Biocompatibility modified starch sponges

A biocompatible, modified starch technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of clinical application limitations, slow absorption by the human body, etc., and achieve non-toxic side effects, good biocompatibility, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Put 2g of pregelatinized hydroxypropyl distarch phosphate 51# into 30ml of water, stir continuously to make the starch granules fully swell and disperse in the water to form a uniform suspension, add a few drops of glycerin as a forming agent, and then pour it into the container , pre-cooled at -40°C for 22 hours, then placed in a freeze dryer, and freeze-dried at -40°C with a vacuum of less than 20 Pa for 20 hours to obtain the hemostatic sponge A.

[0090] Take 3g of 51# hemostatic sponge A, add 30ml of water, and form a coagulated water mixture viscous glue after absorbing water, and its viscous work index is 76.42g·sec.

[0091] The test method of the viscous work index of the present invention adopts a physical property analyzer (texture analyzer); the test conditions are: under normal temperature, the speed before the test: 0.5mm / sec; the test speed: 10mm / sec.

[0092] The viscous work index means that the probe will be subjected to the cohesive force of the sampl...

Embodiment 2

[0094] Put 1g of pregelatinized hydroxypropyl distarch phosphate 51# into 30ml of water, stir constantly to make the starch granules fully swell and disperse in the water to form a uniform suspension, then pour it into a container and pre-cool at -40°C After 22 hours, put it into a freeze dryer, freeze-dry for 20 hours at -50°C and a vacuum of less than 20 Pa, and obtain the hemostatic sponge B.

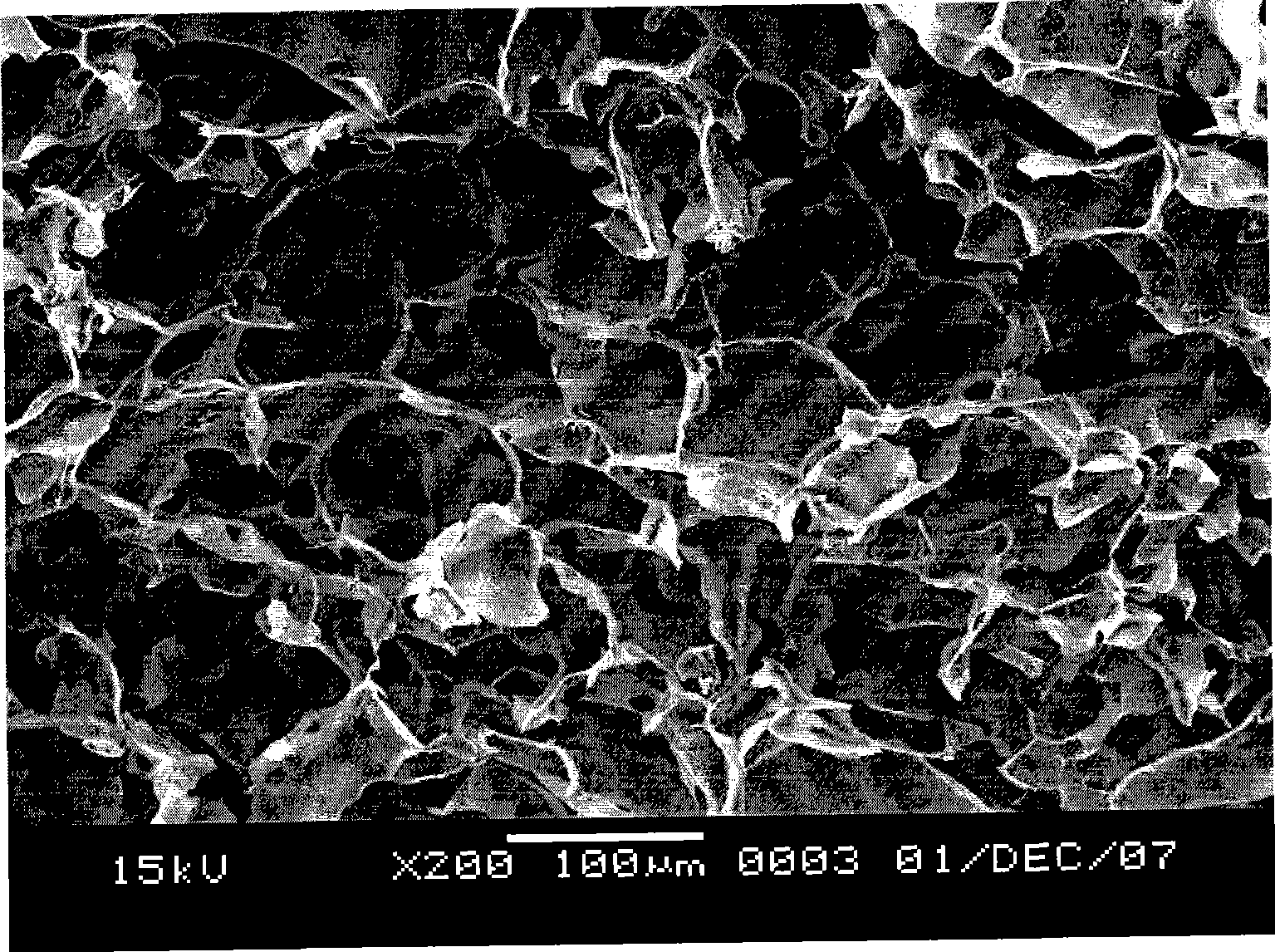

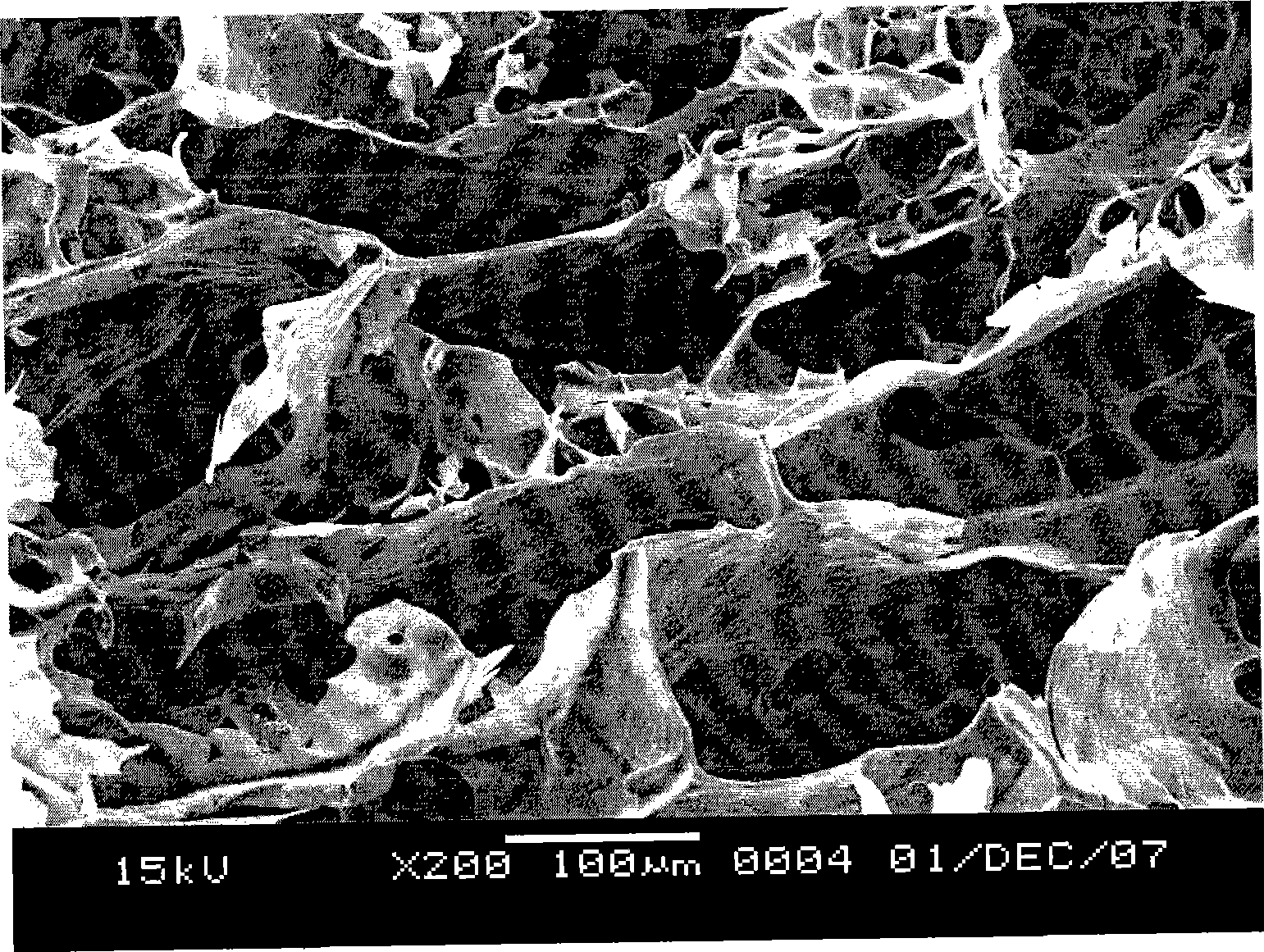

[0095] see figure 1 Scanning electron micrograph of the section of the hemostatic sponge A, figure 2 As shown in the scanning electron micrograph of the section of the hemostatic sponge B, adding a plasticizer during the preparation process reduces the pore size of the sponge pores and increases the density and specific surface area.

Embodiment 3

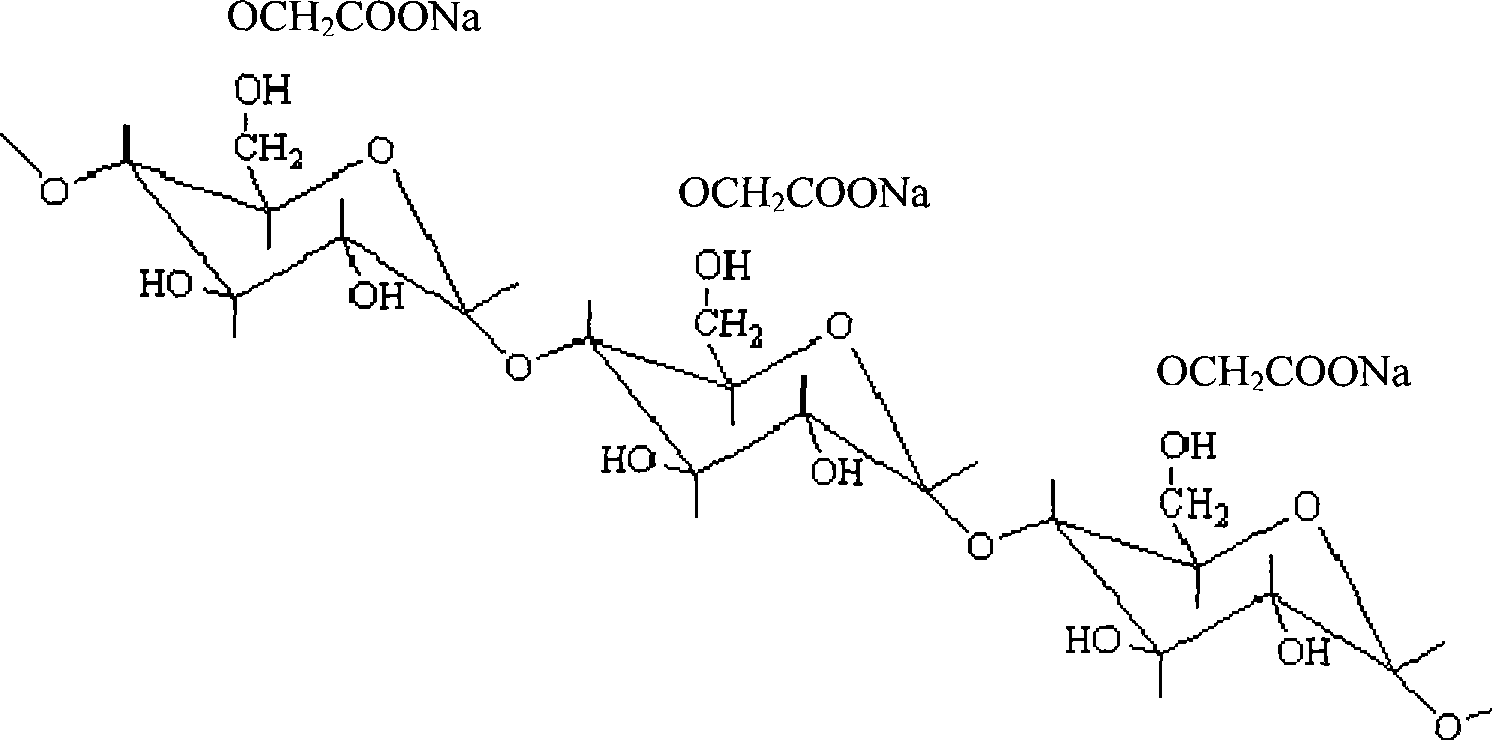

[0097] Put 2g of carboxymethyl starch 66# into 30ml of water, stir continuously to make the starch granules fully swell and disperse in water to form a uniform suspension, then pour it into a container, pre-cool at -40°C for 22 hours, and then put it in In a freeze dryer, freeze-dry for 20 hours at -50°C and a vacuum of less than 20 Pa to obtain a hemostatic sponge C.

[0098] Take 1.5g of 66# hemostatic sponge C, add 30ml of water, and form a coagulated water mixture viscous glue after absorbing water, and its viscous work index is 162.68g·sec.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com