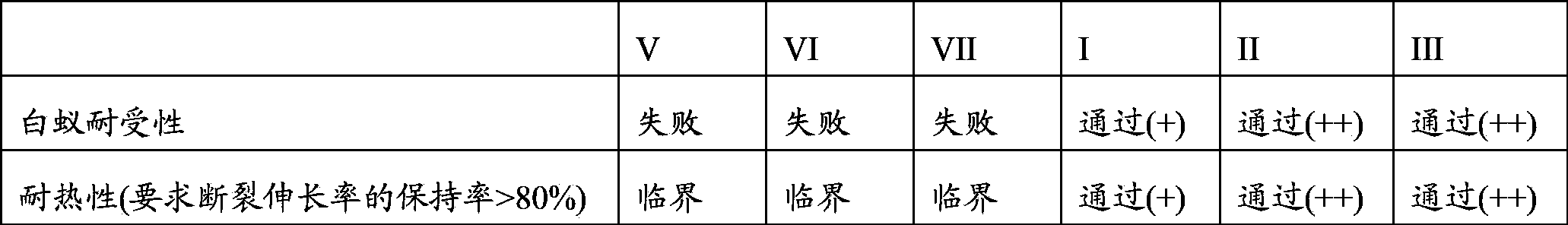

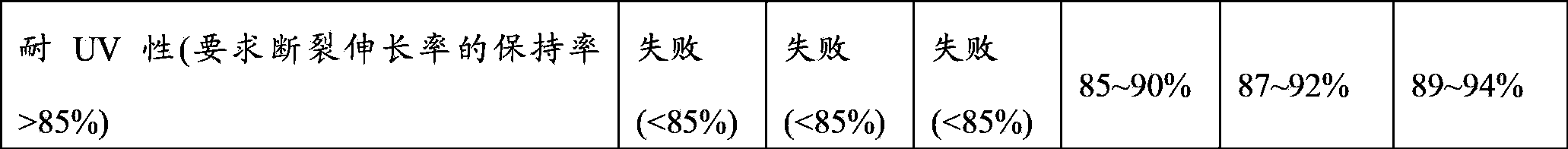

Termite-resistant cable sheath polyamide composition, cable sheath, production method and use

InactiveCN103881372AThe result is obviousEasy to processPlastic/resin/waxes insulatorsInsulated cablesFiberPolymer science

The invention provides a termite-resistant cable sheath polyamide composition, a cable sheath, a production method and use. The invention relates to the use of the polyamide composition in production of single-layer or multi-layer cable sheaths which are resistant to damages caused by termite, and the polyamide composition comprises the following materials: a) at least one aliphatic polyamide with at least two units corresponding to the following formula X.Y, wherein the X.Y represents a unit obtained by polycondensation of a diamine with X carbon atoms and a dicarboxylic acid with Y carbon atoms, and the sum of X and Y is strictly greater than 18; b) at least one UV absorber and possible at least one UV stabilizer; and c) at least one antioxidant preferably with the weight ratio of antioxidant to light stabilizer being less than or equal to 0.7. The invention also relates to the cable sheath made from the polyamide composition provided by the invention, the production method of the cable sheath provided by the invention, and the use of the cable sheath provided by the invention in cables or fiber cables.

Owner:阿科玛(苏州)高分子材料有限公司

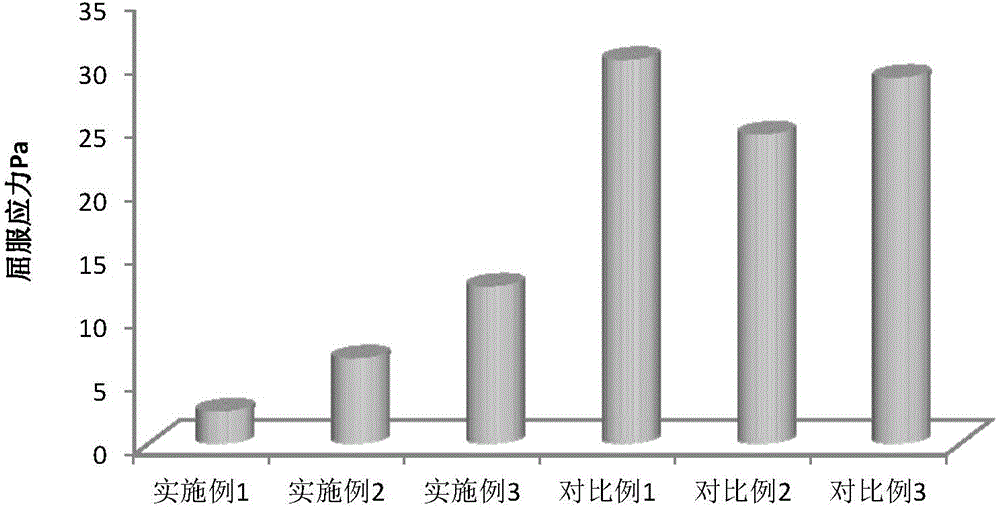

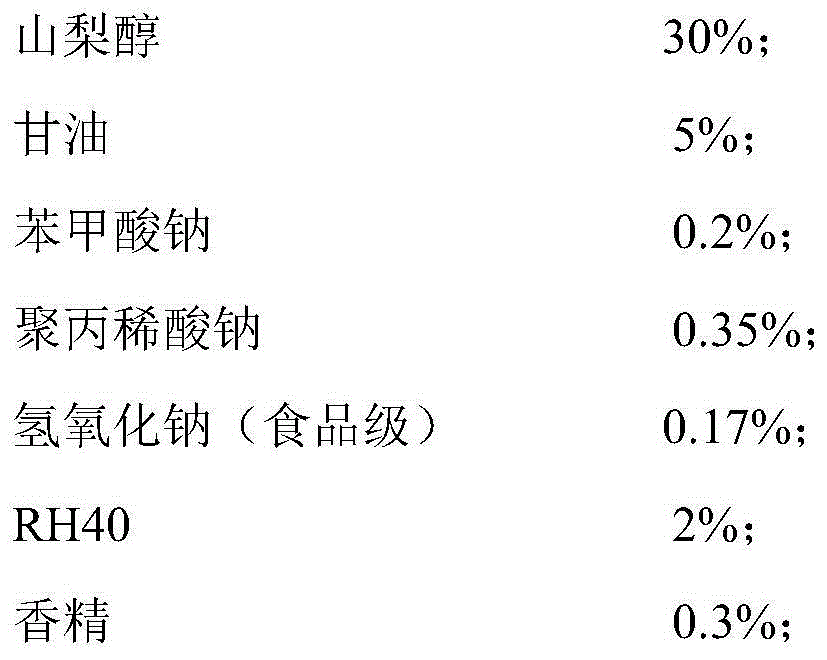

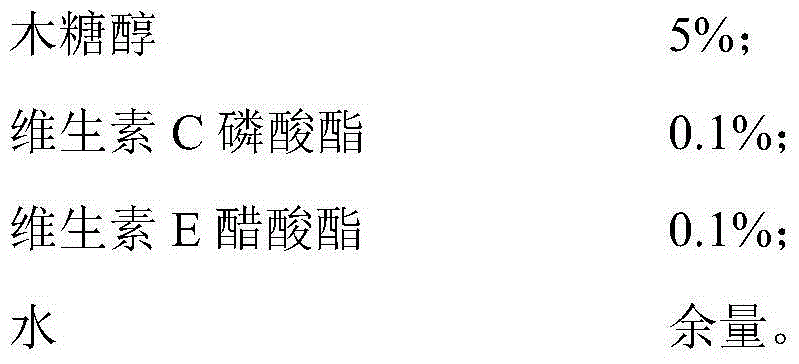

Child toothpaste composition

ActiveCN104905987APseudoplasticThixotropicCosmetic preparationsToilet preparationsToothpasteVeterinary medicine

The invention discloses child toothpaste composition. The child toothpaste composition comprises, by weight, 0.1-5 percent of thickener, 0.5-4 percent of solubilizer, 1-60 percent of humectant, 10-90 percent of water, 0.1-2 percent of essence and the balance other components. Abrasives are not added into the child toothpaste composition, and toothpaste body is transparent, generates a little or nearly no foam, is easy to extrude and brush, so that friction to the surfaces of teeth is reduced. The child toothpaste composition is high in safety with the pH range being 5.5-7.5, and can be used as training toothpaste for children at the age of 2-6.

Owner:GUANGZHOU LIBY

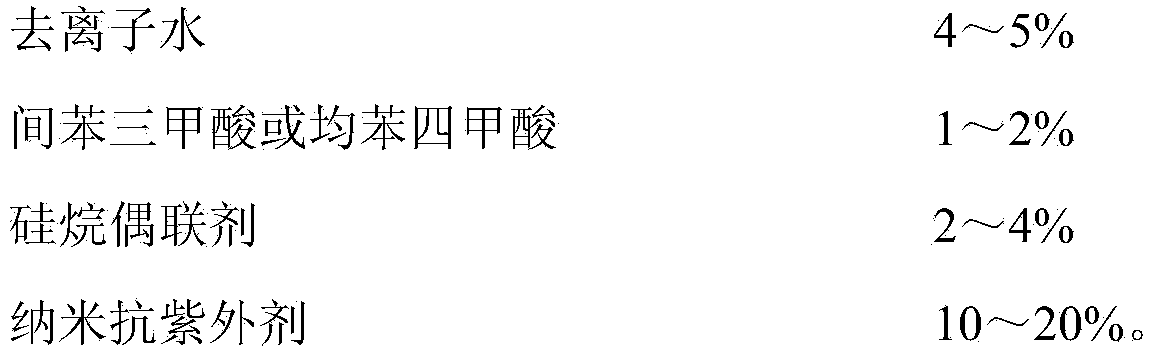

Uvioresistant nylon-6 fiber for ultrathin and light fabric and preparation method thereof

ActiveCN103774272AImprove liquidityBarrier transmissionMelt spinning methodsArtifical filament manufactureIn situ polymerizationNylon 6

The invention relates to an uvioresistant nylon-6 fiber for an ultrathin and light fabric and a preparation method of the uvioresistant nylon-6 fiber. The uvioresistant nylon-6 fiber is formed by branched-chain nylon-6 functional master batches and conventional nylon-6 chips through blending and spinning, wherein the branched-chain nylon-6 functional master batches account for 6-10% in weight percentage; the preparation method comprises the steps of firstly, preparing the branched-chain nylon-6 functional master batches through in-situ polymerization or blending; secondly, crystallizing and drying the branched-chain nylon-6 functional master batches and the conventional nylon-6 chips respectively and mixing, and then performing vacuum drying to obtain blended chips; and finally, performing melt spinning to the blended chips with melt spinning equipment. The using amount of ultraviolet absorbents is reduced, the fiber spinnability is improved, the uvioresistant and the ultraviolet aging resistant effects are ensured; the fabric can strongly absorbing ultraviolet radiation while light weight is ensured, and is suitable for developing thin and light clothes in summer.

Owner:中国化学纤维工业协会

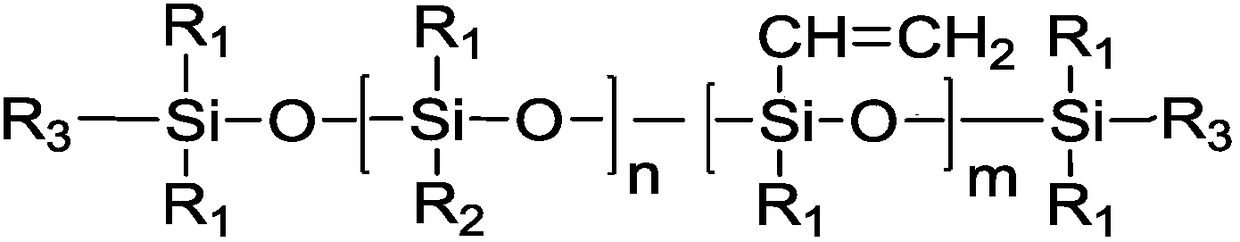

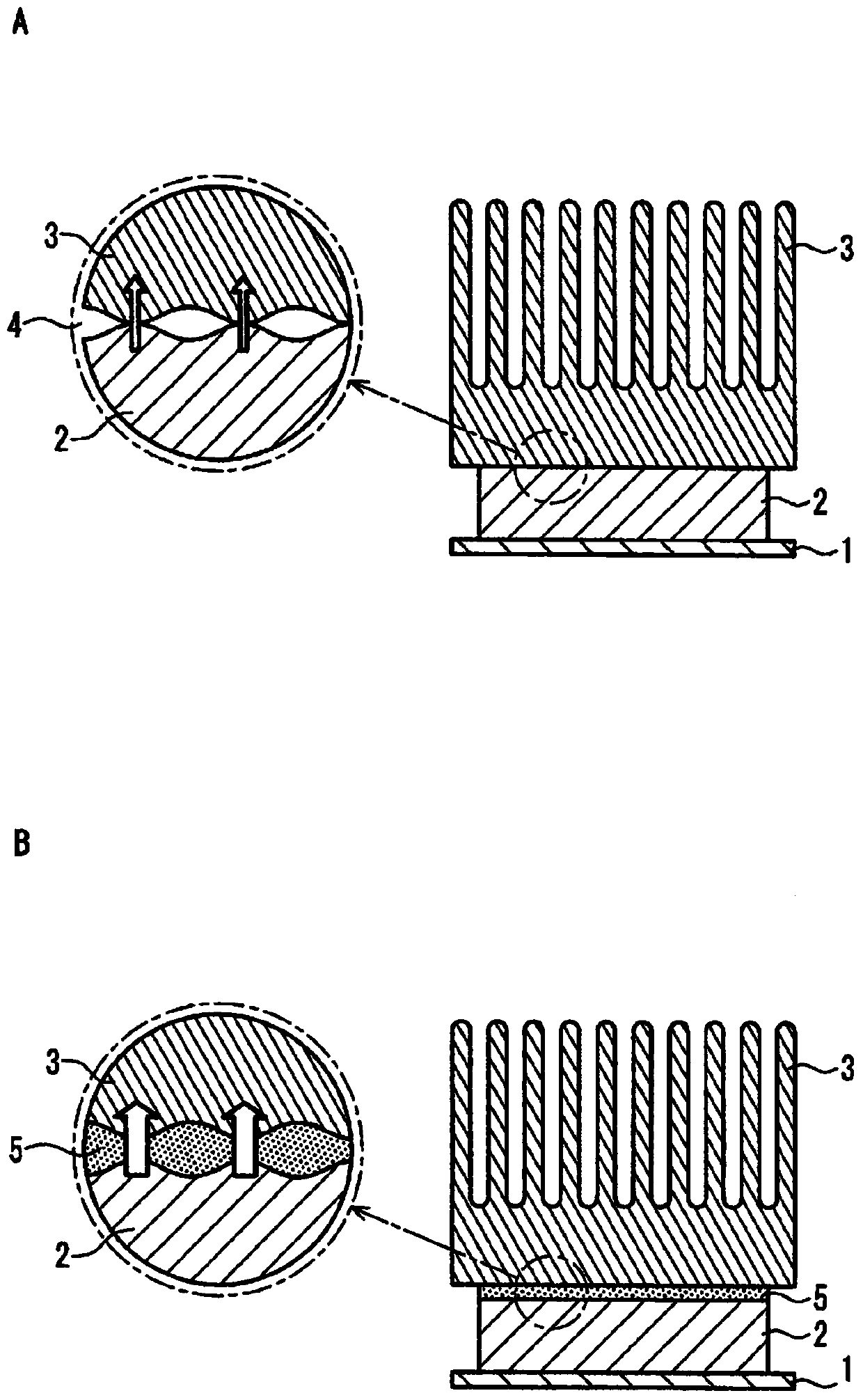

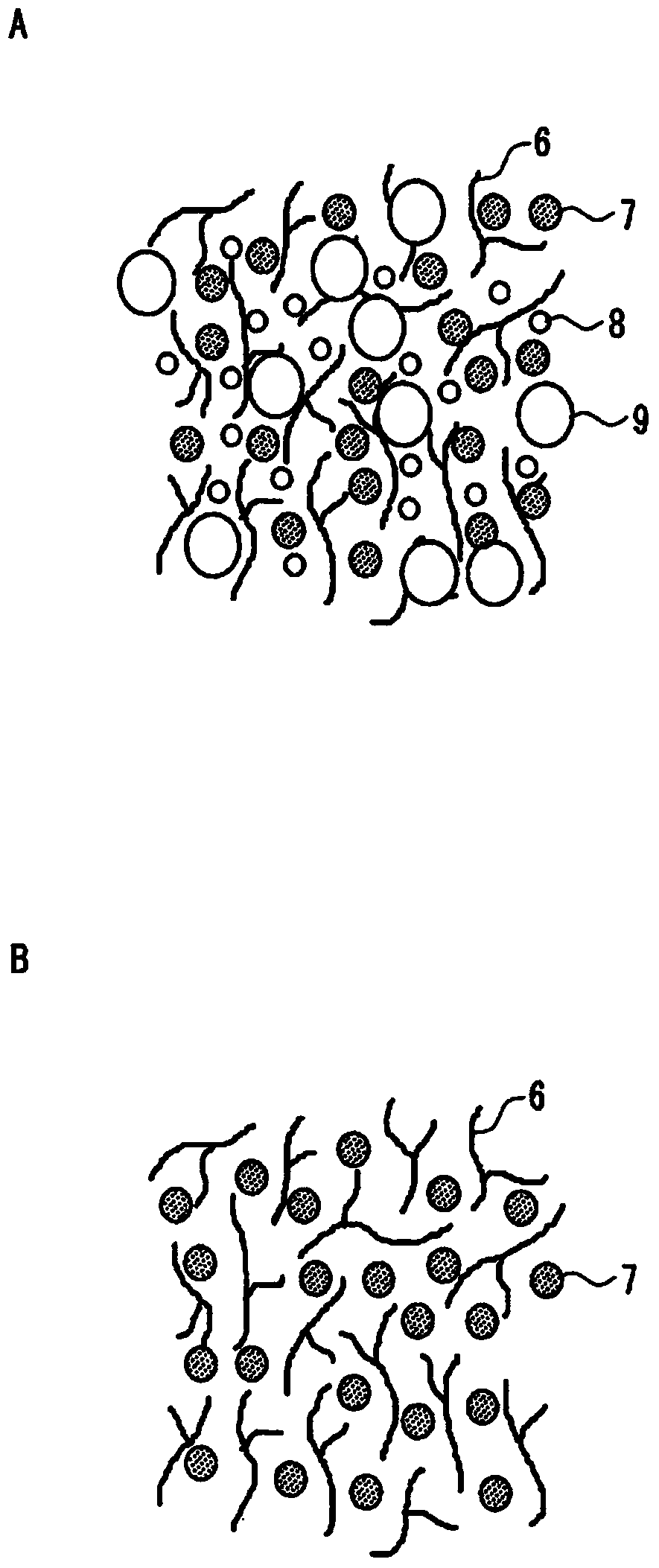

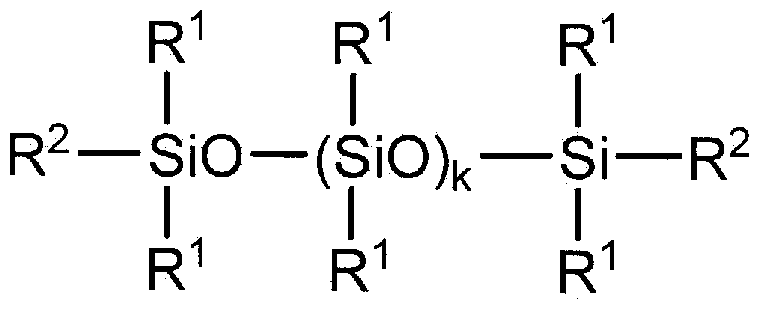

Putty-like heat transfer material and method for producing same

InactiveCN104136569AImprove liquidityEasy to squeeze outSemiconductor/solid-state device detailsSolid-state devicesParticulatesHydrogen atom

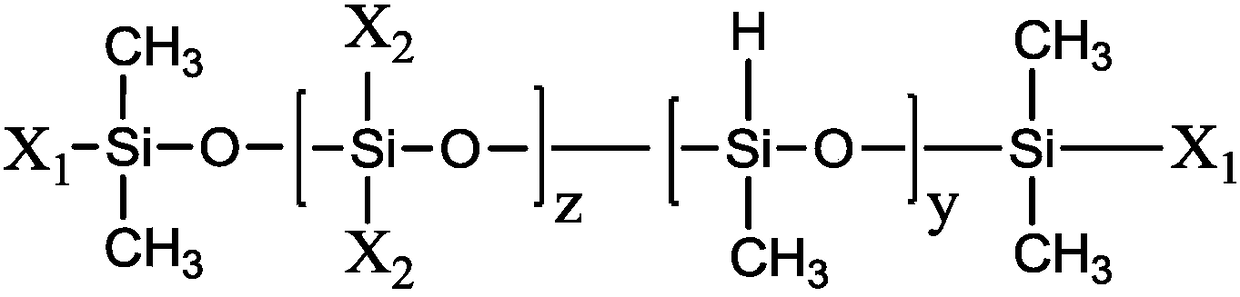

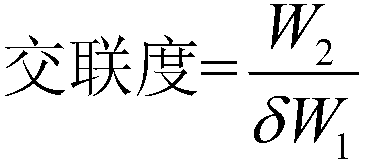

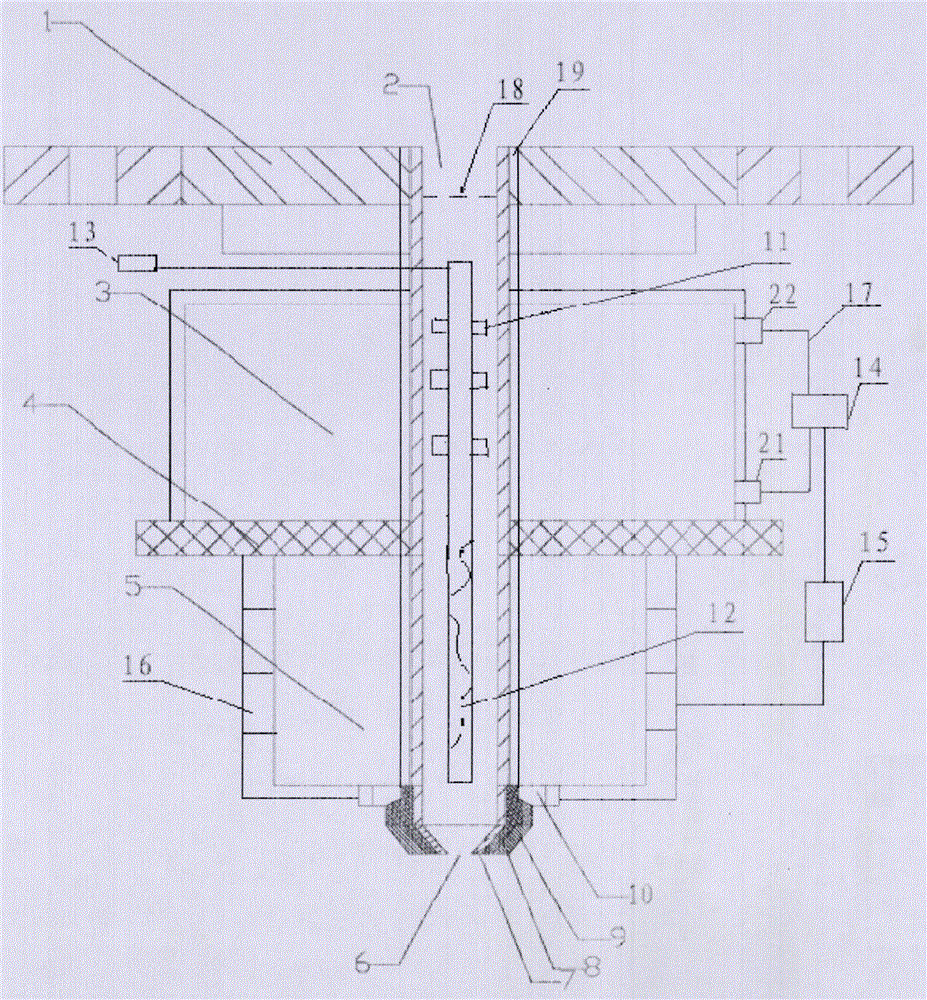

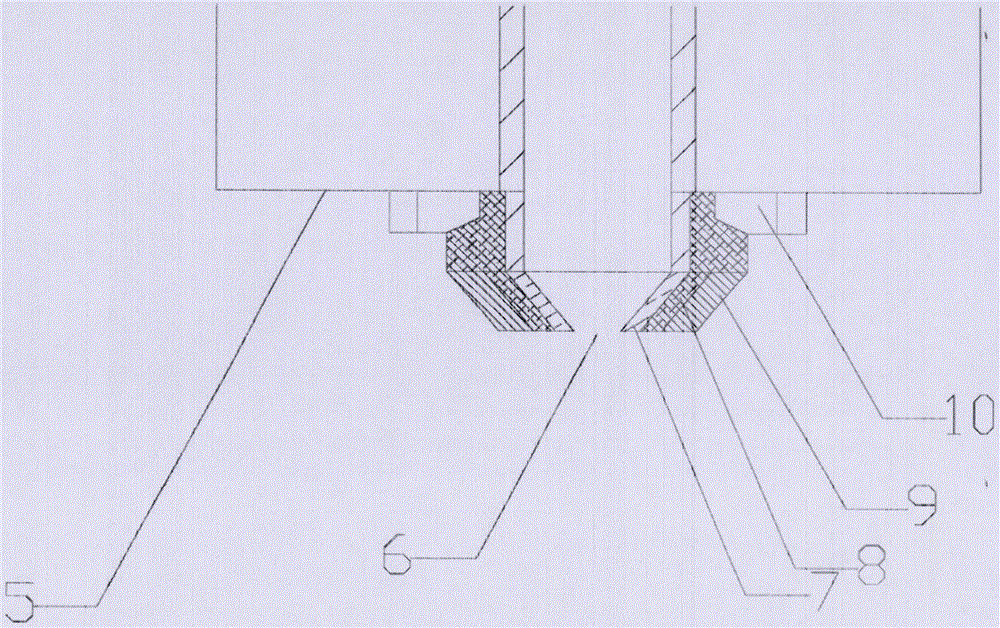

A putty-like heat transfer material according to the present invention comprises heat-conductive particles dispersed in an organopolysiloxane, wherein the organopolysiloxane is a silicone sol produced by partially crosslinking a base polymer (a) with a crosslinking component (b), wherein the base polymer (a) comprises an organopolysiloxane that contains at least two alkenyl groups each bound to a silicon atom located at the terminal of the molecular chain (also referred to as "silicon-atom-bound alkenyl groups") per molecule on average, the crosslinking component (b) comprises an organopolysiloxane that contains at least two hydrogen atoms each bound to a silicon atom per molecule on average, and the partial crosslinking is carried out at such a ratio that the amount of the crosslinking component (b) is less than 1 mole relative to 1 mole of the silicon-atom-bound alkenyl group contained in the component (a). Thus, provided are: a putty-like heat transfer material which can exhibit good fluidability even when an inorganic particulate filler is added in a larger amount, can be extruded through a tube or a syringe readily, and can have a self-shape-retaining property when being allowed to stand; and a method for producing the putty-like heat transfer material.

Owner:FUJI POLYMER INDUSTRIES CO LTD

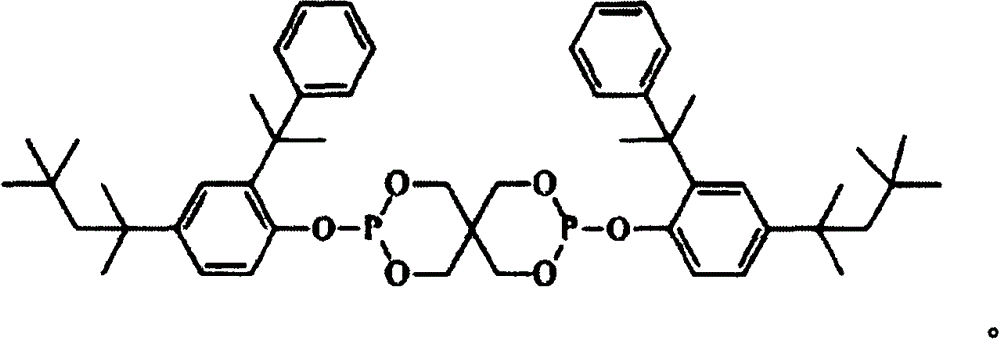

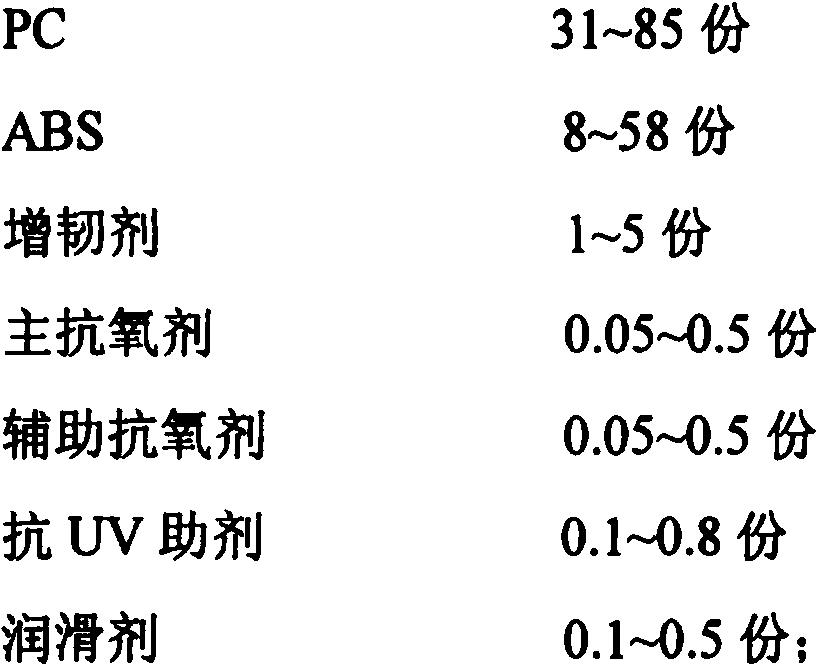

PC/ABS alloy with excellent weather resistance and preparation method of PC/ABS alloy

The invention relates to a PC / ABS alloy with excellent weather resistance. The PC / ABS alloy is prepared from the following components in parts by weight: 31-85 parts of PC, 8-58 parts of ABS, 1-5 parts of a toughening agent, 0.05-0.5 part of a main antioxidant, 0.05-0.5 part of an auxiliary antioxidant, 0.1-0.8 part of an anti-UV additive and 0.1-0.5 part of a lubricant. The PC / ABS alloy is prepared by putting the components into a high-speed mixing machine, sufficiently mixing, discharging out, further putting into a screw extruder, and extruding to pellet when controlling the rotation speed of the screw extruder to be 300-500rpm and the temperature to be 225-255 DEG C, so as to obtain a product. Compared with the prior art, the PC / ABS alloy is relatively good in synergistic effect as the toughening agent, the antioxidants and the anti-UV additive are used together, the weather resistance of the PC / ABS alloy is improved, the brittleness of the material is also effectively degraded, the toughness of the material is improved, and excellent mechanical property of the material is stilled maintained for a long time under the condition that the requirements on the weather resistance of the PC / ABS alloy are relatively high.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

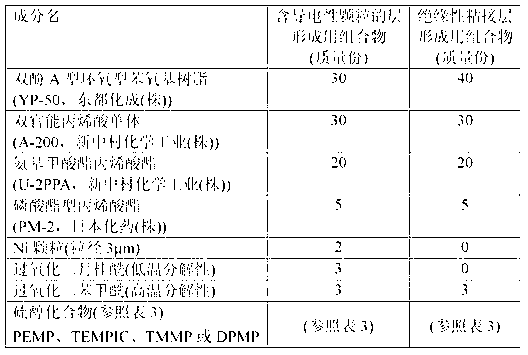

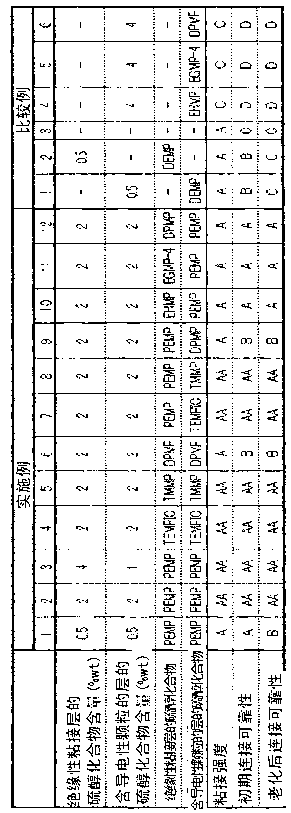

Anisotropic conductive film

ActiveCN102763283AHas captureEasy to squeeze outNon-insulated conductorsNon-macromolecular adhesive additivesAnisotropic conductive filmThiol

An anisotropic conductive film obtained by laminating an insulating adhesive layer that comprises a polymerizable acrylic compound, a film-forming resin and a polymerization initiator with a conductive-particle-containing layer that comprises a polymerizable acrylic compound, a film-forming resin, a polymerization initiator and conductive particles, wherein the insulating adhesive layer and the conductive-particle -containing layer each contain a thiol compound in order to further improve the reliability of connection without lowering the bond strength to an adherend. The thiol compound includes pentaerythritol tetrakis(3-mercaptopropionate), tris-[(3-mercaptopropionyloxy)-ethyl]-isocyanurate, trimethylol-propane tris(3-mercaptopropionate), dipentaerythritol hexakis(3-mercaptopropionate), and so on.

Owner:DEXERIALS CORP

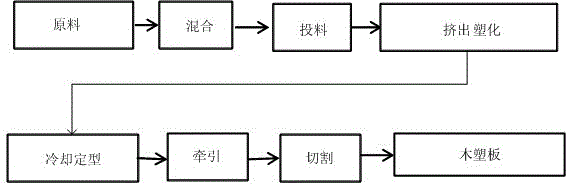

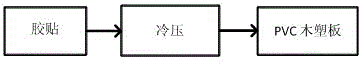

PVC wood plastic plate preparation process

InactiveCN105082719AImprove melt strengthPrevent thermal degradationSynthetic resin layered productsCellulosic plastic layered productsSodium bicarbonateWax

The present invention relates to a PVC wood plastic plate and preparation method therefor. The PVC wood plastic plate mainly comprises a PVC layer and a wood plastic plate layer. The PVC layer is prepared by the following raw materials: PVC resin, stone powder, DINP, epoxy soybean oil, and auxiliary materials; and the wood plastic plate is prepared by the following raw materials in parts by weight: 75 parts of PVC resin (8 type), 10 parts of wood powder, 8 parts of straws, 28 parts of light calcium carbonate, 2.8 parts of a Ca-Zn composite stabilizer, 0.75 part of a LG60 internal lubricant, 6 parts of a foaming regulator LP-90, 0.35 parts of PE wax, 0.45 parts of an AC foaming agent, 3 parts of CPE, 4 parts of a JM01 reinforcing agent, and 0.6 parts of sodium bicarbonate; The PVC wood plastic plate prepared by the preparation process provided by the present invention is low in cost, environment friendly, high in tensile strength, good in thermal resistance, good in wear resistance, less susceptible to deformation, and good in flame retardancy.

Owner:JIANGSU KENTIER WOOD

TPE (thermoplastic elastomer) material for signal transmission line and preparation method of TPE material

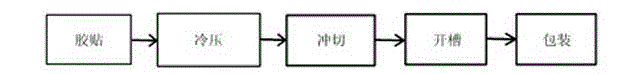

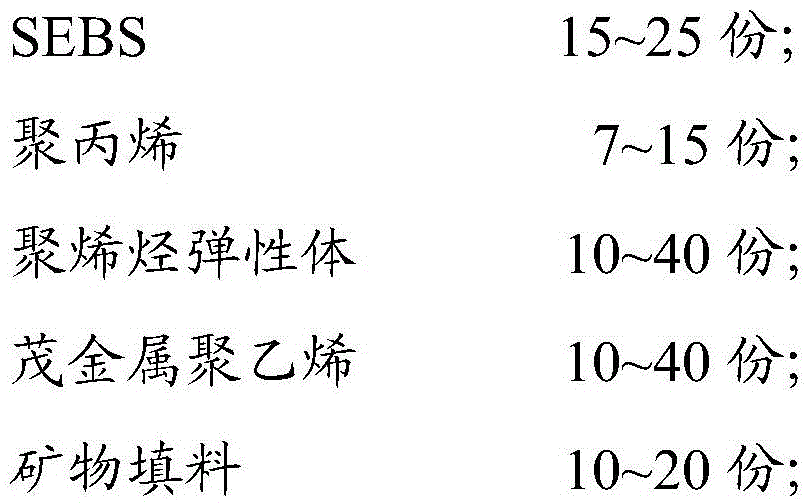

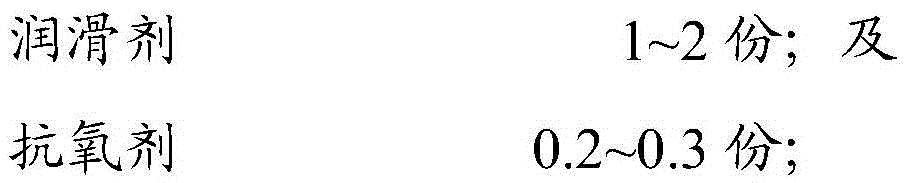

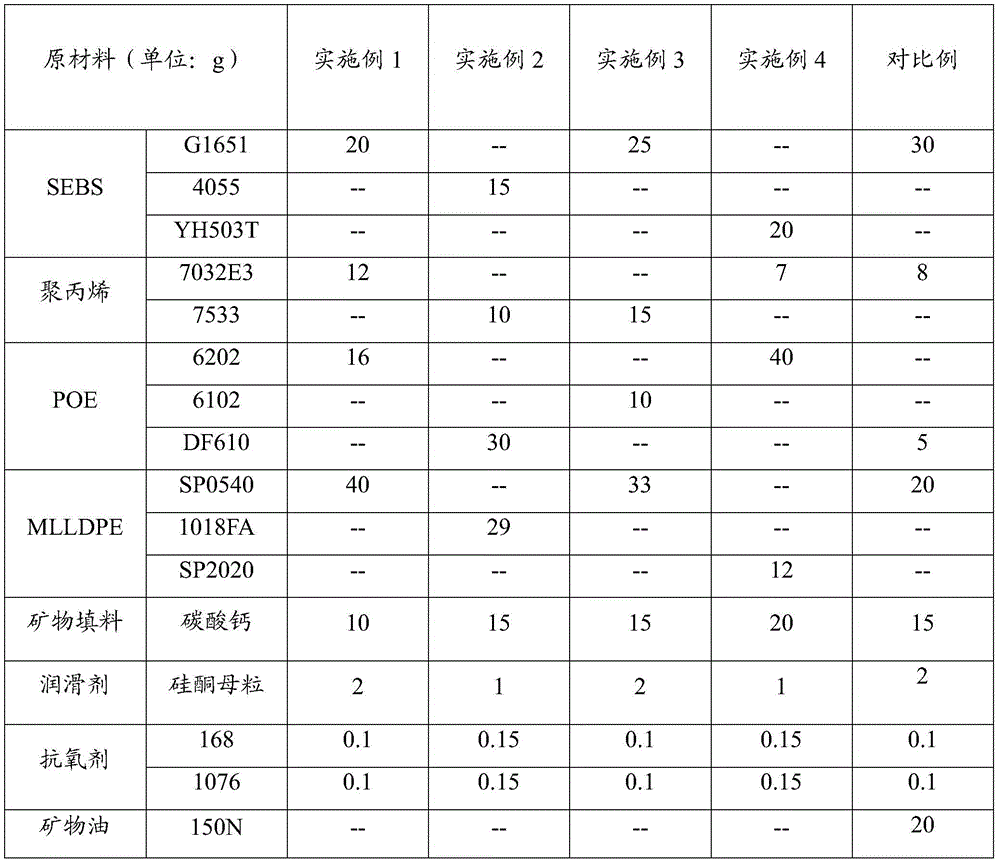

The invention relates to a TPE (thermoplastic elastomer) material for a signal transmission line and a preparation method of the TPE material. The TPE material for the signal transmission line comprises components in parts by weight as follows: 15-25 parts of SEBS (styrene-ethylene-butylene-styrene), 7-15 parts of polypropylene, 10-40 parts of polyolefin elastomer, 10-40 parts of metallocene polyethylene, 10-20 parts of mineral filler, 1-2 parts of a lubricant and 0.2-0.3 parts of an antioxidant, wherein the TPE material for the signal transmission line does not contain paraffin oil. Compared with a traditional TPE material system for wire materials, the TPE material is free of mineral oil and avoids an oil outlet phenomenon, the prepared elastomer material is easy to extrude at low temperature, and further, the extruded wire material is not prone to yellowing, has smooth hand feeling and dry and clean surface and is not sticky and dust-adsorbing.

Owner:SUNGALLON PLASTICS SHENZHEN CO LTD

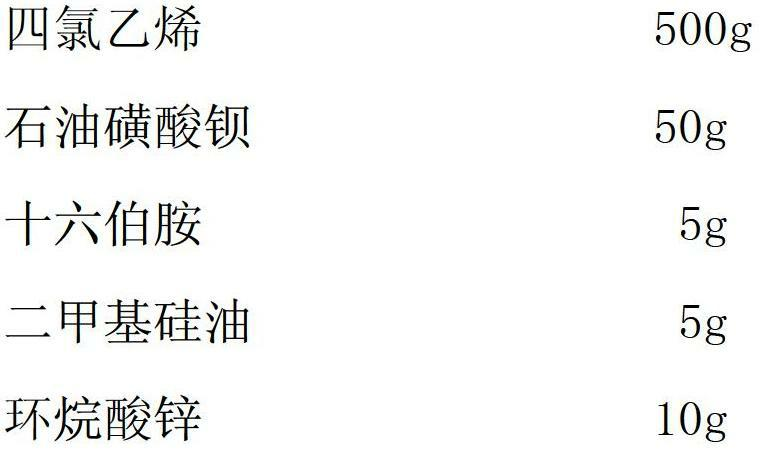

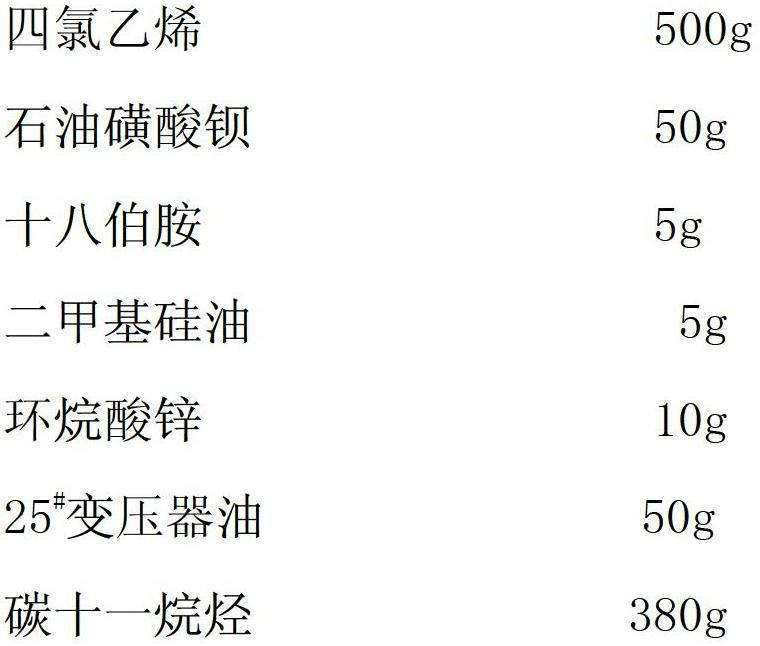

Electric equipment moisture resistance, corrosion resistance and insulation protection agent and preparation method thereof

The invention relates to an electric equipment moisture resistance, corrosion resistance and insulation protection agent and a preparation method thereof. The protection agent contains the raw materials by weight percentage: 20-50 percent of tetrachloroethylene, 1-10 percent of rust inhibitor, 0.1-1 percent of dehydrating agent, 0.5-2 percent of film-forming agent, 5-10 percent of transformer oil and the balance of hydrocarbonic solvent. After being sprayed on a piece of electric equipment, the protection agent can not only remove the moisture and the damp on the electric equipment, but also form a half-dry protective film on the surface of the electric equipment, and the protective film does not hamper the connection of the circuit of the equipment. The protective film protects the electric equipment against the encroachment of damp and corrosive gases and can improve the insulation intensity of the electric equipment. The protective film can endure the voltage of 20KV and can be used when the electric equipment is in work. The invention has simple and scientific action mechanism, and through the reasonable combination such as the solvent, the dehydrating agent, the rust inhibitor and the film-forming agent, the protection agent reaches the functions of dispersing water, resisting damp and corrosion and improving the insulation intensity of the electric equipment.

Owner:华阳新兴科技(天津)集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com