Probiotic yogurt and preparation method thereof

A technology of probiotics and yogurt, applied in milk preparations, dairy products, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

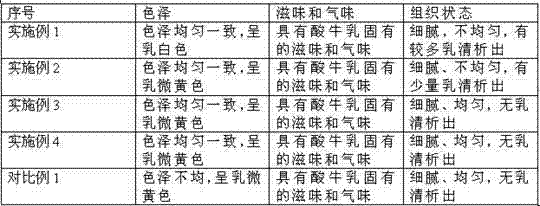

Examples

preparation example Construction

[0023] Based on the above-mentioned probiotic yogurt, the present invention also provides a preparation method for the probiotic yogurt, the specific preparation steps are as follows:

[0024] 1) Heat the raw milk to 45-55°C, add inulin and white sugar, continue to heat up to 60-70°C, and then filter through a filter to obtain the raw material base liquid;

[0025] 2) After pouring the raw material base liquid into the sterilizer for sterilization, preheat at a temperature of 55~65°C;

[0026] 3) Pour the preheated raw material base liquid into the homogenizer, and homogenize under the condition of a pressure of 8~10MPa;

[0027] 4) Heat the homogenized raw material base liquid to 90~95°C, keep it warm for 3~8 minutes, and then cool it to 40~45°C;

[0028] 5) At a temperature of 42~43°C, inoculate the probiotics into the raw material base liquid, then stir and ferment evenly until the pH value reaches 4.2~4.5, stop the fermentation, and cool the product to 15~ within 30 minut...

Embodiment 1

[0037] Ingredients of raw milk: 100g of fresh milk, 1.2g of whole milk powder, 1.34g of food additives, 3.5g of concentrated whey protein, 30mg of taurine, 3mg of niacinamide, and 0.8mg of zinc citrate.

[0038] Among them, the food additives are sodium carboxymethylcellulose, polydextrose, citric acid, lactic acid, sodium tripolyphosphate, sodium citrate, guar gum, glycerol monostearate fatty acid ester, sucrose fatty acid ester, aspartame Blend of Sweet (with Phenylalanine), Acesulfame K, Natural Vitamin E, Xanthan Gum, or Emulsified Silicone Oil.

[0039] The above-mentioned ingredients are transferred to a pressurized concentration tank through a balance tank, concentrated under reduced pressure, and solids are strengthened by adding milk powder to obtain milk, wherein the added amount of milk powder is 2% of the total weight of the above-mentioned ingredients, and the remaining The following preparation process is the same as step 1) to step 5) in the above preparation me...

Embodiment 2

[0042] Ingredients of raw milk: 100g of fresh milk, 1.2g of whole milk powder, 1.34g of food additives, 3.5g of concentrated whey protein, 30mg of taurine, 3mg of niacinamide, and 0.8mg of zinc citrate.

[0043] Among them, the food additives are sodium carboxymethylcellulose, polydextrose, citric acid, lactic acid, sodium tripolyphosphate, sodium citrate, guar gum, glycerol monostearate fatty acid ester, sucrose fatty acid ester, aspartame Blend of Sweet (with Phenylalanine), Acesulfame K, Natural Vitamin E, Xanthan Gum, or Emulsified Silicone Oil.

[0044] Whole preparation process is identical with embodiment 1.

[0045] Wherein, the content of inulin is 20% by weight based on the weight of the probiotic yoghurt, and the probiotic is a mixed strain of Streptococcus thermophilus and Bifidobacterium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com