Preparation of hyperbranched starch-based water reducing agent

A water-reducing agent and starch-based technology, applied in the field of modified starch water-reducing agents, can solve the problems of poor fluidity and long retardation time of water-reducing agent, so as to improve the retarding performance, improve the water-reducing efficiency, and reduce the amount of addition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

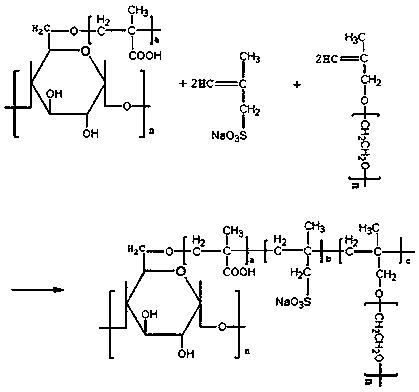

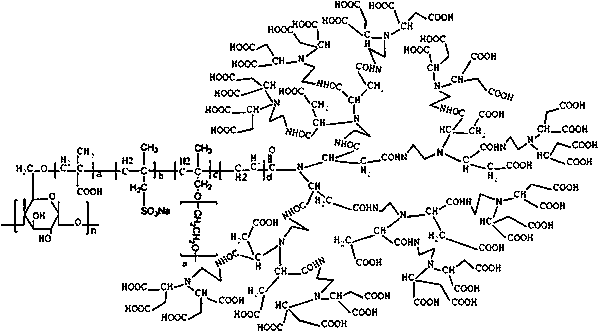

[0042] (1) Weigh 32.00g (0.1mol) starch and 150.00g (0.4mol) water, first add starch and water into a four-neck flask with a magnetic stirrer, then add an appropriate amount of ammonium persulfate 8.00g to dissolve, and then Add 8.00g of methacrylic acid, raise the temperature to 40°C, and react at normal pressure for 6h; cool down to room temperature, then add 8.00g (0.8mol) sodium styrene sulfonate, and react at room temperature for 4h; then add 8g of methallyl poly Oxyethylene ether was reacted for 4 hours to obtain pregelatinized starch.

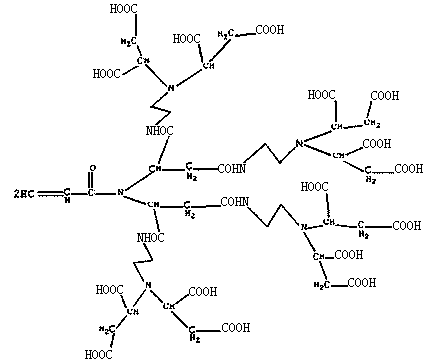

[0043] (2) Using amidation, under the action of the condensing agent CDI, N-methylmorpholine is used as the organic base, acrylamide and maleic acid are used as monomers, and the condensation reaction is carried out in DMF under an ice-water bath. Reaction 12 ~48h, by repeatedly adding AB2 monomers, to control the number of hyperbranched generations, and synthesize the first and second generation hyperbranched polymers. Take a certain a...

Embodiment approach 2

[0046] (1) Weigh 32.00g (0.1mol) starch and 150.00g (0.4mol) water, first add starch and water into a four-neck flask with a magnetic stirrer, then add an appropriate amount of ammonium persulfate 8.00g to dissolve, and then Add 8.00g of methacrylic acid, raise the temperature to 40°C, and react at normal pressure for 6h; cool down to room temperature, then add 8.00g (0.8mol) sodium styrene sulfonate, and react at room temperature for 4h; then add 8g of methallyl poly Oxyethylene ether was reacted for 4 hours to obtain pregelatinized starch.

[0047] (2) Using amidation, under the action of the condensing agent CDI, N-methylmorpholine is used as the organic base, acrylamide and maleic acid are used as monomers, and the condensation reaction is carried out in DMF under an ice-water bath. Reaction 12 ~48h, by repeatedly adding AB2 monomers, to control the number of hyperbranched generations, and synthesize the first and second generation hyperbranched polymers. Take a certain a...

Embodiment approach 3

[0050] (1) Weigh 32.00g (0.1mol) starch and 150.00g (0.4mol) water, first add starch and water into a four-neck flask with a magnetic stirrer, then add an appropriate amount of ammonium persulfate 8.00g to dissolve, and then Add 8.00g of methacrylic acid, raise the temperature to 40°C, and react at normal pressure for 6h; cool down to room temperature, then add 8.00g (0.8mol) sodium styrene sulfonate, and react at room temperature for 4h; then add 8g of methallyl poly Oxyethylene ether was reacted for 4 hours to obtain pregelatinized starch.

[0051] (2) Using amidation, under the action of the condensing agent CDI, N-methylmorpholine is used as the organic base, acrylamide and maleic acid are used as monomers, and the condensation reaction is carried out in DMF under an ice-water bath. Reaction 12 ~48h, by repeatedly adding AB2 monomers, to control the number of hyperbranched generations, and synthesize the first and second generation hyperbranched polymers. Take a certain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com