Probiotic yoghurt with hypoglycemic effect and preparation method thereof

A technology of probiotics and yogurt, applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of adding yogurt, not focusing on it, and yogurt that does not have the ability to lower blood sugar, achieving a delicate taste, increasing blood sugar High blood sugar effect and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0101] The present application also provides a method for preparing probiotic yoghurt with hypoglycemic effect, which is characterized in that it comprises the following steps:

[0102] Preparing the Pueraria root extract: pulverizing the Pueraria root, adding water, heating, extracting, and filtering to obtain the Pueraria root extract;

[0103] Preparation of mixture 1: adding xylitol to milk to obtain mixture 1;

[0104] Preparation of mixture 2: adding protein liquid and prebiotics to the mixture 1 to obtain mixture 2;

[0105] Prepare fermentation medium: mix the kudzu root extract with the mixture 2, then heat up, homogenize, and sterilize to obtain a fermentation medium;

[0106] post-fermentation ripening: the fermentation medium is inoculated with the first probiotic and the second probiotic for fermentation and post-ripening to obtain the probiotic yoghurt.

[0107] "Extraction" in this application refers to the preparation of useful components (such as components ...

Embodiment 1

[0141] (1) Take 100g of kudzu root, wash it, dry it, crush it, add 1.5kg of water, soak it for 0.6h, extract it after heating to 106°C for 1.2h, and obtain 1.4kg of kudzu root extract after filtering;

[0142] (2) After filtering 250kg of fresh milk, heat it to 40°C, then add 11.2kg of xylitol, and after the xylitol dissolves, heat it to 90°C and keep it warm for 25min to obtain mixture 1;

[0143] (3) Cool the mixture 1 to 40°C, then add 1.8kg protein solution and 80g fructo-oligosaccharide to the mixture 1, keep stirring for 30min to obtain mixture 2;

[0144] (4) After mixing 1.4kg of kudzu root extract with the mixture two, the temperature was raised to 60°C, homogenized at 25MPa, and then pasteurized at 85°C for 15s to obtain a fermentation medium;

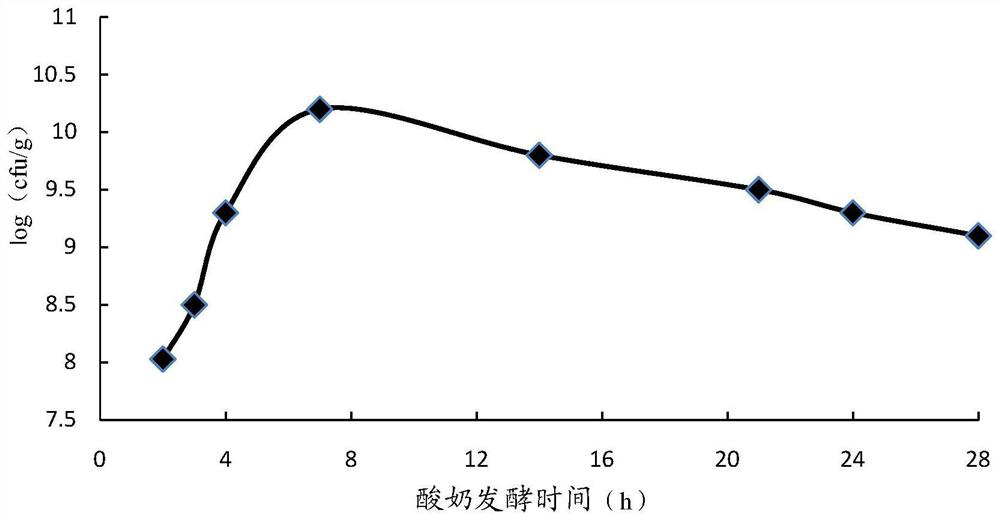

[0145] (5) Cool the fermentation medium to 38°C, inoculate 140g of the first probiotic and 90g of the second probiotic on the fermentation medium for fermentation, and terminate the fermentation until the acidity of the ferme...

Embodiment 2

[0148] (1) Take 129g of kudzu root, wash it, dry it, crush it, add 2.0kg of water, soak it for 0.6h, extract it after heating to 106°C for 1.2h, and obtain 1.8kg of kudzu root extract after filtering;

[0149] (2) After filtering 300kg of fresh milk, heat it to 40°C, then add 13.1kg of xylitol, and after the xylitol dissolves, heat it to 90°C and keep it warm for 25min to obtain mixture 1;

[0150] (3) Cool the mixture 1 to 40°C, then add 2kg protein solution and 100g fructo-oligosaccharide to the mixture 1, keep stirring for 30min to obtain mixture 2;

[0151] (4) After mixing 1.8kg of kudzu root extract with the mixture two, the temperature was raised to 60°C, homogenized at 25MPa, and then pasteurized at 85°C for 15s to obtain a fermentation medium;

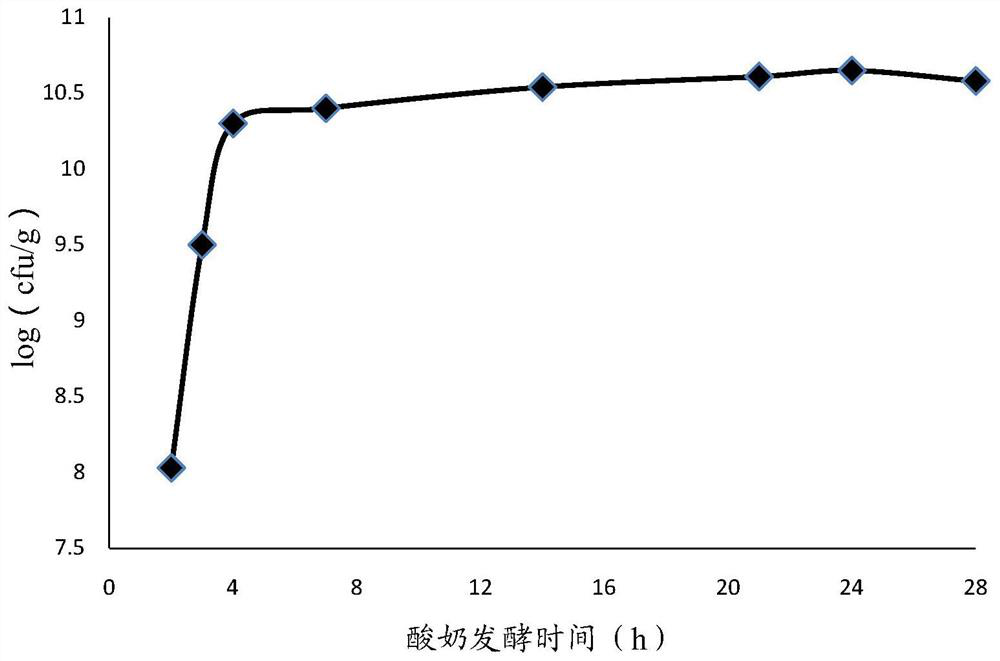

[0152] (5) Cool the fermentation medium to 38°C, inoculate 90g of the first probiotic and 110g of the second probiotic on the fermentation medium for fermentation, and terminate the fermentation until the acidity of the fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com