Ceramic tile with function of imitating effect of black galaxy marble, and production technology thereof

A production process, marble technology, applied in construction, building construction, covering/lining, etc., can solve the problems of wet tile surface, low tile service life, etc., to achieve uniform structure, guaranteed service life, and extremely high linear expansion coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

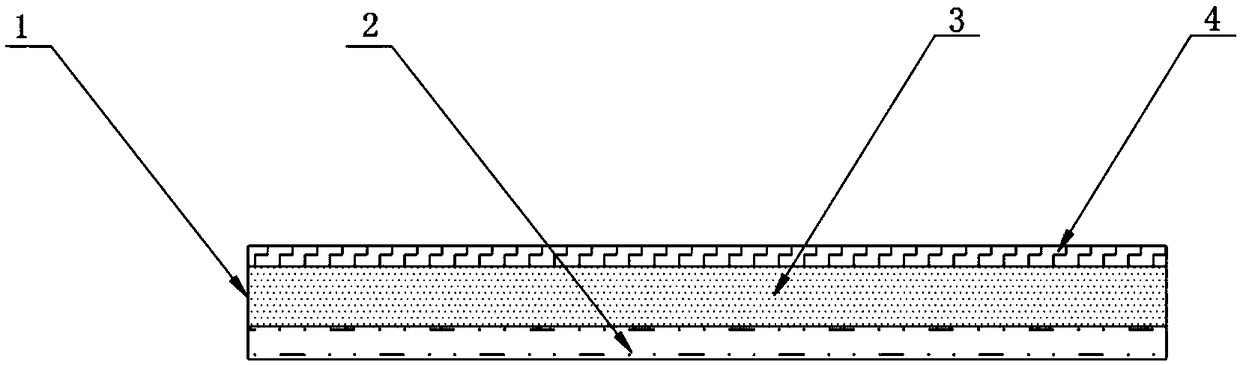

[0023] The present invention provides such figure 1 A ceramic tile with imitation black gold sand marble effect shown includes a main body 1. The main body 1 includes a bottom base layer 2, a middle connection layer 3 and a smooth surface layer 4. The bottom base layer 2 is arranged at the bottom of the inner wall of the main body 1. The top of the bottom base layer 2 is provided with a middle connection layer 3 , and the top of the middle connection layer 3 is provided with a smooth surface layer 4 .

[0024] The molar hardness of the main body is 5-6, and the density is 2.63g / cm 3 -2.80g / cm 3 , the compressive strength is 150-330Mpa, and the bending strength is 15-35Mpa.

[0025] The middle connection layer 3 includes silica sol, adhesive and filler.

[0026] The present invention also provides a ceramic tile production process imitating black gold sand marble effect, and its specific steps are:

[0027] Step 1: firing the marble base stone at a firing temperature of 800...

Embodiment 2

[0031] Embodiment two, different from embodiment one is:

[0032] The present invention also provides a ceramic tile production process imitating black gold sand marble effect, and its specific steps are:

[0033] Step 1: firing the marble base stone at a firing temperature of 1400° C. for a firing time of 4 hours, and polishing and polishing with an edger and a grinder to obtain the bottom base layer 2;

[0034] Step 2: Mix black gold sand, clay, and quartz sand together and grind them together. The components of black gold sand, clay, and quartz sand are: 30 parts of black gold sand, 15 parts of clay, and 30 parts of quartz sand. Add 10 parts of zirconium silicate and 3 parts of thickener, and then press it. After the pressing is completed, apply the top glaze on the green body. After applying the top glaze, print the flashing glaze with a screen printing machine, and then fire it at a high temperature of 1400 ° C. Make the surface smooth layer 4, after the surface smooth l...

Embodiment 3

[0037] Embodiment three, different from embodiment one and embodiment two is:

[0038] The present invention also provides a ceramic tile production process imitating black gold sand marble effect, and its specific steps are:

[0039] Step 1: firing the marble base stone at a firing temperature of 1100° C. for 5 hours, and polishing and polishing with an edger and a grinder to obtain the bottom base layer 2;

[0040] Step 2: Mix black gold sand, clay, and quartz sand together and then grind them. The components of black gold sand, clay, and quartz sand are: 25 parts of black gold sand, 15 parts of clay, and 33 parts of quartz sand. Add 8 parts of zirconium silicate and 5 parts of thickener, and then press it. After the pressing is completed, spread the top glaze on the green body. After the top glaze is applied, the flashing glaze is printed by a screen printing machine, and then fired at a high temperature of 1300 ° C. Make the surface smooth layer 4, after the surface smoot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com