Patents

Literature

75results about How to "Strong typical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

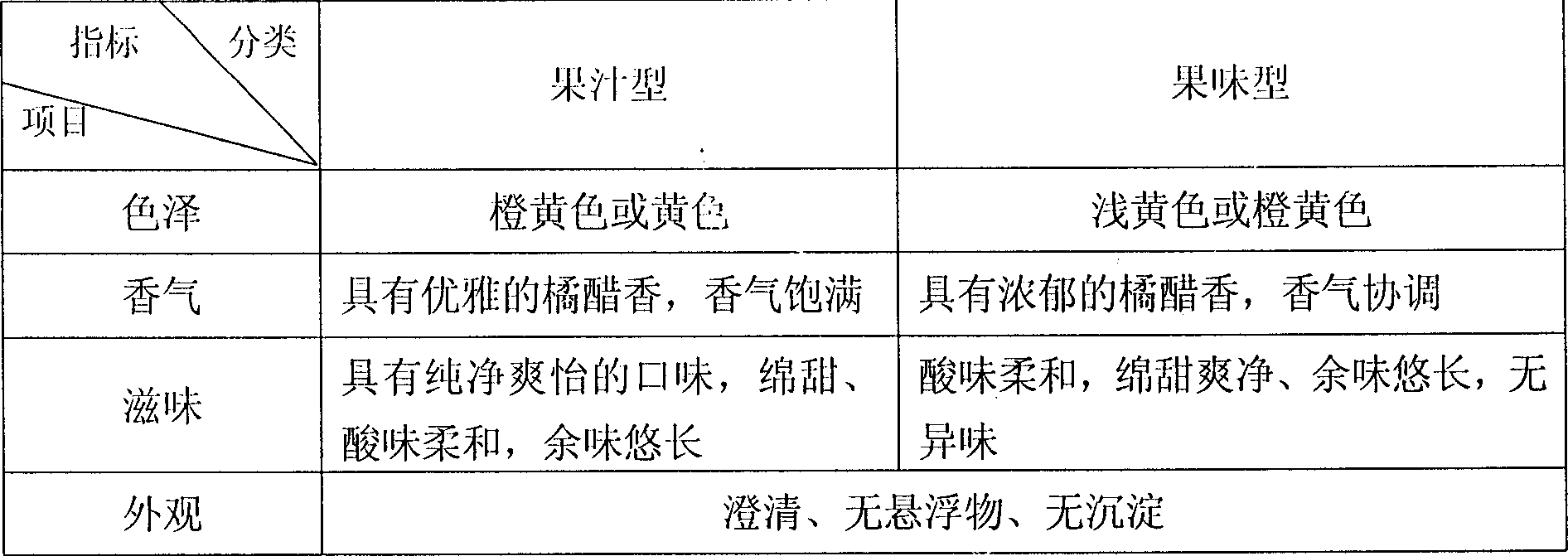

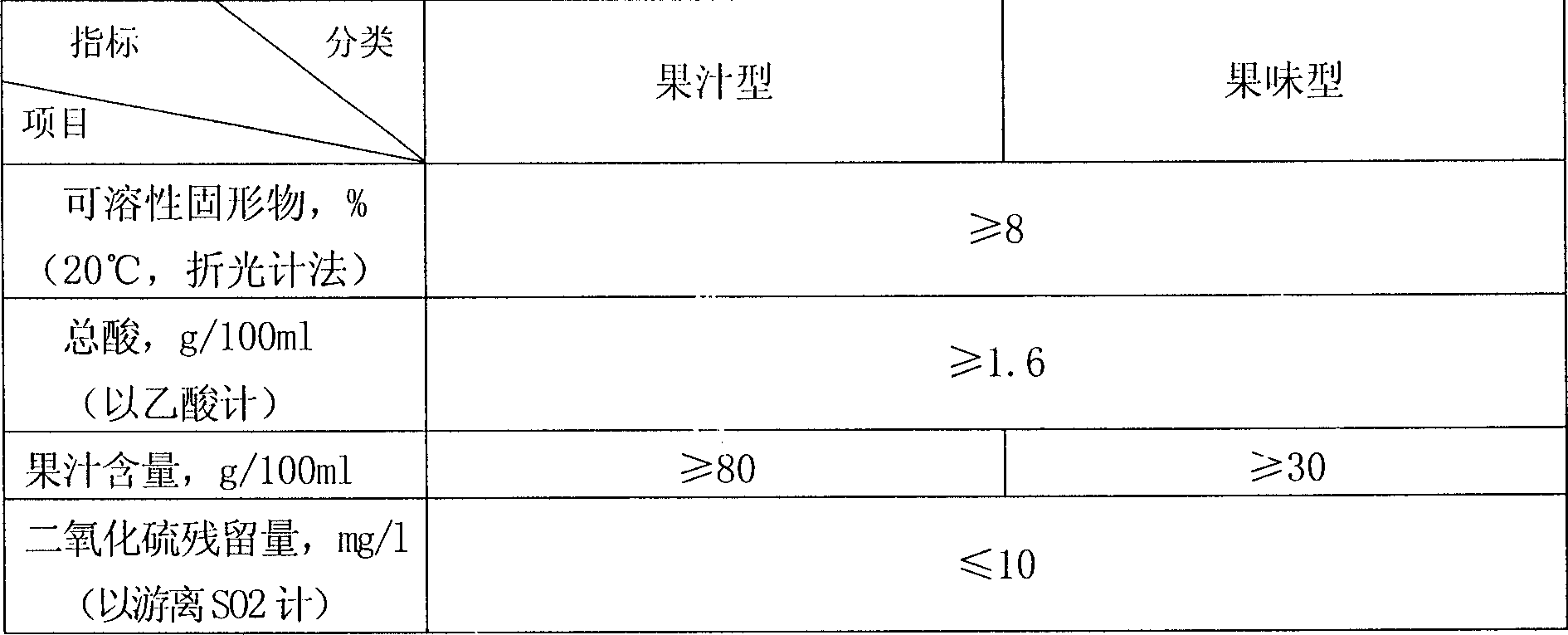

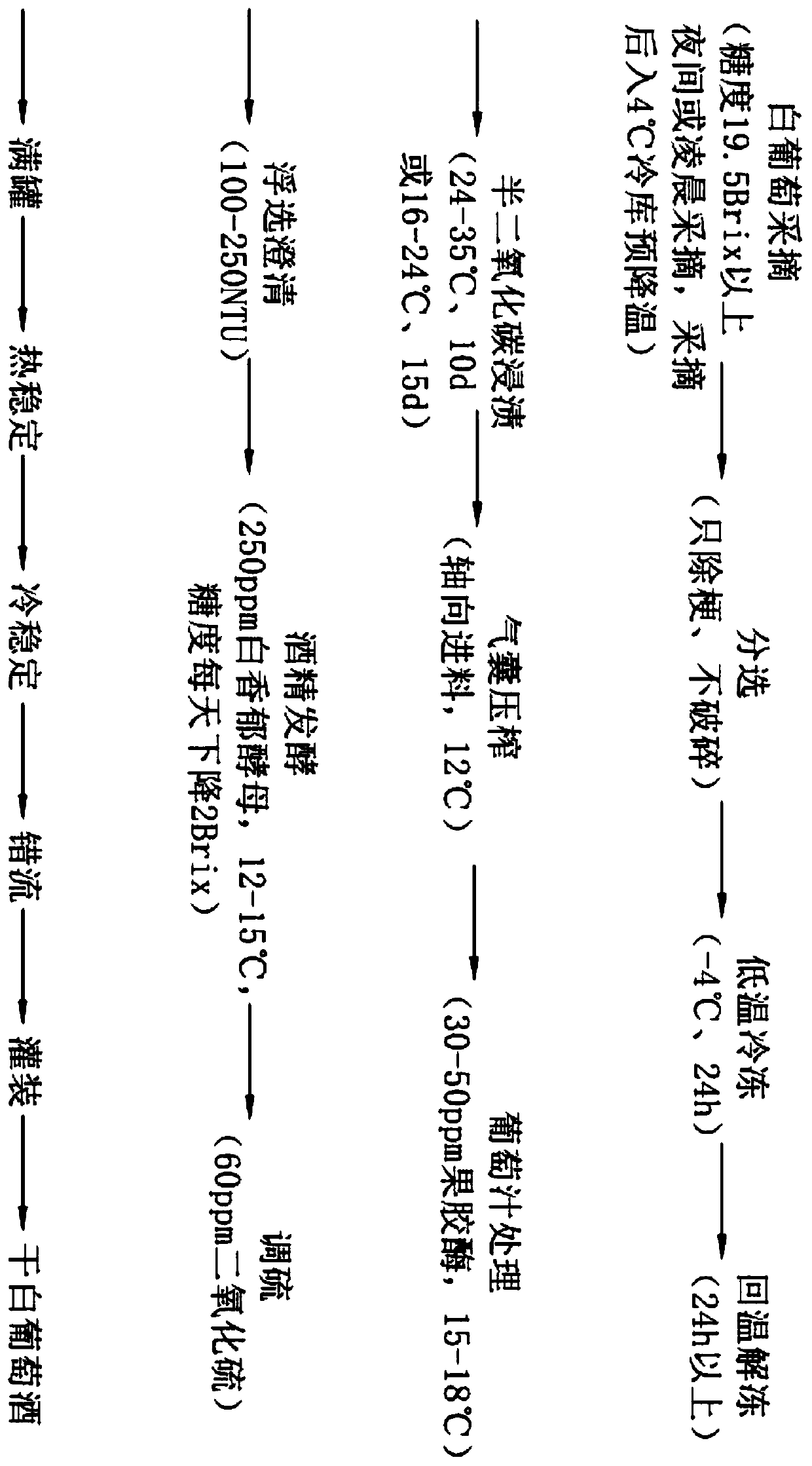

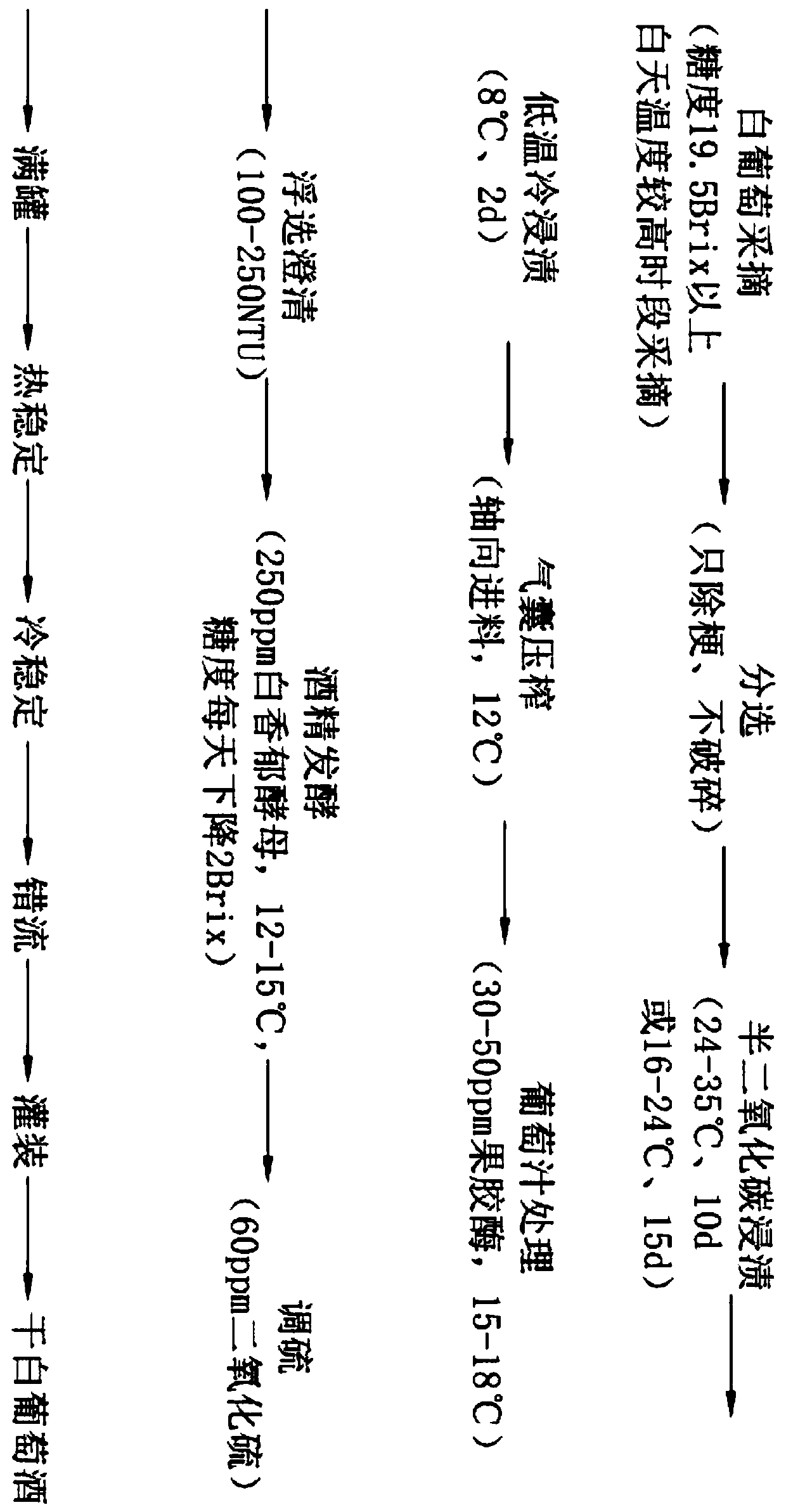

Organe fruit vinegar drink and its producing method

The orange fruit vinegar drink contains organe fruit vinegar as main component as well as honey, cane sugar, ginger, red data, wolfberry fruit, black plum and organe peel. Its production process includes pelling and squeezing fresh orange, centrifugal separation, elimianting bitter, low temperature alcohol fermentation, acetic acid fermentation, aging, filtering, sterilizing, adding partial orange juice and / or orange essence and other steps. The orange fruit vinegar drink has most flavor and nutritious components of orange, has certain invigorating health function and is suitable for various people.

Owner:湖南省农业科学院农产品加工研究所

Raspberry and grape foaming wine brewing process

ActiveCN104789403AImprove freshnessLow costMicroorganism based processesWine preparationYeastFruit wine

The invention relates to a foaming fruit wine processing technology, particularly to a fresh sulfur-free raspberry and grape foaming wine and a production technology thereof. The raspberry and grape foaming wine is prepared from raspberry and grape according to certain proportion ratio through high-temperature extraction and low-temperature fermentation. A brewing method for the raspberry and grape foaming wine is simple to operate, and all processes of low-temperature fermentation, tank sealing pressure boosting, yeast separation and fragrance formation are finished in one fermentation tank; enough pressure is achieved by carbon dioxide generated by self fermentation, and no secondary fermentation is needed; in the whole brewing process, no sulfur dioxide or other preservative is needed, and the wine is beneficial to human health. The wine is bright red, ruby red, purple red, brownish red and the like, has special fruity flavor and wine flavor, is strong and harmonious in fragrance, pure and refreshing in taste, full in wine body, lasting in aftertaste and strong in typicality, and belongs to the fresh foaming wine.

Owner:宁夏泾河源农业科技发展有限公司

Wine of low or free alcohol and its brewing method

The invention disclosed the method of brewing the non-low alcohol grape wine, which is enzyme treatment and penetration vaporzatioin method. The characteristics of the invention is the alcohol ranging from 0.5% to 7%, the sugar content which is the glucose below 12g / L in baked mold and below 120g / L in sweet mold, the total acid ranging from 4.5 to 8.0g / L measured by dihydroxysuccinic acid, the extract above 15g / L, free sulfur dioxide below 50mg / L, and total sulfur dioxide below 250mg / L. The said non-low alcohol grape wine is harmonization, delicate fragrance, suitable for the particular group and occasion,

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

Preparation method of jujube wine

InactiveCN101748024AThe taste is full and mellowJujube keepAlcoholic beverage preparationFruit wineDistillation

The invention relates to a preparation method of jujube wine, comprising the following steps: multi-strain fermentation, secondary distillation and / or jujube immersing in primary pulp wine. Jujube wine prepared by the method can have the nutrition of fruit wine and the style of white wine, can also have jujube flavor of prepared wine, and at the same time can reach mellow of wine quality and rich jujube flavor.

Owner:杨中华

Method for brewing exogenous amino acid regulating and controlling fruit wine

ActiveCN101260351ATo promote metabolismLow total sugar (g/L glucose meter) contentAlcoholic beverage preparationFruit wineArginine

The invention discloses a brewing method using extraneous source amino acid to regulate and control fruit wine. The method comprises that: fruit raw materials undergo pretreatment, crushing and constituent adjustment, and are added with compound amino acid such as glutamic acid and so on; full-range low temperature fermentation is performed; proline is added, aged, blended, clarified and filtered in post-fermentation process; and finally fermenting fruit wine is obtained through brewing, wherein, amino acid is added before the fermentation until the concentration of the amino acid is between 150 and 210ppm, the complex formula ratio of the fruit wine is that: the mass ratio of glutamic acid, arginine and serine is 3-4:1-2:0-1; when the main fermentation is finished, lees are separated, and the proline is added into wine liquid until the concentration of the wine liquid is between 50 and 100ppm. The fruit wine brewed by the invention has attractive luster, limpidness, mellow taste, strong sense of structure, outstanding typicality, harmonic fruit fragrance and wine fragrance, rich nutrition, simple process and low cost.

Owner:SOUTH CHINA UNIV OF TECH

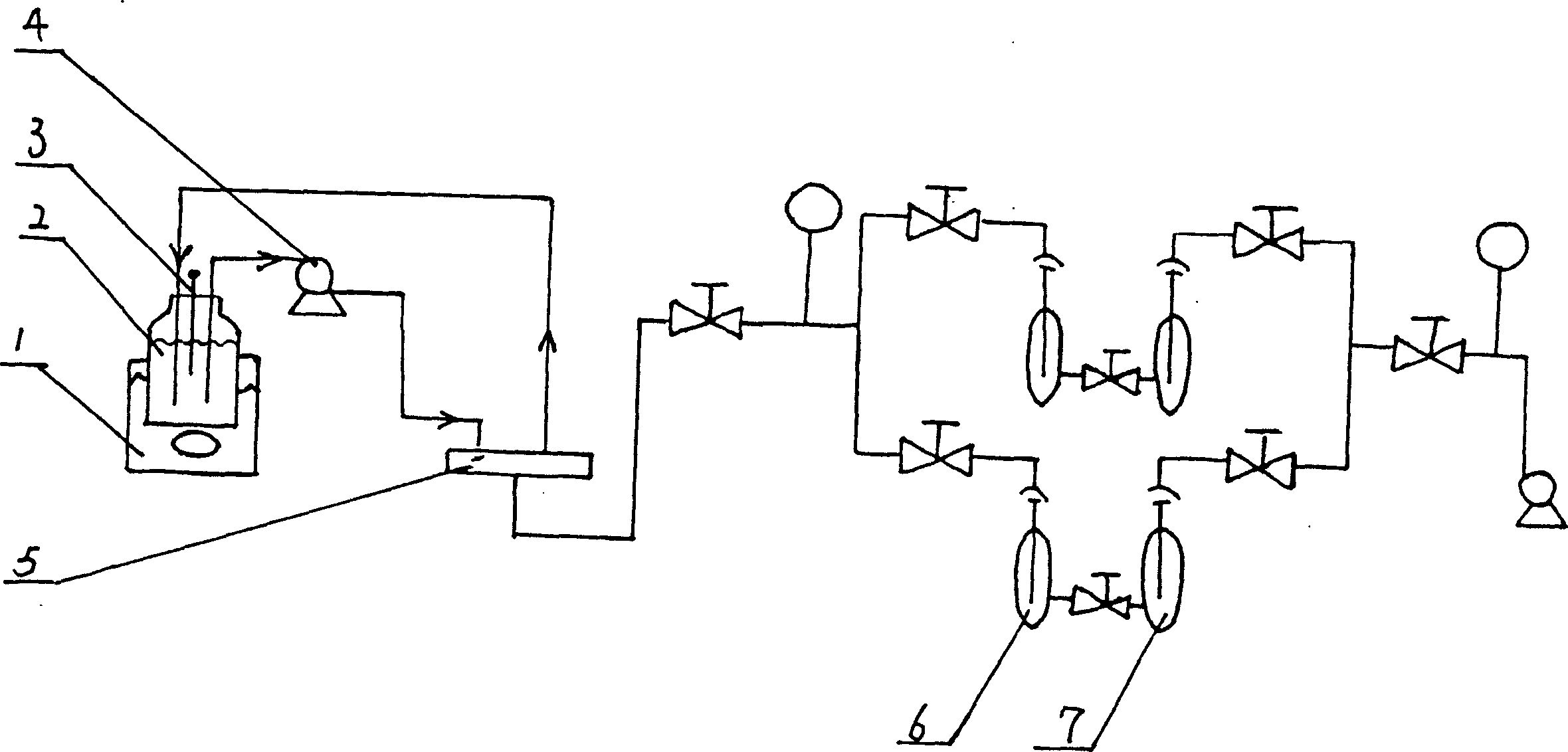

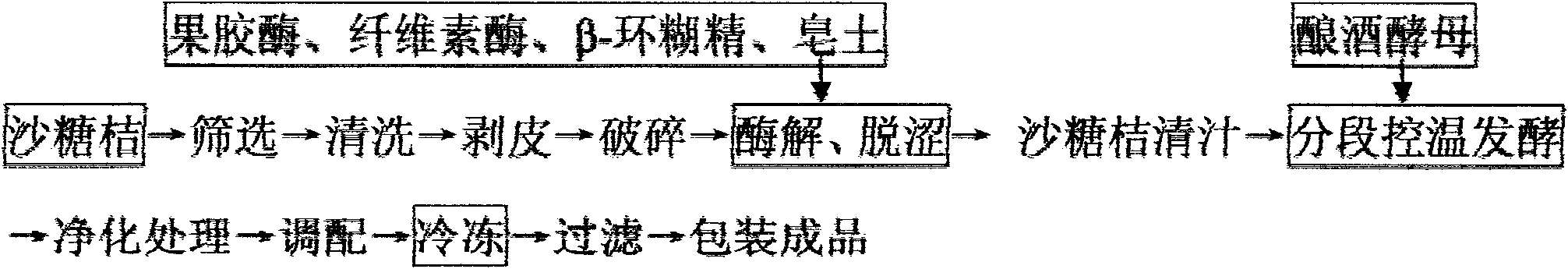

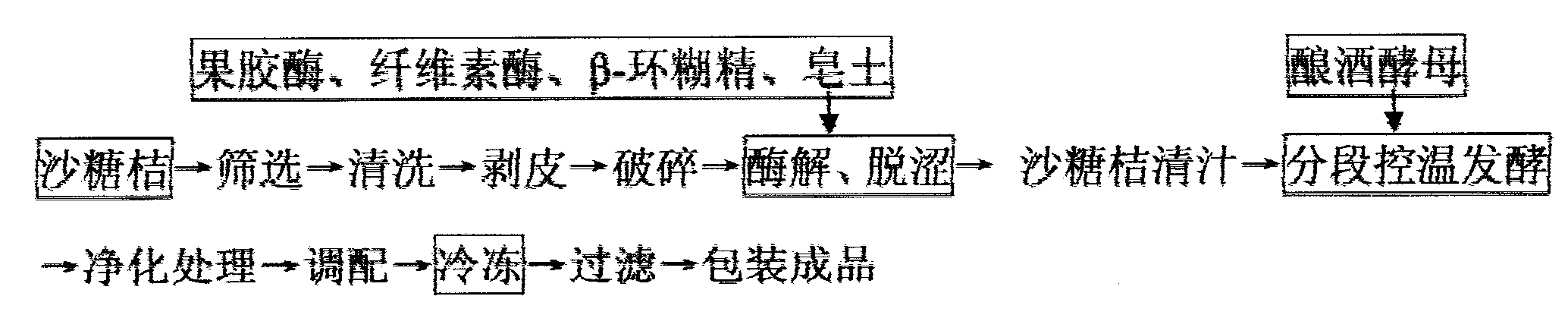

Production method of sugar orange fruit wine

InactiveCN101899372AImprove qualityGood relief from bitternessAlcoholic beverage preparationMicroorganism based processesPectinaseFruit wine

The invention provides a production method of sugar orange fruit wine, which comprises the following steps: taking fresh fruits of sugar oranges as a raw material; carrying out processes of separation, cleaning, peeling off, crushing and the like; then adding various enzymes including pectinase, cellulase, bentonite and the like; carrying out enzymolysis at 12-18DEG C; then adding puckery-losing agent to removing the bitter and astringent; transferring ferment serum in a fermentation tank; carrying out sectionalized low temperature fermentation by utilizing Saccharomyces cerevisiae, i.e. fermenting at 15-20DEG C for 3-5 days and carrying out tanks switching; fermenting again at 18-20DGE C for 7-15 days after the serum separation; adding clarifying agent to clarify the obtained raw wine; standing for 8-10 days; racking and filtering; storing at 15-18 DEG C and ageing for 3-6 months; freezing over 7 days at the temperature of 0.5DEG C higher than the freezing point of the wine; and then carrying out rough filtration and refining filtration. The invention has good enzymolysis and puckery-losing effect, has high juice yield over 85% and clear juice, can keep the fruity smell of wine products, avoids the entering of the harmful arene, and has good stability after tartar is separated out through freezing.

Owner:YUNFU HUANAN LIQUOR

Special type rice wine and preparation method thereof

ActiveCN104263587ACompatibility is reasonableReasonable dosageDigestive systemAlcoholic beverage preparationBiotechnologyMedicinal herbs

The invention discloses special type rice wine and a preparation method thereof and belongs to the technical field of wine brewing. The preparation method of the special type rice wine comprises steps as follows: 1, soaking glutinous rice with water and steaming the glutinous rice until rice grains fully absorb the water; 2, washing the just steamed glutinous rice with cold water for cooling, mixing the glutinous rice with distiller's yeast, and performing culture until the distiller's yeast alcoholic strength is in a range of 10-11%; 3, crushing raspberries, fragrant solomonseal rhizome and poria cocos into powder, covering the powder with gauze, soaking the powder together with longan, Chinese dates, almonds, red oranges, Chinese wolfberries, mulberries, hawthorn fruits and polygonatum with water, boiling the mixture with big fire and small fire, and finally, filtering the mixture to obtain juice of the medicines; 4, spreading the glutinous rice, evenly mixing the glutinous rice with the distiller's yeast, adding raw wheat koji and cooked wheat koji, adding the juice of the medicines and water, and evenly stirring and fermenting the mixture; performing primary fermentation for 6-7 days and then performing low-temperature secondary fermentation; 5, after fermentation, performing treatment according to conventional steps to obtain the special type rice wine. The special type rice wine is amber in color, tastes mellow and sweet, has the fresh and elegant medicine aroma and has a certain health care function.

Owner:HUBEI CHUBO ECOLOGICAL AGRI TECH DEV

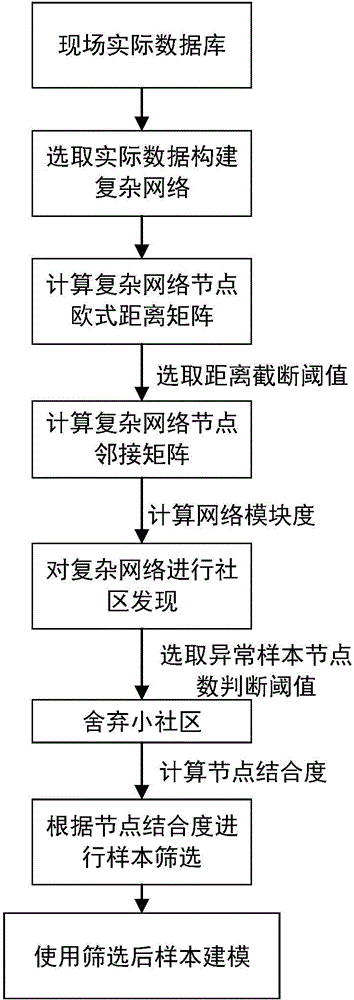

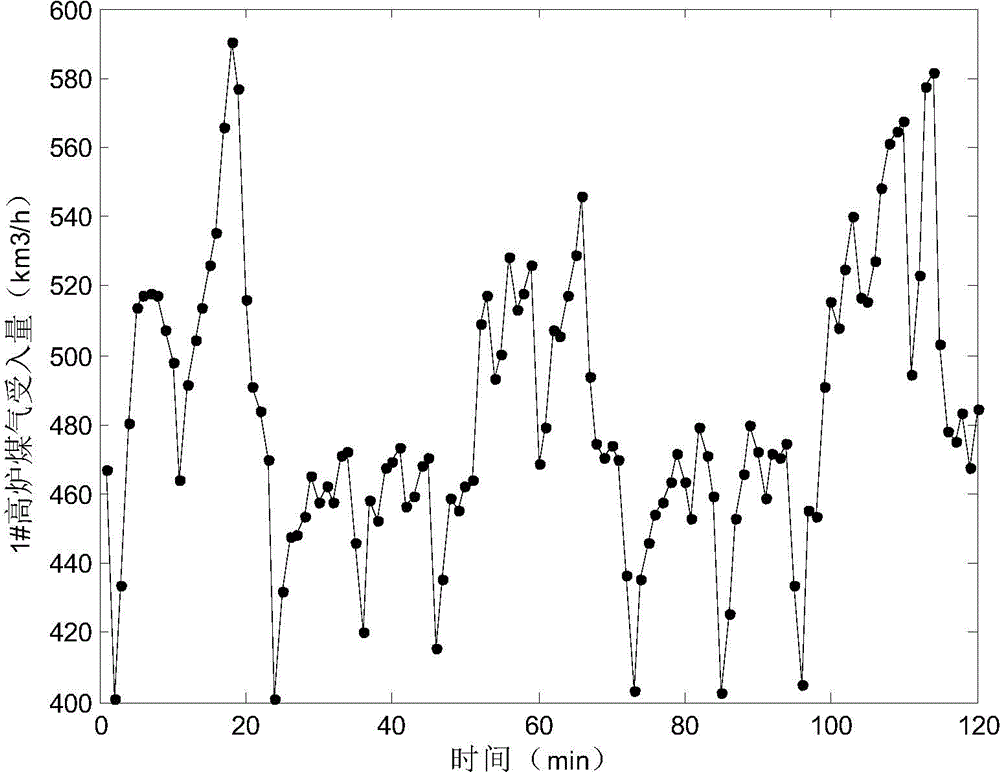

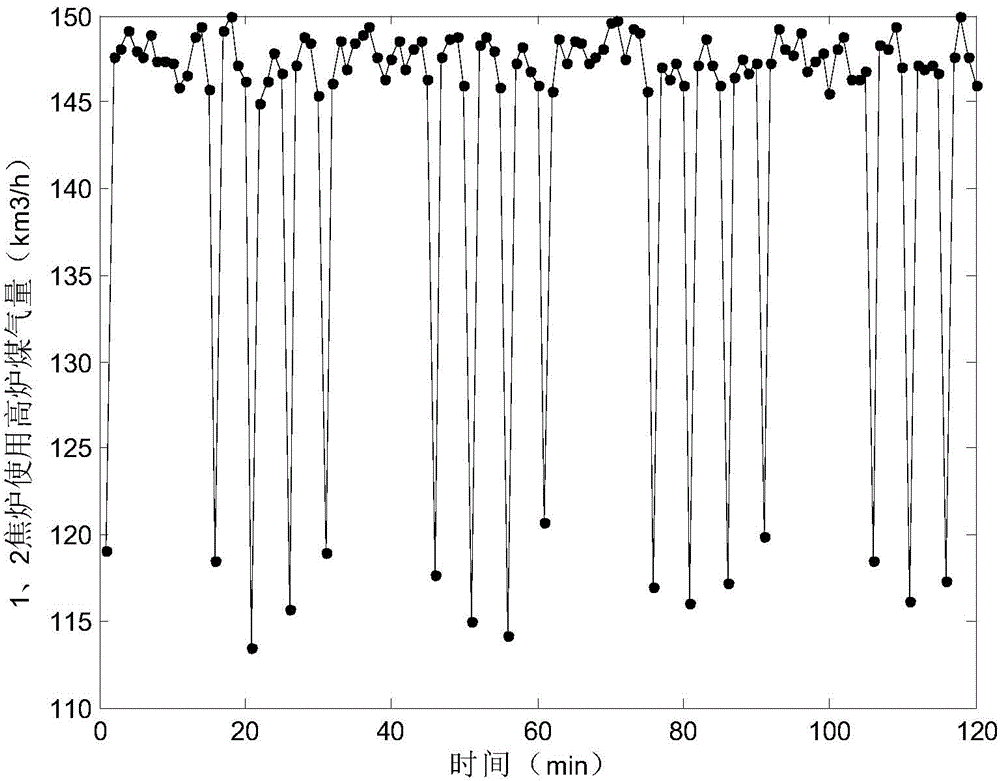

Industrial data sample screening method based on complex network community discovery

InactiveCN104572985AImprove forecast accuracyEffective trainingRelational databasesSpecial data processing applicationsNODALAlgorithm

An industrial data sample screening method based on complex network community discovery comprises the steps of firstly using target data structure initial samples as complicated network nodes, calculating distances among the nodes, comparing the distances with interceptive threshold values to obtain an adjacent matrix representing node connecting relation, then using modularity maximization as an optimization objective, performing community discovery in the complicated network represented by the adjacent matrix, obtaining sample community division of corresponding problems under different situations, finally network node 'combination degree' evaluation indexes are provided, descending sorting is conducted on nodes in the network according to a combination degree value, a sample re-structure sample set is selected from each community according to a combination degree value average, and accordingly reduction of data sample sets is achieved under the situation that useful information in an original sample set is retained. Screened data samples are adopted to perform soft measurement, prediction and case-based reasoning, the accuracy of an established model can be further improved, and guarantee is provided for implementation of data-based optimized dispatching in the industrial process.

Owner:DALIAN UNIV OF TECH

Functional compound berry wine and production method thereof

ActiveCN103756844ASolve rationalityRich in compositionAlcoholic beverage preparationMicroorganism based processesYellow raspberryMicroorganism

The invention discloses functional compound berry wine and a production method thereof; the functional compound berry wine is produced from the following berries in percentage by weight: 5-7% of cranberry, 4-6% of vaccinium uliginosum, 6-8% of blackcurrant, 5-7% of garnetberry, 12-14% of red raspberry, 20-22% of black raspberry, 6-8% of yellow raspberry, 5-8% of pineberry, 4-7% of strawberry, 5-8% of sea-buckthorn, 9-12% of mulberry and 5-7% of medlar. The production method comprises the following specific steps: the berries are weighed for cleaning, mixed, and frozen at the low temperature; the mixed berries, after being broken through expansion, are put in a fermentation tank for synchronously heating; when the berries are fermented, the sugar degree is regulated; sulfur dioxide is added to stop the fermentation; the skins and the residues are separated; raw wine is precipitated by adopting a natural precipitation method; supernate is pumped out; a clarifying agent is added to separate the precipitates to obtain the clarified wine; particle impurities are removed through filtering; microorganisms are removed to obtain the qualified wine product. The berry raw materials and the weight ratio thereof are reasonably matched, so that the composition of functional components in the wine product is enriched, and the taste characteristic of the product is improved; the functional compound berry wine is drunk for refreshing.

Owner:山东尚美健康产业技术发展有限公司

Sesame flavor liquor and production process thereof

The invention discloses sesame flavor liquor and a production process thereof. The preparation method comprises the following steps of: adding 800-900 parts of sorghum, 100-200 parts of crushed wheat and 50-100 parts of wheat bran to 200-300 parts of waste lees, complementing seriflux to mix, loading in a steamer and steaming to prepare fermented grain; stirring the fermented grain and most of distilled distillate after steaming according to a ratio of 1 to (4-5), ventilating and cooling; adding 80-120 parts of distills and 200-260 parts of mouldy bran, complementing seriflux and heaping for 1-2 days to prepare slag grain; cooling a small part of distilled distillate after steaming and adding distills in 3-5 percent of distills and 4-6 percent of mouldy bran by the distillate amount to prepare reflux fermented grain; cooling and putting the reflux fermented grain in a pool bottom, cooling and putting the slag grain at the mid-upper part of a fermentation pit and sealing the fermentation pit to ferment for 40-60 days; stirring 120-150 parts of loaded steaming rice husk liquor after steaming to the fermented slag grain, stirring 30-50 parts of loaded steaming rice husk liquor after steaming to the reflux fermented grain to obtain raw sesame flavor liquor of the invention. The process reaches the liquor yield of 34-36 percent and decreases the production cost.

Owner:山东景芝白酒有限公司

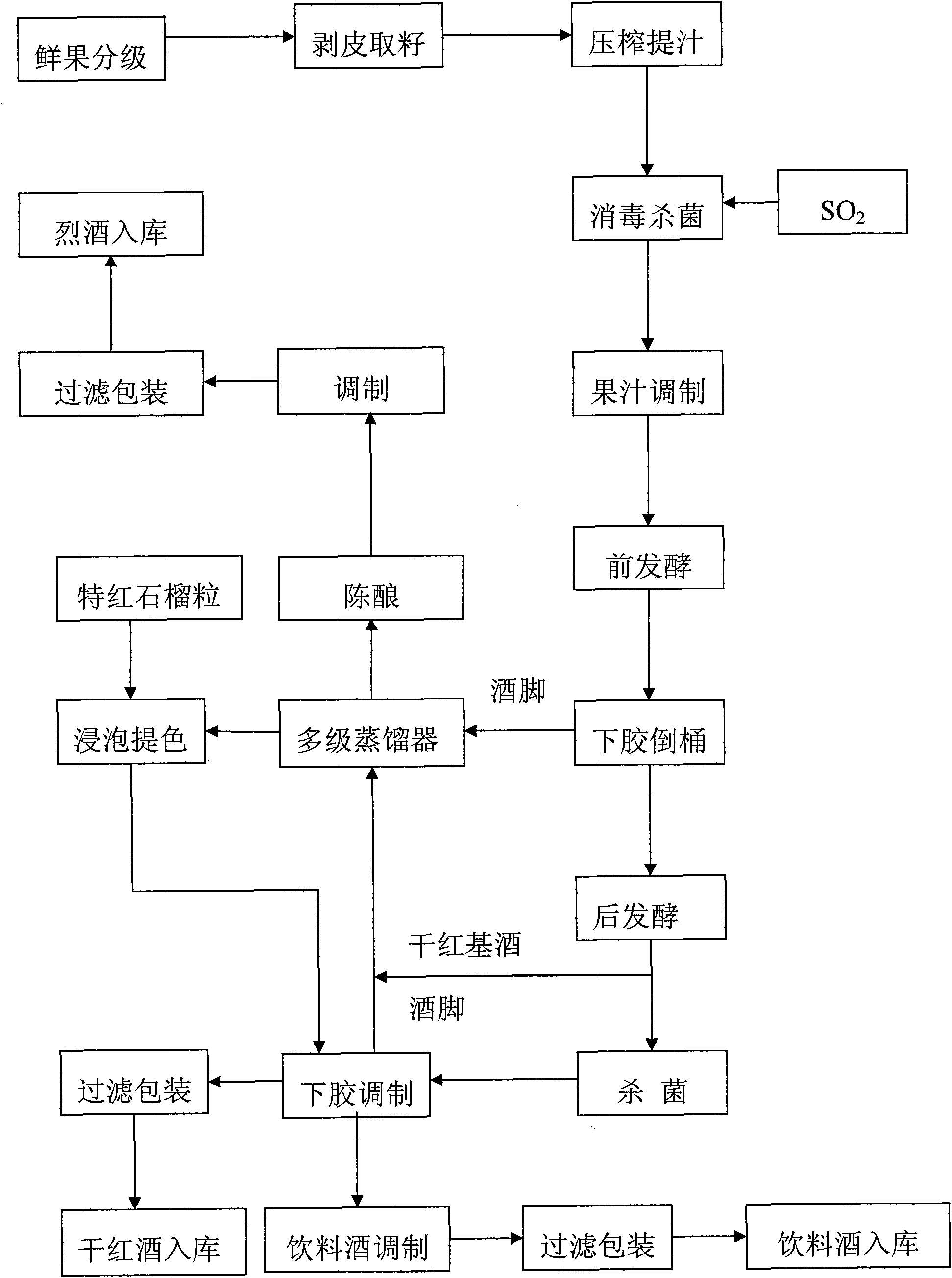

Pomegranate full juice fermented wine and preparing method thereof

InactiveCN101586066AKeep the natural flavorMaintain nutrientsAlcoholic beverage preparationMicroorganism based processesYeastAlcohol

The invention relates to a pomegranate full juice fermented wine and preparing method thereof, the fermented wine contains alcohol and other natural nutrition components obtained by pomegranate full juice fermentation, the pomegranate full juice is juice squeezed by mixing acid pomegranate and sweet pomegranate fruits together according to arbitrary weight proportionality, also can be juice obtained by mixing normal juice and condensed juice respectively squeezed by the acid pomegranate and the sweet pomegranate fruits according to the arbitrary weight proportionality, the wine solution obtained by full juice fermentation is extra dry red wine base wine and is distillated to obtain pomegranate heavy wine. The preparing method of the acid pomegranate extra dry red wine comprises: squeezing pomegranate juice and sterilizing; rectifying the fruit juices; controlling the sugar degree and acidity; adding into bacteria to perform primary fermentation; separating and removing deposited matters by glue; fermenting after sworting; clearing by secondary sworting; filtering and rectifying; disinfecting and sterilizing to obtain the completed product pomegranate extra dry red wine. The invention has characteristics of full juice fermentation, no mixed water, holding natural local flavor and nutrition component of acid pomegranate, being capable of aging, long preserving time, short cultivation process of fermentation bacteria, easy obtaining, strong fermentation efficiency and simple and easy operation. The product is in good taste, the transparence is good, the wine taste is pure, the wine body is abundant, the acid pomegranate extra dry red wine not only has same color and luster, but also has unique local flavor, and can be widely used for rectifying the pomegranate wine beverage.

Owner:张建伟

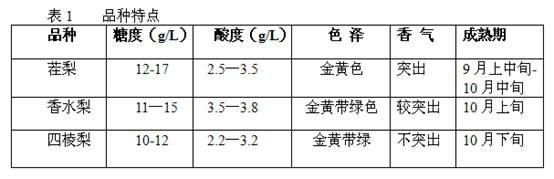

Technology for producing wine through fermenting Laiyang pears

The invention which relates to a technology for producing a wine through fermenting Laiyang pears belongs to the technical field of wine brewing technologies. The technology comprises the following steps: 1, cleaning the Laiyang pears; 2, fragmenting and beating the Laiyang pears; 3, sending a slurry obtained after the fragmentation to an enzymatic hydrolysis tank, and carrying out enzymatic hydrolysis; 4, filtering by a filter press; 5, fermenting by adding yeasts; 6, reladling to separate out wine lees; 7, carrying out colloid deposition processing; 8, filtering after the clarification; 9, ageing in an ageing tank; 10, filtering after the ageing; 11, carrying out balance blending; 12, refrigerating, and filtering; 13, storing for a short period, 14, blending; 15, sterilize-filtering; and 16, filling. According to the invention, a biological technology is utilized to brew the full-juice fermentation Laiyang pear wine, the production technology is scientific and reasonable, and the prepared Laiyang pear wine which is yellow green has the characteristics of moderate acidity, long aftertaste after drinking, strong typicality, no pegging on teeth and the like, and is a unique high-grade fruit wine, so a new approach for the exploitation of the Laiyang pears into high-end products is provided in the invention.

Owner:姜志德 +1

Air-drying red wine and brewing process thereof

The invention provides an air-drying red wine and a brewing process thereof. The brewing process comprises the following steps of: sorting raw material wine grape, checking, air drying, removing branches and crushing, performing alcoholic fermentation, fermenting apple emulsion, aging in wooden barrels, blending, settling, filling, storing in bottles, packing and warehousing. According to the invention, through grape variety selection, delayed grape pickup, natural air-drying condition selection, research on the aging process of air-dried grape and selection of yeasts and pectinases used in air-drying red wine, the quality of the air-drying red wine is improved, and the obtained red wine is deep ruby red, clear and transparent, fragrant and complex and has the advantages of aged wine fragrance, oak fragrance, black berry fragrance, dried fruit fragrance, mellow and full mouthfeel, gentle taste, long aftertaste, remarkable typicality, and has potential aging characteristic and unique sensory characteristics.

Owner:SINO FRENCH JOINT VENTURE DYNASTY WINERY

Method for making waxberry vinegar

InactiveCN102242047AAlcohol conversion rate is highFast acid productionMicroorganism based processesVinegar preparationFiltrationSubmerged fermentation

The invention discloses a method for making waxberry vinegar, which comprises the following steps of: 1, sorting, namely selecting waxberry materials; 2, deseeding; 3, squeezing; 4, performing ultrahigh temperature (UHT) sterilization; 5, performing primary fermentation, namely adding active dry yeast Q23 into a fermentation tank filled with waxberry juice, performing alcoholic fermentation on the waxberry juice to obtain waxberry wine, and controlling the fermentation temperature to be between 23 and 28DEG C; 6, performing secondary fermentation to obtain waxberry raw vinegar; 7, clarifying; 8, filtering; 9, performing secondary UHT sterilization, namely pumping the waxberry vinegar subjected to fine filtration into a UHT sterilizer for sterilization; and 10, filling. The waxberry juice is subjected to two-stage liquid state submerged fermentation to form the waxberry vinegar, and the waxberry vinegar is dark amber and clarified, and has luster, natural inherent aroma of waxberries, full, smooth and mild mouthfeel, and high typicality.

Owner:浙江聚仙庄饮品有限公司

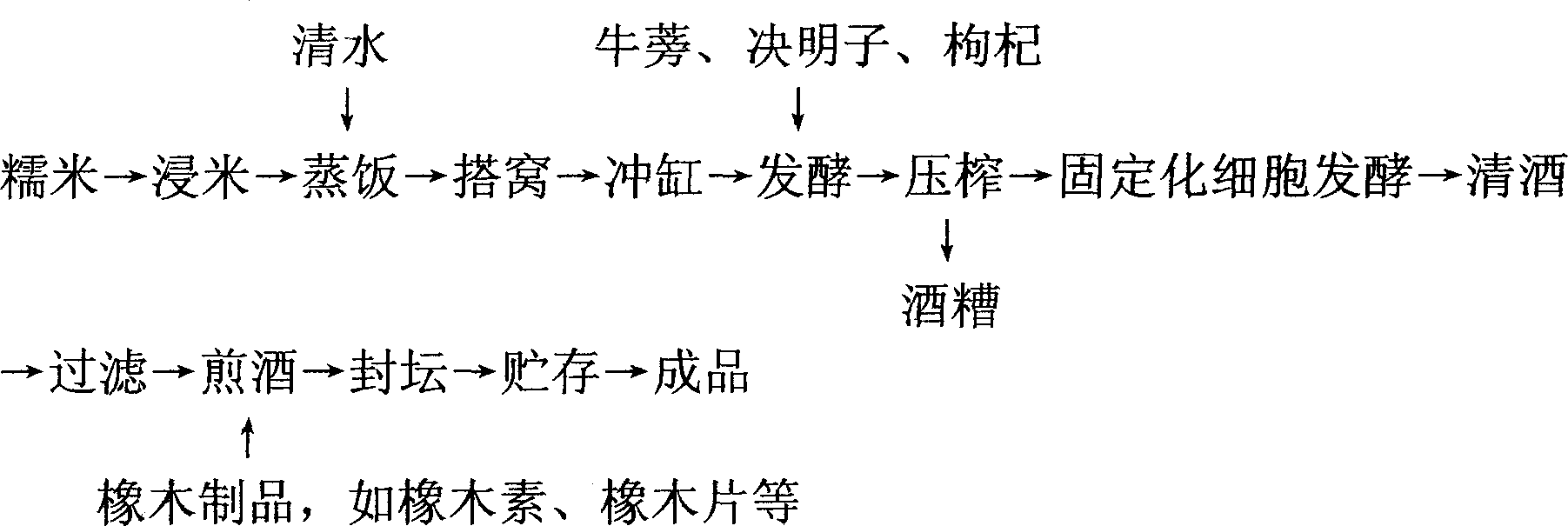

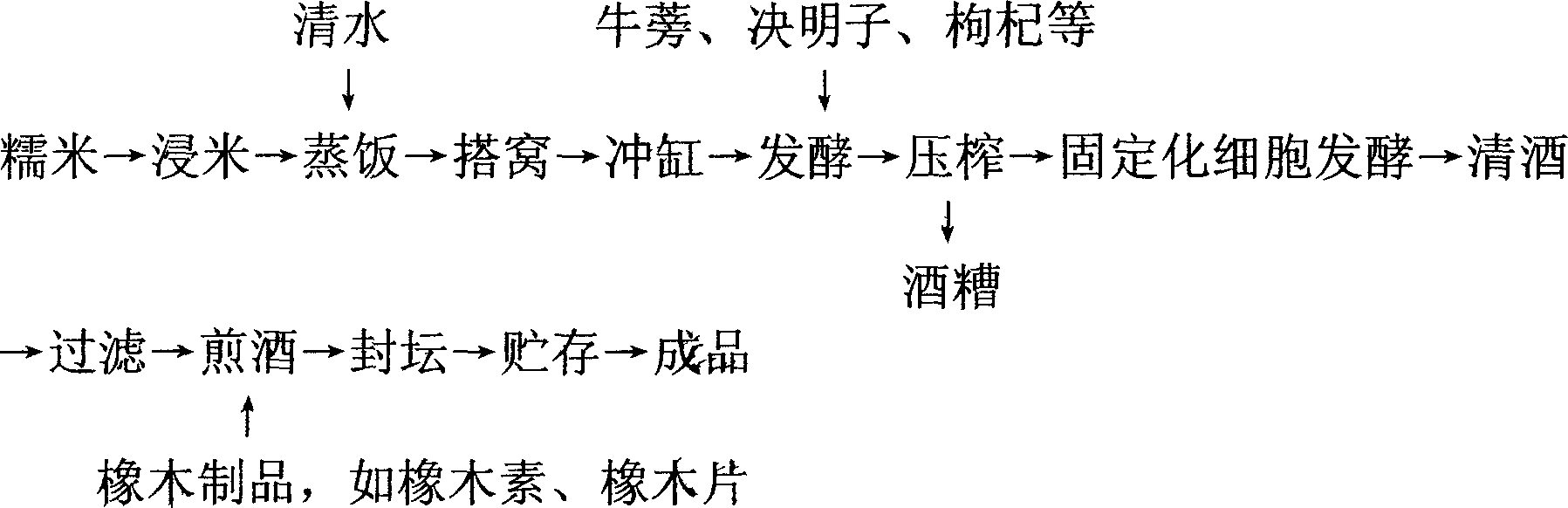

Brewing method for nevol flavor yellow wine

The brewing process of novel flavor yellow wine features the addition of burdock fruit, cassia seed, wolfberry fruit, etc in the fermentation step, and the addition of oak chip, etc before the wine jar is sealed and while the wine is still hot. The present invention makes the yellow wine possess unique flavor and has the health functions of the said Chinese medicinal materials and the unique scent of oak.

Owner:杨国军

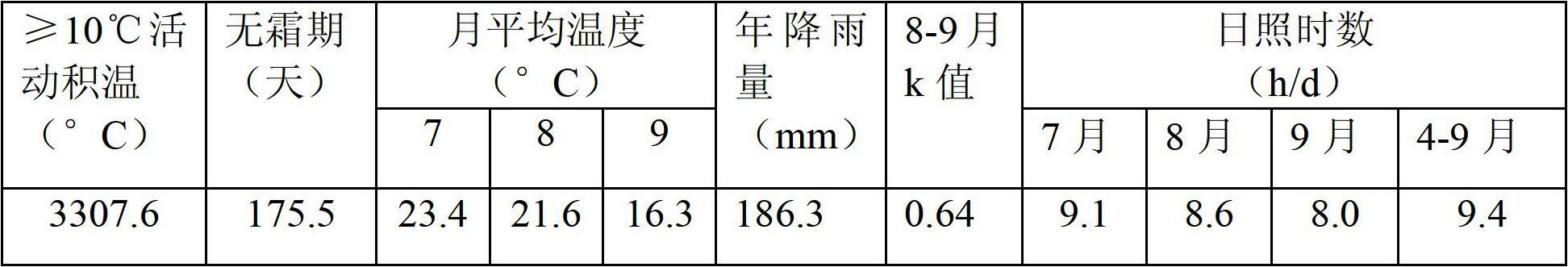

Processing method of dry type fragrant pear fermented wine

ActiveCN103451066AAvoid the black core problemIncrease the juice yieldMicroorganism based processesAlcoholic beverage preparationBiotechnologyFlavor

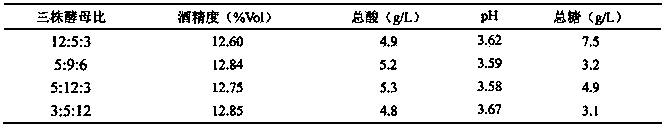

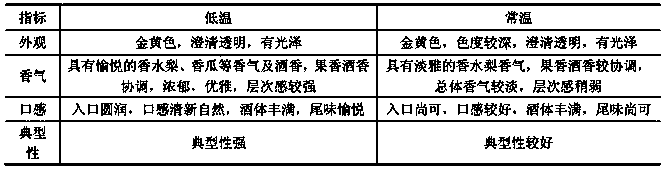

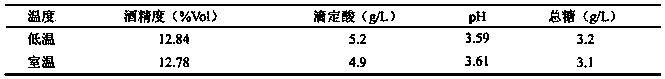

The invention relates to a processing method of dry type fragrant pear fermented wine. The method takes fragrant pears as the raw materials and prepares the dry type fragrant pear fermented wine with rich nutrition and good quality by the processes such as low-temperature expansion culture with frozen yeast, low-temperature fermentation with a mixed yeast strain and wine pouring and aging. According to the method provided by the invention, the dry type fragrant pear fermented wine is produced by adopting three strains of low-temperature saccharomyces cerevisiae and performing low-temperature expansion culture and low-temperature (10-12 DEG C) fermentation, wherein the mixed volume ratio (WL300:D576:WET136) of the culture solution is 5:9:6, and the problems of insufficient fragrance, insufficient acidity and non-thorough fermentation of the fragrant pear wine fermented with a single yeast are solved; since the raw materials are treated by a stage cooling freezing means, the problem of black kernel of the fragrant pear fruit caused by quick cooling is avoided, and the cell structure of the fragrant pears is broken by the freezing, thereby being favorable for increasing the juice yield of the fragrant pear; the fragrance component of the fragrant pears and the good flavor feature of wine are maintained to the greatest degree.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method for producing kiwi fruit wine with immobilized yeast

InactiveCN102978074AImprove fermentation effectHigh ethanol production efficiencyAlcoholic beverage preparationOn/in organic carrierSaccharic acidAlcohol content

The invention provides a method for producing kiwi fruit wine with immobilized yeast. The method comprises the following steps of: preparing juice; preparing suspension and immobilized yeast beads; and fermenting the kiwi fruit wine, specifically, carrying out low temperature centrifugation and sterilization on the kiwi juice obtained in the step 1 after regulating the kiwi juice with saccharic acid, then pumping the kiwi juice into a fermentation tank, inoculating the immobilized yeast beads to ferment the kiwi juice at 18-22 DEG C, transferring the kiwi juice to after fermentation when the alcohol content of the fermentation liquor no long rises and filtering the kiwi juice after adopting natural clarification, thus obtaining the kiwi fruit wine. The method has the beneficial effects that the prepared immobilized kiwi fruit wine yeast has SO2 tolerated concentration of 160-180mg / L, high fermentation capacity, high alcohol production efficiency and high aroma producing capacity; and the made raw wine is clear and transparent, has light yellow color and has VC content of 80-130mg / L, alcoholic strength of 12-15 degrees (v / v), strong aroma and strong typicality.

Owner:SICHUAN NONGXINGYUAN AGRI DEV

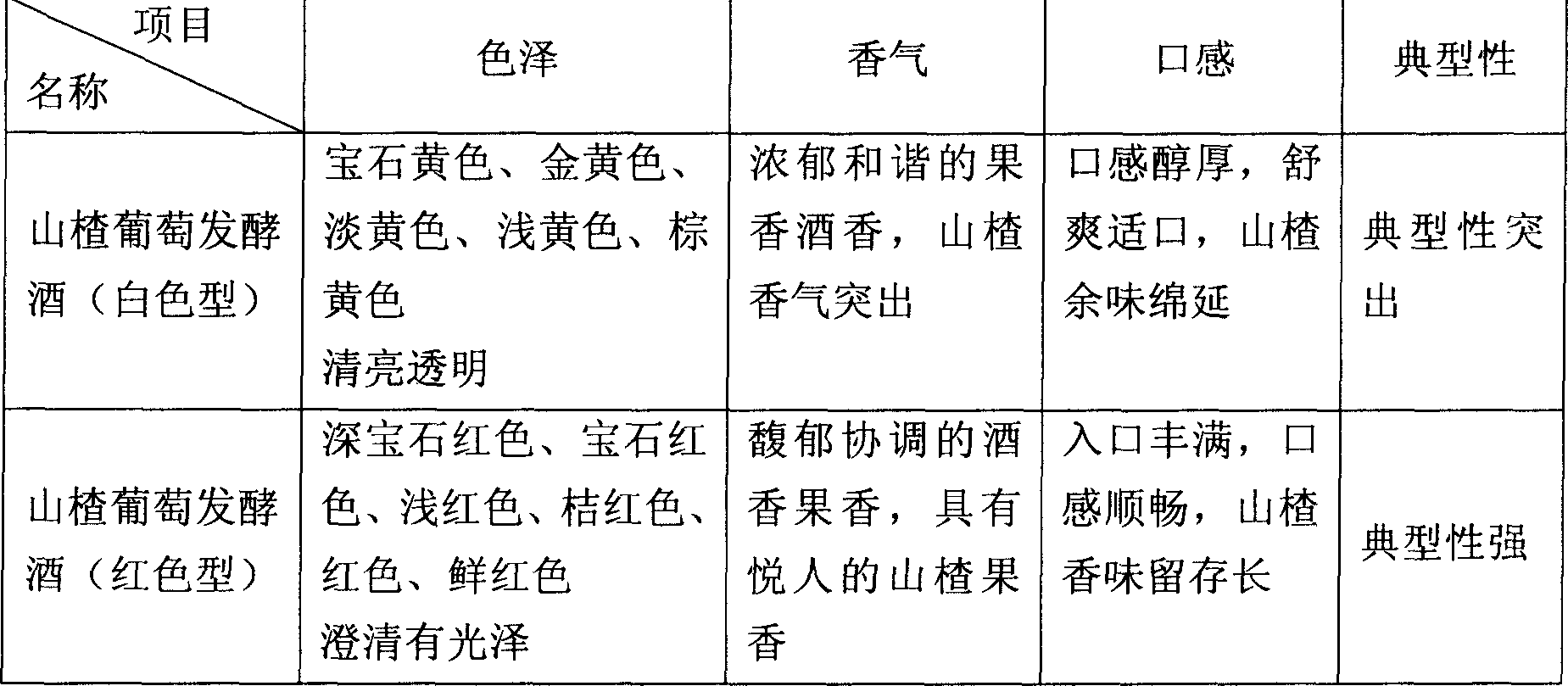

Mixed fermented wine of haw and grape and its brewing process

The present invention relates to mixed fermented wine of haw and grape and its brewing process. The mixed fermented wine of haw and grape is made with haw and grape in certain ratio, and through crushing, eliminating stem, making juice or mashed fruit, adding SO2, cane sugar or glucose, inoculating yeast, fermentation and regulating sugar content. It has the flavor and health functions of both haw wine and grape wine, excellent look and fragrance, high quality, sour and sweet taste and other advantages.

Owner:谢明勇

Method for producing round date wine

The production process of round date wine includes pulping round date, mixing with proper amount of SO2 and pectic enzyme and decomposing slurry at certain temperature; letting stand to clarify to eliminate deposited stone and pee; fermentation through adding saccharomycete and at controlled temperature; adding more SO2; filtering with diatomite; letting stand at minus 1 deg.c for several days, filtering and ageing; adding proper amount of white sugar; heating to disinfect and cooling to normal temperature. The said controlled process can inhibit betero bacteria and other negative factors and ensure no damage to the nutritious matter in round date.

Owner:高万财

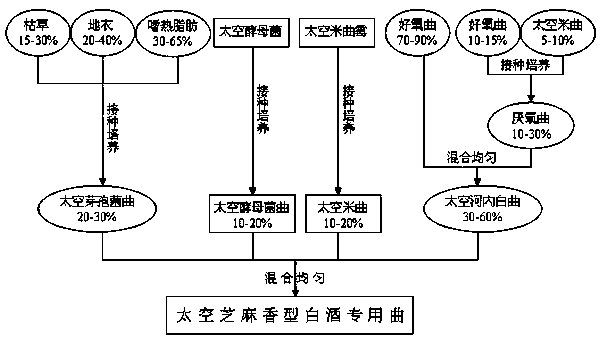

Preparation method for special wine-making starter for space sesame-fragrance type wine

ActiveCN103865725AQuality assuranceGuaranteed stabilityAlcoholic beverage preparationAspergillusMutation breeding

The invention discloses a preparation method for a special wine-making starter for space sesame-fragrance type wine. According to the preparation method disclosed by the invention, space bacillus, space saccharomycetes, space aspergillus oryzae and space Hanoi aspergillus which are subjected to space mutation breeding are used for preparing a space bacillus starter, a space saccharomycetes starter, a space aspergillus oryzae starter and a space Hanoi aspergillus starter according to processes respectively, and then the space bacillus starter, the space saccharomycetes starter, the space aspergillus oryzae starter and the space Hanoi aspergillus starter are mixed according to a ratio of 20-30%: 10-20%: 10-20%: 30-60% to prepare the special starter for space sesame-fragrance type wine, wherein the space bacillus starter is prepared by a zymomonas fermentation and compounding process; the space Hanoi aspergillus starter is prepared by a two-step fermentation method; starter pool culture for space bacillus is carried out by a method of sterilizing raw materials, then cooled to 60-70 DEG C, and replenished with saccharifying enzyme to increase reducing sugar; and meanwhile, space aspergillus oryzae is added, thus further improving the quality of the special starter for space sesame-fragrance type wine. The special starter for space sesame-fragrance type wine produced by the method is stable in quality, capable of increasing wine yield by 3-5%, reducing fermentation period by 3-5 days, increasing the content of the characteristic constituents of the sesame-fragrance type wine by 5-10%, and reducing the dosage of the starter by 2-7%; and the produced raw wine is full in body, gentle in fragrance and with a typical sesame-fragrance style.

Owner:泰山酒业集团股份有限公司 +1

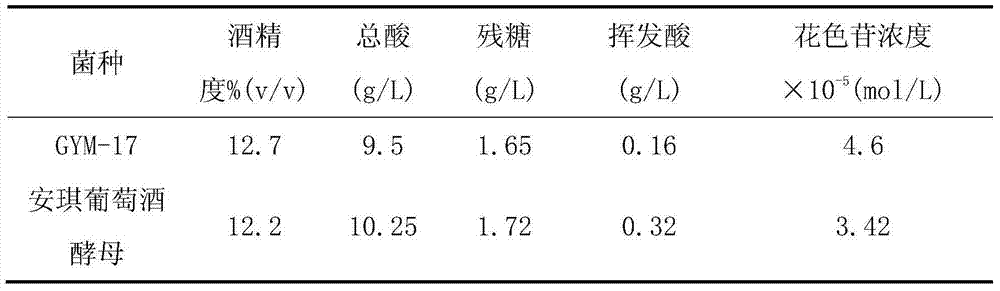

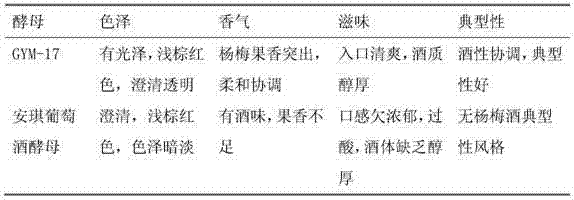

Saccharomyces cerevisiae for producing waxberry fruit wine by fermentation

InactiveCN103773701AStrong targetingStrong fermentation abilityFungiMicroorganism based processesBiotechnologyFruit wine

The invention relates to a saccharomyces cerevisiae for producing a waxberry fruit wine by fermentation. The saccharomyces cerevisiae is characterized in that the saccharomyces cerevisiae strain is derive from soil of an ancient waxberry garden in laifeng county, Hubei province, is used for producing waxberry fruit wine by fermentation, has stronger pertinence on waxberry fruit wine fermentation, has favorable wine making and aroma forming capabilities, is high in fermentation speed, strong in fermentative capability and good in tolerance, has been preserved in the China Center for Type Culture Collection in Wuhan University in Luojia hill, Wuchang, Wuhan, Hubei on march 27, 2013, and the is named as GYM-17. The preservation number of the saccharomyces cerevisiae strain is CCTCC NO:M2013107.

Owner:来凤县古杨梅食品开发有限责任公司

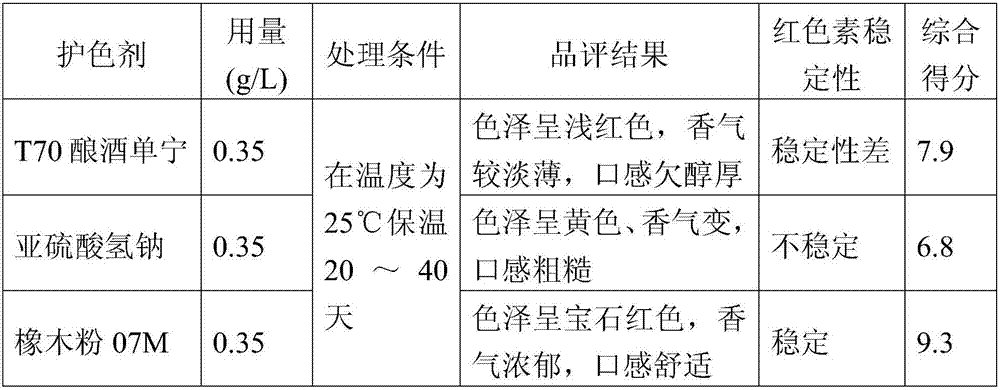

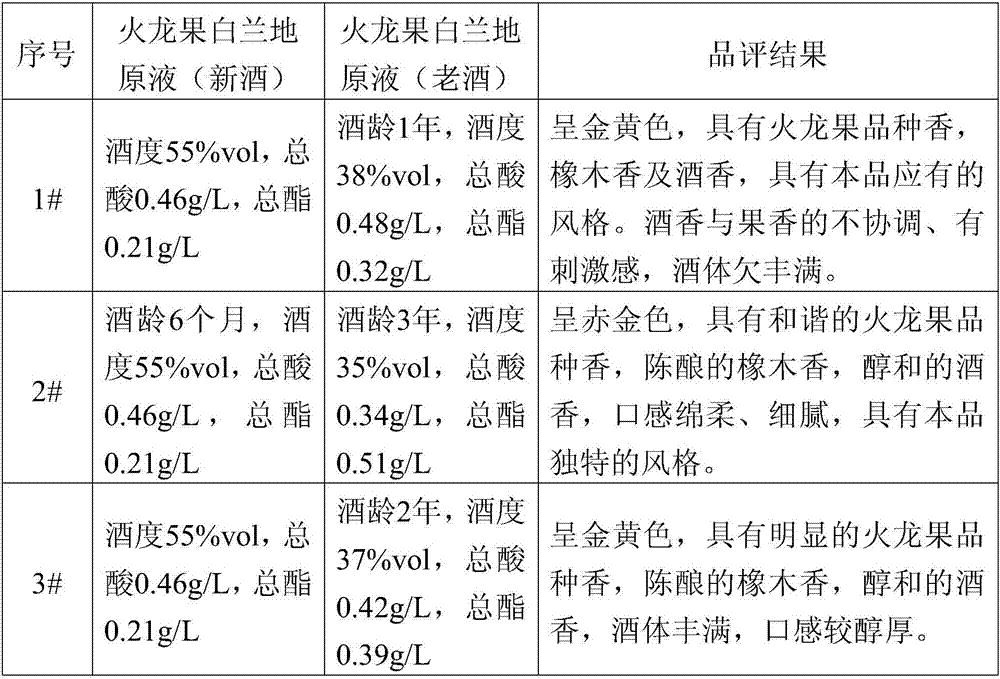

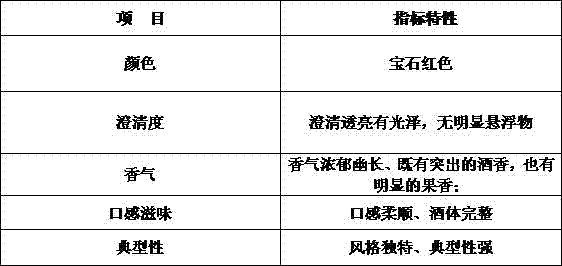

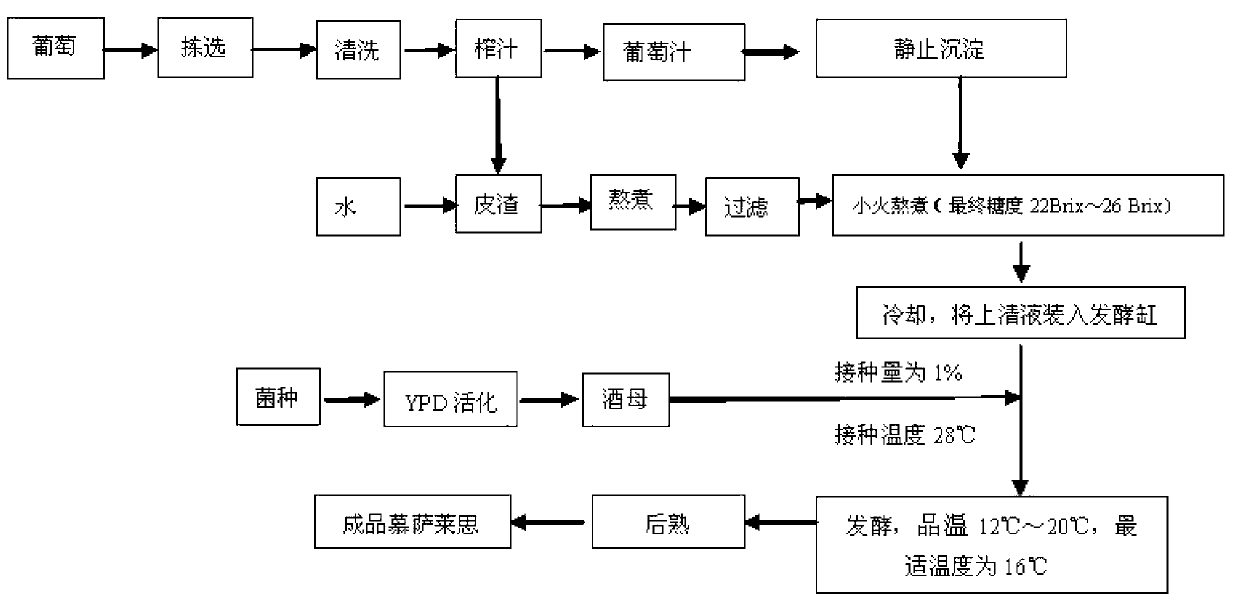

Fermented red pitaya wine, pitaya brandy and production method thereof

ActiveCN107502515ASolve difficult filterGuaranteed normal fermentationAlcoholic beverage preparationPectinaseYeast

The invention discloses fermented red pitaya wine, pitaya brandy and a production method thereof. The method includes: integrally crushing red pitayas, and adding pectinase for enzymolysis; adding yeast, yeast nutrients, vitamin C and chitosan to realize mixed fermentation; after fermentation is in full play, performing low-temperature fermentation through maceration, and carrying out aging, purifying, oak powder treatment, freezing and sterilization aftertreatment to obtain the fermented red pitaya wine; subjecting the prepared original wine to crude distillation and rectification, storing and aging to obtain red pitaya brandy. Whole-fruit fermentation is adopted, technical simplicity and low equipment input cost are realized, and the comprehensive utilization rate of red pitayas is increased; the red pitaya wine is rich in fruity aroma, rich and full in texture, stable in the presence of light, thermal and the like and free of fading, suspensions, precipitates and turbidity after normal-temperature placement over one year; the pitaya brandy is unique in nutrient and aroma, prominent in typicality and superior in quality.

Owner:佛山市五谷丰登农业技术推广有限公司

Rapid making method for all-natural fruit wine

The invention discloses a rapid making method for all-natural fruit wine. The rapid making method comprises unit operation steps as follows: careful selection and detection for fruits as raw materials, impurity removing, cleaning and disinfection, crushing, inoculated fermentation, wine liquid and peel pomace separation, after-ripening and clarification, pouring into jars for obtaining clarified wine, detection and obtaining of a finished product. Different from a traditional method, the method is short in technological process and simple and convenient to operate, production cycle of the fruit wine is shortened by 70% or higher, the fruit wine with pleasant aroma, complete wine body, complex flavor, unique style, strong typicality, remarkable bouquet, obvious fruit flavor and long quality guarantee period can be made in 45-50 days without artificially adding preservatives or other additives, and health physiochemical indexes and hygienic indexes of the fruit wine are remarkably better than those of fruit wine meeting national or international standards. The whole process from the inoculated fermentation to the finished product output is executed in a closed multifunctional fruit wine making system, so that time and labor are saved, the efficiency is high, the cost is low, and the method is energy-saving and environment-friendly and has obvious benefits.

Owner:ZHENGZHOU LANCI BIOENG CO LTD

Low-temperature yeast for brewing musalaisi, preparation method and prepared musalaisi

ActiveCN103343093AImprove fermentation performanceImprove toleranceFungiMicroorganism based processesBiotechnologyAlcohol content

The invention discloses a low-temperature yeast (Saccharomyces cerevisiae) CGMCC No. 7512 for brewing musalaisi, and the musalaisi prepared through fermentation by using the strain. According to the invention, through analysis of different temperatures, sugar contents, alcohol contents and low nitrogen tolerance, an initial fermentation test, detections of wine production, flocculability, self solubility, H2S production capacity and biogenic amine production property, a pectinase activity test and a beta-glucosidase activity determination test, the low-temperature musalaisi yeast with excellent brewing performance can be screened, and is widely applied in fields of light industry production and the like.

Owner:TARIM UNIV

Ginger grape Cognac and preparation process thereof

The ginger-grape dry wine is prepared with ginger in 30-35 wt% and grape 65-70 wt%. The preparation process includes the following steps: treating fresh ginger and grape to obtain ginger juice and grape juice; mixing ginger juice, grape juice and distiller's yeast and fermentation; distillation to obtain wine; ageing inside oak tierce for three months; blending, inspection and bottling. The ginger-grape dry wine has unique fragrance of both ginger and grape, the features of grape wine, and excellent health functions of regulating blood and vital energy, strengthening immunity, promoting blood circulation, etc. It is also suitable for use in cooking beef, mutton and fish.

Owner:高国尧

Brewage method of Zaosu pear brandy

InactiveCN105462761ASolve storage difficultiesSolve low alcohol contentMicroorganism based processesAlcoholic beverage preparationBiotechnologyAlcohol content

The invention relates to a brewage method of Zaosu pear brandy, which comprises the following steps: (1) activating Saccharomyces cerevisiae VL1 in a yeast water bath to obtain activated yeast; (2) adding sodium ascorbate into juiced Zaosu pear, and regulating the sugar degree and pH value to obtain a raw juice; (3) adding the activated yeast into the raw juice, and fermenting at constant temperature to obtain a dry-type Zaosu pear wine juice; (4) distilling the dry-type Zaosu pear wine juice with strong fire, and removing the feint to obtain a primary distilled wine body; (5) distilling the primary distilled wine body with mild fire, and removing the foreshot; when the alcohol content of the distillate is less than or equal to 55 %vol, stopping distillation, and removing the wine body; (6) carrying out redistillation on the distillate with the alcohol content of less than or equal to 55 %vol and the feint with the alcohol content of less than or equal to 5 %vol to obtain brandy raw liquor; (7) preparing naturally aged and oak-added aged brandy unblended liquors; and (8) mixing the naturally aged and oak-added aged brandy unblended liquors proportionally, diluting, adding caramel and honey, blending, filtering and filling to obtain the Zaosu pear brandy. The method has the advantages of accessible raw materials and simple technique, and can easily implement industrial production.

Owner:GANSU AGRI UNIV

Dry white wine and aroma-enhancing brewing method thereof

The invention discloses dry white wine and an aroma-enhancing brewing method thereof, and belongs to the technical field of wine processing. The key point of the technical scheme is the aroma-enhancing brewing method of the dry white wine. The method comprises the following steps: grape raw material treatment, semi-carbon dioxide impregnation, squeezing, clarification, fermentation, thermal stabilization treatment, cold stabilization treatment and cross flow. The method promotes the release of aroma substances in pericarp cells and further enhances the extraction of resveratrol in pericarp, and particularly improves the flower-and-fruit aroma intensity of neutral white grape varieties such as Chardonnay, so that the aroma expression of white wine is no longer limited by the attributes of grape varieties. The obtained dry white wine is rich in aroma, complex in flavor, complete in wine body, unique in style and strong in typicality, and health-care functions are further improved.

Owner:青岛华东葡萄酿酒有限公司

Joint production method for brandy and fruit vinegar

PendingCN106434257AReduce pressure on environmental protectionImprove the level of deep processingVinegar preparationChemistryFruit drinks

The invention provides a joint production method for brandy and fruit vinegar. The fruit vinegar is prepared from a by-product-residual distillation liquor obtained in fruit brandy production, a large quantity of by-product-residual distillation liquor obtained in fruit brandy production is used, and meanwhile the environmental protection stress is relieved; the brandy and the fruit vinegar are jointly produced by taking juice as raw materials, the deep processing level of fruits is increased, the local fruit resources are fully utilized, and meanwhile clean production is achieved. By controlling the distillation conditions, the total titrable acid value (the mass percentage concentration) of the residual distillation liquor of the fruit brandy ranges from 1.0 wt% to 1.4 wt%, and the alcohol degree (the volume percentage concentration) ranges from 4.0 degrees to 5.0 degrees; after acetic acid fermentation is conducted, the fruit vinegar with the mass concentration of 3.5 wt%-4.0 wt% can be obtained, the acetic acid concentration of the fruit vinegar meets the national standard 'fermented vinegar GB18187-2000' of liquid fermented vinegar, and the fruit vinegar has the high fruit typicality and the original unique fragrance of the fruits.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of red yeast rice polypeptide seasoning liquid based on red yeast rice distillers' grains and red yeast rice polypeptide seasoning liquid prepared by preparation method

The invention provides a preparation method of red yeast rice polypeptide seasoning liquid based on red yeast rice distillers' grains. According to the method, preferred cellulases, alpha-amylases, glucamylase and compound protein enzymes are adopted for multistage enzymolysis of red yeast rice yellow wine lees, so that zymolyte rich in soluble amino acid, polypeptide, protein and saccharide can be obtained, the utilization rate of protein of distillers' grains is 74.0% or above, and the total utilization rate of the distillers' grains achieves 76.6% or above; the distillers' grain enzymatic hydrolysate is used as a substrate, and Maillard reaction fragrance enhancement technical parameters are adjusted and controlled, so that the red yeast rice polypeptide seasoning liquid being red brownand clear in color, delicious in fragrance, rich in sauce fragrance, high in red yeast rice typicality, and concerted in fragrance and taste can be prepared. The amino acid nitrogen content in products is 0.5g / 100mL or above, and the polypeptide (molecular weight is 180Da-2000Da ) content achieves 100g / L or above. The red yeast rice yellow wine lees are developed into quality polypeptide seasoning liquid, so that resource waste of distillers' grains is avoided, waste is turned into wealth, the added value of the products is greatly increased, and the preparation method has good economic and social benefits.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

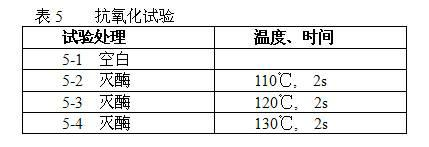

Process for making plum wine

InactiveCN110835594AReduce usageHigh fermentation clarityAlcoholic beverage preparationBiotechnologyFruit wine

The invention discloses a process for making plum wine, and belongs to the technical field of fruit wine making. The process comprises the steps of picking raw materials, carrying out primary cleaningand screening, carrying out secondary cleaning, drying, canning and impregnating, carrying out enzymolysis, allowing clarification to take place, fermenting, pouring out a liquor, fermenting with malic acid and lactic acid, storing, aging, fining, filtering, carrying out oxidation resistance treatment, blending, carrying out freezing treatment, filtering with a sterilization plate, performing stability test, carrying out precision filtration, and carrying out quality inspection and filling, to be specific, carrying out quality inspection according to the enterprise standard, and filling afterqualification is confirmed. The plum wine made via the process has the advantages of good taste, stable quality and the like, nutritional ingredients in fruits are retained, the plum wine has outstanding typicality, has no added essence, pigment or preservative, and is a safety healthy food.

Owner:贵州绿色山水农业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com