Preparation process of fireproof and wear-resistant calcined basic zinc carbonate

A preparation process, zinc carbonate technology, applied in the direction of zinc compounds, inorganic chemistry, nanotechnology, etc., can solve the problems of specific surface area of basic zinc carbonate, suspension of reaction solution, single function, etc., and achieve good stoichiometry The effect of high stability, narrow particle size distribution and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

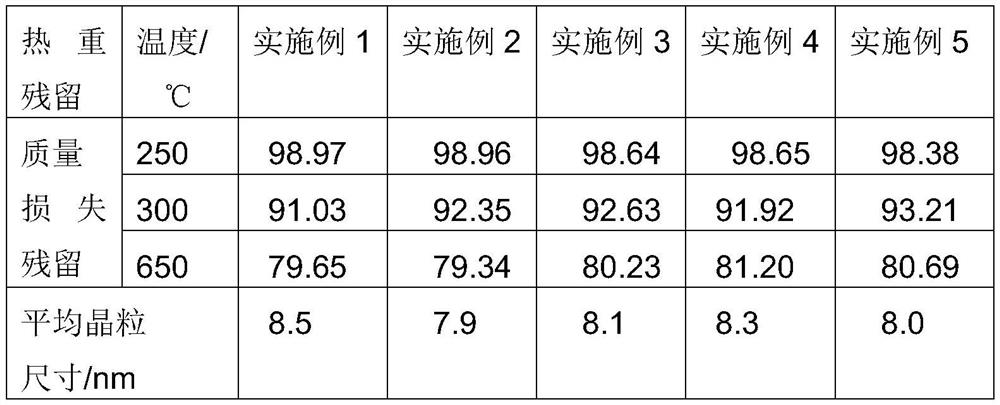

Examples

Embodiment 1

[0032] The preparation process of the fireproof and wear-resistant calcined basic zinc carbonate comprises the following steps:

[0033](1) Preparation of zinc sulfate solution: put zinc oxide ore in the leaching device, pour sulfuric acid with a concentration of 20% into the leaching device, then use an electric stirring device to stir for 1.5 hours, then acid leaching for 4.0 hours h, after the leaching is finished, filter and purify the leaching solution in the leaching device to obtain a zinc sulfate solution; the liquid-solid ratio of the zinc oxide ore to sulfuric acid is 5:1, and the stirring speed of the electric stirring device is 220r / min;

[0034] (2) Preparation of reaction solution: heat the zinc sulfate solution to 80° C., add potassium permanganate for oxidation, mechanically stir for 1.5 hours, adjust the pH to 5.2 to 5.4 with ammonia water; keep the temperature for 1 hour, cool to room temperature, filter, The zinc sulfate solution for preliminary iron removal...

Embodiment 2

[0037] The preparation process of the fireproof and wear-resistant calcined basic zinc carbonate comprises the following steps:

[0038] (1) Preparation of zinc sulfate solution: put the zinc oxide ore into the leaching device, pour sulfuric acid with a concentration of 21% into the leaching device, then use an electric stirring device to stir, the stirring time is 1.8h, and then acid leaching 4.0 -5.0h, after the leaching is finished, filter and purify the leaching solution in the leaching device to obtain a zinc sulfate solution; the liquid-solid ratio of the zinc oxide ore to sulfuric acid is 5:1, and the stirring speed of the electric stirring device is 250r / min;

[0039] (2) Preparation of reaction solution: heat the zinc sulfate solution to 80-90° C., add potassium permanganate for oxidation, mechanically stir for 1.5 hours, adjust the pH to 5.2-5.4 with ammonia water; keep the temperature for 2 hours, cool to room temperature, Filtrate to obtain the zinc sulfate solut...

Embodiment 3

[0042] The preparation process of the fireproof and wear-resistant calcined basic zinc carbonate comprises the following steps:

[0043] (1) Preparation of zinc sulfate solution: put zinc oxide ore in the leaching device, pour sulfuric acid with a concentration of 20-23% into the leaching device, and then use an electric stirring device to stir for 2.0 hours, then acid After leaching for 4.0h, after the leaching is over, filter and purify the leaching solution in the leaching device to obtain a zinc sulfate solution; the liquid-solid ratio of the zinc oxide ore to sulfuric acid is 5:1, and the stirring speed of the electric stirring device is 250r / min;

[0044] (2) Preparation of reaction solution: heat the zinc sulfate solution to 80-90° C., add potassium permanganate for oxidation, mechanically stir for 1.5 h, adjust the pH to 5.2-5.4 with ammonia water; keep the temperature for 1, cool to room temperature, Filtrate to obtain the zinc sulfate solution for preliminary iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com