Multi-component silicone sealant and preparation method thereof

A silicone sealant, multi-component technology, applied in the field of sealants, can solve the problem that the single-component silicone sealant cannot meet the needs of quick processing of doors and windows, etc., and achieves convenient color matching, easy mixing, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

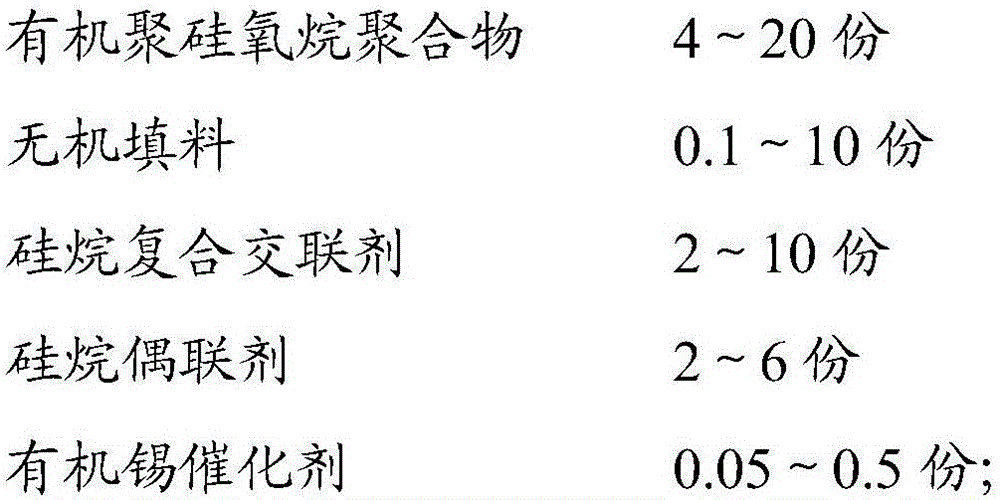

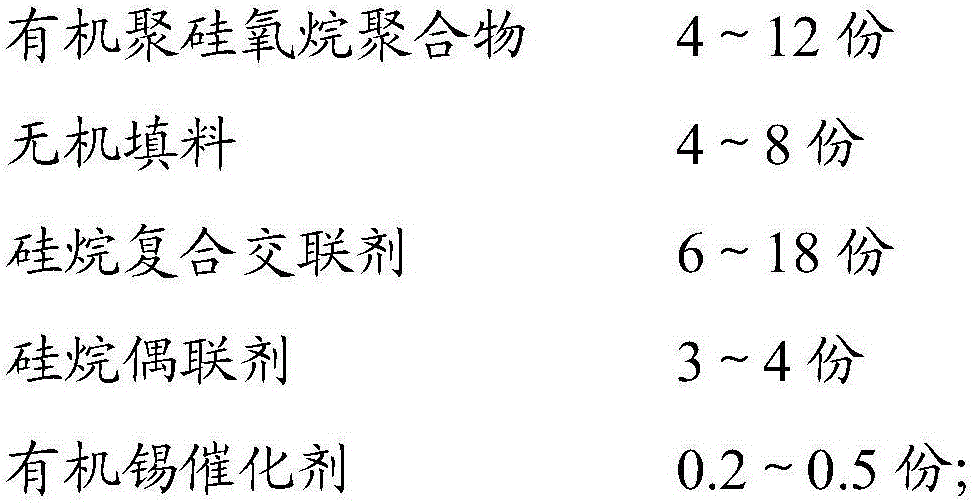

[0061] The multi-component silicone sealant of this embodiment is composed of component A, component B and component C, and the preparation raw materials of each component are as follows (in parts by weight):

[0062] Component A: 90 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 12000 mPa.s, 10 parts of simethicone oil with a viscosity of 100 mPa.s, and 100 parts of nano-active calcium carbonate.

[0063] Component B: 4 parts of simethicone oil with a viscosity of 1000mPa.s, 2 parts of nano-active calcium carbonate, 2 parts of heavy calcium carbonate, 3 parts of tetrabutylketoxime silane, 3 parts of dimethyl dibutylketoxime silane 2 parts of γ-aminopropyltriethoxysilane, 1 part of γ-glycidyloxypropyltrimethoxysilane, and 0.2 part of dibutyltin dilaurate.

[0064] Component C: 6 parts of simethicone oil with a viscosity of 350 mPa.s, 2 parts of carbon black, and 2 parts of fluorosilicone defoamer.

[0065] The preparation method of the multi-component silicone...

Embodiment 2

[0072] The multi-component silicone sealant of this embodiment is composed of component A, component B and component C, and the preparation raw materials of each component are as follows (in parts by weight):

[0073] Component A: 100 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 6000 mPa.s, 80 parts of nano-active calcium carbonate, 40 parts of heavy calcium carbonate, and 0.5 part of polyamide wax.

[0074] Component B: 12 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 1500mPa.s, 8 parts of nano-active calcium carbonate, 2 parts of tetrabutylketoxime silane, vinyl tributylketoxime silane 3 parts, 3 parts of methylvinyl dibutylketoxime silane, 3 parts of γ-aminopropyl trimethoxysilane, 1 part of epoxycyclohexyl triethoxysilane, 0.2 part of dibutyltin diacetate.

[0075] Component C: 8 parts of dimethyl silicone oil with a viscosity of 1000 mPa.s, 3 parts of iron oxide red, and 1 part of fluorosilicone defoamer.

[0076] The preparation me...

Embodiment 3

[0083] The multi-component silicone sealant of this embodiment is composed of component A, component B and component C, and the preparation raw materials of each component are as follows (in parts by weight):

[0084] Component A: 100 parts of trimethoxy-terminated polydimethylsiloxane with a viscosity of 20000 mPa.s, 70 parts of nano-active calcium carbonate, 50 parts of silicon micropowder, and 0.6 part of polypropylene glycol.

[0085] Component B: 12 parts of simethicone oil with a viscosity of 12000mPa.s, 6 parts of nano-active calcium carbonate, 4 parts of phenyltributanoximinosilane, and 3 parts of methylvinylbis(N-methylacetamido)silane 3 parts of N-β-aminoethyl-γ-aminopropyltriethoxysilane, 1 part of epoxycyclohexyltriethoxysilane, and 0.2 parts of dibutyltin bis(β-diketone ester).

[0086] Component C: 10 parts of dimethyl silicone oil with a viscosity of 1000 mPa.s, 2 parts of carbon black, 2 parts of orange red, and 2 parts of fluorosilicone defoamer.

[0087] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com