Patents

Literature

328results about How to "Reasonable formula design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Health food for reinforcing immune function of human body and preparation technique thereof

ActiveCN101292742ACheap sourceStable sourceImmunological disordersFood preparationPharmacyCordycepin

The invention aims at providing a health-care food enhancing immune function of human body and provides a preparation technique thereof. The health-care food, according to weight proportion, is produced by raw materials comprising 10-50 portions of gen-seng, 10-50 portions of glossy ganoderma and 10-50 portions of zymotic cordycepin powder; the raw materials comprising the gen-seng, the glossy ganoderma and the zymotic cordycepin powder are positioned in a hop-pocket; the processed raw materials are carried out heating and decoction for 1-3 times (each time is for 1-2 hours) after being added with water for soaking for one hour; extraction solution is mixed, filtered and concentrated to defined amount; after being cooled, concentrated solution is carried out high-speed centrifugal impurity removal; the obtained concentrated solution is produced into required preparation independently or by adding with accessories acceptable in medical science with the conventional processes of pharmacy.

Owner:JIANGZHONG PHARMA

Hot melt adhesive

InactiveCN102653665ASuitable for production process requirementsReasonable formula designMacromolecular adhesive additivesEpoxyPolyolefin

The invention discloses a hot melt adhesive which comprises the following components in parts by mass: 5-10 parts of EVA (ethylene-co-vinyl acetate), 2-6 parts of tackifier, 5-10 parts of diluent, 0.5-1.5 parts of antioxidant and 0.5-1.5 parts of plasticizer. The tackifier is one of rosin resin, petroleum resin, terpene resin, phenolic resin and epoxy resin; the diluent includes one or both of wax and low-molecular polyolefin; the antioxidant is phenolic antioxidant; and the plasticizer is DCHP (Dicyclohexyl phthalate). The EVA contains 20-30% of vinyl acetate monomer; and the wax is microcrystalline wax with molecular weight of 3,000-4,000 and melting point of 65-85 DEG C.

Owner:成都鑫三洋科技发展有限公司

Multiple microorganism straw fermented fodder and leaven and its preparing method

InactiveCN1425317AImprove disease resistanceHigh nutritional valueBacteriaFood processingMicroorganismBiotechnology

The microbe fermented feed is produced through preparing fermenting agent with several kinds of microbial strains, mixing supplementary material, straw and activated fermenting agent, fermentation inside one container of fermenting pond. The fermenting agent has wide application range of fermentation conditions and various straw and vine, green or dry, of different crops may be used as the main material for producing the fermented feed. The fermented feed has good feeding effect, and is delicious and easy to digest and absorb.

Owner:TIANJIN DAMEI SCI & TECH

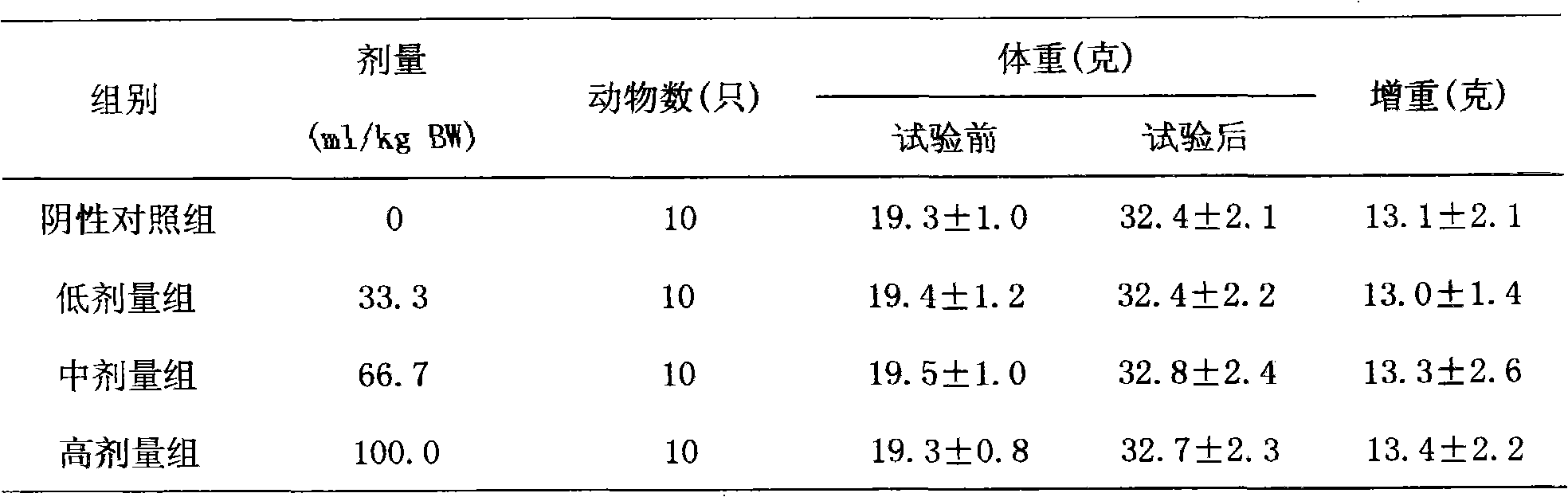

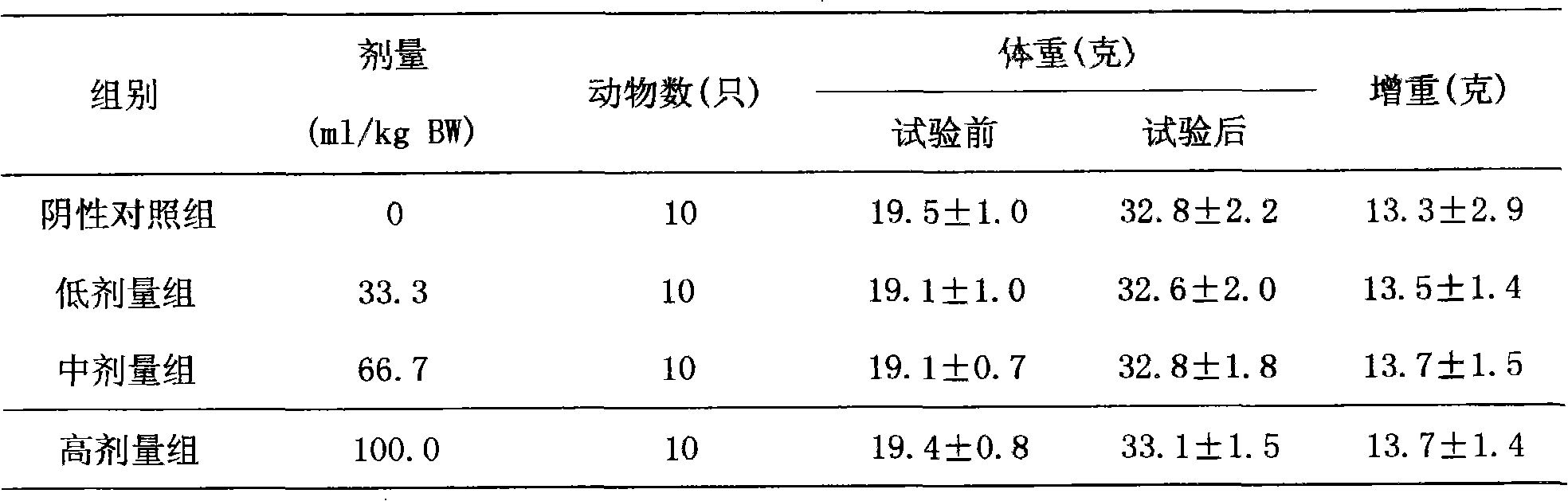

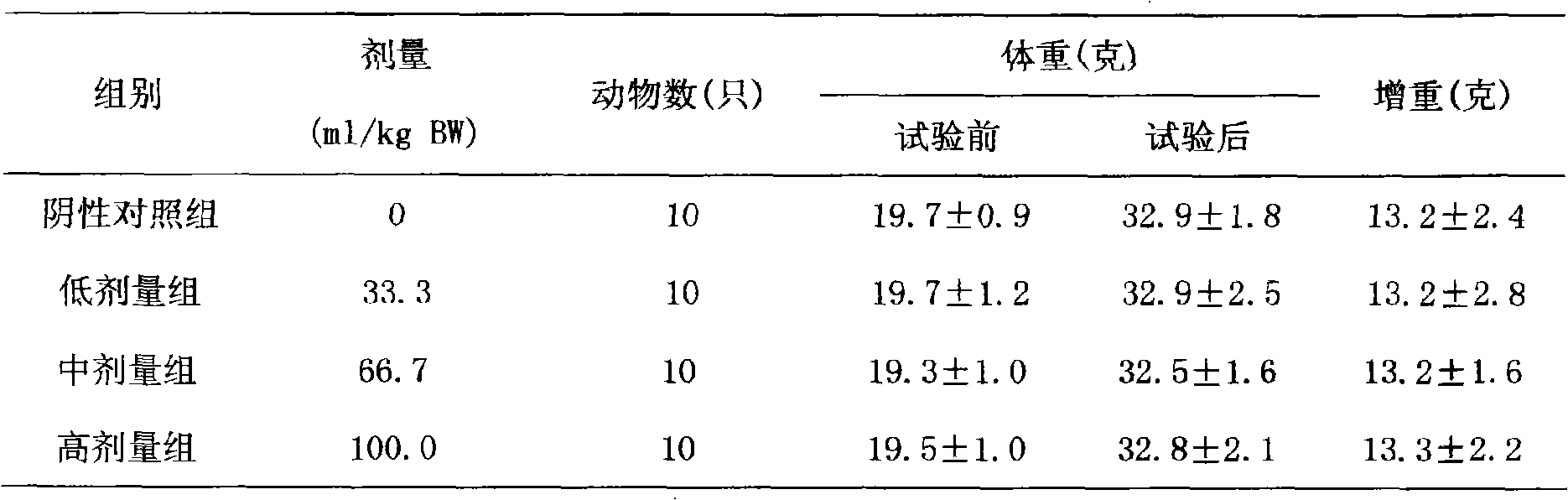

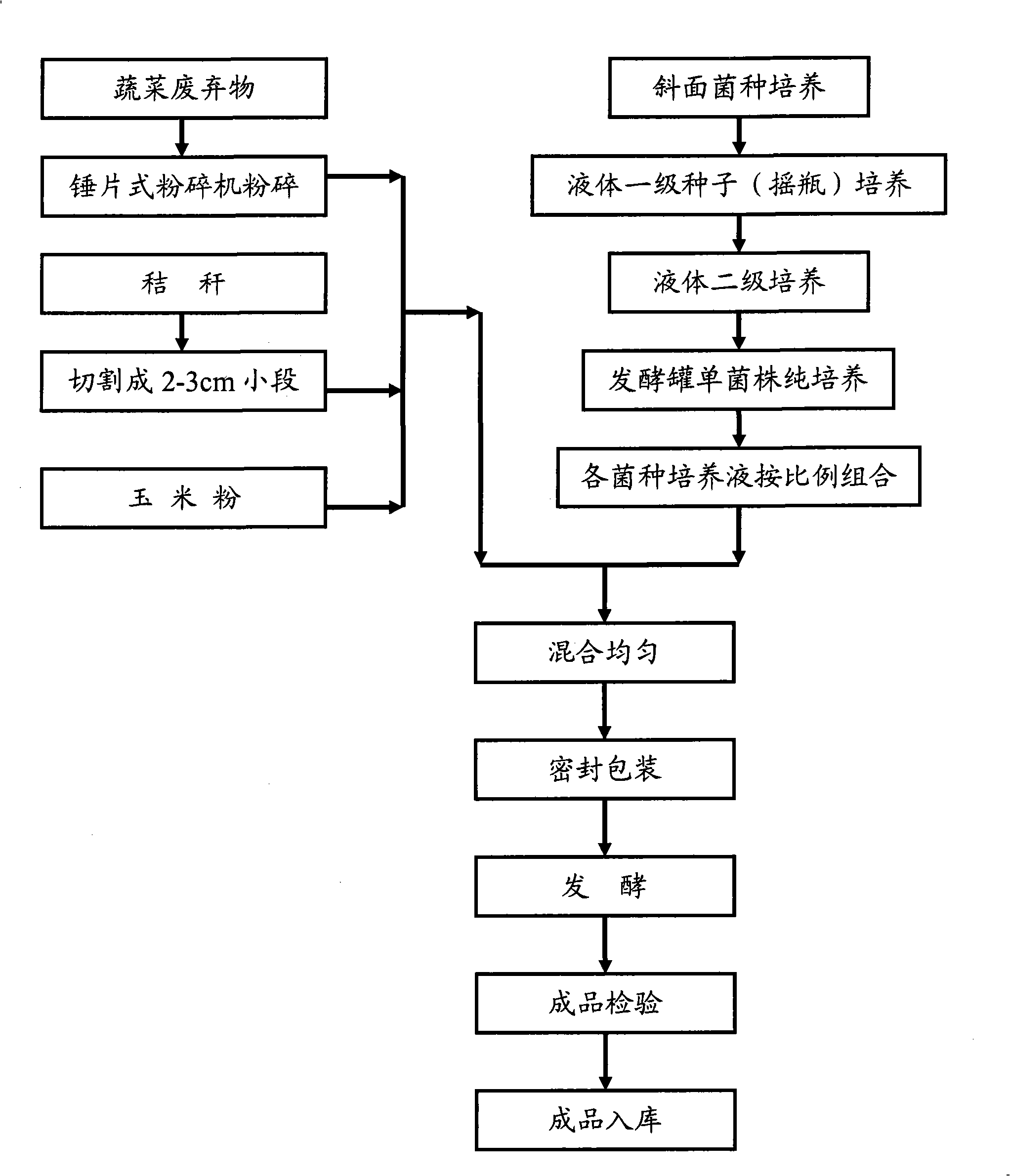

Fermented abandoned vegetable feedstuff and preparation method thereof

InactiveCN101401616AAdaptableSuitable for a wide range of raw materialsFood processingAnimal feeding stuffBiotechnologyMicroorganism

The invention relates to fermentation waste vegetables feed and a preparation method. The fermentation waste vegetables feed consists of mixed raw materials and microorganism living bacteria liquid, wherein the mixed raw materials consist of vegetable waste materials, straw and corn powder; and each ton of the mixed raw materials are formed according to the weight ratio (w / w): 70 to 80 percent of waste vegetables, 20 to 25 percent of straw, and 4 to 6 percent of corn powder. Each ton of the mixed raw materials are added with 30 to 40 milliliters of the microorganism living bacteria liquid, and the content of living bacteria for the microorganism living bacteria liquid is between 1.0x10<9>cfu / mL and 1.0x10<11>cfu / mL. The fermentation waste vegetables feed and the preparation method have the advantages of reasonable formulation, scientific production method, wide applicable areas, simple operation, easy master, low cost, reasonable formula design, convenient production, suitability for broad peasant households and livestock breeding plants, safe and no toxity, and great adaptability to fermentation conditions, and can be used as feed of cows, sheep, geese, and so on, make full use of side products in agriculture industry, realize reasonable use of the resources, and provide new techniques for clean and sustainable agricultural industry.

Owner:北京阔利达生物技术开发有限公司 +1

Power-steering high-pressure hose and production process thereof

ActiveCN102040782AReasonable formula designGood physical and mechanical propertiesFlexible pipesPower steeringChemistry

The invention relates to a power-steering high-pressure hose which comprises five layers, namely, an inner adhesive layer, a weaving layer, a middle adhesive layer, a weaving layer, and an outer adhesive layer which are arranged sequentially from inside to outside. The power-steering high-pressure hose is reasonable in formula design, and prepared by using chlorinated polyethylene elastomers, ethylene vinyl acetate elastomers or butyronitrile / polrvinyl chloride alloy elastomers and butadiene adhesive resins as raw materials, therefore, the excellent physical and mechanical properties of sizing materials are ensured, and a good adhesive force is obtained between chlorinated polyethylene rubbers and a reinforcing fiber layer, wherein the adhesive strength at least can reach 28N / cm under thetest condition that the ASTM413 (American society for testing material 413) extension rate is 30mm / min. In the invention, the chlorinated polyethylene rubbers are really be applied to the power-steering high-pressure hose so as to meet the demands of the current car market.

Owner:QINGDAO SUNSONG CO LTD

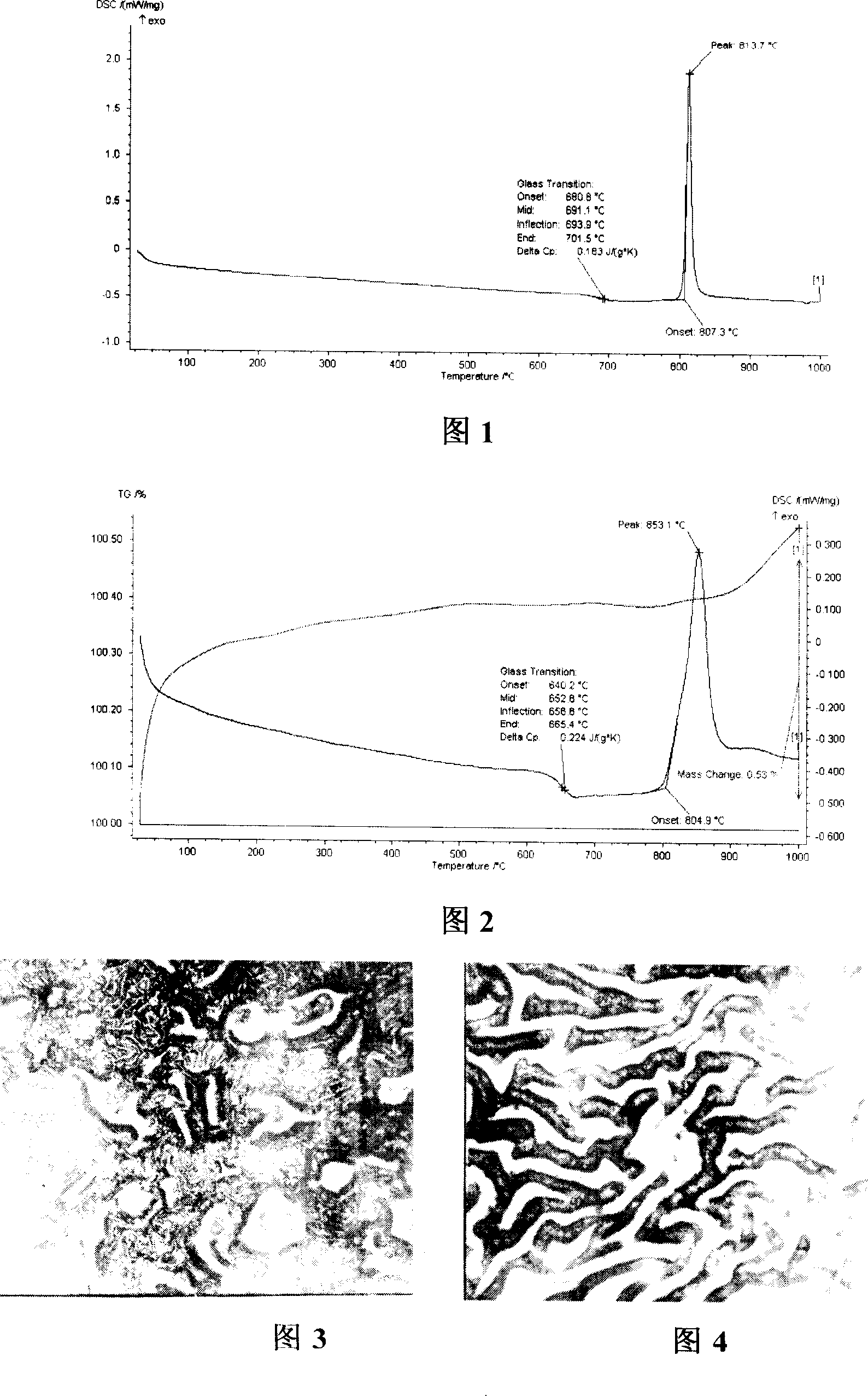

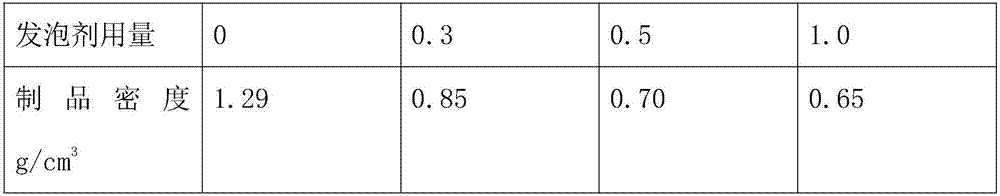

Microcrystal glass made from titanium-containing magnetic iron are tailings

This invention provides a glass ceramic produced by debris of magnetite that contains titanium. it takes titanium-containing debris as the main raw material, plus quartz sand that SiO2 purity greater than 96% and content of 18% ~ 30%; With further increase feldspar that content of 2% to 5% as additives; the weight percentage of above glass ceramic composition: SiO2: 55 ~ 65, Al2O3: 4 to 10, CaO: 10 ~ 20, MgO: 3-7, TiO2: 4 to 7, Fe2O3: 4.0 ~ 9.5, ZrO2: 0 ~ 1.5 , K2O - Na2O: 4 to 9. This invention can comprehensive utilize of titanium containing vanadium and titanium magnetite debris, can effectively solve the problem of environmental and safety issues caused by the long-term accumulation of debris, and reduce production costs.

Owner:CHONGQING UNIV

Microbial fermented feed, microbe mother liquor for fermented feed and its production process

InactiveCN1608486AImprove disease resistanceLow costFood processingAnimal feeding stuffBiotechnologyMicroorganism

The present invention is microbial fermented feeds, microbe mother liquor for fermented feeds and their production process. Several microbe strains may be used in anaerobic fermentation of various crop stalk powder, husk, bran, bean residue, etc. to produce various kinds of fermented feed. The present invention has reasonable composition, scientific production process, wide application range and other advantages, and the fermented feed has low cost high feeding efficiency and capability of raising animal's resistance.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Optics parts surface detergent

InactiveCN101368137AEasy to cleanLess corrosiveNon-ionic surface-active compoundsOrganic detergent compounding agentsSurface-active agentsCleansing Agents

The invention provides a cleaner for the surface of an optical element, comprising pH regulator, surface active agent, solubilizer, corrosion inhibitor and purified water; wherein, the weight percentage of the pH regulator is 1 percent to 22 percent, the weight percentage of the surface active agent is 1 percent to 5 percent, the weight percentage of the solubilizer is 1 percent to 5 percent, the weight percentage of the corrosion inhibitor is 1 percent to 5 percent and the rest is purified water; the cleaner is applicable to the cleaning of the dirty on the surface of the optical element, has reasonable formulation design, low cost and safe and convenient use, and meets the requirements of environment protection; and the cleaned waste liquid is convenient to be treated and discharged.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Method for preparing hot melt adhesive

InactiveCN102653666ASuitable for production process requirementsReasonable formula designMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEpoxyPolyolefin

The invention discloses a method for preparing hot melt adhesive. The method comprises the steps of: mixing EVA (ethylene-vinyl acetate), a tackifier and a diluent according to parts by weight, and then heating, stirring, smelting and cooling the mixture. The hot melt adhesive comprises 5-10 parts of EVA, 2-6 parts of a tackifier, 5-10 parts of a diluent, 0.5-1.5 parts of an antioxidant and 0.5-1.5 parts of a plasticizer; the tackifier is one of abietic resin, petroleum resin, terpene resin, phenolic resin and epoxy resin; the diluent is one or two of wax and micro-molecular polyolefin; and the antioxidant is a phenolic antioxidant; and the plasticizer is DCHP (dicyclohexylphthalate). The stirring speed is 200-750 rpm; the heating temperature is 200-400 DEG C; and the cooling temperature is 10-25 DEG C.

Owner:成都鑫三洋科技发展有限公司

Electronic instrument panel surface detergent

InactiveCN101368141AImprove permeabilityWash thoroughlyNon-ionic surface-active compoundsOrganic detergent compounding agentsOzone layerSolid particle

The invention provides a cleaner for the surface of an electronic instrument panel, comprising solubilizer, surface active agent, pH value regulator, antifoaming agent and deionized water; the weight percentage of all the components is as follows: 3 percent to 10 percent of the solubilizer, 3 percent to 12 percent of the surface active agent, 2 percent to 8 percent of the pH value regulator, 2 percent to 8 percent of the antifoaming agent and the rest is the deionized water; the cleaner is water soluble liquid and the pH value thereof is 11 to 12; the cleaner is applicable to the cleaning technique of the surface of the electronic instrument panel, can effectively remove the pollutants including rosin, soldering tin, oil stain, finger prints and solid particles and the like stained on the surface of the electronic instrument panel, has good permeability and thorough cleaning, is not easy to generate residue, has little corrosion, safe and reliable use and no damage to the ozone layer, meets the requirements of environment protection and has reasonable formulation design, simple preparation technique and low cost.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Electronic instrument detergent

InactiveCN101368138AEasy to cleanEase of handling emissionsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOzone layerAntistatic agent

The invention provides a cleaner of an electronic instrument, comprising phosphate, surface active agent, antistatic agent, pH value regulator and deionized water; the weight percentage of all the components is: 3 percent to 12 percent of the phosphate, 3 percent to 12 percent of the surface active agent, 3 percent to 8 percent of the antistatic agent, 2 percent to 8 percent of the pH value regulator and the rest is the deionized water; the pH value of the mixing liquid is 11 to 12; the cleaner is applicable to the cleaning technique of a circuit board and parts of the electronic instrument, can effectively remove organics and dusts and the like stuck in the long time operation of the electronic instrument, can eliminate static, has low corrosion and safe and reliable use, does not damage the ozone layer, conforms to the requirements of environmental protection, etc. and has reasonable formulation design, simple preparation technique and low cost; and the cleaned waste liquid is convenient to be treated and discharged.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Wood plastic composite section bar and production technology thereof

InactiveCN107501805AImprove mechanical propertiesReasonable formula designProduction rateFoaming agent

The invention discloses a wood plastic composite section bar and a production technology thereof. The wood plastic composite section bar comprises the following raw materials in parts by weight: 40-60 parts of PVC, 10-15 parts of wood powder, 20-30 parts of CACO3, 1-3 parts of a stabilizer, 1-2 parts of a foaming agent, 1-2 parts of a lubricating agent and 4-6 parts of processing additives. The wood plastic composite section bar is reasonable in formula design, has a coupling toughening function, is capable of promoting the mechanical properties of material, is beneficial to the promotion of rigidity and thermal deformation of products and is available for indoor and outdoor wood plastic products and products with higher requirement on thermal deformation; a toughening agent CPE is added, so that the toughness of the product is higher; the wood plastic composite section bar has high heat stability, weather fastness and anti-ultraviolet function; the section bar is high in compatibility with resin, high in dispersibility, and capable of increasing production rate and promoting the surface glossiness of products; the wood plastic composite section bar has anti-fogging and antistatic functions; the wood plastic composite section bar is suitable for production wood plastic skirting lines, door pocket lines, sill lines, ecological wood, hollow panels, floor boards, stair railings, ventilated windows, micro-foamed cabinet panels, wave panels, and other products.

Owner:安徽淮宿建材有限公司

Feed for pregnant sows

The invention relates to a feed for pregnant sows, which comprises the following components in percentage by weight: 40 to 45 percent of corn, 28 to 32 percent of wheat bran, 10 to 15 percent of wheat, 5 to 8 percent of dehulled soybean meal, 2 to 5 percent of maize embryo meal, 1.5 to 2 percent of rock flour, 0.8 to 1.2 percent of calcium hydrophosphate, 0.4 to 0.5 percent of salt, 0.008 to 0.012 percent of enzyme preparation, 0.1 to 0.2 percent of lysine, 0.08 to 0.12 percent of Meixiaoan (a product for preventing and removing mould, removing poison and promoting growth), 0.03 to 0.06 percent of choline, 0.02 to 0.05 percent of vitamins for sows, 0.2 to 0.3 percent of minerals for sows, 0.02 to 0.03 percent of Mailunxiang (a seasoning product from Myron company) and 0.01 to 0.02 percent of Mailuntian (a seasoning product from Myron company. The formula of the feed is reasonably designed, and can provide more complete and balance nutrients for pregnant sows. The raw materials of the feed are cheap, so the cost of the feed for pregnant sows is reduced.

Owner:SUZHOU HAIJINGLING INDAL

Polybasic silver solder

ActiveCN103111770AReduce dosageImprove plasticityWelding/cutting media/materialsSoldering mediaRare-earth elementMetallurgy

The invention relates to polybasic silver solder characterized in that the polybasic silver solder comprises, by weight, 12-28% of Ag, 37-49% of Cu, 1.0-3.0% of In, 0.5-2.5% of Ni, 0.001-0.1% of rare earth elements and the balance Zn, wherein the polybasic silver solder contains little precious metal of silver, and the content of the silver is reduced by about 20% compared with high-silver solder such as Bag40CuZnSn. Therefore, production cost is greatly reduced, and use amount of the precious metal of the silver is saved.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

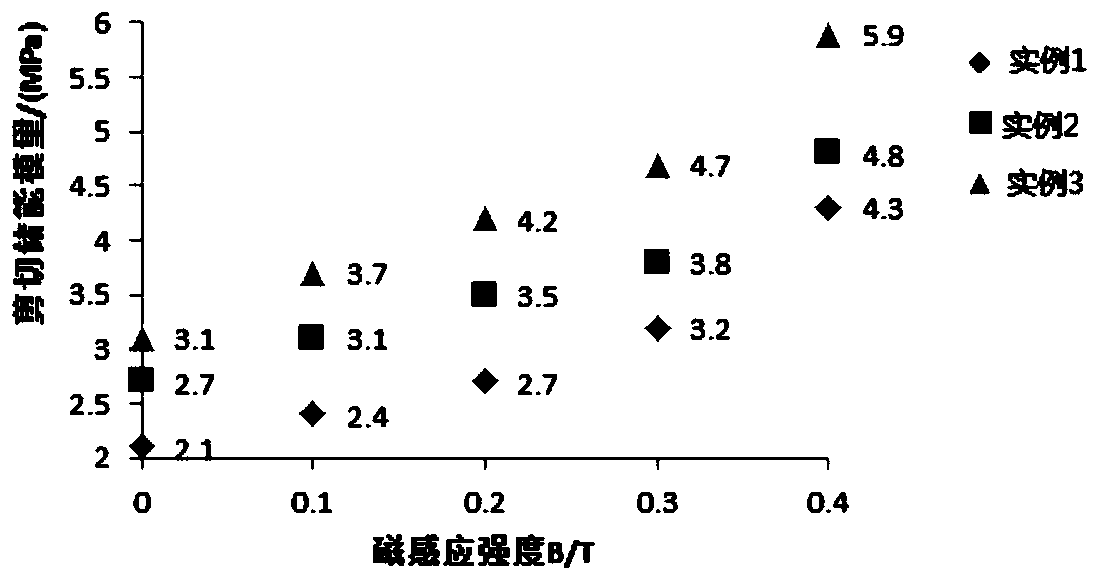

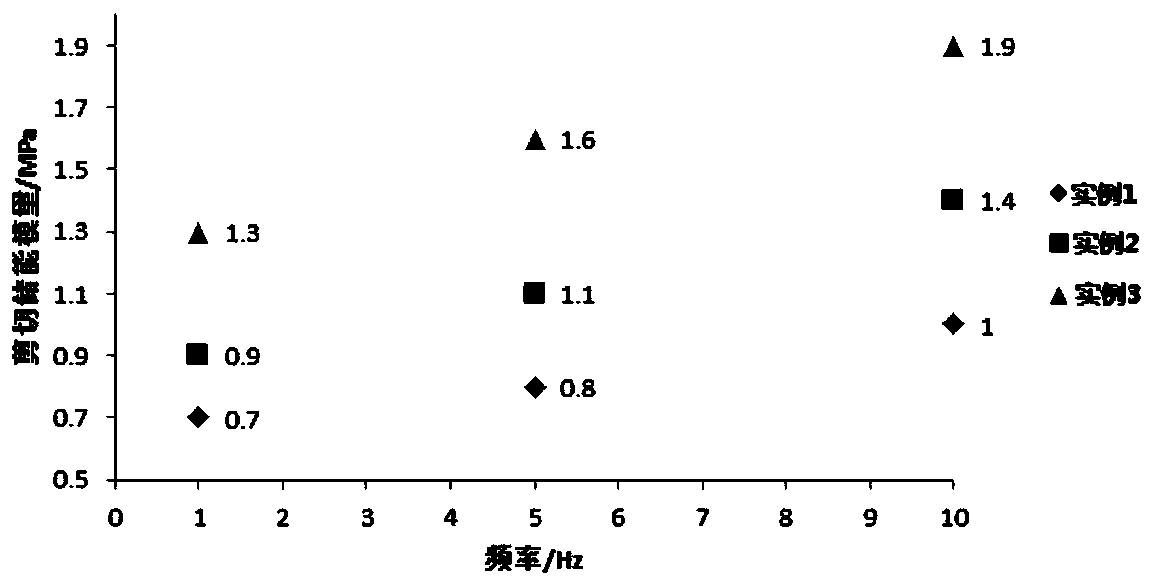

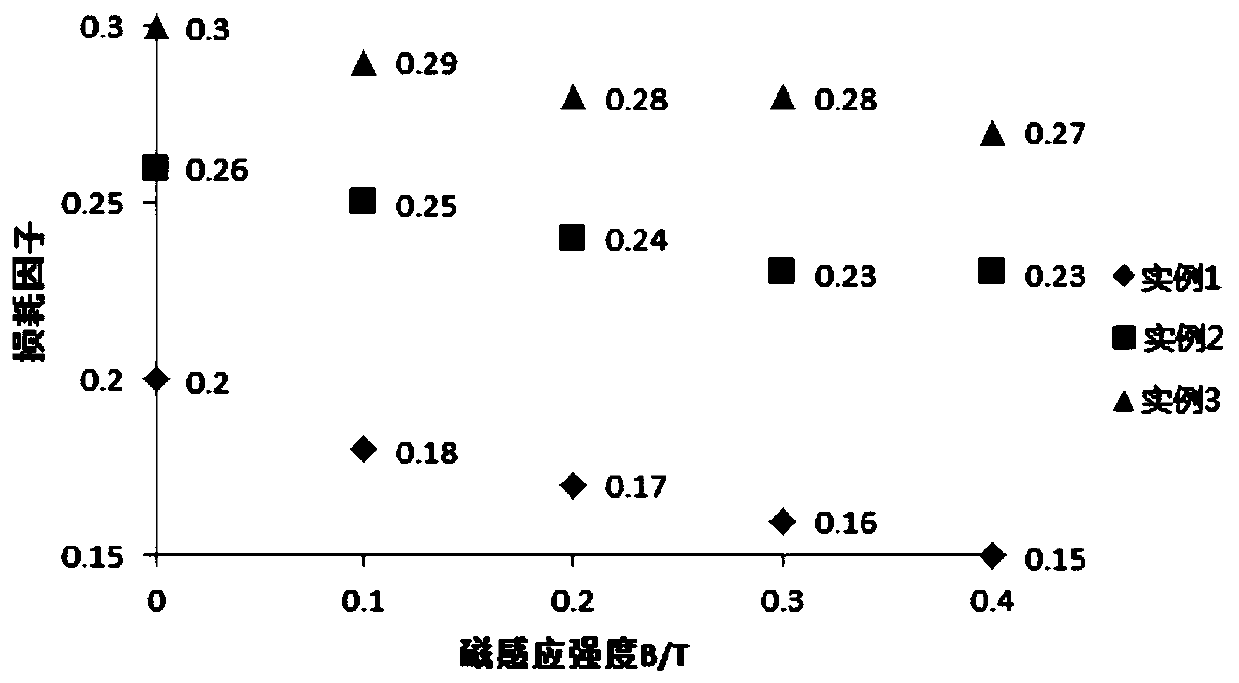

Magnetorheological elastomer, preparation method and application thereof

The invention relates to a magnetorheological elastomer, a preparation method and application thereof. The elastomer comprises the following components in parts by weight: 100-150 parts of a rubber matrix, 600-700 parts of magnetic particles, 16-25 parts of a vulcanizing agent, 4-5 parts of an accelerator and 120-180 parts of a filling material, and the filling material comprises 20-30 parts of aplasticizer, 30-50 parts of a dispersant, 50-60 parts of a binder, 10-20 parts of a reinforcing agent and 10-20 parts of a cold-resistant agent. The components are matched and cooperated with each other, so that the bonding strength of the interface between the magnetic particles and the matrix is improved, the magnetic permeability is improved on the premise of ensuring the saturation magnetization strength, and the eddy current loss is reduced. A part made of the magnetorheological elastomer material has good mechanical properties and good damping and shear storage modulus when in use. The good mechanical properties and good damping and shear storage modulus have obvious effect on vibration reduction and isolation design, and the magnetorheological elastomer is suitable for popularization and application..

Owner:SHENYANG JIANZHU UNIVERSITY

Novel color carbon treatment agent for leather and preparation method thereof

InactiveCN102839540ASolving Dispersion ProblemsSolve the fineness problemFibre treatmentColor effectSolvent

The invention discloses a novel color carbon treatment agent for leather and a preparation method thereof, relating to a surface treatment agent for synthetic leather. The color carbon treatment agent disclosed herein comprises 10-40% of alkyd resin, 1-10% of nitro-cotton, 0.5-1% of levelling agent, 1-10% of matting powder, 5-25% of carbon black, 5-25% of color pigment, 30-60% of solvent, 0.5-2% of dispersant, and 1-5% of stripping aid. According to the invention, the problems of dispersion and fineness of the carbon black and color pigment are solved, by adding the color pigment to compound with the carbon black and simultaneously polishing the product, the leather surface presents a synthetic and complete color effect and has a certain metal luster, the formula design is reasonable, the component cooperation is advanced, the product performance is excellent and stable, the technology is advanced, and the operationality is strong.

Owner:HANGZHOU COLORICH CHEM MATERIALS

Anti-crack mortar and preparation method therefor

InactiveCN104973832ASimple processEasy to implementSolid waste managementHardnessPulverized fuel ash

The present invention relates to an anti-crack mortar and a preparation method therefor. The anti-crack mortar comprises the following components by weight percentage: 28-30% of cement, 10-6% of coal ash or 5%-10% of glass powder, 5% of heavy calcium, 57-59% of medium-coarse sand, 0.3% of HPMC, 1.5-2% of latex powder, 0.2% of water Shen agent, 0.3% of polypropylene fiber and 0-0.3% of other additives, wherein the HPMC is hydroxypropyl methylcellulose with viscosity being 100,000. According to the present invention, waste coal ash (glass powder) is used, so as to protect the environment and save energy; The mortar has good fluidity and water retention, thereby facilitating mixing. The hardened mortar has high hardness and high strength, and is non-toxic and high in stability.

Owner:杭州正博新型建筑材料有限公司

Preparing method of high-strength woodworking adhesives

InactiveCN102977799AAvoid damageImprove water resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveSodium bicarbonatePolyvinyl alcohol

The invention discloses a preparing method of high-strength woodworking adhesives. The preparing method comprises, by weight, 3-5 parts of rubber smoked sheets, 8-10 parts of corn starch, 0.5-1 modified wood ash, 1-2 parts of carboxymethy cellulose, 5-8 parts of styrene, 2-3 parts of polyisobutylene, 1-2 parts of sodium tripolyphosphate, 1-2 parts of azobisformamide, 3-4 parts of epoxy four hydrogen phthalate ester, 1-2 parts of urea, 2-3 parts of acrylic ester, 3-5 parts of acrylic acid, 1-2 parts of ammonium persulfate, 2-3 parts of fatty alcohol-polyoxyethylene ether, 3-4 parts of acetic styrene-acrylic emulsion, 1-2 parts of sodium bicarbonate, 3-5 parts of attapulgite, 1-2 parts of sodium lauryl sulfate, 10-12 parts of water glass, 5-8 parts of polyvinyl alcohol, and 120-150 parts of water. According to the preparing method, the ingredient design is reasonable, materials are easy to obtain, a production process is simple, equipment matching is simple, production quality is stable, adhesion force is strong, hardening performance is good, quick drying and no-bubble are achieved, the modified wood ash is added, damage of water molecules to the adhesives is effectively reduced, water resistant performance of the adhesives is greatly improved, due to the fact that hydrophilic performance of the adhesives is reduced, good quick drying performance is achieved, meanwhile adhesion strength is greatly improved, and water resistance is significantly improved.

Owner:合肥帝奥木业有限公司

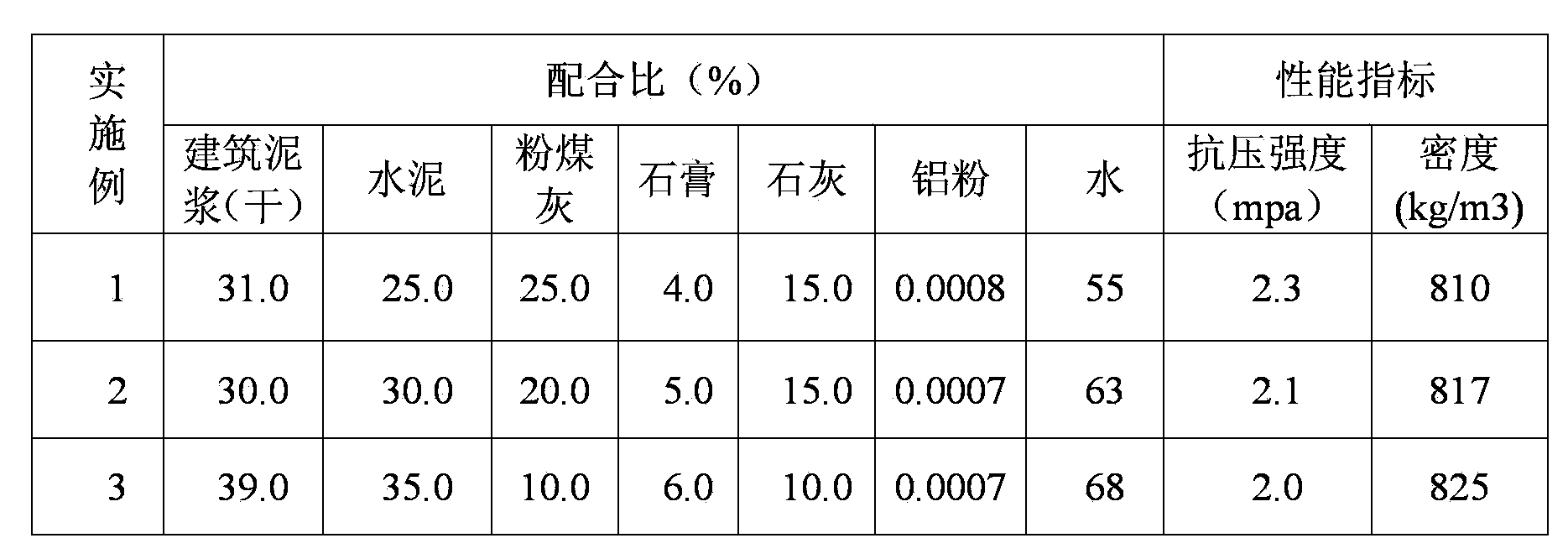

Non-autoclaved aerated concrete block manufactured from building slurry and manufacturing method thereof

The invention discloses a non-autoclaved aerated concrete block manufactured from building slurry and a manufacturing method thereof, belonging to the technical field of building materials. The block comprises the following components in percentage by weight: 30%-45% of dry weight building slurry, 25%-40% of cement, 10%-25% of lime, 15%-30% of coal ash, 2%-8% of plaster and the balance being a foaming agent. The manufacturing method comprises the following steps of weighing each component and water; firstly, preparing an aluminum powder paste solution, then uniformly mixing the other components with the aluminum powder paste solution, and pouring the mixture into a mold; and carrying out delaying-curing hot cell maintenance, demolding, cutting and stacking maintenance so as to prepare the non-autoclaved aerated concrete block manufactured from the building slurry. According to the manufacturing method, the waste building slurry is utilized for manufacturing the non-autoclaved aerated concrete block, the energy-saving and environment-friendly effects are achieved, waste materials are recycled, and a good social benefit is achieved; the strength of the produced block is high, the block does not need to be autoclaved, the cost is low, and three wastes are not generated during a production process.

Owner:杨林江

Gel type emulsion explosive and preparation thereof

InactiveCN101328099AImprove intrinsic safetyImprove securityExplosive working-up apparatusLow speedEmulsion explosive

The invention discloses a gel-type emulsion explosive and a method for preparing the same. The explosive is prepared by 75%-86% of ammonium nitrate, 4%-7% of emulsifier-compound grease, 0.5%-4% of crystal modifier and water balance, different models of coal permissible products are prepared by adding 3%-7% of flame reducer into the explosive. When preparation, the ammonium nitrate, crystal modifier, water and flame reducer are mixed, heated and dissolved to form an oxidant water solution as an aqueous phase solution, the emulsifier-compound grease is heated to form a combustible agent solution as an oil phase solution, the aqueous phase solution and oil phase solution are pumped into an open type emulsifier for emulsification after accurate measurement and are sensitized to finished products in a low speed mixing device by means of a belt device. The explosive energy of the product can be released to a maximum extent, the density can reach 1.4g / cm<3>, the explosion strength can reach 360ml and the detonation velocity can reach 6500m / s.

Owner:耿一平

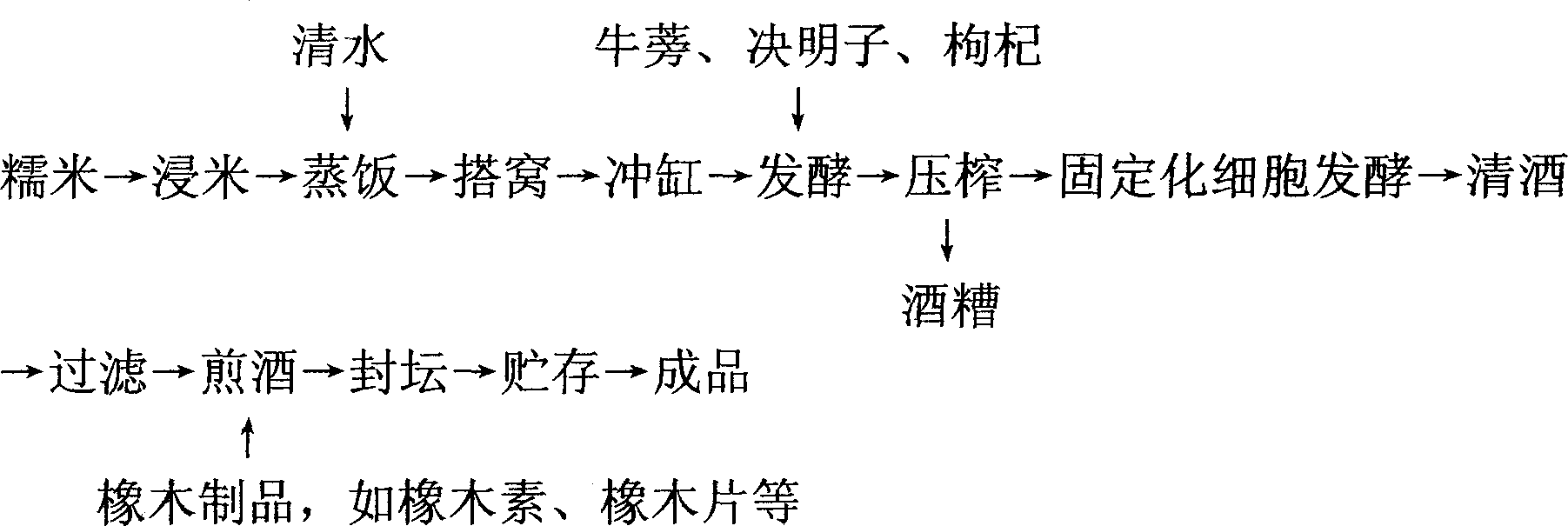

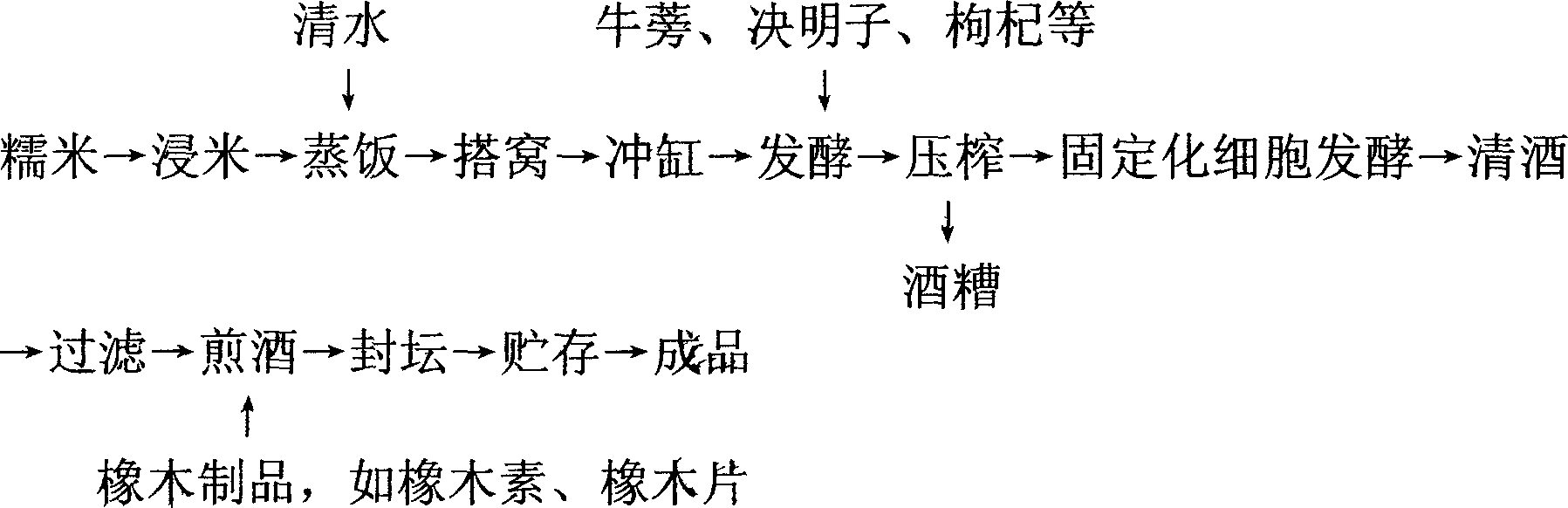

Brewing method for nevol flavor yellow wine

The brewing process of novel flavor yellow wine features the addition of burdock fruit, cassia seed, wolfberry fruit, etc in the fermentation step, and the addition of oak chip, etc before the wine jar is sealed and while the wine is still hot. The present invention makes the yellow wine possess unique flavor and has the health functions of the said Chinese medicinal materials and the unique scent of oak.

Owner:杨国军

Ceramic sanding agent and preparation method thereof

InactiveCN101368082AReduce wearImprove processing efficiencyOther chemical processesSurface roughnessCeramic

The invention provides a ceramic abrasive and a preparation method thereof. The ceramic abrasive comprises sulphur, animal oil, an inorganic base, an industrial lubricant, an activator, paraffin and pure water through mixing. The ceramic abrasive is characterized in that the sulphur accounts for 0.1 to 2 percent by weight; the animal oil accounts for 20 to 30 percent by weight; the inorganic base accounts for 2 to 5 percent by weight; the industrial lubricant accounts for 1 to 5 percent by weight; the activator accounts for 0.1 to 2 percent by weight; the paraffin accounts for 1 to 3 percent and pure water accounts for the remaining percentage. The roughness of ceramic surfaces is reduced by increasing the grinding lubricity and reducing the damage to marble so that the ceramic has excellent function for grinding surfaces. The preparation process of the abrasive has the advantages of simplicity, being operated simply, meeting environmental requirements and low manufacturing cost.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Water-based epoxy paint and preparation method thereof

InactiveCN104910759AIncrease crosslink densityImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

The invention provides a water-based epoxy paint and a preparation method thereof. The paint comprises an amino resin, a leveling agent, distilled water, a water-based epoxy acrylic resin, a dispersing agent, a defoaming agent, iron oxide black, superfine talcum powder, precipitated baryte, zinc phosphate, a rust inhibitor and the like; and a nano MoS2 anti-wear agent and a nano CaCO3 ultraviolet absorbent are further added to enhance the properties. By reasonably designing the component types and contents, the thickness of the paint film can reach 100 mu m above, the water resistance is greater than 240 hours, the transmittivity for ultraviolet light with the wavelength of 290-400nm is less than 0.4, the wear-resistant revolution number is up to 1000-1400, the mass loss of the paint film is less than 0.07 g / 100r, and the salt spray resistance is greater than 200 hours. The paint can be brushed on the internal and external walls of an iron building, has excellent protective effect, and is especially suitable for protecting iron building cultural relics.

Owner:JIANGSU UNIV OF TECH

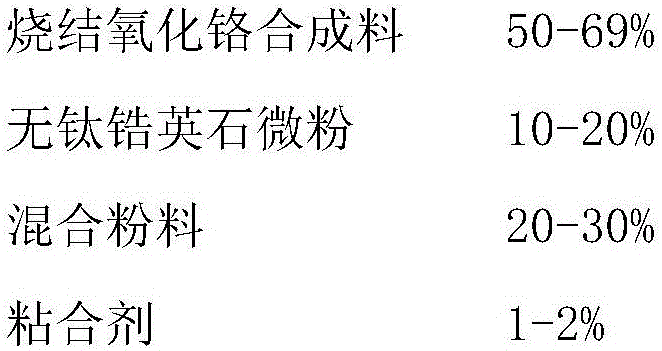

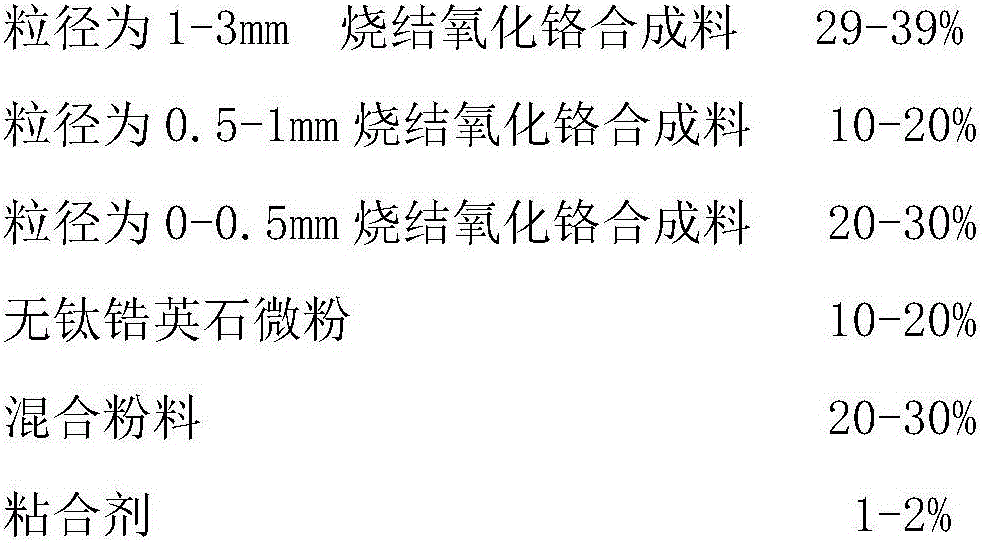

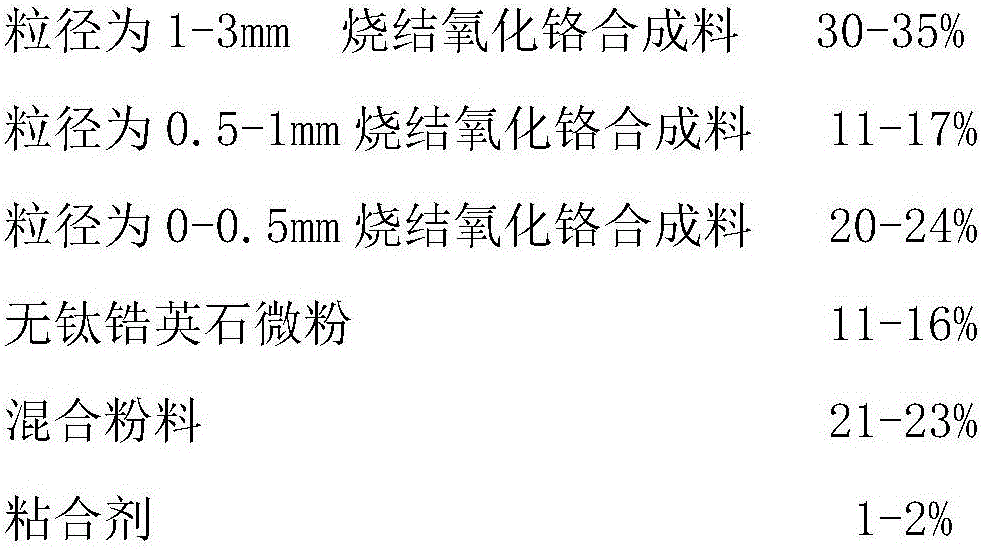

Chromic oxide refractory material and preparation method thereof

The invention discloses a chromic oxide refractory material which is prepared from aggregate, a substrate material and an adhesive. The aggregate is a sintered chromic oxide synthesized particle material with the particle size of 0-3mm; the substrate material comprises titanium-free zirconite micropowder and mixed powder with the particle size of less than 20 mu m; the chromic oxide content in the sintered chromic oxide synthesized particle material is greater than or equal to 85%; the zirconium silicate content in the titanium-free zirconite micropowder is greater than 99%; and the mixed powder comprises chromic oxide, zirconium oxide, silicon oxide or titanium oxide powder. The chromic oxide refractory material cannot be stripped and molten into the glass metal in the use process, and meanwhile, the chromic oxide has very high glass corrosion resistance, and the corrosion resistance of the product is further enhanced.

Owner:广州市石基耐火材料厂

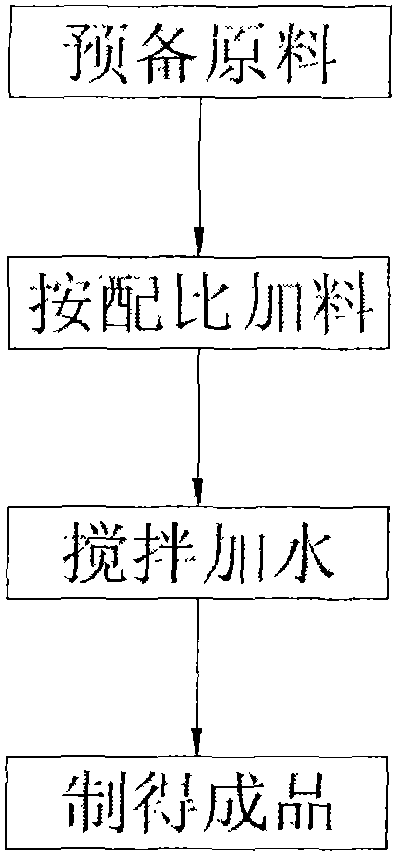

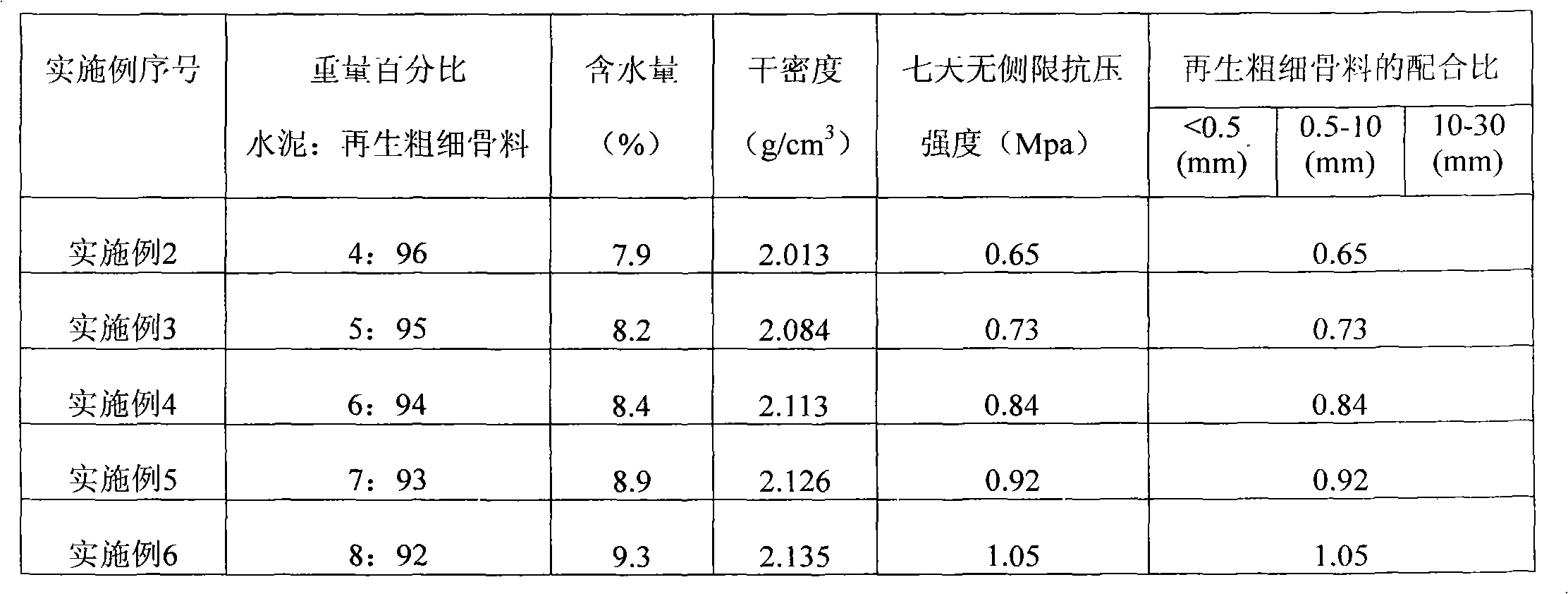

Method of stably regenerating gravel from cement, and product of the method

ActiveCN103848605AEasy to getHigh compressive strengthSolid waste managementSocial benefitsTime limit

The invention discloses a method of stably regenerating gravel from cement. The method includes steps of: 1) preparing raw materials comprising the cement and regenerated crude and fine aggregate; 2) adding the raw materials according to a ratio; and 3) stirring, and adding water to obtain a finished product. The invention also discloses a product obtained by the method. The method is simple in preparation technology, easy to achieve, and high in production efficiency, and can rapidly and stably produce the gravel product with high compressive strength by utilization of the cement. The method has high production efficiency, largely reduced cost, and good economic and social benefit, and protects the environment. The design of the formula is reasonable. The raw materials are easily available. Processes of traditional gravel exploiting are effectively simplified. The compressive strength of the product is high and can meet requirements of buildings with respect to material performances, thus solving the gravel resource shortage problem and achieving objectives of environment protection and sustainable development. The product is easy to construct, shortens the time limit for a project, improves the construction efficiency and facilitates wide popularization and application.

Owner:北京鼎创环保有限公司

Novel water boiling fried dough twist and preparation method of novel water boiling fried dough twist

The invention provides a water boiling fried dough twist and a preparation method of the novel water boiling fried dough twist. The fried dough twist comprises outer wrappers and stuffing, wherein the outer wrappers are made from the following ingredients including minced fillet, carrageenan, starch, roe, soy isolate protein, fat lining, ice water, common salt, sugar, monosodium glutamate, phosphate and seasoning. The stuffing is made from the following ingredients including chicken meat, chicken skin, soy isolate protein, mushroom, cassava modified starch, corn starch, ice water, crispy onion, common salt, seasoning, pigment, white granulated sugar, phosphate and wire drawing protein. The appearance of the water boiling fried dough twist prepared according to the invention is similar to that of the traditional fried dough twist, but the recipe and the preparation process are obviously different from those of the traditional fried dough twist, the first water boiling and then oil frying process is adopted in the preparation method, the quality and the appearance of the products are ensured, meanwhile, the oil frying time is shortened, the oil frying time is only about 3 minutes, and the water boiling fried dough twist belongs to quick freezing water products, can be used for hot pot, barbecue and the like and more preferably conforms to the requirements of people on health, nutrition, and product novelty and creativity.

Owner:天津市宽达水产食品有限公司

Anti-cracking texture paint preparation method and product thereof

InactiveCN102863898AReasonable formula designHigh tensile strengthCoatingsWeather resistanceCrack resistance

The invention discloses an anti-cracking texture paint preparation method and a product prepared by the method. The product is prepared from the following raw materials: water, ethylene glycol, cellulose, preservative, pH regulator, coarse whiting powder, defoaming agent, elastic emulsion, TEXANOL and thickening agent. The method disclosed by the invention has the advantages of simple preparation technique and high production efficiency, and is easy to implement. The method disclosed by the invention has the advantages of simple preparation technique and high production efficiency, and is easy to implement. The anti-cracking texture paint product disclosed by the invention has reasonable formula design, favorable tensile strength, cracking resistance, water resistance, high adhesive force, excellent weather resistance and excellent decorative effect, can be well bonded on the walling, and ensures the walling to have neat and elegant appearance. The anti-cracking texture paint has the advantages of favorable stereoscopic texture, favorable comprehensive properties, high temperature tolerance, high weather resistance, low cracking tendency and long service life, and effectively lowers the maintenance cost. Besides, the construction process is simple, greatly shortens the construction period, enhances the construction efficiency, requires low cost, and is beneficial to wide popularization.

Owner:黄明杰

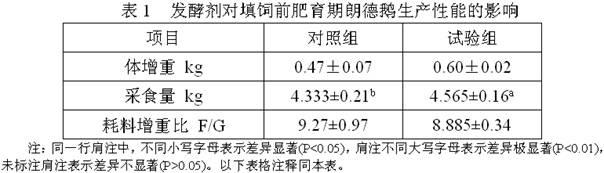

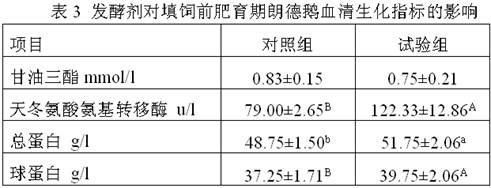

Feed leavening agent and fermented feed for promoting growth and liver development of geese

InactiveCN102524538AImprove growth performanceReasonable formula designAnimal feeding stuffBiotechnologyFermentation starter

The invention belongs to the technical field of feeds for geese, and discloses a feed leavening agent and a fermented feed for promoting the growth and liver development of the geese. The feed leavening agent consists of the following components in percentage by weight: 0.1 to 0.15 percent of bacillus, 0.1 to 0.2 percent of saccharomycetes, 0.3 to 0.4 percent of lactobacillus, 0.2 to 0.3 percent of butyric acid bacteria, 0.05 to 0.1 percent of filiform fungi, 0.5 to 2 percent of aid and the balance of carrier, wherein the bacterial counts of the bacillus in each gram of the leavening agent are1.0*10<9> to 1.5*10<9> colony-forming unit (CFU), the bacterial counts of the saccharomycetes in each gram of the leavening agent are 1.0*10<9> to 2.0*10<9> CFU, the bacterial counts of the lactobacillus in each gram of the leavening agent are 1.0*10<10> to 1.5*10<10> CFU, the bacterial counts of the butyric acid bacteria in each gram of the leavening agent are 4.0*10<9> to 5.0*10<9> CFU, and thebacterial counts of the filiform fungi in each gram of the leavening agent are 0.5*10<9> to 1.5*10<9> CFU. According to the feed leavening agent, antibiotics are not contained in a premix, a formula is reasonable in design, and the components are coordinated organically; and the feed leavening agent is added into the feed for the geese at the fattening stage before force-feeding, so that the development of livers can be promoted, the growth performance and liver-producing performance of the geese can be improved, and a guidance is provided for the goose raising production and the production of the fat livers of the geese.

Owner:陈文

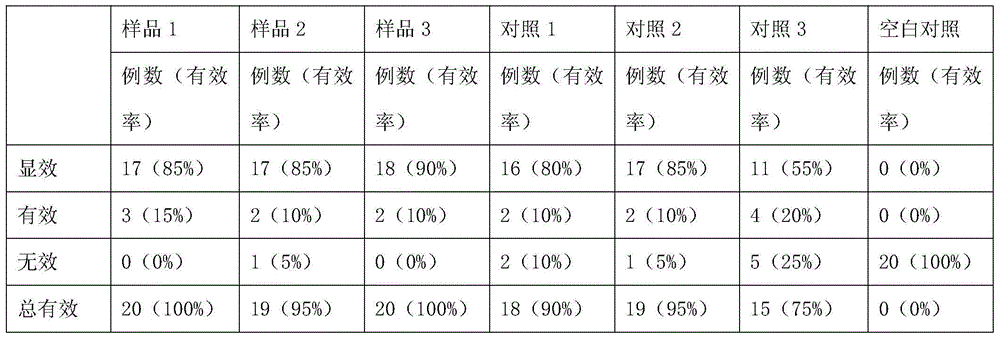

Traditional Chinese medicine extract product for treating chloasma and preparation method for traditional Chinese medicine extract product

ActiveCN104398431AEliminates pigmentationImprove utilizationCosmetic preparationsToilet preparationsMedicinal herbsChinese drug

The invention discloses a traditional Chinese medicine extract product for treating chloasma and a preparation method for the traditional Chinese medicine extract product. The traditional Chinese medicine extract product is prepared from the following raw material medicines in parts by weight: 1.0-3.5 parts of a winter folium mori extract and 1.0-2.4 parts of peony seed oil. With the combination of traditional Chinese medicines and modern preparation processes, cosmetics which can be applied to skin can be prepared, the utilization rate of the traditional Chinese medicine extract is increased, the healthcare function of medicines is improved, and the traditional Chinese medicine extract product is particularly applicable to development of modernization of traditional Chinese medicines and massive health products.

Owner:GUIZHOU SHENQI PHARMA RES INST

Method for processing surface of diesel engine fuel tank machining die

InactiveCN105032827AReasonable formula designImprove efficiencyCationic surface-active compoundsOrganic detergent compounding agentsEthyl acetateFuel tank

The invention relates to the technical field of machining, in particular to a method for processing the surface of a diesel engine fuel tank machining die. The method includes the steps that 1, degreasing cotton is used to stick ethyl acetate to wipe the surface of the die, and then the die is wiped dry through dry cloth; 2, the wiped and dried die is placed into cleaning liquid preheated to 45 DEG C to be soaked for 30 minutes; 3, the die is flushed with water after being fished out till the pH value of the flushing water returns to be neutral; 4, the surface of the die is polished, and anodizing is conducted on the polished die; 5, the die is flushed with water after being fished out till the pH value of the flushing water returns to be neutral, and drying is conducted. The surface processing method is concise in operation technology, cleaning liquid soaking is the most important step, and the formula of the cleaning liquid is reasonably designed, so that the oxidation layer on the surface of the die is rapidly and effectively eliminated, the reutilization rate of the die is increased, and the production cost of enterprises is lowered.

Owner:尚成荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com