Patents

Literature

4719 results about "Saccharum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saccharum is a genus of tall perennial plants of the broomsedge tribe within the grass family. The genus is widespread across tropical, subtropical, and warm temperate regions in Africa, Eurasia, Australia, the Americas, and assorted oceanic islands. Several species are cultivated and naturalized in areas outside their native habitats.

Clear-white gold needle mushroom cultivation method

InactiveCN101366346AAvoid pollutionNo diseaseBio-organic fraction processingOrganic fertiliser preparationSucroseSaccharum

The invention discloses a method for cultivating pure white needle mushrooms. The method comprises the following steps: a strain is prepared; a culture material is prepared; bagging and sterilization are carried out; inoculation is carried out; a mycelium is cultured; nutrition, humidity, temperature, light, air and other culture conditions are strictly controlled during a fruiting period; and harvesting is carried out in an optimum period. the formulation of the culture material is 0 to 32 percent of weed tree sawdust, 0 to 93 percent of cotton seed hulls or wheat straw, straw, corncob and other crop straw, 0 to 20 percent of wheat bran, 0 to 10 percent of corn meal, 0 to 10 percent of soybean meal, 0 to 1 percent of calcium carbonate, 0 to 0.2 percent of monopotassium phosphate, 0 to 0.2 percent of magnesium sulfate, 1 to 1.2 percent of sucrose, 0 to 10 percent of rice bran, 0 to 1 percent of plaster and 0 to 0.02 percent of urea. Quicklime and wettable carbendazim are added during the preparation of the culture material so as to prevent the pollution of undesired bacteria. The technical proposal aims to select proper breeds, popularize local large scale planting and improve cultivation benefit.

Owner:WUHU YESHULIN BIOTECH

Plant nutrient liquid fertilizer

InactiveCN102701861AImprove stress resistanceSolve the problem of lack of nutrientsFertilizer mixturesSucrosePhosphate

The invention relates to a plant nutrient liquid fertilizer. In order to solve the problem of over fertilization, the plant nutrient liquid fertilizer is prepared from the following raw materials in proportion by weight: aqua brassin 12-36, gibberellin 1-4, indoleacetic acid 30-80, abscisic acid 10-20, naphthaleneacetic acid 50-90, salicylic acid 80-180, vitamin C 1-3, cane sugar 40-100, chitin 20-80, 0.05-0.2 percent triacontanol 400-1,000, hydrolyzed protein 2-5, potassium dihydrogen phosphate 300-400, thiourea 40-120, cobalt chloride 5-12, borax 50-100, sodium silicate 30-55, urea 300-500, ammonium molybdate 50-80, copper sulfate 30-65, zinc sulfate 120-200, magnesium sulfate 100-150, calcium chloride 50-120, manganese sulfate 40-80 and water in the amount of 3-8 times the total amount of all the raw materials or water in the amount capable of dissolving all the raw materials, wherein the water is de-ionized water or micro cluster water; and the preparation method is that all the materials are prepared into aqueous solution. The plant nutrient liquid fertilizer has the advantages of favorably solving the problems of over fertilization and shortage of nutrient elements in soil, obviously improving the plant adverse resistance, improving the photosynthesis and the accumulation efficiency of nutritive materials and improving the yield and the quality.

Owner:魏玉芳

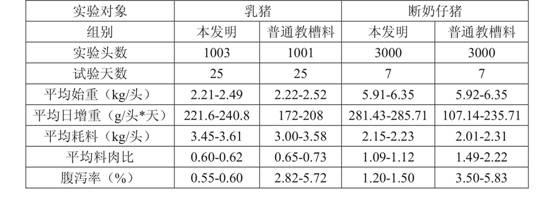

Compound feed for teaching piglets to eat foods other than breast milk

InactiveCN102178115AHealthy micro-ecological balance environmentAvoid damageFood processingAnimal feeding stuffDiseaseSucrose

The invention provides compound feed for teaching piglets to eat foods other than breast milk, which is used for weaning piglets and teaching the piglets to eat foods other than breast milk, and comprises the following components in part by weight: 212.4 parts of corn starch, 154.0 parts of bulked corn, 100.0 parts of 46 percent of bulked bean pulp, 40 parts of fish meal, 100 parts of wheat flour, 5 parts of calcium powder, 21 parts of calcium hydrophosphate, 2 parts of table salt, 20 parts of soybean oil, 5 parts of lysine, 2 parts of threonine, 1.5 parts of choline chloride, 10 parts of premix, 0.2 part of complex enzyme, 0.3 part of pig Duowei, 0.2 part of sweetener, 0.3 part of flavouring agent, 3 parts of baking soda, 20 parts of cane sugar, 30 parts of glucose, 50 parts of egg powder, 70 parts of soy protein concentrate, 50 parts of fermented bean pulp, 6 parts of acidizer, 100 parts of whey powder, 0.5 part of mould removing agent, 0.3 part of antioxidant and 0.3 part of mildewpreventive. In the invention, the problems of incomplete immune functions, low disease resistance, inadequate digestive ferment, incomplete upper gastrointestinal development, low digestion and absorption ability, susceptibility to diarrhea and the like of piglets.

Owner:AGRI SCI & TECH INST CO LTD OF CHENGDU WEST HOPE GRP

Cultivation medium for Pleurotus geesteranus and method for producing the same

InactiveCN101462900AImprove qualityBacteriaBio-organic fraction processingOrganic fertiliser preparationAgricultural scienceSucrose

The invention discloses a pleurotus geesteranus medium and a preparation method thereof. The recipe of the medium comprises (by weight) 60-75% of cotton seed hull or wheat straw or rice straw or corn cob, 7-15% of weed tree sawdust, 8-15% of wheat bran or rice bran, 3-8% of corn flour, 0.5-1.5% of sucrose, 1-1.5% of dried gypsum, 2-2.5% of quicklime, 0.1-0.3% of potassium dihydrogen phosphate and 0.1-0.2% of magnesium sulfate. The preparation method of the medium comprises the following steps: dissolving the quicklime, the dried gypsum, the potassium dihydrogen phosphate and the magnesium sulfate into water; adding the cotton seed hull or the wheat straw or the rice straw or the corn cob and the weed tree sawdust for prewetting; then adding the rice bran, the corn flour, the wheat bran and the sucrose and mixing evenly; and returning the medium having been used for planting the pleurotus geesteranus to field and soil in situ. The technical scheme can cause the pleurotus geesteranus to grow better and avoids the defect of no special medium for the growth of the pleurotus geesteranus in the prior art.

Owner:许忠

Peach gum jelly and preparation method thereof

InactiveCN104256228ATransparent appearanceIncrease elasticityFood ingredient functionsFood preparationCarrageenanSucrose

The invention relates to a peach gum jelly and a preparation method thereof. The preparation method of the peach gum jelly comprises the following steps: (1) preparing peach gum hydrolysate; (2) boiling 100-300 parts of water, 0.1-1.0 part of carrageenan, 0.2-1.2 parts of konjac glucomannan, 5-25 parts of peach gum hydrolysate, 5-15 parts of peach blossom aqueous extract, 3-12 parts of saccharose, 0.002-0.01 part of stevioside, 0.004-0.03 part of sucralose and 0.1-0.5 part of potassium chloride at high temperature; and (3) cooling, adding auxiliary materials, sterilizing and packaging. The jelly prepared by the preparation method has favorable mouthfeel and diversified flavors due to the addition of the peach gum and the peach blossom aqueous extract while the health function of the jelly is increased and is used for reinforcing the physical health of a human body. Compared with a traditional peach gum food, the peach gum jelly prepared by the preparation method can be stored for a long time at normal temperature, has the characteristics of transparent appearance, favorable elasticity, smooth and mellow mouthfeel, sweet and sour taste, diversified flavors and the like and is capable of meeting of different crowds.

Owner:无锡康顿生物科技有限公司

Biological preparation capable of preventing and treating cruciferae club root and use thereof

InactiveCN101416641AGood control effectSolve prevention and control problemsBiocideBacteriaSucroseRussulaceae

The invention relates to a biological agent against crucifer club root and application thereof, belonging to the technical field of bio-pesticide. The strain for production is Bacillus subtilis XF-1, whose preserving number is CGMCC NO.2357. The stain has the characteristics as follows: (1) the primary colony on the LB culture substrate is white and round having a wet surface; the later colony is light yellow having uneven edge with dry and crimple surface; observed from the microscope, the strain is short-bar shaped and movable with spore, peritricha and dimension of 0.7 - 0.8 * 2.0-2.4 mum; (2) the strain is Gram-positive and aerobic and makes use of glycogen, sugar, citrate, gelatin hydrolysate, starch and casein, but does not make use of cellulose, tyrosine and catalase positive; (3) the stain has the function of sterilization, disease prevention, and yield improvement. The embodiment of the invention is as follows: using the test tube of Bacillus subtilis XF-1 stain, shake cultivation, and culture solution for fermentation to prepare biological agent, then applying the biological agent to the rhizosphere soil of crucifer crops, thereby having good effect in preventing and treating, and simple production.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Dehydrated polysaccharide gel containing microorganisms, a sugar and a polyol for producing fermented drinks

Improved fermentation activity of microorganisms in a polysaccharide gel such as an alginate gel is obtained after dehydration, staorage and rehydration by soaking the gel containing the microorganisms prior to dehydration in a sugar solution to provide in the gel an amount of sugar of at least 100 g / kg and less than 500 g / kg of gel, preferably less than 300 g / k of gel. The dehydration may be carried out in a fluidized bed or by lyophilization. The gel may be in the form of beads or fibers having a double layer structure formed by an internal layer or core of gel containing the microorganisms and an external lay er or envelope of gel essentially devoid of the microoraganisms. The sugar is preferably xylose, glucose, fructose, lactose or sucrose, and the sugar solution may contain a polyol such as sorbitol, inositol or glycerol to provide in the gel an amount of polyol of at least 30 g / kg of gel. The sugar solution may also contain a non-ionic surfactant such as sorbitan monostearate as a protecting substance to fur ther improve fermentation activity. The microorganisms in the gel are preferably yeast, and after rehydration the yeast containing gel is used in producing a fermented drink such as in secondary fermentaion of wine to produce sparkling wine or champagne.

Owner:MOET & CHANDON

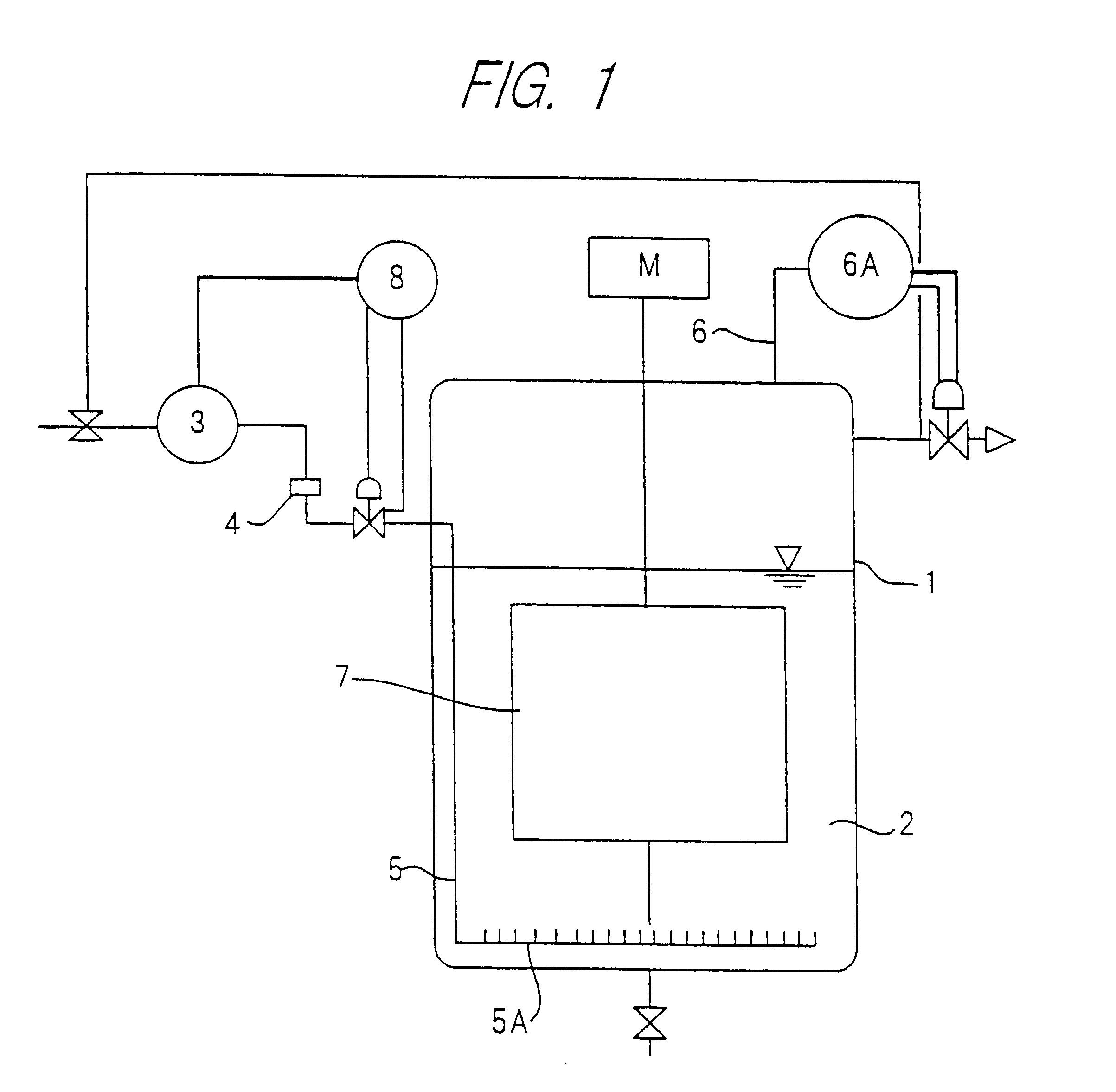

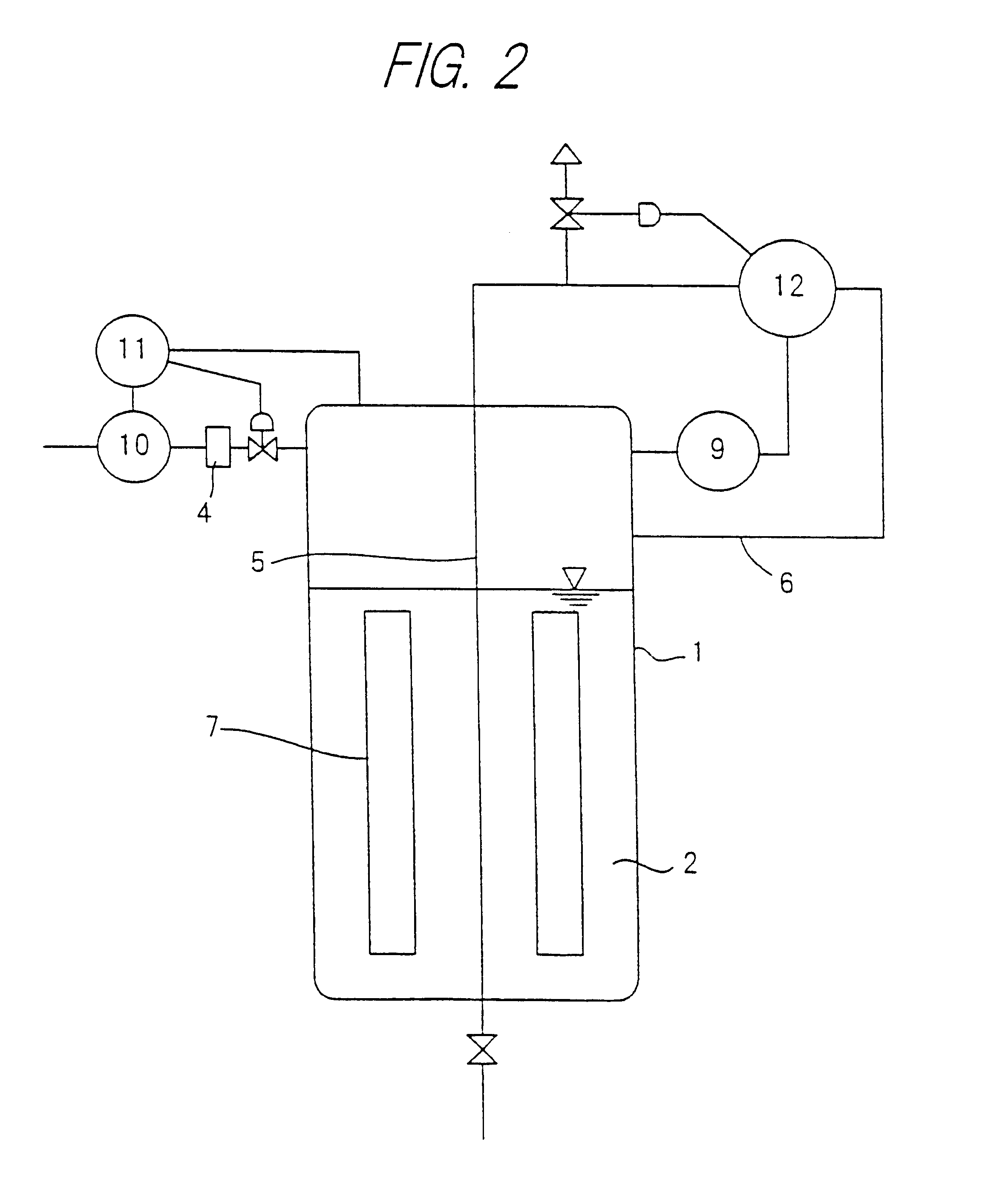

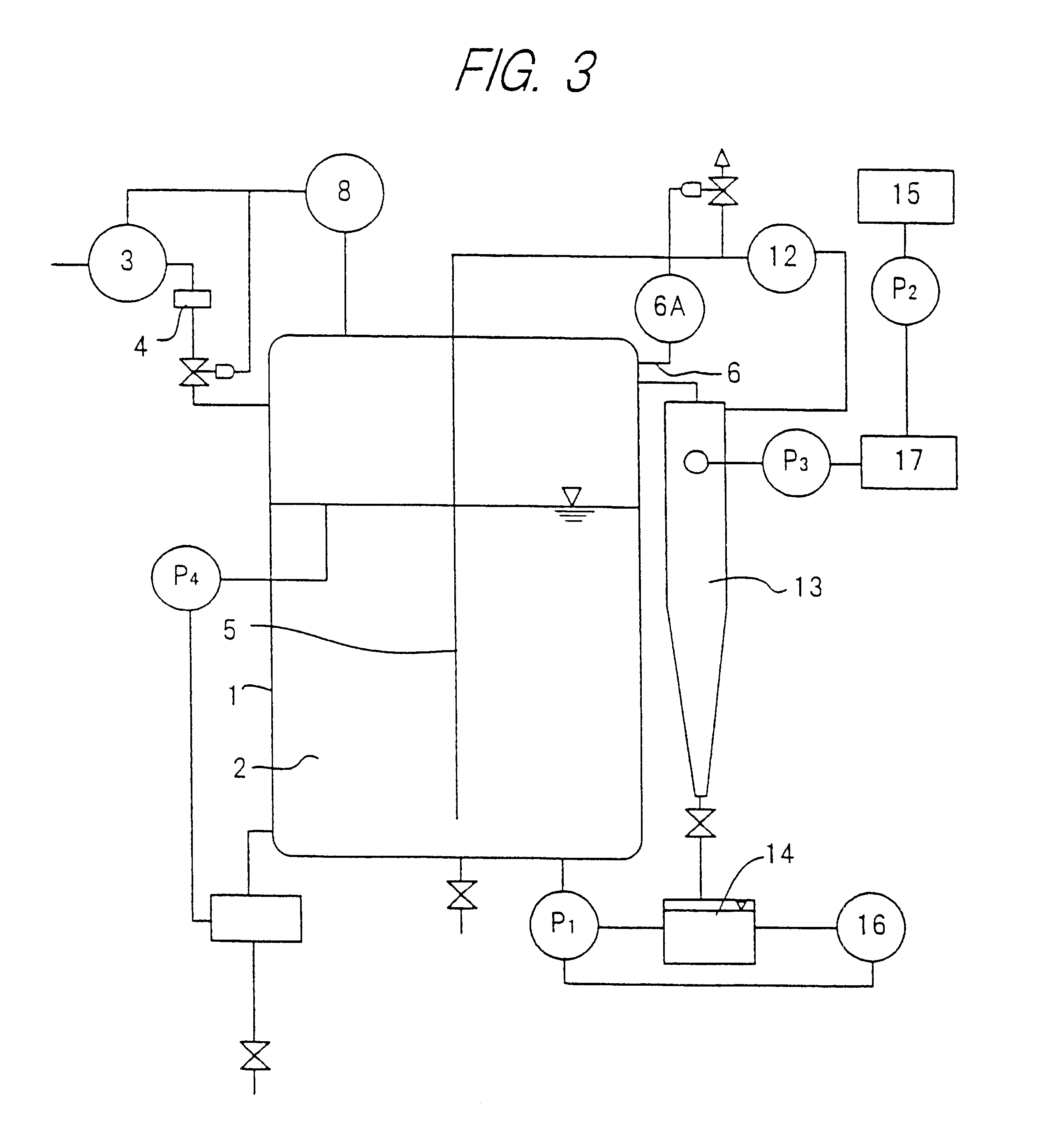

Method for culturing a basidiomycetous fungus in a liquid culture medium

Disclosed is an efficient method for culturing an edible basidiomycetous fungus such as Mushroom Agaricus Blazei Murill in a liquid culture medium to give fungus aggregates of several centimeter size. Characteristically, the liquid culture medium is formulated with sucrose as a carbon source in the form of crude cane sugar in combination with a water-insoluble growth-supporting material in the form of a fine powder to serve as the core of the fungus aggregates as selected from crushed sugarcane, sugarcane bagasse, pine trees and wheat bran. Further characteristically, the culturing procedure is carried out under an oxygen-enriched condition by blowing oxygen-enriched air of at least 30% by volume oxygen into the culture medium under pressurization at 0.12 to 0.5 MPa (absolute) in a specified blowing rate.

Owner:TSUKUBA BIOSYST

Method for planting selenium-enriched pleurotus eryngii and culture medium thereof

InactiveCN101182266AHas a therapeutic effectExcellent biological source of seleniumHorticultureFertilizer mixturesSaccharumAgricultural science

The invention discloses a selenium-enriched pleurotus eryngii planting method and a culture medium, comprising the following steps of confecting the culture medium, bagging, sterilizing, inoculating, fungus growing, bud hastening, producing mushroom and harvesting. The materials of the culture medium is manufactured according the weight portions of 70 to 90 portions of cotton seed shell, 8 to 10 portions of bran, 2 to 3 portions of corn meal, 0.6 to 1.2 portions of sucrose, 0.6 to 1.2 portions of gypsum, 4.5 to 6.5 portions of lime, 100 to 140 portions of water and 0.0011 to 0.0014 portion of sodium selenite. The method of the invention domesticates and cultivates the pleurotus eryngii seeds capability of absorbing and enriching selenium to ensure that the selenium-enriched pleurotus eryngii achieves the balanced production and is on the market all year, which improves the output and increases the economic benefit.

Owner:HANGZHOU NONGFA SCI & TECH DEV

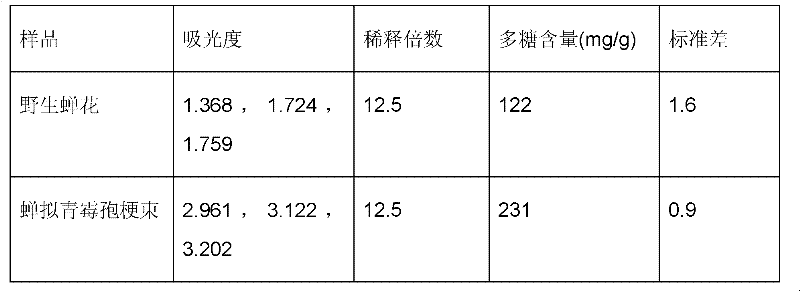

Method for artificially culturing paecilomyces cicadae and application of culturing product thereof

ActiveCN102242070AA Simple Method for Artificially Cultivating Paecilomyces cicadaeReduce manufacturing costCosmetic preparationsSenses disorderSucroseSaccharum

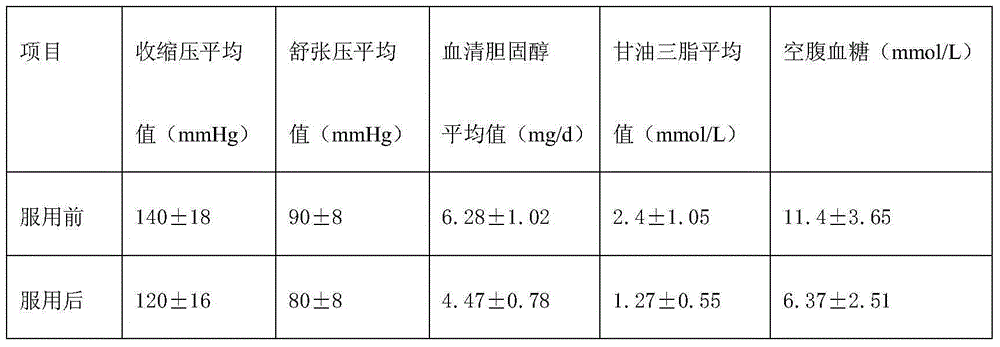

The invention discloses a method for artificially culturing paecilomyces cicadae and application of a culturing product thereof. The method for artificially culturing paecilomyces cicadae in large scales comprises the steps of: preparing strains, dosing and packing into a box, sterilizing, inoculating, solid-fermenting, collecting and the like. The paecilomyces cicadae is cultured by utilizing grains, such as corn flour, bran, wheat, barley, rice, millet, broomcorn and the like and culture mediums of bagasse, cane sugar, shell powder, silkworm chrysalis meal and potassium nitrate. The raw materials are obtained from local resources, a large amount of production cost is saved, the culturing period is shortened, and cordyceps sobolifera obtained by culturing has the advantages of high quality and favorable stability and the like. A culture obtained by the invention can be used for preparing foods, health-care products, drugs and cosmetics with functions of fighting tumor, regulating immunity, reducing blood sugar, blood fat and blood pressure, improving eye sight, resisting radiation, dispelling heat and easing pains, calming and hypnotizing, nourishing and strengthening, improving kidney function and the like.

Owner:ZHEJIANG BIOASIA PHARMA CO LTD

Milk powder

The milk powder is prepared with the materials including: fresh milk or milk powder, defatted milk powder or defatted milk, lactase, desalted whey powder, whey protein powder and / or soybean protein powder, vegetable oil, phospholipid, oligose, honey, calcium lactase, CPP, wolfberry fruit, vitamins and minerals. The product may avoid lactose intolerance, has the effects of resisting fatigue, resisting senility, raising memory and improving gastrointestinal tract function, and has the advantages of no cane sugar, high calcium content and low lactose content.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Method for culturing rare edible fungi including tricholoma lobayense heim and clitocybe maxima by using vine shoot dust

InactiveCN102187787AAchieve biotransformationMaterials are readily availableHorticultureFertilizer mixturesBiotechnologySucrose

The invention discloses a method for culturing rare edible fungi including tricholoma lobayense heim and clitocybe maxima by using vine shoot dust. The method comprises the following steps of: A, preparation of a fermentation culture solution; B, preparation of liquid spawn; C, preparation of granular spawn; D, preparation of a culture medium: selecting 68-72 percent of vine shoot dust, 8-12 percent of cotton seed hull, 8-12 percent of broken dry broad-leaved tree fallen leaves, 8 percent of bran, 1 percent of sucrose and 1 percent of calcined lime in a weight ratio, stirring in a material-water ratio of 1:1.4, bagging, performing conventional sealing, and sterilizing for later use; E, inoculating culture; and F, harvesting. The vine shoot is treated and developed into a raw material for culturing the rare edible fungi including the tricholoma lobayense heim and the clitocybe maxima, a natural culture medium is provided for the fungi culture industry, the biotransformation utilization of the vine shoot is realized, and the culture costs of the tricholoma lobayense heim and the clitocybe maxima are reduced.

Owner:HEBEI UNIVERSITY

Mushroom cultivation substrate

InactiveCN101450879AProtect resourcesMeet nutritional needs for growthHorticultureFertilizer mixturesBiotechnologySaccharum

The invention discloses a pasania fungus culture substrate consisting of solid materials and water. The solid materials comprise the following components by weight percentage: 35 to 40 percent of summer cut mulberry twig chips, 35 to 40 percent of cotton straw chips, 18 to 20 percent of bran coat, 2.5 to 3 percent of corn flour, 1 to 1.2 percent of sugar, and 1.5 to 1.8 percent of gesso. The dosage ratio of the solid materials to the water is 1: (1.2-1.3). The substrate is packed by bags with the bag diameter of between 18 and 22 centimeters. The substrate is used for culturing pasania fungus, and can make full use of local discarded crop resources in accordance with local conditions without consuming wood. The substrate can reduce the cost and effectively improve the quality and yield of the pasania fungus. The economical benefit is improved by 15 to 20 percent than that of the prior pasania fungus culture substrate; therefore, the substrate has important popularization value.

Owner:JIANGYAN MODERN AGRI SCI & TECH EXPERIMENT FIELD

Method for improving quality of the tobacco leaf expanded cut stem by microorganism enzyme

InactiveCN101288505AIncreased total cellulose contentDecreased total cellulose contentFungiTobacco treatmentSucroseSaccharum

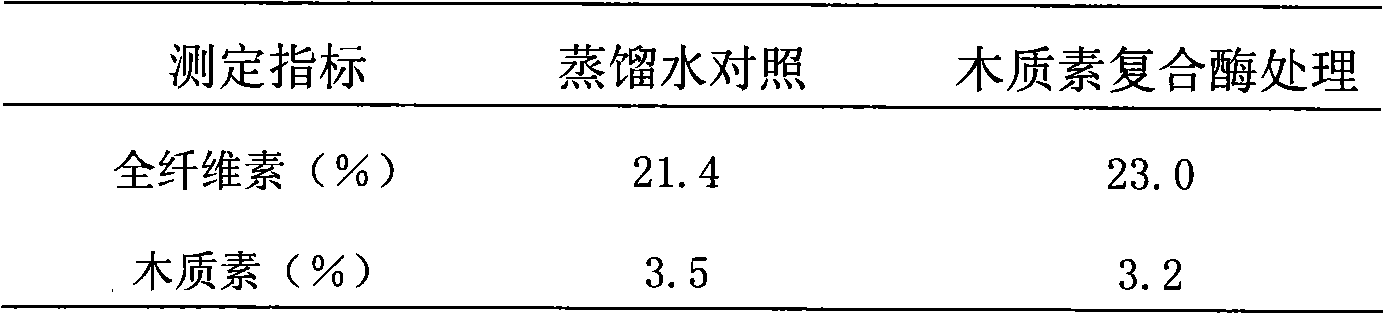

The invention provides a method for improving the quality of expanded cut rolled stem of tobacco by microbial enzyme. The procedures are as follows:1) Preparation of bio-enzyme: (1) Aspergillus niger is activated and cultured by potato cane sugar culture medium and is then transferred into sterilized seed culture medium, and shake cultivation is carried out at the temperature of 28 DEG C for 24 hours with 250r / min<-1>; seed liquid with 10% of inoculation amount is transferred into a sterilized 500ml shake flask (containing 100ml culture liquid for enzyme), and the seed liquid carries out incubation for culturing at the temperature of 25 DEG C for 96 hours and then zymotic liquid is obtained. (2) Extraction of lignin degradation complex enzyme: After being filtered by filter paper, the zymotic liquid is centrifugally separated at the low speed of 1500rpm. The supernatant carries out fractional salting out by (NH4)2SO4 till the saturation is 0.7 to obtain crude enzyme liquid, after the crude enzyme liquid carries out ultrafiltration dialysis, the lignin degradation complex enzyme is obtained. Activities of enzyme components: 350U / L of Lip, 11U / L of MnP and 5.6U / L of Lac; 2) Improvement of the quality of expanded cut rolled stem of tobacco: The expanded cut rolled stem for cigarette is weighed and sprayed evenly by lignin degradation complex enzyme liquid containing 0.2-0.4% of expanded cut rolled stem after being diluted by distilled water at the temperature of 27 DEG C-29 DEG C. The expanded cut rolled stem of tobacco is placed in a sealed container for enzymolysis for 95-97 hours and dried naturally till the moisture content is 12.5%-15%. The result by subjective analysis suggests that the complex enzyme preparation can effectively decrease the lignin content of the expanded cut rolled stem, promote the transformation of aroma matter and improve aroma quality and taste.

Owner:云南万芳生物技术有限公司

Fruity probiotic yogurt slice containing antifreeze sericin peptide and method for preparing same

ActiveCN103109930ARich in physiological functionsRich in antioxidantMilk preparationProbiotic yogurtBiotechnology

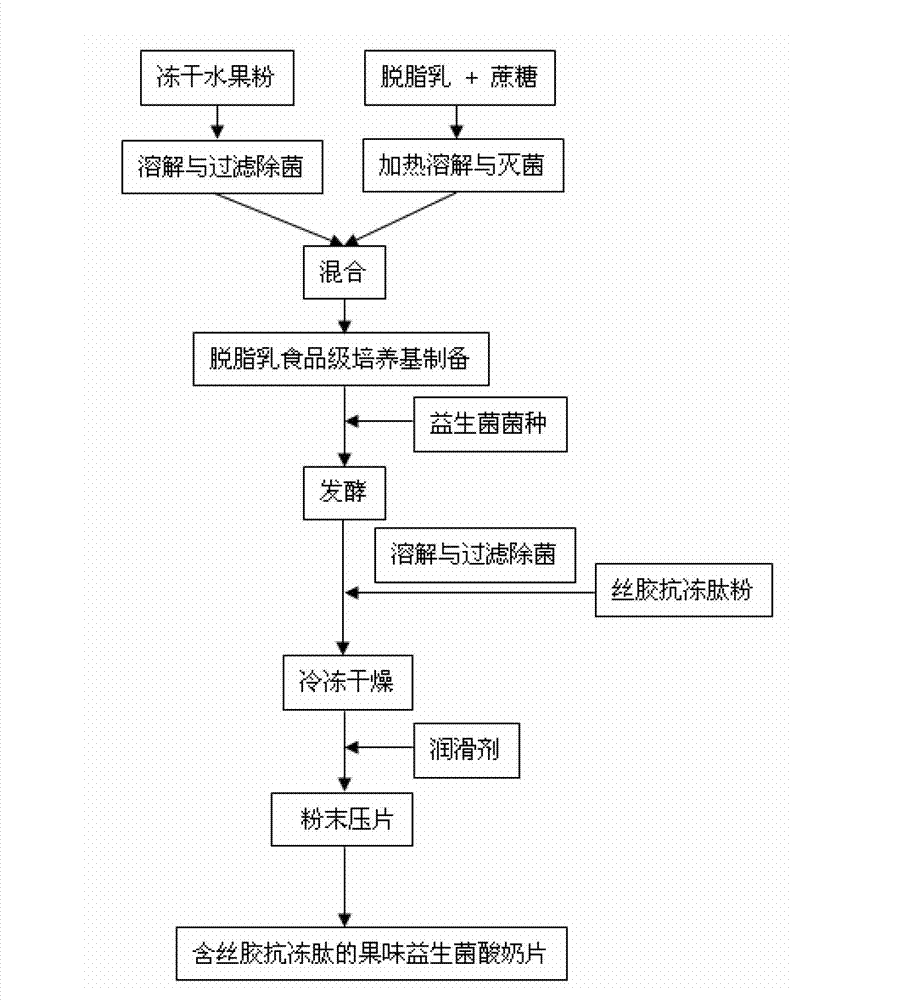

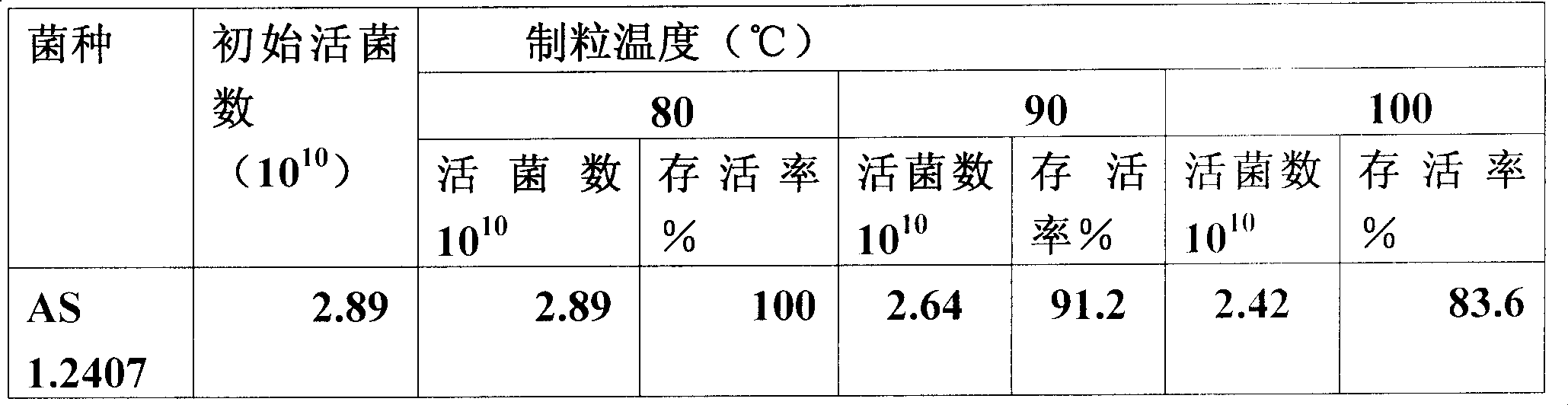

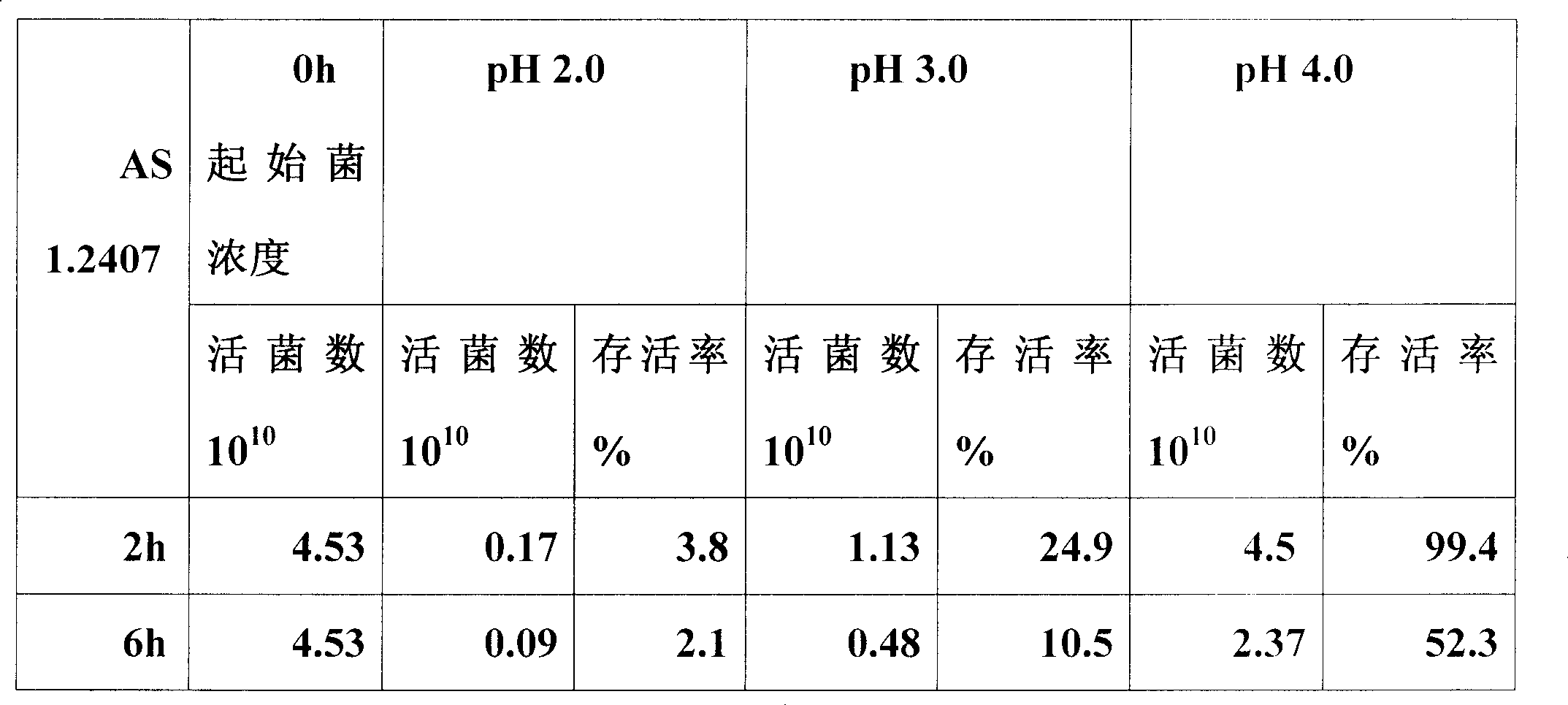

The invention discloses a fruity probiotic yogurt slice containing antifreeze sericin peptide. The raw materials for preparing the fruity probiotic yogurt slice comprise 10-14 parts of skimmed milk powder, 2-5 parts of sucrose, 1-3 parts of sericin peptide, 1-4 parts of fruit material, 0.1-0.6 part of lyophilized active probiotics and 0.1-0.4 part of magnesium stearate. The invention further discloses a method for preparing the product which is the fruity probiotic yogurt slice. The method mainly comprises the following steps of: preparing a skimmed-milk food-grade culture medium, fermenting the probiotics, adding the antifreeze sericin peptide, freezing and drying fermented milk in vacuum, and pressing powder into slices. As the fruity probiotic yogurt slice contains the antifreeze sericin peptide and the lyophilized fruit powder which is rich in the vitamin B group, the number of the probiotics in the fruity probiotic yogurt slice can be increased, the retention time of the activity of the probiotics can be prolonged, and the taste, flavor and nutritional and healthcare values of the fruity probiotic yogurt slice can be improved. The fruity probiotic yogurt slice can serve as a functional food for supplementing the vitamin B group, improving the immunity and promoting the intestinal health.

Owner:SHANGHAI JIAO TONG UNIV

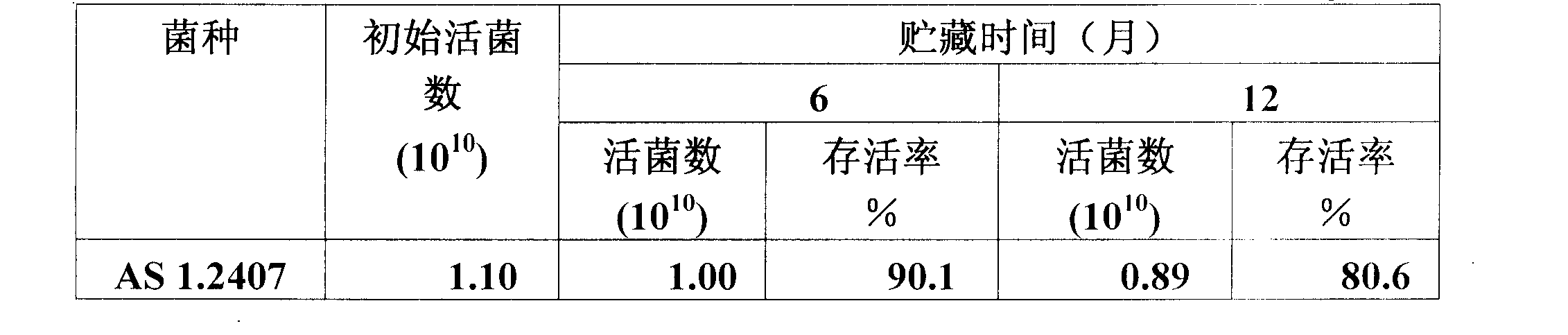

Coagulation bacillus feedstuff supplement and preparation method thereof

ActiveCN101390571AImprove stress resistanceHigh viable countFungiAnimal feeding stuffSucroseCorn meal

The invention relates to a condensate bacillus feed additive and a preparation method, belonging to the technical field of microbial feed additives. The additive uses one or several of the fish meal, soybean meal, cottonseed meal, urea, ammonium sulfate, diammonium hydrogen phosphate, soybean peptone and yeast extract as the nitrogen source, and also takes one or several of the glucose, lactose, starch, cane sugar, maize flour and bran as the carbon source for fermentation; the number of viable bacteria reaches more than 1 multiplying 109 CFU / ml; after the additive is further concentrated and dried or directly adsorbed to the carrier, bacillus powder is obtained through spray-drying, and the number of viable bacteria reaches more than 1 multiplying 1010 CFU / g. The novel bacillus product produced with the submerged liquid fermentation method provided in the invention is free from toxic side effects, drug resistance and residue; the product can endure processing, intestinal habitat and storage.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

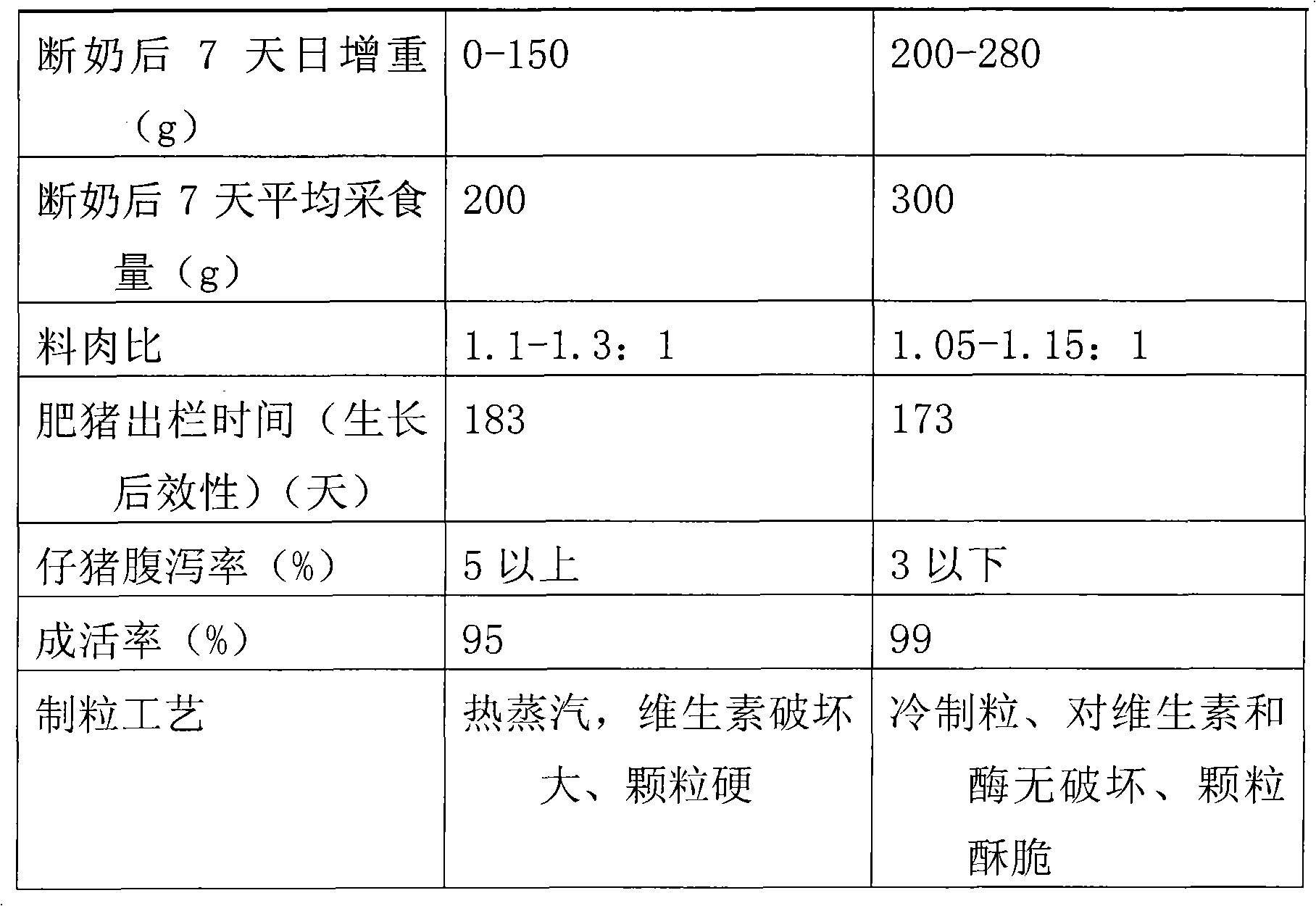

Creep mixed feed for piglets

ActiveCN101961077AImprove orderImprove immunityAnimal feeding stuffAccessory food factorsSucroseSlurry

The invention relates to a pig feed, in particular to a creep mixed feed for piglets. The creep mixed feed for piglets comprises the following raw materials in part by weight: 100 to 300 parts of puffed corn, 100 to 300 parts of rice meal, 100 to 300 parts of flour, 10 to 30 parts of soybean oil, 0.3 to 0.5 part of rovimix 536 compound vitamin, 2.5 to 4 parts of low-copper mineral element, 50 to 100 parts of peeled bean pulp, 30 to 80 parts of fermented bean pulp, 40 to 100 parts of puffed soybean, 30 to 50 parts of steam fish meal, 20 to 50 parts of slurry albumen powder, 20 to 30 parts of dried porcine solubles, 40 to 100 parts of whey powder, 20 to 40 parts of glucose powder, 20 to 40 parts of sucrose, 10 to 50 parts of emulsified fatty powder, 5 to 10 parts of calcium carbonate, 1 to 3 parts of table salt, 5 to 12 parts of calcium biphosphate, 1 to 2 parts of sodium butyrate, 1 to 5 parts of lysine, 0.5 to 3 parts of threonine, 1 to 4 parts of methionine, and 0.5-1 part of TP-100 enzyme. Nutrient components of a product simulate those of breast milk; the creep mixed feed for piglets has high palatability and digestibility; the piglets like eating the feed, so feed intake is large; the product increases the survival rate and the immunity of the piglets, and the piglets do not have loose bowels; and in the product, a process technique of supermicro milling and cold granulating is adopted, and the use ratio of the feed is increased.

Owner:江西大佑农生物科技有限公司

Preparation method of purple sweet potato wine

ActiveCN101724533ABeautiful colorRich and elegant wineMicroorganism based processesAlcoholic beverage preparationPectinaseSucrose

The invention provided a preparation method of a purple sweet potato wine, which is characterized in comprising the following steps of: talking purple sweet potato, cleaning, cutting into pieces or cutting into blocks, steaming to be completely cooked, evenly mixing with water, wherein the quantity of the water is 0.5-3 times of that of the cooked purple sweet potato, adding pectinase and evenly mixing, preserving temperature at 45-55 DEG C for 5-10h, cooling to be 35-40 DEG C to prepare enzymolysis material, and dividing the enzymolysis material into two parts; adding 0.6-1.5% of milled rice koji into one part of the enzymolysis material, and preserving temperature at 35-40 DEG C for 18-24h to prepare bacteria culturing material; and mixing the other part of the enzymolysis material with the bacteria culturing material, adding wine-making yeast expansion culture solution and aroma-producing yeast expansion culture solution, fermenting in a sealing way for 3-4 days, adding sucrose and fermenting in a sealing way for 3-6 days, filtering, adding proper amount of potassium metabisulfite, fomenting at 18-20 DEG C for 15-20 days, removing deposition, ageing, fine filtering, and sterilizing to obtain the final product of the purple sweet potato wine. The preparation method takes the purple sweet potato wine as raw materials, has good product quality, high nutrition value, high commodity additional value and strong practicality.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

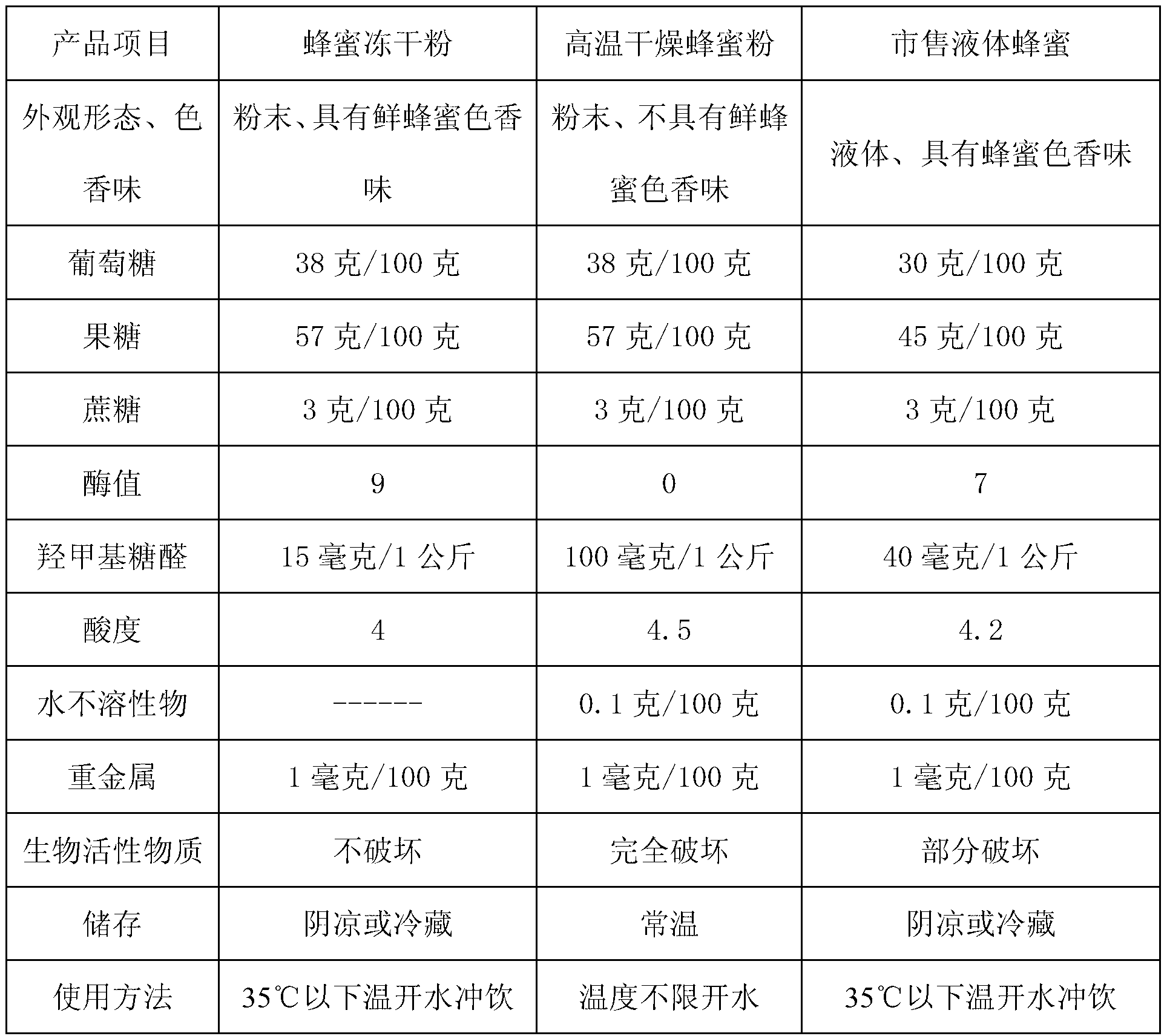

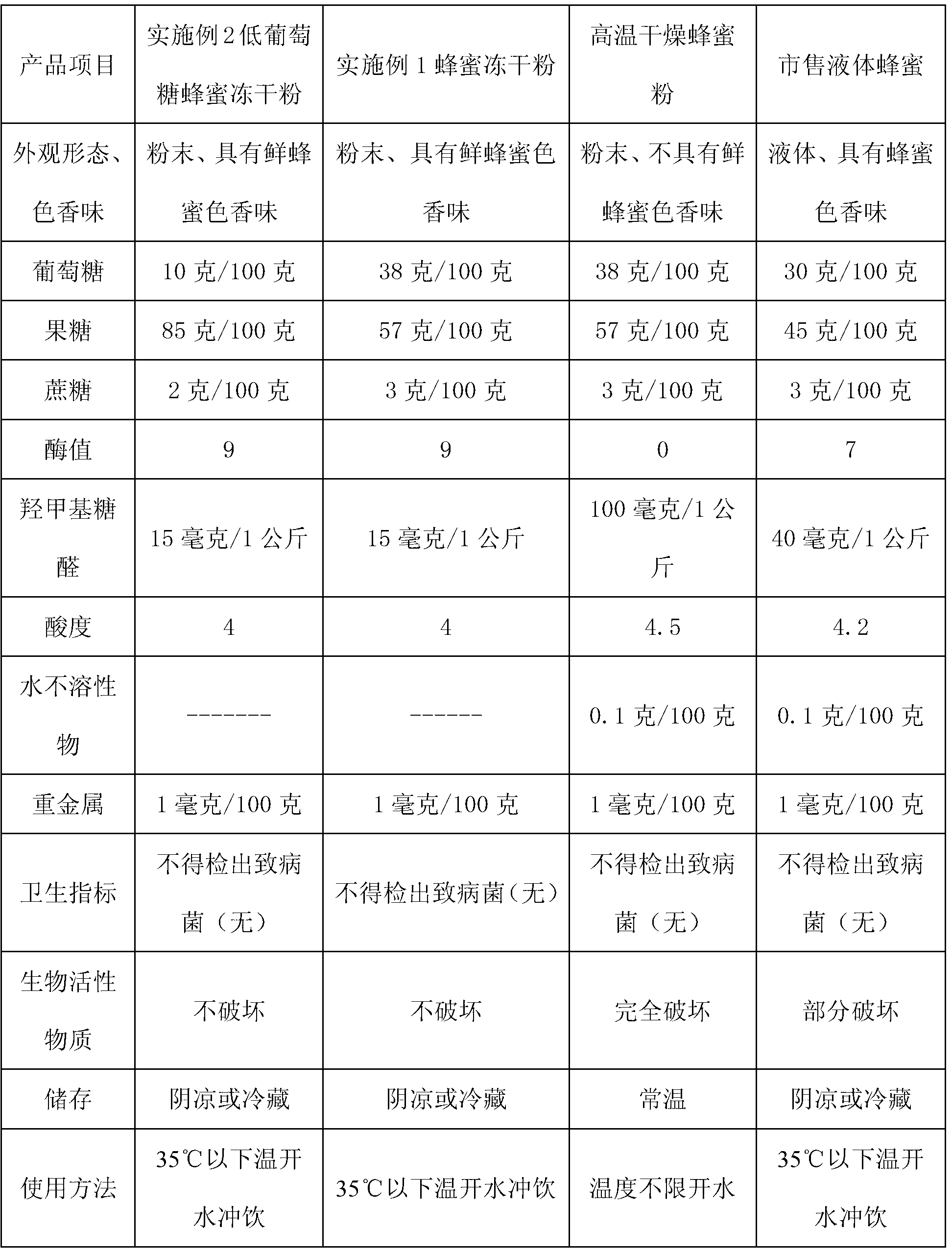

Honey freeze-dried powder and manufacturing method thereof

The invention discloses honey freeze-dried powder. The honey freeze-dried powder comprises honey and the honey is processed into freeze-dried powder packaged in an enclosed package container. 100g of the honey freeze-dried powder comprises 5-38g of glucose, 90 to 40g of fructose and less than 3g of cane sugar and has more than 9 of an enzyme value. Through utilization of a proper amount of cold distilled water for improving original honey water content, honey can form an ice frame structure at a low temperature so that freeze drying is realized and thus the solid-state honey freeze-dried powder is obtained. The honey freeze-dried powder is packaged in the enclosed package container so that original nutrients of fresh honey are retained and long-term preservation is realized.

Owner:徐国华 +1

Root of kudzu vine whole powder

A pueraria lobota root powder for preventing and treating coronary heart disease, hypertension and arteriosclerosis is prepared from the raw pueraria root through peeling, slicing, drying, pulverizing, removing fibres, puffing, pulverizing, and proportionally mixing it with refined rich flour, cane sugar and additive. Its advantages are no loss of active components (such as flavone) and quick dissolving in water.

Owner:LANSHAN GREEN FOOD RONGJIANG COUNTY GUIZHOU PROV

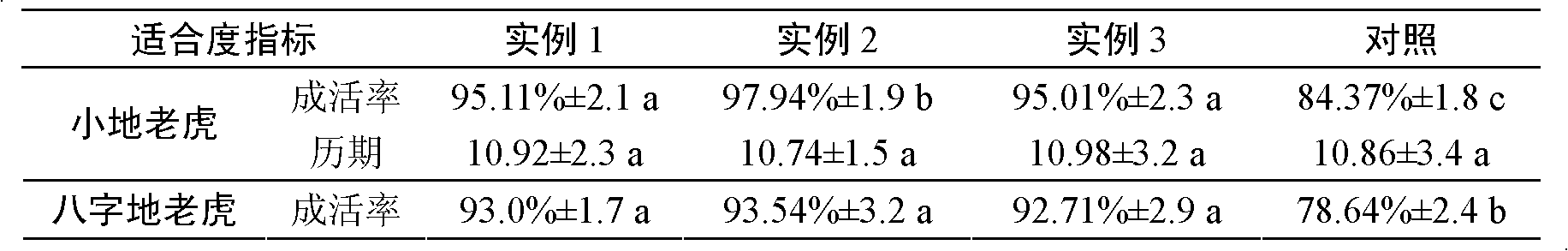

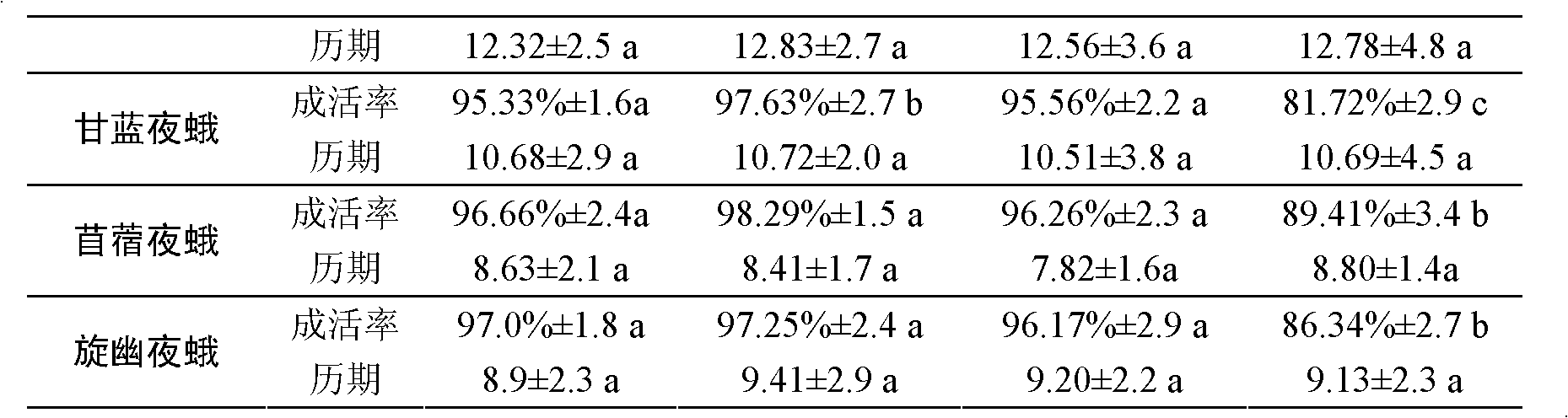

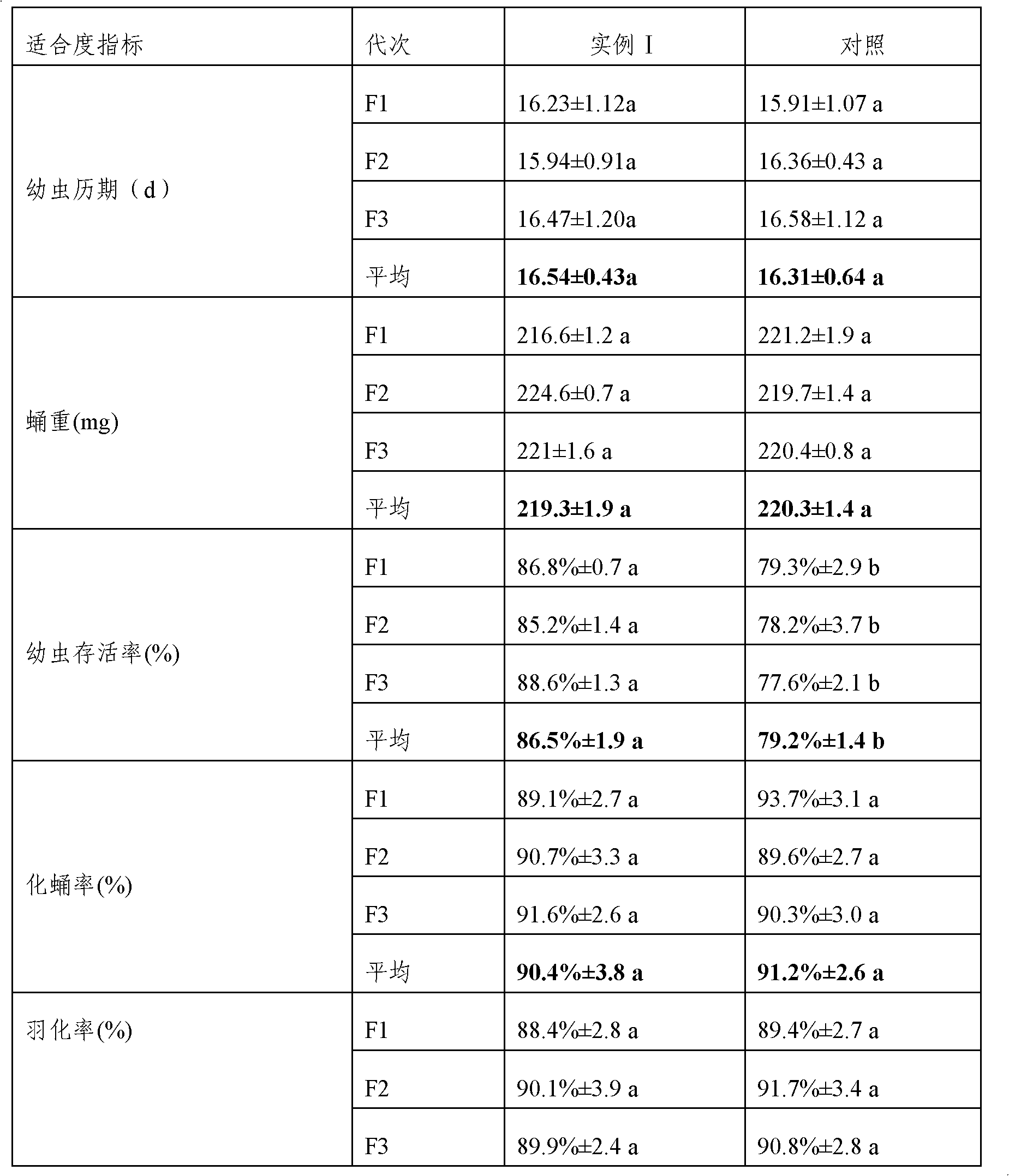

Artificial diet for Lepidopterous young larvae, preparation method for artificial diet and application of artificial diet

The invention provides an artificial diet for Lepidopterous young larvae. The artificial diet for the Lepidopterous young larvae is prepared from the following raw materials in percentage by weight: 2.0 to 3.0 percent of soybean cake meal, 7.0 to 10.0 percent of corn flour, 2.0 to 3.0 percent of Saccharomyces cerevisiae Hansen, 7.0 to 10.0 percent of tomato sauce, 0.8 to 1.2 percent of sucrose, 1.2 to 1.4 percent of agar, 0.2 to 0.5 percent of sorbic acid, 0.05 to 0.1 percent of vitamin B complex, 0.2 to 0.4 percent of ascorbic acid, 0.1 to 0.2 percent of ethyl p-hydroxybenzoate, 0.2 to 0.4 percent of propionic acid and 71.0 to 77.0 percent of water. The invention also provides a method for preparing the artificial diet and application of the artificial diet. The artificial diet is low in manufacturing cost, easy to operate and high in practicability; and by the artificial diet and the raising method for raising the Lepidopterous young larvae, the survival rate of the larvae is high, the workload is low, and manpower and material resources are greatly saved.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

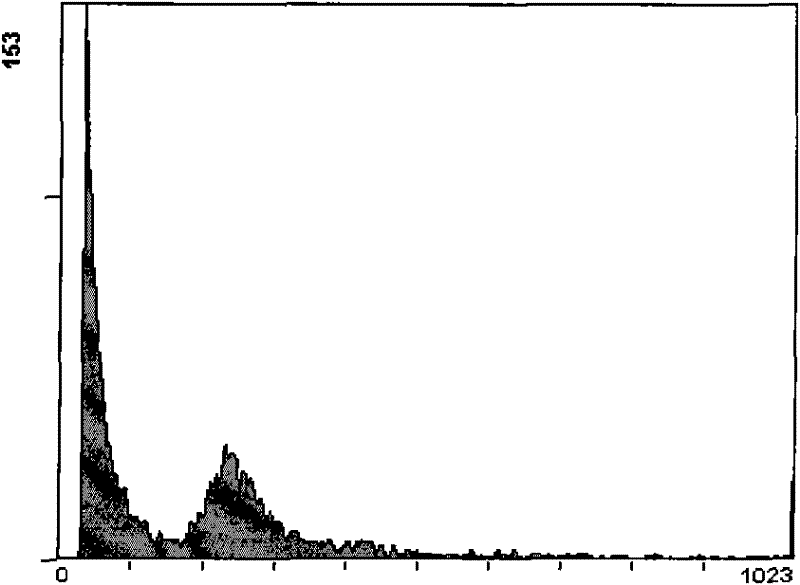

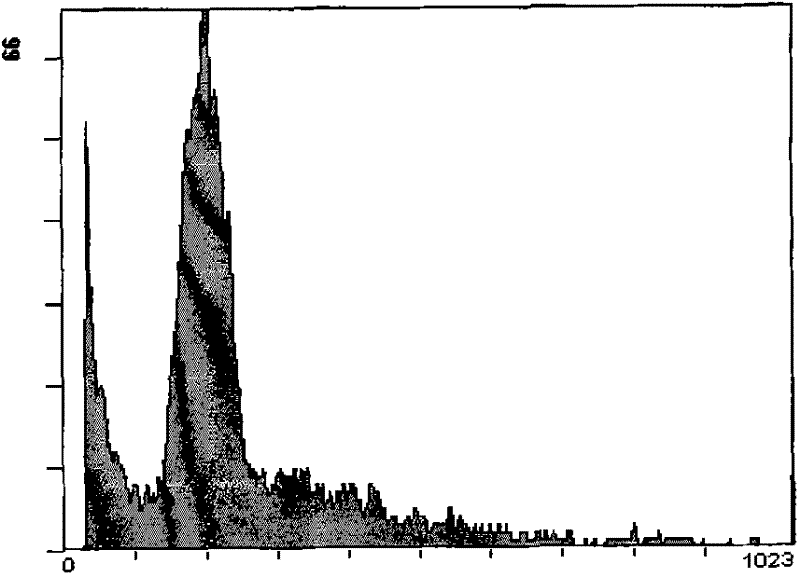

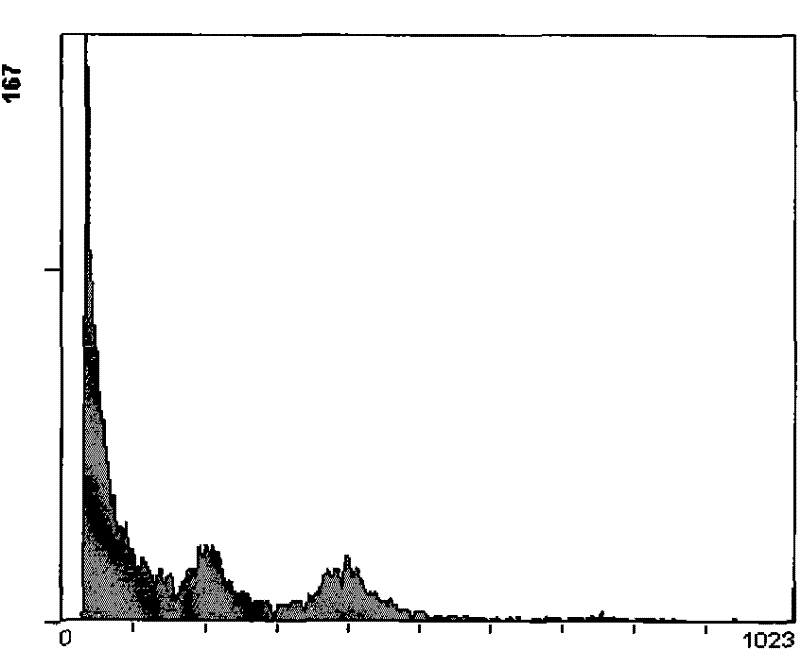

Method for extracting nucleuses of mature leaves of fruit trees suitable for flow cytometry analysis

InactiveCN102243150AIncrease productionIncrease concentrationPreparing sample for investigationBiological testingSucroseSaccharum

The invention provides a method for extracting nucleuses of mature leaves of fruit trees suitable for flow cytometry analysis. In the method, a nucleus extracting solution comprises the following components: 15 to 20mmol / L Tris, 40 to 60mmol / L KCl, 10 to 20mmol / L NaCl, 2 to 5mmol / L Na2EDTA (ethylene diamine tetraacetic acid), 10 to 20mmol / L MgSO4, 40 to 50mmol / L cane sugar, and 0.5 to 1.0 percentTriton X-100; ddH2O is added until the volume is 200ml; and after the pH is regulated to be 7.5 to 8, 200mu liters of 15mmol / L mercaptoethanol is added. The method has wide ranges of applicable varieties and material species, the prepared nucleuses have high purity, the extraction process needs short time, nucleus degradation is prevented, the flow cytometry analysis is facilitated, and the peak of an acquired flow map is thin and high and little influenced by impurity peaks, so that the DNA (deoxyribonucleic acid) ploidy of a plant to be detected can be easily judged.

Owner:CHANGLI INST OF POMOLOGY HEBEI ACADEMY OF AGRI & FORESTRY SCI

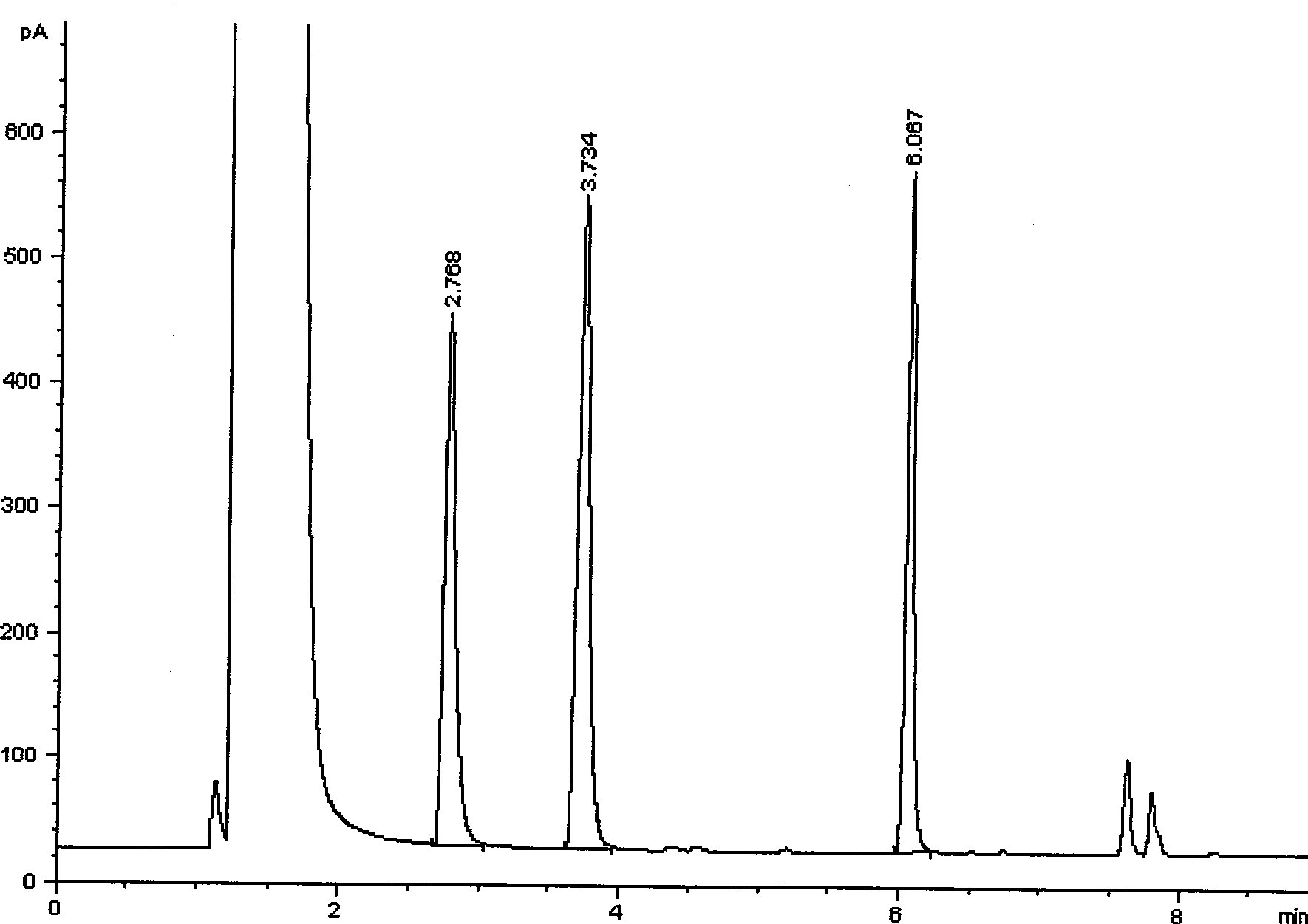

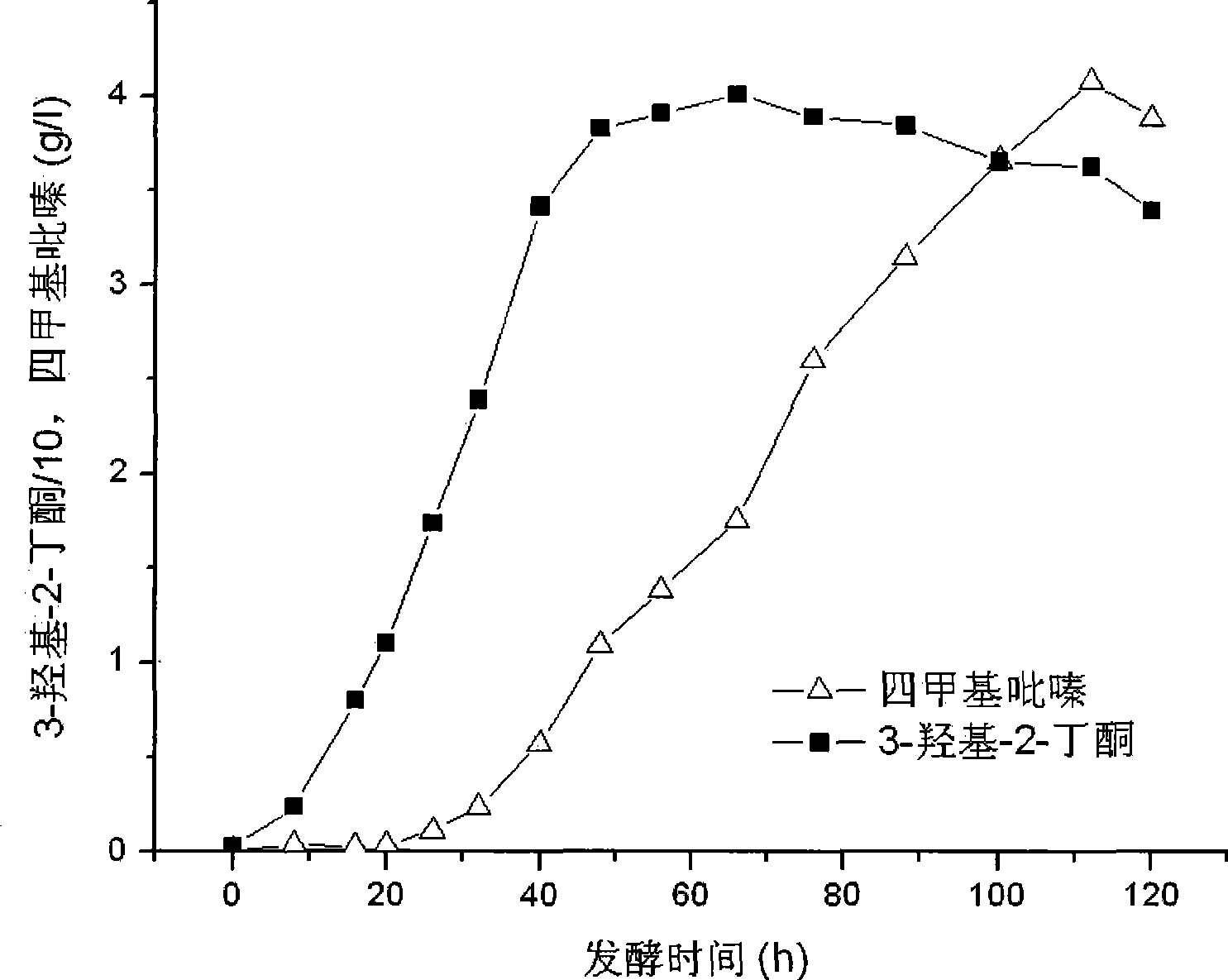

Bacillus subtilis highly producing tetramethylpyrazine and method thereof for fermentation producing tetramethylpyrazine

InactiveCN101445786AIncrease productionRich sourcesBacteriaMicroorganism based processesSaccharumSucrose

The invention relates to a bacillus subtilis highly producing tetramethylpyrazine and a method thereof for fermentation producing tetramethylpyrazine, and belongs to the technical field of bio-engineering. The invention discloses a Bacillus subtilis XZ1124 which can highly produce tetramethylpyrazine, and is preserved in CCTCC, and the preservation number is CCTCC NO: M 208157. The strain is made of Maotai-flavor liquor and high temperature Daqu; the strain is identified as Bacillus subtilis based on colony, cell form, physiological and biochemical characteristics and 16S rRNA gene sequence comparative result thereof. The strain can utilizes glucose, sucrose, molasses and soybean cake powder as substrate, and increases the output of tetramethylpyrazine through accumulating a great deal of endogenous precursors, so as to solve the problems of low product density, exogenous adding precursor requirement, and low precursor utilization rate in tetramethylpyrazine production through microbe fermentation. When sucrose and soybean cake powder are used as substrate, 4.08 g / L of tetramethylpyrazine can obtained through shaking culture of the raw material for 120 h at the temperature of 37 DEG C.

Owner:JIANGNAN UNIV

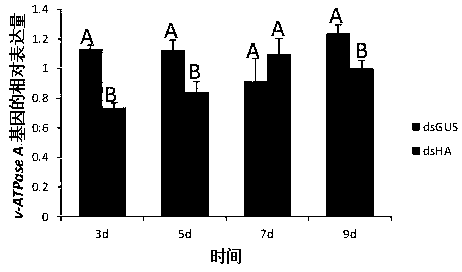

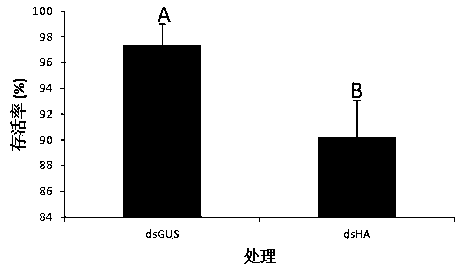

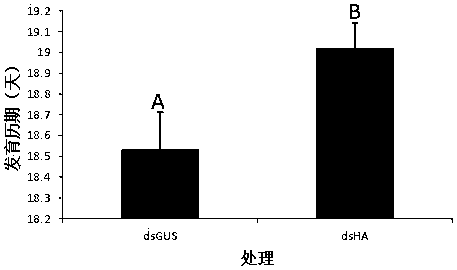

Method for determining influence of exogenous dsRNA on toxicity of ladybugs

ActiveCN107858405ASimple methodImprove effectivenessMicrobiological testing/measurementSaccharumSucrose solution

The invention discloses a method for determining influence of exogenous dsRNA on toxicity of ladybugs. The method comprises the following specific steps: uniformly mixing the exogenous dsRNA into a sucrose solution, directly feeding the ladybugs for 2-3 days and then feeding with pea aphids; then detecting and analyzing the expression changes of target genes in the ladybugs, and observing the biological changes of the ladybugs so as to evaluate the toxicity of the exogenous dsRNA to the ladybugs, wherein the ladybugs include harmonia axyridis, coccinella septempunctata or henosepilachna pusillanima. By the method, direct influence of the exogenous dsRNA on the toxicity of the harmonia axyridis, the coccinella septempunctata or the henosepilachna pusillanima or other ladybugs can be effectively determined; in addition, the method is simple, feasible and high in effectiveness and sensitivity, and has a great significance and an application prospect in study on functions of related genesas well as environmental risk assessment on related RNAi transgenic crops.

Owner:SOUTH CHINA AGRI UNIV

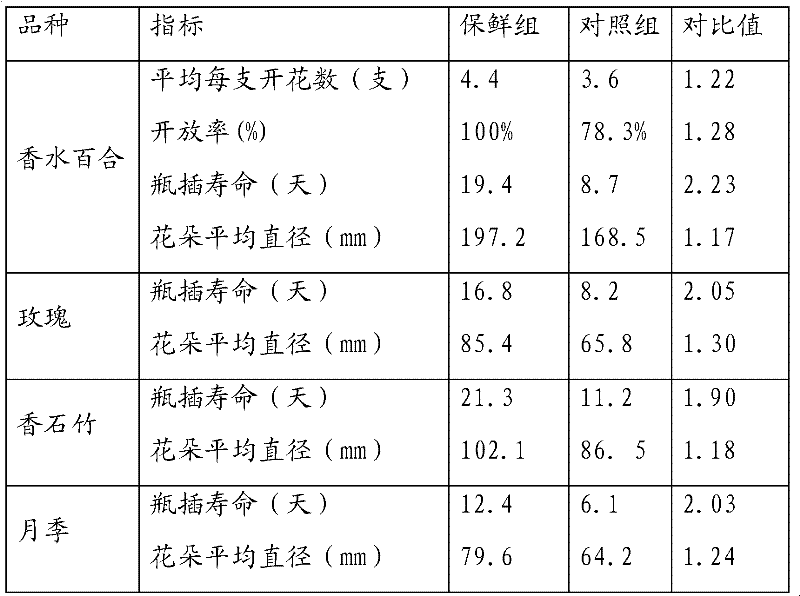

Maca buccal tablets and preparation method thereof

InactiveCN102949431AFacilitated releaseAvoid residual riskAntinoxious agentsPharmaceutical non-active ingredientsSucroseSaccharum

The present invention discloses maca buccal tablets and preparation method thereof. Per 1000 g of the maca buccal tablets is prepared from the following raw materials, by weight, 300-400 parts of a maca fresh product, 400-500 parts of a sugar material, 150-200 parts of pregelatinized starch, and 1-2 parts of a sour agent. According to the present invention, compared with the traditional buccal tablets, the maca buccal tablets have the following characteristics that: the defect that the existing buccal tablets are not suitable for diabetes patients due to sucrose in the existing buccal tablets is overcome; an advanced nanometer grinding technology is adopted to replace the traditional organic extraction technology so as to avoid risk of organic extractant remained in the buccal tablets; the maca root is grinded into nanometer powder during the maca buccal tablet preparation process, such that most of active ingredients in the maca are easily released, and easily absorbed by human body; and the product adopts the advanced buccal tablet production technology, does not require water during taking, and can be taken directly through dissolving in mouth, such that taking is convenient.

Owner:上海中海龙高新技术研究院

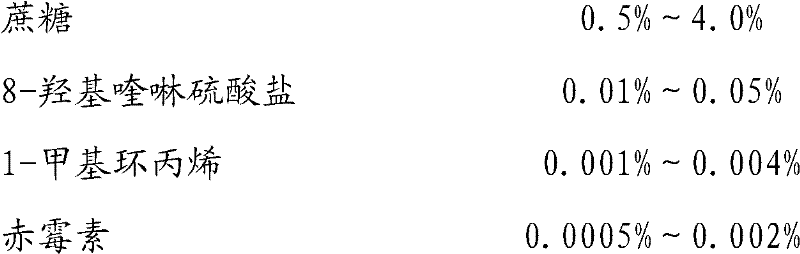

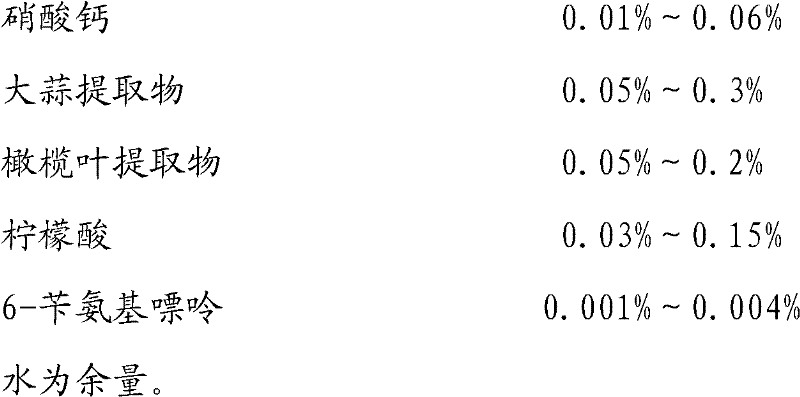

Fresh flower preservative

InactiveCN102187856AGood fresh-keeping effectMeet the needs of spiritual civilizationDead plant preservationGibberellic acidSaccharum

The invention discloses a fresh flower preservative, which comprises the following components in percentage by weight: 0.5 to 4.0 percent of sucrose, 0.01 to 0.05 percent of 8-hydroxyquinoline sulfate, 0.001 to 0.004 percent of 1-methyl cyclopropene, 0.0005 to 0.002 percent of gibberellin, 0.01 to 0.06 percent of calcium nitrate, 0.05 to 0.3 percent of garlic extract, 0.05 to 0.2 percent of oliveleaf extract, 0.03 to 0.15 percent of citric acid, 0.001 to 0.004 percent of 6-benzylaminopurine, and the balance of water. The invention also discloses a preparation method of the fresh flower preservative. The novel biological preservative (carnosine) is blended with the traditional additive, so that the defects of the conventional fresh flower preservative are overcome; the degradability advantage of the biological preservative is used; the fresh flower preservative is a product which is convenient to use and has good fresh keeping effect and no toxic hazard effect; and the fresh flower preservative meets the requirements of customers on spiritual civilization, and a technical scheme and a product are provided for solving the problem of difficulty in keeping flowers fresh.

Owner:HAINAN STAND BIO TECH

Preparation method of saccharose-free functional powdered peony seed oil

ActiveCN105053276AHigh in alpha-linolenic acidHigh nutritional valueEdible oils/fatsAcute hyperglycaemiaOil processing

The invention belongs to the technical field of oil processing, and particularly relates to a preparation method of saccharose-free functional powdered peony seed oil. The method comprises the following steps: (1) dissolving wall materials with distilled water, and heating and stirring to obtain a solution A; (2) adding food functional factors and an emulsifier into peony seed oil, and mixing and stirring uniformly to obtain an emulsion; (3) shearing and emulsifying the emulsion obtained in the step (2) to obtain an emulsion solution; (4) adding the solution A obtained in the step (3) into the emulsion solution obtained in the step (3), and homogenizing at high pressure to obtain a solution B; and (5) spray-drying the solution B obtained in the step (4), thereby obtaining the powdered peony seed oil. The powdered peony seed oil prepared by the method can be compounded with different nutritive substances according to demands of different groups of special people; as the peony seed oil is high in content of alpha-linolenic acid, the powdered peony seed oil is high in nutritive value; and due to containing no saccharose, the powdered peony seed oil is suitable for patients with hyperglycemia and diabetes to take.

Owner:HEZE YAO & SHUN PEONY BIOTECH

Fragrant and sweet taste cigarette tipping paper production method

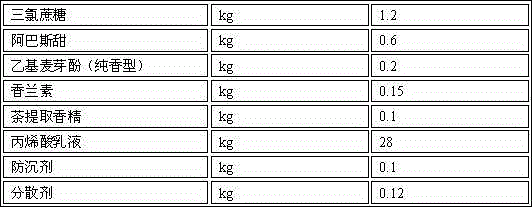

ActiveCN104372719AIncrease the fragranceDifferent pumping sensationSpecial paperPaper coatingHot stampingSucrose

The invention relates to a fragrant and sweet taste cigarette tipping paper production method, which specifically comprises: 1, completely mixing alcohol and an acrylic acid emulsion, then sequentially adding chlorosucrose and aspartame, stirring for 10-20 min, then adding an anti-sedimentation agent and a dispersant, stirring for 5-10 min, adding ethyl maltol (pure flavor type), vanillin and tea extraction essence, stirring for 5-10 min to prepare a fragrant and sweet taste ink, and carrying out sealed storage; 2, printing on a gravure printing machine, wherein the printing plate adopts the laser engraving gravure, the ground color ink adopts the inorganic ink, dilution is performed with alcohol, the final color adopts the fragrant and sweet taste ink to coat, and the printing plate with the mesh depth of 35 [mu]m is adopted; 3, the fragrant and sweet taste ink prepared in the step 1 is coated on the surface of tipping paper, and carrying out sealed storage, wherein the printing speed is 100-120 m / min, and the temperature is 80-100 DEG C; and 4, carrying out hot stamping, slitting and perforating on the tipping paper. With the production method, the cigarette tipping paper is endowed with the sweet taste effect, and the fragrance of the cigarette tipping paper is increased.

Owner:QINGDAO JUSTO PACKAGING +1

Black currant jam for bread with long shelf life and preparation method thereof

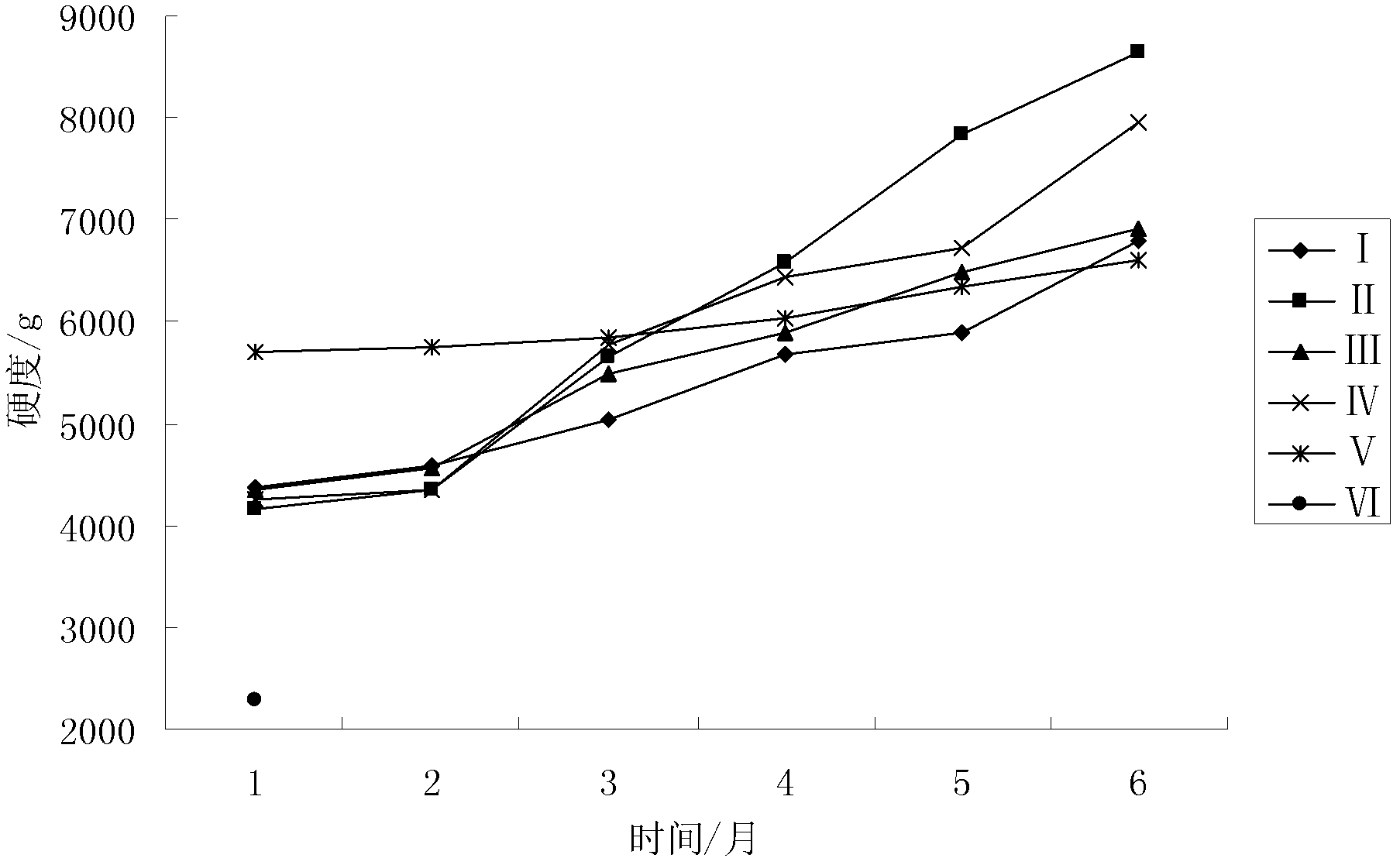

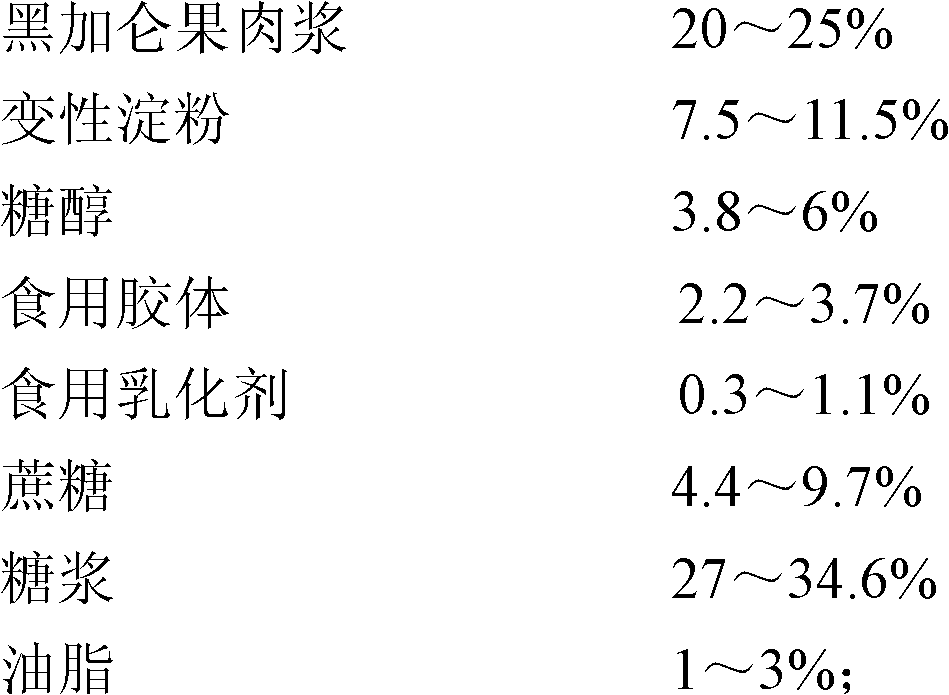

The invention discloses black currant jam for bread with a long quality guarantee period and a preparation method thereof. The black currant jam mainly comprises the following components: 20 to 25 percent of flesh and pulp of black currant, 7.5 to 11.5 percent of modified starch, 3.8 to 6 percent of sugar alcohol, 2.2 to 3.7 percent of edible colloid, 0.3 to 1.1 percent of edible emulsifier, 4.4 to 9.7 percent of sucrose, 27 to 34.6 percent of syrup and 1 to 3 percent of grease. The preparation method comprises the following steps of: mixing the modified starch, the sugar alcohol, the edible colloid, the edible emulsifier, a preservative and the sucrose and stirring uniformly; adding water, the syrup and the grease, raising the temperature to 90 to 95 DEG C, and keeping the temperature until the gelatinization is complete; adding the flesh and pulp of the black currants, continuing to stir and keep the temperature, and controlling the content of a solid matter to 65 to 68 percent; andreducing the temperature, and adding an acidity regulator and an edible essence to obtain the black currant jam for the bread with the long quality guarantee period. The black currant jam for the bread with the long quality guarantee period has the advantages that: the jam has soft texture, moist mouthfeel, rich taste, high water content and low water activity, and is baking-resistant, the sugar degree is 65 to 70 degrees, the water activity is 0.75 to 0.8, and the quality guarantee period of finished bread containing the jam is 3 to 6 months.

Owner:广州合诚实业有限公司

Doukey-hide gelatin-ginseng-radix astragali wine

The invention publishes the preparation methods to produce ass hide and ginseng and stibene wine. This medicated wine has function of curing and health protection. The distilled spirit acts as groundsustance for ass hide and ginseng and stibene wine and then dip ginseng, prepared rehmannia root, dangshen, medlar, astragalus root, angelica, poria conos, licorice root, chuanxiong rhizome, white fat peony and bighead atractylodes rhizome, after this, add ass hide and sugar liquor to get the medicated wine. The thirteen good drug are mixed reasonably, the distilled spirit is used to dip and distill and sugar is used to season, so the drug can be absorbed by men. The invention has many function, such as helping buiding blood and invigoratin qi, strengthening the spleen and stomach, nourishing the heart and tranquilization, nourishing yin and moisturizing the lung, promoting blood circulation and improving acuity of vision and refreshment. It is good for not only weaken habitus but also blood vessel of brain and heart and gynecology illness.

Owner:FUJIAO GROUP CORP SHANDONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com