Patents

Literature

56 results about "Probiotic yogurt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yogurt is a cultured or fermented milk product that is soured and thickened by adding specific lactic acid-producing cultures to milk. The basic cultures or probiotics used to make yogurt are Lactobacillus bulgaricus and Streptococcus thermophilus.

Fruity probiotic yogurt slice containing antifreeze sericin peptide and method for preparing same

ActiveCN103109930BRich in physiological functionsRich in antioxidantMilk preparationProbiotic yogurtBiotechnology

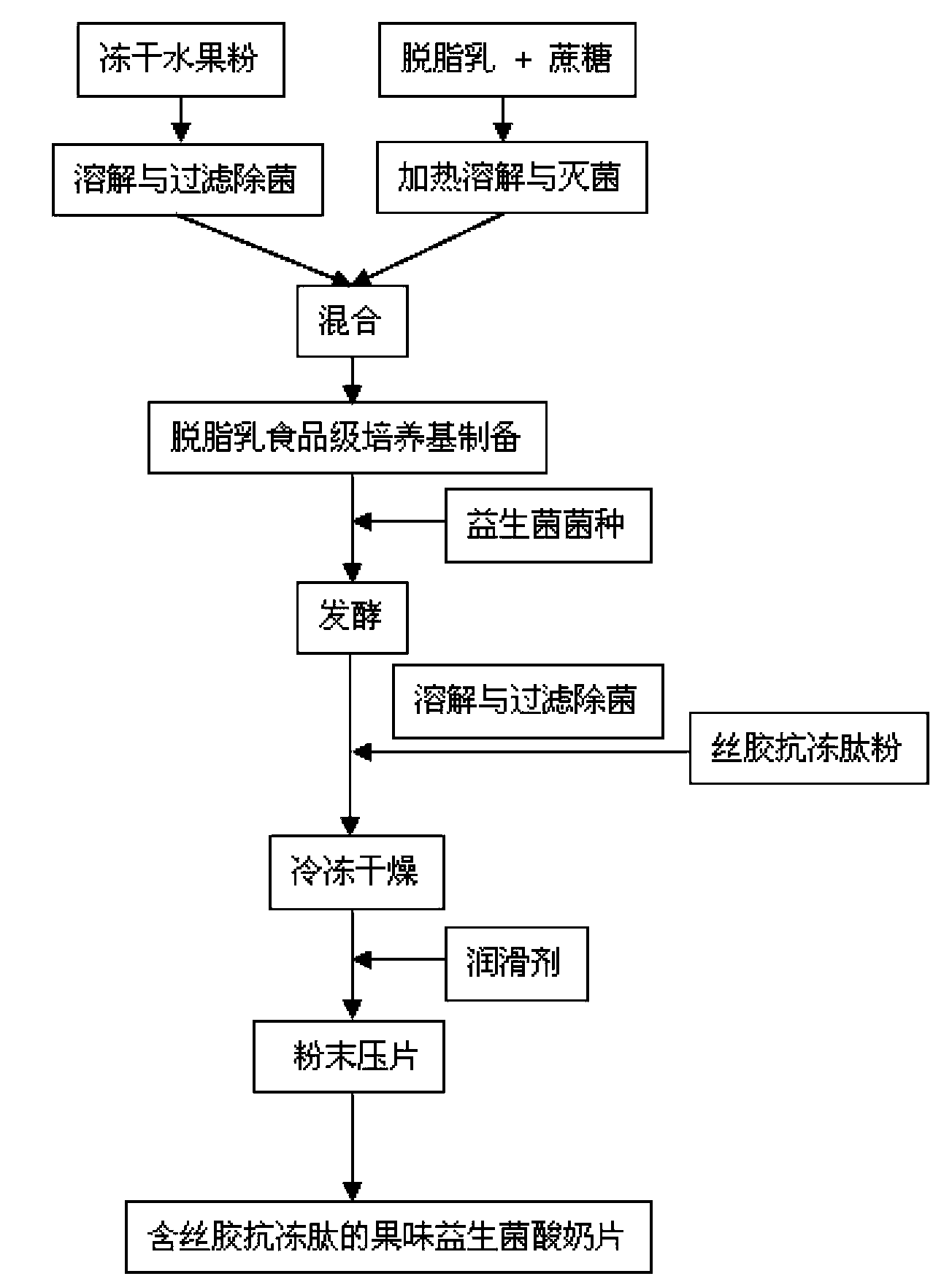

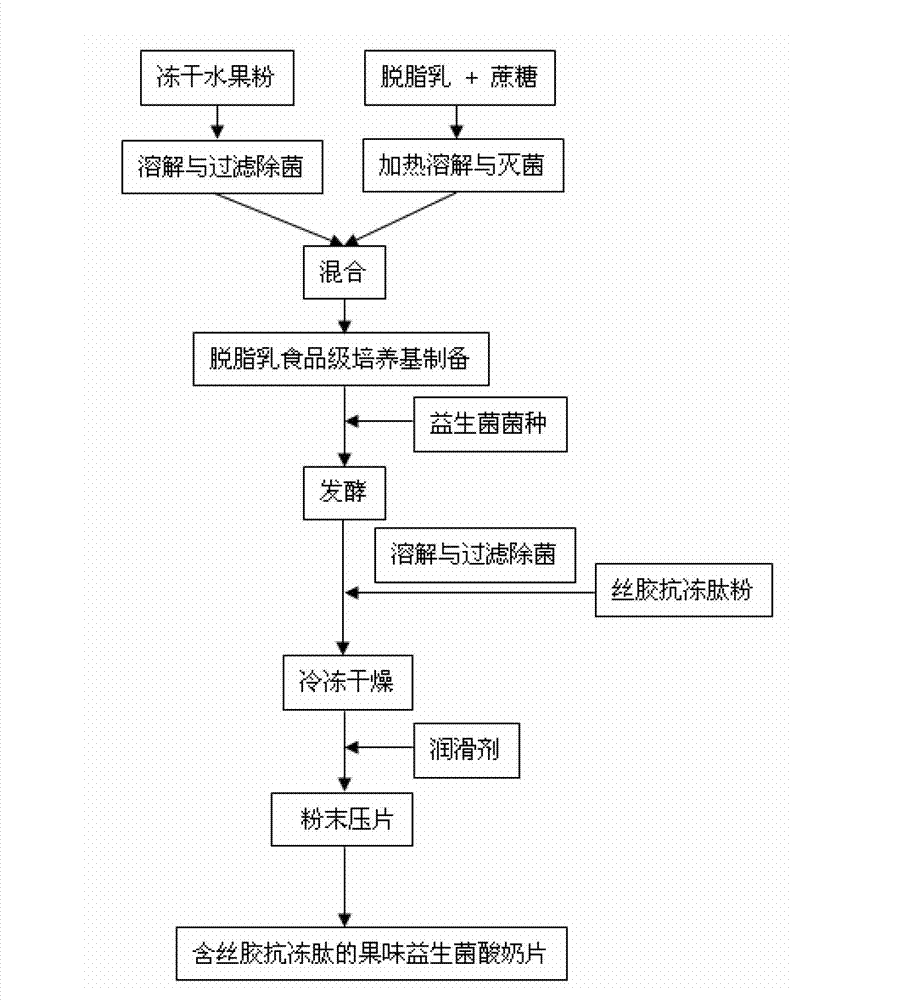

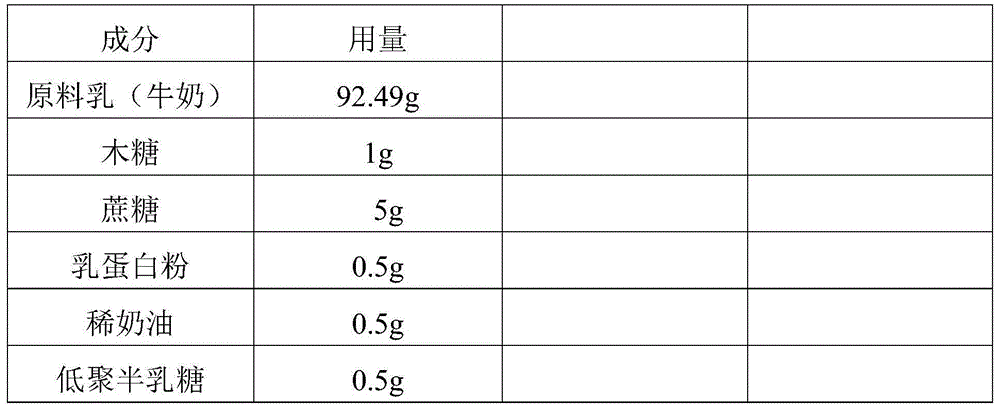

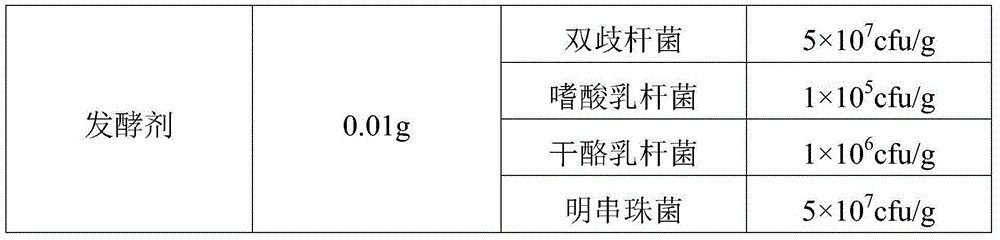

The invention discloses a fruity probiotic yogurt slice containing antifreeze sericin peptide. The raw materials for preparing the fruity probiotic yogurt slice comprise 10-14 parts of skimmed milk powder, 2-5 parts of sucrose, 1-3 parts of sericin peptide, 1-4 parts of fruit material, 0.1-0.6 part of lyophilized active probiotics and 0.1-0.4 part of magnesium stearate. The invention further discloses a method for preparing the product which is the fruity probiotic yogurt slice. The method mainly comprises the following steps of: preparing a skimmed-milk food-grade culture medium, fermenting the probiotics, adding the antifreeze sericin peptide, freezing and drying fermented milk in vacuum, and pressing powder into slices. As the fruity probiotic yogurt slice contains the antifreeze sericin peptide and the lyophilized fruit powder which is rich in the vitamin B group, the number of the probiotics in the fruity probiotic yogurt slice can be increased, the retention time of the activity of the probiotics can be prolonged, and the taste, flavor and nutritional and healthcare values of the fruity probiotic yogurt slice can be improved. The fruity probiotic yogurt slice can serve as a functional food for supplementing the vitamin B group, improving the immunity and promoting the intestinal health.

Owner:SHANGHAI JIAOTONG UNIV

Fruity probiotic yogurt slice containing antifreeze sericin peptide and method for preparing same

ActiveCN103109930ARich in physiological functionsRich in antioxidantMilk preparationProbiotic yogurtBiotechnology

The invention discloses a fruity probiotic yogurt slice containing antifreeze sericin peptide. The raw materials for preparing the fruity probiotic yogurt slice comprise 10-14 parts of skimmed milk powder, 2-5 parts of sucrose, 1-3 parts of sericin peptide, 1-4 parts of fruit material, 0.1-0.6 part of lyophilized active probiotics and 0.1-0.4 part of magnesium stearate. The invention further discloses a method for preparing the product which is the fruity probiotic yogurt slice. The method mainly comprises the following steps of: preparing a skimmed-milk food-grade culture medium, fermenting the probiotics, adding the antifreeze sericin peptide, freezing and drying fermented milk in vacuum, and pressing powder into slices. As the fruity probiotic yogurt slice contains the antifreeze sericin peptide and the lyophilized fruit powder which is rich in the vitamin B group, the number of the probiotics in the fruity probiotic yogurt slice can be increased, the retention time of the activity of the probiotics can be prolonged, and the taste, flavor and nutritional and healthcare values of the fruity probiotic yogurt slice can be improved. The fruity probiotic yogurt slice can serve as a functional food for supplementing the vitamin B group, improving the immunity and promoting the intestinal health.

Owner:SHANGHAI JIAO TONG UNIV

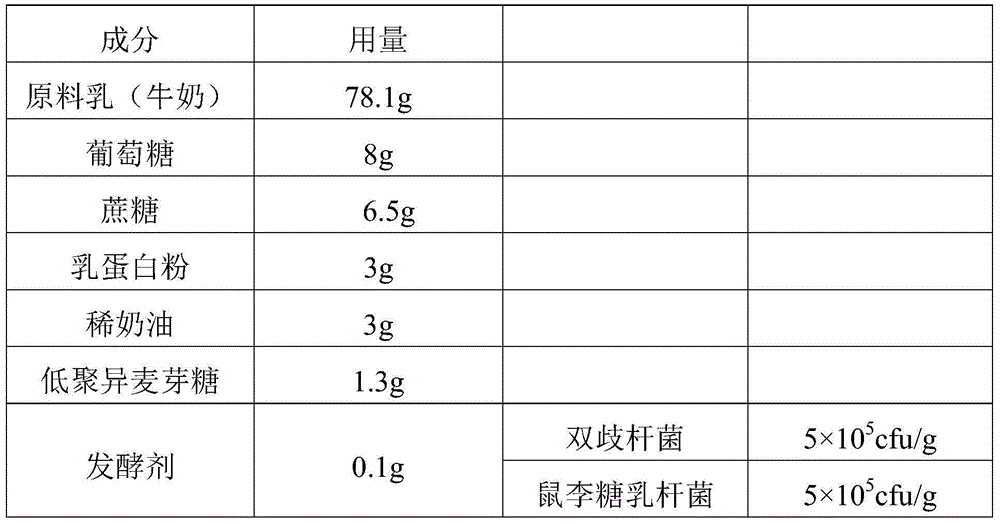

Brown probiotic yogurt and preparation method thereof

The present invention discloses a brown probiotic yogurt and a preparation method thereof. The brown probiotic yogurt includes the following materials: milk 78-97.48%, reducing sugar 1-8%, milk protein powder 0.5-3%, single cream 0.5-3%, sweet substances 0.01-7%, prebiotics 0.5-1.3% and probiotic fermentation agent 0.01-0.1%. The preparation method includes the following steps: 1) the milk is heated to 40-50 DEG C and is mixed with the reducing sugar, and the mixture is heated to 90- 95 DEG C to obtain a material A; 2) the material A is cooled to 40-50 DEG C and mixed with the milk protein powder, single cream, sweet substances and probiotics for 15-30 min to obtain a material B; and 3) the material B is homogenized and sterilized to obtain a fermentation substrate; and 4) the fermentation substrate is cooled to 35-38 DEG C, and probiotics are added into the fermentation substrate for fermentation to obtain the finished products. The yogurt has a probiotic content of 10<10> cfu / 100 g or above 10<10> cfu / 100 g, combines advantages of both brown fermented milk and probiotic fermented milk, and is pure and authentic in mouthfeel.

Owner:BRIGHT DAIRY & FOOD

Yogurt containing chocolate particles and preparation method thereof

The invention provides a probiotic yogurt containing chocolate particles and a production method thereof. The probiotic yogurt containing chocolate particles comprises 0.5-14% of chocolate particles. The preparation method comprises the step of mixing jam containing chocolate particles and probiotic yogurt base materials to prepare the probiotic yogurt containing chocolate particles. The probiotic yogurt containing chocolate particles is characterized in that ingredients of chocolate are controlled, the oil content and the glucide content of the chocolate particles are respectively controlled to no less than 49% and no more than 10%, and the chocolate particles can be kept indissolvable almost in the original shape when added and crisp in the storage life of the yogurt by using an appropriate technology. The invention provides a novel yogurt which is delicious and nutritious and has good shelf-life stability.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Brown skimmed drinkable probiotics yoghurt and preparation method thereof

The invention provides a kind of brown skimmed drinkable probiotics yoghurt and a preparation method thereof, and belongs to the technology field of dairy products. The preparation method comprises following steps in sequence: maillard reaction, homogeneous sterilization, fermentation, demulsification, and post-treatment, and specifically comprises following steps: (1) the maillard reaction: reducing sugar is added into skimmed milk, when the concentration of the reducing sugar in the milk arrives at 20 to 40 g / L, the skimmed milk, which has been added with reducing sugar, is heated to 95 to 100 DEG, the temperature is maintained for 2 to 3 hours to carry out the maillard reaction; (2) the fermentation: basic bacteria and probiotics are added to carry out fermentation at the temperature of 38 to 44 DEG C; (3) yoghurt after demulsification is subjected to a homogeneous sterilization of 10 to 15 MPa, and finally to a post-treatment. The method has the advantages of simple technology, easy operation, and low cost; the obtained product has the advantages of unique flavor and good mobility, and is capable of being drunk directly; the fat content of the product is lower than 0.5%, probiotics bacteria is abundant, the content of active lactic acid bacteria is not smaller than 1 * 108 cfu / mL, and the product is more nutritional.

Owner:SHANDONG DEYI DAIRY IND

Method for producing probiotics yoghurt enriched with selenium amino acid and its products

ActiveCN1943366AHigh viable countImprove conversion rateMilk preparationBacteria material medical ingredientsProbiotic yogurtSheep milk

The invention relates to a kind of Se-enhanced amino acid yoghourt manufacture method and the product hemogenization the mixture of the fresh milk (ewes' milk or remade milk) and the sugar, then high temperature sterilization, cooling down, adding the the Se amino acid transform and the probiotics growth accelerant, then inoculating the Bifidobacterium, Strptococcus thermophilus, Lactobacillus acidophilus, Lactobacillus bulgaricus, fermentation and cool storage. The cfu of the Bifidobacterium, Strptococcus thermophilus, Lactobacillus acidophilus , Lactobacillus bulgaricus will be up to 109 / mL,107 / mL,108 / mL,108 / mLand 108 / mL the Se concentration will be up to 0.1-0.32mg / L, among this, 50% is from the Se-amino acid. Such product is safety and integrated multi-function contained with the yoghourt, probiotics and the organic Se. It will do benefit to our body entironment, anti-pathogeny microorganism. It can enhance the body immunity function and illness resistance.

Owner:NANJING AGRICULTURAL UNIVERSITY

Probiotics yoghourt powder and preparation method thereof

The invention provides probiotics yoghourt powder and a preparation method thereof. Lactobacillus delbrueckii subsp.bulgaricus, rhamnose lactobacillus, lactobacillus paracasei and streptococcus thermophilus are used as original strains, cultivation of the original strains is enlarged, powder freeze-dried culture is prepared, and composite probiotics starter culture is prepared so as to obtain probiotics starter culture. After nonreactive milk is standardized, white granulated sugar is added according to 6.5% of the weight of the nonreactive milk, and instant milk powder is made through process such as concentration, superhigh temperature instant sterilization and spray drying. 2.5 grams of composite probiotics starter culture is added into each kilogram of the instant milk powder and mixed evenly to be vacuum packaged to make the probiotics yoghourt powder.

Owner:张玉文

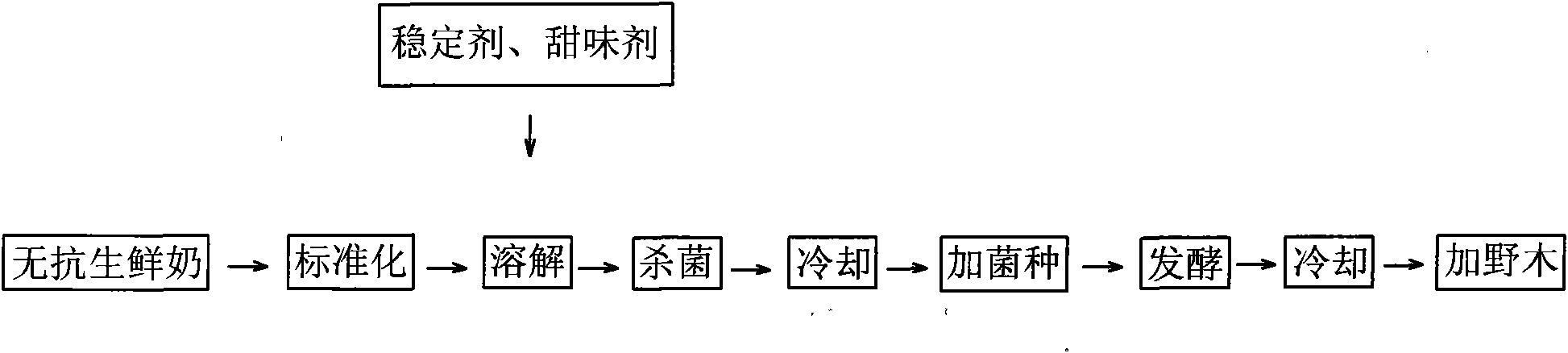

Bifidobacterium multi-probiotics multi-functional yoghurt

InactiveCN101611738APromote growth and developmentAchieve anti-aging and anti-tumorMilk preparationProbiotic yogurtThreonine

The invention discloses bifidobacterium multi-probiotics multi-functional yoghurt. Antibiotics-free fresh milk is added with a multi-probiotics compounded colony taking bifidobacterium as a main material for fermentation so as to form stirred youghurt with comprehensive and rich nutrients and outstanding health care function. The yoghurt is prepared from the fresh milk, xylitol, stevioside, compound probiotics, prebiotics of xylo-oligosaccharides, stauntonvine juice, a compound stabilizing agent and the like, can comprehensively strengthen the synergetic complementation in the fermentation process, realizes low heat and high nutrient, provides rich nutrients such as B1, B2, B6, B12, alanine, valine, aspartic acid, threonine and the like, can improve the gastrointestinal function, improves the content of superoxide dismutase (SOD) in the fermented dairy to remove free radicals in a human body, has the effects of antitumor and radiation prevention, promotes the growth and development of children, strengthens the immunity, and is a multi-functional drink suitable for both the old and the young.

Owner:ZUNYI DAIRY

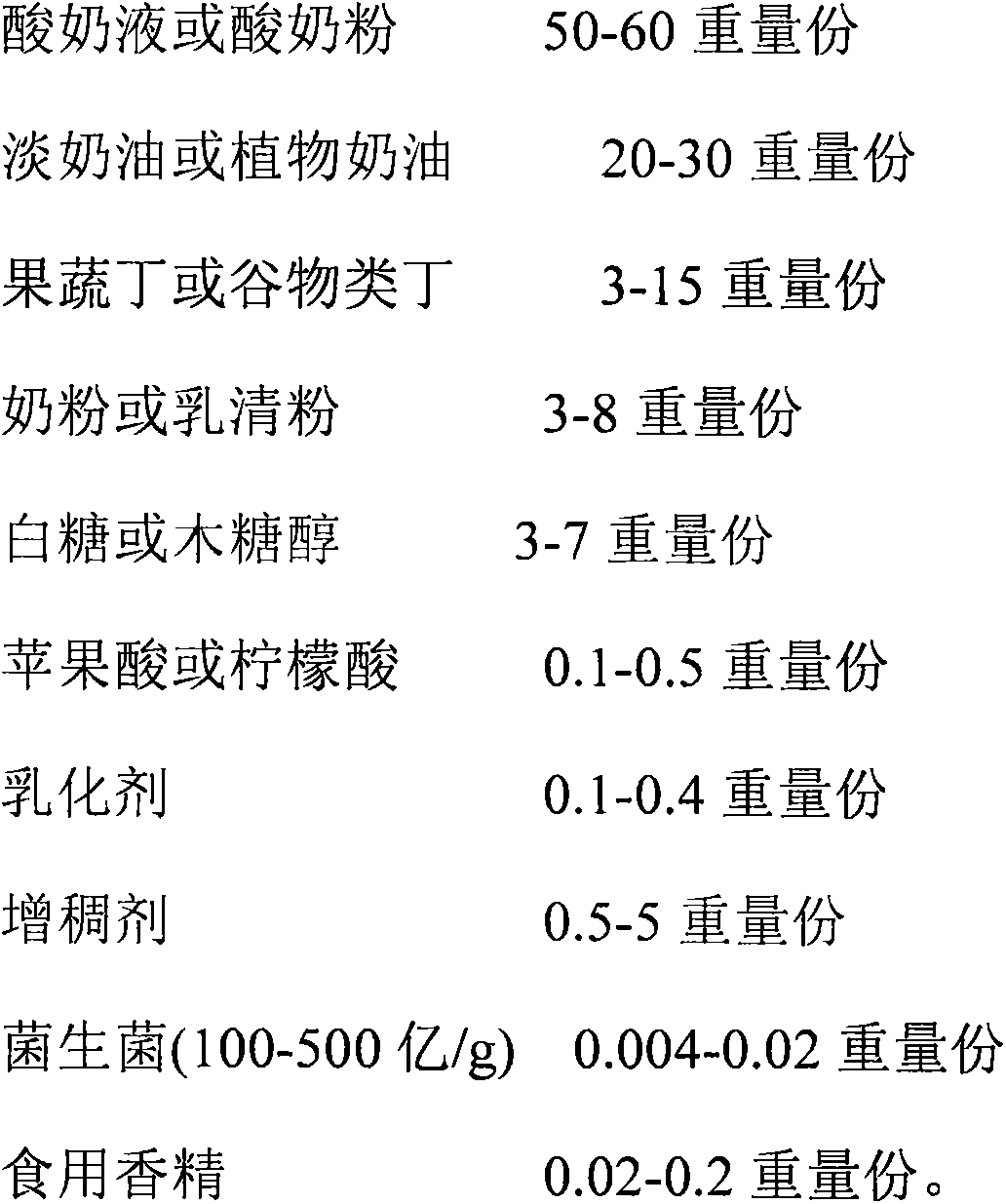

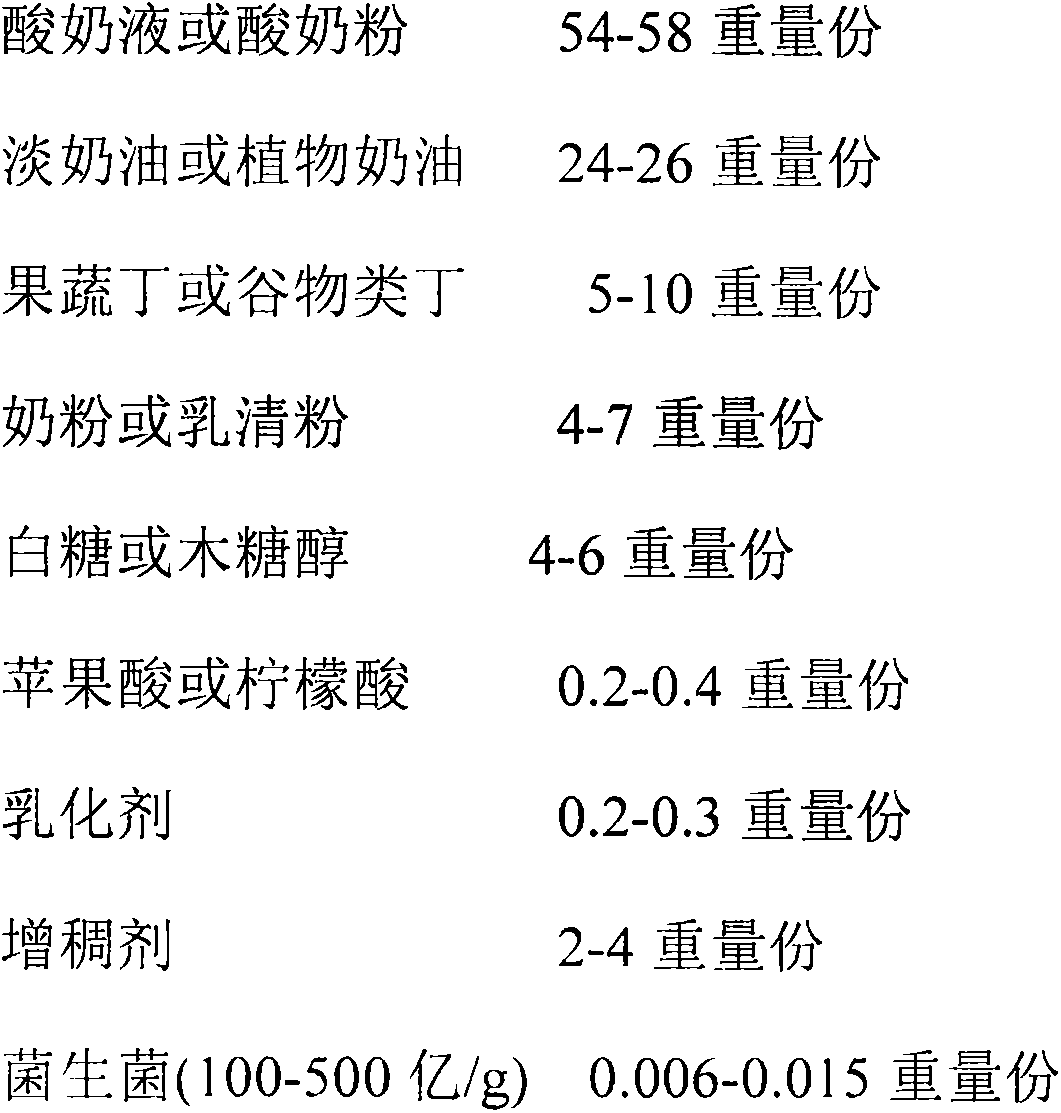

Fruit dice and vegetable dice probiotic yoghourt and making method thereof

The invention discloses fruit dice and vegetable dice probiotic yoghourt and a making method thereof. Raw materials which can be used for the fruit dice and vegetable dice probiotic yoghourt are various fermentation yoghourt, yoghourt powder, fruit dices, vegetable dices, nut dices, grain dices, coarse cereal dices, plant cream, animal cream, unsalted butter or unsalted butter fermentation liquor,fruit juice, vegetable juice, milk powder, whey powder, starch, white sugar and xylitol, food additives can be malic acid, citric acid, pectin, xanthan gum, an emulsifying agent, modified starch andedible essence, and bacteria species contain lactic acid bacteria, bifidobacterium and the like. According to fruit and vegetable yoghourt through vacuum freezing drying, the edible manner of the yoghourt and the fruits and vegetables is changed, the promotion range is extended, the mouth feel and the flavor are improved, the nutrient structure of products is enriched, probiotics can well improveintestinal tracts of bodies, various shapes can be made, and the fruit dice and vegetable dice probiotic yoghourt melts when being put in mouths, is suitable for mid-aged people and aged people and babies to eat, is a fashion food for young people, and is convenient to eat and carry.

Owner:福建欧瑞园食品有限公司

Processing method for zero-additive probiotics yoghourt

ActiveCN102726523AHigh nutritional valueGuaranteed fermented flavorMilk preparationBiotechnologyFood additive

The invention relates to a processing method for a dairy product, and particularly relates to a processing method for zero-additive probiotics yoghourt. The processing method for the zero-additive probiotics yoghourt comprises the following steps: adding prepared milk and invert sugar powder according to certain proportion of ingredients to a dosing tank; and performing homogenization, sterilization and inoculating fermentation to acquire probiotics yoghourt. The probiotics yoghourt acquired form the above-mentioned method is not added with food additives and uses natural food materials, so that pure fermentation flavour of microorganism is guaranteed by not adding essence; moreover, the number of viable bacteria in the probiotics yoghourt can be kept to achieve a high nutritional value.

Owner:ZHEJIANG INM FOOD

Solidification type low-fat and sucrose-free probiotic yogurt

The invention discloses solidification type low-fat and sucrose-free probiotic yogurt. The yogurt comprises raw materials in parts by weight as follows: 850-900 parts of fresh skim cow's milk, 50-60 parts of xylitol, 0.110-0.114 part of stevioside, 2-4 parts of milk protein powder, 5-8 parts of whey protein powder, 0.1-0.5 part of pectin, 0.3-0.7 part of agar, 0.1-0.5 part of yogurt essence and 150-250 U of lactic acid bacteria. Natural xylitol and stevioside are used to replace traditional sucrose, so that the prepared yogurt has the characteristics of decayed tooth resistance, high sweetness, low heat energy, stable property and the like, is suitable for diabetes people, has pure flavor and has no obvious difference from full-sucrose yogurt. The used bifidobacterium lactis and lactobacillus acidophilus belong to probiotics and have probiotic functions of enhancing immunity, resisting oxidation and the like. The product stabilization system consists of milk protein powder, whey protein powder, pectin and agar, whey precipitation is effectively reduced, and the product stability and fat satiety are improved.

Owner:ANHUI XINXIWANG BAIDI MILK CO LTD

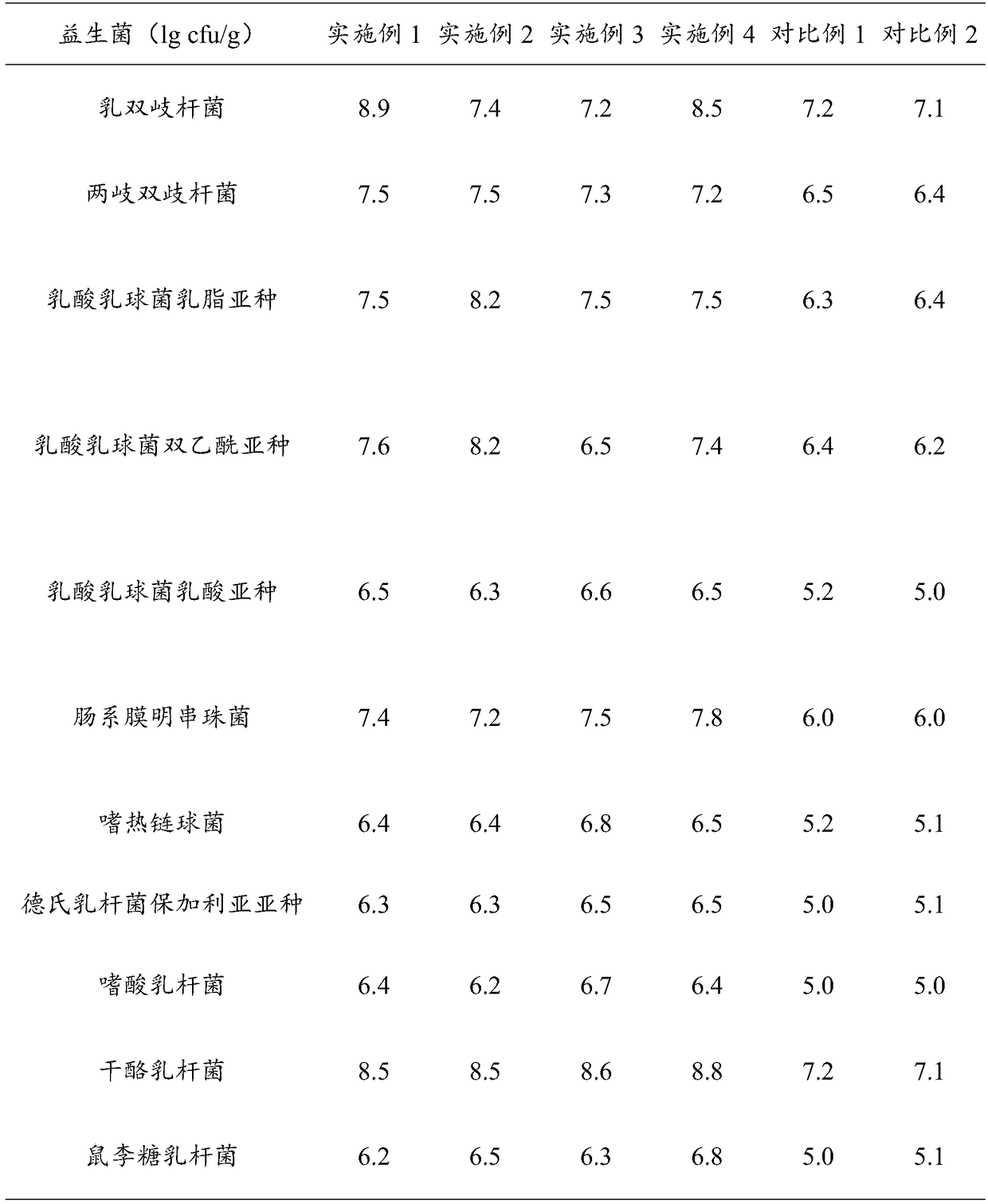

Composite probiotic yoghurt and preparation method thereof

The invention discloses composite probiotic yoghurt and a preparation method thereof. The composite probiotic yogurt comprises the following raw materials in mass percentage: 89.595-99.19% of cow milk, 6-7% of white granulated sugar, 1.3-2.8 of a milk protein powder, 0.5-1.5% of prebiotics and 0.005-0.01% of composite probiotics. The preparation method comprises the following steps: (1) after preheating the cow milk, adding the white granulated sugar, the milk protein powder and the prebiotics, and carrying out heat-preservation mixing to obtain a mixed liquid; (2) homogenizing and sterilizingthe mixed liquid, and after cooling, inoculating the mixed probiotics for fermentation so as to obtain fermented liquid; and (3) cooling the fermented liquid, and carrying out filling to obtain the composite probiotic yogurt. Through adding the composite probiotics for fermentation, the obtained yoghurt contains many kinds of probiotics, and the number of viable bacteria of the probiotics after fermentation reaches 1010 cfu / g, the product is soft in flavor, and the yogurt is healthy and delicious pure probiotic yoghurt.

Owner:BRIGHT DAIRY & FOOD CO LTD

Purple-sweet-potato probiotic sour-milk and preparation method thereof

The invention discloses purple-sweet-potato probiotic sour-milk and a preparation method thereof. The preparation method of the purple-sweet-potato probiotic sour-milk comprises the following steps: (1), preparing purple sweet potato paste; (2), pouring white granulated sugar, white granulated sugar, galacto-oligosaccharides and the purple sweet potato paste into fresh milk, wherein the ratio of the white granulated sugar to the galacto-oligosaccharides to the purple sweet potato paste to the fresh milk is 0.5-0.7kg: 0.5-0.7kg: 0.8-1.2kg: 8-10kg, carrying out preheating until the temperature of the mixture is 60-70 DEG C, homogenizing the heated mixture, sterilizing the homogenized mixture at 90-100 DEG C for 3-7 minutes, and cooling the sterilized mixture to 40-45 DEG C; (3), adding mixed probiotics into the cooled mixture; and (4), fermenting the mixture in a constant-temperature incubator at 40-45 DEG C; and the purple-sweet-potato probiotic sour-milk is prepared after fermentation. The invention has the following beneficial effects: the purple sweet potatoes and the fresh milk are utilized as raw materials, and the mixed probiotics composed of bacillus bifidus, lactobacillus bulgaricus, streptococcus thermophilus, lactobacillus acidophilus, lactobacillus casei and the like are used for carrying out fermentation, so that the prepared purple-sweet-potato probiotic sour-milk with novel flavor is bright in color, good in taste and rich in nutrition, and has very good health-care functions.

Owner:HEBEI UNIV OF ENG

Probiotics yogurt nut meat and preparation method thereof

InactiveCN107950972AKeep aliveImprove utilizationMilk preparationFood scienceProbiotic yogurtFood flavor

The invention provides probiotics yogurt nut meat and a preparation method thereof. The preparation method comprises the following steps that the nut meat is roasted and preliminarily cooked; 2) sweetwater is sprayed to the nut meat processed by the step 1) and simultaneously probiotics yogurt mixed powder is added on the nut meat processed by the step 1), the sweet water, the nut meat and the probiotics yogurt mixed powder are stirred, and the nut meat needs to be coated with coating flours evenly; 3) the nut meat is polished; 4) the nut meat is roasted one more time, and the probiotics yogurt nut meat is obtained. Compared with the prior art, according to the method, the ratio of raw materials and production process parameters are strictly controlled, so that the probiotics yogurt nut meat is rich in nutrients, good in appearance, full of milk flavor and novel in taste and fills up the lack of the nut meat with probiotics yogurt taste in markets; moreover, during the production process, rate of finished products yield is high, cases that the nut meat is over-roasted or still raw are few, the utilization rate of the coating flours is high and the cost is reduced.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS

Cane sugar-free composite probiotic yogurt and preparation method thereof

InactiveCN111387288AEnsure health needsGreat tasteMilk preparationLactobacillusBiotechnologyProbiotic yogurt

The embodiment of the invention provides cane sugar-free composite probiotic yogurt and a preparation method thereof. The yogurt is made of the following basic components in parts by weight: 899-999.89 parts of raw milk, 0.1-100 parts of a natural sweet substance and 0.01-1 part of probiotics, wherein the probiotics comprise at least ten types of probiotics. The preparation method comprises stepsof material mixing, homogenization, sterilization, fermentation and canning. By adopting the yogurt, demands of customers on health and good taste of yogurt can be met.

Owner:元气森林(北京)食品科技集团有限公司

Probiotic dairy products with date syrup additive

InactiveUS20160183550A1Extended storage lifeImprove textureMilk preparationLactobacillusProbiotic yogurtCream cheese

The probiotic dairy products with date syrup additives include probiotic yogurts made from both fresh and dried milk, as well as probiotic soft cream cheese. With the addition of date syrup, the probiotic dairy products have increased storage lifetimes, improved textures and tastes, and greater concentrations of probiotic bacterial cultures. The date syrup has a concentration of 5-20 vol %. Optimal results are found for a date syrup concentration of 15 vol %.

Owner:ALEID SALAH MOHAMMED +2

Formulations of Concentrated Prunes and Prebiotics as Laxatives and Dietary Supplements

The present invention describes a formulation comprising a prune and / or plum concentrate, and one or more water-soluble, non-digestible, prebiotic oligosaccharides. Optionally, one or more low calorie sweeteners, an antioxidant, calcium sennosides, or sennosides extract, PEG-3350, licorice, cocoa, coffee, tea flavors; fruit flavorings and spice flavorings, gelatin, agar-agar, carrageenan, pectin or cocoa powder are added. Other ingredients may be present as dietary supplements such as water-soluble vitamins, lipid-soluble vitamins; amino acids, maltodextrin, resveratrol, caffeine, mineral supplements, or natural sleep aids for use as a laxative, A variety of formulations are possible, such as premix, a laxative+energy power drink or power bar, or as a prebiotic supplement in probiotic yogurts, or in the form of gummies, chocolates, candies, and desserts such as red beans Japanese desserts. These present formulations are improved for taste, fast acting, portable and palatable laxatives, and as dietary supplements.

Owner:JIVA PHARMA

Lactobacillus casei capable of reducing cholesterol and method for producing probiotic yogurt from same

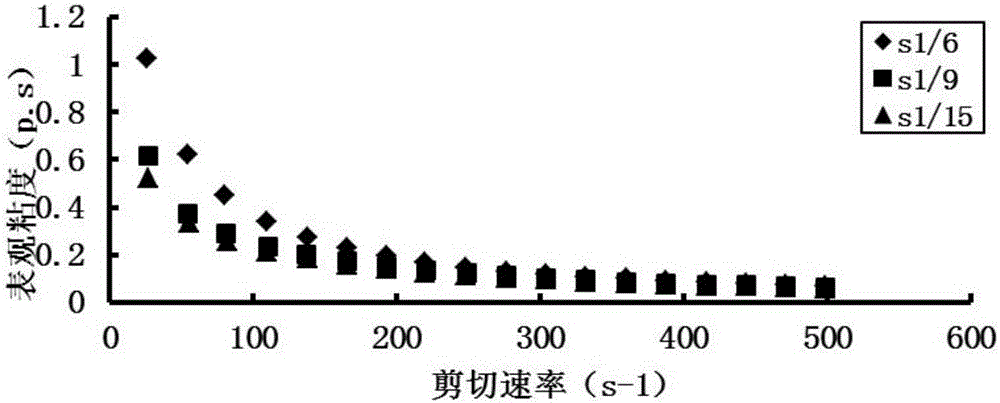

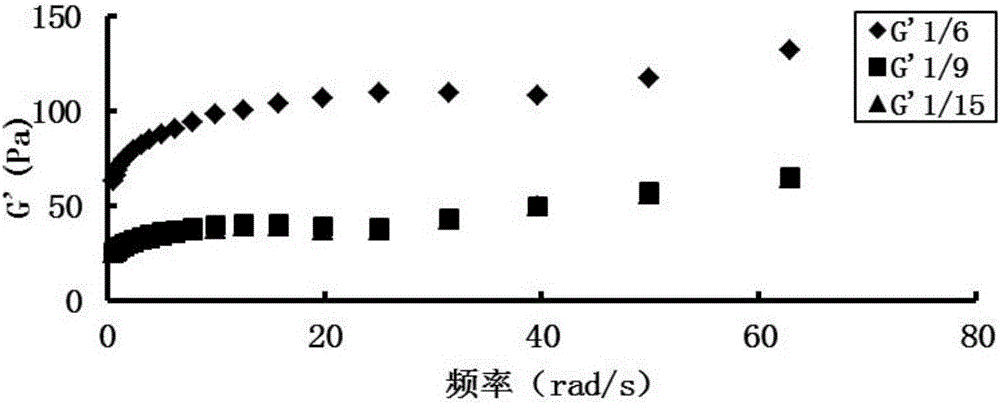

InactiveCN104774783AAcidification after reductionIncrease viscosityMilk preparationBacteriaProbiotic yogurtBile salt hydrolase

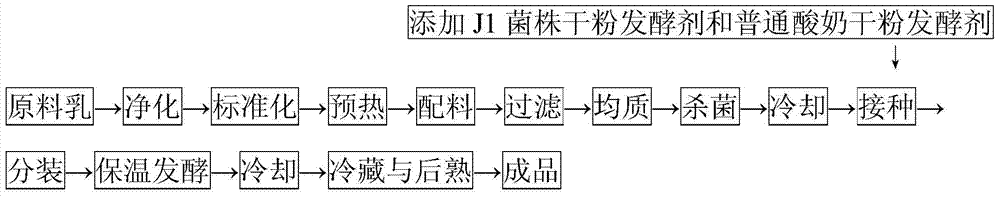

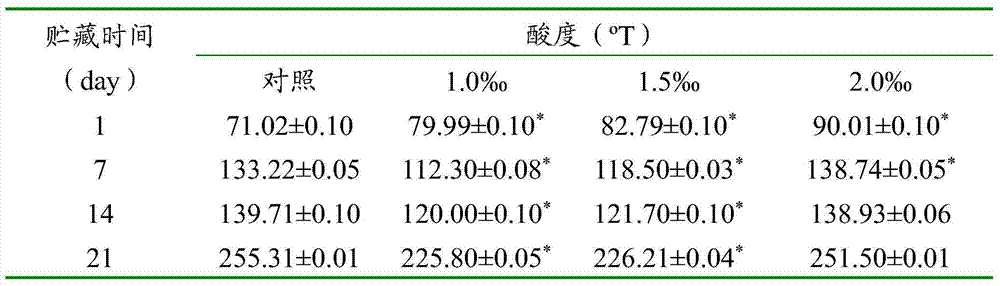

The invention provides Lactobacillus casei J1 capable of reducing cholesterol. According to a technical scheme in the invention, the Lactobacillus casei J1 is separated and screened from Tibetan kefir (also called as kefir grain) cultured in a common household and is preserved in China General Microbiological Culture Collection Center on September 11, 2006, with an accession number of CGMCC No. 1808. The invention also discloses a method for producing probiotic yogurt by using the Lactobacillus casei J1. On the basis of no change of common yoghourt fermentation process, the yoghourt capable of reducing serum cholesterol can be prepared by utilizing the characteristic that the J1 strain produces bile salt hydrolase, and the problem of precipitation of whey of the yoghourt is overcome. The method for producing the probiotic yogurt has the advantages of simple process, a short fermentation period, low cost and applicability to large-scale industrial production.

Owner:BEIJING SCITOP BIO TECH CO LTD

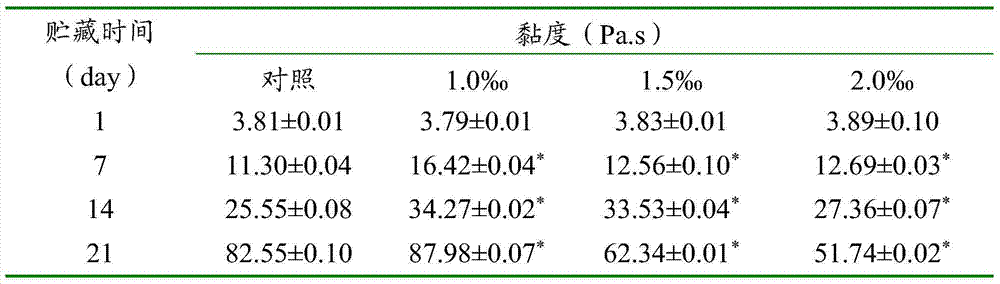

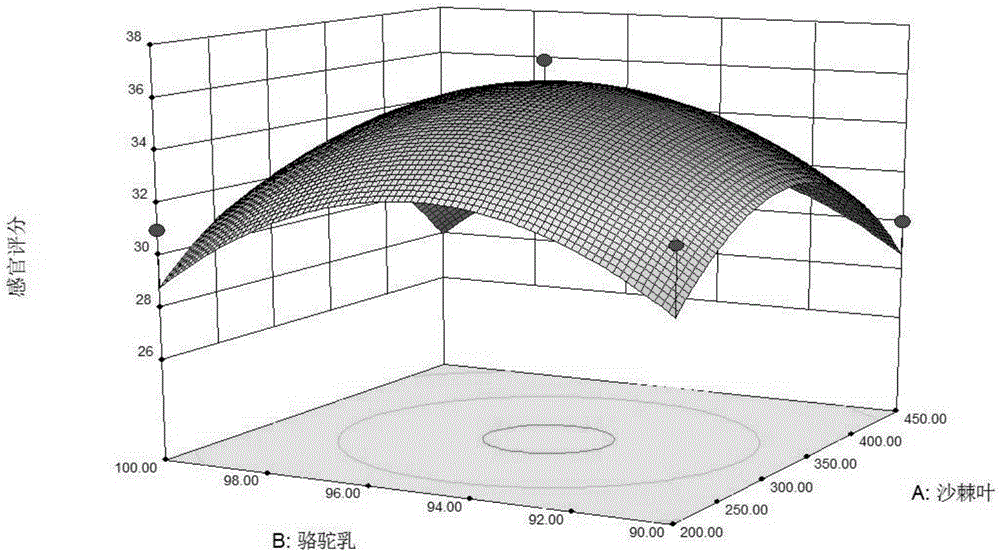

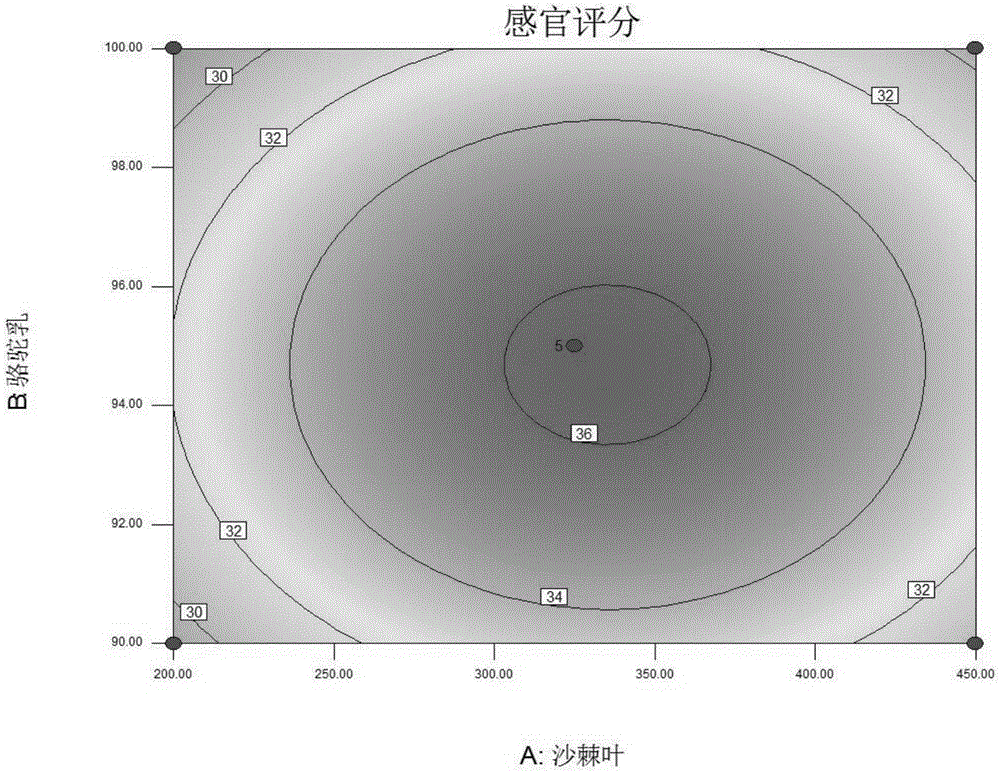

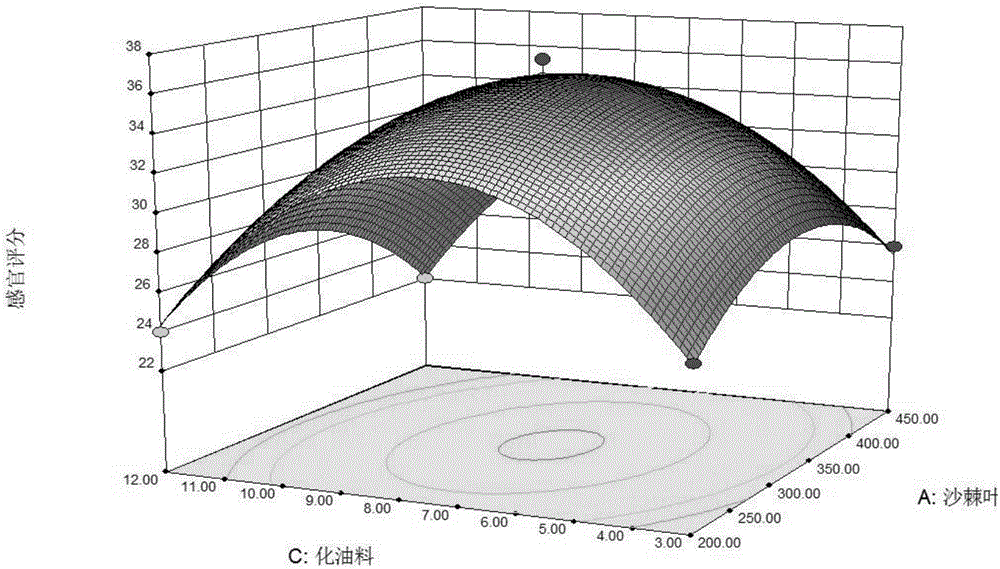

Milk tablets prepared from seabuckthorn flavone and camel milk and preparation method of milk tablet

InactiveCN106332968AFull of nutritionEasy to eatMilk preparationOther dairy technologyProbiotic yogurtSpleen

The invention discloses milk tablets prepared from seabuckthorn flavone and camel milk and a preparation method of the milk tablets. Seabuckthorn flavone is extracted through ultrasonic to serve as an inner core; the fresh camel milk is selected as a raw material to be filtered with sterile gauze and then fermented through lactic acid compound bacteria, fermentation is conducted, and camel yogurt is obtained, wherein the lactic acid compound bacteria are probiotic yogurt which is prepared by mixing and fermenting, by weight, 2 parts of lactobacillus casei, 1 part of enterococcus faecium, 4 parts of streptococcus thermophilus, 2 parts of diacetyl streptococcus and 1 part of lactobacillus bifidus; a frozen and dried camel yogurt particle layer serves as an outer pack to be pressed into core-encapsulated tables through a rotary type core encapsulating tablet press. The milk tablets prepared from seabuckthorn flavone and camel milk are prepared through transparent film coating, it is proved through functional trials that the mouse NK cell viability, the spleen index and the thymus index can be significantly increased, the mouse immunity is enhanced, and the wide practicability and the development value are achieved.

Owner:天山牧歌投资管理有限公司

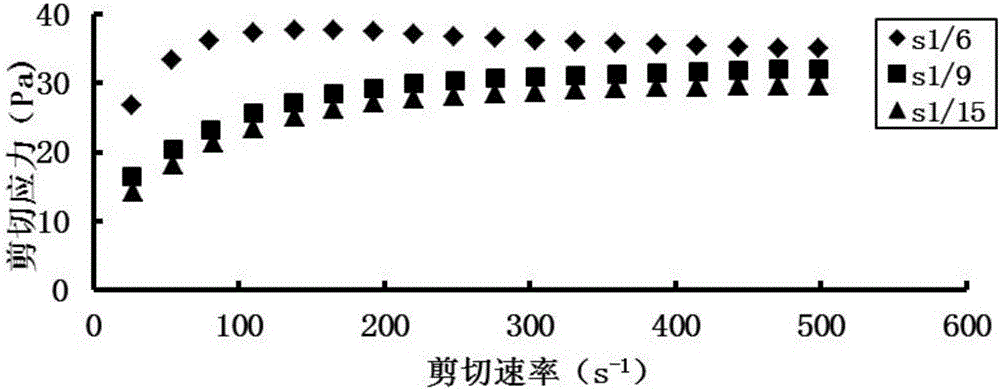

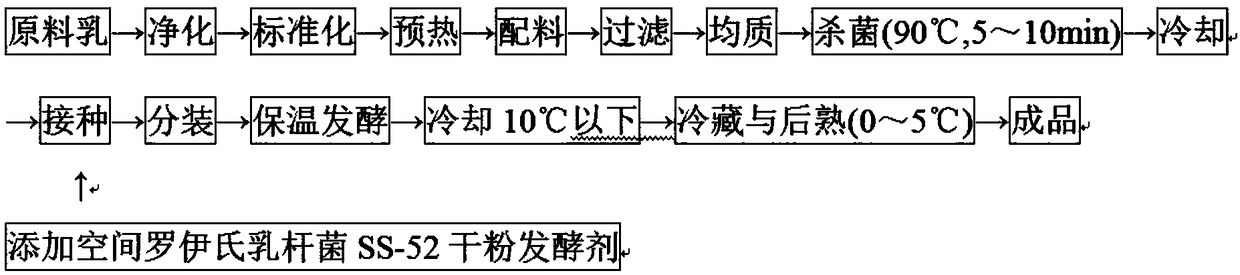

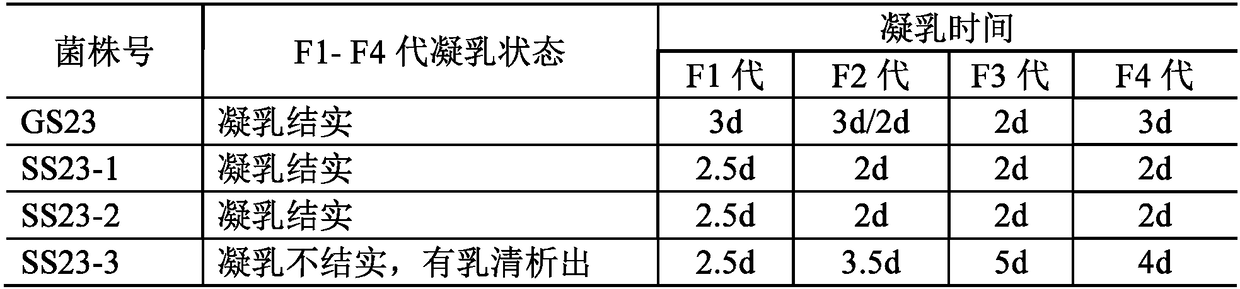

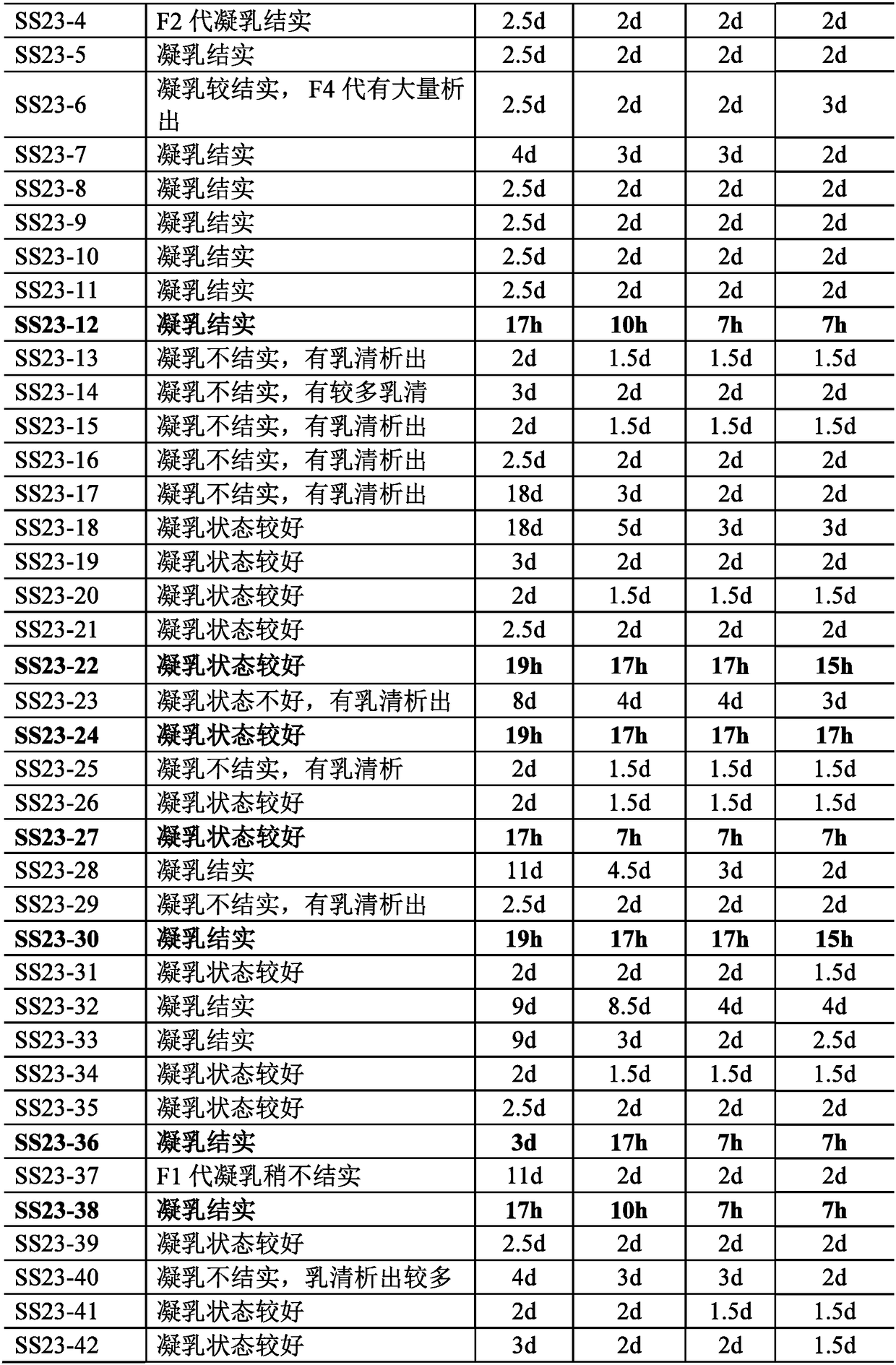

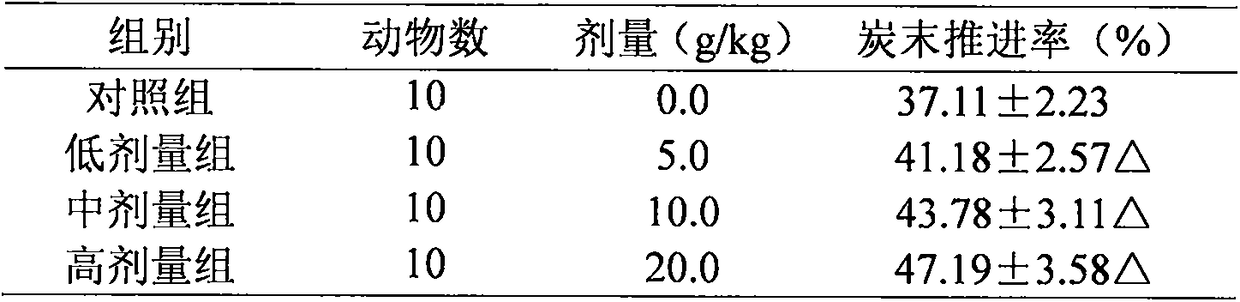

Lactobacillus reuteri SS23-52, preparation of dry powder leavening agent thereof, and applications of lactobacillus reuteri SS23-52 and dry powder leavening agent in pure probiotic yogurt

The invention discloses lactobacillus reuteri SS23-52, preparation of a dry powder leavening agent of the lactobacillus reuteri SS23-52, and applications of the lactobacillus reuteri SS23-52 and the dry powder leavening agent in pure probiotic yogurt. The lactobacillus reuteri SS23-52 protected by the invention is preserved in the China General Microbiological Culture Collection Center, and is assigned with the accession number of CGMCC No.15152. The pure probiotic yogurt prepared by adopting the lactobacillus reuteri SS23-52 and the dry powder leavening agent of the lactobacillus reuteri SS23-52 has rich flavor of roasted wheat, is fine and smooth as well as lubricant in mouthfeel, is moderate in sweetness and acidity, and has firm curd, the separate-out of whey is little, the curd forming time is shortened to 3.5h, and the curd forming time for preparing commercial common yogurt by virtue of the symbiotic effects of the two bacteria including streptococcus thermophilus and Lactobacillus delbrueckii subsp.bulgaricus is broken through. The raw materials for preparing the pure probiotic yogurt are easily available, the fermentation process is simple, the fermentation period is short, the operation is simple, the requirements for the devices are low, the cost is low, and the industrial production can be realized.

Owner:FULLARTON BIOENG TECH BEIJING CO LTD

Yoghurt containing dark chocolate particle and preparation method thereof

InactiveCN102499283AGuaranteed nutritional valueLow in sugarMilk preparationProbiotic yogurtDark chocolate

The invention discloses yoghurt containing dark chocolate particles and a preparation method thereof; granular dark chocolate is added into yoghurt, and has a weight of 2%-4% of the total yoghurt weight. The yoghurt of the invention not only maintains the nutrition of probiotic yoghurt, but also is added with the nutrition of dark chocolate. Probiotics in the yoghurt can secrete substances which are beneficial for human body, and the dark chocolate has low sugar content and high calorie. The mixing provides the yoghurt with unique flavor of mocha, and the granular chocolate has chewing sense; the yoghurt can meet popular taste, and is probiotic yoghurt with abundant nutrition and unique flavor.

Owner:重庆光大(集团)有限公司

Probiotic yogurt biscuit and preparation method thereof

InactiveCN108835164ALaxativeImprove gastrointestinal functionDough treatmentModified nutritive productsProbiotic yogurtSucrose

The invention relates to probiotic yogurt biscuit and a preparation method thereof. According to the technical scheme, a cookie or a crisp biscuit or a hard biscuit or a fermented biscuit is preparedfrom, by weight, 1-10 parts of probiotic yogurt powder, 1-10 parts of prebiotics, 1-10 part of water-soluble dietary fiber, 10-20 parts of butter, 5-15 parts of shortening, 15-25 parts of cane sugar,5-15 parts of eggs, 20-35 parts of low-gluten flour, 2-8 parts of starch, 0.5-2.5 parts of salt and 0.1-2 part of baking soda. The probiotic yogurt biscuit has the functions of regulating intestinal flora, relaxing bowels and improving gastrointestinal functions.

Owner:南昌群元科技有限公司

Production process of passion fruit flavored probiotic yoghourt

InactiveCN104430877AImprove immunityPrevent colorectal cancerMilk preparationProbiotic yogurtBifidobacterium

The invention provides a production process of passion fruit flavored probiotic yoghourt. The production process comprises the following steps: collecting milk; pretreating; preparing materials; preheating; degassing; homogenizing; sterilizing; inoculating, wherein strains comprise bifidobacterium, lactobacillus acidophilus and enterococcus in a volume ratio of 0.5 to 0.6 to 1.5, the inoculating amount is 3%-4% and the inoculating temperature is 40-42 DEG C; stirring for 15-20 minutes after inoculating; fermenting, namely fermenting the mixed materials at 40-42 DEG C for 4-6 hours; controlling the acidity in a fermenting process; carrying out emulsion breaking after the materials are fermented to the final acidity; cooling to 18-24 DEG C; adding passion fruit juice and filling and freezing. The probiotic yoghourt provided by the invention has the following physicochemical indexes: the content of fat is more than or equal to 2.5%, the content of protein is more than or equal to 2.3%, the content of non-fat milk solids is more than or equal to 6.5%, the acidity (DEG T) is 70DEG T -110DEG T, the content of white granulated sugar is more than or equal to 5.0%, the content of the passion fruit juice is more than or equal to 10%, and the viable bacterium group of probiotics is 106CFU / ml-108CFU / ml.

Owner:LIUZHOU SANYUAN TIANAI DAIRY

Production process of passion fruit and water-chestnut flavored probiotic yoghourt

The invention provides a production process of passion fruit and water-chestnut flavored probiotic yoghourt. The production process comprises the following steps: collecting milk; pretreating; preparing materials; preheating; degassing; homogenizing; sterilizing; inoculating, wherein strains comprise bifidobacterium, lactobacillus acidophilus and enterococcus in a volume ratio of 0.5 to 0.5 to 1.2, the inoculating amount is 3%-4% and the inoculating temperature is 40-42 DEG C; stirring for 15-20 minutes after inoculating; fermenting, namely fermenting the mixed materials at 40-42 DEG C for 4-6 hours; controlling the acidity in a fermenting process; carrying out emulsion breaking after the materials are fermented to the final acidity; cooling to 18-24 DEG C; adding passion fruit juice and water-chestnut juice; and filling and freezing. The passion fruit and water-chestnut flavored probiotic yoghourt provided by the invention has a unique flavor, is sour and sweet, and palatable, and also has a fresh mouth feel and a harmonious taste; and meanwhile, the passion fruit and water-chestnut flavored probiotic yoghourt has the health and nutritional functions of passion fruits and water-chestnuts, and has a good health effect.

Owner:LIUZHOU SANYUAN TIANAI DAIRY

Drinking type fermented probiotic yoghourt capable of reducing blood uric acid and preparation method of drinking type fermented probiotic yoghourt

ActiveCN112021407ALower blood uric acidHigh Adaptive SynergyMilk preparationOther dairy technologyBiotechnologyProbiotic yogurt

The invention relates to the technical field of probiotic yoghourt, and aims to provide drinking type fermented probiotic yoghourt capable of reducing blood uric acid in order to give full play to thehealth-care effect of lactobacillus fermentum 2644 for reducing the blood uric acid content. The fermented probiotic yoghourt is prepared by fermenting lactobacillus fermentum 2644 and contains a fermented product and viable bacteria of lactobacillus fermentum 2644. A step of adding a chicory, cape jasmine and mulberry leaf extracting solution to participate in fermentation is also included. Thefermented probiotic acid contains a fermentation product and viable bacteria of lactobacillus fermentum 2644, has the effect of reducing the content of blood uric acid in a body, expands the use pathof lactobacillus fermentum 2644 and the function of probiotic yoghourt, and meanwhile, creatively proposes that lactobacillus fermentum 2644 is matched with traditional Chinese medicine components toform a formula, the drinking type probiotic yoghourt with the effect of obviously reducing the content of the blood uric acid is obtained.

Owner:HANGZHOU WAHAHA TECH +1

Production technology of cranberry flavor probiotic yogurt

The invention provides a production technology of cranberry flavor probiotic yogurt. The production technology comprises the following steps: collecting milk; pretreating; blending; preheating; degassing; homogenizing; sterilizing; inoculating bacteria including bifidobacterium, lactobacillus acidophilus and enterococcus with the volume ratio of 0.5 to 0.5 to 1.8, wherein the inoculating amount is 3-4%, and the inoculating temperature is 40-42 DEG C; stirring for 15-20 minutes after inoculation; fermenting, namely, fermenting the uniformly mixed materials at the temperature of 40-42 DEG C for 4-6 hours, controlling the acidity in the fermentation process, demulsifying until fermenting to the terminal acidity, and reducing the temperature to 18-24 DEG C; adding cranberry pulp; and filling and refrigerating. The cranberry flavor probiotic yogurt is sour and sweet, is unique in flavor, has the health and nutritional functions of cranberries, and has good health efficacy.

Owner:LIUZHOU SANYUAN TIANAI DAIRY

Process for producing corn-konjak-flavor probiotic yogurt

InactiveCN104430879AWith health functionHas nutritional functionMilk preparationBiotechnologyProbiotic yogurt

The invention provides a process for producing corn-konjak-flavor probiotic yogurt. The process comprises the following steps: collecting milk, pretreating, proportioning materials, pretreating, degassing, homogenizing, sterilizing, inoculating, mixing for 15-20 minutes, fermenting, adding corn slurry and konjak slurry, filling and performing cold preservation, wherein strains comprise bifidobacterium, lactobacillus acidophilus and enterococcus, and the volume ratio of the three strains is 0.5: 0.5: 1.6, the inoculation amount is 3-4 percent, the inoculation temperature is 40-42 DEG C; and the step of fermentation comprises fermenting uniformly-mixed materials under 40-42 DEG C for 4-6 hours by controlling the acidity, demulsifying after fermentation reaches the final acidity, and cooling to 18-24 DEG C. The corn-konjak-flavor probiotic yogurt obtained according to the process disclosed by the invention has unique flavor, is sour and sweet, has aroma of corn and konjak, scientific formula and balanced nutrition, can be easily absorbed by human bodies, and has a good health care effect.

Owner:LIUZHOU SANYUAN TIANAI DAIRY

Probiotic yogurt and preparation method thereof

PendingCN104255915AHigh in beneficial bacteriaIncrease health functionMilk preparationBiotechnologyProbiotic yogurt

The invention discloses probiotic yogurt and a preparation method thereof. The probiotic yogurt contains inulin the content of which is 0.1-20% by weight. The probiotic yogurt is prepared by the following steps of preparing materials, preheating, homogenizing, sterilizing, inoculating and fermenting, has the advantages of regulating the balance of human intestinal microecology, improving function of intestines, controlling the blood fat, improving the immunity of human bodies and being high in dietary fiber content and the like. Moreover, the preparation process is simple, and is easy to operate.

Owner:ZUOYUAN GRP

Probiotic yoghurt with hypoglycemic effect and preparation method thereof

The invention discloses a probiotic yoghourt with a hypoglycemic effect, which is characterized in that the probiotic yoghourt is prepared from a radix puerariae extracting solution, xylitol, milk, prebiotics, protein liquid, first probiotics and second probiotics. The invention further discloses a preparation method of the probiotic yoghurt with the hypoglycemic effect, which is characterized by comprising the following steps: preparing the radix puerariae extracting solution: crushing radix puerariae, adding water, heating, extracting, and filtering to obtain the radix puerariae extracting solution; preparing a mixture I: adding the xylitol into the milk to obtain the mixture I; preparing a mixture II: adding the protein liquid and the prebiotics into the mixture I to obtain the mixture II; preparing a fermentation culture medium: mixing the radix puerariae extracting solution with the mixture II, and then heating, homogenizing and sterilizing to obtain the fermentation culture medium; and fermentation and after-ripening: inoculating the fermentation culture medium with the first probiotics and the second probiotics for fermentation and after-ripening to obtain the probiotic yoghourt.

Owner:XIAN GIANT BIOGENE TECH CO LTD

Strawberry-state probiotic yogurt production process

The present invention provides a strawberry-taste probiotic yogurt production process, which comprises: collecting milk; carrying out a pretreatment; preparing materials; preheating; degassing; homogenizing; sterilizing; inoculating, wherein the strains comprise Bifidobacterium, Lactobacillus acidophilus and enterococci, the volume ratio of the three strains is 0.5:0.5:1.5, the inoculating amount is 3-4%, the inoculating temperature is 40-42 DEG C, and stirring is performed for 15-20 min after inoculating; fermenting, wherein the uniformly-mixed material is fermented for 4-6 h at a temperature of 40-42 DEG C, the acidity is controlled during the fermenting process, demulsification is performed after the fermenting achieves the end point acidity, and cooling is performed to achieve 18-24 DEG C; adding a strawberry jam; and filling, and carrying out cold preservation. The physical and chemical indicators of the strawberry-taste probiotic yogurt of the present invention are as the follows: the fat content is more than or equal to 2.5%, the protein content is more than or equal to 2.3%, the non-fat milk solid content is more than or equal to 6.5%, the acidity (DEG T) is 70-110 DEG T, the white granulated sugar content is more than or equal to 5.0%, the strawberry jam content is more than or equal to 10%, and the live flora of the probiotics is 106-108 CFU / ml.

Owner:LIUZHOU SANYUAN TIANAI DAIRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com