Non-autoclaved aerated concrete block manufactured from building slurry and manufacturing method thereof

A technology for aerated concrete and construction mud, which is applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc. The effect of high strength and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

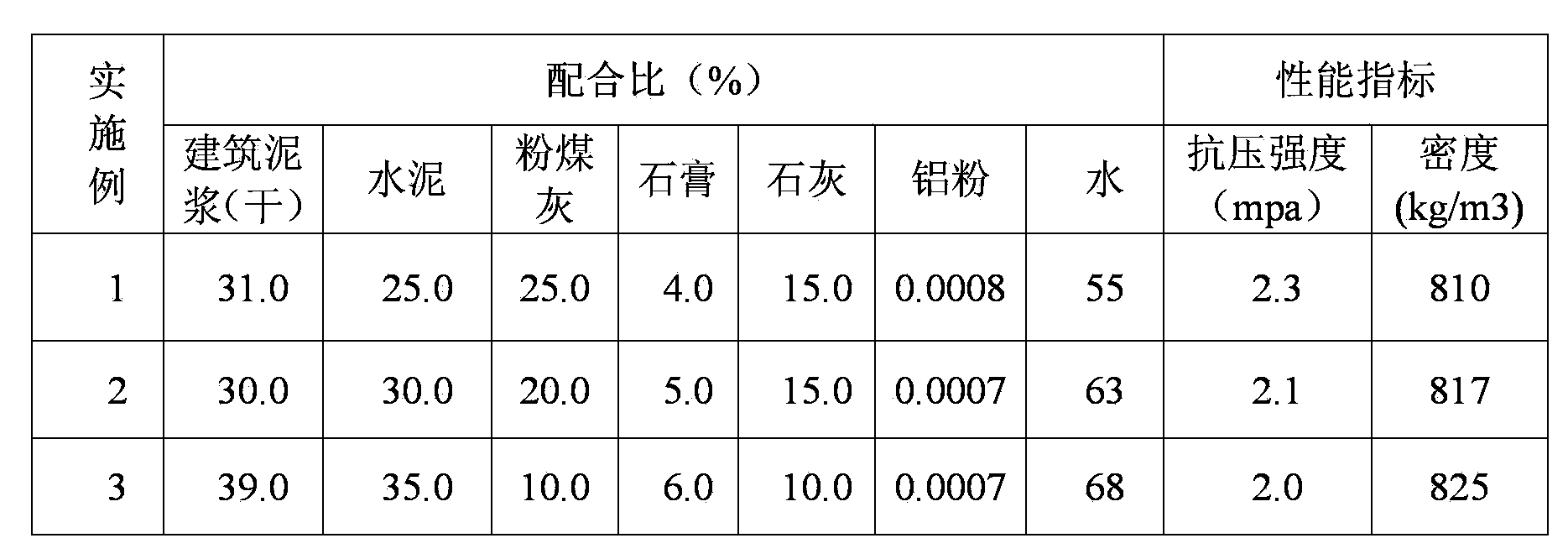

Embodiment 1

[0023] Embodiment 1: the percentage by weight is: dry weight construction mud 31.0%, cement 25.0%, lime 15.0%, fly ash 25.0%, gypsum 4.0%, each component of the aluminum powder of 0.0008% weighs, then takes by weighing water, The weight of water is 55% of the total weight of the above dry powder materials; mix aluminum powder and water evenly to prepare an aluminum powder paste solution, and then mix construction mud, cement, lime, fly ash, and gypsum with the prepared aluminum powder paste solution Evenly, pour it into the non-steaming aerated concrete block mold; after 4 hours of curing in a static heating chamber, demoulding and cutting, stacking and curing for 28 days, the non-steaming aerated concrete block made of construction mud is obtained. The performance indicators are shown in Table 1.

Embodiment 2

[0024] Embodiment 2: the percentage by weight is: dry weight construction mud 30.0%, cement 30.0%, lime 15.0%, fly ash 20.0%, gypsum 5.0%, each component of the aluminum powder of 0.0007% is weighed, then takes by weighing water, The weight of water is 63% of the total weight of the above dry powder materials; mix aluminum powder and water evenly to prepare an aluminum powder paste solution, and then mix construction mud, cement, lime, fly ash, and gypsum with the prepared aluminum powder paste solution Evenly, pour it into the non-steaming aerated concrete block mold; after 4 hours of curing in a static heating chamber, demoulding and cutting, stacking and curing for 28 days, the non-steaming aerated concrete block made of construction mud is obtained. The performance indicators are shown in Table 1.

Embodiment 3

[0025] Embodiment 3: the percentage by weight is: dry weight construction mud 39.0%, cement 35.0%, lime 10.0%, fly ash 10.0%, gypsum 6.0%, each component of the aluminum powder of 0.0007% is weighed, then takes by weighing water, The weight of water is 68% of the total weight of the above dry powder materials; mix aluminum powder and water evenly to prepare an aluminum powder paste solution, and then mix construction mud, cement, lime, fly ash, and gypsum with the prepared aluminum powder paste solution Evenly, pour it into the non-steaming aerated concrete block mold; after 4 hours of curing in a static heating chamber, demoulding and cutting, stacking and curing for 28 days, the non-steaming aerated concrete block made of construction mud is obtained. The performance indicators are shown in Table 1.

[0026] Table 1

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com