Patents

Literature

194results about "Cobalt carbonates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cathode material for lithium secondary battery and method of producing same

InactiveUS20060121350A1Stable supplyImprove sinterabilityOxygen/ozone/oxide/hydroxideElectrode manufacturing processesElectrical batteryPhysical chemistry

Stable supply of a cathode material for a lithium secondary battery that exels in sinterbility and composition stability and can exhibit satisfactory battery performance is accomplished by reducing to 100 ppm or less both the contents of Na and S being impurity elements in multiple oxides as materials for a cathode material for a lithium secondary battery and carbonic salts as precursor materials for the production of a cathode material for a lithium secondary battery.

Owner:NIKKO MATERIALS CO LTD

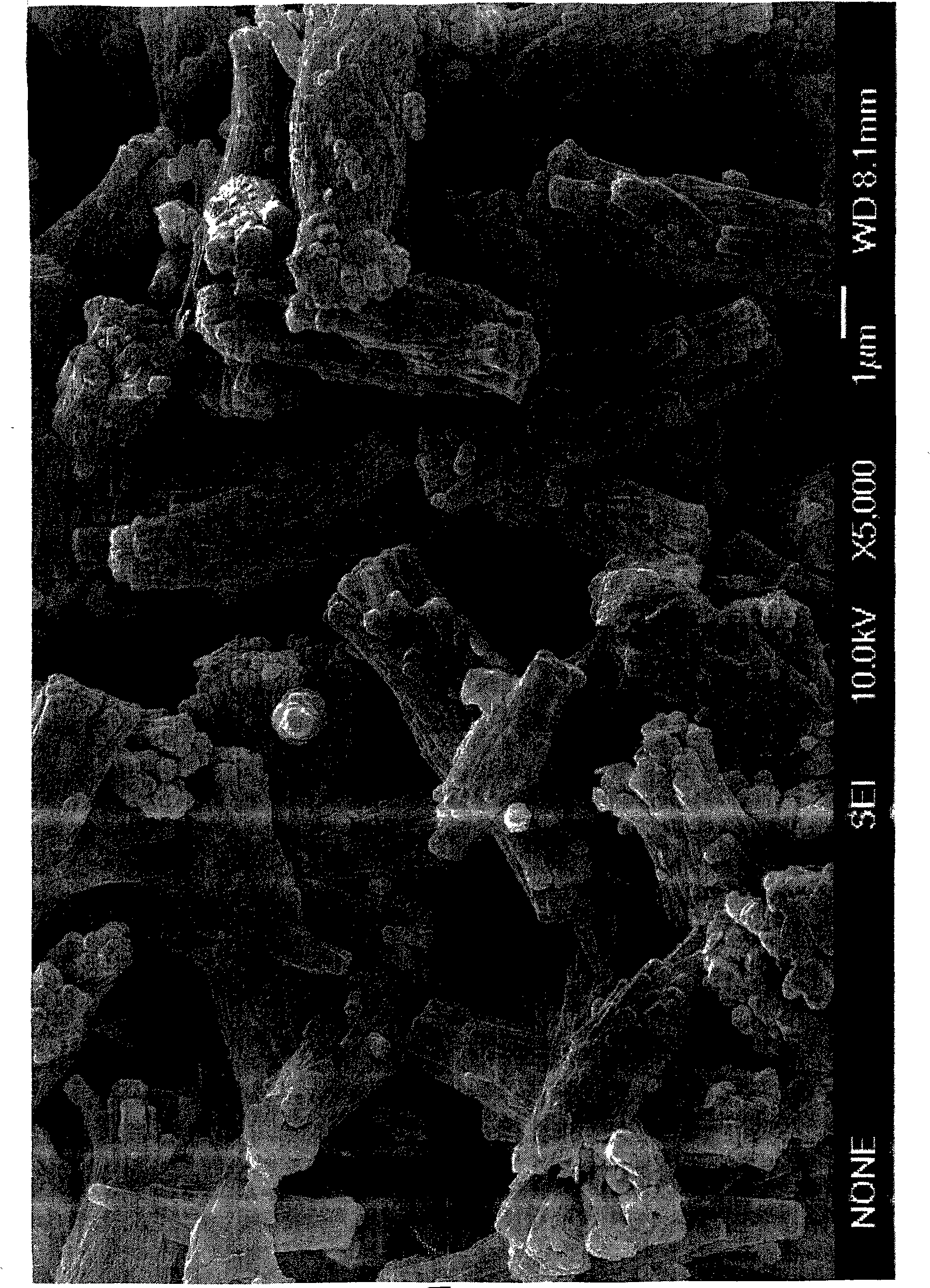

Preparation technology for spherical lithium cobalt oxide doped with Ti, Mg and Al

InactiveCN102583585ASimple processReaction is easy to controlCell electrodesCobalt carbonatesSlurryCarbonate

The invention relates to the field of lithium ion battery materials and particularly relates to a preparation technology for spherical lithium cobalt oxide doped with Ti, Mg and Al. According to the preparation technology, pure water serves as base solution under the conditions that temperature ranges from 40 DEG C to 80 DEG C and a stirring speed is controlled to 60-180 r / min, ammonium bicarbonate is added into the base solution to adjust the alkalinity of the base solution to range from 5 to 30, cobalt-salt mixed solution and ammonium bicarbonate solution are continuously pumped into the base solution in parallel flow and are subjected to sedimentation reaction under the temperature of 40-80 DEG C, the solid content and the alkalinity of slurry in a reaction system are controlled, reaction feed liquid flows out continuously from an overflow gate at the upper part of a reaction kettle to enter into an ageing kettle and then is washed by a washing press and dried by a vacuum drier, spherical cobalt carbonate is subjected to primary calcination to obtain cobaltosic oxide, and the cobaltosic oxide and a lithium source are subjected to secondary calcination to obtain the spherical lithium cobalt oxide doped with Ti, Mg and Al. According to the invention, the process is simple, the reaction is easy to control, the production cost is low, the product application range is wide, and thus, the method is relatively large in production value; and the spherical lithium cobalt oxide is stable in performance and better in overcharging prevention performance.

Owner:ANHUI ALAND NEW ENERGY MATERIALS

Method for producing fine spherical particles of carbonate or hydroxide of nickel, cobalt or copper

InactiveUS6197273B1Amino compound purification/separationOxide/hydroxide preparationSal ammoniacCobalt metal

The invention provides a process for production of fine spherical particles of a carbonate or a hydroxide of nickel, cobalt or copper which comprises: dissolving a carbonate or a hydroxide of nickel, cobalt or copper having the general formula (I)wherein M represents Ni, Co or Cu, and x and y are numerals satisfying the followings: 0<=x<=2, 0<=y<=2 and x+y=2, in aqueous ammonia, converting the resulting solution to a W / O emulsion containing droplets of the solution in a non-aqueous medium, and then removing volatile components including ammonia from within the droplets, thereby precipitating a basic carbonate or a hydroxide of a metal selected from nickel, cobalt and copperin the droplets.The fine spherical particles of a carbonate or a hydroxide of nickel, cobalt or copper obtained according to the process of the invention are especially useful as a precursor for the manufacture of uniform, fine spherical particles of nickel, copper or cobalt metal, as well as useful as themselves as a catalyst for use in organic synthesis, a carrier, a pigment, a filler or a glaze.

Owner:SAKAI CHEM IND CO LTD

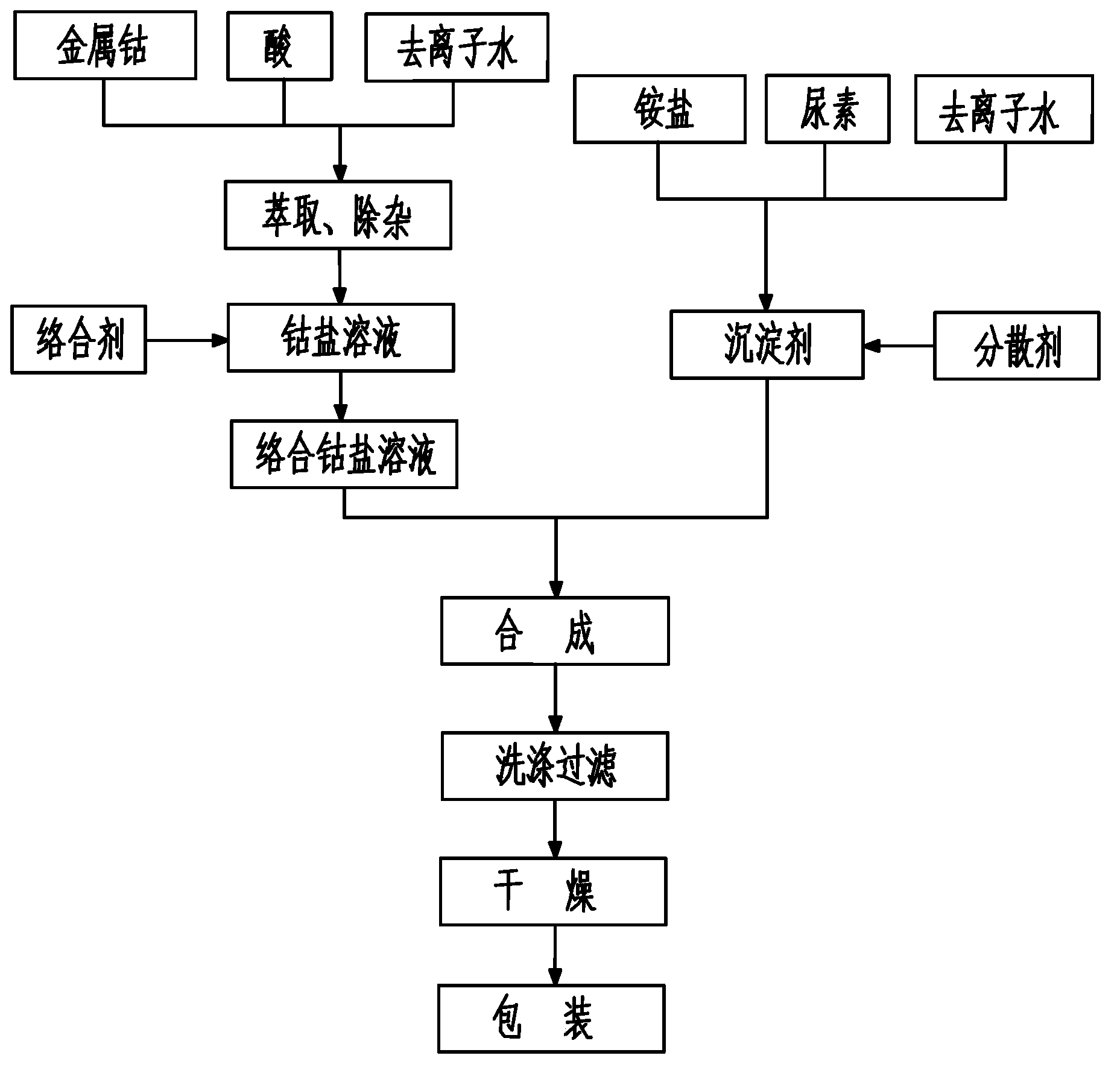

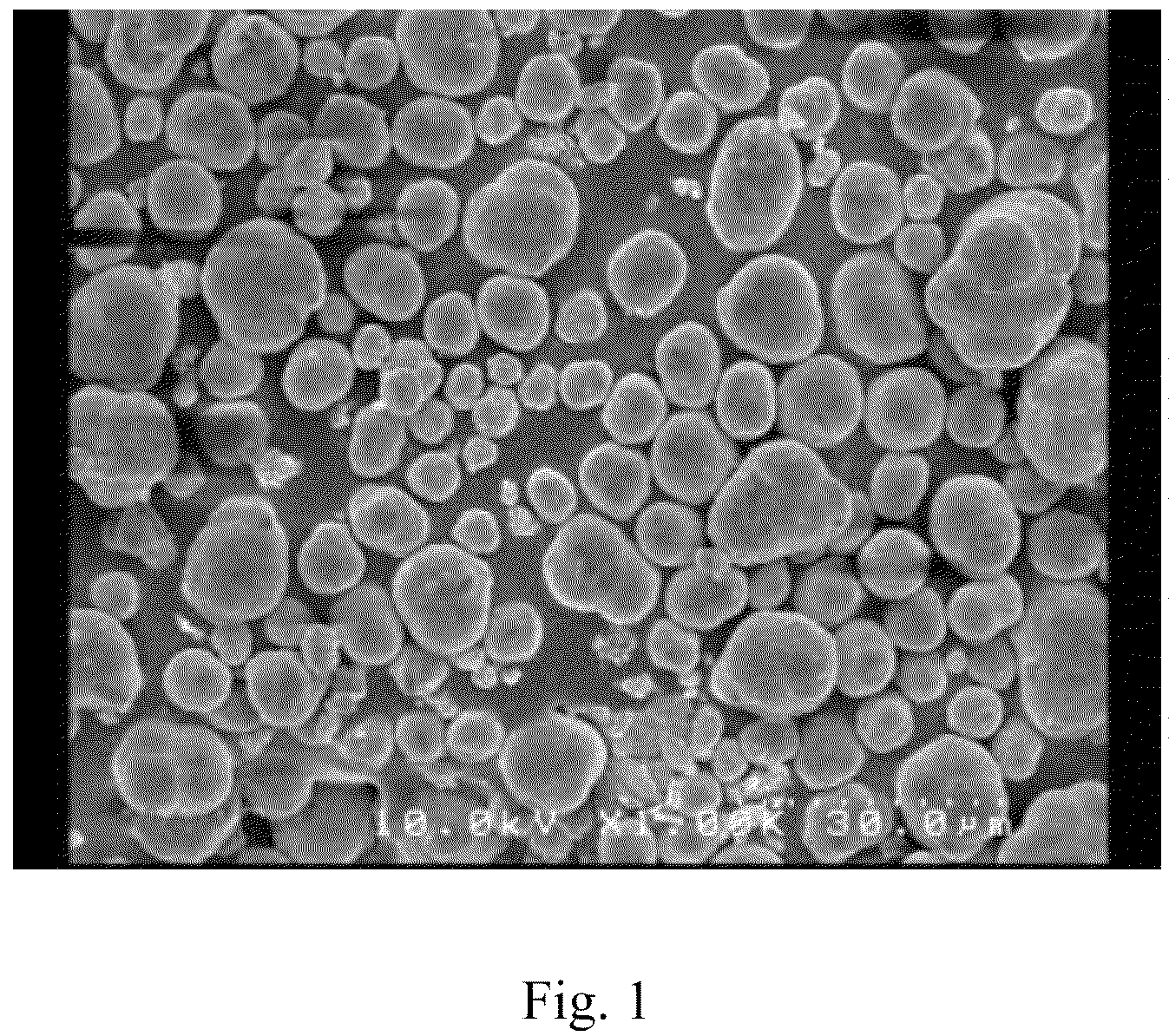

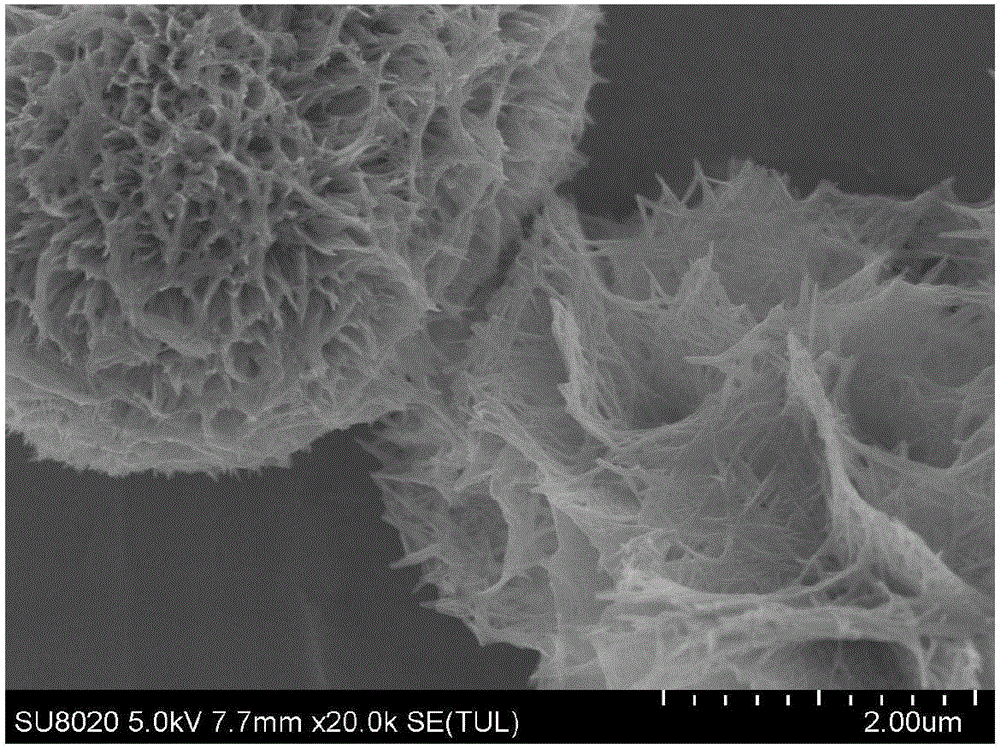

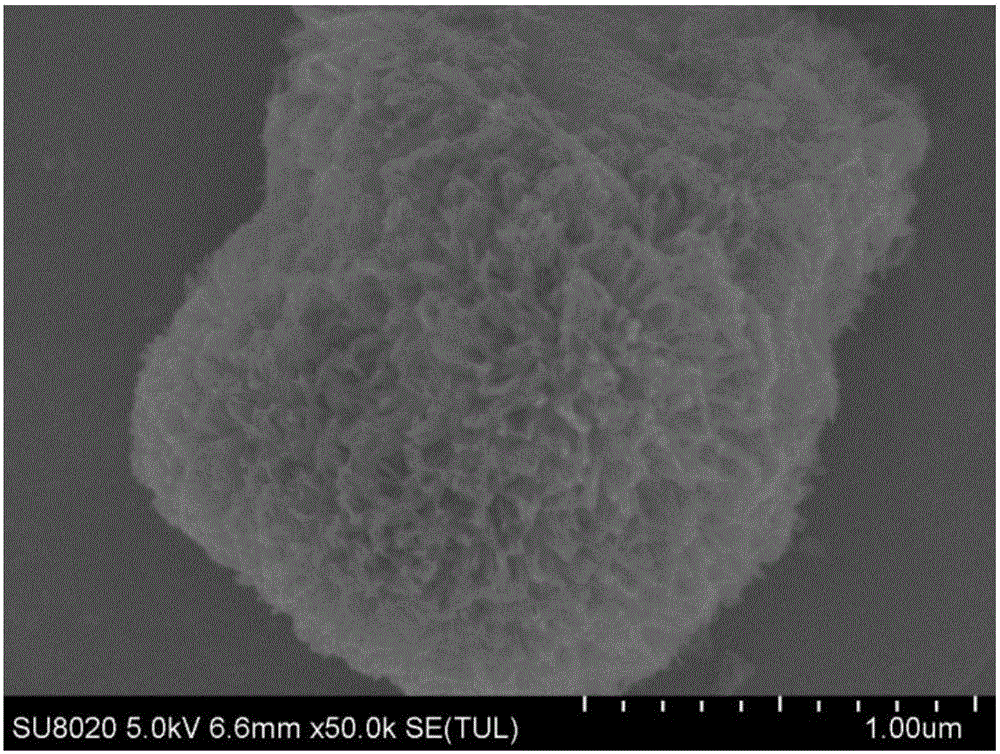

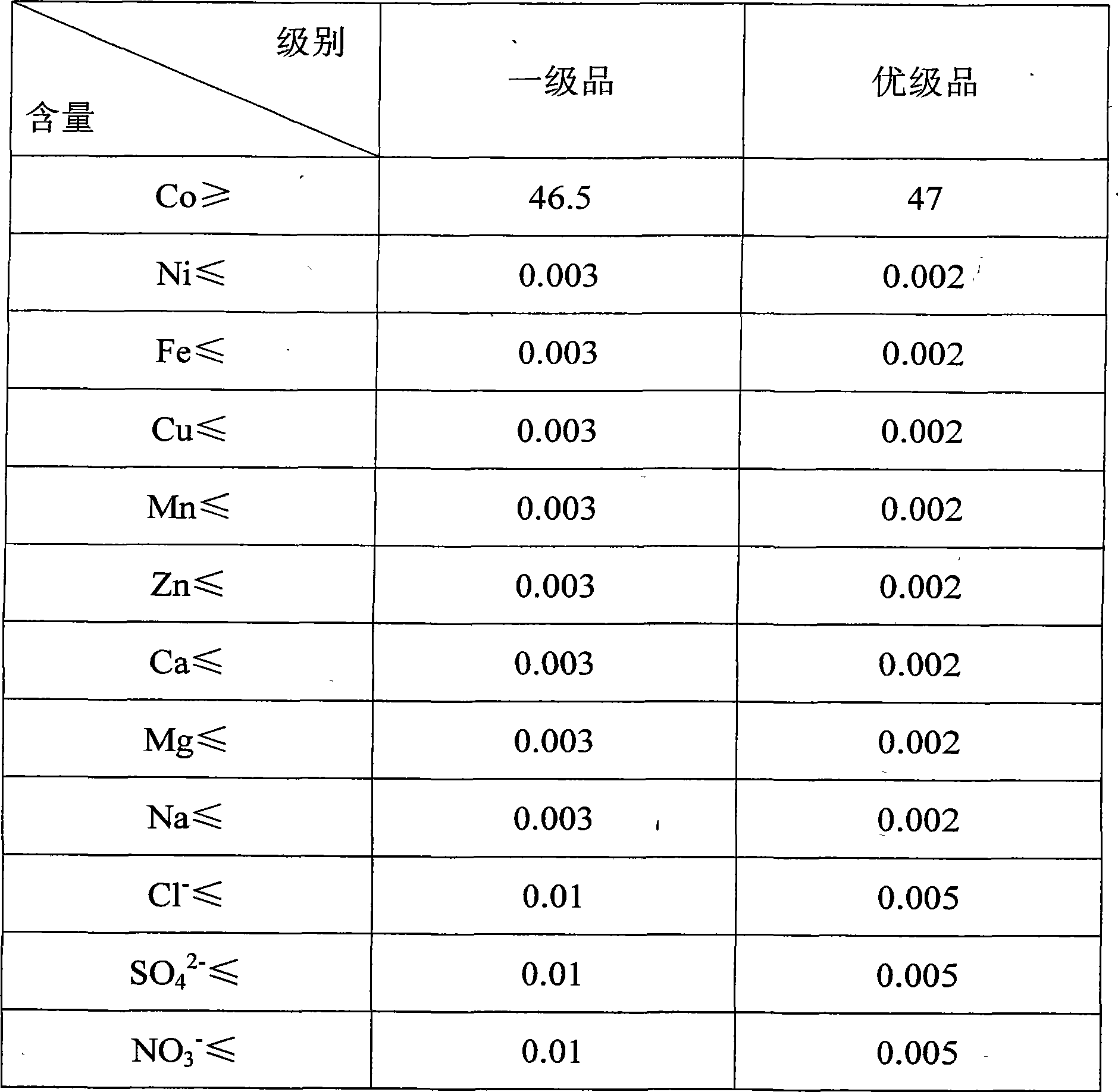

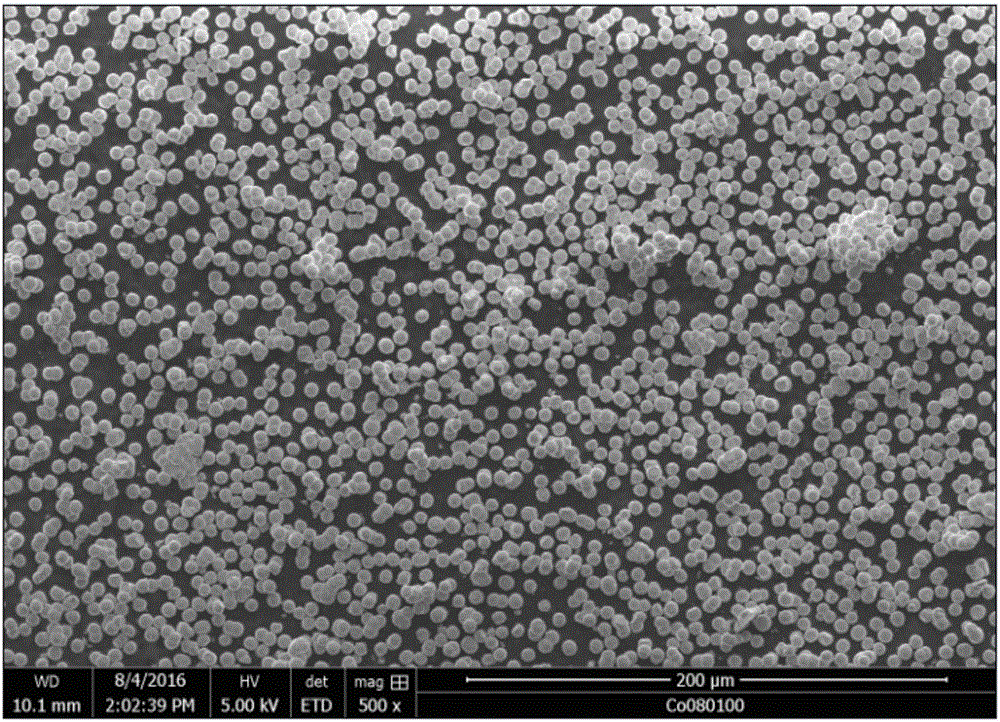

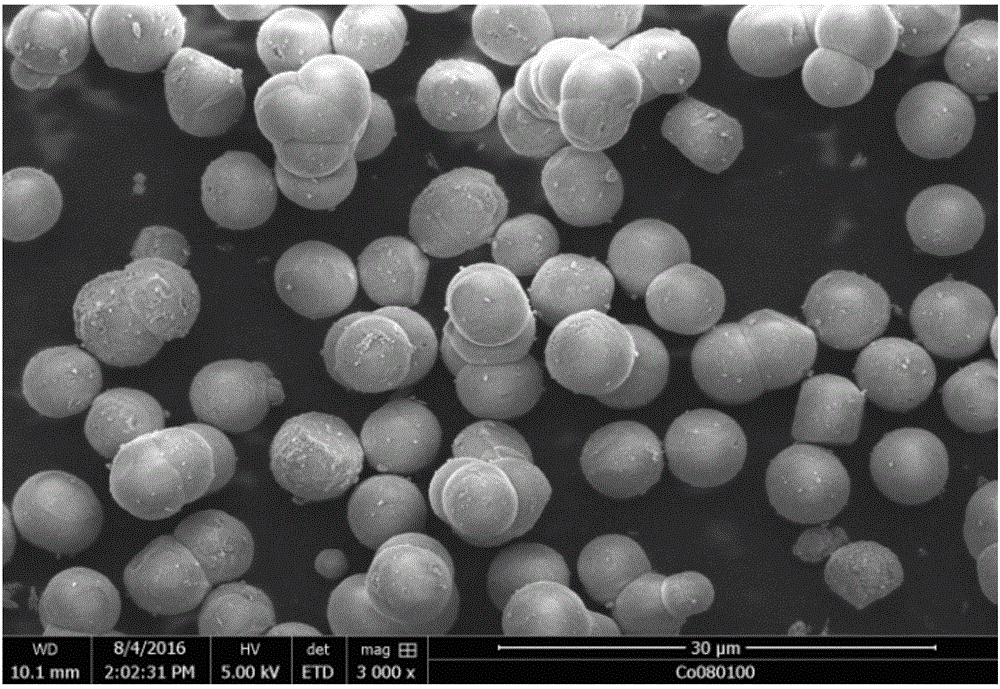

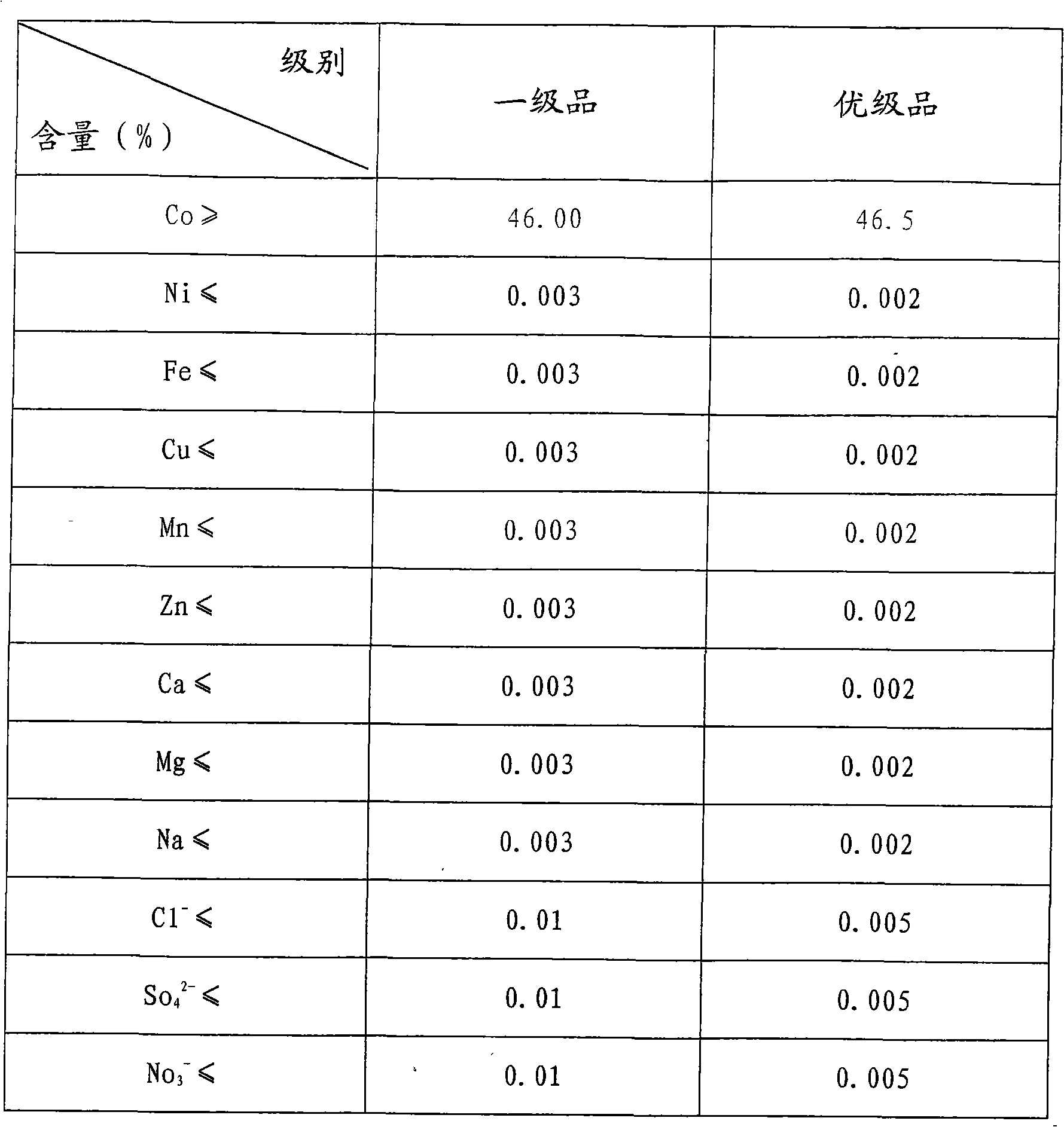

Preparation method of high-purity superfine spherical cobalt carbonate

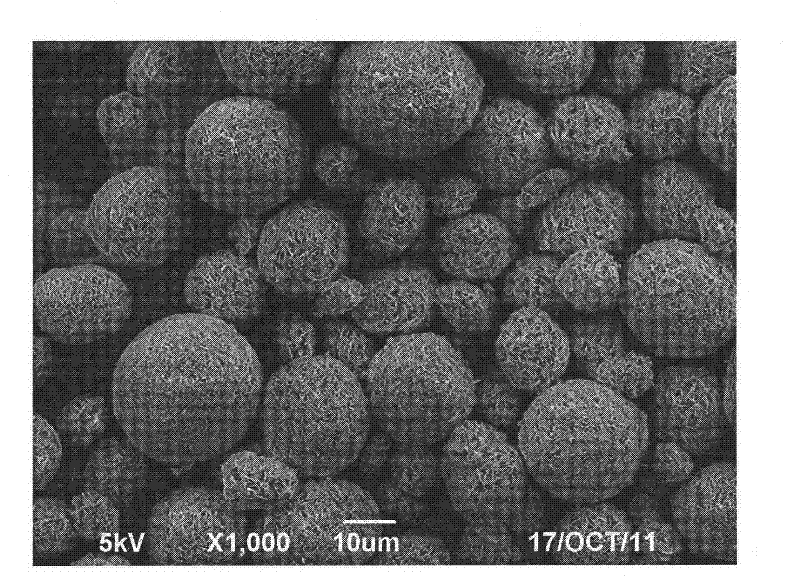

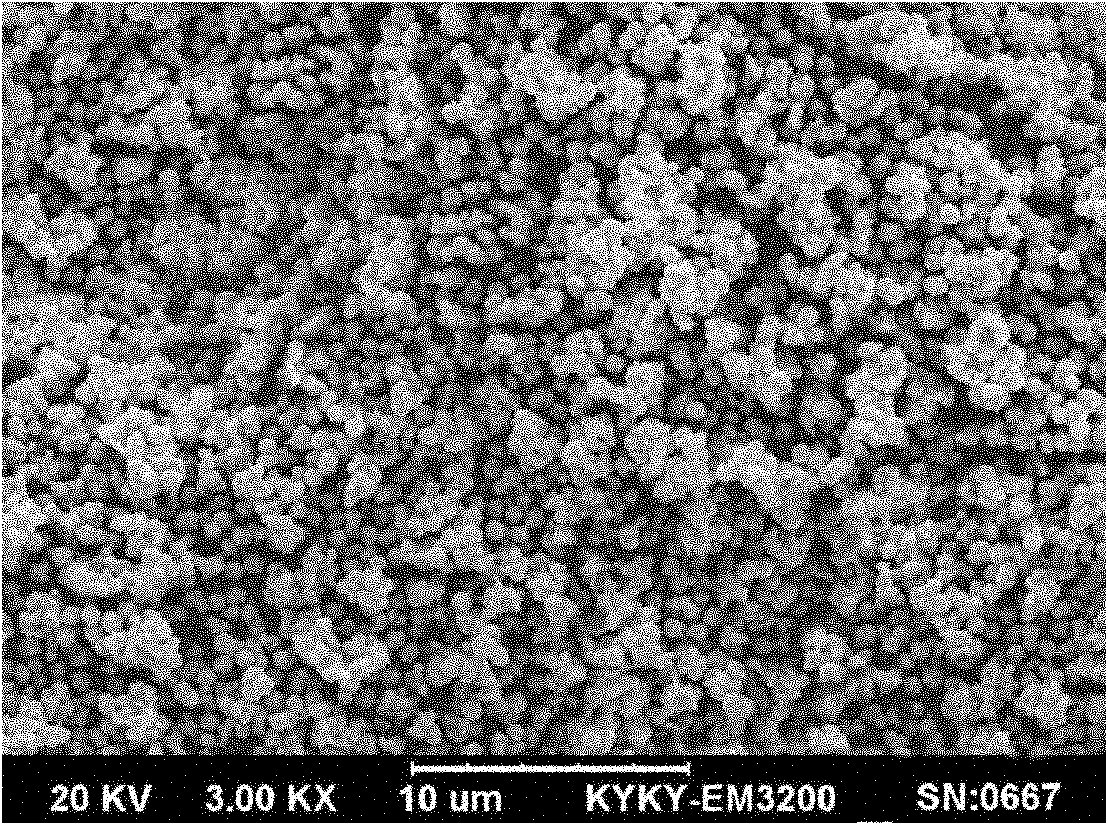

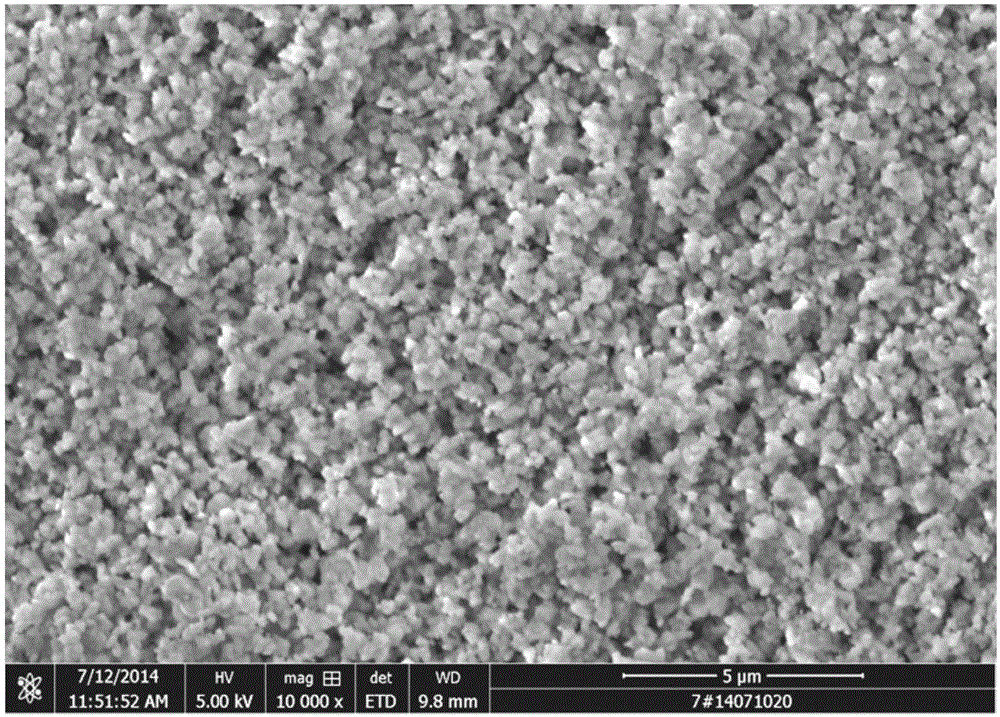

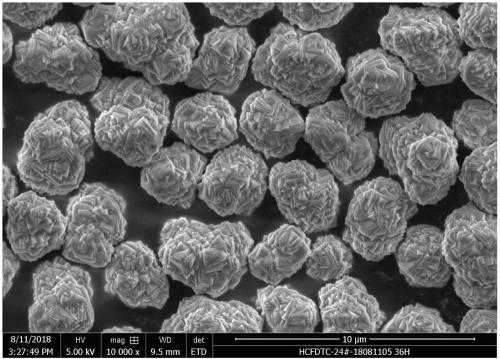

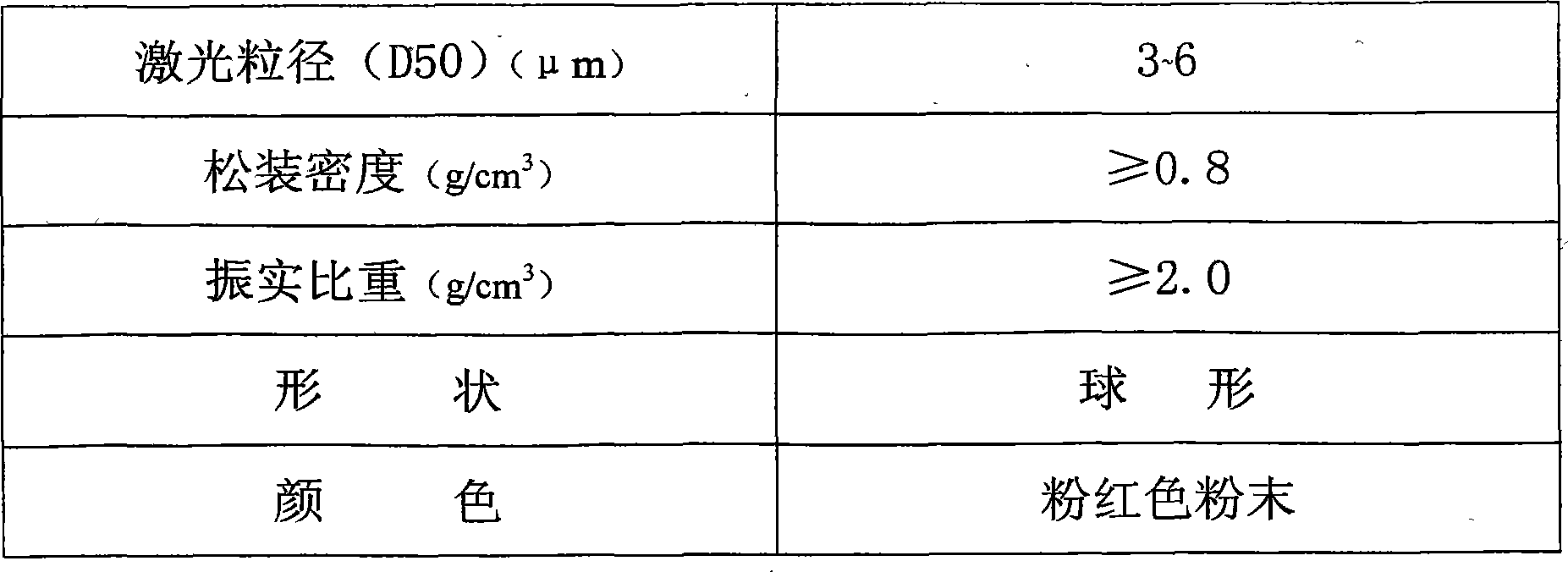

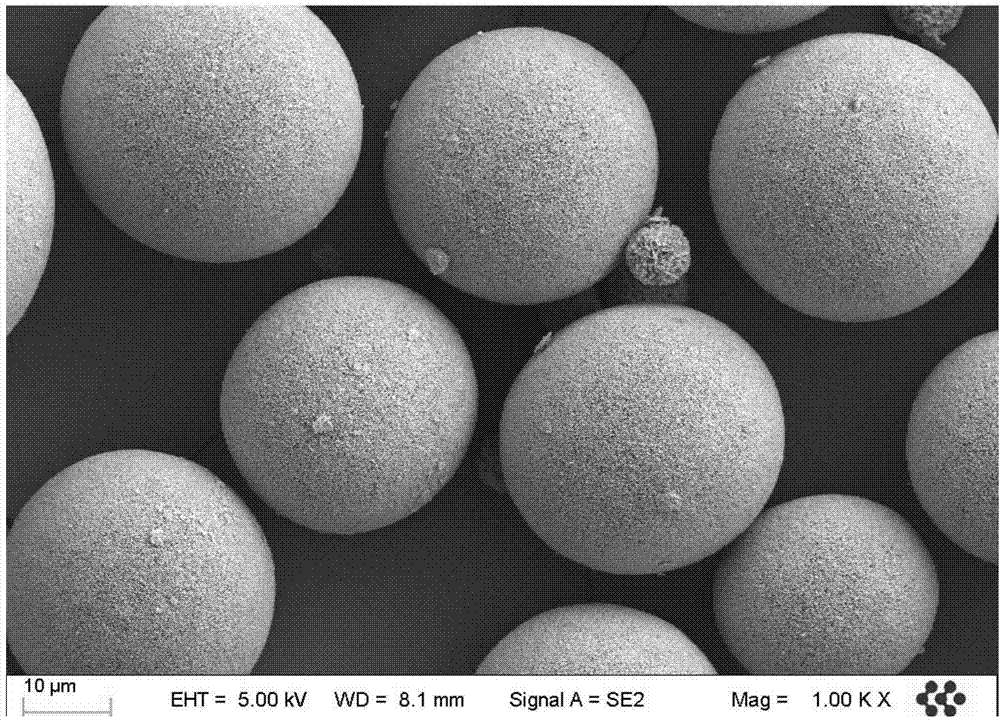

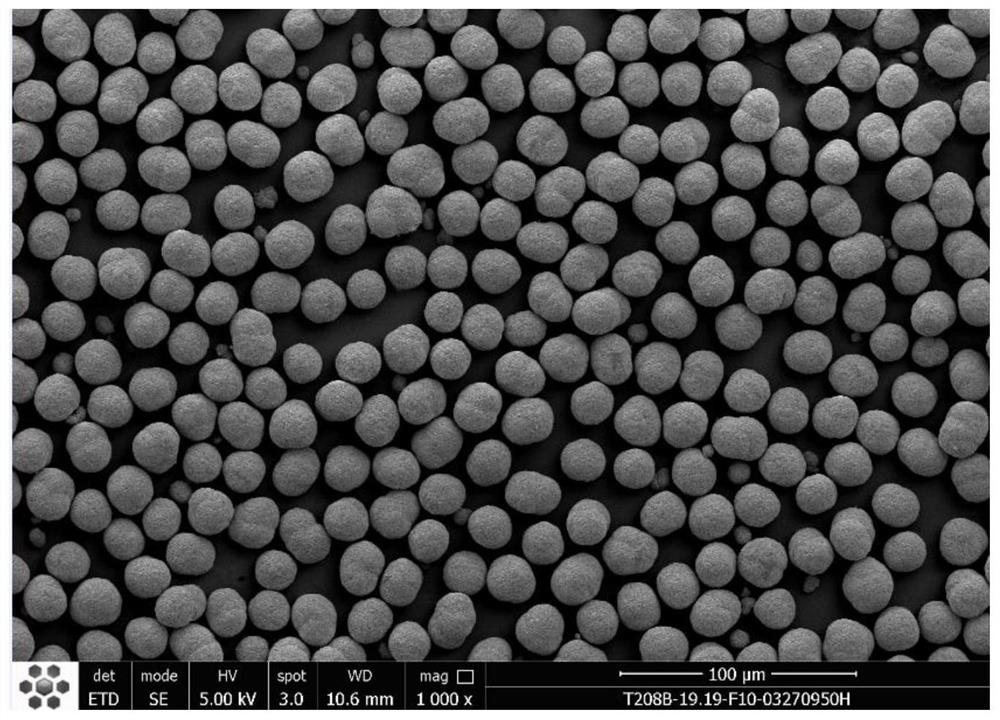

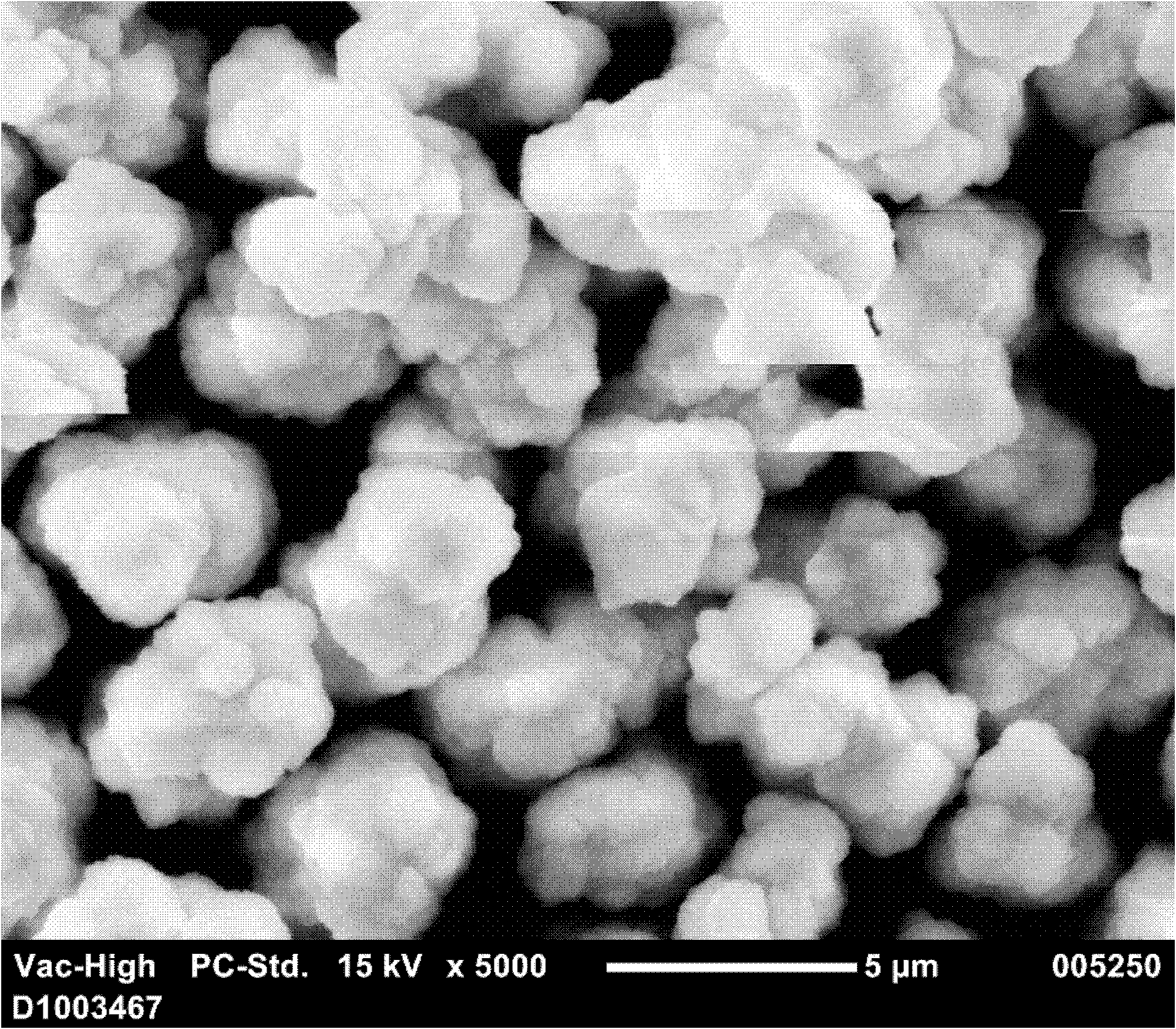

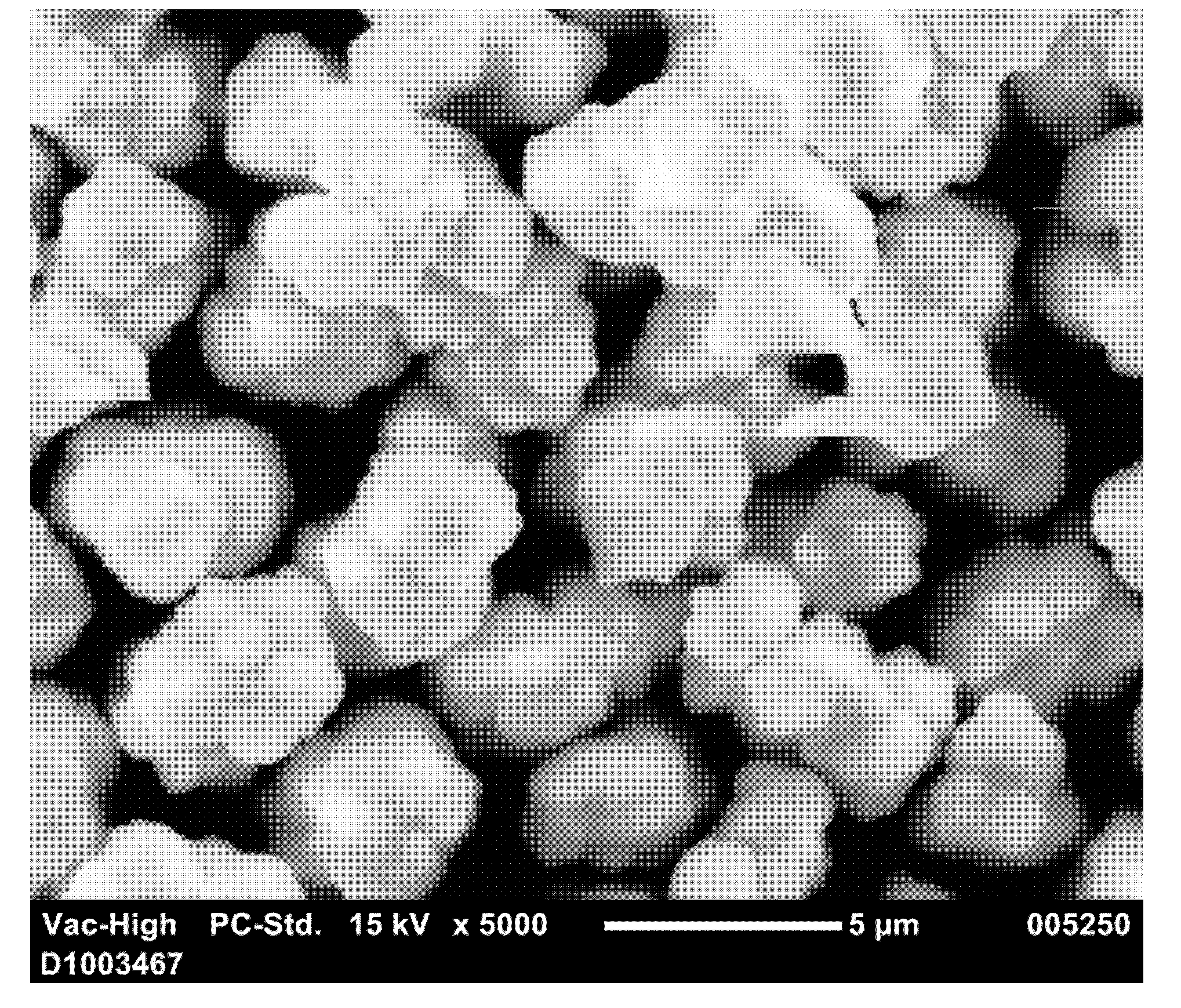

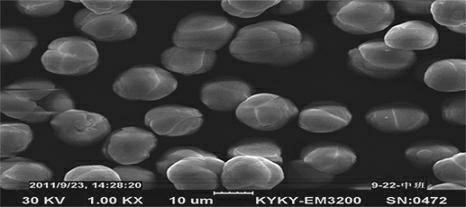

ActiveCN103771545AQuality improvementImprove liquidityCobalt carbonatesGranularityReaction temperature

The invention discloses a preparation method of high-purity superfine spherical cobalt carbonate, and belongs to the field of preparation of metal powder materials. The preparation method is as follows: metal cobalt is used as a raw material to prepare a cobalt salt solution, a complexing agent is used for prepare a complexed cobalt salt solution from the cobalt salt solution, a mixture of an ammonium salt and urea is prepared in to a precipitant solution, a dispersant is added into the precipitant solution, the complexed cobalt salt solution and the precipitant are added agent according to a certain volume ratio by a parallel flow feeding method into a reactor for reaction, the reaction temperature is controlled at 50-80 DEG C, the pH value is controlled to 7.8-8.3, and the stirring speed is 60-200rpm, and finally the superfine spherical cobalt carbonate is obtained by washing, filtering and drying of prepared cobalt carbonate. The preparation method has the advantages of simple production process, easy control, short production cycle, high efficiency and continuous production, a prepared cobalt carbonate product has the advantages of good mobility, uniform particle size distribution, spherical microtopography, high chemical purity and good chemical properties.

Owner:YUCHEN ADVANCED ENERGY MATERIALS & TECH WUXI

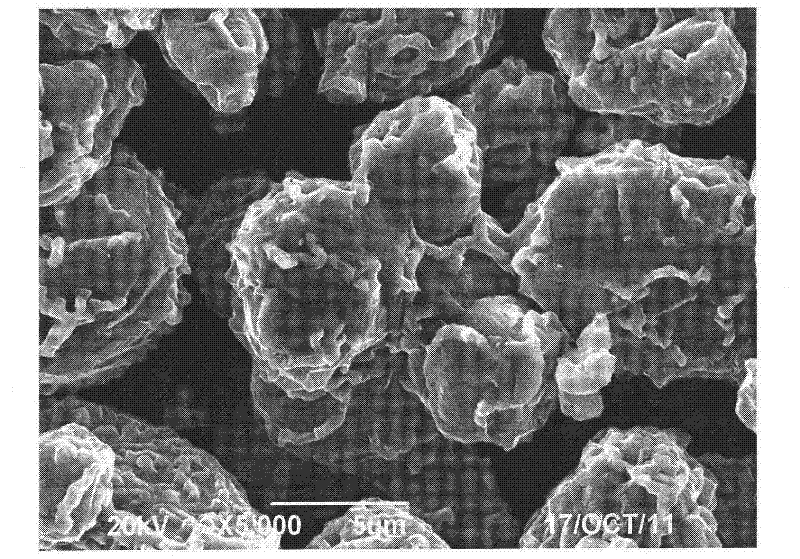

Composite carbonate and method for producing the same

InactiveUS20090194746A1Reduce the amount of wasteGood effectNon-metal conductorsConductive materialManganeseCobalt atom

The present invention provides a nickel atom-, manganese atom- and cobalt atom-containing composite carbonate that is high in specific surface area and large in tap density, and useful as a raw material for producing a lithium nickel manganese cobalt composite oxide to be used in a positive electrode active material for use in a lithium secondary battery, and provides a method for industrially advantageously producing the composite carbonate. The composite carbonate includes nickel atoms, manganese atoms and cobalt atoms, and has an average particle size of 5 μm or more and less than 20 μm, a BET specific surface area of 40 to 80 m2 / g and a tap density of 1.7 g / ml or more.

Owner:NIPPON CHECMICAL IND CO LTD

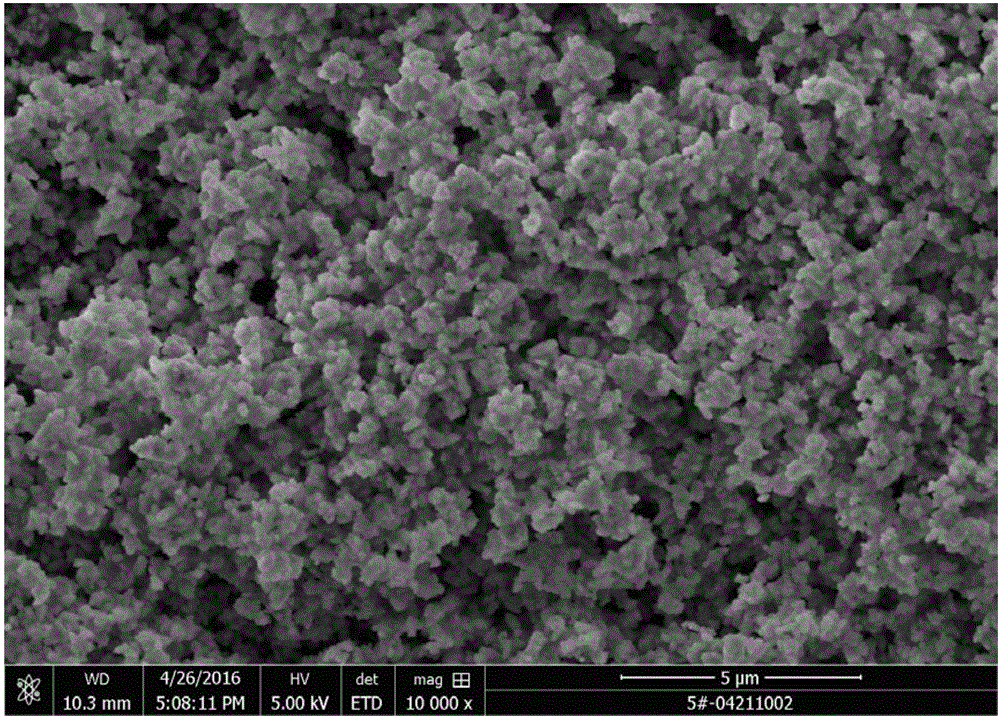

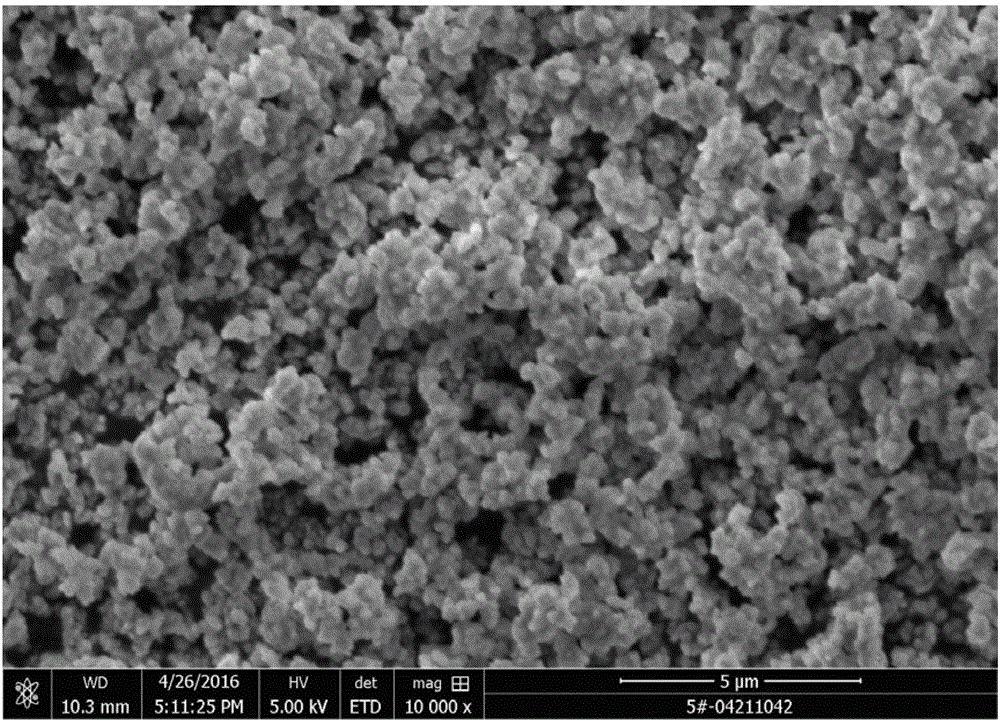

Preparation method of high-gravity spherical cobalt carbonate

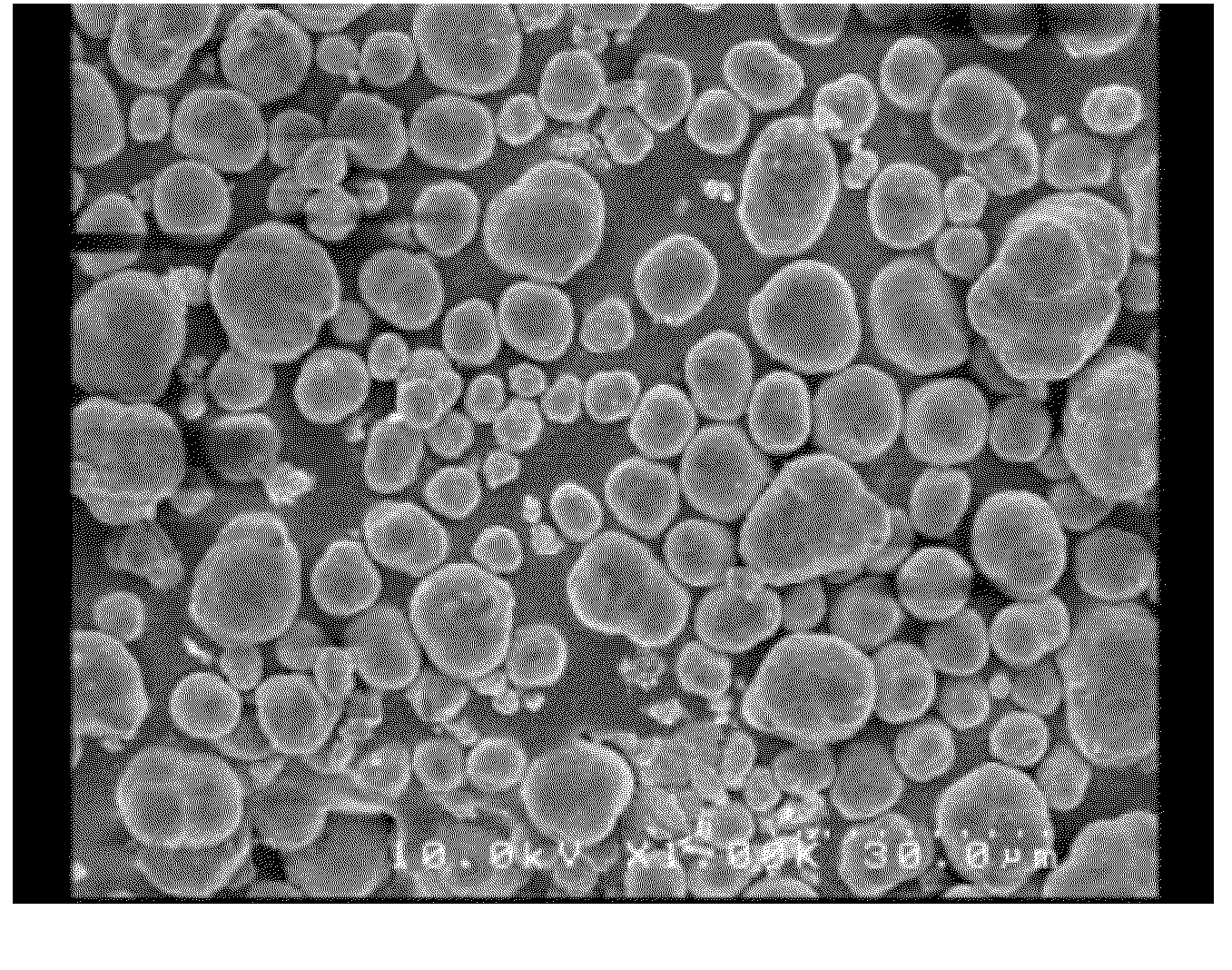

InactiveCN101973592AHigh degree of sphericityProportionally largeCobalt carbonatesPh controlReaction temperature

The invention relates to a preparation method of high-gravity spherical cobalt carbonate, comprising the following steps of: with a water-soluble cobalt salt as a raw material and ammonium hydrogen carbonate as a precipitant adding a cobalt salt aqueous solution and an ammonium hydrogen carbonate aqueous solution into a reactor at the same time by adopting a first-slow and rear-quick stage feeding manner at reaction temperature of 60-90DEG C under a stirring condition, wherein a feeding speed ratio of the cobalt salt aqueous solution of a slow feeding stage to a quick feeding stage is 1:2.5-1:10, and the feeding volume of the slow feeding stage occupies 25-60 percent of the total feeding volume; controlling pH of a reaction solution between 7.0 and 7.5; then, reducing the temperature to carry out heat preservation reaction; and filtering, drying and washing a reaction product to obtain the high-gravity spherical cobalt carbonate. Under the condition of high temperature, a first-slow and rear-quick stage speed-control feeding manner is adopted to prepare cobalt carbonate which has the advantages of high spherical degree, high gravity, controllable grain diameter, good dispersive property and good flow property and can satisfy different product requirements; meanwhile, the invention has short reaction time and is beneficial to the increasing of the production efficiency.

Owner:安徽寒锐新材料有限公司

Process for rapidly producing basic nickel carbonate or basic cobaltous carbonate

InactiveCN101708868AReduce pollutionRapid productionNickel carbonatesCobalt carbonatesChlorideUltimate tensile strength

The invention discloses a process for rapidly producing basic nickel carbonate or basic cobaltous carbonate, comprising the following steps of: dissolving, synthetizing, filtering, water scrubbing and drying. The dissolving proportion by weight of nickel chloride or cobalt chloride in the dissolving process is NiCl2:H2O=1:4-8, CoCl2:H2O=1:4-8, and the dissolving proportion by weight of sodium carbonate is Na2CO3:H2O=1:4-8. Aqueous alkali and a nickel chloride or cobalt chloride solution are added by adopting a spray mode in the synthetic process. The synthetic reaction time is 2-4 hours. The invention not only has simple process, short production cycle, low labor intensity and arbitrary enlargement of production scale but also has simple and practicable operation, low cost, stable quality and high efficiency. The process has the characteristics of fast production, high quality of products and high efficiency; products can be turned out after water scrubbing at one time, and therefore, electricity, water, labor and time are saved. The products have even and superfine granules without crushing and sieving, thereby being beneficial to application.

Owner:江西核工业兴中科技有限公司

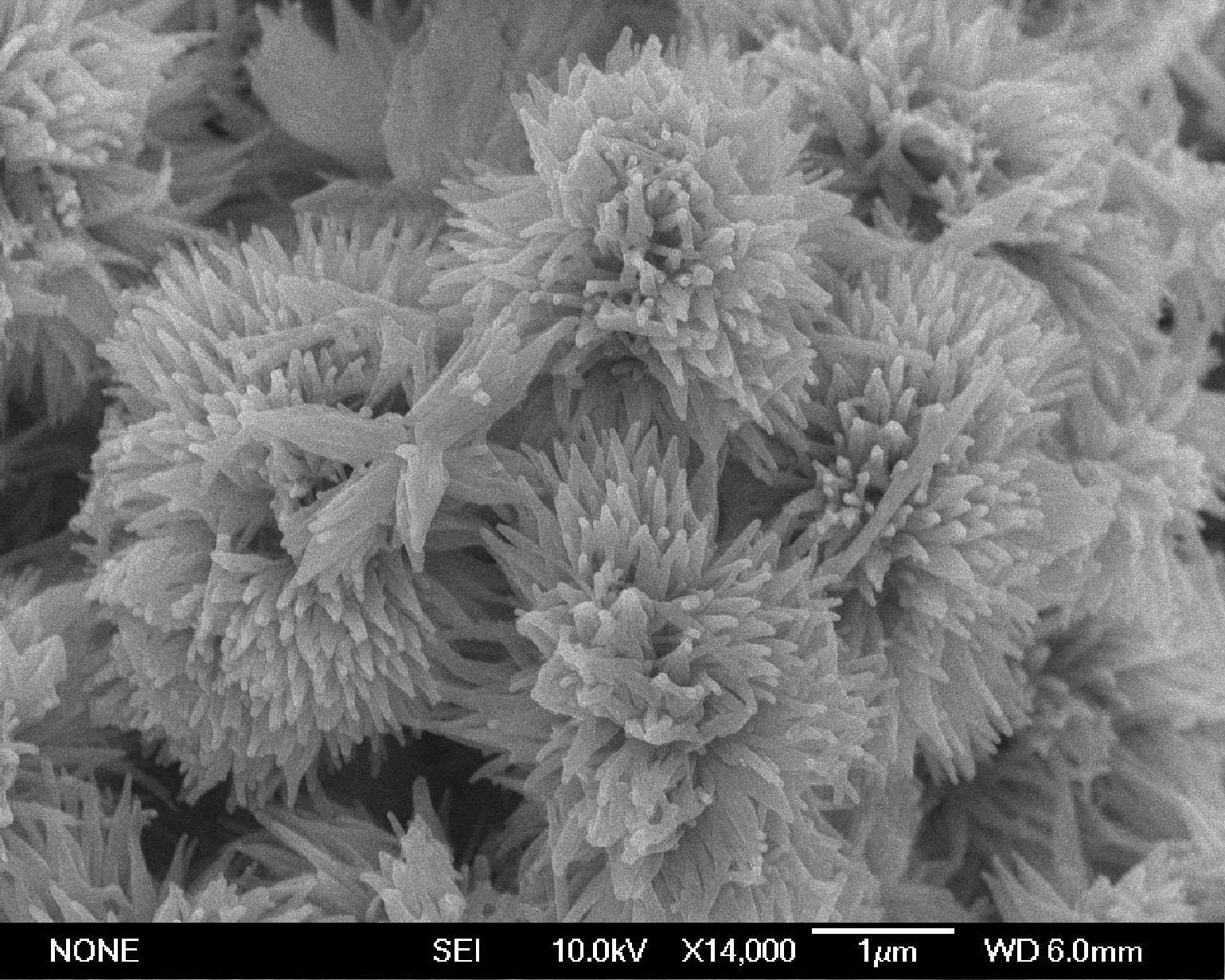

Method for preparing supercapacitor electrode material basic nickel-cobalt carbonate through hydrothermal method

InactiveCN106587171AFully moistenedFull penetrationHybrid capacitor electrodesNickel carbonatesNickel saltHigh pressure

The invention discloses a method for preparing a supercapacitor electrode material basic nickel-cobalt carbonate through a hydrothermal method. The method comprises the following steps that metal nickel salt and / or metal cobalt salt and urea are weighed separately and mixed with deionized water, and stirring is performed so that solids can be dissolved to obtain a mixed solution; the mixed solution is poured into a high-pressure reactor, sealing is performed for performing a reaction for 10-16 h under the temperature of 80-110 DEG C, and a reaction product is obtained; the reaction product is separated, washed and dried to obtain basic nickel-cobalt carbonate. According to the method for preparing the supercapacitor electrode material basic nickel-cobalt carbonate through the hydrothermal method, on the basis of control over raw material compatibility and reaction conditions, the three-dimensional porous structure and morphology can be obtained, sufficient wetting and permeation of an electrolyte are promoted, the superficial area of active substances is sufficiently utilized, and the electrochemical performance is improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

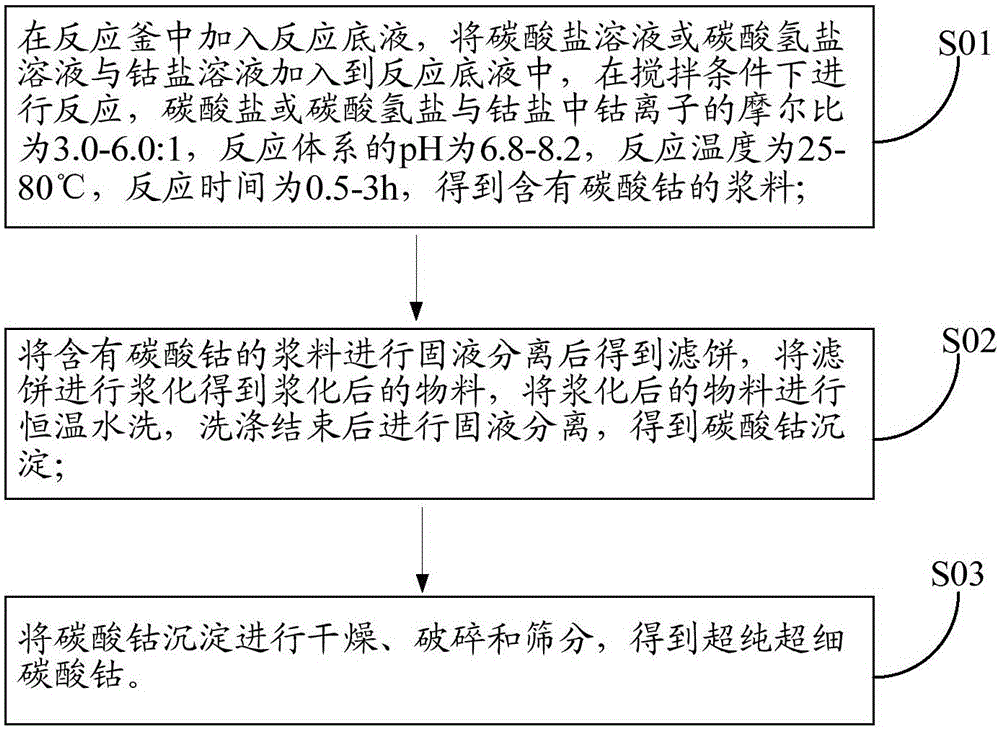

Preparation method for ultrapure ultrafine cobalt carbonate

InactiveCN106395916AReduce manufacturing costLow metal element impuritiesCobalt carbonatesCobalt saltReaction temperature

The invention provides a preparation method for ultrapure ultrafine cobalt carbonate. The preparation method comprises the following steps: (1) adding a base reaction solution into a reaction vessel, adding a carbonate solution or bicarbonate solution and a cobalt salt solution into the base reaction solution, and carrying out a reaction under stirring so as to obtain slurry containing cobalt carbonate, wherein a mol ratio of carbonate or bicarbonate to cobalt ions in the cobalt salt is (3.0-6.0): 1, the pH value of a reaction system is 6.8 to 8.2, reaction temperature is 25 to 80 DEG C and reaction time is 0.5 to 3 h; (2) subjecting the slurry containing cobalt carbonate to solid-liquid separation so as to obtain a filter cake, conveying the filter cake to a slurrying tank for slurrying so as to obtain a slurried material, conveying the slurried material to a washing tank for washing at a constant temperature and carrying out solid-liquid separation after completion of washing so as to obtain a cobalt carbonate precipitate; and (3) drying, crushing and sieving the cobalt carbonate precipitate so as to obtain ultrapure ultrafine cobalt carbonate. The preparation method provided by the invention is low in cost, simple in process flow and easy to operate.

Owner:JINGMEN GEM NEW MATERIAL +1

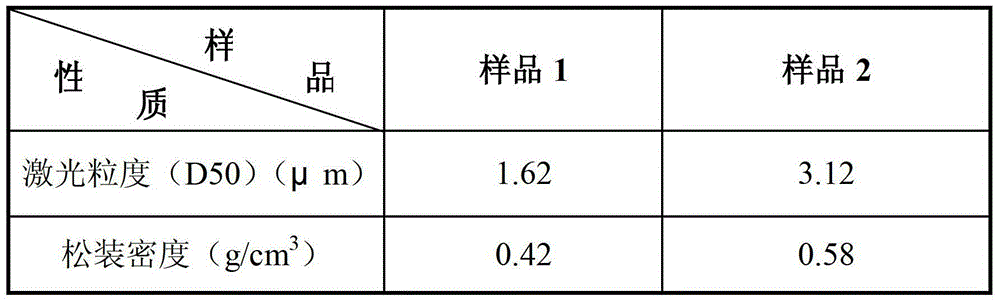

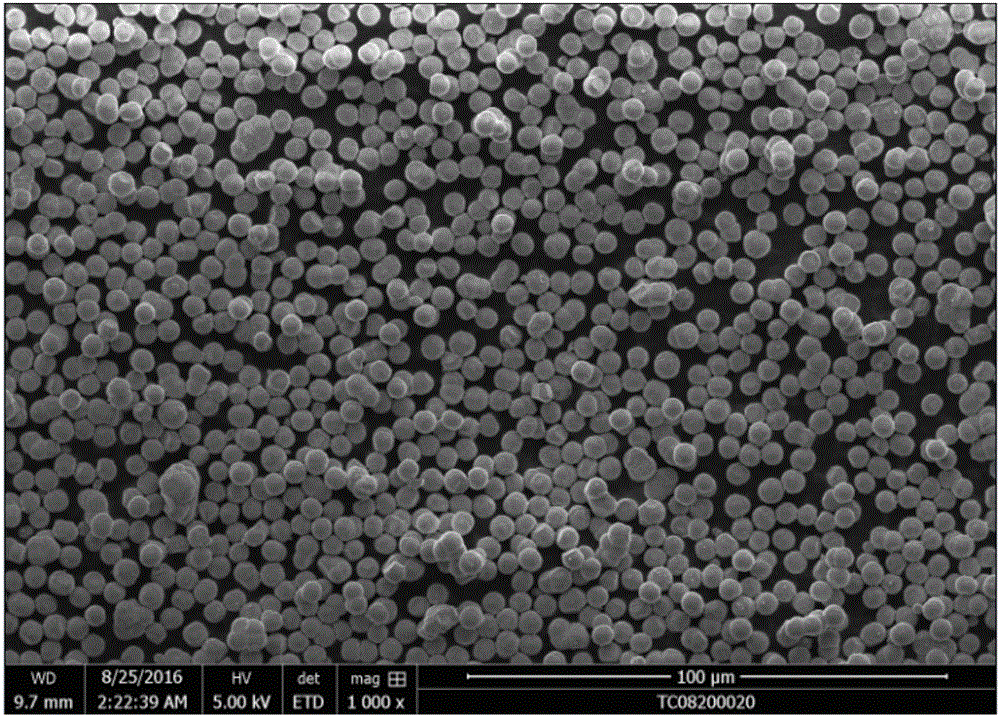

Method for preparing small-particle size large-bulk cobalt carbonate

The invention discloses a method for preparing small-particle size large-bulk cobalt carbonate. The method comprises the following steps: heating an ammonium carbonate base solution of certain concentration; respectively adding soluble cobalt salt and ammonium carbonate into the ammonium carbonate base solution according to certain velocities while stirring to react so as to obtain crystal slurry of cobalt carbonate after a certain time of the reaction; and by taking the crystal slurry of cobalt carbonate as a base solution, adding cobalt salt and ammonium carbonate to react for a certain time, thereby obtaining the target cobalt carbonate. The cobalt carbonate prepared by using the method has the characteristics of being small in particle size and large in bulk density.

Owner:JINGMEN GEM NEW MATERIAL

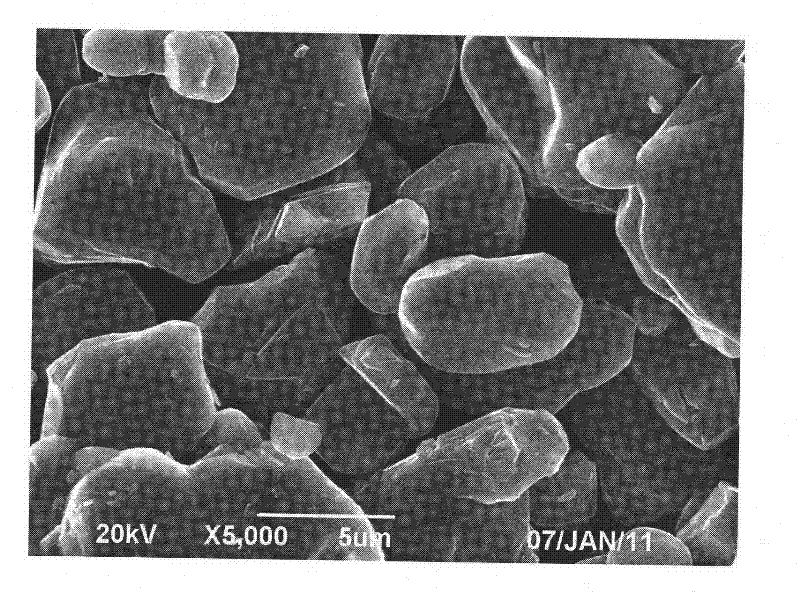

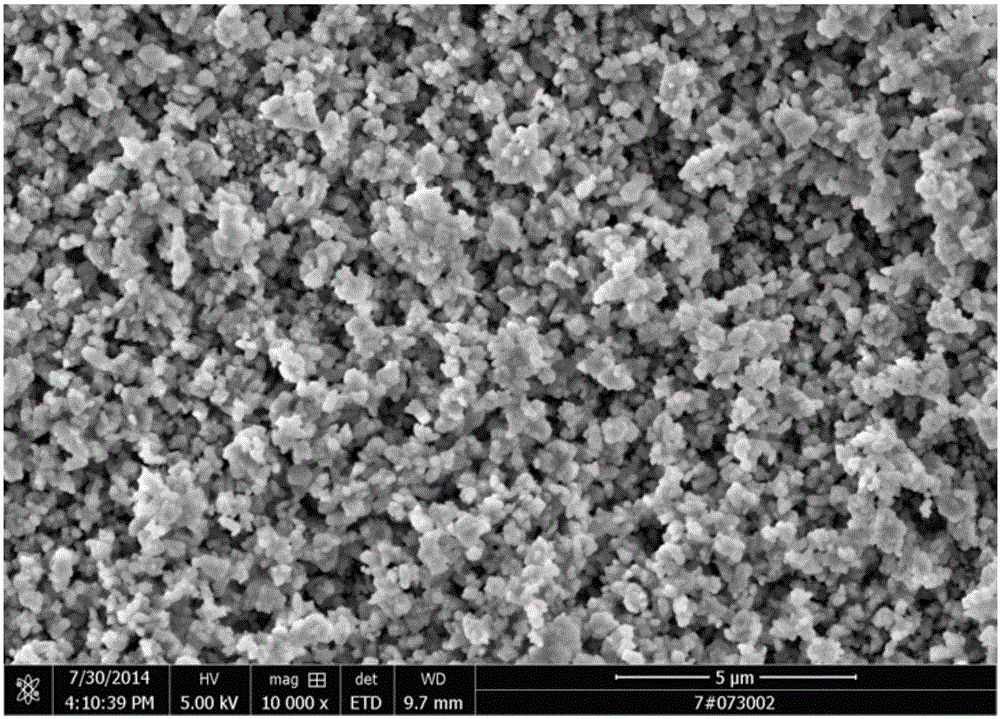

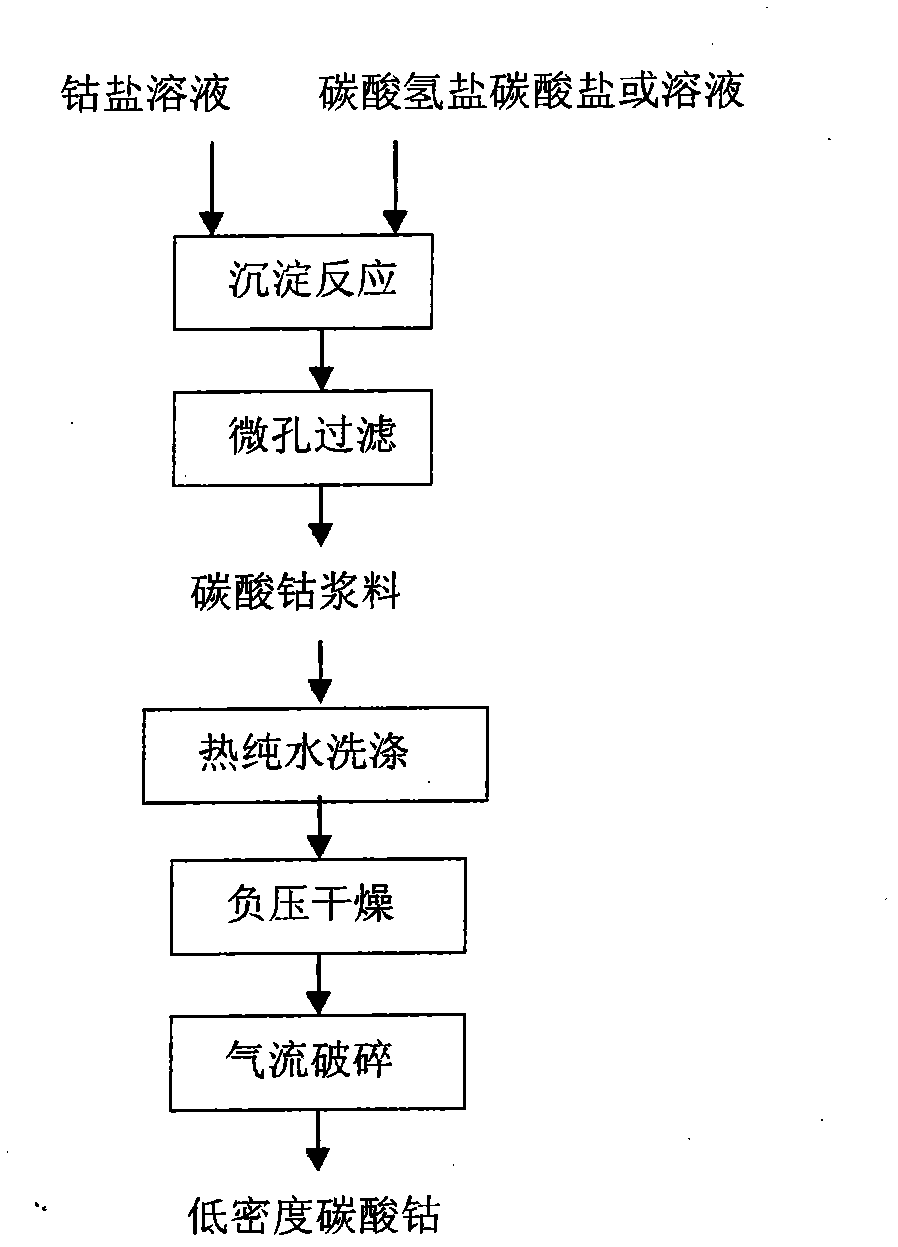

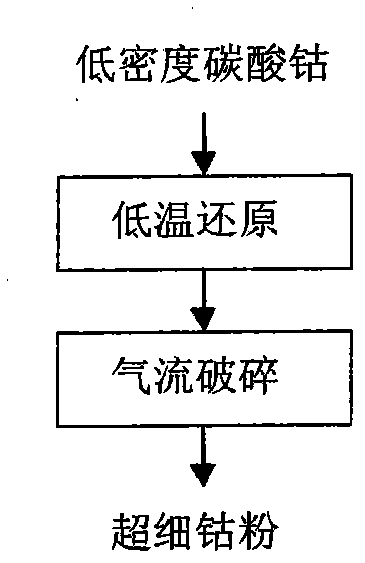

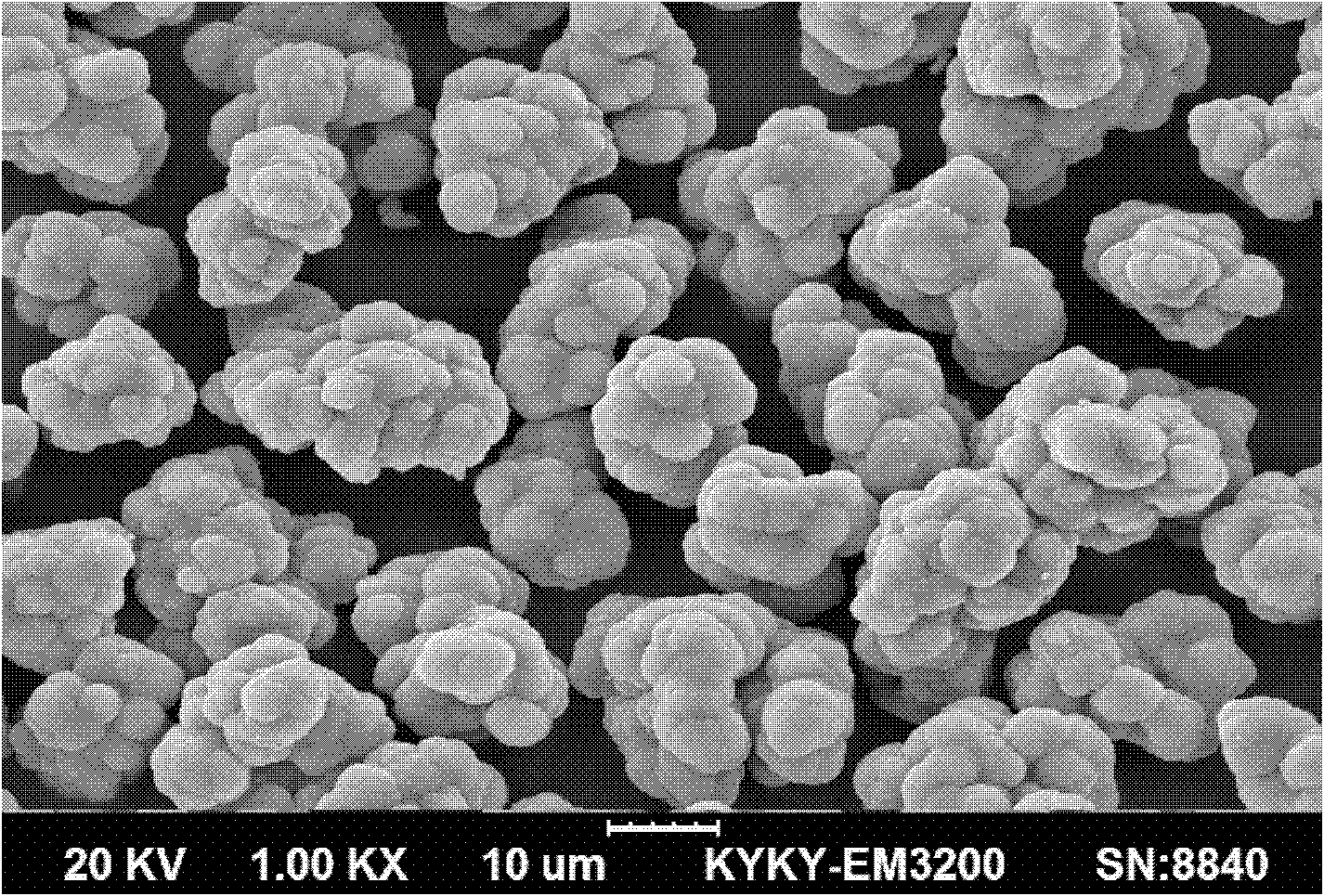

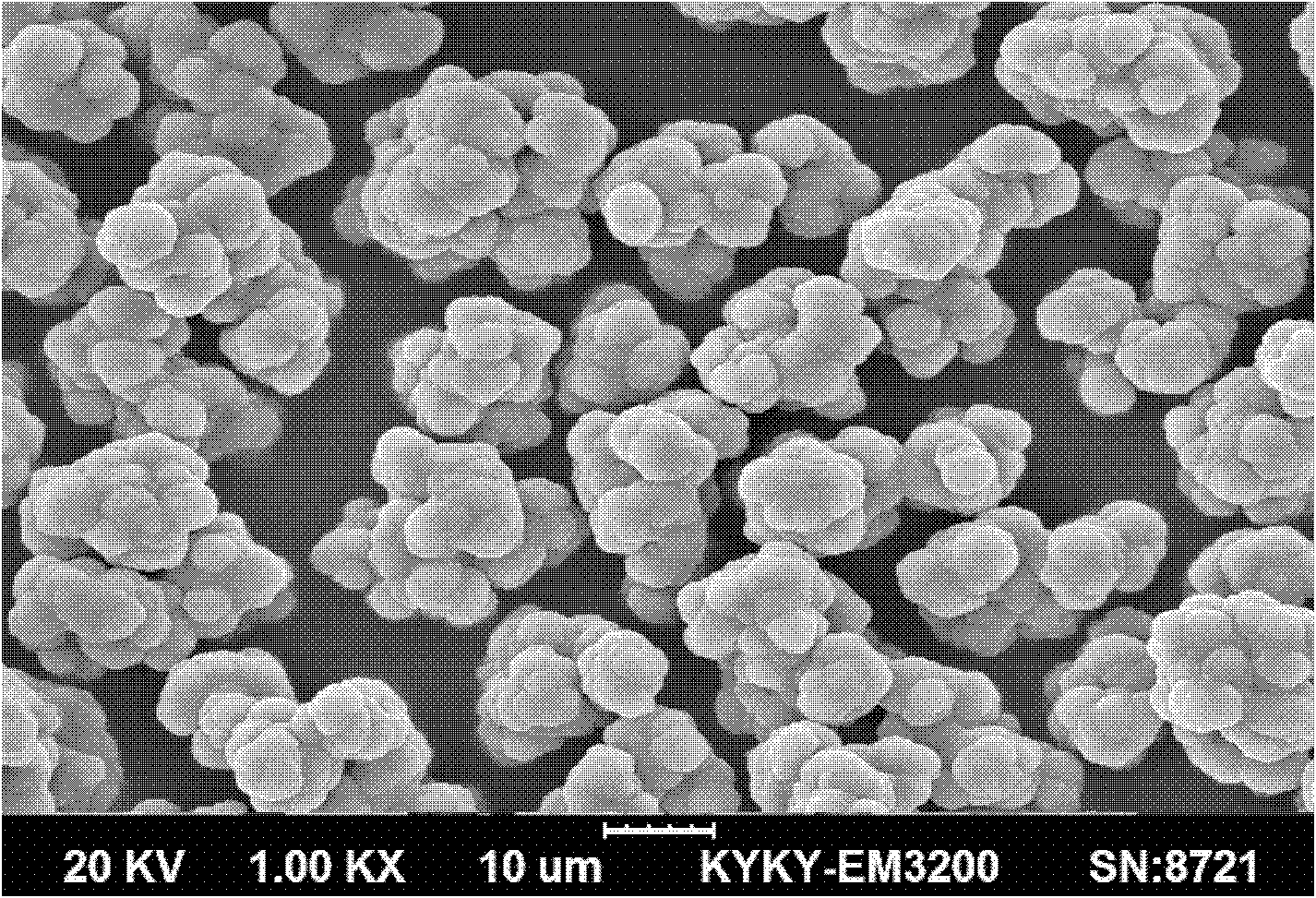

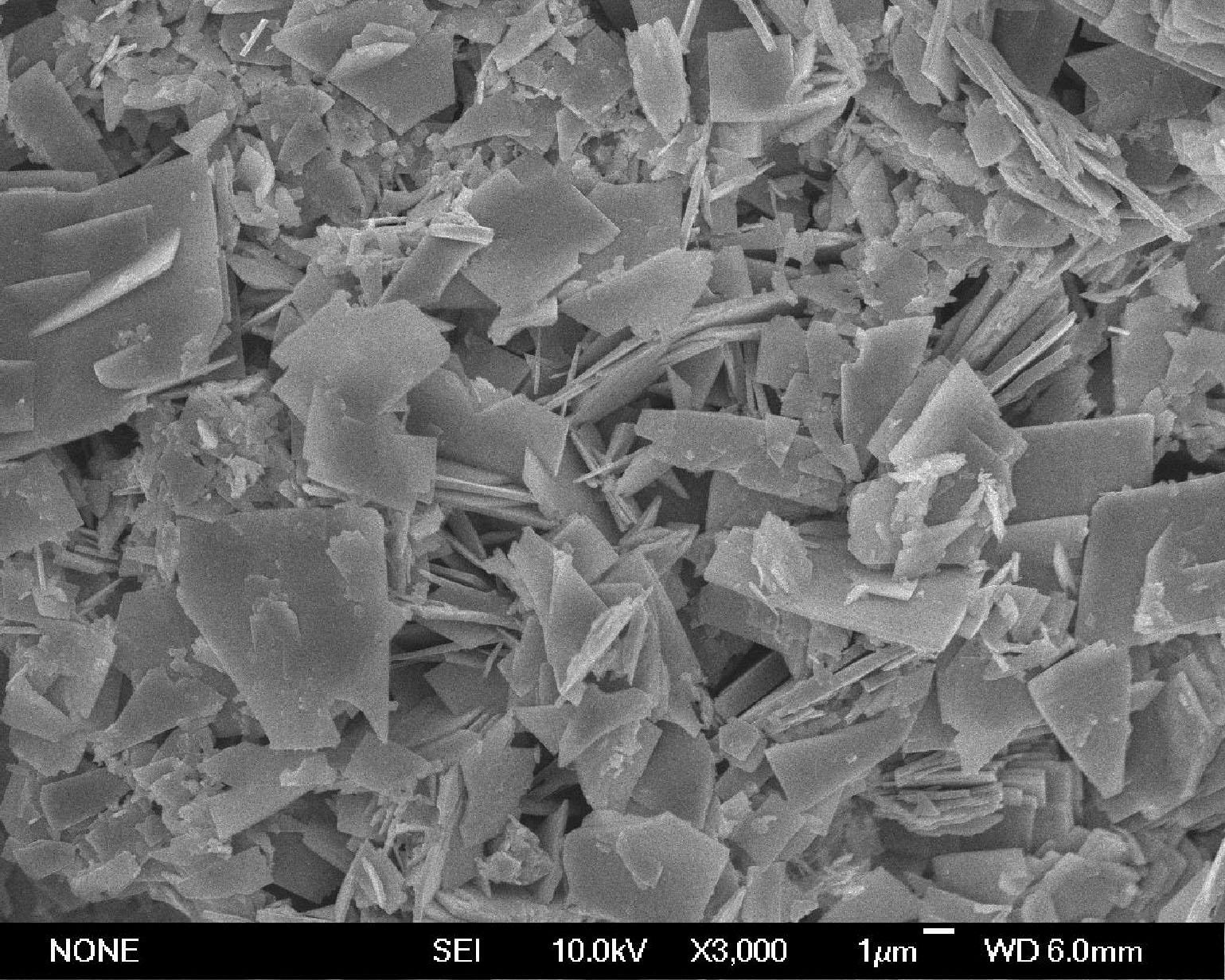

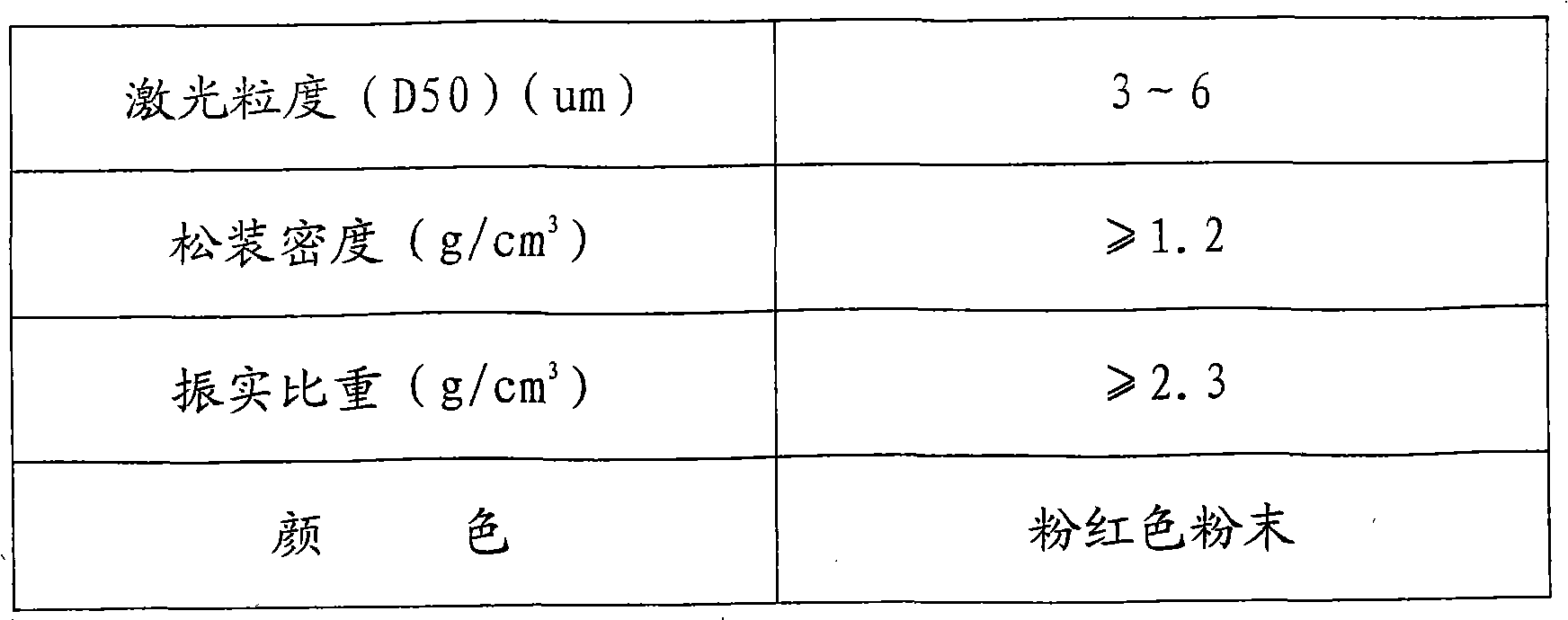

Cobalt carbonate preparation method and superfine cobalt powder preparation method

InactiveCN102910686ALow bulk densityUniform particle sizeNanotechnologyCobalt carbonatesApparent densityFiltration

The invention provides a cobalt carbonate preparation method and a superfine cobalt powder preparation method, which are applicable to the technical field of cobalt powder preparation. The cobalt carbonate preparation method comprises the following steps of: mixing a cobalt salt solution and soluble carbonate or soluble hydrocarbonate under a condition with temperature of 0-30 DEG C and pH value of 5.5-8.0; carrying out millipore filtration on an obtained mixture after reaction; collecting and washing filter residues; drying the washed filter residues under a negative pressure condition at 50-80 DEG C, so as to obtain a cobalt carbonate precursor; and carrying out airflow crushing and classification on the cobalt carbonate precursor, so as to obtain cobalt carbonate. The cobalt carbonate preparation method and the superfine cobalt powder preparation method, provided by the invention, have the advantages of mild technical condition, high production benefits, low apparent density of the obtained cobalt carbonate and uniform particle size and is suitable for industrial production.

Owner:GEM CO LTD +1

Method for preparing spherical carbonate

ActiveCN101857278AReduce processing stepsExcellent indicatorsNickel carbonatesCobalt carbonatesManganateSlurry

The invention discloses a method for preparing spherical carbonate serving as a cell fuel precursor. At present, the preparation of a nickel-cobalt lithium manganate anode material mainly adopts a co-precipitation method, and the obtained materials are generally irregular granules with low practical value. The method is characterized by comprising the following steps of: taking tail ammonium chloride solution as reaction base solution, adding metal chlorate solution and ammonium carbonate into the base solution at the same time with stirring to produce precipitation reaction at the temperature of between 40 and 80 DEG C, ensuring that the pH value of the solution at the end point is between 7.0 and 7.5, preserving heat and ageing the solution, and washing and drying the obtained slurry to obtain a spherical carbonate product, wherein the metal chlorate solution is one or mixture of cobalt chloride, nickel chloride and manganese chloride, and the concentration of the ammonium chloride is 10 to 30 grams per liter. The tail solution is used as the base solution, and the pH value of the solution at the end point is between 7.0 and 7.5 by using the liquid-phase precipitation method so that the spherical carbonate product with large grain diameter is obtained and all indexes are excellent.

Owner:ZHEJIANG HUAYOU COBALT

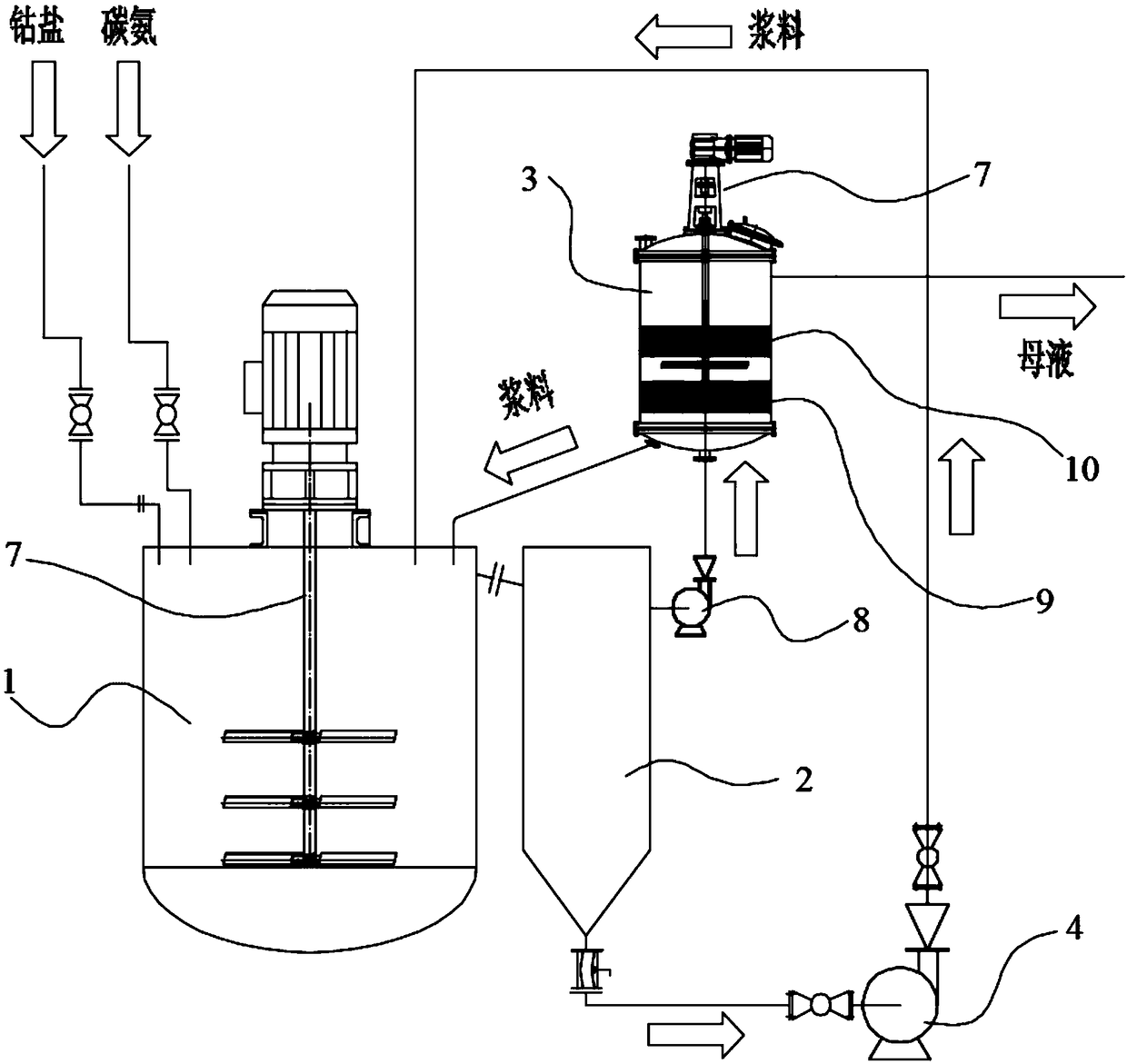

Cobalt carbonate and cobaltosic oxide granularity controlled production process

InactiveCN109368709AHigh densityUniform shapeCobalt oxides/hydroxidesCobalt carbonatesCobalt(II,III) oxideProduct demand

The invention discloses a cobalt carbonate and cobaltosic oxide granularity controlled production process. The cobalt carbonate and cobaltosic oxide granularity controlled production process comprisesthe steps: firstly, a cobalt chloride solution and an ammonium bicarbonate solution are fed into a seed crystal reaction kettle to react under reaction conditions; feeding of cobalt chloride is increased in the later stage to obtain seed crystal cobalt carbonate; then the cobalt carbonate is distributed in a finished product reaction kettle to react, in the reaction process, the feeding quantityof the ammonium bicarbonate solution is adjusted, the alkaline environment is gradually lowered to the weak alkali environment, and the weak alkali environment is maintained; the feeding quantity of the cobalt chloride is increased every a period of time in the middle and later periods of a reaction, and finally, finished cobalt carbonate particle products with the required particle size are obtained; and cobalt carbonate particles are washed and dried, and then subjected to aerobic calcination in a rotary kiln, and cobaltosic oxide black powder is obtained. The produced cobalt carbonate particles are good in compactness and uniform in morphology and granularity, the specific surface area is adjusted according to product demands, the cobalt carbonate particles can be well controlled in therequired granularity, and calcined cobaltosic oxide is uniform in granularity, compact in particle, and also uniform in morphology.

Owner:JINGMEN GEM NEW MATERIAL +1

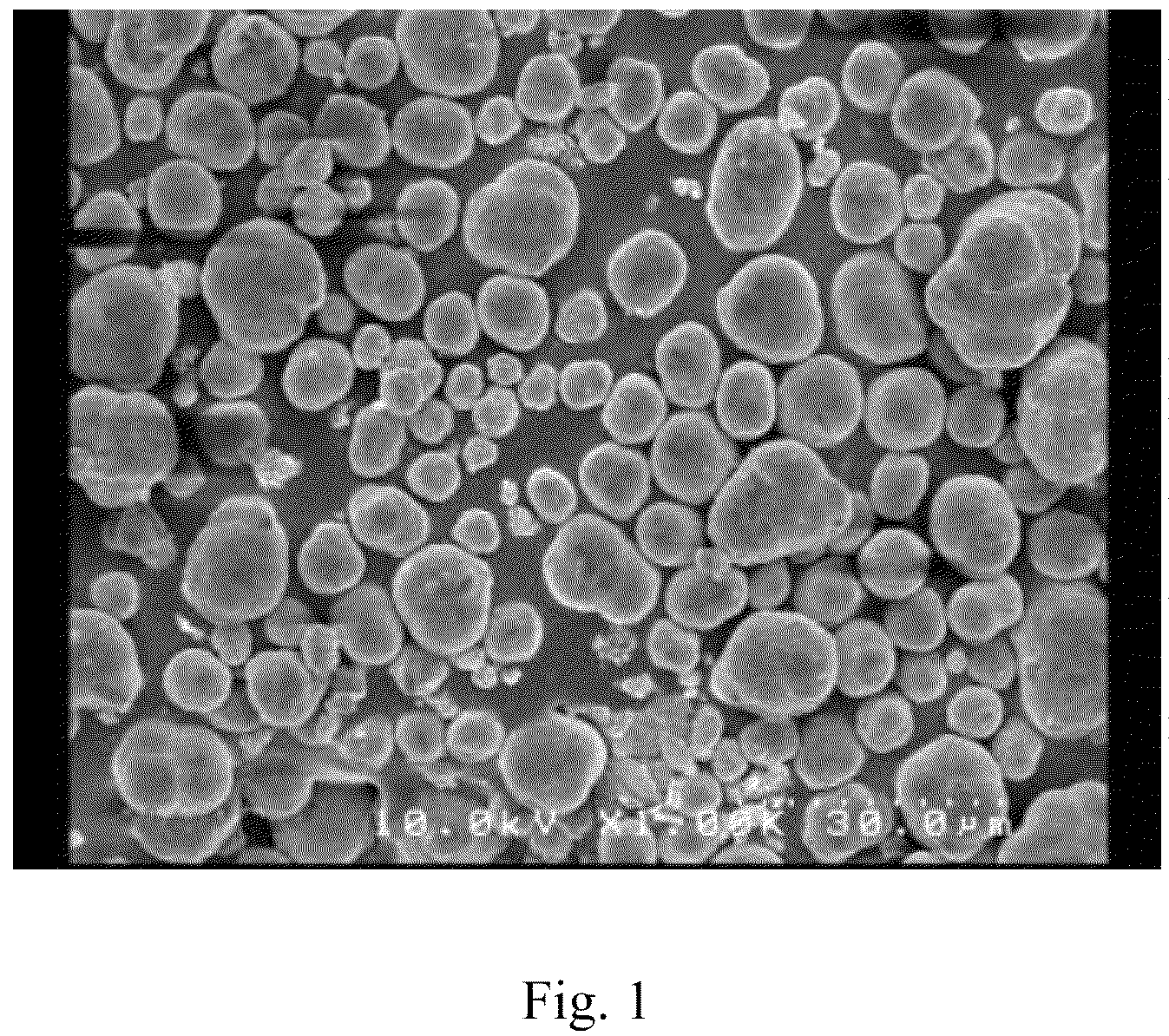

Method for producing spherical cobaltous carbonate

InactiveCN101376529ANormalized Uniform GrowthEnsure controllabilityCobalt carbonatesReaction temperatureSpherical shaped

The invention relates to a manufacturing method of spherical cobalt carbonate. At first, a cobalt chloride solution and an ammonium hydrocarbonate solution are led to flow into a reaction tank according to a certain flow rate, the reaction temperature is controlled between 5 and 9 DEG C by a refrigerator; the reaction is conducted under the condition that the pH value is 7.2 to 7.3; when the liquid level of a ground-paste reaches 1.5m<3> in the reaction tank, the ground-paste is discharged into an ageing tank, the ground-paste in the ageing tank is heated until the temperature ranges from 43 to 47 DEG C, is processed through standing, precipitation and growth, is filtered, pulped and washed after being aged for 18 hours, and then is dried and secondary-recovered by a cyclone separating device and a pouched trapper to obtain the finished product. The manufacturing method is characterized in that the refrigerator is utilized to reduce the reaction temperature during the reaction process, and a product crystal is led to grow canonically and evenly instead of being influenced by temperature no longer and grow to a spheroid finally under the conditions of constant flow, constant temperature and constant pH value. At the same time, the production mode adopts the standing and ageing without stirring to achieve the determinacy on particle nucleation condition and manufacturing time during the product is manufactured, thereby ensuring the controllability on particle diameter and shape of the precipitate particles.

Owner:周红阳

Method for continuously preparing large-particle-size spherical cobalt carbonate

The invention discloses a method for continuously preparing large-particle-size spherical cobalt carbonate. All the cobalt carbonate production methods in China at present adopt an intermitted technique which has the characteristics of aggregated particle, poor dispersity and poor flowability. The method comprises the following steps: by using pure water as bottom liquor, adding a parallel flow of an excessive 10-30% precipitant solution and a soluble cobalt salt-activator mixed solution into a reaction kettle while controlling the pH value at 6.5-7.5, the temperature at 30-90 DEG C and the stirring speed at 200-100 rpm; starting continuous feeding and continuous output when achieving the overflow port; and filtering the reaction product, washing and drying to obtain the large-particle-size spherical cobalt carbonate. The particle size of the cobalt carbonate product forms standard normal distribution; the cobalt carbonate product has the advantages of uniform particle and favorable flowability; and D50 is 15-30mm.

Owner:ZHEJIANG HUAYOU COBALT

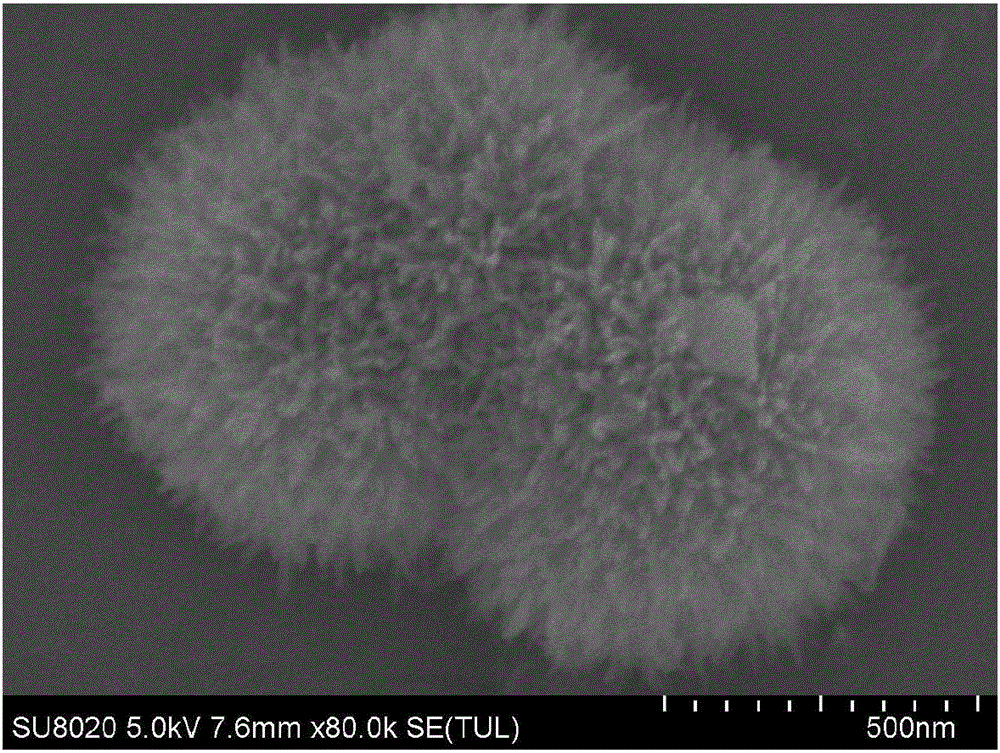

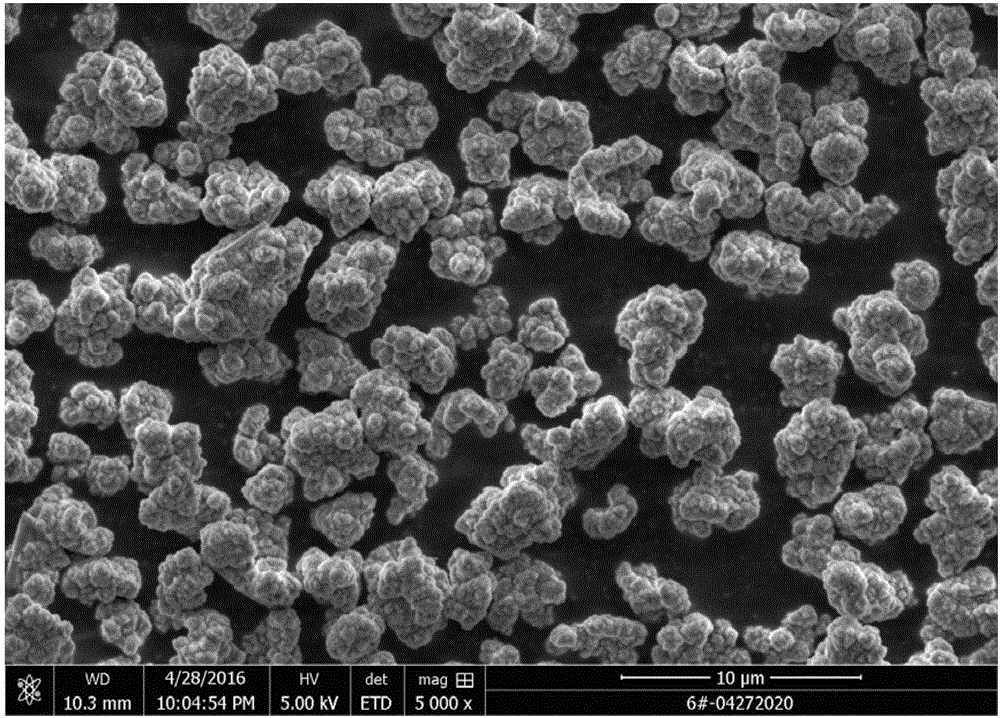

Doped large-particle cobalt carbonate and preparation method thereof

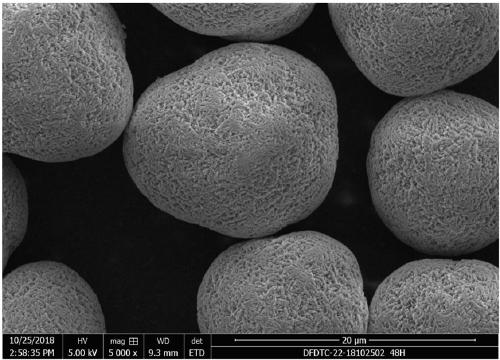

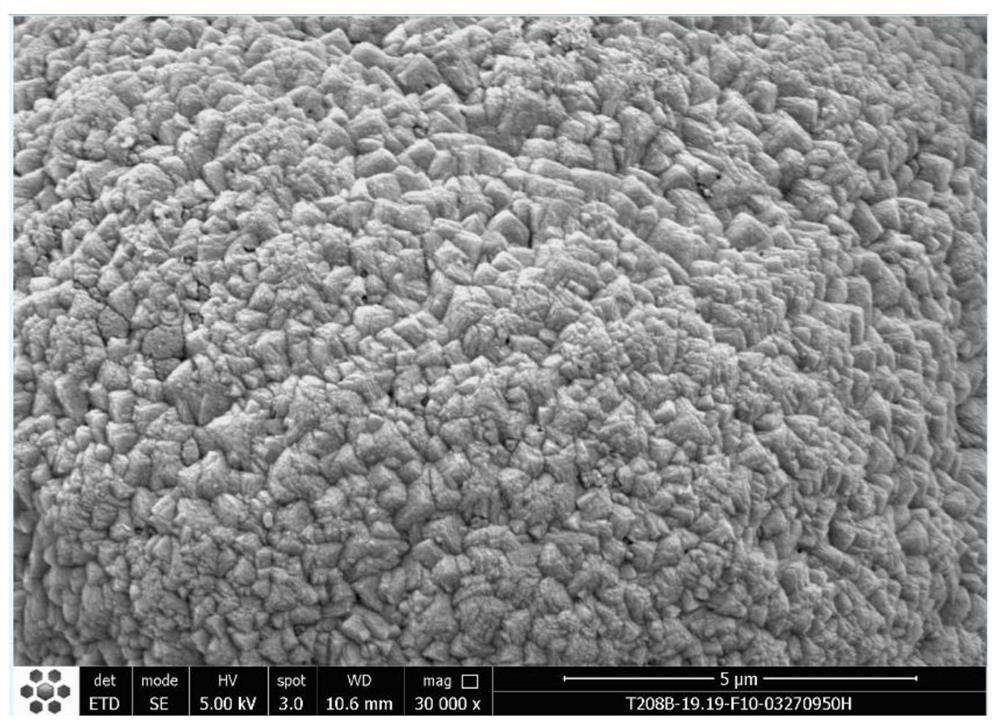

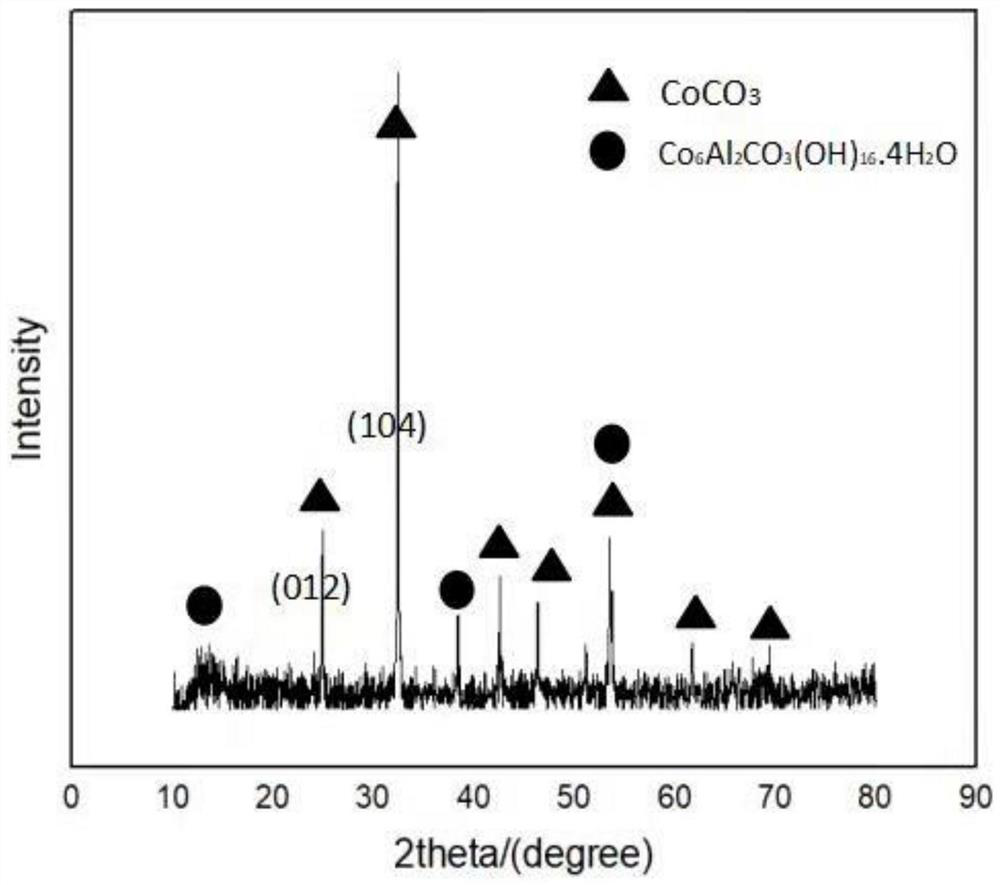

ActiveCN113307308AHigh tap densityNarrow particle size distributionCobalt carbonatesCrystallinityCobalt

The invention relates to doped large-particle cobalt carbonate and a preparation method thereof. The large-particle cobalt carbonate is doped with metal elements, primary particles are conical in morphology and form spherical secondary particles, and the particle size distribution range of the secondary particles is that (D90-D10) / D50 is larger than or equal to 0.3 and smaller than or equal to 0.5; and the preparation method comprises the following steps: nucleation, concentration, growth in a seed crystal kettle, and growth of the seed crystal in different kettles. The doped large-particle cobalt carbonate is high in crystallinity, beneficial to uniform distribution of doped element aluminum, high in tap density, narrow in particle size distribution and beneficial to reduction of aluminum segregation of small particles; and according to the preparation method, the D50 rising speed and the solid content rising speed are strictly controlled, uniform growth of cobalt carbonate particles is guaranteed by adjusting the flow and the rotating speed in different solid content intervals, the concentration process greatly saves the standing waiting time, the efficiency is high, and the obtained product is good in performance and has a wide market prospect.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

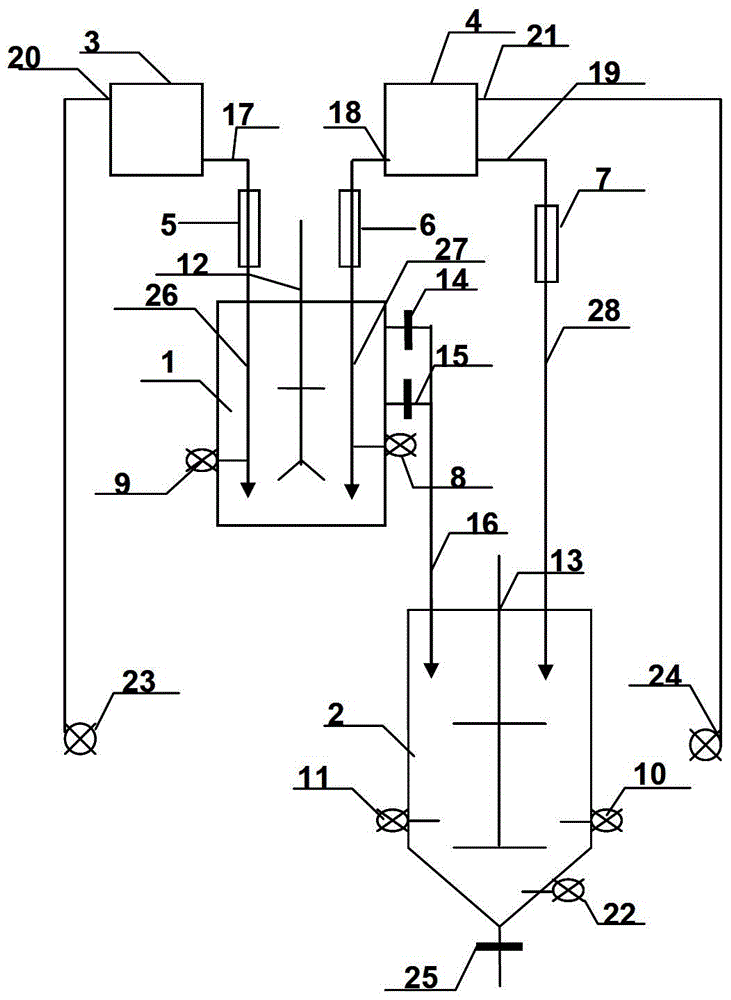

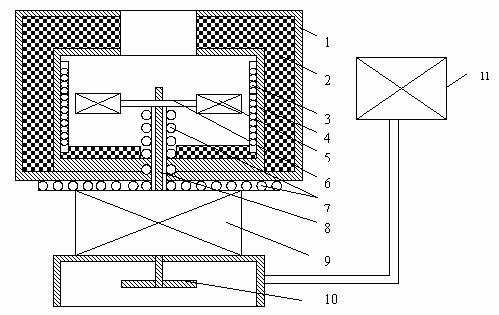

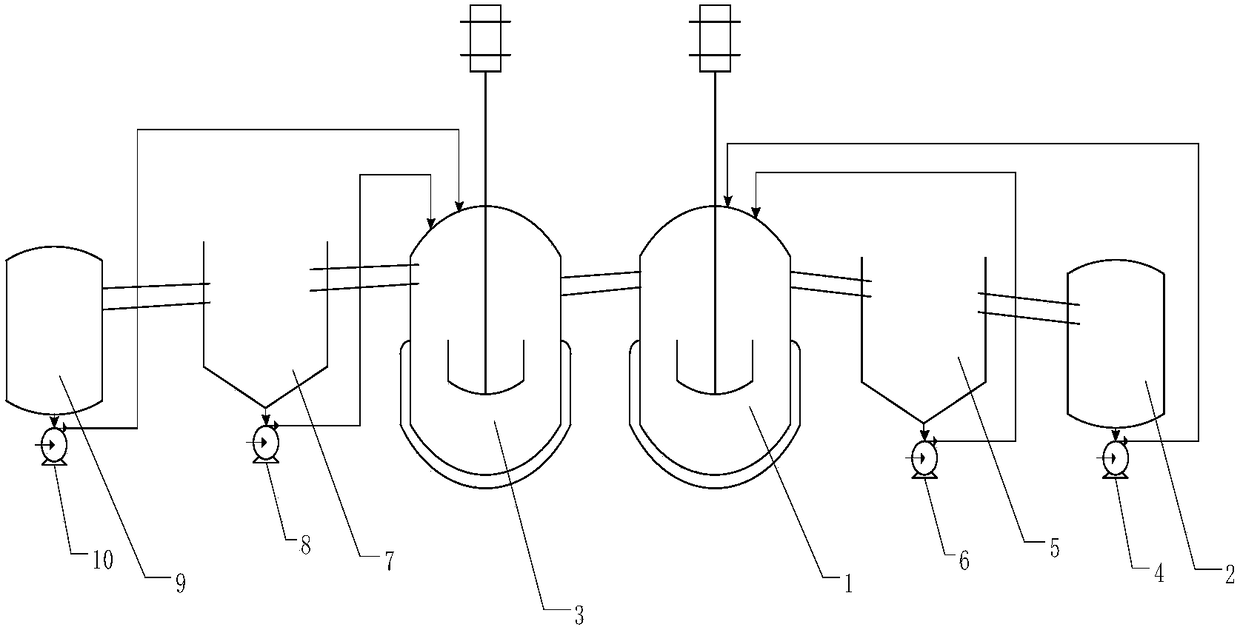

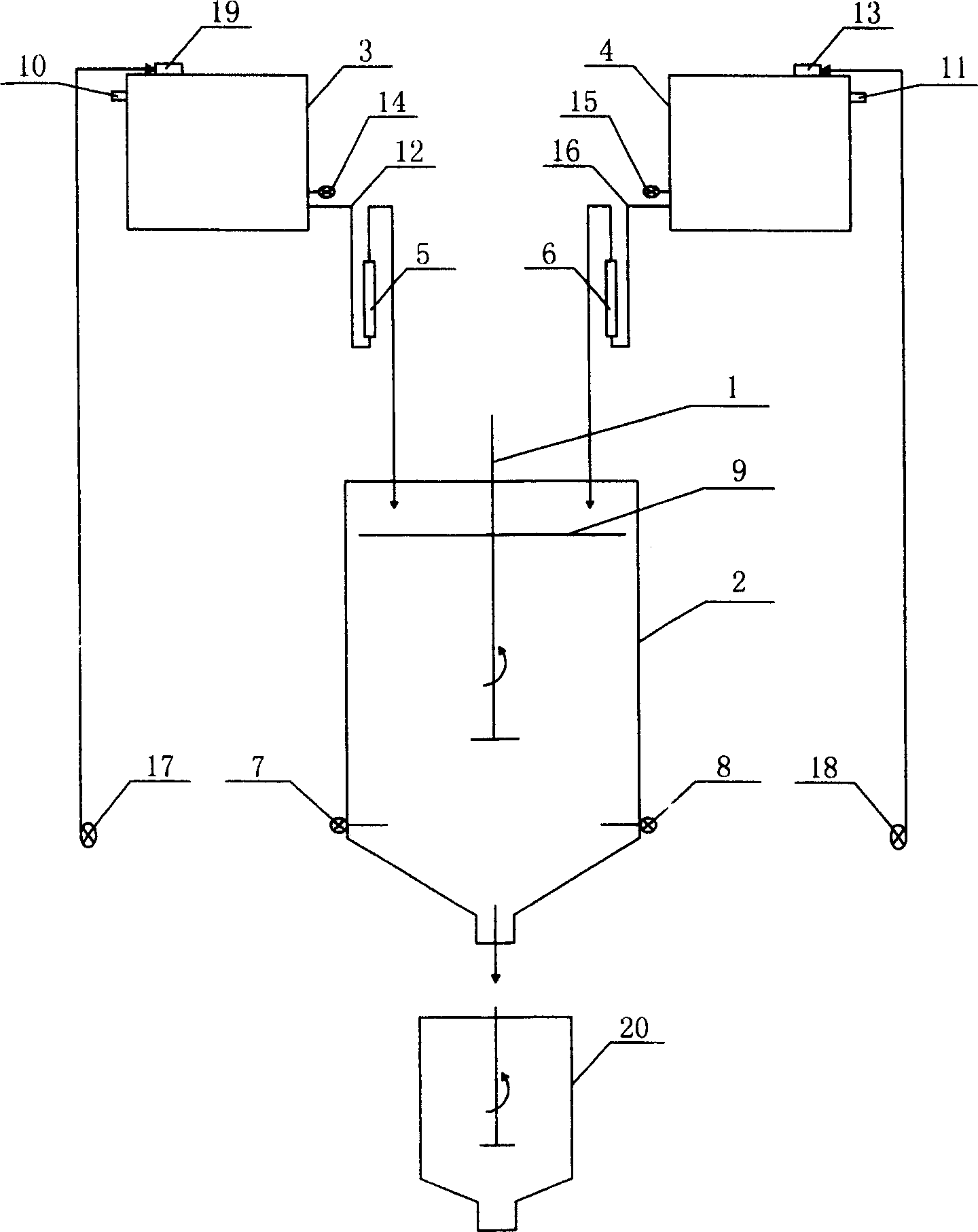

Process and device for continuous production of superfine cobalt carbonate powder

ActiveCN104418388AIncrease sedimentation rateHigh purityCobalt carbonatesFiltrationFirst-order reaction

The invention discloses a process for continuous production of superfine cobalt carbonate powder, the process includes two stages: first order reaction is homogeneous nucleation, the temperature is controlled at 15 to 30 DEG C, the pH value is 5.8-6.8, the vortex stirring speed is 800-1200R / min; and second stage reaction is growth and crystallization, the reaction temperature is controlled at 40 to 55 DEG C, the pH value is 6.8-7.2, the advection stirring speed is 200-400R / min, and a wet material is obtained by filtration of a precipitation material. The characteristics of the process are that: nucleation and growth processes are effectively separated, controllable cobalt carbonate powder particle size and morphology can be ensured, the co precipitation of impurity ions can be effectively avoided due to low pH value, and the product purity is improved. The invention also provides a device for the continuous production of the superfine cobalt carbonate powder, the characteristics are that: the device includes two stages of reactors, the process parameters can be independently set to facilitate independent performing of the nucleation and growth process.

Owner:JINGMEN GEM NEW MATERIAL

Method for preparing alkaline cobalt carbonate under hyper-gravity hydrothermal condition

InactiveCN102145924AReaction is easy to controlEasy to industrializeNanotechnologyCobalt carbonatesOrganosolvReaction temperature

The invention relates to a method for preparing alkaline cobalt carbonate under hyper-gravity hydrothermal condition. The method comprises the following specific steps of: adding a certain amount of cobalt salt into deionized water to obtain a metal salt solution with the concentration between 0.1 mol / L and 2 mol / L; dissolving a corresponding chemical reagent which can produce CO3<2-> at the reaction temperature between 50 DEG C and 250 DEG C; adding a certain amount of organic solvent which has higher density in comparison with water and is insoluble in water or a water-soluble high molecular compound with density higher than that of water into the prepared solution, wherein the volume ratio of the organic solvent or the water-soluble high molecular compound to an aqueous solution is 1:1-1:100; filling the mixed solution into a reaction kettle, sealing, fixing the reaction kettle on a fixing bracket in a hearth and undergoing a hydrothermal reaction at certain temperature in the presence of hyper-gravity, wherein the reaction temperature is between 50 DEG C and 250 DEG C, the reaction time is between 0.1 hour and 5 hours, and relative centrifugal force is between 500 / g and 10,000 / g; and filtering, cleaning repeatedly and drying in vacuum to obtain a needed material. By adopting the method, a substrate-free alkaline cobalt carbonate membrane can be directly prepared; and equipment is simple, the reaction is easy to control, and industrialization is easy to realize.

Owner:TONGJI UNIV

Method for producing cobalt carbonate

ActiveCN101830521AGuaranteed Bulk DensitySolving Diffusion ProblemsCobalt carbonatesTime ratioAqueous solution

The invention relates to a method for producing cobalt carbonate, which can improve the yield of a product and reduce the cobalt content of waste liquid. The method for producing the cobalt carbonate comprises the following steps of: dripping CoCl2 aqueous solution with cobalt concentration of 130 + / - 5g / L into 250 + / - 10g / L NH4HCO3 aqueous solution at the temperature of between 40 and 60 DEG C and at the stirring speed of 100 to 130 revolutions per minute, wherein the volume ratio of the NH4HCO3 aqueous solution to the CoCl2 aqueous solution is 1.6 to 1.7, the dripping process is divided into a quick dripping section and a slow dripping section, the time ratio of the quick dripping section to the slow dripping section is 1:2-2:1, the color gradually becomes deep red along with the dripping of the CoCl2 solution at the quick dripping section, the quick dripping section is finished when the solution becomes pink and then the dripping speed is changed into slow dripping; and continuously stirring the solution for 1 hour after the dripping is finished, then performing solid-liquid separation, washing the solid by using pure water of 70 DEG C till the pH of the filtrate is 7, dehydrating the solid, and drying the solid to obtain the cobalt carbonate.

Owner:GEM JIANGSU COBALT IND CO LTD

Method for preparing small-particle-size cobalt carbonate

The invention discloses a method for preparing small-particle-size cobalt carbonate, which comprises the following steps: preparing solution A with a cobalt slat concentration of 0.1 to 10M and an additive concentration of 0.05 to 5M by dissolving an industrial cobalt salt and an additive in deionized water; preparing solution B with a precipitator concentration of 0.1 to 10M and a complexing agent concentration of 0.05 to 5M by dissolving an industrial precipitator and a complexing agent in deionized water; filling deionized water which accounts for 1 / 10 to 3 / 10 of the volume of the reactor into the reactor, filling the solution A and the solution B into the reactor according to a volume ratio of 1:1 to 1:5 to perform a precipitation reaction, controlling the pH value to be 6 to 10, and reacting for 4 to 10 hours; and overflowing the precipitator formed by the reaction into a washing and filtering device, washing the precipitator till the pH value of the washing water is between 6.5 and 7.5, filtering, and drying the filter cake in an oven at 80 to 120 DEG C for 2 to 10 hours to obtain small-particle-size cobalt carbonate powder. In the invention, the small-particle-size cobalt carbonate powder prepared by a controlled synthesis process has high flowability, small particle size, uniform particle size distribution, and large specific surface area and makes the realization of industrial production easy.

Owner:JIANGSU FANGZHOU NEW ENERGY

Process for Heap Leaching of Nickeliferous Oxidic Ores

InactiveUS20110150729A1Easy to processReduce consumptionSolvent extractionIron compoundsPregnant leach solutionFerrous

A process for the recovery of nickel and cobalt from a nickeliferous oxidic ore by heap leaching and / or atmospheric agitation leaching, the process including the steps of: mixing a sulfur containing reductant selected from reductants that do not include copper into a nickeliferous oxidic ore; leaching the reductant / ore mixture with an acidic leach reagent to produce a pregnant leach solution including nickel, cobalt, iron substantially in a ferrous form and other acid soluble impurities; and recovering the nickel and cobalt from the pregnant leach solution.

Owner:BHP BILLITON SSM TECH PTY LTD

Method of precipitation of metal ions

ActiveUS20110280778A1Low production costLow priceAluminium hydroxide preparationMercury oxidesCalcium bicarbonateIndium

The present invention relates to a method of precipitation of metal ions. Mineral(s), oxide(s), hydroxide(s) of magnesium and / or calcium are adopted as raw materials, and the raw material(s) is processed through at least one step of calcination, slaking, or carbonization to produce aqueous solution(s) of magnesium bicarbonate and / or calcium bicarbonate, and then the solution(s) is used as precipitant(s) to deposit rare earth, such as nickel, cobalt, iron, aluminum, gallium, indium, manganese, cadmium, zirconium, hafnium, strontium, barium, copper and zinc ions. And at least one of metal carbonates, hydroxides or basic carbonates is obtained, or furthermore the obtained products are calcined to produce metal oxides. The invention takes the cheap calcium and / or magnesium minerals or their oxides, hydroxides with low purity as raw materials to instead common precipitants such as ammonium bicarbonate and sodium carbonate etc. The calcium, magnesium, carbon dioxide etc are efficiently and circularly used, and the environment pollution by ammonium-nitrogen wastewater, high concentration salts wastewater is avoided, and both of the discharge of greenhouse gas carbon dioxide and the production cost of metal are decreased.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Composite carbonate and method for producing the same

ActiveUS20110114900A1Reduce the amount of wasteConductive materialCarbonate/bicarbonate preparationManganeseCobalt atom

The present invention provides a method for producing a nickel atom-, manganese atom- and cobalt atom-containing composite carbonate that is high in specific surface area and large in tap density, and useful as a raw material for producing a lithium nickel manganese cobalt composite oxide to be used in a positive electrode active material for use in a lithium secondary battery. The composite carbonate includes nickel atoms, manganese atoms and cobalt atoms, and has an average particle size of 5 μm or more and less than 20 μm, a BET specific surface area of 40 to 80 m2 / g and a tap density of 1.7 g / ml or more.

Owner:NIPPON CHECMICAL IND CO LTD

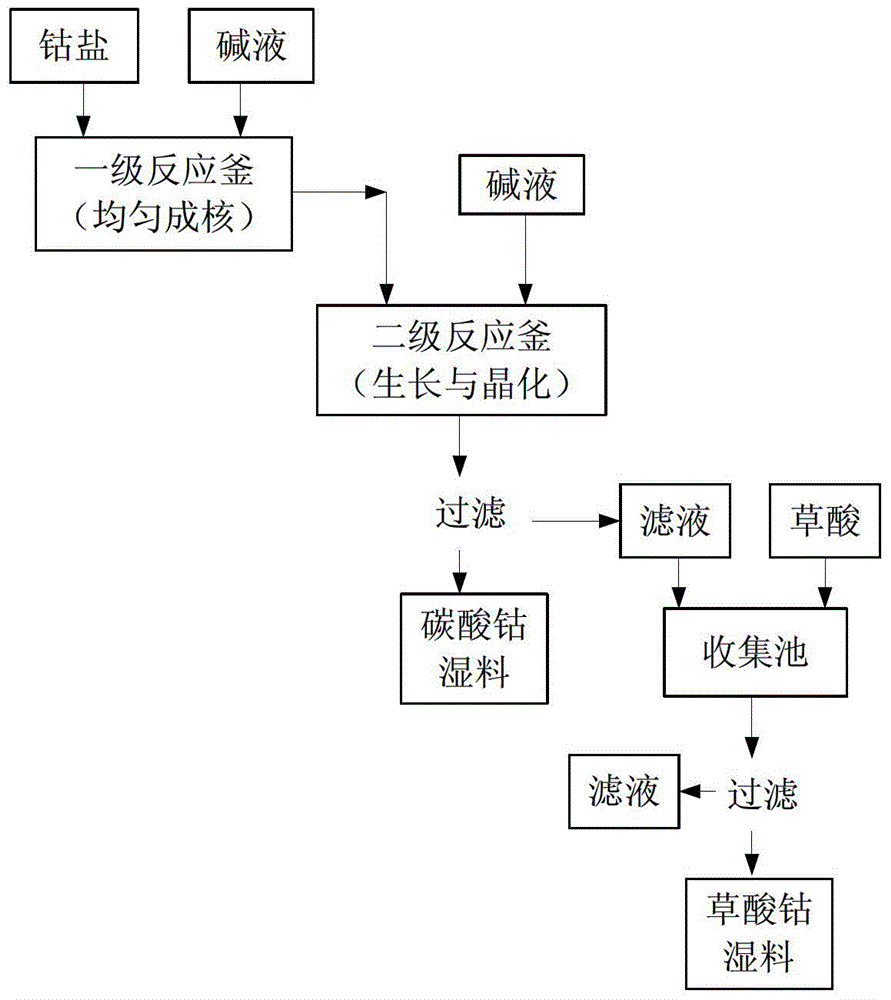

Method and system for preparing cobalt carbonate

The invention provides a method for preparing cobalt carbonate. The method comprises the following steps: S1, adding a cobalt salt solution and an ammonium hydrogencarbonate solution into a seed crystal kettle, reacting for 20-30 hours, and then increasing the flow rate of the cobalt salt solution by 20-40L / h every 15-20h until cobalt carbonate seed crystals with the particle diameter D50 of 11.5-14.0 microns are obtained; S2, adding the cobalt carbonate seed crystals into a finished product kettle, and adding the cobalt salt solution and the ammonium hydrogencarbonate solution into the finished product kettle; S3, reacting for 15-20 hours, and then increasing the flow rate of the cobalt salt solution in the S2 by 40-60L / h until a finished cobalt carbonate product with the tap density of 2.5-2.8g / cm<3> is obtained. Through control of the flow rate of the cobalt salt solution in different time periods, the process of preparing the cobalt carbonate is performed smoothly, so that more cobalt carbonate seed crystals conforming to morphological features and the finished cobalt carbonate product are obtained; in addition, the cobalt carbonate seed crystals are used for preparing the cobalt carbonate finished product, so that the yield and the preparation efficiency of the cobalt carbonate finished product are improved.

Owner:JINGMEN GEM NEW MATERIAL

Production equipment and technique for ultramicro powder of cobalt carbonate

The present invention discloses a production equipment of ultramicrofine cobaltous carbonate powder and its production process. Said production equipment includes cobalt salt header tank, precipitating agent header tank, reactor under two header tanks, stirrer placed in the reactor, sieve-plate fixed on the stirring shaft, material-discharging hole positioned in the lower end of the reactor and ageing tank, and the top of the above-mentioned every header tank is equipped with a material inlet, and its lower portion has a material liquor outlet. Besides, said invention also provides the concrete technological condition for producing ultramicrofine cobaltous carbonate powder.

Owner:湖南鼎伦新材料有限公司

Preparation method of small-particle size spherical cobalt carbonate

ActiveCN106629870AGuaranteed uniformityReduce processing costsCobalt carbonatesCobalt saltNucleation

The invention discloses a preparation method of small-particle size spherical cobalt carbonate. The preparation method comprises the following specific steps: 1, converging cobalt salt and an ammonium bicarbonate solution, adding into a reaction kettle for reacting, controlling the pH value in the reaction process so as to adjust the pH value of a system after half an hour to 7.0+ / -0.1; 2, further converging and adding the cobalt salt and an ammonium bicarbonate solution, keeping the pH in the step 1, continuing reacting for 2h, and precipitating; 3, performing solid-liquid separation and drying the solution after precipitation in the step 2 to obtain the small-particle size spherical cobalt carbonate. By the preparation method, through process control over the pH value, nucleation among cobalt carbonate particles and the uniformity of a growth condition are maintained, so that the isotropy of precipitates and the solution are achieved, and thus on the basis of the nucleation, the spherical cobalt carbonate is formed through outward, uniform and spherical growth. In addition, the preparation method is low in process cost and easy to popularize.

Owner:JINGMEN GEM NEW MATERIAL

Process for preparing high-density cobaltous carbonate

Disclosed is a production method of high-density cobalt carbonate, comprising steps as follows: firstly, a cobalt chloride solution and an ammonium carbonate solution are flowed according to a certain flux into a reactor to react for 9 hours at a temperature of 45 to 50 DEG C and at a pH value of 7.65 to 7.75 to form slurry which flows into a cobalt-depositing tank for particle growing, and ages for 2 hours, and is treated by filtering, slurrying and washing, and then enters a flash dryer for spin drying, and finally passes a cyclone separating device and a bag-type collector to achieve secondary recovery to obtain the finished product. The production method is characterized in that firstly the processes of continuous ultramicro deposition and particle growing under the conditions of constant current, constant pH value and constant temperature are adopted in the course of deposition, and then filtering and washing are adopted; and the concentration stability of reactants during the deposition reaction and the continuity of the process can be better achieved after the process of spin drying by the flash dryer, so that the products in terms of particle nucleation conditions and production time can be deterministic during production, and the particle size and morphology of the deposit can be controlled, thereby achieving consistency of high-density quality and stability of the products.

Owner:周红阳

Preparation method of cobalt carbonate for battery

ActiveCN102616865ADense nucleiFavorable for attachment growthCobalt carbonatesElectrical batteryProcess engineering

The invention discloses a preparation method of cobalt carbonate for a battery. The preparation method comprises the following steps of: firstly adding an ammonium bicarbonate solution as a base solution; then adding a cobalt liquid for the neutralization precipitation reaction again; adding the ammonium bicarbonate solution and the cobalt liquid at the same time to a reaction system by adopting a simultaneous feeding mode till the pH of the reaction system is 6-7; moreover, keeping the pH of the whole system to be stabled to be 6-8 in the feeding process; also monitoring the dimension of cobalt carbonate particles; stopping feeding when D50 in the average particle size distribution index of cobalt carbonate reaches the stipulated requirement, thus the whole neutralization precipitation reaction is finished; and filtering and drying discharged materials after the reaction products in a reaction tank is subjected to heat preservation and aging continuously, thereby obtaining the required cobalt carbonate. The preparation method provided by the invention is simple and has low cost, two stage matching of the neutralization precipitation reaction is reasonable, the appropriate matched parameters are optimized, thereby preparing and obtaining the similar-spherical cobalt carbonate with great apparent density and uniform and controllable particle size.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD

Method for fast crushing separating extracting tungsten carbide and cobalt carbonate by using waste ultra-fine hard alloy body

InactiveCN101239720AEfficient removalUniform grainTungsten/molybdenum carbideCobalt carbonatesCemented carbideHardness

The present invention provides a method of quick crashing separating and extracting tungsten carbide and cobalt carbonate utilizing waste superfine cemented carbides engine, characterized in that the method adopts waste superfine cemented carbides engine as basic material, tungsten-carbide powder and cobalt carbonate powder are obtained by breaked, ball milled, baked, then feeding in reaction kettle, blending by adding acid liquor and catalyst, then filter pressed and dried, the invention adopts equipment higher-mode vibration break, cementing phase liquefaction separation and pressing filter treatment, not only enhances productivity effect and capacity, but also effectively removes hazardous element and impurity element, the powder is further thining and extracted, and has a high production activity; the prepared cemented carbides obtains evenly distribution crystal grain, hardness and intensity synchronously enhances under the same process, the performance index exceeds native material product.

Owner:ZHUZHOU JINGZHU CEMENTED CARBIDE NEW MATERIAL

Composite carbonate and method for producing the same

InactiveUS7897069B2Reduce the amount of wasteNon-metal conductorsConductive materialManganeseCobalt atom

The present invention provides a nickel atom-, manganese atom- and cobalt atom-containing composite carbonate that is high in specific surface area and large in tap density, and useful as a raw material for producing a lithium nickel manganese cobalt composite oxide to be used in a positive electrode active material for use in a lithium secondary battery, and provides a method for industrially advantageously producing the composite carbonate. The composite carbonate includes nickel atoms, manganese atoms and cobalt atoms, and has an average particle size of 5 μm or more and less than 20 μm, a BET specific surface area of 40 to 80 m2 / g and a tap density of 1.7 g / ml or more.

Owner:NIPPON CHECMICAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com