Patents

Literature

1241 results about "Pregelatinized starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

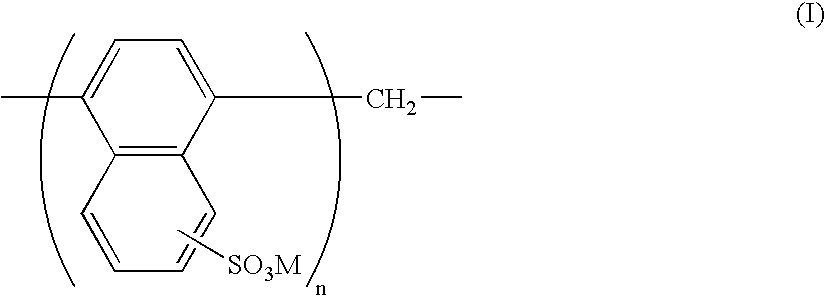

Low dust gypsum wallboard

ActiveUS20070048490A1High strengthReduce weightConstruction materialCovering/liningsDust controlSlurry

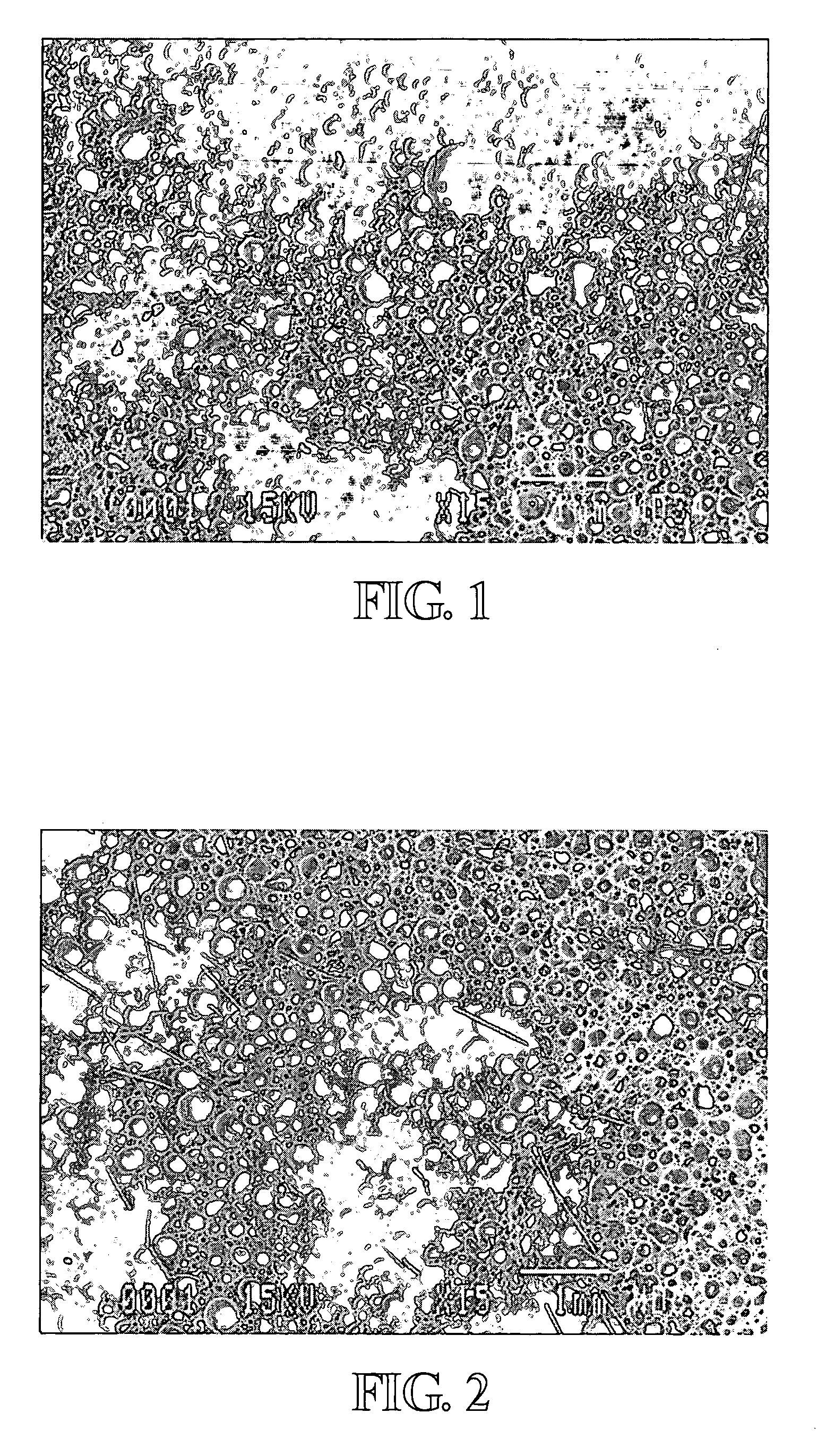

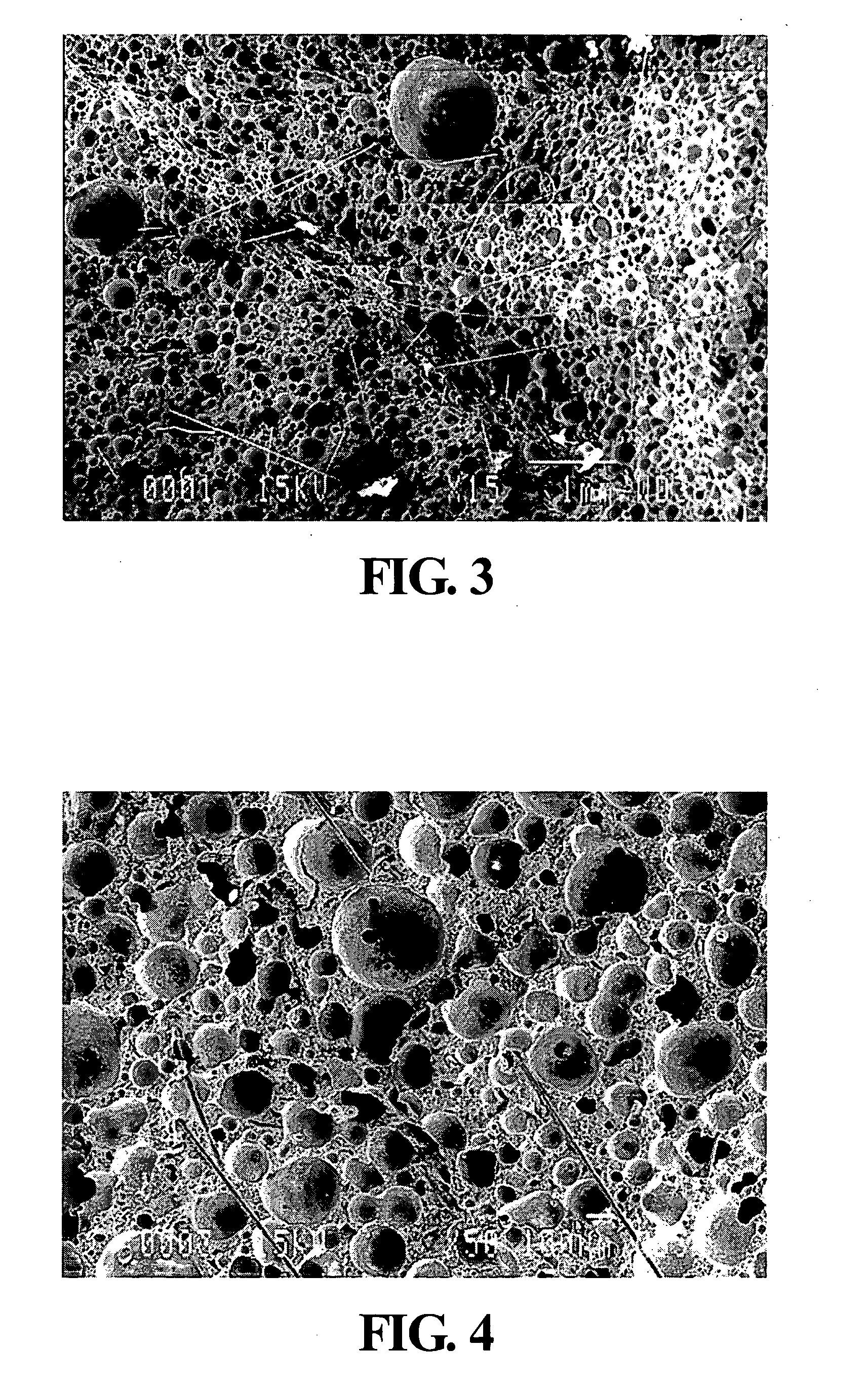

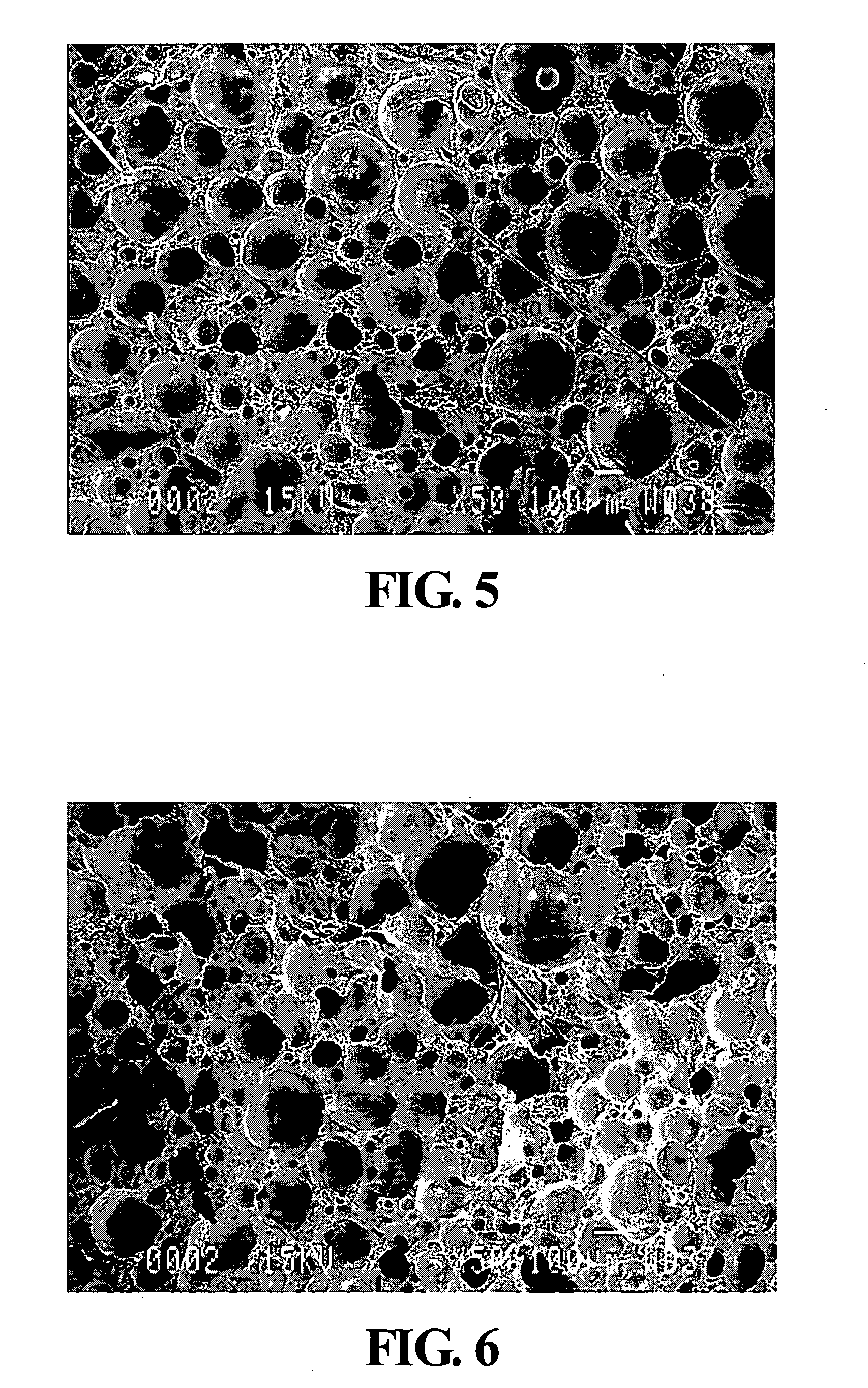

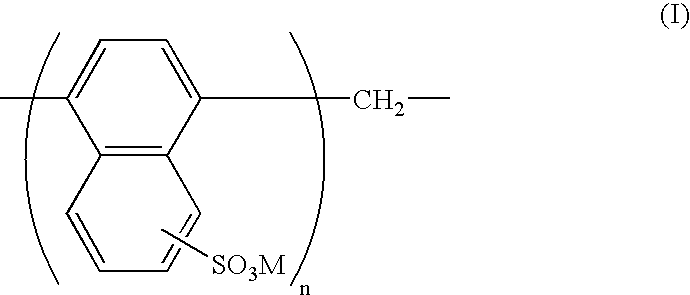

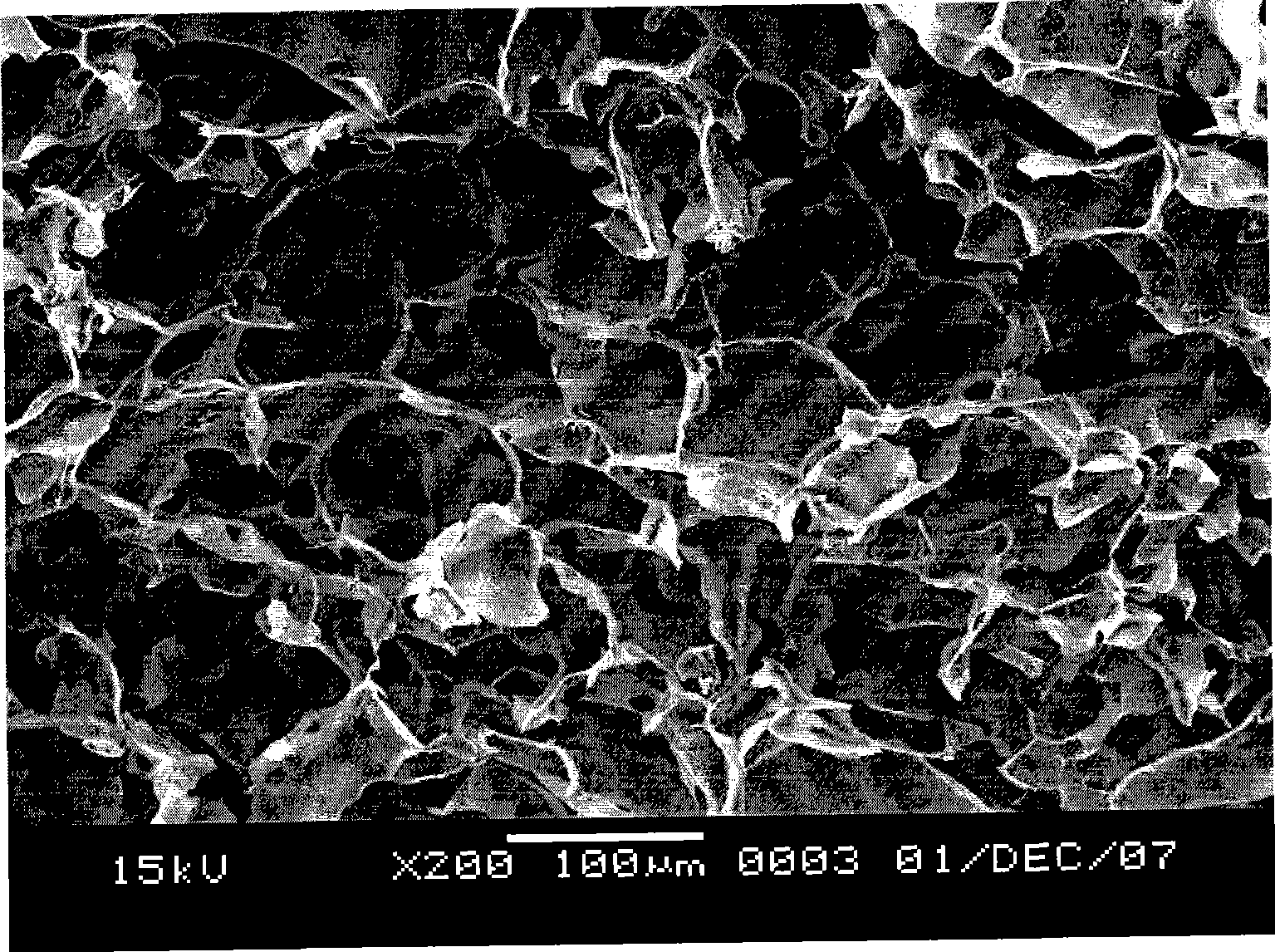

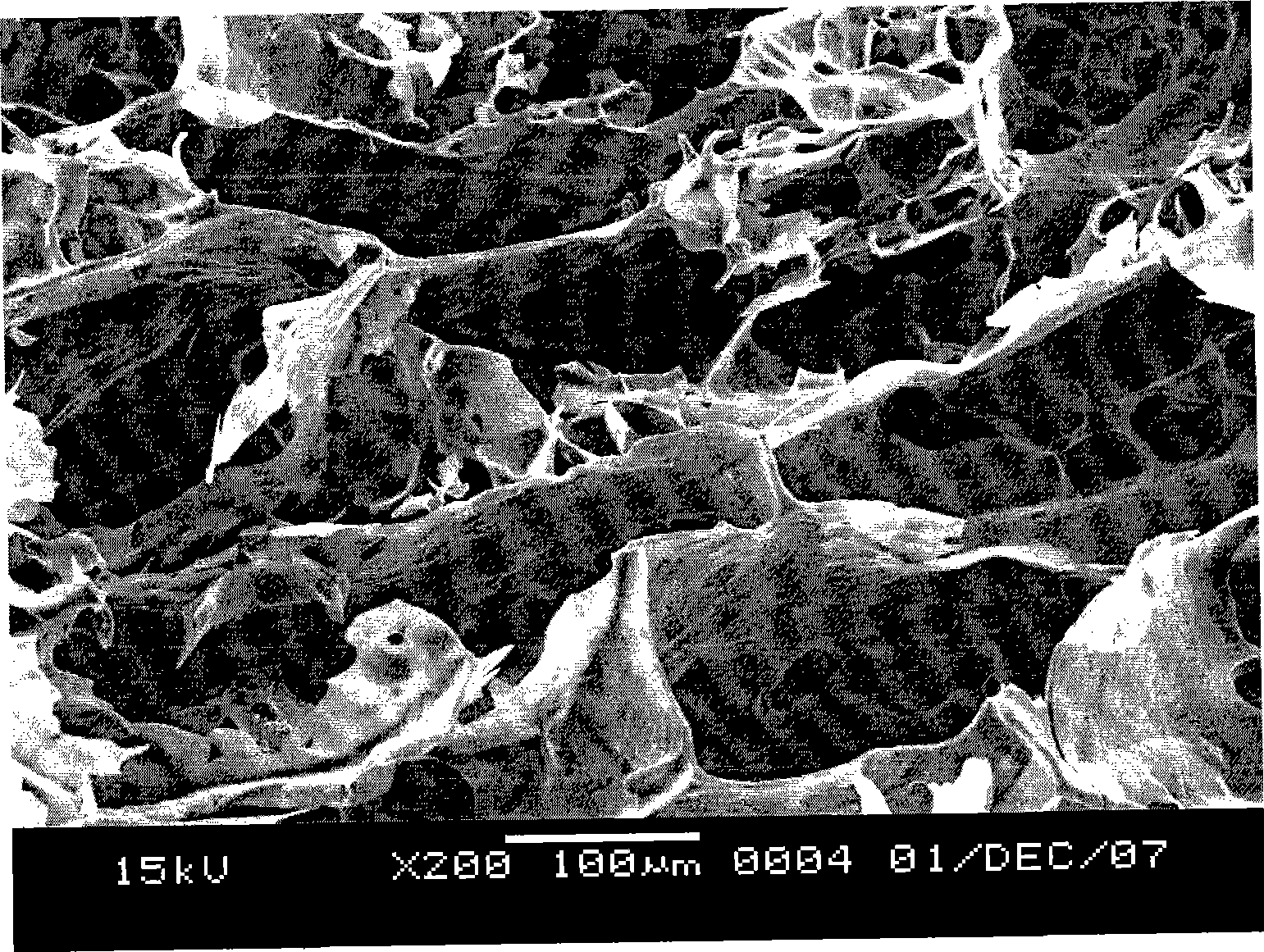

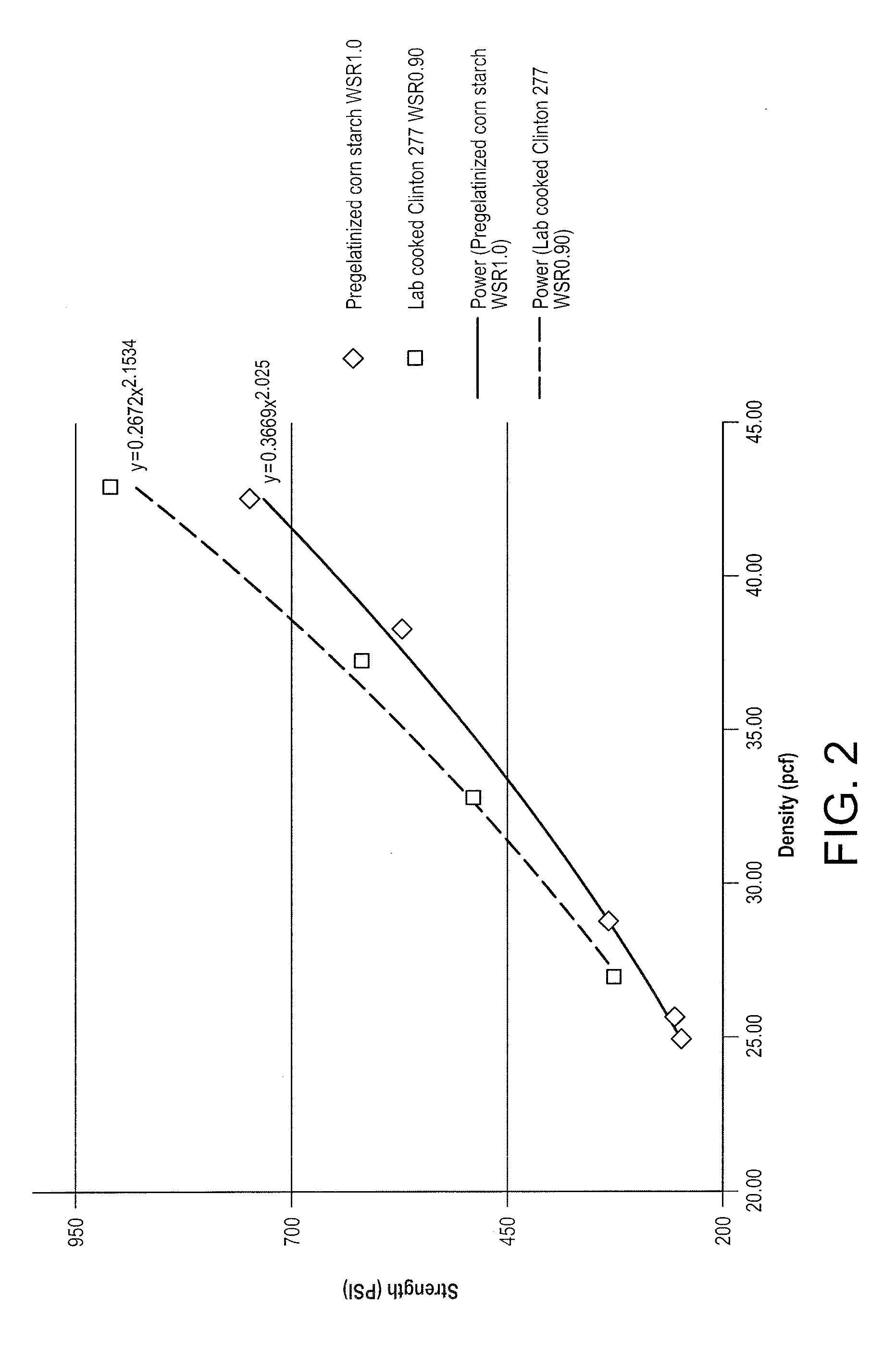

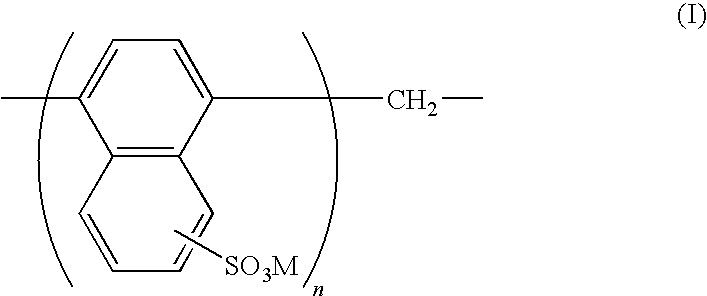

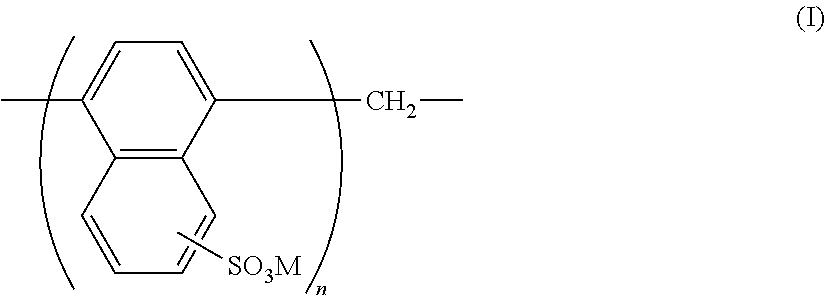

This invention provides low dust low density gypsum wallboard products having high total core void volumes, corresponding to low densities in the range of about 10 to 30 pcf. The wallboards have a set gypsum core formed between two substantially parallel cover sheets, the set gypsum core preferably having a total void volume from about 80% to about 92%, and made from a slurry including stucco, pregelatinized starch, and a naphthalenesulfonate dispersant. The combination of the pregelatinized starch and the naphthalenesulfonate dispersant also provides a glue-like effect in binding the set gypsum crystals together. The wallboard formulation, along with small air bubble voids (and water voids) provides dust control during cutting, sawing, routing, snapping, nailing or screwing down, or drilling of the gypsum-containing products. This invention also provides a method of making the low dust low density gypsum products including the introduction of soap foam in an amount sufficient to form a total void volume, including air voids, preferably from about 80% to about 92% in the set gypsum core, corresponding to a set gypsum core density from about 10 pcf to about 30 pcf. The wallboards produced by the method generate significantly less dust during working.

Owner:UNITED STATES GYPSUM CO

High starch light weight gypsum wallboard

The invention generally provides gypsum-containing slurries including stucco, naphthalenesulfonate dispersant, and pregelatinized starch. The naphthalenesulfonate dispersant is present in an amount of about 0.1%-3.0% by weight based on the weight of dry stucco. The pregelatinized starch is present in an amount of at least about 0.5% by weight up to about 10% by weight of pregelatinized starch by weight based on the weight of dry stucco in the formulation. Other slurry additives can include trimetaphosphate salts, accelerators, binders, paper fiber, glass fiber, and other known ingredients. The invention also comprises the gypsum-containing products made with such slurries, for example, gypsum wallboard, and a method of making gypsum wallboard.

Owner:UNITED STATES GYPSUM CO

High starch light weight gypsum wallboard

The invention generally provides gypsum-containing slurries including stucco, naphthalenesulfonate dispersant, and pregelatinized starch. The naphthalenesulfonate dispersant is present in an amount of about 0.1%-3.0% by weight based on the weight of dry stucco. The pregelatinized starch is present in an amount of at least about 0.5% by weight up to about 10% by weight of pregelatinized starch by weight based on the weight of dry stucco in the formulation. Other slurry additives can include trimetaphosphate salts, accelerators, binders, paper fiber, glass fiber, and other known ingredients. The invention also comprises the gypsum-containing products made with such slurries, for example, gypsum wallboard, and a method of making gypsum wallboard.

Owner:UNITED STATES GYPSUM CO

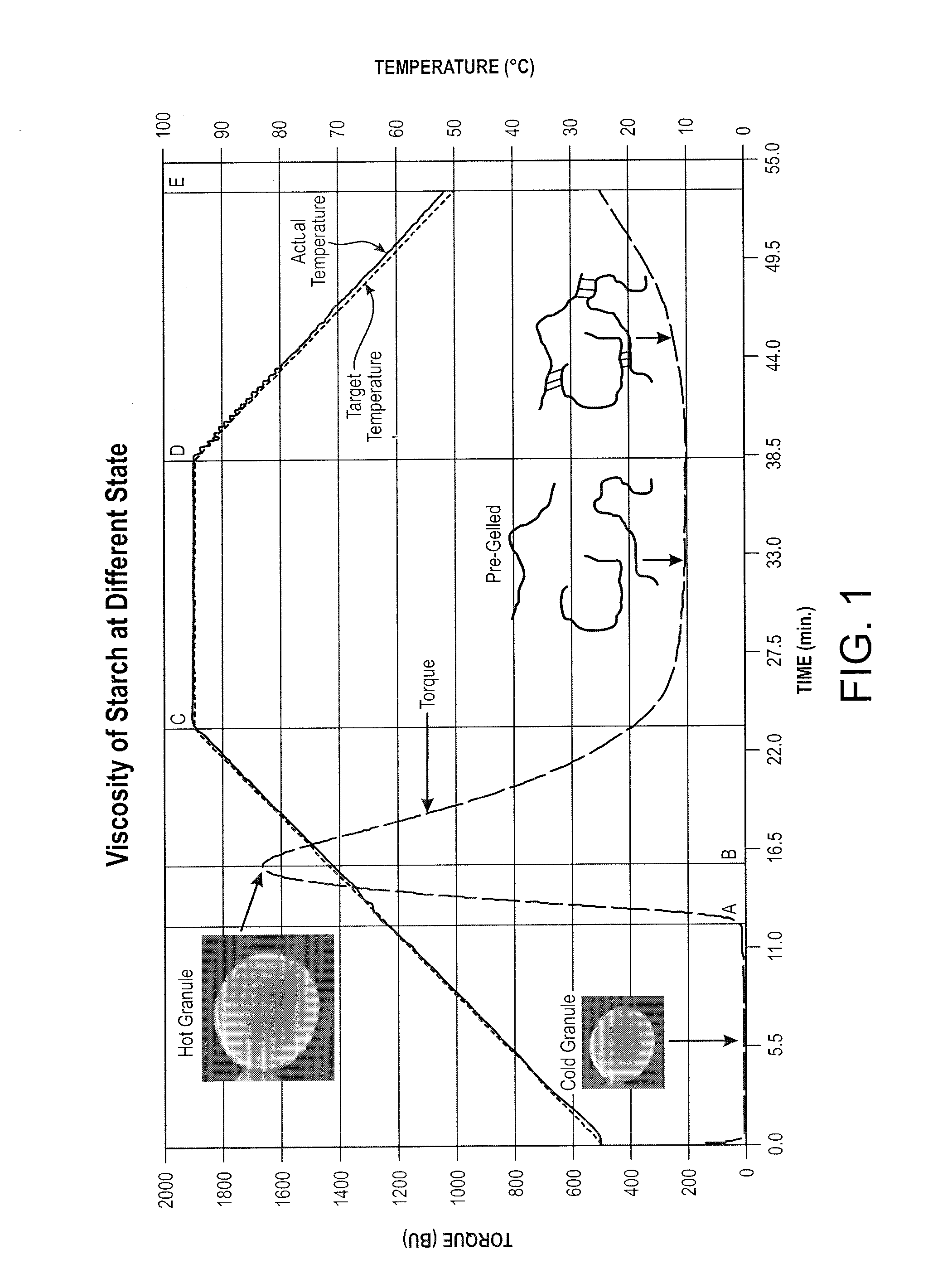

Pregelatinized starch with mid-range viscosity, and product, slurry and methods related thereto

Disclosed are product (e.g., panels), slurry, and methods relating to a pregelatinized starch having a mid-range viscosity (i.e., from about 20 centipoise to about 700 centipoise).

Owner:UNITED STATES GYPSUM CO

Biocompatibility modified starch sponges

ActiveCN101455857AFlexibleActive bleeding is easily controlledAbsorbent padsBandagesFreeze-dryingBiocompatibility Testing

The invention relates to biocompatible modified starch sponge and use of the biocompatible modified starch sponge as a hemostatic material, an anti-adhesion material, a material for promoting tissue healing, a surgical sealant or a wound tissue adhesive. Modified starch is one or a combination of more than one among pre-gelatinized starch, acid modified starch, dextrin, oxidized starch, esterified starch, etherified starch, crosslinked starch, grafted starch and composite modified starch. The sponge is prepared by vacuum freeze drying of the modified starch and other biocompatible hemostatic material, coagulant, plasticizer and so on. The biocompatible modified starch sponge has the advantages that the biocompatible modified starch sponge has flexible form and good biocompatibility, can be directly acted on bloody wound surfaces, avoids the conditions of hypersusceptibility, infection and difficult healing of wounds caused by adoption of hemostatic materials such as animal source / human source collagens, obviously improves the water absorption speed, has larger viscosity, forms a zymoplastic mixture which has good adhesion, calks broken tissues and blood vessels, and is used for hemostasis of active hemorrhage.

Owner:BEIJING UNIVERSAL LIKANG TECH CO LTD

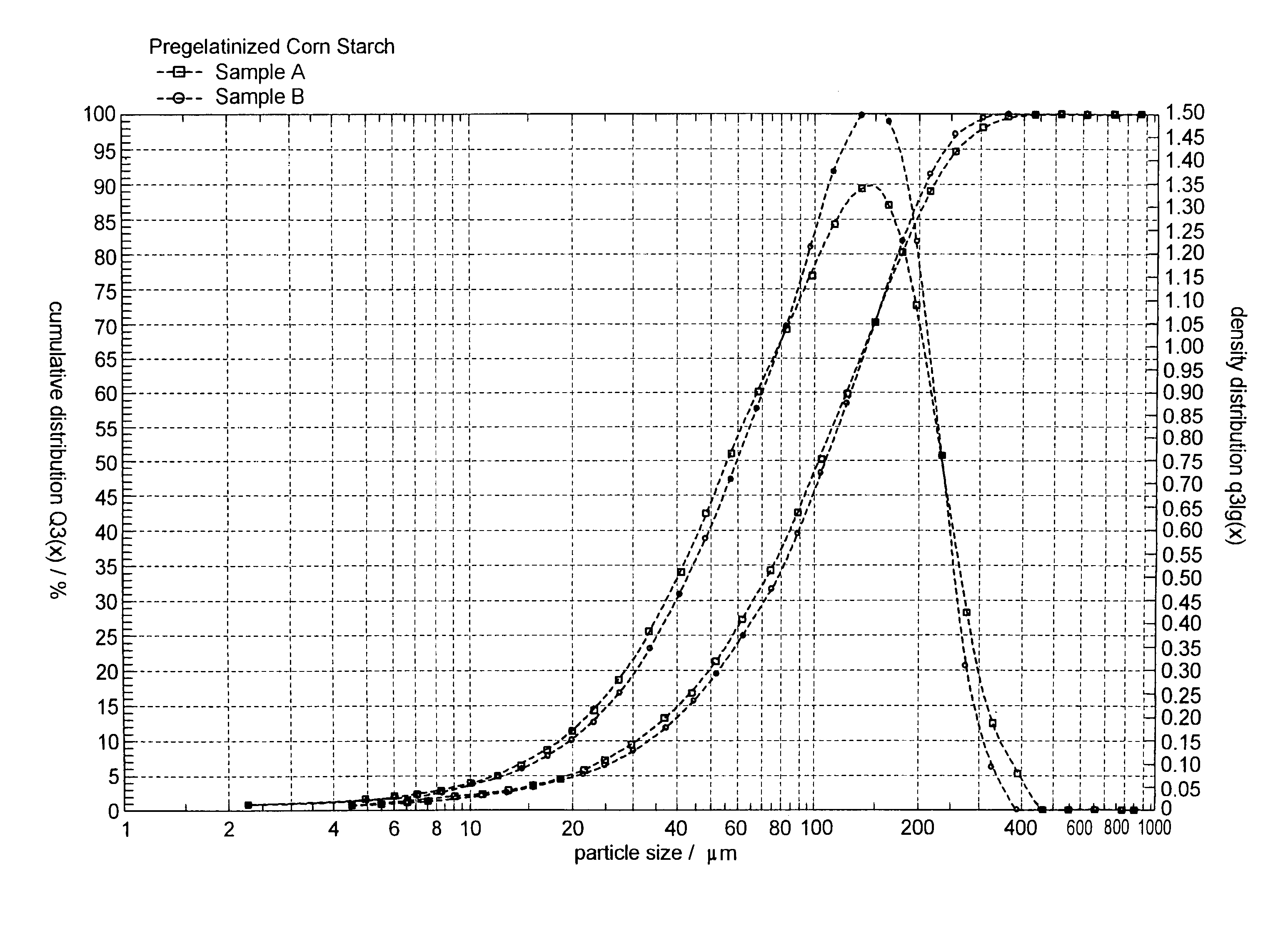

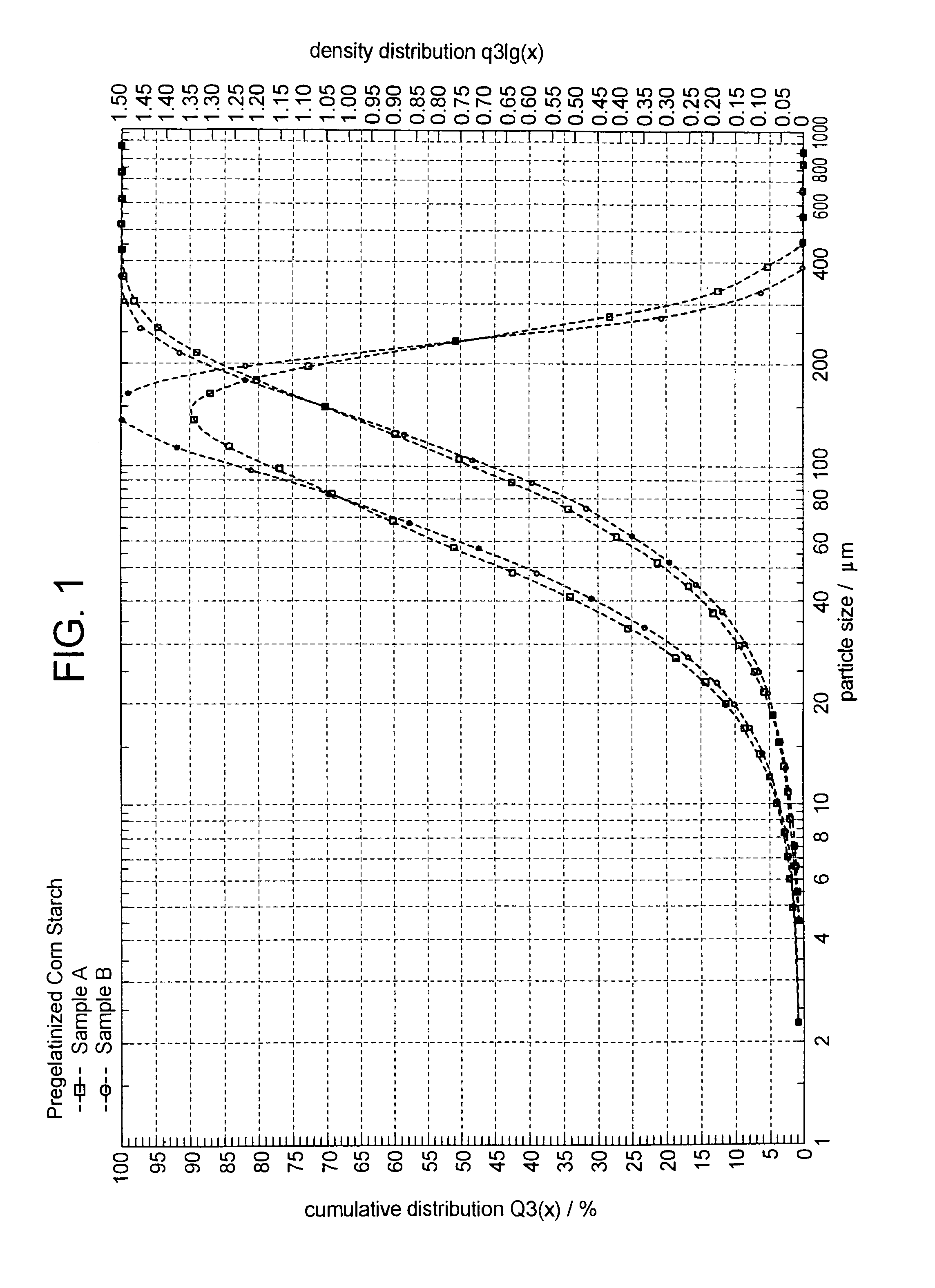

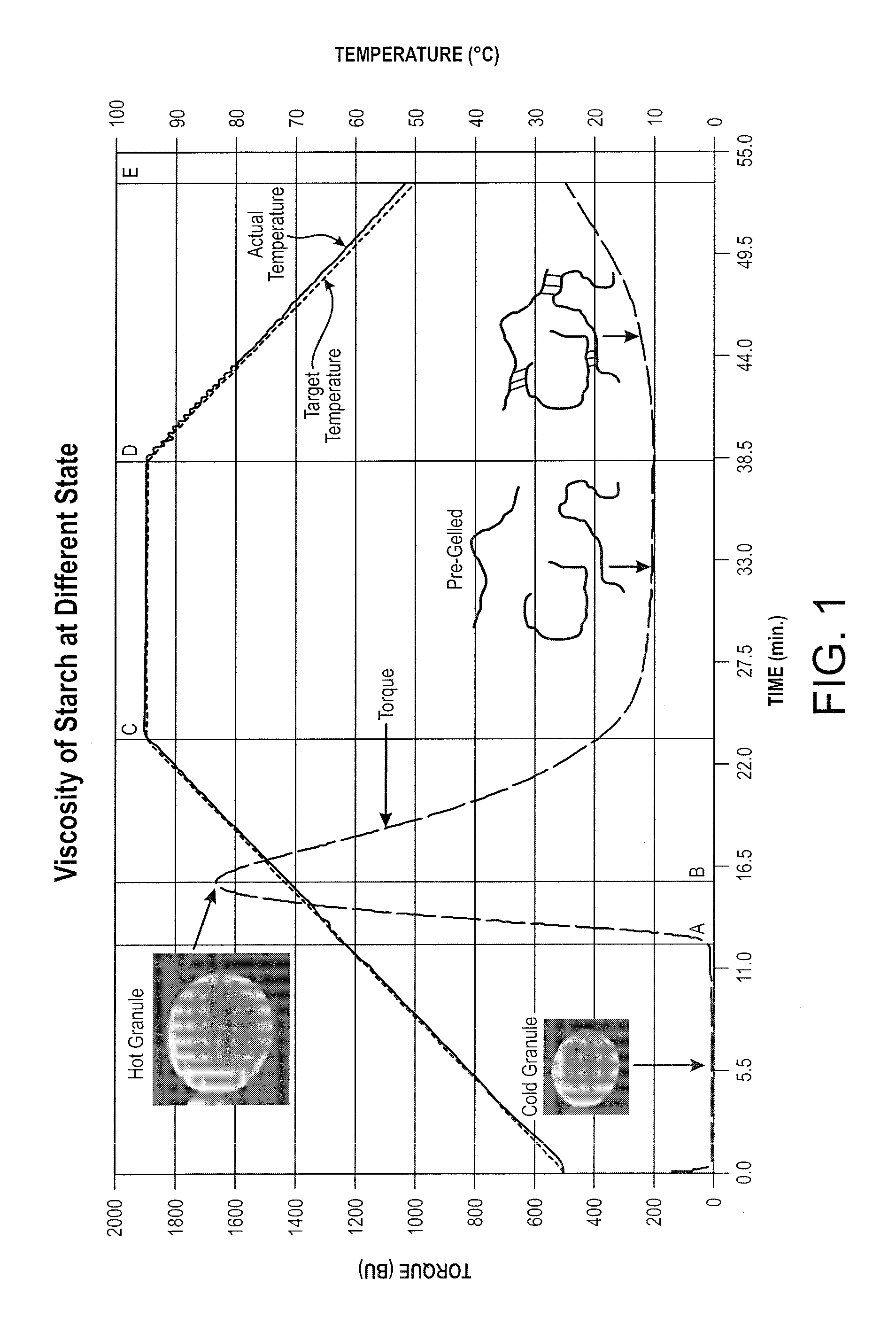

Method of water dispersing pregelatinized starch in making gypsum products

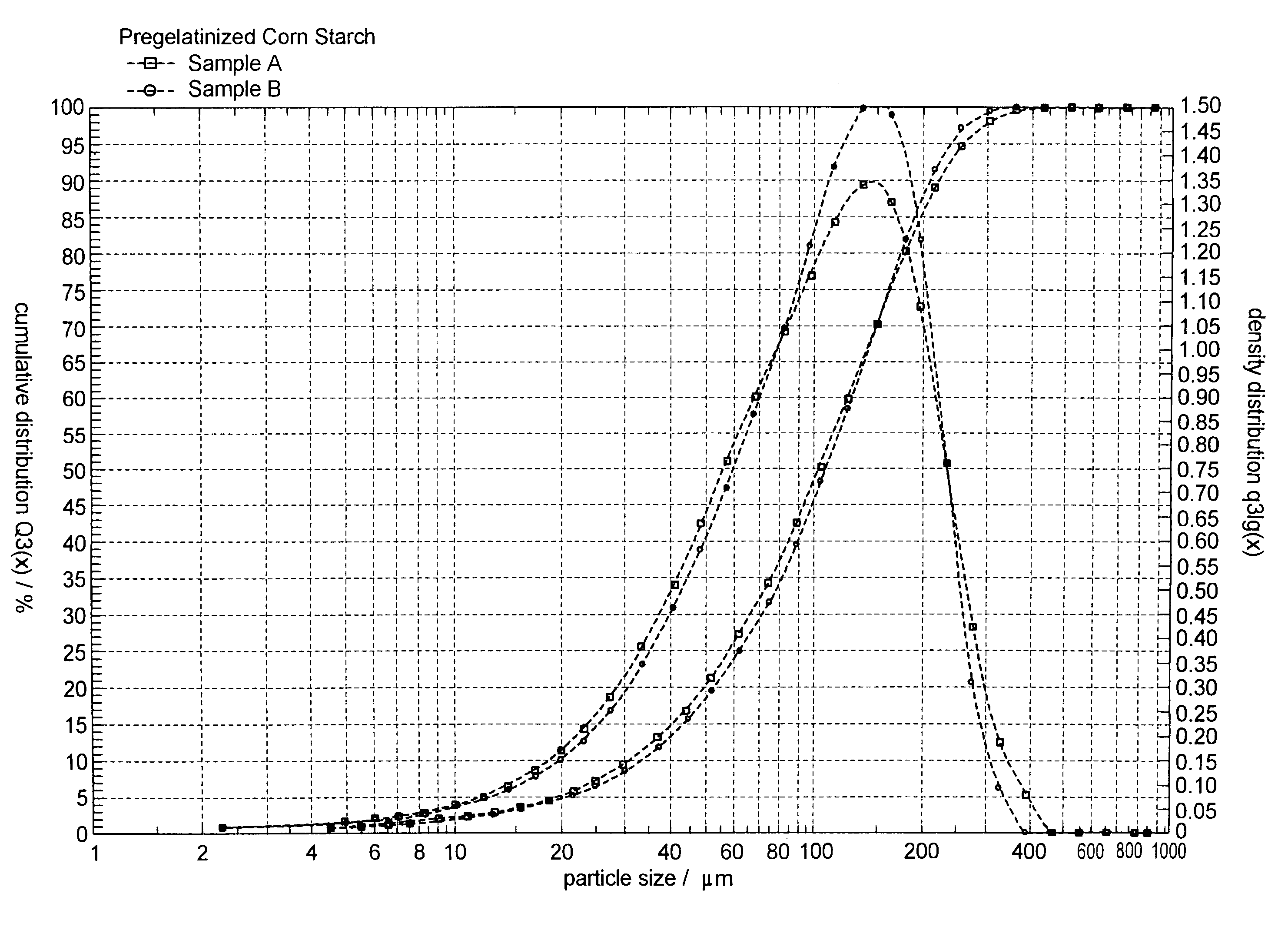

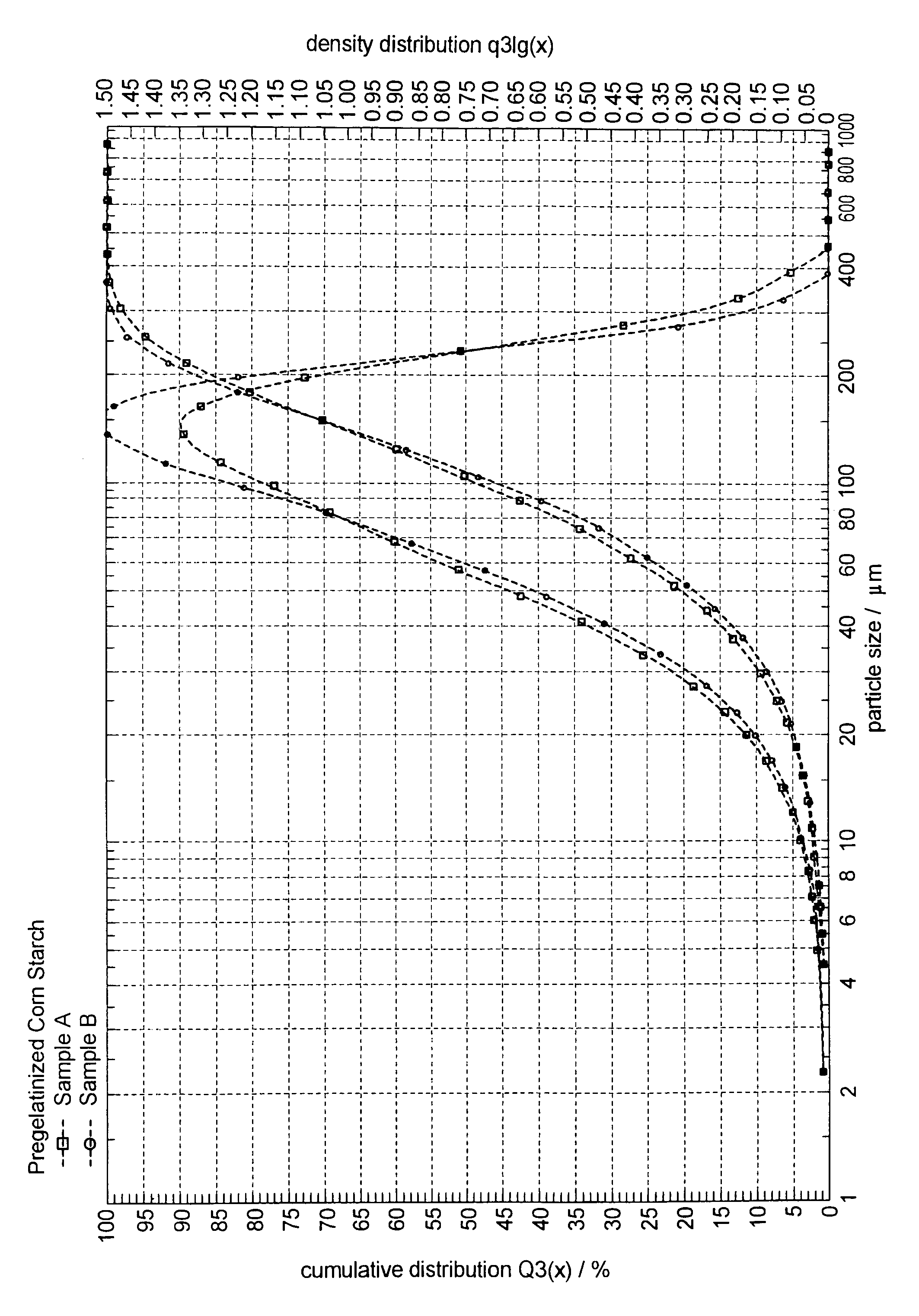

The invention provides in one embodiment a gypsum-containing slurry including stucco and an aqueous pre-dispersion of a pregelatinized starch. Also provided is a method of making gypsum wallboard by providing a pre-dispersion of the pregelatinized starch in water, and adding the pregelatinized starch pre-dispersion to the gypsum-containing slurry. The pregelatinized starch can have a particle size distribution within the following range: d (0.1)=about 20μ-35μ, d (0.5)=about 60μ-110μ, d (0.9)=about 100μ-220μ.

Owner:UNITED STATES GYPSUM CO

Method of preparing pregelatinized, partially hydrolyzed starch and related methods and products

Disclosed are methods relating to an extruded pregelatinized, partially hydrolyzed starch prepared by mixing at least water, non-pregelatinized starch, and acid to form a starch precursor. The acid can be a weak acid that substantially avoids chelating calcium ions or a strong acid in a small amount. In the method, pregelatinization and acid-modification of the starch precursor occurs in one step in an extruder. Also disclosed are methods of preparing board using the starch prepared according to the methods, as well as starches and boards prepared by various methods of the invention.

Owner:UNITED STATES GYPSUM CO

Pregelatinized starch with mid-range viscosity, and product, slurry and methods related thereto

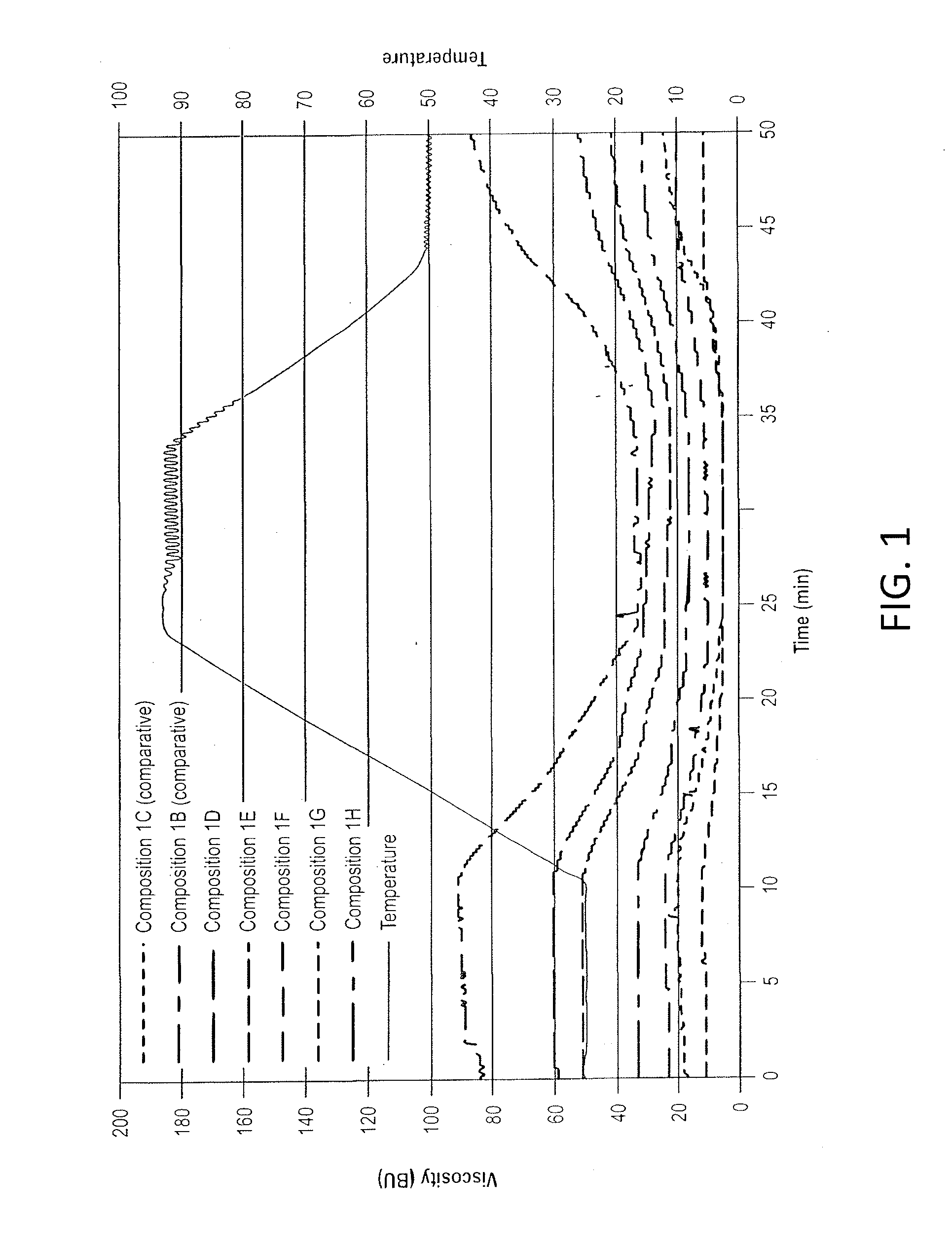

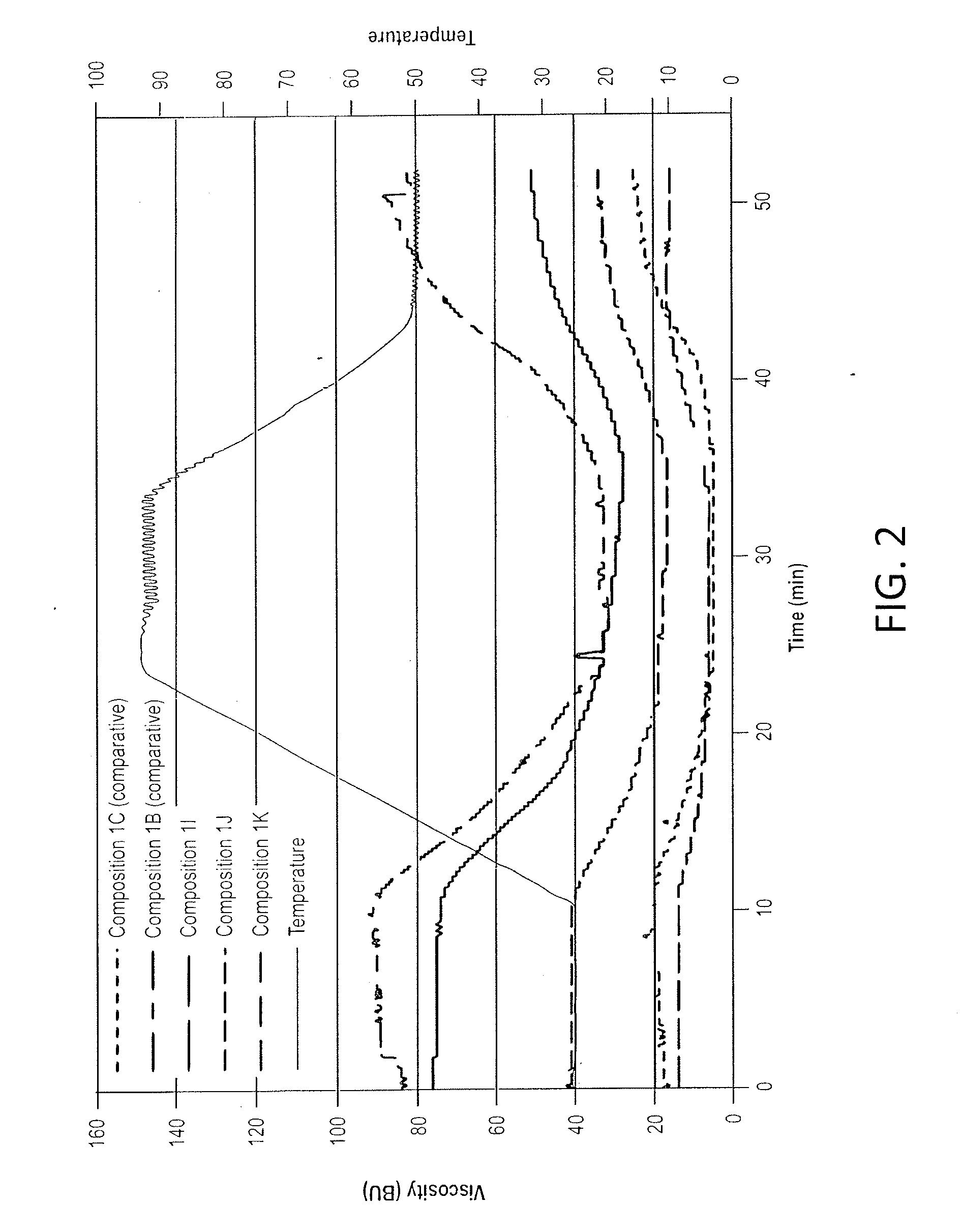

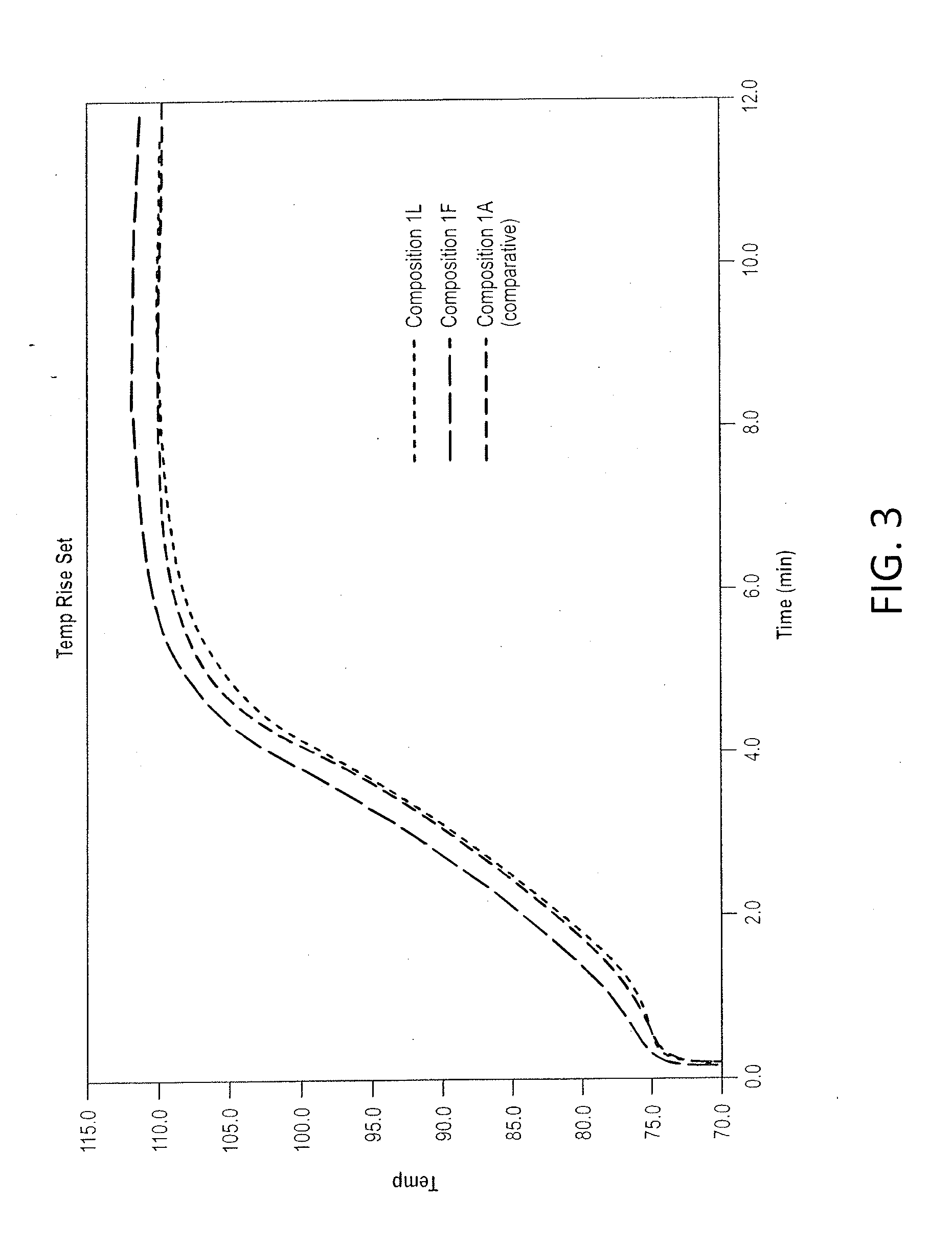

ActiveUS20140113128A1High compressive strengthConstruction materialSolid waste managementSlurryViscosity

Disclosed are product (e.g., panels), slurry, and methods relating to a pregelatinized starch having a mid-range viscosity (i.e., from about 20 centipoise to about 700 centipoise), and an extruded pregelatinized starch.

Owner:UNITED STATES GYPSUM CO

Internal wall putty and production process thereof

The invention belongs to the technical field of building materials, and particularly relates to an internal wall putty which comprises the following components in parts by weight: 150-300 parts of white cement, 500-900 parts of calcium carbonate powder, 10-50 parts of grey desert soil, 1-8 parts of cellulose ether, 7-30 parts of polymer latex powder, 1-10 parts of water repellent, 0.05-3 parts of starch ether and 0.5-7 parts of wood fiber. Compared with the prior art, the internal wall putty has the advantages that 107 glue water or 801 glue water is not used, thus formaldehyde is not contained, the environment is protected; and pregelatinized starch is not used, and the water repellent is added, thus the internal wall putty has the function of preventing water and moisture. In addition, with the white cement and the calcium carbonate powder as the strength basis and the grey desert soil as an auxiliary strength material, the strength of the internal wall putty is ensured; due to the synergistic effect of the cellulose ether and the starch ether, the water-retaining property and the application property of the internal wall putty are ensured; and because the polymer latex powder is added, the flexibility of the internal wall putty and the adhesion of the polymer latex powder and the wall are improved.

Owner:黄明杰

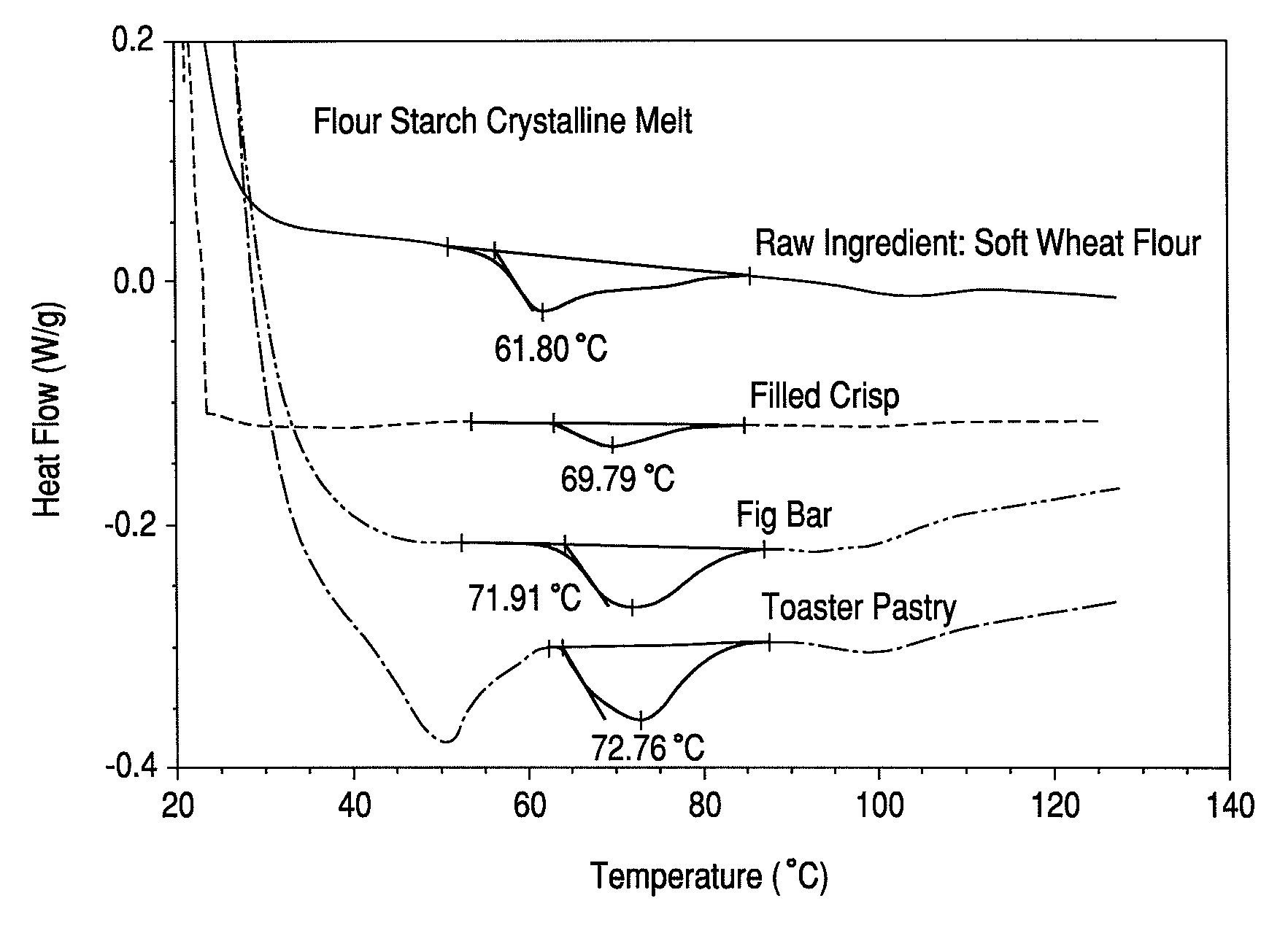

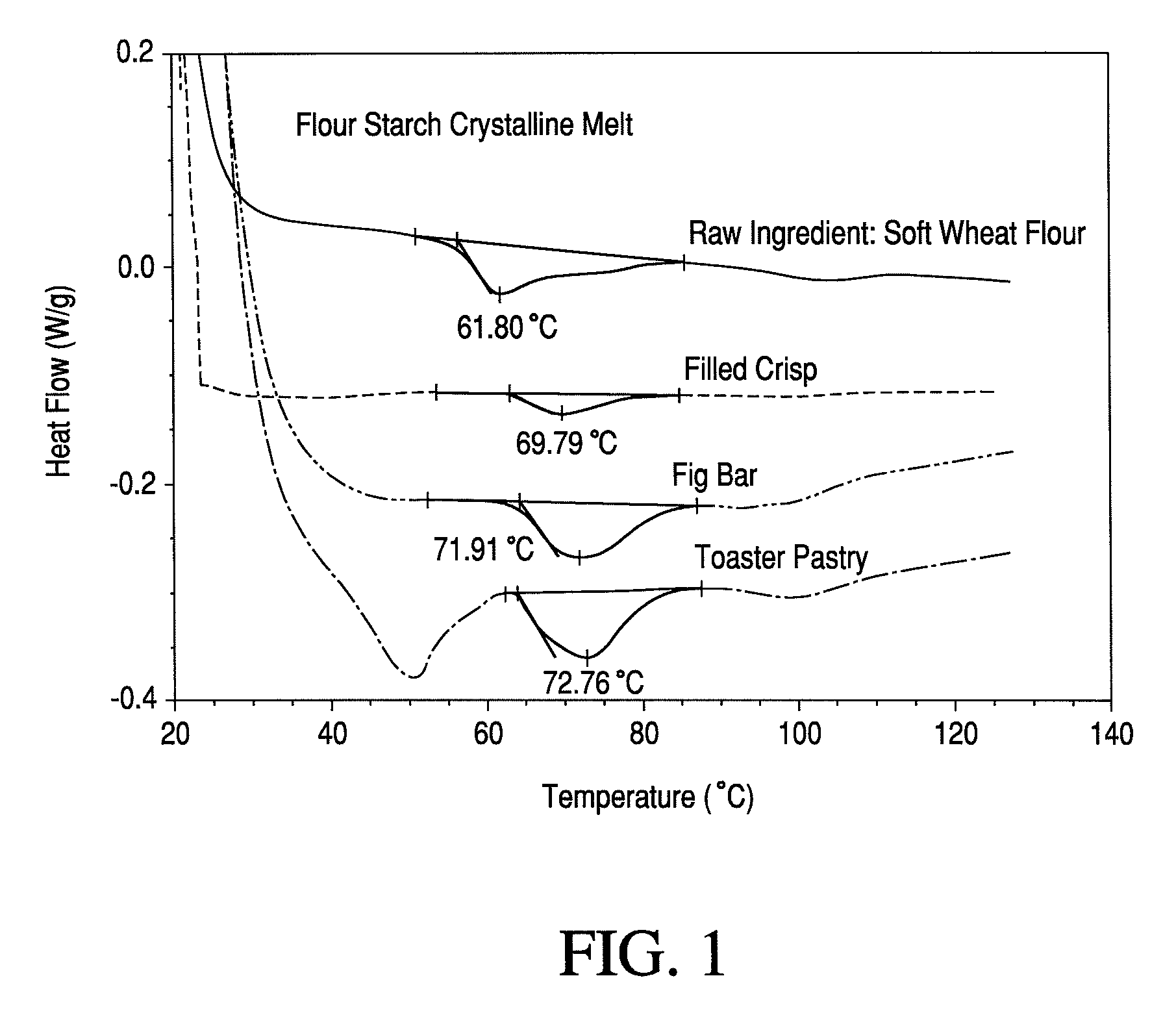

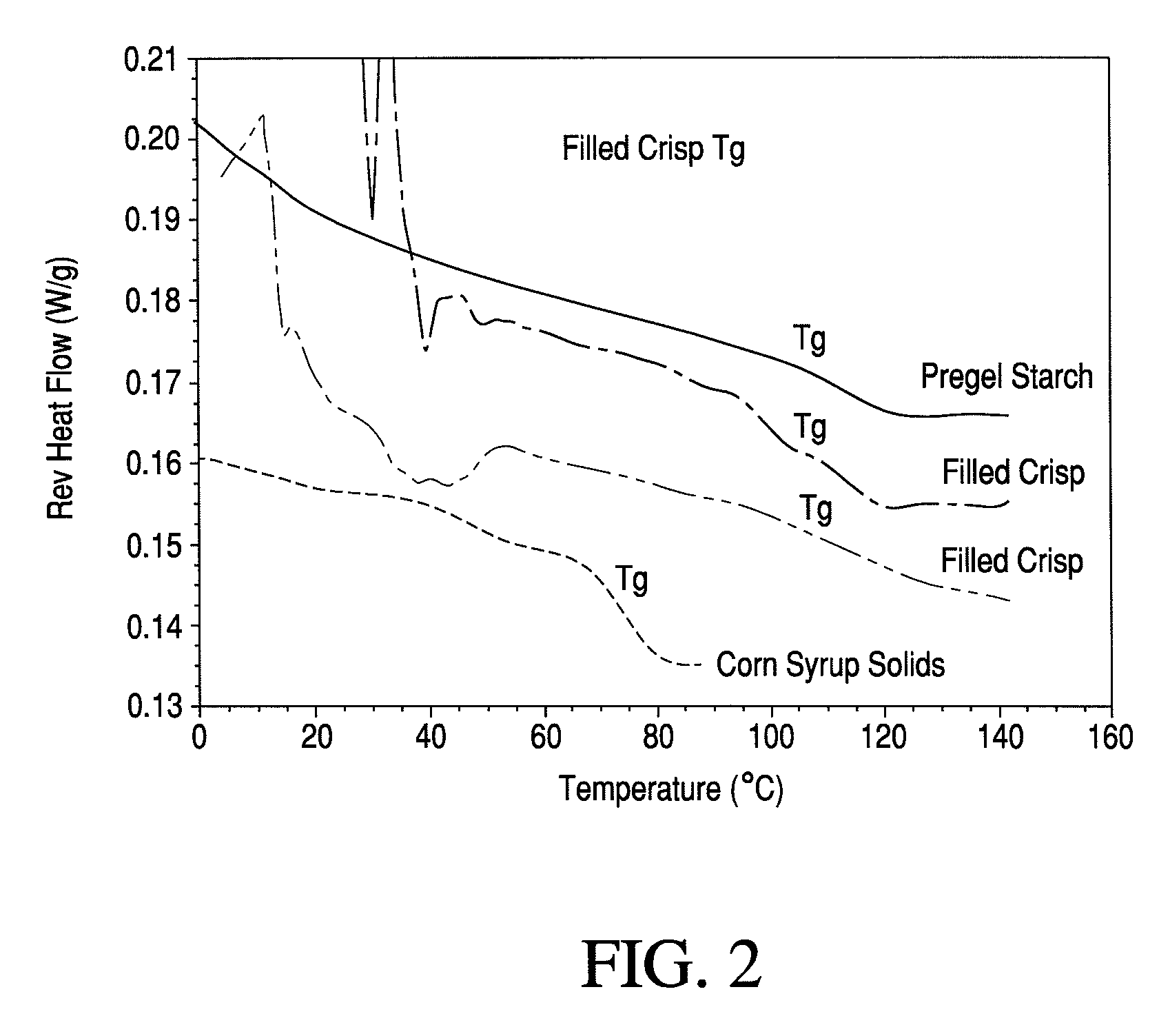

Filled, baked crispy snack having a high moisture content

ActiveUS20090220654A1Improve gelatinizationIncreased TgDough treatmentConfectioneryHigh resistanceReady to eat

A shelf-stable, filled, baked crispy snack which possesses a crispy textured casing and a moist, soft textured filling over a prolonged period of time is obtained by formulating a casing which when baked has a high glass temperature (Tg) at a high moisture content. Increasing the degree of starch gelatinization to increase the Tg may be achieved during baking and by the addition of a pregelatinized starch. The high Tg baked casing permits the use of a high moisture content filler in high amounts to provide a shelf-stable substantial textural dichotomy in the filled, baked, crispy snack. The filled, baked snack exhibits an unexpectedly high resistance to deformation or peak force at high baked casing moisture contents. The baked snack is ready-to-eat out of the packaging and does not have to be toasted, microwaved or further baked, cooked, or heated for consumption, or to achieve a crisp textured casing.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Low calorie injection molded starch-based pet chew bodies

Injection molded starch-based chew products are provided which are tough, non-brittle, non-slimy, quick to hydrate, low calorie and high in total dietary fiber. The starch-based chew products are formulated from a combination of resistant starch and pregelatinized starch or pre-cooked flour along with plasticizer, water, lubricants and other optional ingredients.

Owner:SERGEANTS PET CARE PRODS

Water soluble adhesive

InactiveCN101058701AGood adhesionStrong adhesionNon-macromolecular adhesive additivesStarch adhesivesCellulosePolymer science

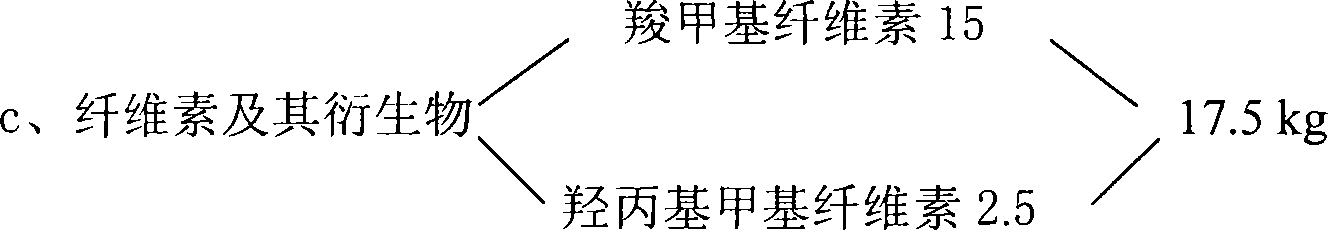

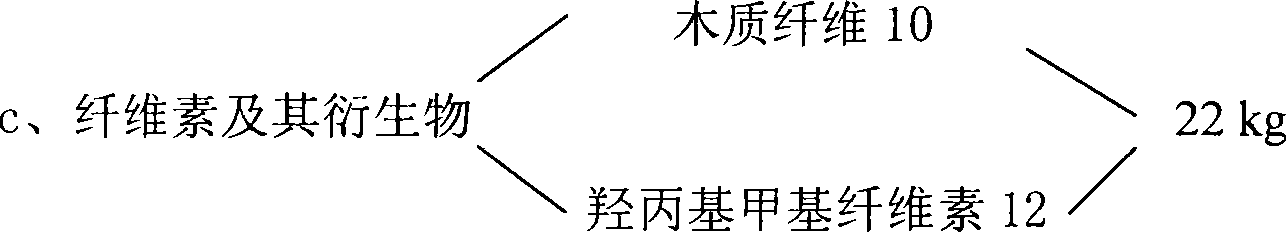

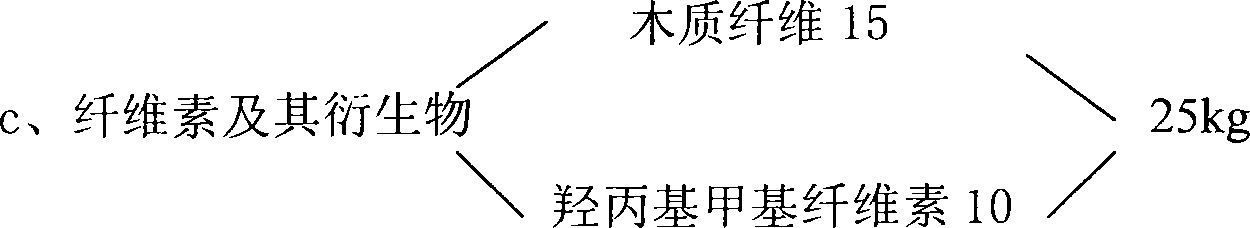

The invention discloses a water-soluble adhesive, which comprises the following parts: 30-65% pregelatinized starch, 10-20% 2488 polyvinyl alcohol, 13-37% cellulose and its derivant, 0-20% redispersion emulsion powder, 0. 15-0. 5% thickener and 0. 3-0. 8% high-activity zinc oxide, wherein each component is stirred evenly under the drying condition to form the product; the grain size of pregelatinized starch is 20-40 or 80-100 order, which can be allocated into gel powder to form common glue with 6% water after stirring 30min or interior-exterior wall putty powder adhesive after blending diflying powder or cement with weight at 0. 2: 10 directly.

Owner:陈峰磊

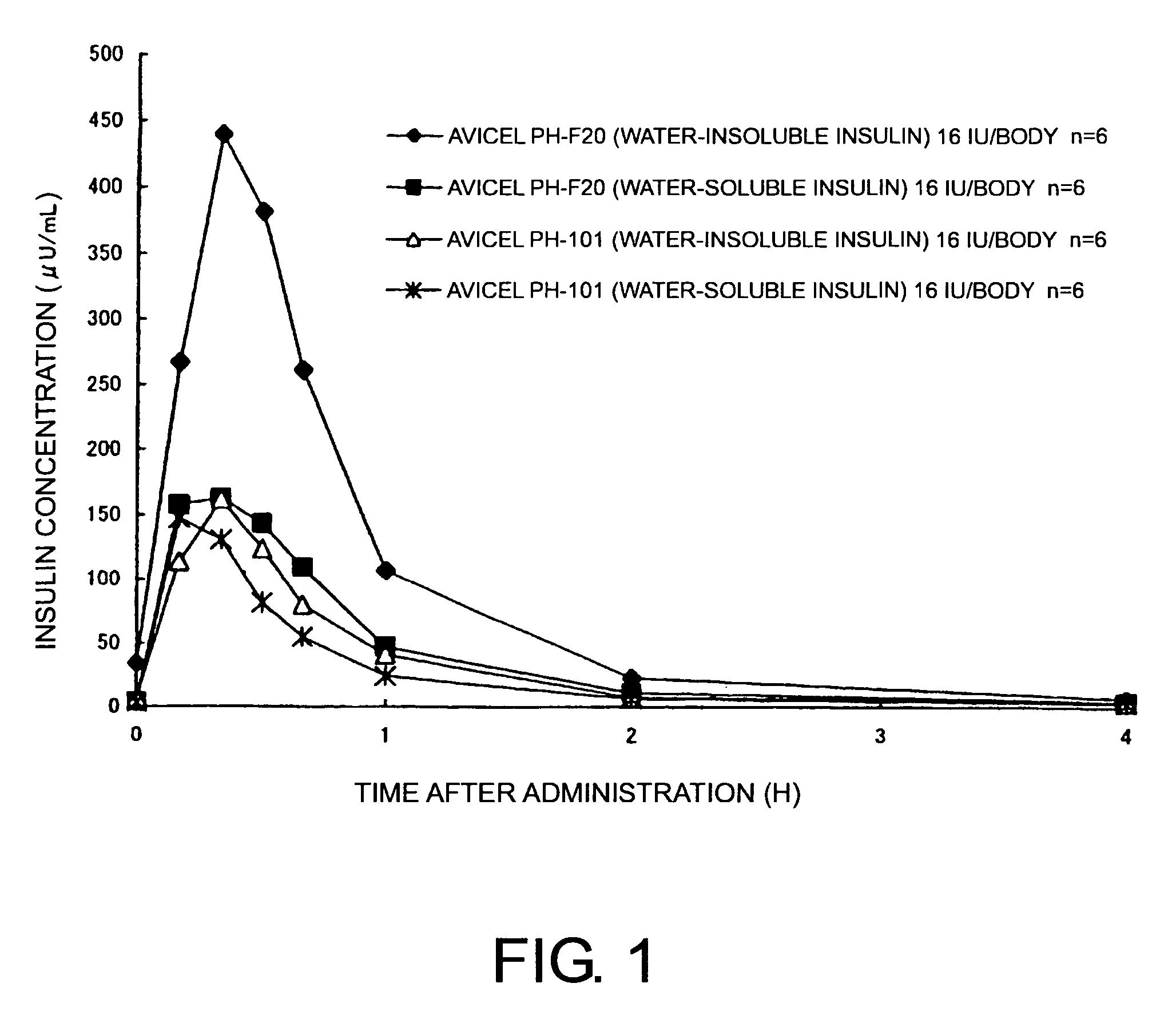

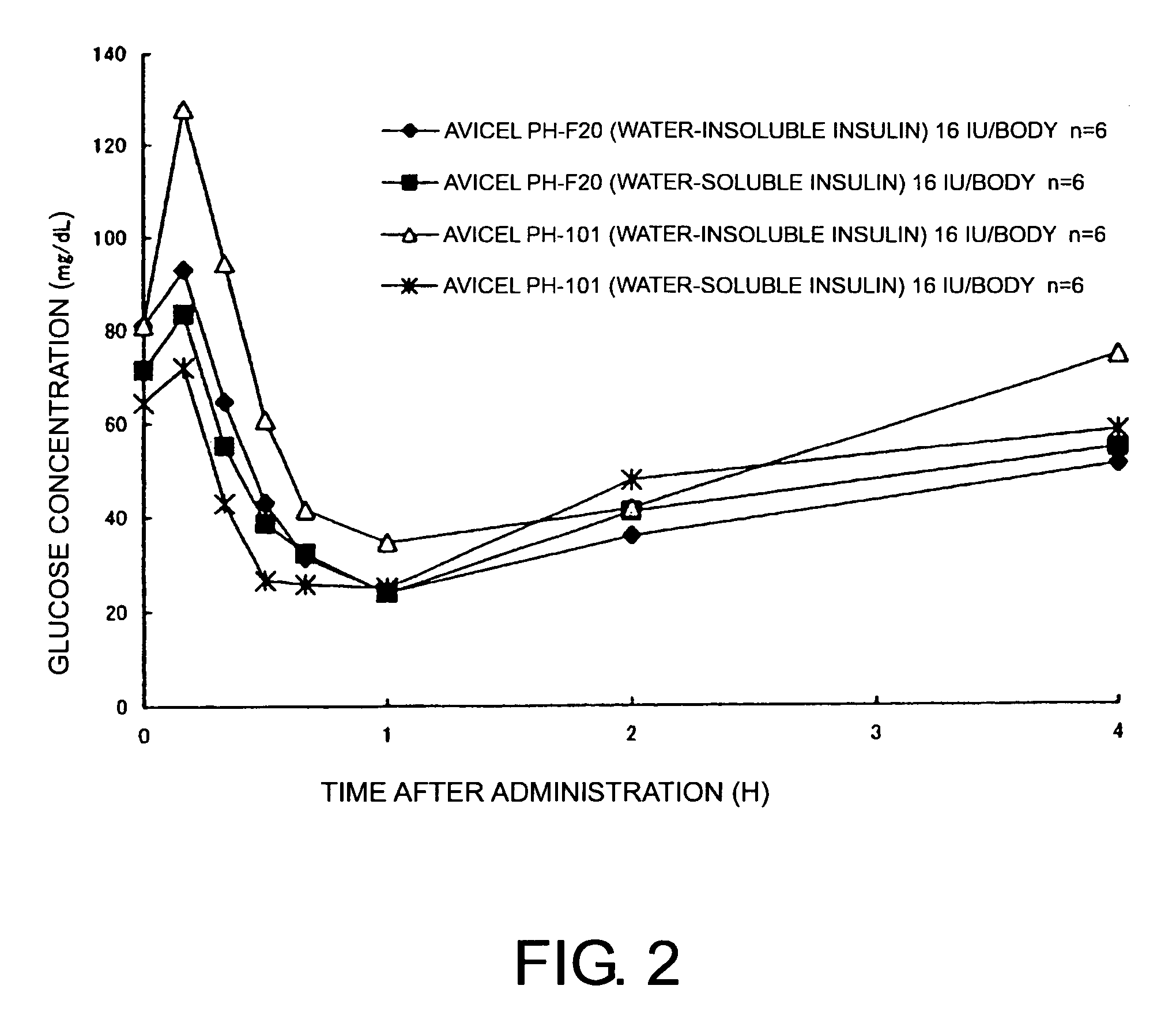

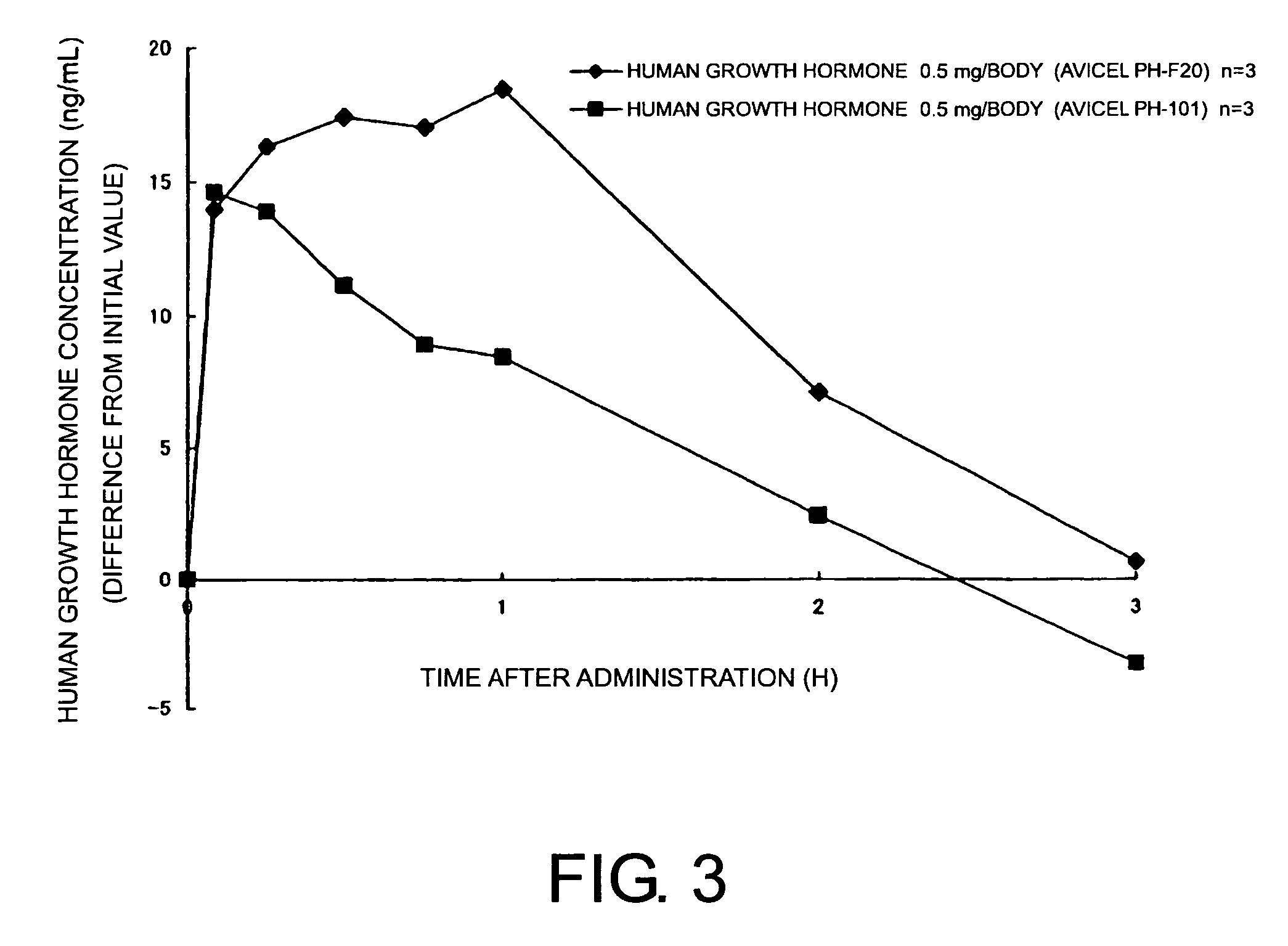

Compositions for nasal administration of pharmaceuticals

Compositions for nasal administration, which comprise a pharmaceutical, a physiologically active peptide, or a peptide-related compound, and as the carrier thereof, crystalline cellulose with a specific particle diameter and / or partially pregelatinized starch are provided. Such compositions improve the in vivo absorption efficiency of pharmaceuticals.

Owner:SHIN NIPPON BIOMEDICAL LAB

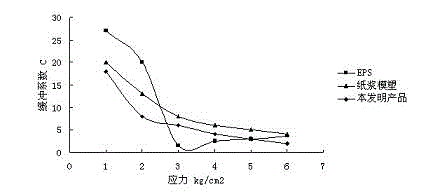

Wood-residue fiber foamed cushion packaging material and preparation method thereof

The invention provides wood-residue fiber foamed cushion packaging material and a preparation method thereof, which can be used to solve the problem of being not environment friendly and high cost of the existing packaging material. The basic components and corresponding dry mass fraction of the basic components are as follow: 31-35 parts of wood-residue fiber; 20-30 parts of pre-gelatinized starch; 10-13 parts of polyvinyl alcohol gum; 3-7 parts of a foaming agent; 1-4 parts of activator; and 5-10 parts of a nucleating agent. The preparation method comprises the processes of preparation of raw materials, billet making and mould pressing. The used material resource is rich in source, the energy consumption and cost of raw material are low. The manufacturing process is simple and the production cycle is short, and there is no pollution to the environment. The packaging material has the advantages of good vibration damping and cushioning performance, antistatic performance, corrosion protection, wide range of application and good prospect of market application. With the progress and development of such technology, the packaging material is expected to become the ideal substitute of the foam packaging material.

Owner:NORTHEAST FORESTRY UNIVERSITY

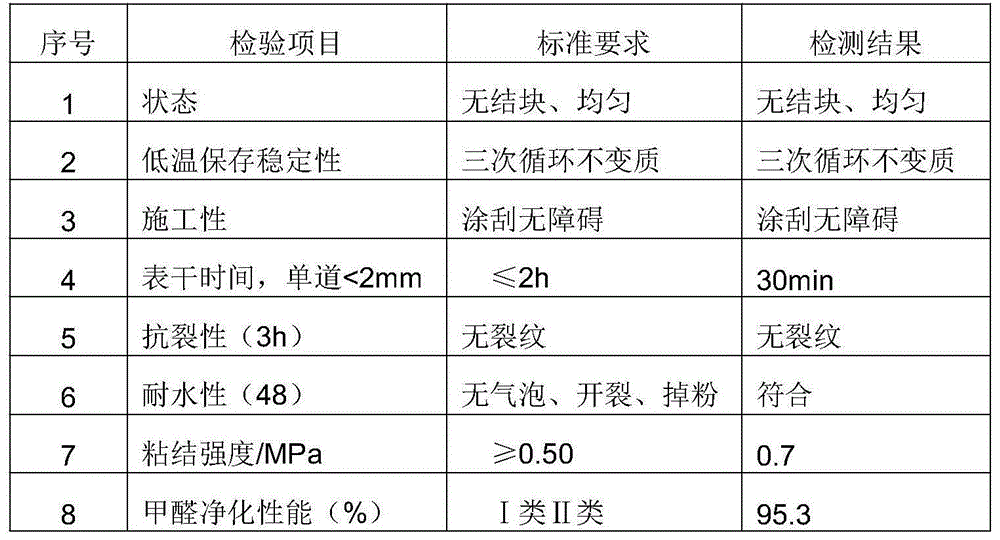

Environment-friendly diatom ooze composite and preparation method thereof

ActiveCN105110761AGood construction performanceImprove water absorptionHazardous substancePolyvinyl alcohol

The invention discloses an environment-friendly diatom ooze composite and a preparation method thereof, and belongs to the technical field of composites for buildings. The environment-friendly diatom ooze composite is prepared from, by mass, 30-50% of diatomite, 3-12% of heavy calcium powder, 8-20% of quartz sand, 10-15% of pH conditioning agents, 6-10% of calcined kaolin, 4-10% of talcum powder, 5-10% of sepiolite, 2-5% of pigments, 2-4% of pregelatinized starch, 1-3% of hydroxypropyl methyl cellulose, 1-2% of dispersible latex, 1-2% of starch ether, 0.5-2% of sodium tripolyphosphate, 0.5-2% of sodium hexametaphosphate, 0.5-1% of polyvinyl alcohol, 0.1-0.5% of guar gum and 0.1-3% of nanometer titania. The preparation method is simple and easy to construct, and the diatom ooze is porous matter, can adsorb and decompose hazardous substances such as methanal and methylbenzene and has the functions of regulating humidity and removing peculiar smell.

Owner:宁波鉴合科技有限责任公司

High-temperature self-gelation and baking-resistant cake stuffing pre-mix powder and preparation and application thereof

The invention discloses high-temperature self-gelation and baking-resistant cake stuffing pre-mix powder and preparation and application thereof. The cake stuffing pre-mix powder comprises the following components: 40-50 percent pre-gelatinized starch, 12-15 percent methyl cellulose, 1-12 percent xanthan gum, 20-25 percent sorbitol powder, 8-15 percent powdered sugar and 3-5 percent corn starch. The cake stuffing is in a half-solidification state and has a certain viscosity when being stirred with the pre-mix powder; the situation that a feeding head leaks due to the good liquidity of paste is avoided when the paste is filled in a paste filling machine; meanwhile, the viscosity degree can meet the requirements of normal extrusion of the paste filling machine, and the normal production efficiency is not affected; during the baking, the half-solidification stuffing paste can be automatically solidified into a solid state, the overflowing boiling phenomena of the stuffing can be reduced,a cavity can not be formed in the cake, and the organization and appearance of the cake can not be affected; and the water in the baked stuffing can not transfer to the cake embryo, so that the watercontent in the cake embryo can not increase to affect the guarantee period of the cake. According to the invention, the cake paste is first filled in the cake stuffing, and then the high-temperature baking step is carried out, so that the guarantee period risks of the cake are greatly reduced.

Owner:广州合诚实业有限公司

High Starch Light Weight Gypsum Wallboard

InactiveUS20100239886A1High strengthReduce weightLamination ancillary operationsSolid waste managementGlass fiberFiber

The invention generally provides gypsum-containing slurries including stucco, naphthalenesulfonate dispersant, and pregelatinized starch. The naphthalenesulfonate dispersant is present in an amount of about 0.1%-3.0% by weight based on the weight of dry stucco. The pregelatinized starch is present in an amount of at least about 0.5% by weight up to about 10% by weight of pregelatinized starch by weight based on the weight of dry stucco in the formulation. Other slurry additives can include trimetaphosphate salts, accelerators, binders, paper fiber, glass fiber, and other known ingredients. The invention also comprises the gypsum-containing products made with such slurries, for example, gypsum wallboard, and a method of making gypsum wallboard.

Owner:UNITED STATES GYPSUM CO

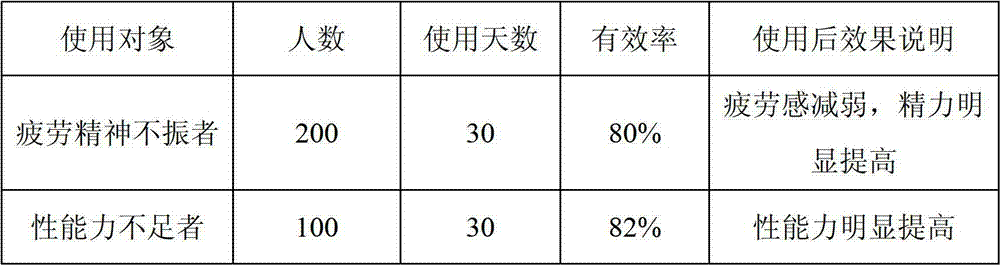

Maca buccal tablets and preparation method thereof

InactiveCN102949431AFacilitated releaseAvoid residual riskAntinoxious agentsPharmaceutical non-active ingredientsSucroseSaccharum

The present invention discloses maca buccal tablets and preparation method thereof. Per 1000 g of the maca buccal tablets is prepared from the following raw materials, by weight, 300-400 parts of a maca fresh product, 400-500 parts of a sugar material, 150-200 parts of pregelatinized starch, and 1-2 parts of a sour agent. According to the present invention, compared with the traditional buccal tablets, the maca buccal tablets have the following characteristics that: the defect that the existing buccal tablets are not suitable for diabetes patients due to sucrose in the existing buccal tablets is overcome; an advanced nanometer grinding technology is adopted to replace the traditional organic extraction technology so as to avoid risk of organic extractant remained in the buccal tablets; the maca root is grinded into nanometer powder during the maca buccal tablet preparation process, such that most of active ingredients in the maca are easily released, and easily absorbed by human body; and the product adopts the advanced buccal tablet production technology, does not require water during taking, and can be taken directly through dissolving in mouth, such that taking is convenient.

Owner:上海中海龙高新技术研究院

Cool, fragrant and sweet additive for cigarettes and preparation method and application of cool, fragrant and sweet additive

InactiveCN108669622AIncrease appetiteIncrease pleasureTobacco preparationTobacco treatmentAcetic acidNicotiana tabacum

The invention relates to a cool, fragrant and sweet additive for cigarettes and a preparation method and application of the cool, fragrant and sweet additive, and belongs to the field of cigarettes and tobacco. 20%-35% of menthyl acetate, 20%-50% of beta-cyclodextrin or pregelatinized starch and 30%-45% of deionized water are mixed in percentages by mass, and are ground for 1-4 hours at the room temperature to obtain paste, and the paste is placed in a light-shading and shade place in an exposed manner for 12-36 hours to obtain the additive. By the additive, the fragrance of the cigarettes canbe increased, the cigarettes are cool, fragrant and sweet obviously, and have abundant fragrance, irrigation is reduced, and smoking satisfaction and enjoyment of the cigarettes are improved.

Owner:CHINA TOBACCO YUNNAN IND

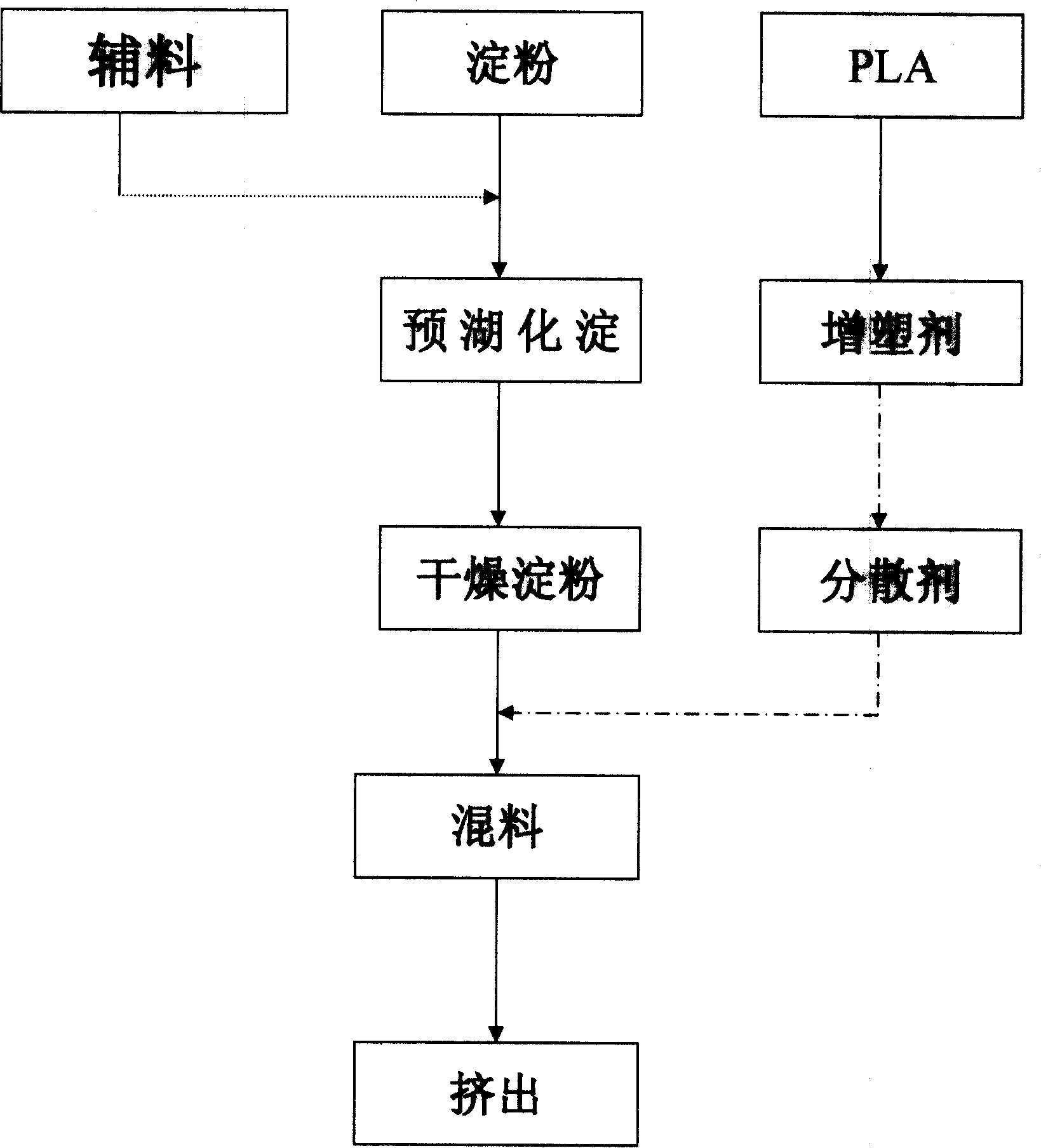

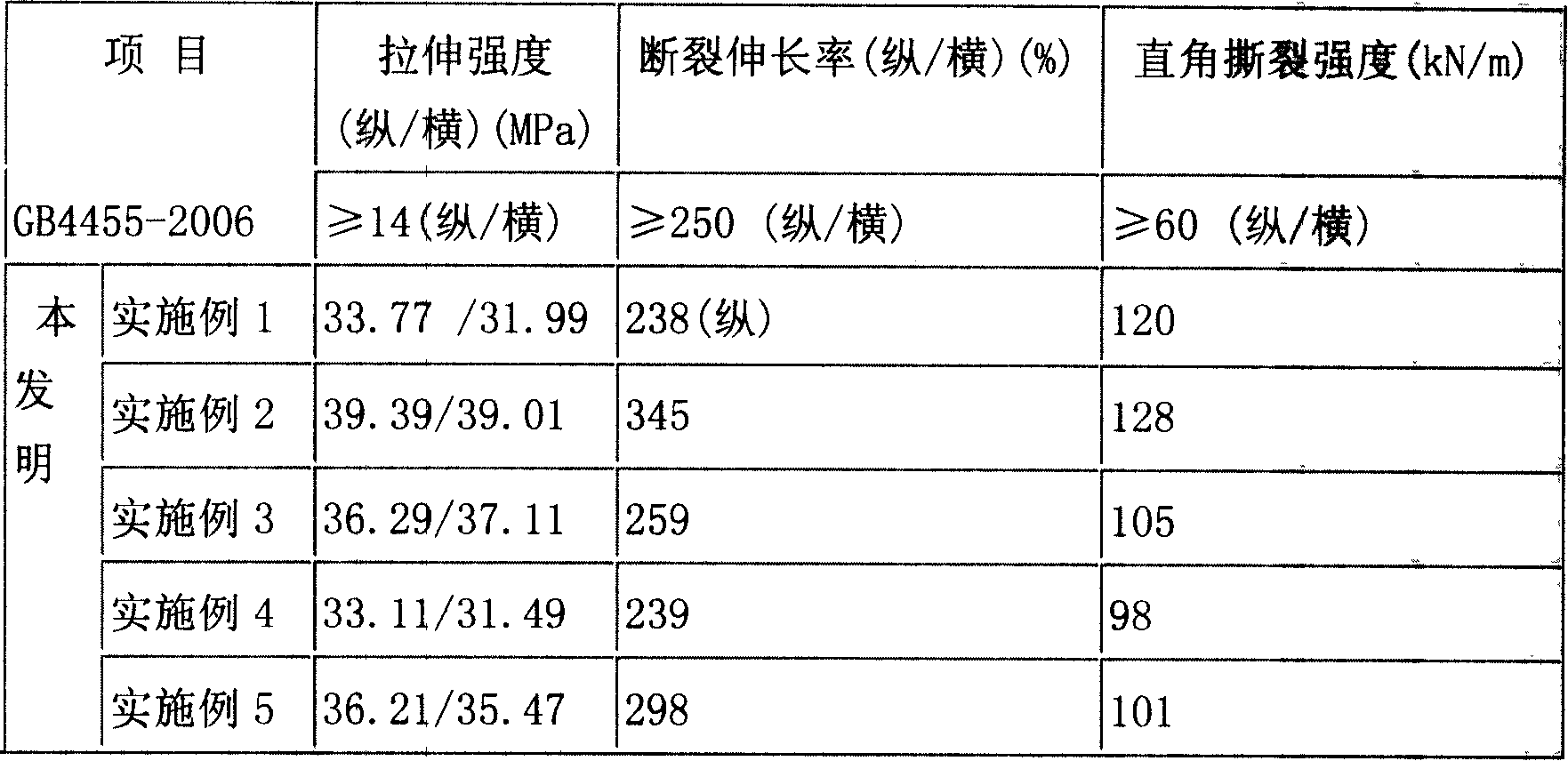

Nano composite biological degradation plastic and preparing method thereof

The present invention discloses one kind of nanometer composite biodegradable plastic and its preparation process. The nanometer composite biodegradable plastic consists of polylactic acid 200-600 weight portions, modified starch 300-700 weight portions, nanometer montmorillonite 200-400 weight portions, plasticizer 25-55 weight portions and dispersant 10-70 weight portions. The modified starch is polyglycol and glycerin modified pregelatinized starch comprising starch 100 weight portions, polyglycol 0.1-10 weight portions and glycerin 0.1-10 weight portions. The nanometer composite biodegradable plastic may be applied in producing high quality agricultural film and packing film with obvious biodegradability, high mechanical and physical performance.

Owner:LUDE GASOLINEEUM CHEM BEIJING

Method for producing high-flowability pregelatinized starch

InactiveCN102134281AImprove liquidityLoose structurePharmaceutical non-active ingredientsFood preparationQuality controlMixed materials

The invention provides high-flowability pregelatinized starch and a method for preparing the same by mechanical activation, which belong to the technical field of starch modification processing. The method comprises the following steps: uniformly mixing starch and a certain amount of flow aid in a high-speed mixer uniformly, pre-drying the starch by using heat generated in a high-speed mixing process, and controlling the water content in the starch to be lower than 15 percent; and placing the uniformly mixed materials in a ball mill containing a milling medium, well regulating the temperature for constant-temperature dissolution in water, performing mechanical activation for a certain time period, taking the starch out, and sieving the starch with a 80 to 100-mesh sieve. The method has the advantages of simple process and equipment, small investment, environmentally-friendly process, low production cost, easy product quality control and the like. The prepared product has the characteristics of high flowability, loose structure, uniform particles and precision control over pregelatinization degree and can be widely used in industrials and fields of foods, pharmaceuticals, chemicals and the like.

Owner:GUANGXI UNIV +2

Environmentally-friendly interior wall putty powder, putty paste, and preparation methods of putty powder and putty paste

InactiveCN103525151AReduce the content of heavy metal elementsImprove impact resistanceFilling pastesCrack resistanceHydroxyethyl cellulose

The invention discloses an environmentally-friendly interior wall putty powder, a putty paste, and preparation methods of the putty powder and the putty paste. The putty powder comprises, by weight, 45-72 parts of talcum powder, 18-30 parts of heavy calcium carbonate, 5-10 parts of calcium bentonite, 0.6-1.5 parts of carboxymethylcellulose sodium, 1-5 parts of polyacrylamide, 0.3-1.7 parts of hydroxyethyl cellulose, 0-20 parts of building gypsum powder, 0-0.8 parts of carboxymethyl cellulose, 0-8 parts of alpha-pregelatinized starch, 0-3 parts of hydroxypropyl methyl cellulose and 0-0.5 parts of sodium dodecyl benzene sulfonate. The preparation method of the putty powder comprises the following steps: uniformly mixing the above components, stirring for 10-15min, and discharging the above obtained mixture. The putty paste is obtained by adding water having a weight 0.3-0.5 times the weight of the putty powder and uniformly stirring. The putty powder / putty paste contains no or a tiny amount of formaldehyde and an extremely low content of heavy metal elements, is an environmentally-friendly product, and has the advantages of excellent impact resistance, excellent hydrophobicity and waterproofness, high elasticity, good crack resistance, stable storage and easy construction.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

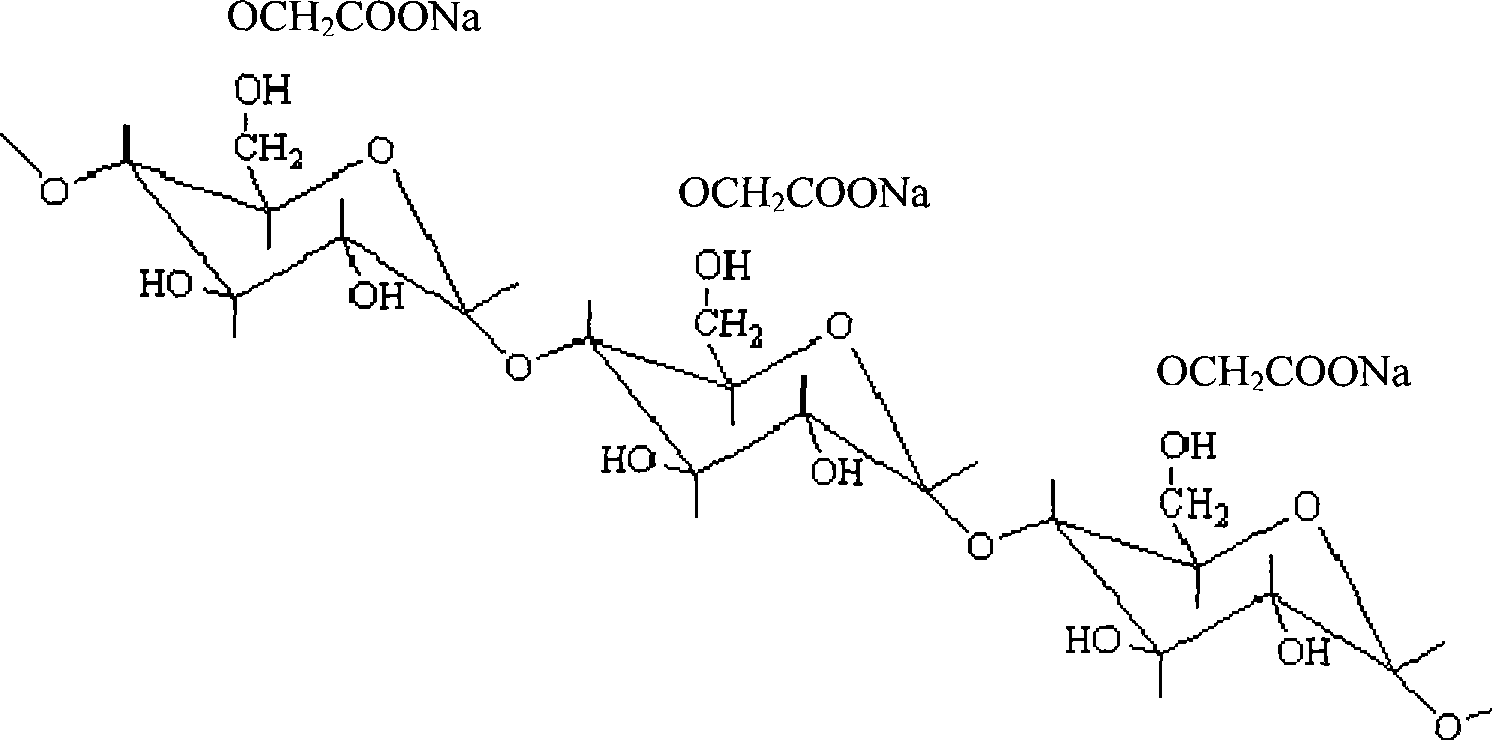

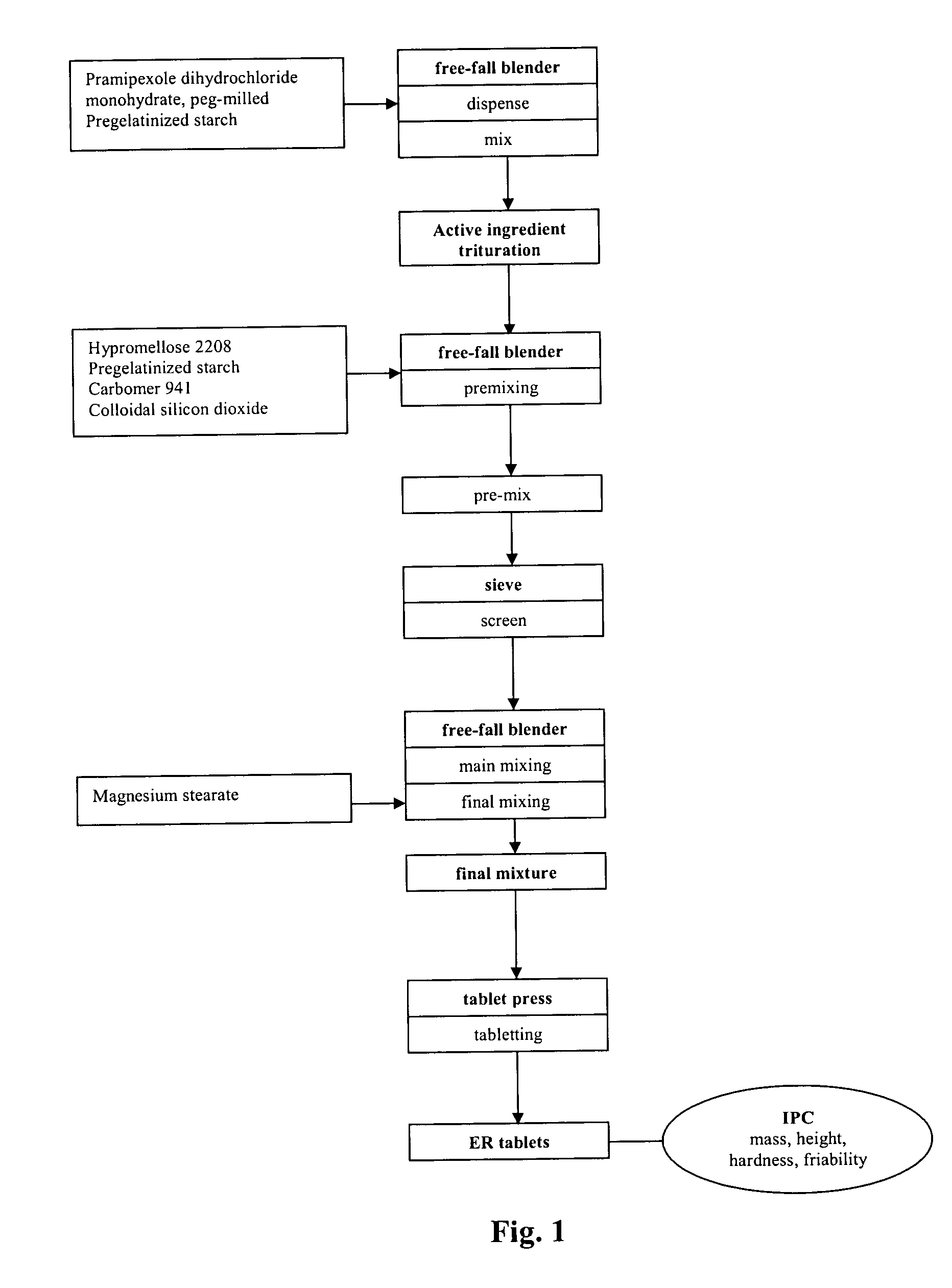

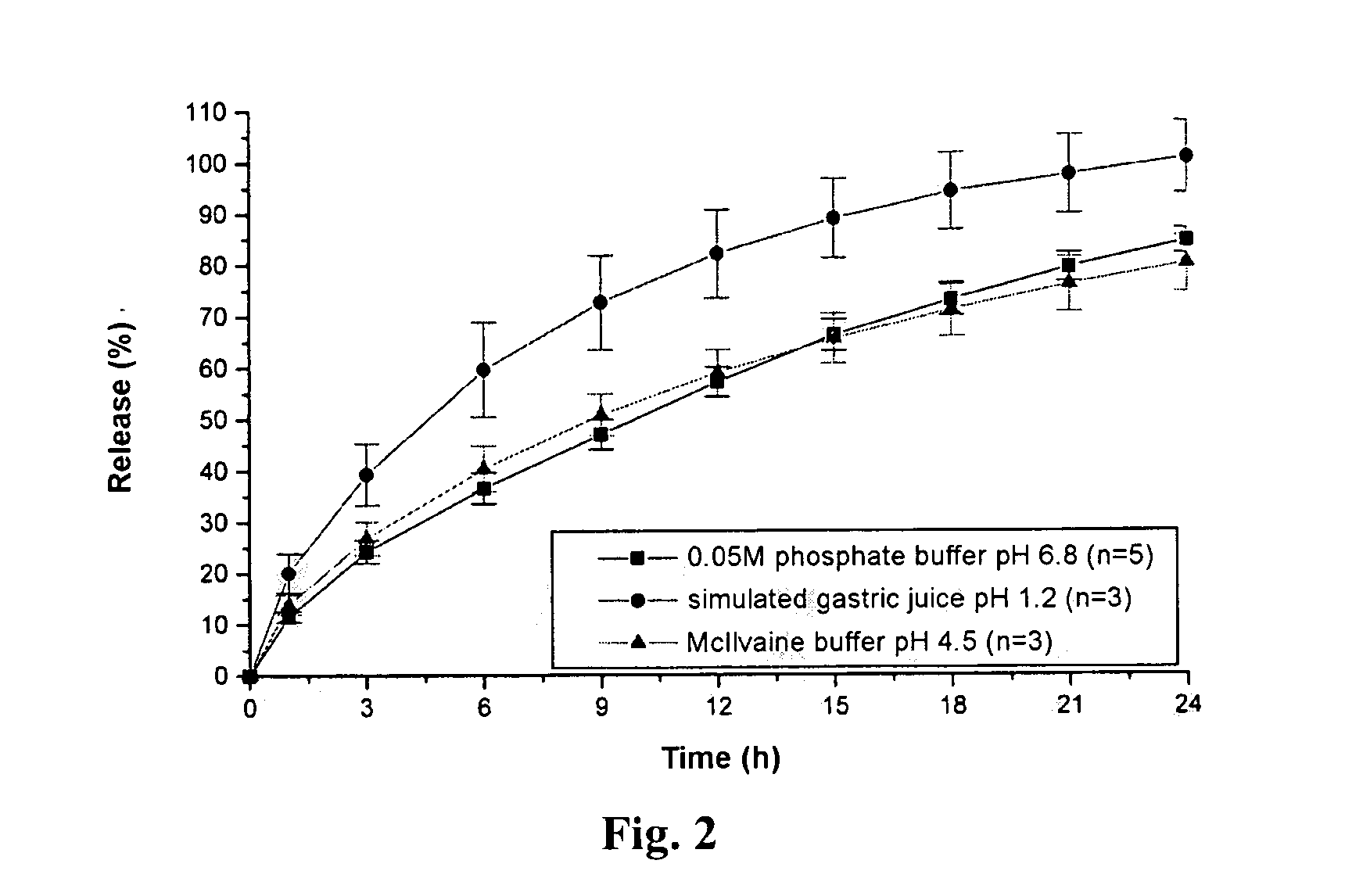

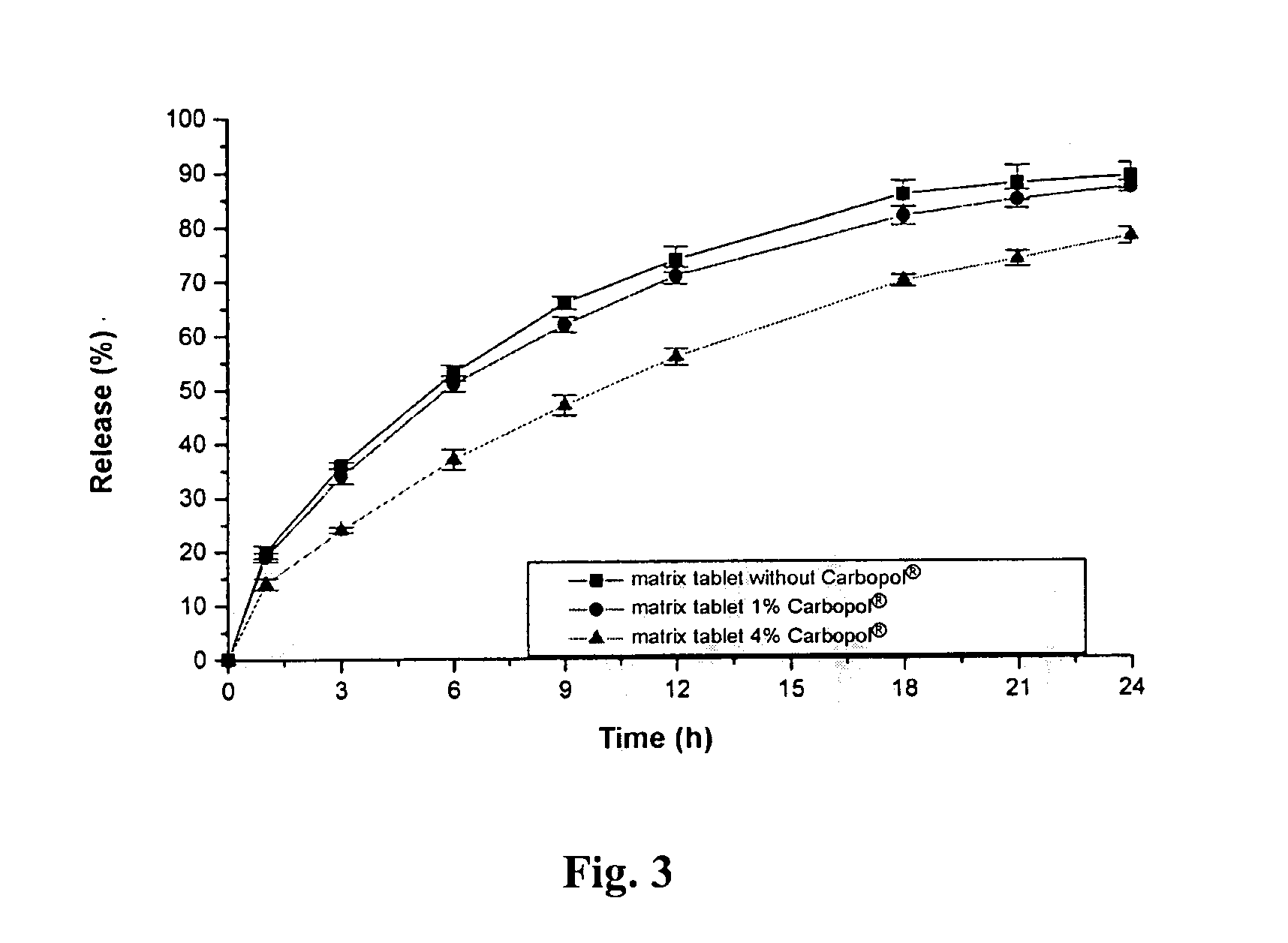

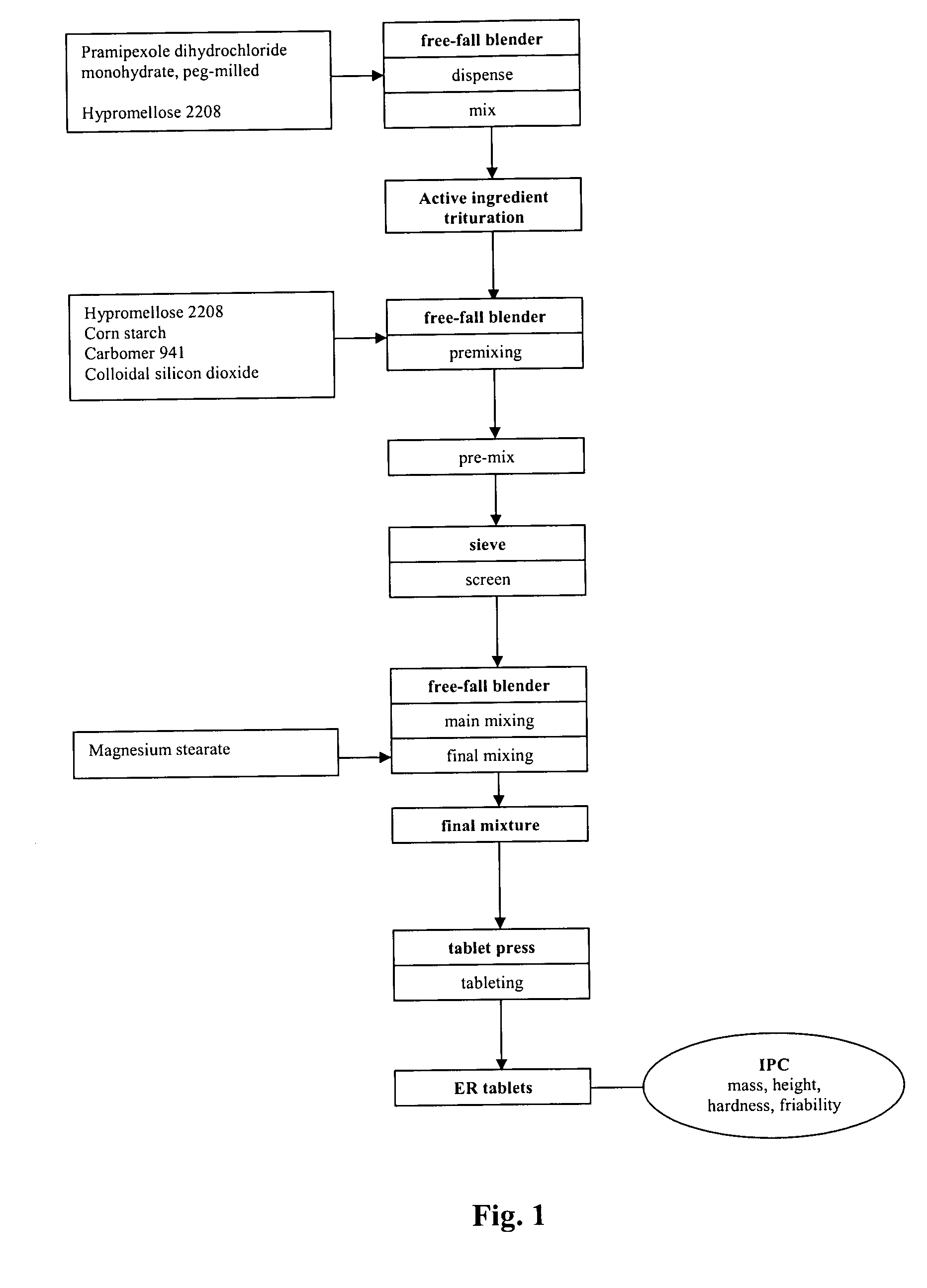

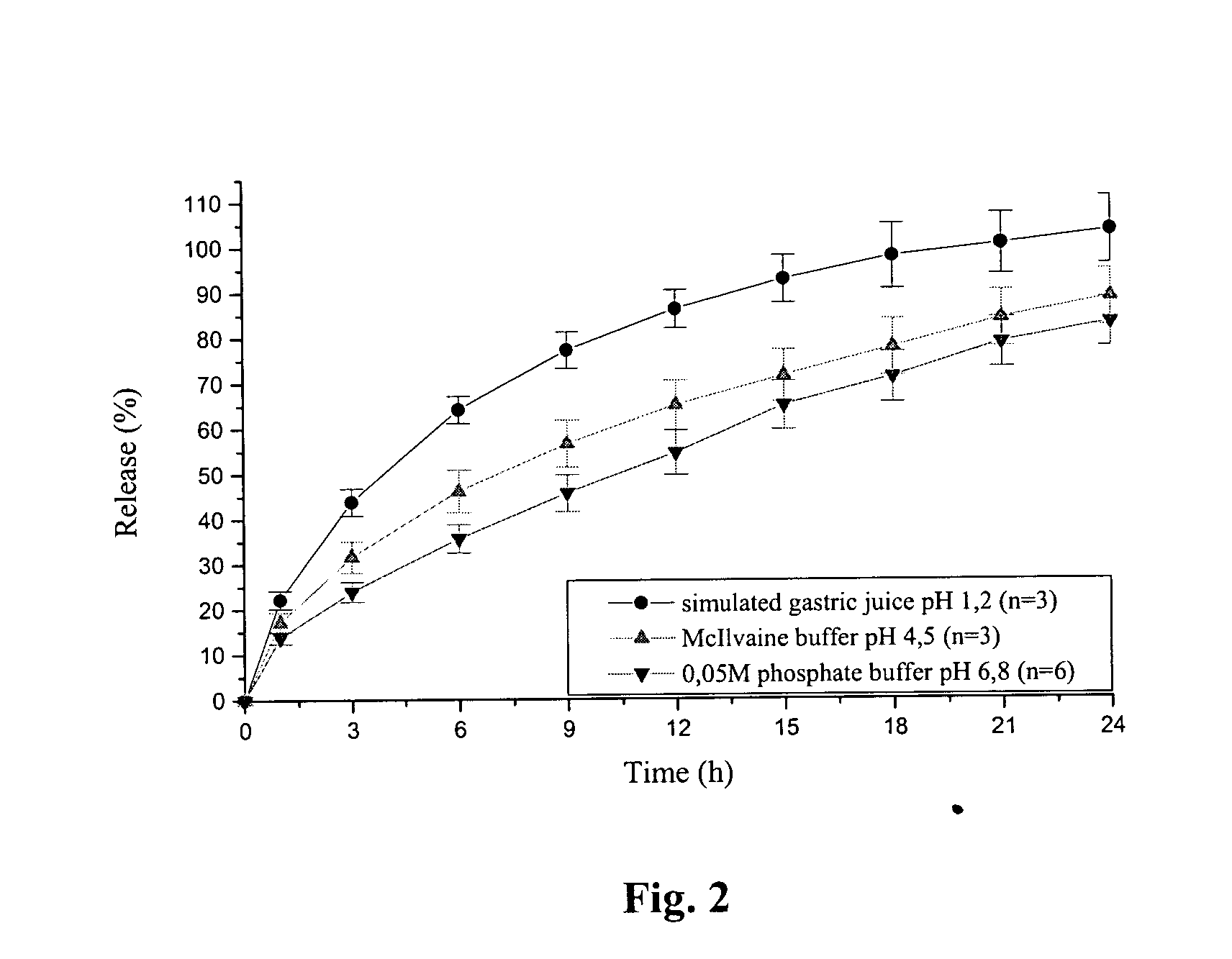

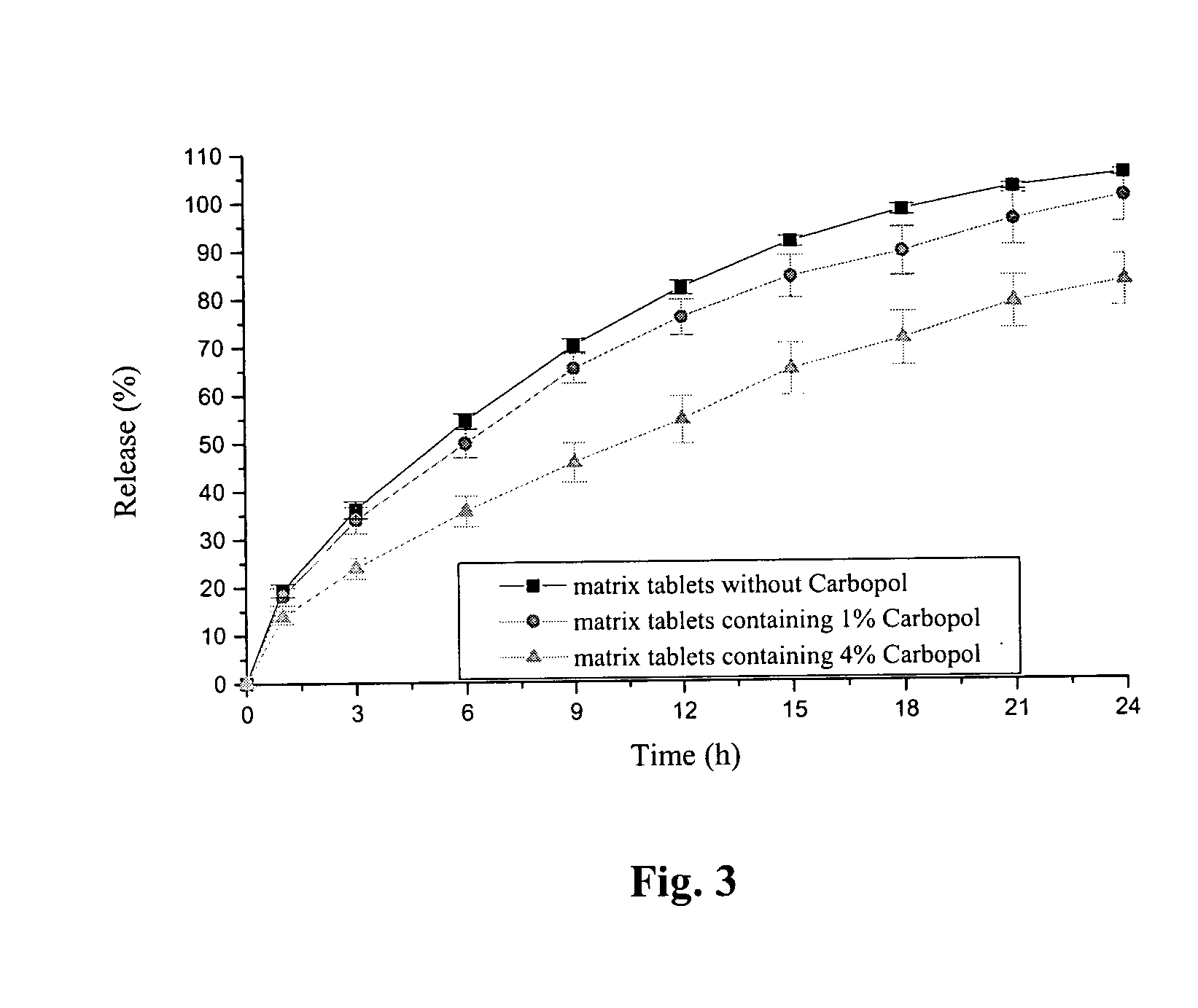

Extended release tablet formulation containing pramipexole or a pharmaceutically acceptable salt thereof

InactiveUS20060051417A1Improve complianceImprove conveniencePowder deliveryOrganic active ingredientsExtended release tabletsPramipexole

An extended release tablet formulation comprising pramipexole or a pharmaceutically acceptable salt thereof in a matrix, the matrix comprising at least two water swelling polymers, wherein one of the polymers is pregelatinized starch, and wherein another one of the polymers is an anionic polymer.

Owner:BOEHRINGER INGELHEIM INT GMBH

Adefovir dipivoil dispersion tablet and preparing method

InactiveCN1562046AGood disintegration timeGood dissolution rateOrganic active ingredientsAntiviralsCarboxymethyl starchLactose

A dispersing tablet of adefovirdipivoxil ester is prepared from adefovirdipivoxil ester, pregelatinized starch, microcrystalline fibres, lactose, carboxymethyl starch sodium, sodium laurylsulfate, and magnesium stearate through respective sieving, proportionally mixing and die pressing.

Owner:JIANGZHONG PHARMA

Adhesive controlled release fertilizer and preparation method thereof

ActiveCN101985409ASimple production processReduce manufacturing costFertilizer mixturesCellulosePolyvinyl alcohol

The invention provides an adhesive controlled release fertilizer and a preparation method thereof. The adhesive controlled release fertilizer consists of the following components in percentage by weight: 4 to 10 percent of pregelatinized starch, 2 to 4 percent of tung oil, 3 to 6 percent of disproportionated rosin, 7 to 15 percent of attapulgite powder, 0 to 15 percent of lignosulfonate, 0 to 15 percent of weathered coal, 0 to 6 percent of polyvinyl alcohol, 0 to 6 percent of carboxy methyl cellulose, and the balance of fertilizer. The preparation method comprises the following steps of: adding water which is 10 to 20 percent based on the total weight of the materials into the fertilizer to ensure that partial fertilizer is dissolved; adding an adhesive material with stirring in the process of heating until the solution is boiling; fully mixing uniformly, continuously stirring to ensure that the mixture is dried till the moisture is less than 10 percent; and granulating by using a granulator, or melting the mixture for spraying granulation. The adhesive controlled release fertilizer can release the fertilizer nutrient releasing speed to improve the nutrient utilization rate, the production process is simple, and the production cost is relatively low.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI +1

Extended release tablet formulation containing pramipexole or a pharmaceutically acceptable salt thereof

ActiveUS20060198887A1Improve complianceImprove conveniencePowder deliveryOrganic active ingredientsExtended release tabletsPramipexole

Owner:BOEHRINGER INGELHEIM INT GMBH

Method of water dispersing pregelatinized starch in making gypsum products

Owner:UNITED STATES GYPSUM CO

Production method of selenium-rich rice

InactiveCN103652644AIntegrity guaranteedSimple production processFood ingredient as antioxidantYeast food ingredientsNutrient solutionRice grain

The invention provides a production method of selenium-rich rice, belonging to a rice processing method. The production method comprises the following concrete steps: 1, bulking: bulking the processed rice on the market by using a hot and humid bulking device to form a plurality of micropores on the whole rice grain; 2, spraying and stirring: spraying a selenium-rich nutrient solution into the bulked micropores; 3, drying: drying the sprayed rice; and 4, packing: quantitatively subpacking the rice as required to obtain a finished product of the selenium-rich rice. The selenium-rich nutrient solution is prepared by uniformly mixing an organic solution with pregelatinized starch, gelatin liquid, lysine and threonine according to the designed dose. The invention provides the novel production method of the selenium-rich rice.

Owner:王国清

Pharmaceutical composition

ActiveUS20090143404A1Reduce the burden onIncrease the burdenOrganic active ingredientsNervous disorderOral medicationLurasidone

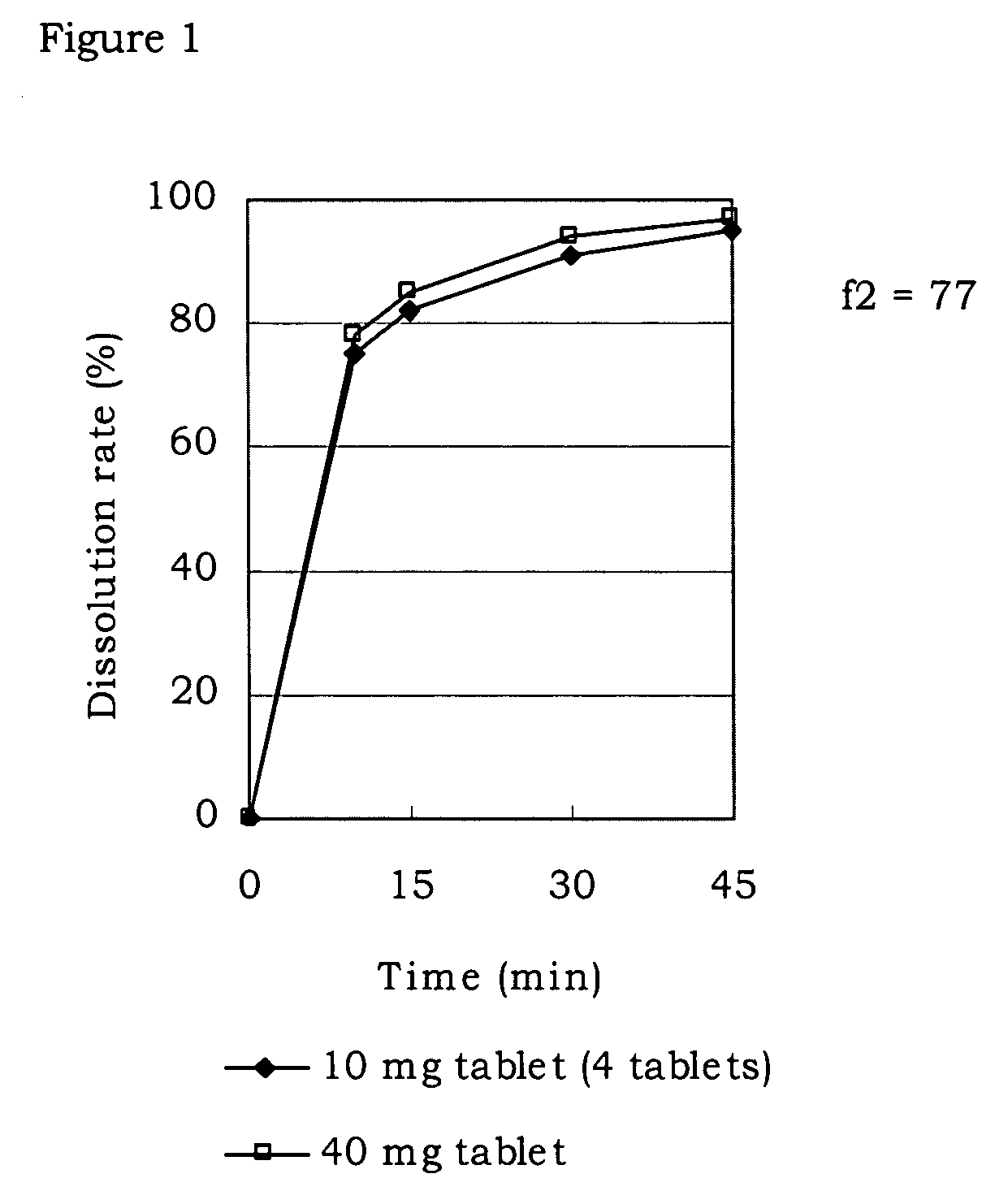

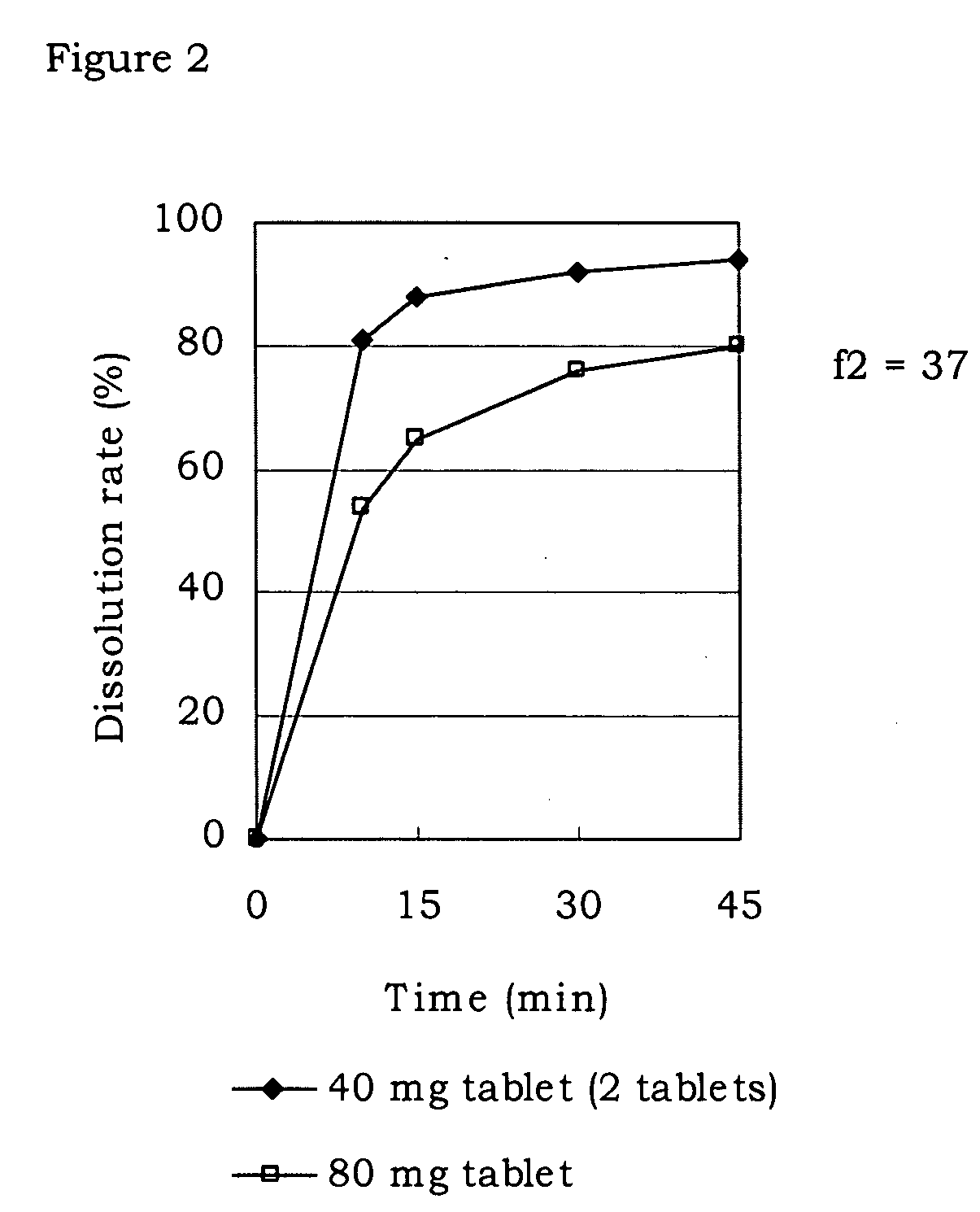

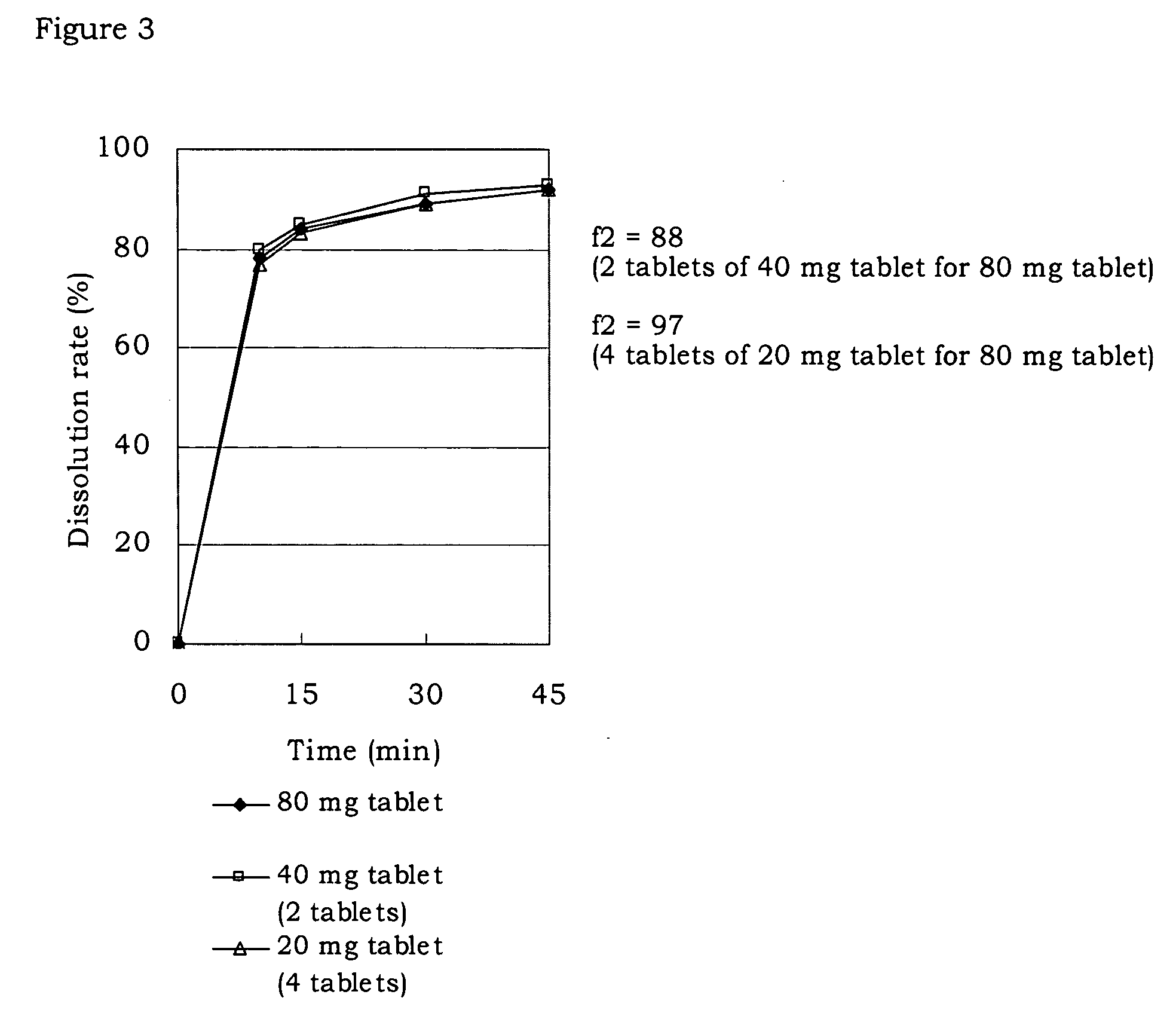

A preparation for oral administration comprising: a pregelatinized starch comprising N-[4-[4-(1,2-benzisothiazol-3-yl)-1-piperazinyl]-(2R,3R)-2,3-tetramethylene-butyl]-(1′R,2′S,3′R,4′S)-2,3-bicyclo[2,2,1]-heptanedicarboxyimide hydrochloride (lurasidone) represented by the formula (1) as an active ingredient; a water-soluble excipient; and a water-soluble polymeric binder, the preparation exhibiting an invariant level of elution behavior even when the content of its active ingredient is varied.

Owner:SUMITOMO DAINIPPON PHARMA CO LTD

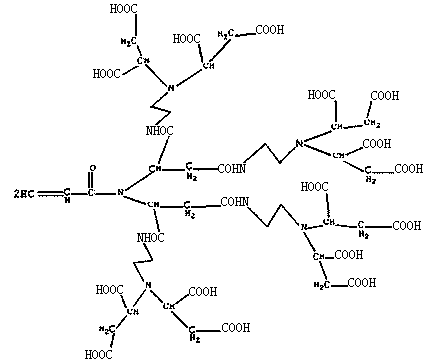

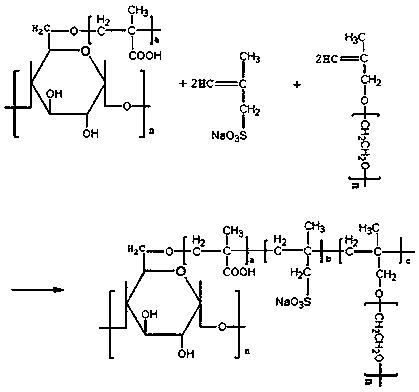

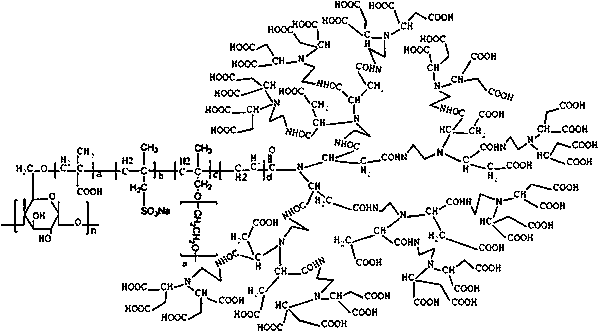

Preparation of hyperbranched starch-based water reducing agent

The invention relates to the technical field of retarding high efficiency water reducers, in particular to application of hyperbranched starch-based water reducing agent with a terminal carboxyl hyperbranched polyamide-amine in improvement of flow property of concrete. The hyperbranched starch-based water reducing agent is synthesized by firstly carrying out pretreatment on starch, then synthesizing a terminal carboxyl hyperbranched polymer, and grafting hyperbranched polyamide-amine onto the pregelatinized starch. After being applied to the field of high efficiency water reducers, the hyperbranched starch-based water reducing agent can well improve the flowing property of the concrete; the hyperbranched starch-based water reducing agent is simple and convenient in synthesis process and suitable for industrial production, thus being a retarding high efficiency water reducer with excellent performance.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com