Honey freeze-dried powder and manufacturing method thereof

A technology of freeze-dried honey powder and a manufacturing method, which is applied in the field of freeze-dried honey powder and its manufacturing, can solve the problems that the freeze-dried method cannot be directly used, the liquid honey cannot be stored for a long time, and the nutritional value is reduced, so as to achieve long-term preservation, Easy to store and eat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

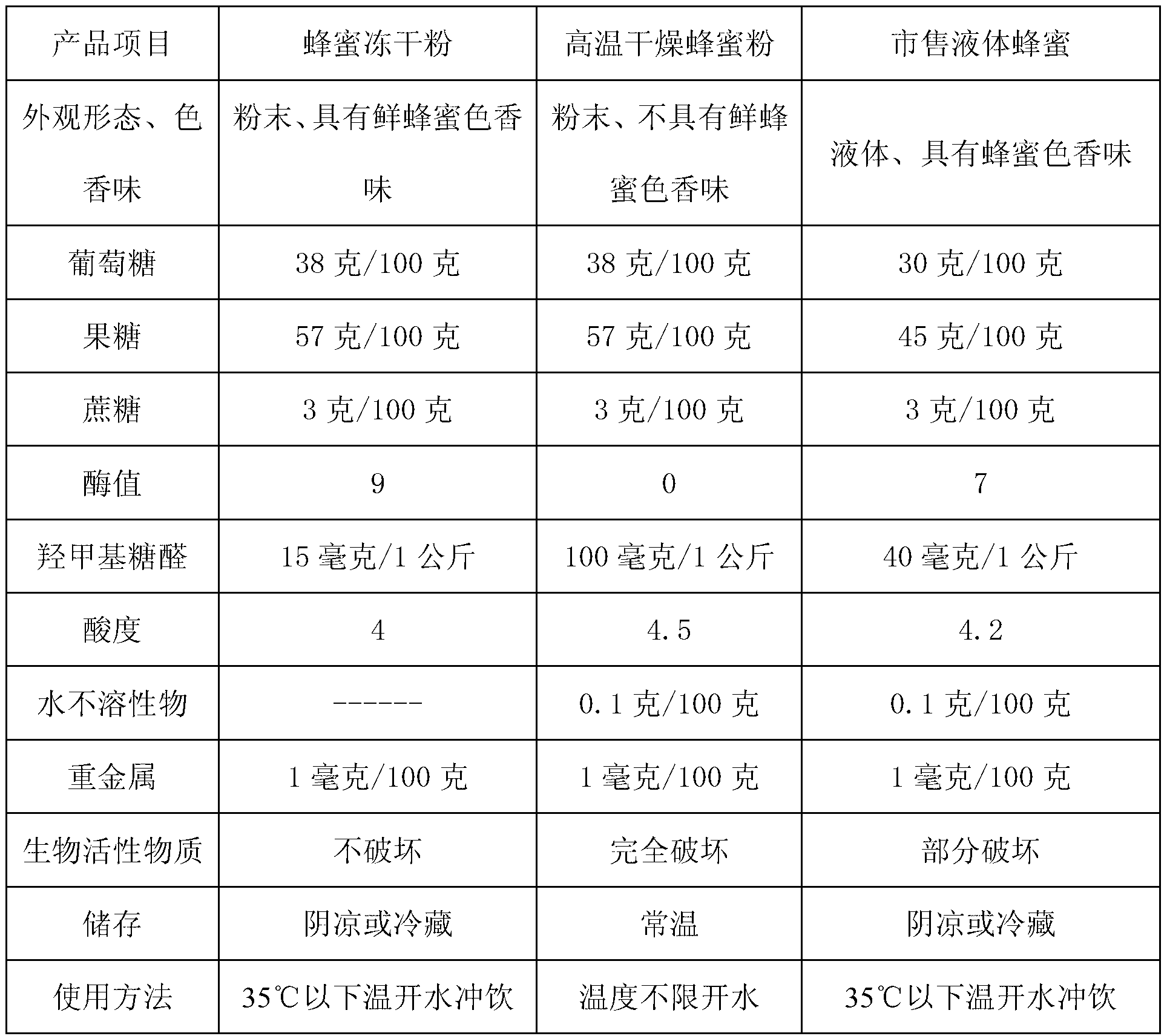

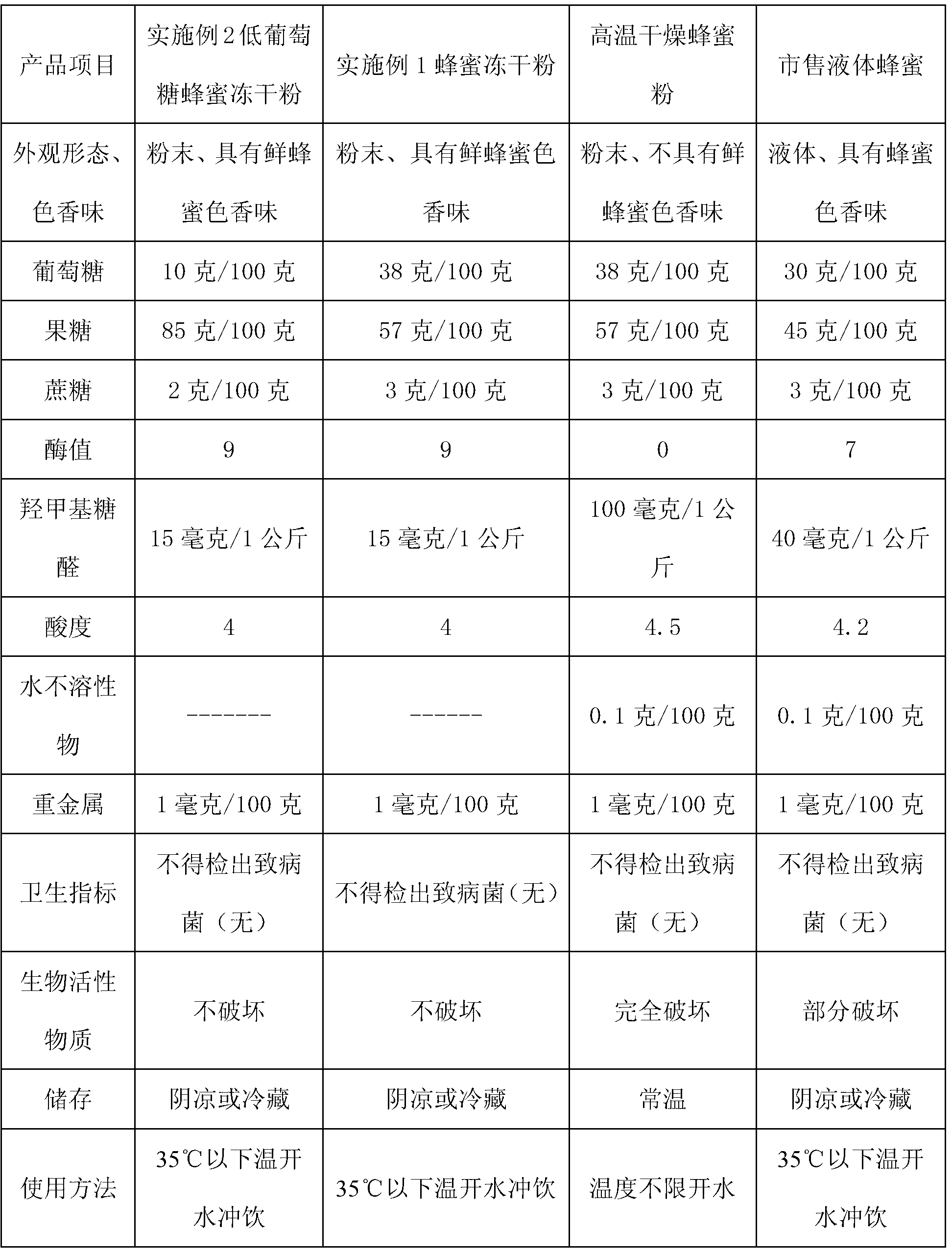

[0024] The honey freeze-dried powder described in this embodiment includes honey, and the honey is a powdery freeze-dried powder sealed in a sealed packaging container. The powdered freeze-dried powder has a glucose content of 38 grams, a fructose content of 57 grams, a sucrose content of less than 3 grams, and an enzyme value greater than 9 per 100 grams of the powdered freeze-dried powder.

[0025] The manufacture method of this powdery freeze-dried powder can be to take fresh honey and add cold distilled water to form honey dilution liquid first, the content of cold distilled water in the honey dilution liquid is 30% to 80%, then divide into packing container and put into freeze-drying box Ultra-low temperature freeze-drying is carried out in the middle, firstly, the temperature is lowered until the diluted honey liquid freezes to form an ice shelf structure, and then vacuumized and continuously dried until the water content is lower than 2%. The first step of cooling down ...

Embodiment 2

[0031] The honey freeze-dried powder provided in this embodiment is also a powdered freeze-dried powder packaged in a sealed packaging container, and the powdered freeze-dried powder is the glucose content per 100 grams of the powdered freeze-dried powder It is 5 grams to 10 grams, the fructose content is 90 grams to 85 grams, and the enzyme value is greater than 9.

[0032] The production method of this powdery freeze-dried powder with low glucose content can be to get natural fresh honey first, add glucose to the natural fresh honey to become sugar-adjusted honey liquid, and make the glucose content in the sugar-adjusted honey liquid greater than the original fructose content , place the adjusted sugar-adjusted honey liquid in a constant temperature environment of 10 ° C ~ 16 ° C, so that the glucose in the sugar-adjusted honey liquid crystallizes and precipitates rapidly at this temperature, take the supernatant for later use, and take the precipitate and weigh it with an ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com