Lactobacillus reuteri SS23-52, preparation of dry powder leavening agent thereof, and applications of lactobacillus reuteri SS23-52 and dry powder leavening agent in pure probiotic yogurt

A technology of Lactobacillus reuteri, starter, applied in the direction of Lactobacillus, bacteria used in food preparation, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

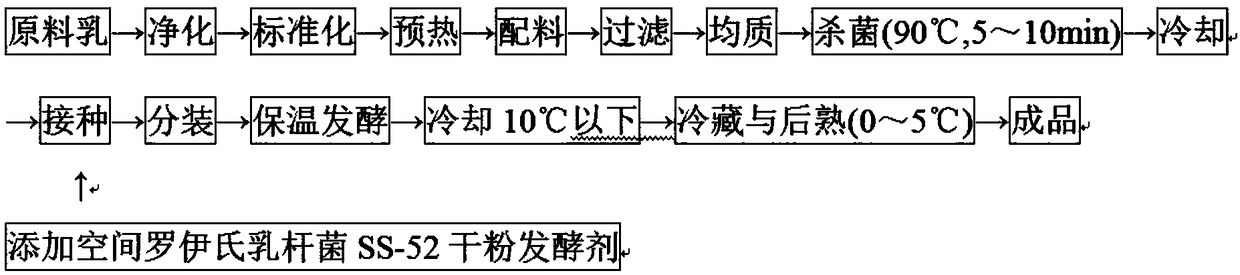

Method used

Image

Examples

Embodiment 1

[0091] Embodiment 1, the screening of Lactobacillus reuteri strain in space

[0092] 1. Space mutagenesis of bacterial strains

[0093] Lactobacillus reuteri (Lactobacillus reuteri) GS23 on the ground was carried back by Tiangong-2 and Shenzhou-11 spacecraft to obtain space mutagenic strains, from which 115 strains were isolated and purified, and the strain codes were respectively marked as SS23-1 to SS23- 115.

[0094] 2. Strain activation

[0095] Put Lactobacillus reuteri (Lactobacillus reuteri) GS23 and strains SS23-1 to SS23-115 frozen in a -80°C freezer into 5mL MRS liquid medium at 2% to 3%, respectively, and culture at 37°C After 16 hours, it was used for subsequent experiments after three consecutive generations of activation.

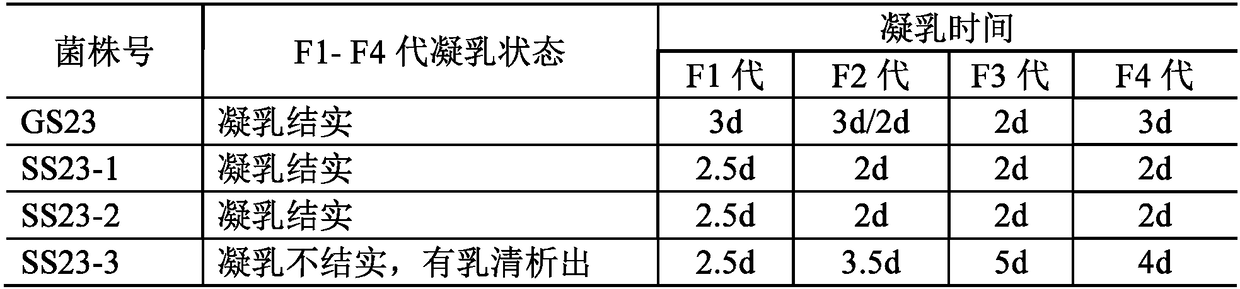

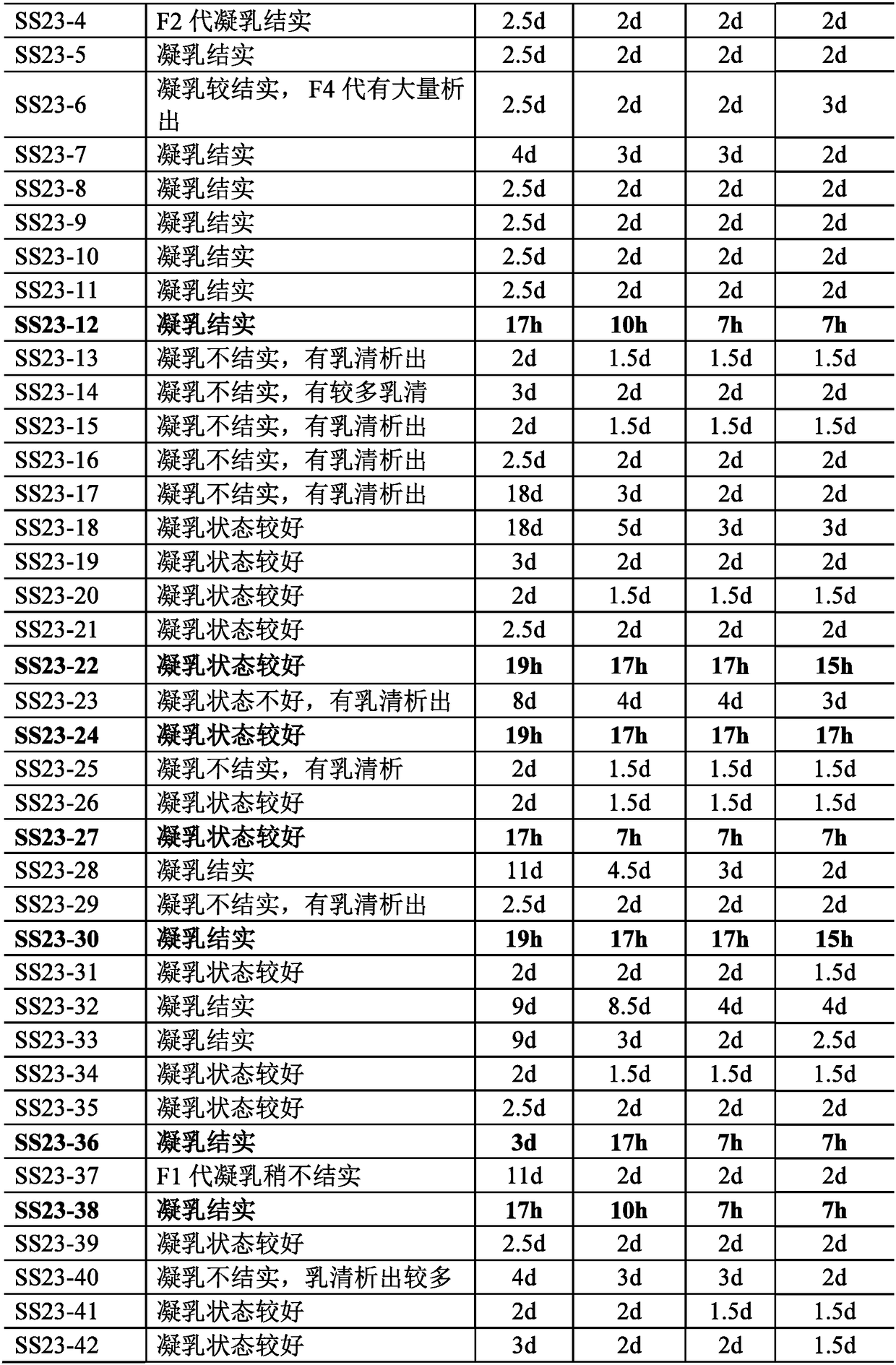

[0096] 3. Primary screening of strains

[0097] The liquid MRS culture of Lactobacillus reuteri (Lactobacillus reuteri) GS23 obtained in step 2 and bacterial strain SS23-1 to SS23-115 is inserted in a 5mL skim milk test tube according to t...

Embodiment 2

[0129] Embodiment 2, optimization of space Lactobacillus reuteri SS23-52 high-density fermentation conditions

[0130] 1. Preparation of Lactobacillus reuteri SS23-52 starter in space

[0131] Put Lactobacillus reuteri SS23-52 glycerol preservation tubes into 5mL MRS liquid culture medium at 2% to 3% (volume percentage concentration), and activate it by static culture at 37°C for 16 hours. The activated MRS test tube culture Move into the Erlenmeyer flask filled with 200mL sterilized MRS medium by 2% (volume percentage concentration), and leave it to culture at 37°C for 16h to obtain the Lactobacillus reuteri SS23-52 starter culture. The number of live bacteria of Lactobacillus is 7.5×10 9 CFU / mL.

[0132] The detection method of the Lactobacillus reuteri SS23-52 starter in space: take 1 mL starter and put it into 99 mL of sterilized physiological saline, and use a slap-type homogenizer to process it at a speed of 8000 to 10000 r / min for 2 minutes, fully After shaking, make 1...

Embodiment 3

[0167] Embodiment 3, the preparation of Lactobacillus reuteri SS23-52 dry powder starter

[0168] 1. Centrifugal concentration and optimization of protective agent formula

[0169] 1, the space lactobacillus reuteri SS23-52 starter prepared by the step 1 of embodiment 2 is by 3% (volume percentage concentration, the number of live bacteria of space lactobacillus reuteri SS23-52 in the starter is 7.5 × 109 CFU / mL, that is, the number of live bacteria of Lactobacillus reuteri SS23-52 in the fermentation system is 2.3×10 8 CFU / mL) inoculum amount was inoculated in a 5L automatic fermenter containing 2.4L liquid MRS medium, the fermentation temperature was controlled at 37°C, the pH of the fermentation system was 6.8, the stirring speed was 120-150r / min, and the fermentation time was 16h to obtain the fermented liquid.

[0170] 2. As shown in Table 13, prepare 30 mL of 8 different combinations of lyoprotectants with distilled water, and sterilize them with high-pressure steam at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com