Mixed fermented wine of haw and grape and its brewing process

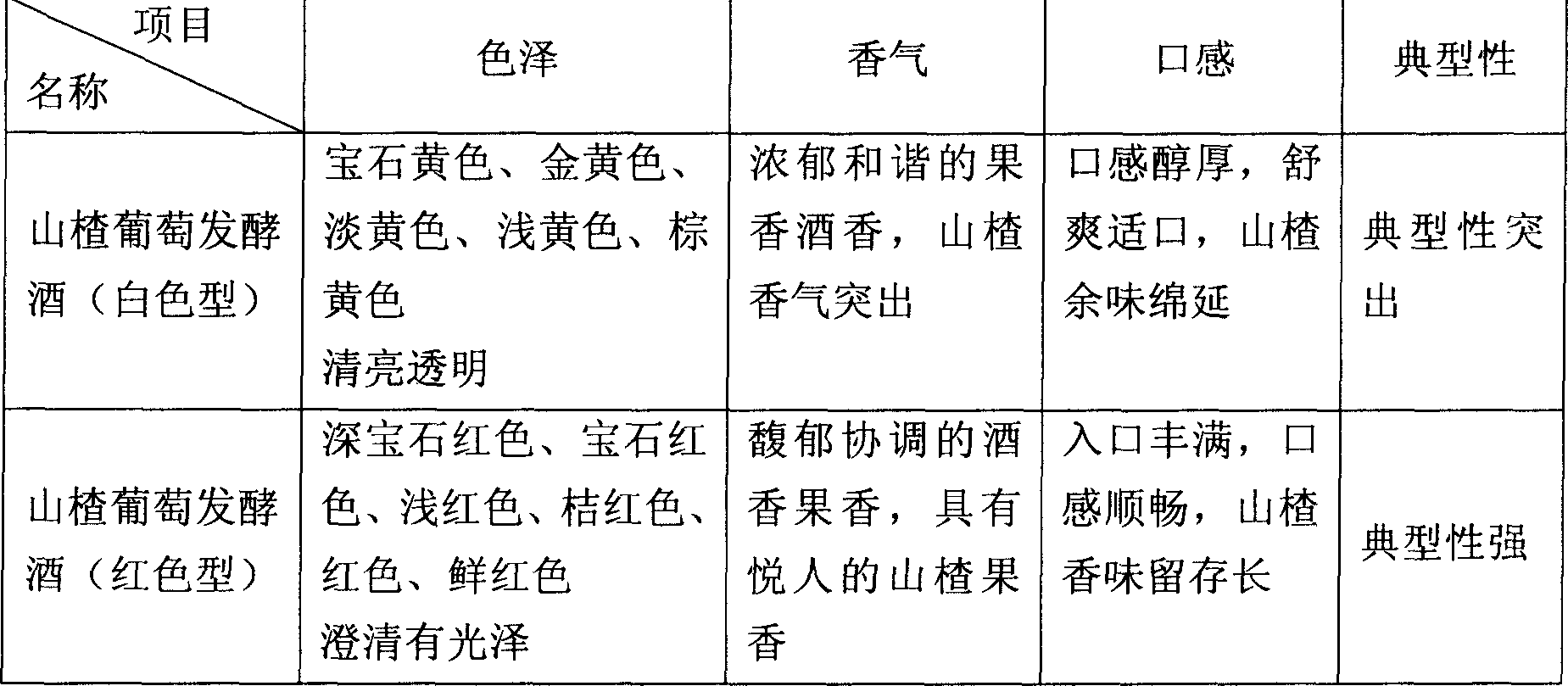

A technology of mixed fermentation and wine, applied in the preparation of alcoholic beverages, can solve the problems of single flavor and far difference, and achieve the effect of reducing storage costs, pure and harmonious hawthorn flavor, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mix the sorted and cleaned fresh and ripe white grapes with fresh hawthorn at a weight ratio of 95%:5%, crush and remove the stems, and make a pulp, add 80mg / L of sulfur dioxide to the pulp and mix evenly, adjust with sucrose When the sugar content reaches 230g / L, add 100mg / L dry yeast for fermentation, and the fermentation temperature is 20°C. When the sugar content is less than 4.0g / L, separate and press to obtain the clear liquid, and add sulfur dioxide to the clear liquid to 50 mg / L. During the aging period Half a year, remove the wine legs during the aging period, then use bentonite for gumming treatment, and then filter, freeze, fine filter and other processes, put it aside for one month, and then use sucrose to make dry fermented hawthorn wine (total sugar ≤ 4.0g / L ), thermally stabilized at 72°C (1.5 hours), cooled and filtered, and then pasteurized for bottling to make fermented hawthorn wine.

Embodiment 2

[0022] Mix the sorted and cleaned fresh ripe red grapes with fresh hawthorn at a weight ratio of 86%:14%, then crush and remove the stems to make fruit juice or pulp, add 80mg / L of sulfur dioxide to the pulp and mix evenly. Use sucrose to adjust the sugar content to 250g / L, add 100mg / L dry yeast for fermentation, and ferment at 21°C. When the sugar content is less than 4.0g / L, separate and press to obtain the clear liquid, and add sulfur dioxide to the clear liquid to 50mg / L , the aging period is half a year. During the aging period, the wine legs are removed, and then the glue is treated with bentonite, and then filtered, frozen, and finely filtered. ~12.0g / L), thermally stabilized at 70°C (1.8 hours), cooled and filtered, and then pasteurized for bottling to make fermented hawthorn wine.

Embodiment 3

[0024] Mix the sorted and cleaned fresh ripe white grapes with fresh hawthorn at a weight ratio of 74%:26%, crush and remove the stems, and make a pulp, add 80mg / L of sulfur dioxide to the pulp and mix evenly, adjust with sucrose When the sugar content reaches 280g / L, add 100mg / L dry yeast for fermentation, and the fermentation temperature is 25°C. When the sugar content is less than 4.0g / L, separate and press to obtain the clear liquid, and add sulfur dioxide to the clear liquid to 50 mg / L. During the aging period Half a year, remove the wine legs during the aging period, then use bentonite for gumming treatment, and then filter, freeze, fine filter and other processes, let it stand for a month, and then use sucrose to make semi-sweet fermented hawthorn wine (total sugar 12.1~50.0g / L), thermally stabilized at 76°C (1 hour), cooled and filtered, and then pasteurized in bottling to make fermented hawthorn wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com