Process and device for continuous production of superfine cobalt carbonate powder

A technology of cobalt carbonate powder and process, applied in the direction of cobalt carbonate, etc., can solve the problems of difficult treatment of waste liquid and uneven particle size, and achieve the effects of reduced coprecipitation, small and stable crystal nuclei, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

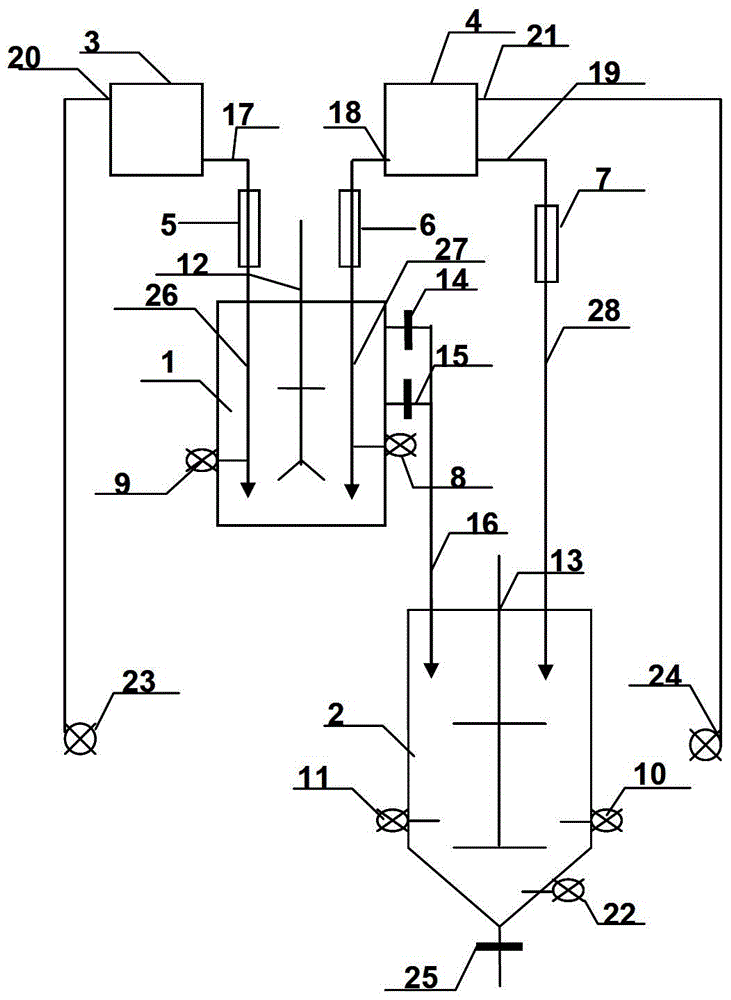

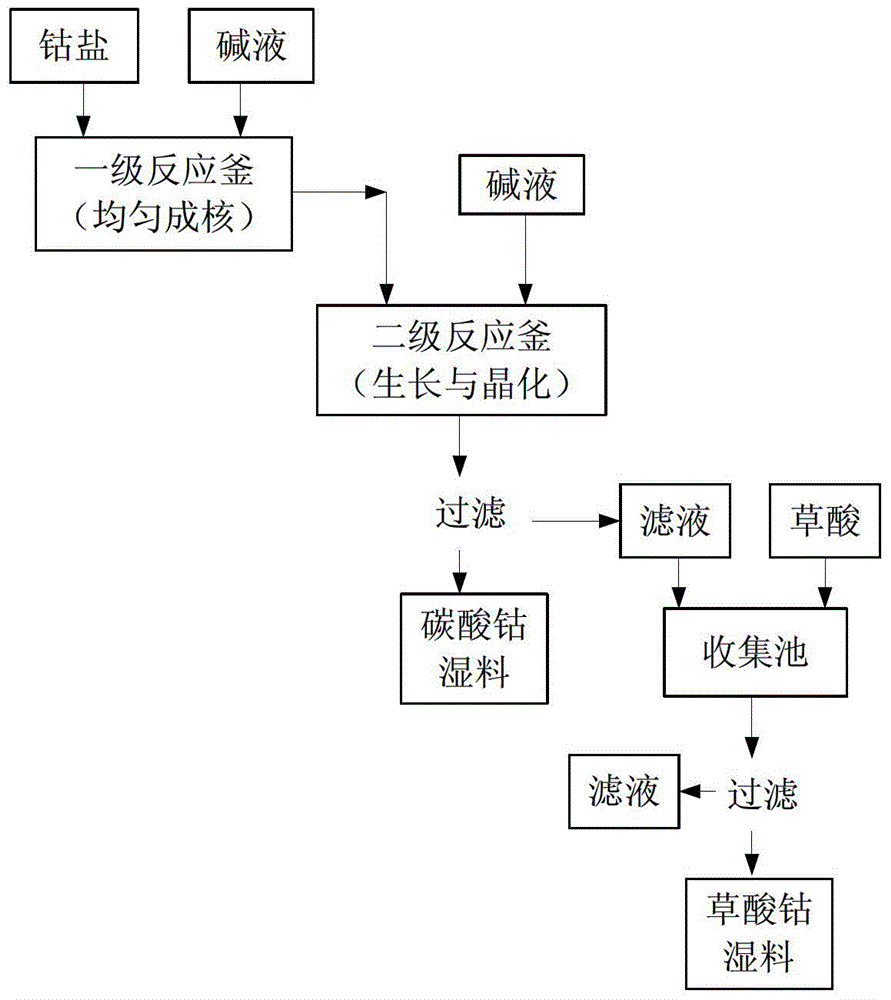

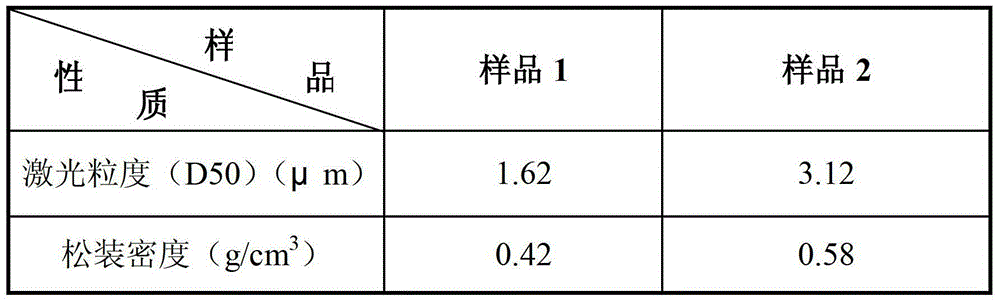

[0055] figure 1 It is a schematic diagram of a device for continuous production of ultrafine cobalt carbonate powder. Such as figure 1 Shown, a kind of device of continuous production superfine cobalt carbonate powder comprises two-stage reactor, wherein comprises a primary reactor 1 for nucleation reaction and a secondary reactor 2 for growth and crystallization process; The device also includes a cobalt salt storage tank 3 for storing the feed liquid and a precipitant storage tank 4 for storing the lye; the primary reaction kettle 1 is provided with a temperature regulator 8, a pH value regulator 9 and a vortex Stirrer 12; also be provided with independent temperature regulator 10, pH value regulator 11 and flow mixer 13 in described secondary reactor; The overflow ports 14 and 15 with valves are respectively located at 1 / 8h and 1 / 2h from the top of the reactor (h is the height of the primary reactor); the side wall of the secondary reactor 2 is provided with a material in...

Embodiment 2

[0058] A kind of technique of producing superfine cobalt carbonate powder, comprises the steps:

[0059] (1) Prepare cobalt nitrate solution and ammonium carbonate solution

[0060] Configure the volume in the configuration slot to be 10m 3 , a cobalt nitrate solution with a concentration of 60g / L and a volume of 20m 3 , ammonium carbonate solution with a concentration of 100g / L, and then pumped into the cobalt liquid storage tank and the precipitant storage tank respectively.

[0061] (2) First-order reaction—uniform nucleation

[0062] First, add 300L pure aqueous solution dissolved with 1Kg of ammonium nitrate into the primary reactor as the bottom liquid, turn on the turbine agitator and the pre-used overflow valve, then turn on the cobalt liquid delivery pump and the lye liquid delivery pump, and open the cobalt liquid respectively The flow meters of the storage tank and the precipitant storage tank make the cobalt salt solution flow into the reaction kettle at a flow ...

Embodiment 3

[0068] A kind of technique of producing superfine cobalt carbonate powder, comprises the steps:

[0069] (1) Prepare cobalt chloride solution and ammonium bicarbonate solution;

[0070] Configure the volume in the configuration slot to be 10m 3 , a cobalt chloride solution with a concentration of 80g / L and a volume of 20m 3 , ammonium bicarbonate solution with a concentration of 150g / L, and then pumped into the cobalt liquid storage tank and the precipitant storage tank respectively.

[0071] (2) First-order reaction—uniform nucleation

[0072] First, add a mixture of 300L pure water and 0.5L hydrochloric acid into the primary reactor as the bottom liquid, open the turbine agitator and the pre-used overflow valve, then open the cobalt liquid delivery pump and lye delivery pump, and turn on the cobalt liquid The flow meters of the liquid storage tank and the precipitant storage tank allow the cobalt salt solution to flow into the reactor from the bottom of the first-stage re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com