Brown probiotic yogurt and preparation method thereof

A probiotic, brown technology, applied in milk preparations, dairy products, applications, etc., can solve the problems of the total number of viable bacteria not reaching the order of magnitude of the application effect, the long fermentation time of probiotics, and the growth restriction of probiotics, etc., to achieve a pleasant flavor. , full taste, pure taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

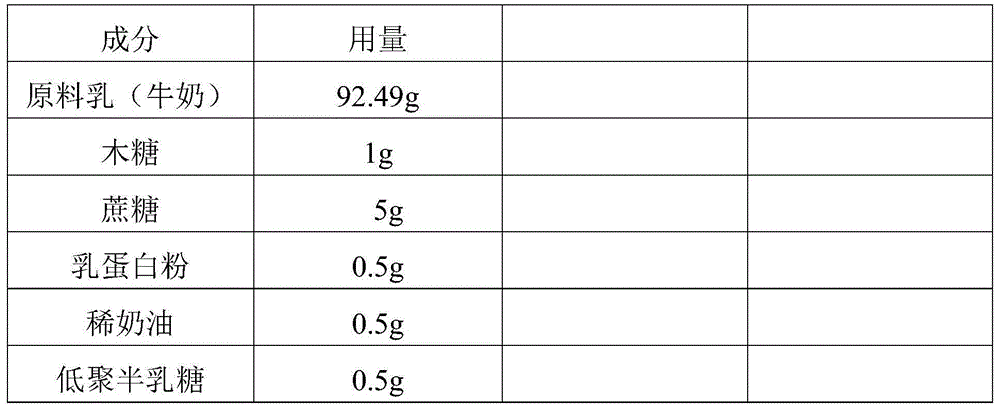

[0033] formula:

[0034]

[0035]

[0036] The process steps are as follows:

[0037] 1. Heat the raw milk to 40°C, add xylose, stir to dissolve, then raise the temperature to 90°C, and keep it warm for 30 minutes to obtain material A;

[0038] 2. Cool the material A obtained in step 1 to 50°C, add milk protein powder, cream, sucrose and galacto-oligosaccharide, keep stirring for 30 minutes, and obtain material B;

[0039] 3. Raise the temperature of the material B obtained in step 2 to 60°C, homogenize at 60°C and 25Mpa, pasteurize at 85°C for 15s, and obtain the fermentation substrate;

[0040] 4. Cool the fermentation substrate obtained in step 3 to 38°C, add starter at 38°C to ferment until the terminal acidity is 75°T, cool to 16°C, fill, and refrigerate at 4°C.

Embodiment 2

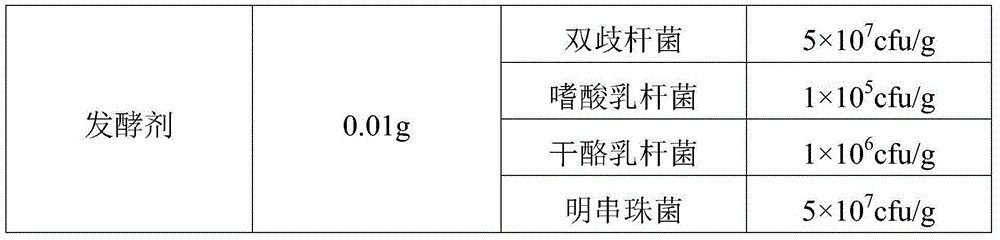

[0042] formula:

[0043]

[0044] The process steps are as follows:

[0045] 1. Heat the raw milk to 50°C, add glucose, stir to dissolve, then raise the temperature to 95°C, and keep it warm for 120 minutes to obtain material A;

[0046] 2. Cool the material A obtained in step 1 to 40°C, add milk protein powder, cream, sucrose and isomaltooligosaccharide, keep stirring for 15 minutes, and obtain material B;

[0047] 3. Raise the temperature of the material B obtained in step 2 to 65°C, homogenize at 65°C and 18Mpa, pasteurize at 85°C for 15s, and obtain the fermentation substrate;

[0048] 4. Cool the fermentation substrate obtained in step 3 to 35°C, add starter at 35°C to ferment until the final acidity is 80°T, cool to 22°C, fill, and refrigerate at 10°C.

Embodiment 3

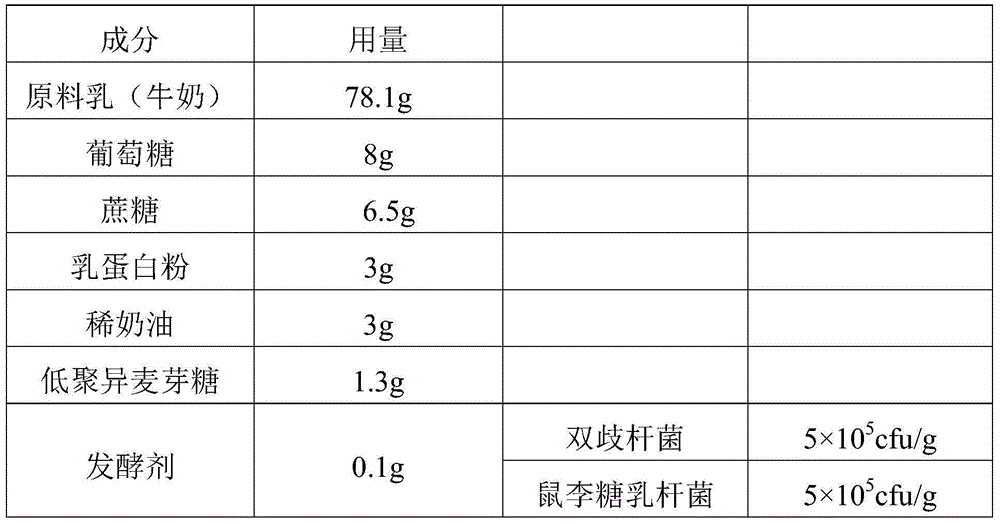

[0050] formula:

[0051]

[0052] The process steps are as follows:

[0053] 1. Add 150kg of whole milk powder into 850L of water and dissolve completely to make reconstituted milk;

[0054] 2. Heat the reconstituted milk obtained in step 1 to 45°C, add glucose, stir to dissolve, heat up to 95°C, and keep it warm for 120 minutes to obtain material A;

[0055] 3. Cool the material A obtained in step 2 to 50°C, add milk protein powder, cream, sucrose, and isomaltooligosaccharide, and keep stirring for 30 minutes to obtain material B;

[0056] 4. Raise the temperature of the material B obtained in step 3 to 65°C, homogenize at 65°C and 20Mpa, pasteurize at 85°C for 15s, and obtain the fermentation substrate;

[0057] 5. Cool the fermentation substrate obtained in step 4 to 37°C, add starter at 37°C to ferment until the terminal acidity is 80°T, cool to 20°C, fill, and refrigerate at 4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com