Patents

Literature

327 results about "Oxidised starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

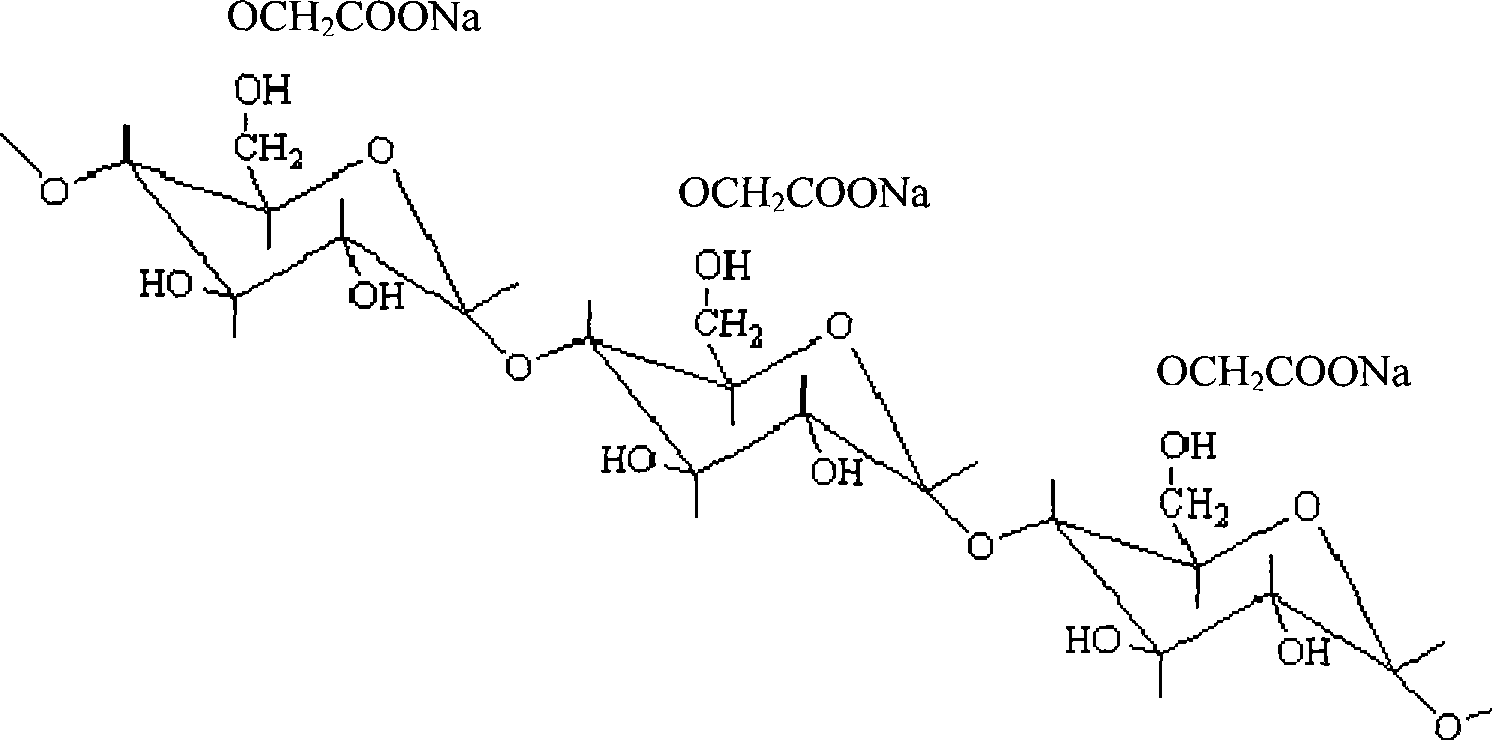

Oxidized Starch. Oxidized Starch is a modified starch shaped, produced and manufactured by means of oxygenation of high excellence quality native tapioca starch with a changed variety of oxidizing agents and oxidized starch as are attained.

Charcoal-based microbial soil conditioner and preparation method thereof

ActiveCN104789226AReduce hydrogen ion levelsRaise the pHAgriculture tools and machinesOther chemical processesAureobasidium sp.Bacillus thuringiensis

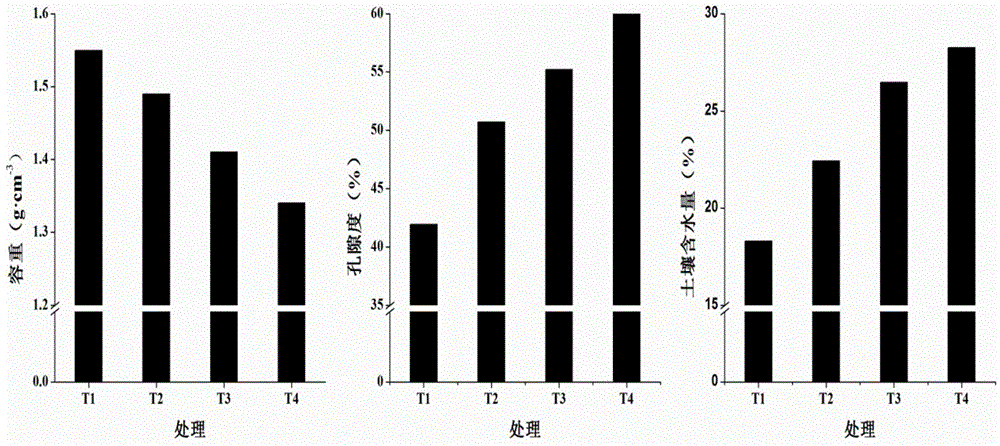

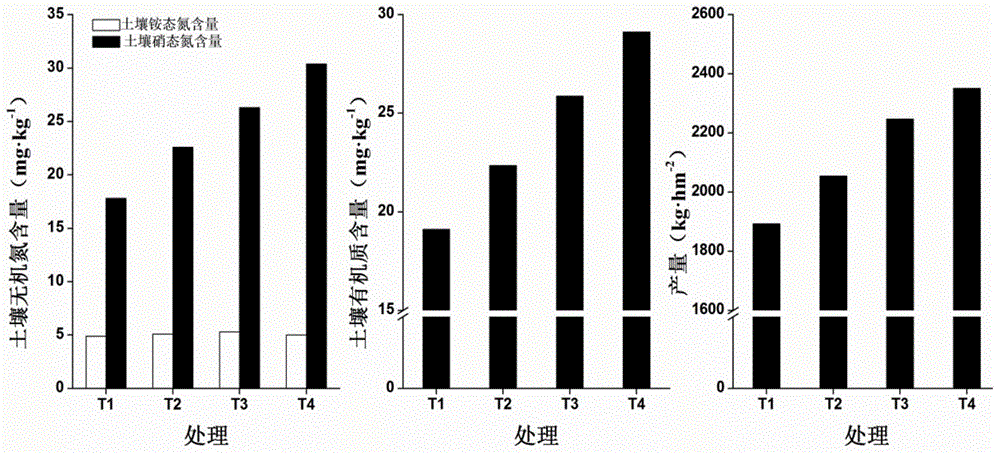

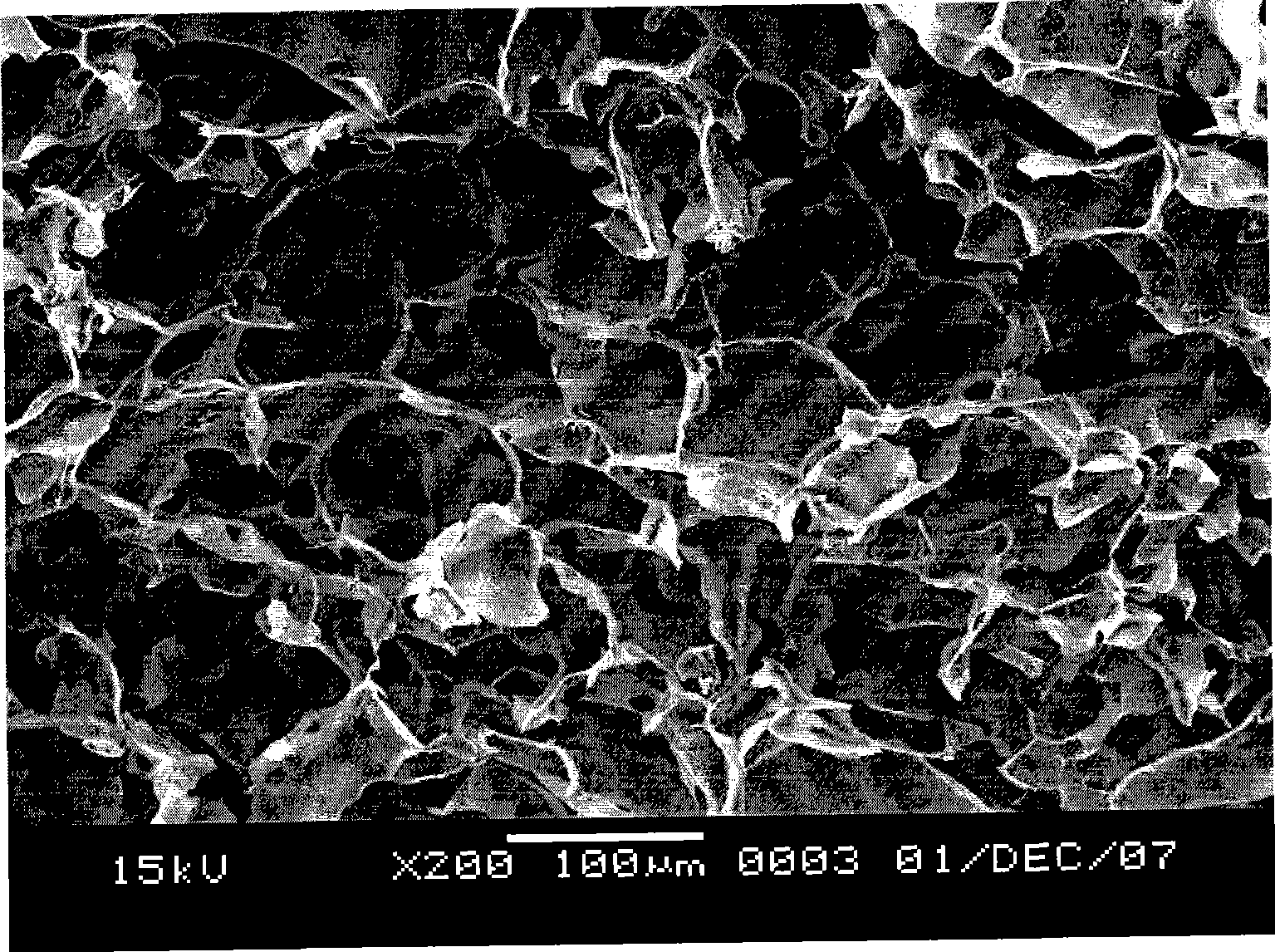

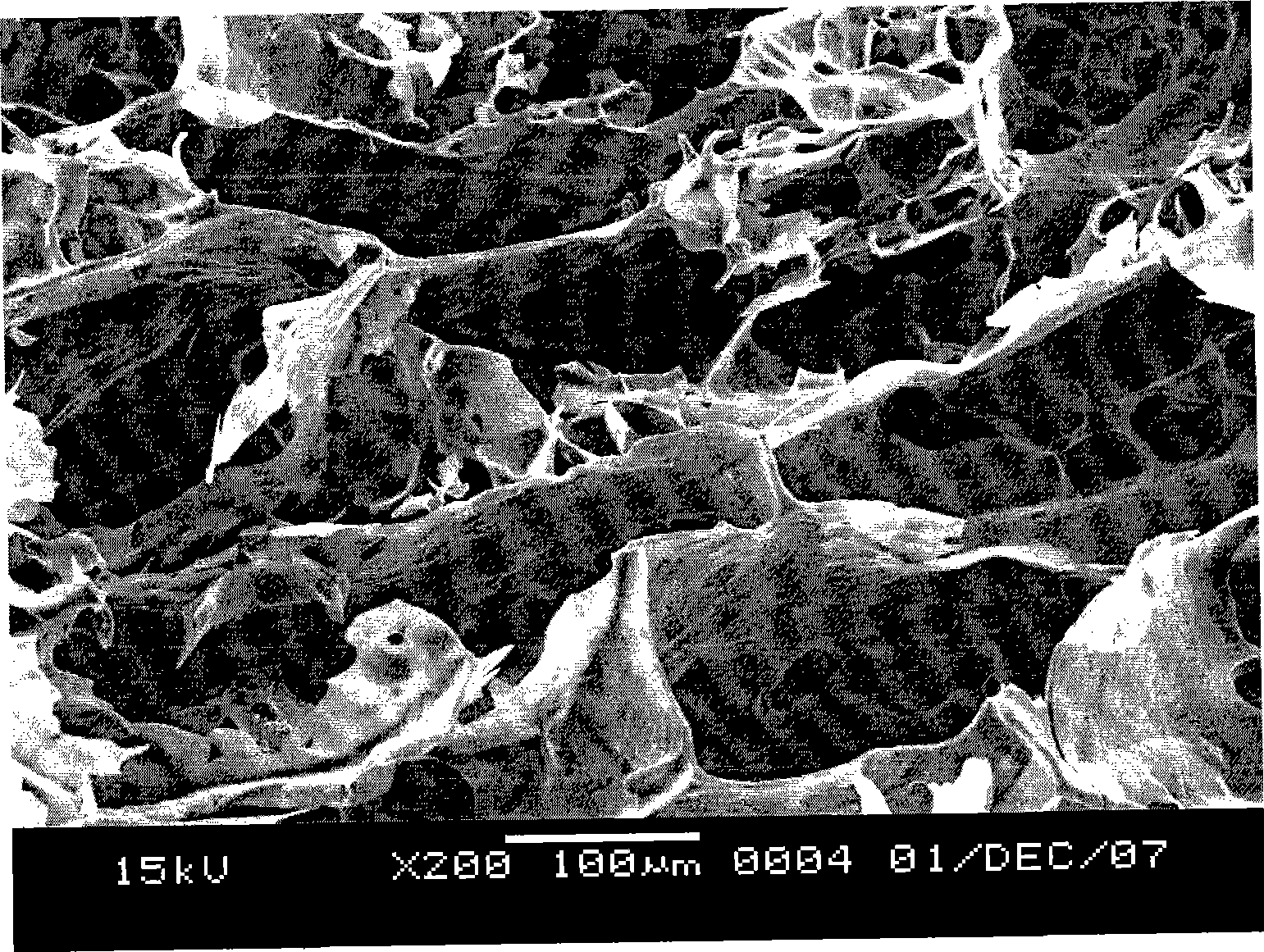

The invention discloses a charcoal-based microbial soil conditioner. The charcoal-based microbial soil conditioner comprises, by weight, 80-85 parts of charcoal, 10-13 parts of a composite microbial flora and 1-2 parts of an oxidized starch adhesive, and the composite microbial flora comprises photosynthetic bacteria, actinomyces, lactic acid bacteria, microzyme, Bacillus subtilis and Bacillus thuringiensis. The invention also discloses a preparation method of the charcoal-based microbial soil conditioner. The combined effect of charcoal and microbes alleviates soil acidification, reduces the unit weight of soil and increases the permeability and the water content of soil; soil organic matter formation is promoted to improve the validity of mineral elements; and the abundance of microbes at the rhizosphere of crops is cultivated to improve the rhizospheric environment of plants in order to make pathogen microbes difficultly grow and breed, so the insect diseases of crops is reduced, and soil heavy metal pollution is alleviated and restored.

Owner:迪斯科科技集团(宜昌)有限公司

Biocompatibility modified starch sponges

ActiveCN101455857AFlexibleActive bleeding is easily controlledAbsorbent padsBandagesFreeze-dryingBiocompatibility Testing

The invention relates to biocompatible modified starch sponge and use of the biocompatible modified starch sponge as a hemostatic material, an anti-adhesion material, a material for promoting tissue healing, a surgical sealant or a wound tissue adhesive. Modified starch is one or a combination of more than one among pre-gelatinized starch, acid modified starch, dextrin, oxidized starch, esterified starch, etherified starch, crosslinked starch, grafted starch and composite modified starch. The sponge is prepared by vacuum freeze drying of the modified starch and other biocompatible hemostatic material, coagulant, plasticizer and so on. The biocompatible modified starch sponge has the advantages that the biocompatible modified starch sponge has flexible form and good biocompatibility, can be directly acted on bloody wound surfaces, avoids the conditions of hypersusceptibility, infection and difficult healing of wounds caused by adoption of hemostatic materials such as animal source / human source collagens, obviously improves the water absorption speed, has larger viscosity, forms a zymoplastic mixture which has good adhesion, calks broken tissues and blood vessels, and is used for hemostasis of active hemorrhage.

Owner:BEIJING UNIVERSAL LIKANG TECH CO LTD

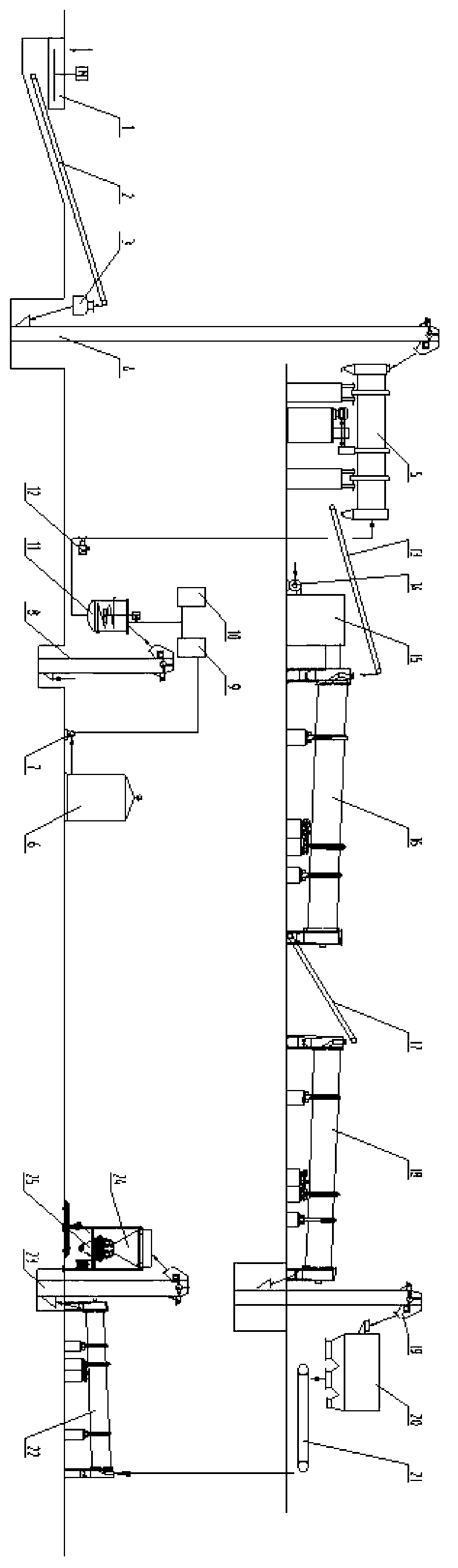

Industrial production method and device of urea-formaldehyde slow-release compound fertilizer

ActiveCN103011982ALow free formaldehyde contentMeet needsAgriculture gas emission reductionFertilizer mixturesPotassiumNitrogen

The invention relates to an industrial production method and device of a urea-formaldehyde slow-release compound fertilizer and a device thereof. The industrial production method comprises the steps of adding water and oxidized starch to a reaction still and then pasting, adding urea of which the nitrogen content is 46wt% and formalin, stirring, dissolving and then adjusting the pH value to 8.5-8.8 by an alkaline matter, reacting at constant temperature of 60 DEG C to obtain reaction liquid; adjusting the pH value to 5.4-5.1 by the reaction liquid; reacting for 45 minutes at the constant temperature of 65-68 DEG C, then adjusting the pH value to 6.8-7.2, and terminating reaction to obtain the urea formaldehyde condensation product solution; mixing the urea formaldehyde condensation product solution with nitrogen, phosphorus and potassium materials, pelletizing, drying and cooling to below 35 DEG C, and screening to obtain the urea-formaldehyde slow-release compound fertilizer. The industrial production device of the urea-formaldehyde slow-release compound fertilizer is also provided by the invention. Urea formaldehyde is taken as a skeleton; rapid disintegration phenomenon of fertilizer particles caused by water absorption expansion is effectively prevented; the urea-formaldehyde slow-release compound fertilizer has good nutrient slow-release performance, and is high in pelletizing rate in the production process and strong in granule hardness, and the total nutrient content is improved.

Owner:河南豫邮金大地科技服务有限公司

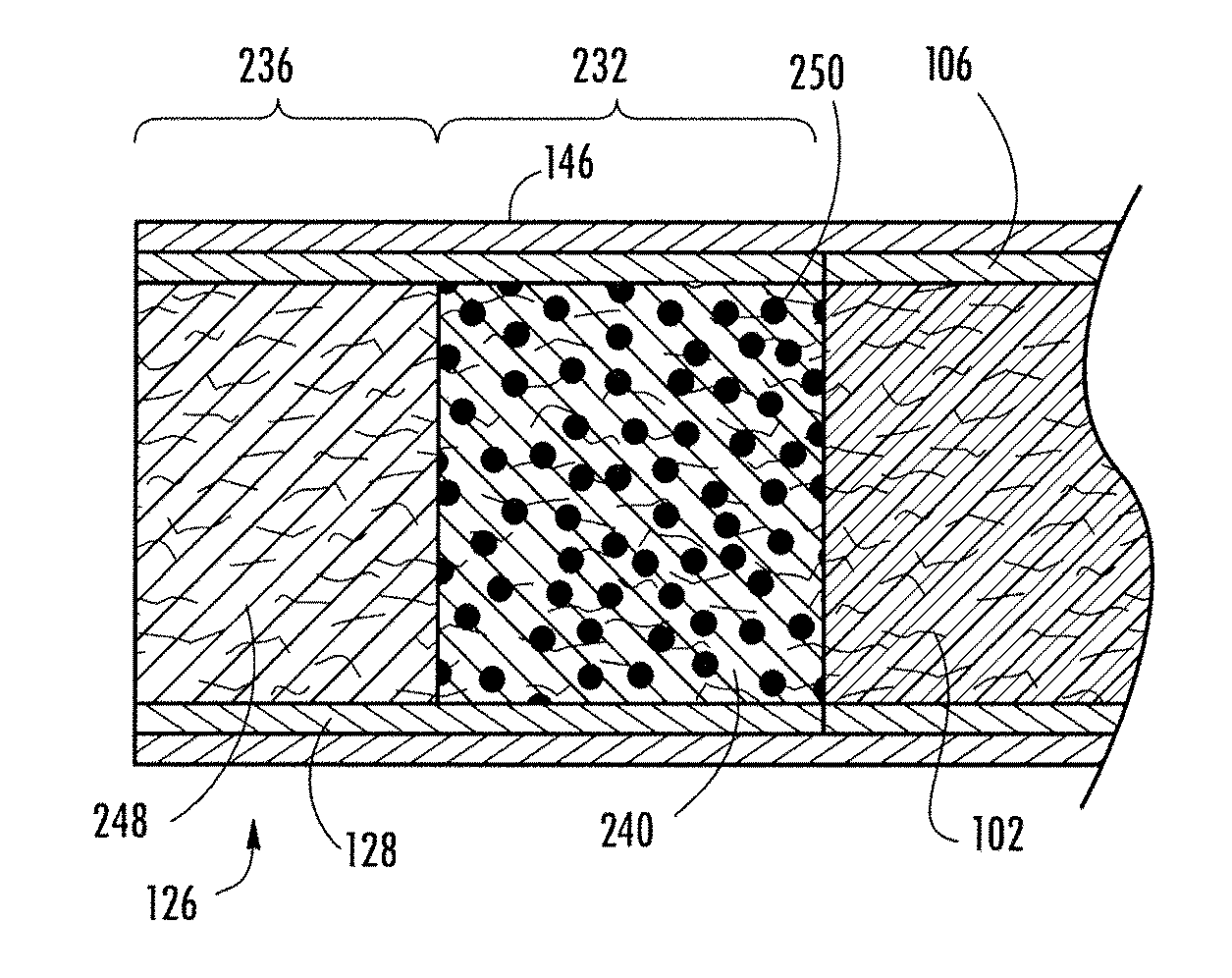

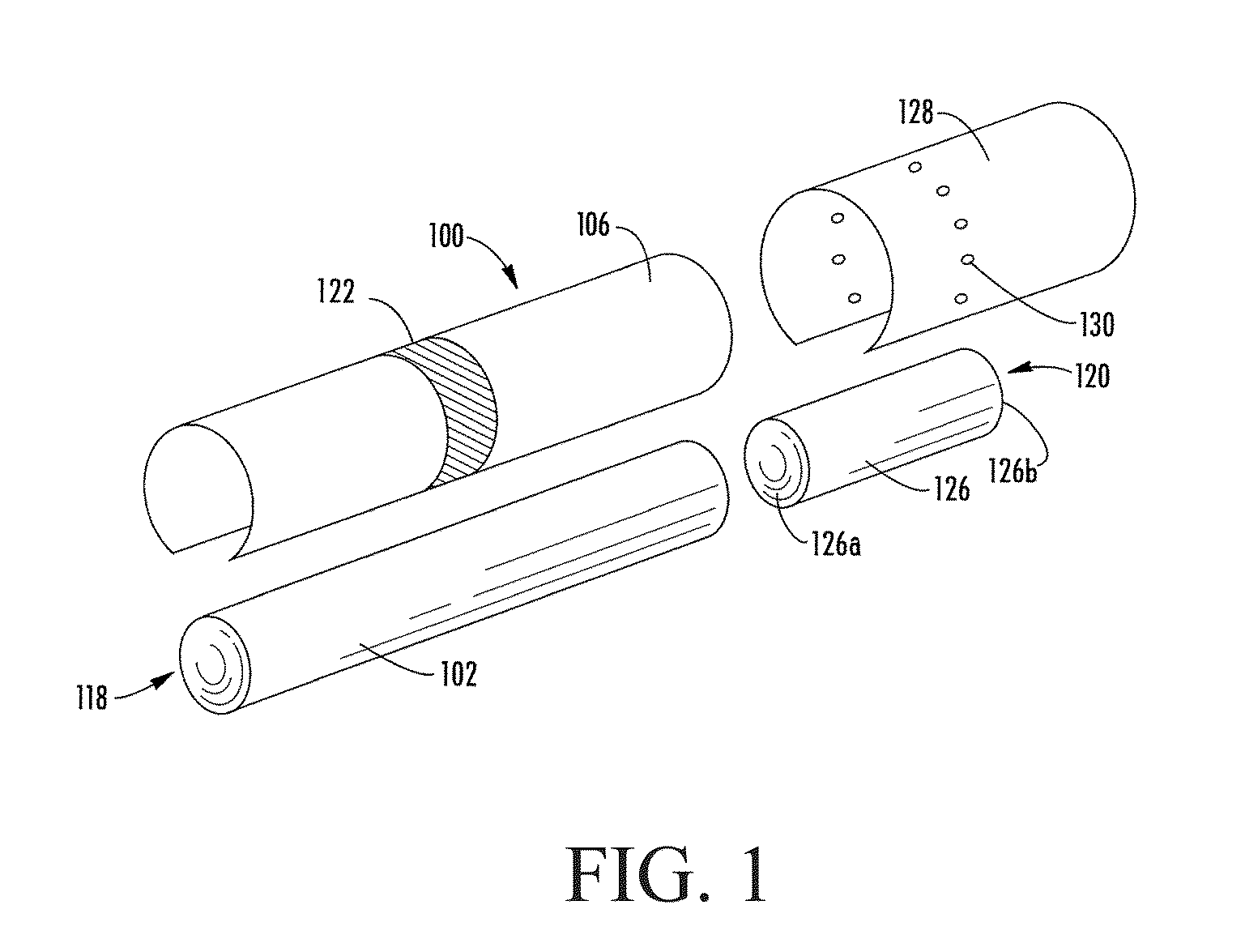

Degradable filter element for smoking article

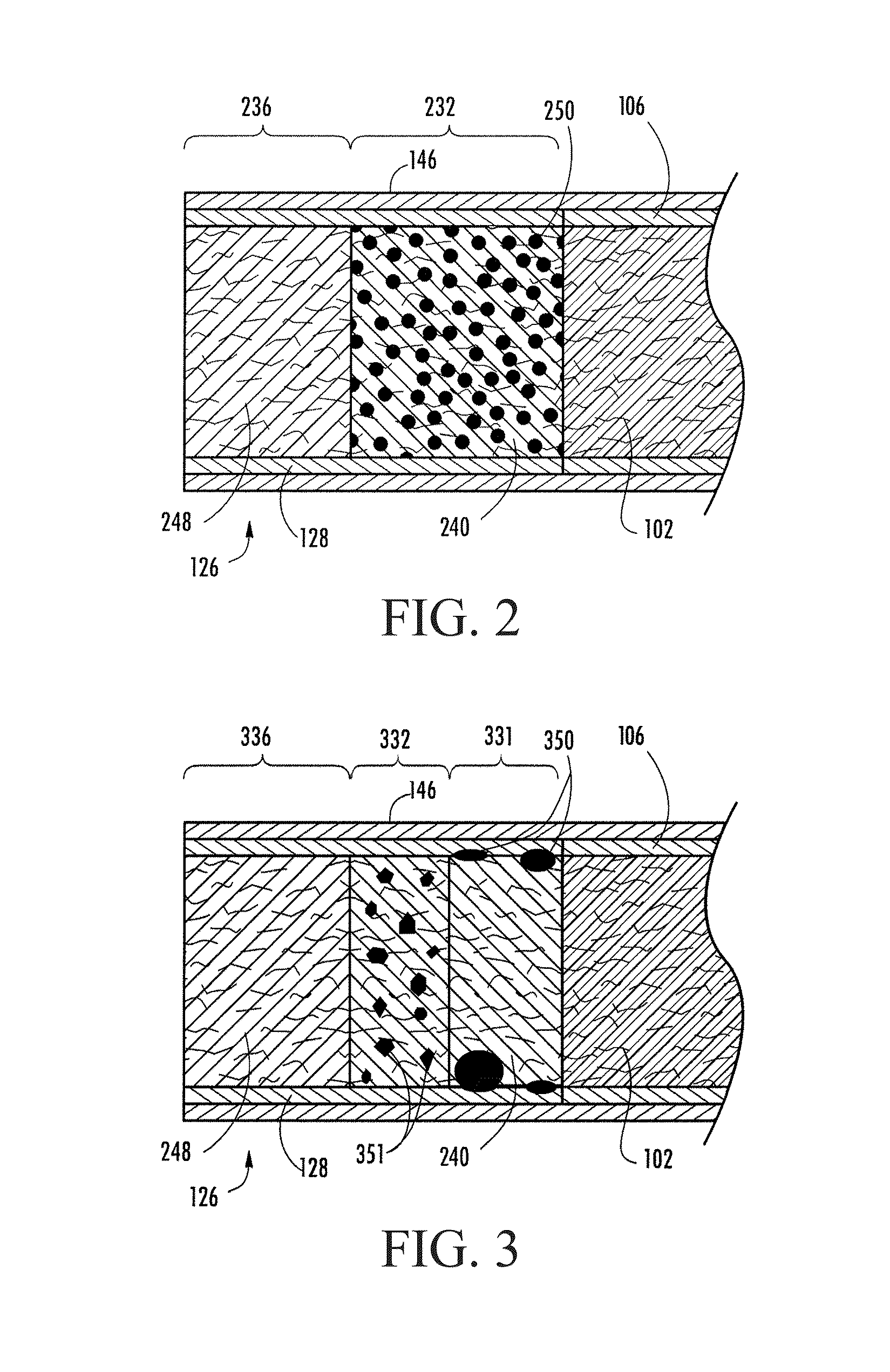

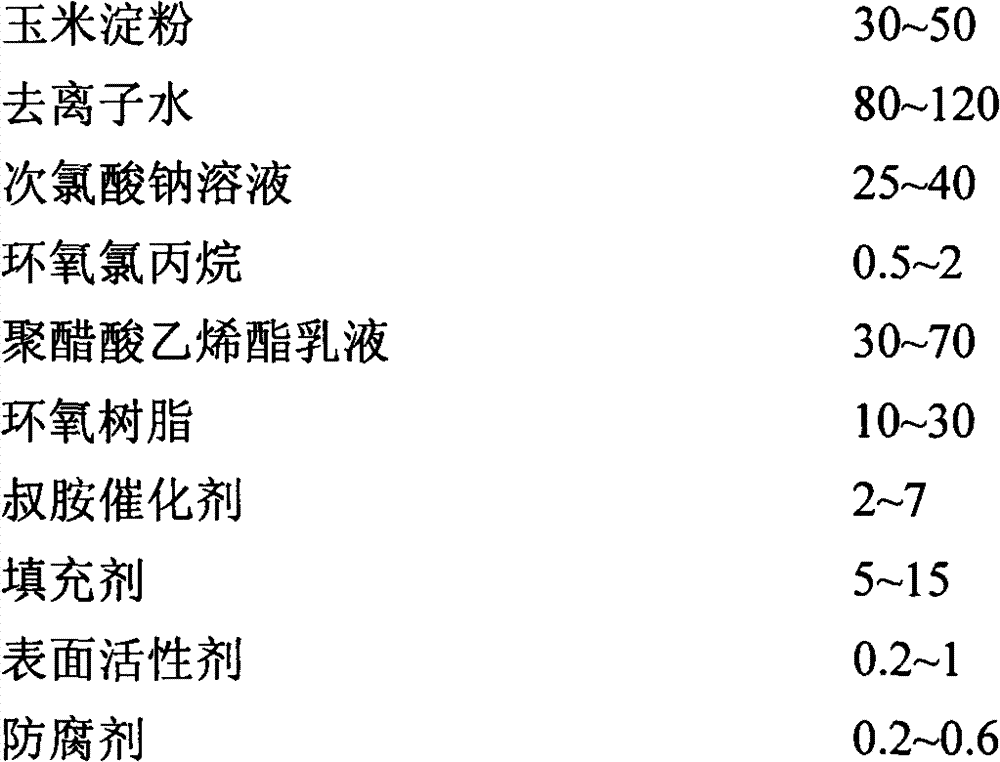

InactiveUS20120000481A1Improve degradation rateIncrease usable surface areaTobacco treatmentTobacco smoke filtersFiberPolymer science

A filter material configured for use as a filter element of a smoking article is provided, the filter material including at least one segment of fibrous tow having a plurality of superabsorbent objects dispersed therein, the superabsorbent objects comprising a starch material. Exemplary starch materials include naturally-occurring starch, hydroxyalkylated starch, starch esters, ionically modified starch, oxidized starch, hydrolyzed starch, plasticized starch, gelatinized starch, grafted starch, crosslinked starch, transglycosylated starch, starch ethers, and mixtures thereof, as well as blends of starch with other polymers. Filter elements and smoking articles, such as cigarettes, that contain the filter material are also provided. A method of preparing polymer fibers for use in filter elements is also provided, the method including adding the starch material to a fiber precursor solution prior to fiber extrusion or dry-blending the starch material with the polymer material to be formed into fibers.

Owner:R J REYNOLDS TOBACCO COMPANY

3D (Three-dimensional) printing material

The invention relates to a 3D (three-dimensional) printing material, which comprises powered ink and a bonder, wherein the powdered ink comprises 100 parts by weight of polyamide, 50 to 80 parts by weight of oxidized starch, 10 to 30 parts by weight of rosin resin, 5 to 80 parts by weight of pigment, 5 to 30 parts by weight of filler and 0.1 to 0.5 part by weight of degassing agent; the bonder comprises 100 parts by weight of epoxy resin, 10 to 30 parts by weight of rosin resin, 5 to 30 parts by weight of filler, 0.1 to 1.5 parts by weight of leveling agent and 0.1 to 0.5 part by weight of degassing agent. According to the 3D printing material, the thermoplastic oxidized starch is adopted, and can be well bonded with the epoxy resin, so that the bonding power between the powdered ink and the bonder is improved, and a solid part with high bonding strength and high firmness is favorably obtained.

Owner:SHANGHAI BANZAN MACROMOLECULE MATERIAL

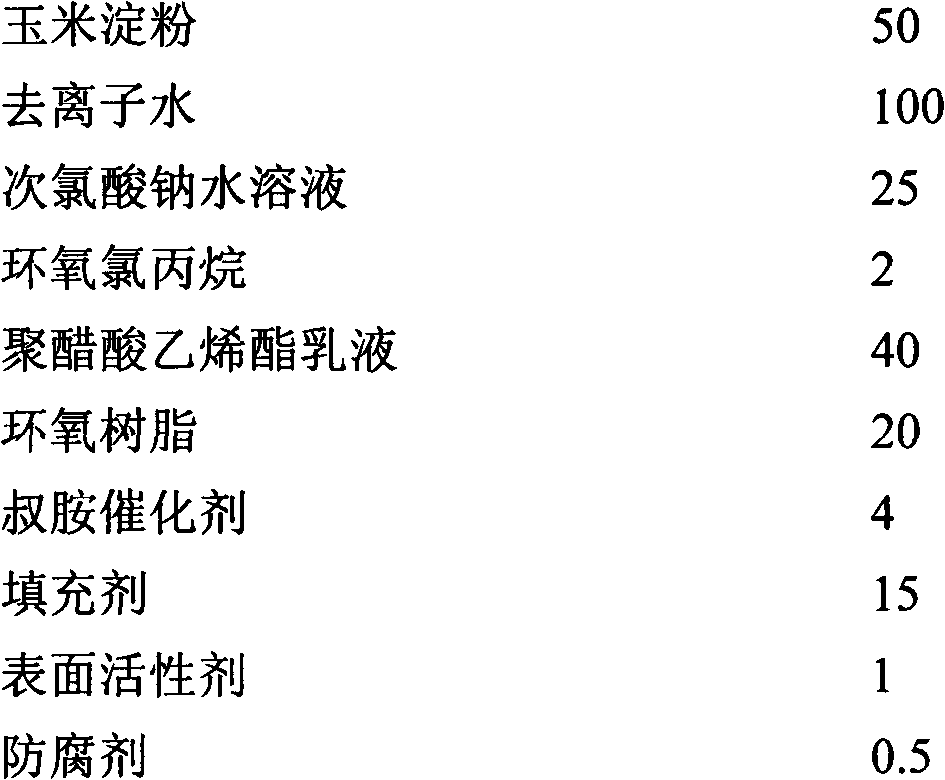

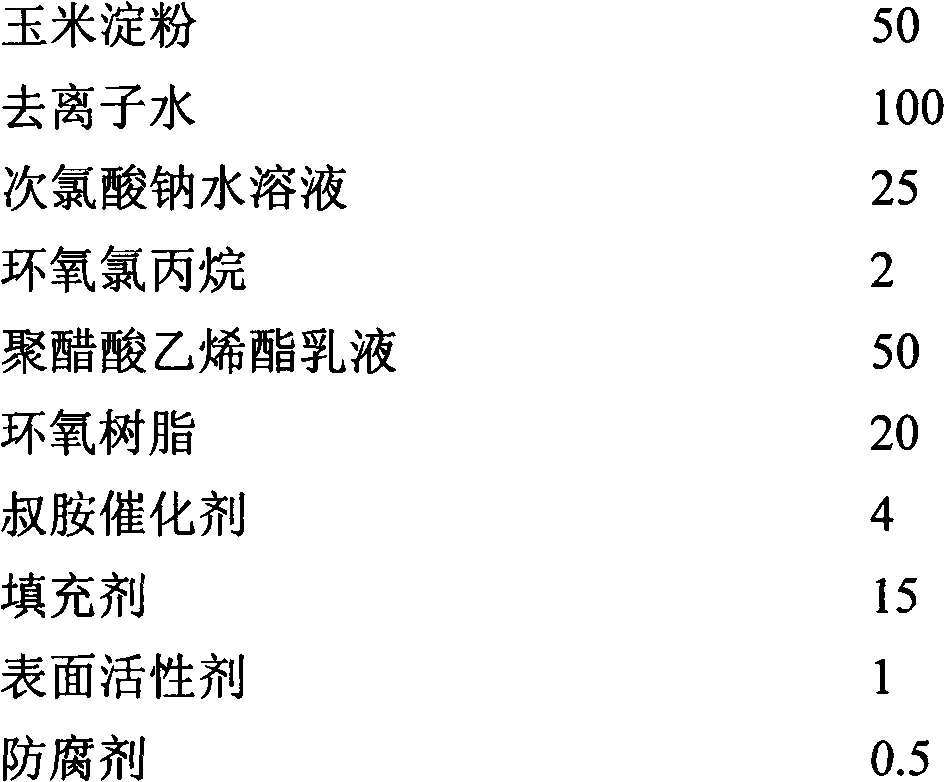

Modified starch adhesive and method for preparing same

InactiveCN102732186AGood compatibilityRaw materials are cheap and easy to getMonocarboxylic acid ester polymer adhesivesStarch derivtive adhesivesEpoxyAdhesive

The invention discloses a modified starch adhesive and a method for preparing the same. The modified starch adhesive comprises the following components by weight: 30-50 parts of corn starch, 80-120 parts of deionized water, 25-40 parts of sodium hypochlorite solution, 0.5-2 parts of epichlorohydrin, 30-70 parts of polyvinyl acetate emulsion, 10-30 parts of epoxy resin, 2-7 parts of tertiary amine catalyst, 5-15 parts of filler, 0.2-1 part of surfactant, and 0.2-0.6 part of preservative, wherein the sodium hypochlorite solution serves as the oxidant, the polyvinyl acetate emulsion serves as the high-cohesive-energy reinforcement component, and the epoxy resin servers as the water-tolerant modified component. The method for preparing the modified starch adhesive comprises the following steps: mixing the oxidized starch emulsion prepared in advance, the polyvinyl acetate emulsion and the epoxy resin according to proportion uniformly, adding the catalyst, the filler and the preservative, and stirring quickly and uniformly. The modified starch adhesive disclosed by the invention has the advantages of high shear strength, high water-tolerant shear strength, moderate viscosity, good liquidity, moderate primary drying time, low cost and excellent integrated performance.

Owner:EAST CHINA UNIV OF SCI & TECH

Boilproof alumen-free sheet jellies and processing method thereof

The invention discloses boilproof alumen-free sheet jellies and a processing method thereof. The boilproof alumen-free sheet jellies comprise the raw materials of starch, oxidized starch, sodium alginate, sodium dihydrogen phosphate, disodium hydrogen phosphate, sodium carbonate, salt and water. The boilproof alumen-free sheet jellies have the advantages that: the oxidized modified starch is applied to the process for preparing the sheet jellies for the first time; the paste liquid of the oxidized starch is transparent; the paste strip is short; and gelatinous property and film-forming property are high. The oxidized starch has a coordinated compatible and complementary action with the sodium alginate, the sodium dihydrogen phosphate, the disodium hydrogen phosphate, the sodium carbonate and the salt to form a good network structure. Therefore, the prepared sheet jellies have the characteristics of good mouthfeel, boiling resistance, no turbid soup, no broken strips and high transparency. The used oxidized starch has the advantages of simple preparation, eating safety and low cost.

Owner:黑龙江北大荒斯达奇生物科技有限公司

Degradable seedling culture container, and preparation method and application thereof

ActiveCN102504560APromote degradationQuick breakdownCultivating equipmentsPotato starchPolyvinyl alcohol

Owner:JIANGSU ACAD OF AGRI SCI

Preparation method for environment-friendly starch-based binder

InactiveCN102367367AImprove stabilityImprove adhesionProtein adhesivesStarch derivtive adhesivesPolyvinyl alcoholCitric acid

The invention discloses a preparation method for an environment-friendly starch-based binder. According to the method, oxidized starch and modified protein are mixed according to a mass ratio of 2:1 to 5:1; polyvinyl alcohol is added according to a mass ratio of oxidized starch to polyvinyl alcohol of 2:1 to 5:1 and uniformly mixed with oxidized starch and modified protein, and an obtained mixture is subjected to a reaction for 2 to 5 hours at a temperature of 50 to 80 DEG C; first liquid of the binder is prepared; the first liquid of the binder is taken out, an auxiliary agent is added, and the environment-friendly starch-based binder is prepared by uniformly mixing the first liquid of the binder and the auxiliary agent; the auxiliary agent is borax and / or citric acid, and the amount of the auxiliary agent accounts for 2 to 5% of the amount of dry starch base. The oxidation starch is prepared by using sodium periodate as an oxidizing agent and mixing the oxidizing agent with starch at a temperature of 20 to 50 DEG C; the raw material in the invention, starch, undergoes a chemical reaction with protein and produces firm chemical bonds, which enables a net structure of the binder to be formed; the net structure and the action of cross-linking agents allow the binder to have improved stability and enhanced water resistance; the invention enables cost to be saved and the goal of environmental protection to be realized.

Owner:SOUTH CHINA UNIV OF TECH

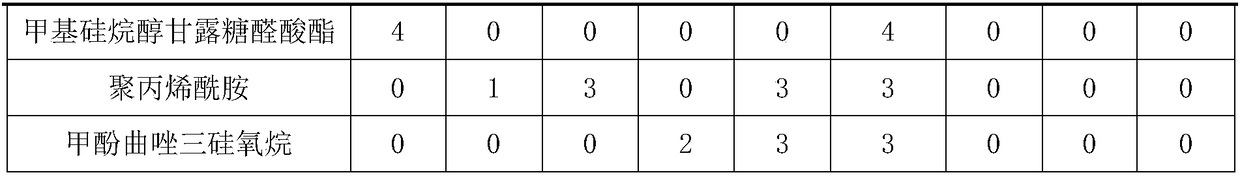

Special slurry for sizing warp containing polyester staple fibers

Owner:徐州众恒淀粉科技有限公司

Preparation process for urea formaldehyde slow-release and controlled-release compound fertilizer

InactiveCN103351222AIncrease profitEnsure safetyFertilizer mixturesAgricultural engineeringPotassium hydroxide

The invention relates to the field of fertilizers for crops and particularly relates to a preparation process for a urea formaldehyde slow-release and controlled-release compound fertilizer. The preparation process is characterized by comprising the following steps of: (1) adding 430kg of urea into a reaction kettle, adding water with the weight equal to 1.5-4 times of mass of the urea and stirring to dissolve the urea, regulating the pH to be 8-9 by utilizing borax and potassium hydroxide, and carrying out stirring reaction for about 1 hour at 75-80 DEG C; (2) adding oxidized starch with the weight equal to 8-10% of that of the urea, stirring for 15-20 minutes, and regulating the pH to be neutral by utilizing calcium oxide, so as to prepare a urea formaldehyde slow-release agent; and (3) weighing solid materials which are crushed to be 80 meshes according to the weight ratio of nitrogen to phosphorus to potassium to middle-trace elements being 4:1:2:1, putting the solid materials into a stirring machine to be uniformly stirred, putting the uniformly stirred materials into a pelletizer, and spraying the urea formaldehyde slow-release agent to carry out pelleting. With the adoption of the technical scheme, the novel slow-release and controlled-release compound fertilizer has the advantages that not only can the utilization rate of the fertilizer be improved, the food security can be guaranteed, and the environmental pollution can be alleviated; lifetime requirements of crops can be met after the fertilizer is applied once, the labor intensity of famers can be greatly alleviated, and the production inputs can be decreased.

Owner:HUBEI HUAFENG BIOLOGICAL CHEM

Esterified-starch-modified waxy corn wet glue and preparation method thereof

ActiveCN102757745AIncrease paste areaReduce decoration costsMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesBiotechnologyWaxy corn

The invention belongs to the field of auxiliary binders in the wallpaper industry and particularly relates to an esterified-starch-modified waxy corn wet glue. The esterified-starch-modified waxy corn wet glue is mainly prepared from the following raw materials in parts by weight through gelatinization, cross-linking and complexation: 76-77 parts of de-ionized water, 5-7 parts of esterified starch A, 3-5 parts of esterified starch B, 4-6 parts of oxidized starch, 4-6 parts of modified waxy corn starch, 0.5-0.8 part of acrylamide, 0.1-0.15 part of nonferrous aluminum sulfate, 0.4 part of sodium benzoate, 0.1-0.15 part of a defoaming agent, 2 parts of urea, 1-1.2 parts of ethylene glycol, 0.2-0.4 part of a bactericide and 2-4 parts of white latex. The invention also provides a preparation method of the modified waxy corn wet glue. The esterified-starch-modified waxy corn wet glue, disclosed by the invention, is extracted and purified from natural waxy corns, belongs to circular plant products and is a renewable resource, so that the policy of saving energy in China is performed better; and meanwhile, the esterified-starch-modified waxy corn wet glue has the advantages of strong bonding power and capabilities of being mixed with water for 100%, improving the bonding area of wallpaper and reducing decoration cost for a user.

Owner:GAREFU TECH CO LTD

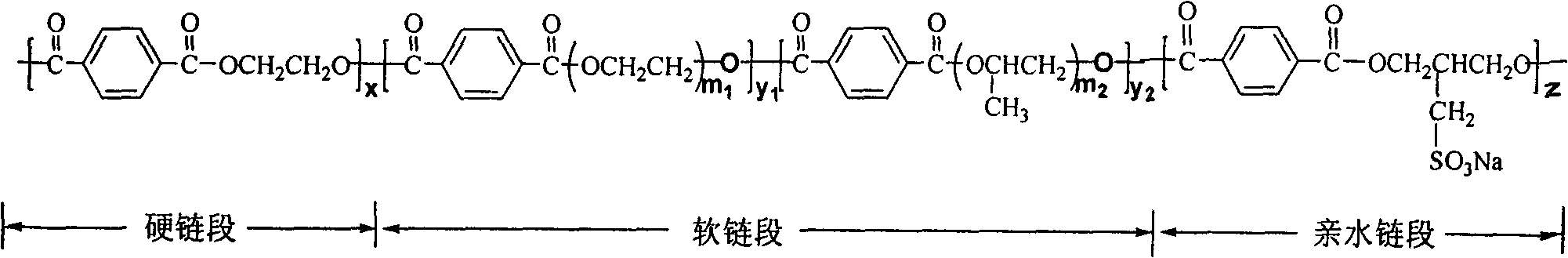

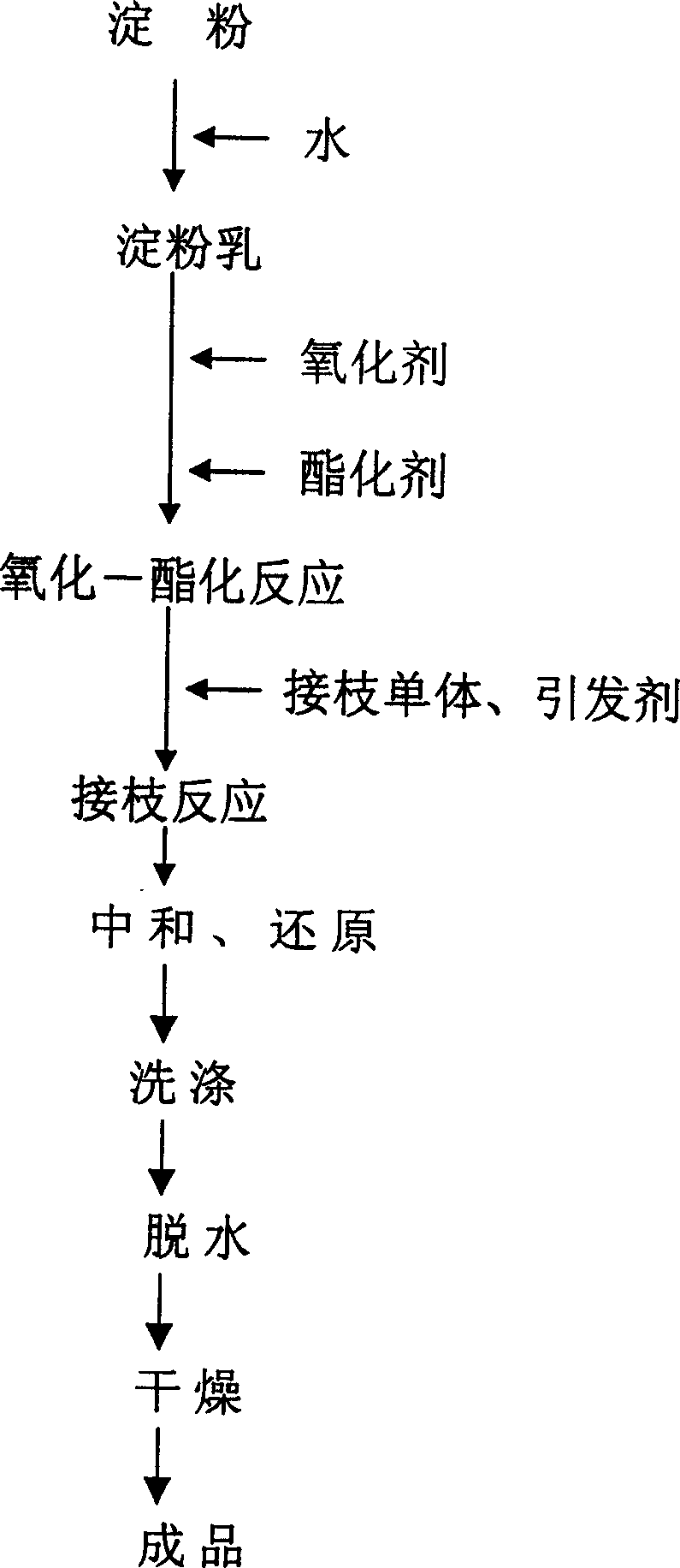

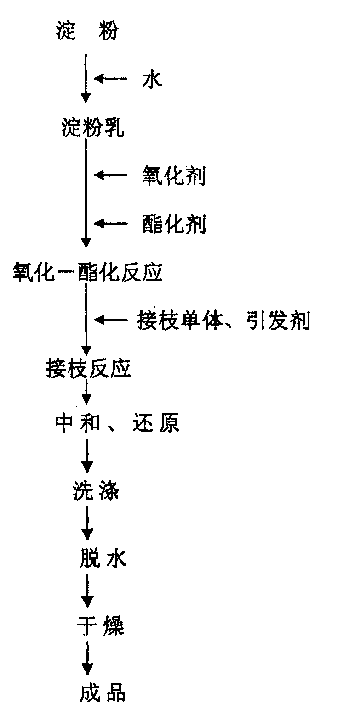

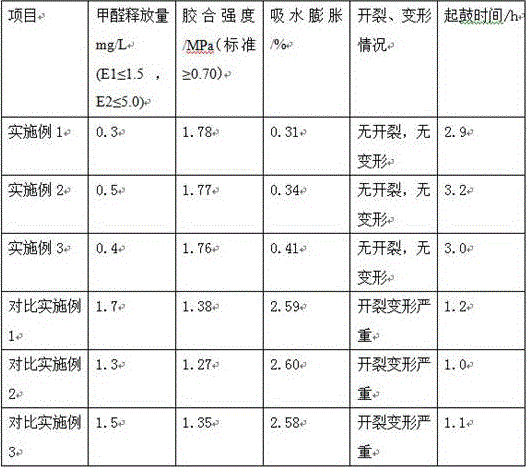

Oxidation-esterification-grafting three element complex denatured starch and its preparation method and application

InactiveCN1478795AProcess Design SciencePractical process designStarch dervative coatingsStarch derivtive adhesivesOxidised starchChemistry

Owner:JIANGNAN UNIV

Admixtures for mineral binders based on (oxidised) sugar and hydrogenated sugar, admixture-containing mineral binders, and a process for the preparation thereof

InactiveUS20030010254A1Improve mechanical propertiesImprove plasticityCosmetic preparationsSugar derivativesPhosphateArabitol

The invention relates to a novel admixture for mineral binders, composed of a composition containing at the same time a sugar or an oxidized sugar and a hydrogenated sugar. The oxidized sugar may consist, in particular, of gluconic acid or one of its salts or an oxidized starch hydrolysate. The hydrogenated sugar may consist in particular of maltitol, sorbitol, mannitol, xylitol, arabitol, or a hydrogenated starch hydrolysate containing at least 40% by weight of maltitol. Within the admixture, this composition may be combined with conventional admixtures such as phosphates, borates, or amines. The combination of a sugar or an oxidized sugar and a hydrogenated sugar within this composition makes it possible to obtain synergistic effects, particularly in terms of plasticity and mechanical properties of the mineral binders. The admixtures claimed may be used equally well for admixing with cements, raw materials for cements as for admixing with mortars, slurries and concretes. They may also be used in other sectors such as, for example, the plaster industry, particularly as complexing agents or hydration or dehydration controllers.

Owner:ROQUETTE FRERES SA

Method for preparing compound modified starch for replacing gelatin

The invention relates to a method for preparing compound modified starch for replacing gelatin, which comprises the steps of: first, mixing rice starch and water to form starch milk; adding an oxidant for reaction to obtain oxidized starch, then adding a cross-linking agent for reaction to obtain cross-linking starch, and then adding epoxypropane and alkali liquor for hydroxypropylate reaction to obtain the compound modified starch finally. The compound modified starch has performance advantages of various modified starches, good water-solubility, low pasting temperature, low viscosity of pasting, high stability, strong gelatinization, good freeze thawing stability and high transparency. The method has simple synthesizing process, low cost, high yield, and simple operation and is expected to replace gelatin and be applied actually in preparation of capsule wall material, jelly and candy.

Owner:ZHEJIANG UNIV

Method for producing particle board by adopting moisture-proof composite urea resin

ActiveCN106313205AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesWear resistantAdhesive

The invention discloses a method for producing particle board by adopting moisture-proof composite urea resin. The method comprises the steps of material preparation, drying, debarking, sand removing, sorting, grinding, glue blending, hot pressing molding and the like. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and a moisture-proof agent is also added to prepare the moisture-proof composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced particle board is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage. The particle board produced by the method disclosed by the invention is low in formaldehyde residual volume, also stable in quality, hard to damage, good in water resistance and good in moisture resistance.

Owner:广西横县新威林板业有限公司

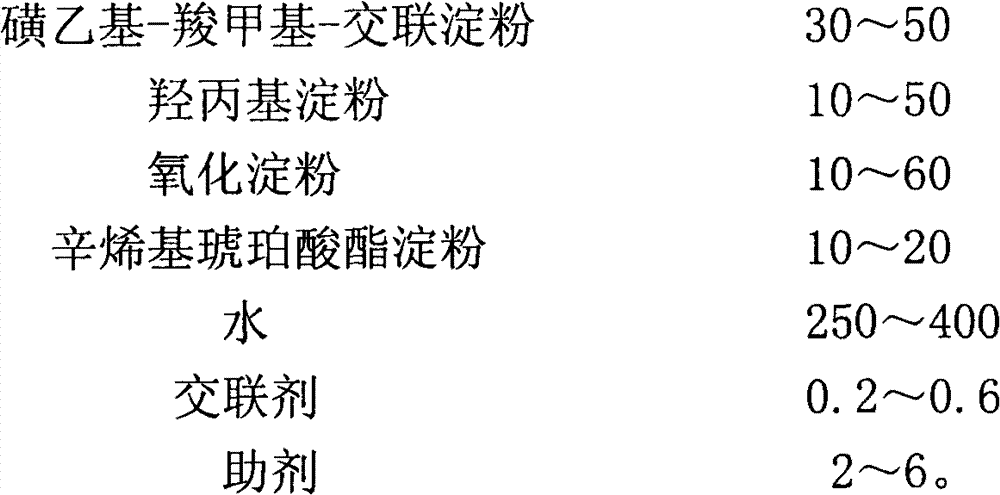

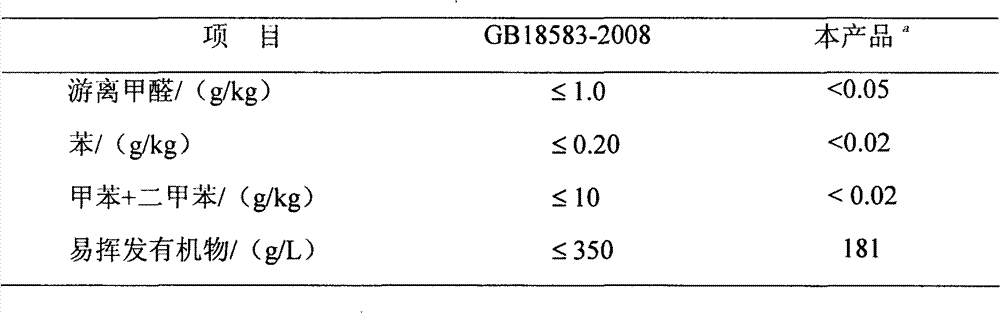

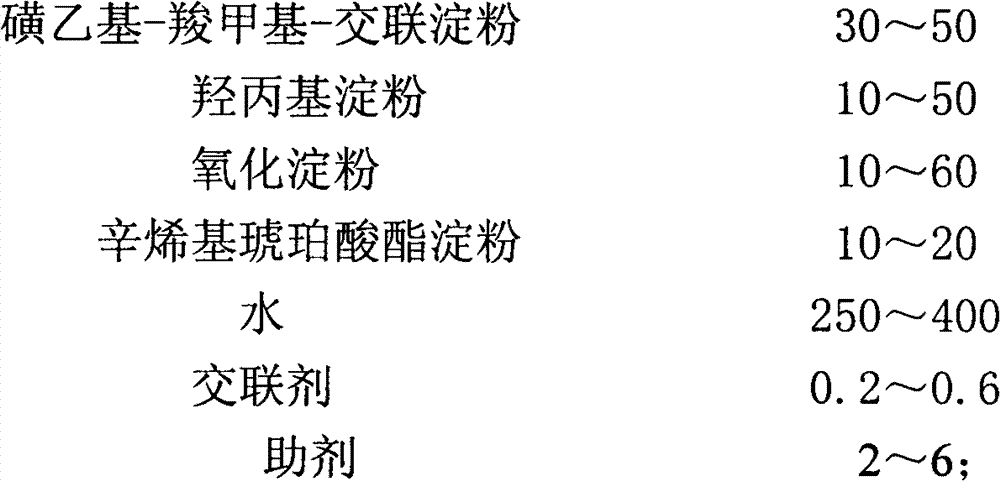

Method for preparing sulfoethyl-carboxymethyl-crosslinked starch based wallpaper adhesive

Owner:GANSU GLDARK NEW MATERIAL +1

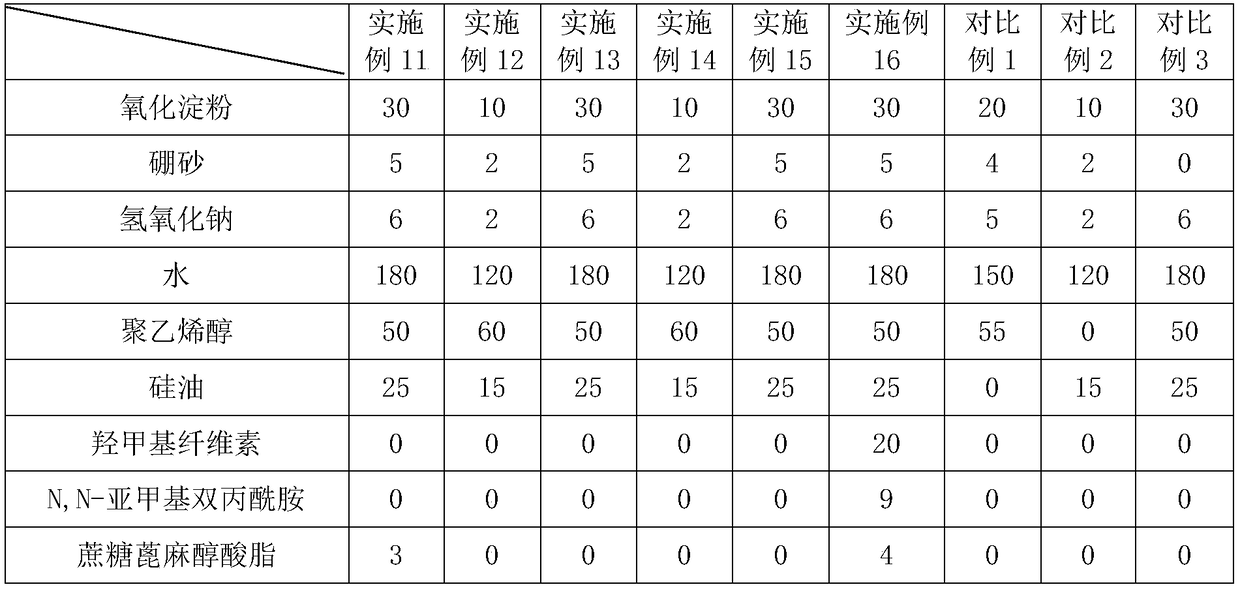

Glue for corrugated paper

ActiveCN108531111AHigh strengthHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberWheat starch

The invention discloses glue for corrugated paper. The glue comprises, by weight, 10-30 parts of oxidized starch, 2-5 parts of borax, 2-6 parts of sodium hydroxide, 120-180 parts of water, 50-60 partsof polyvinyl alcohol and 15-25 parts of silicone oil. The glue has the advantages that the glue comprise the oxidized starch, borax and sodium hydroxide, and the oxidized starch after being glued promotes bonding of fiber in the corrugated paper, so that strength of the corrugated paper is improved; the oxidized starch is prepared by oxidizing one of wheat starch, corn starch and tapioca starch,thereby being convenient to obtain, easy to degrade and environment-friendly; polyvinyl alcohol has good film forming performance and forms a flexible film on the surface of the corrugated paper, so that the strength of the corrugated paper is further enhanced; the silicone oil is dispersed in raw materials of the glue, and the corrugated paper after being glued has good moistureproof performance,so that the strength, the moistureproof performance and environment-friendly effect of the corrugated paper are improved; the glue is applied in production of high-strength low-gram-weight corrugatedpaper.

Owner:温岭市森林包装有限公司

Preparation method of compound water retention gel based on starch-grafted acrylic acid, sodium alginate and slag

The invention discloses a preparation method of compound water retention gel based on starch-grafted acrylic acid, sodium alginate and slag, which comprises the following steps: mixing sodium alginate as an organic matrix and slag as an inorganic porous filler to obtain a dispersion solution, oxidizing starch, grafting sodium hydroxide neutralized acrylic acid, mixing, and crosslinking sodium alginate and oxidized starch with acrylic acid and N,N'-methylenebis(acrylamide) as crosslinkers. The addition of calcium ions enhances the double effect of complexation between sodium alginate and oxidized starch, so that the three-dimensional grid of the prepared water retention gel has different sizes, which is in favor of improving the mechanical strength and water retention property of the water retention agent.

Owner:ANQING NORMAL UNIV

Ecological briquette surface curing agent and its preparing method

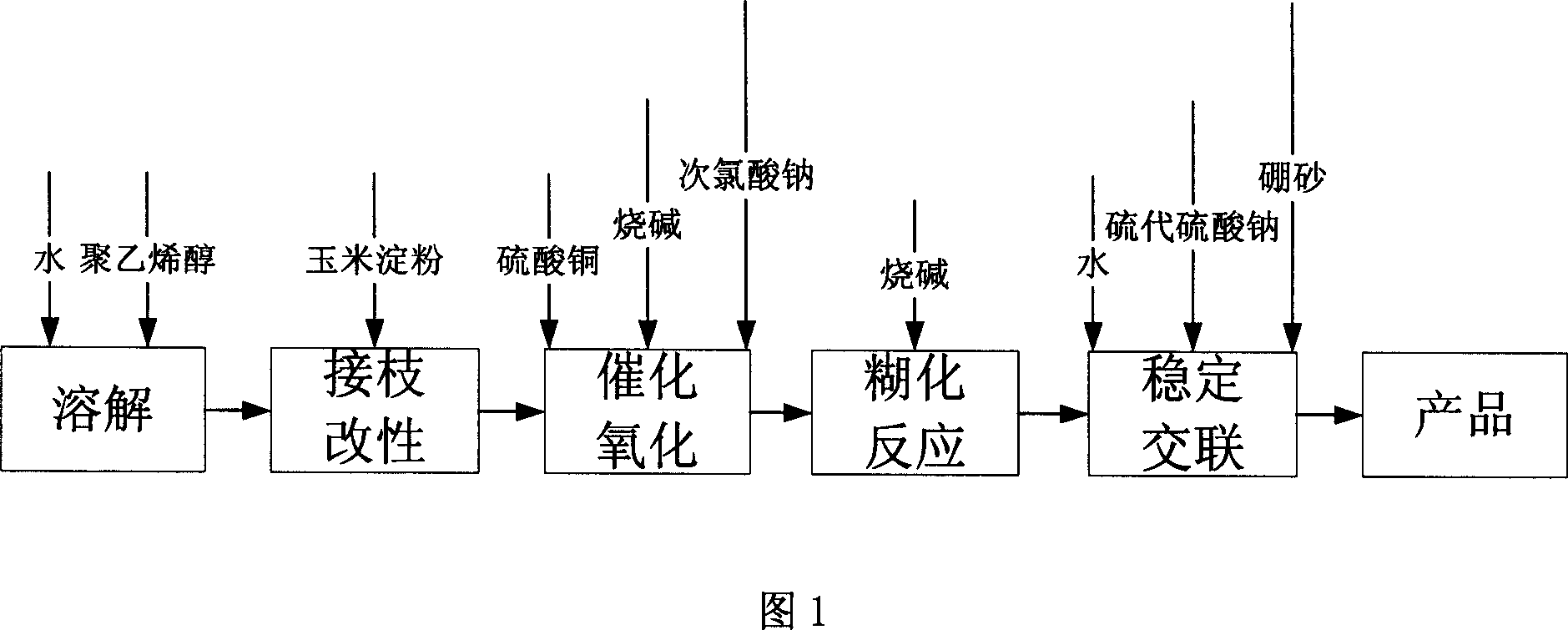

InactiveCN1935931AReduce flying lossReduce pollutionOther chemical processesTransportation itemsCross-linkSocial benefits

The invention relates to ecotype coal surface curing agent and the preparing method. It includes the following steps: using polyvinyl alcohol, corn starch as basic material, and water as solvent; grafting modification for the polyvinyl alcohol, corn starch; adding catalyst and oxidant to produce oxidized starch; adding caustic soda to gelatinize; adding water to dilute; adding stabilizer and cross-linking agent to prepare other component. It has the features of nontoxic, tasteless, satisfying environmental protection demand, strong coal cohesive force, wide material sources, economic, practical, and huge economic and social benefits for coal railway transportation.

Owner:BEIJING JIAOTONG UNIV

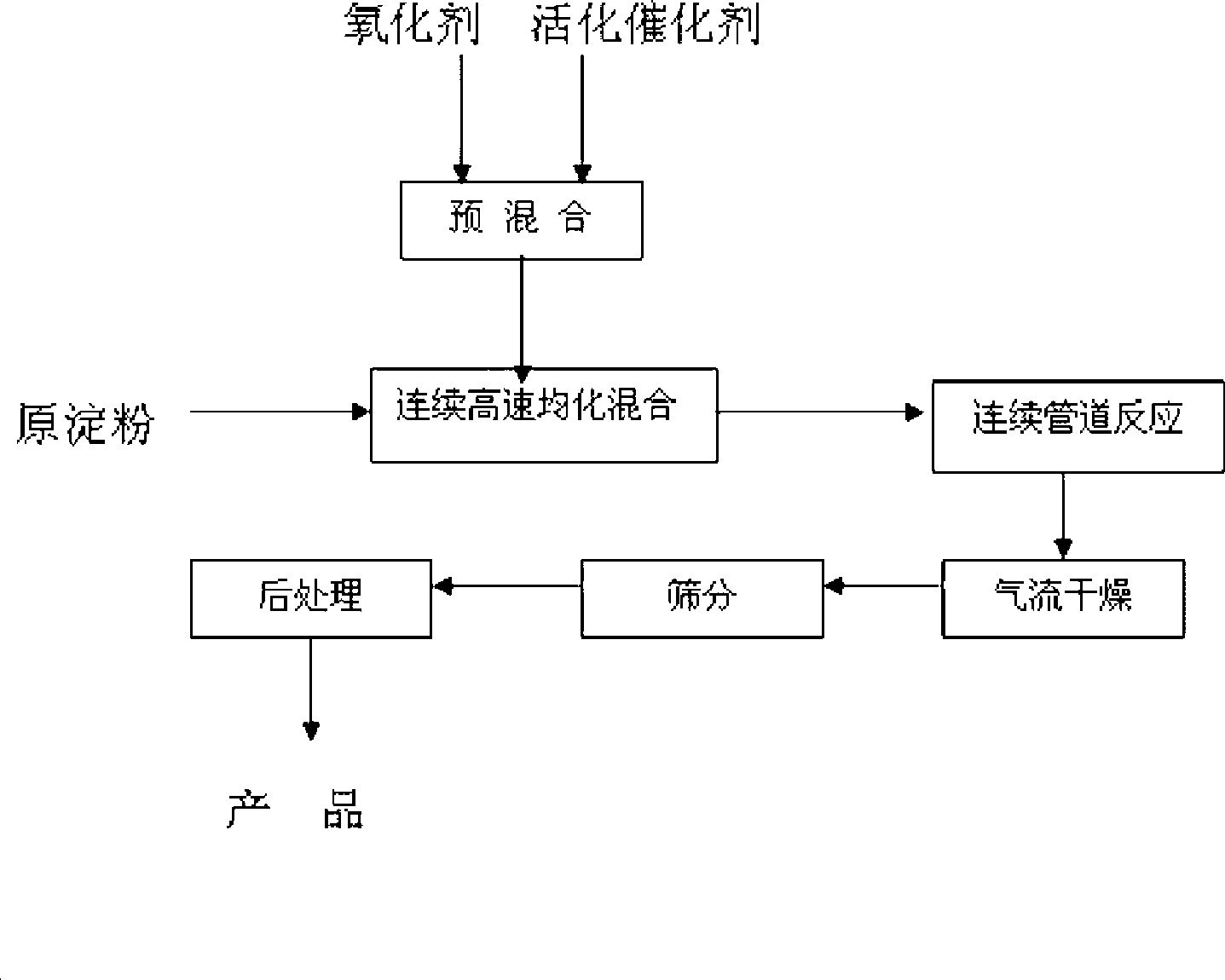

High efficiency and clean production method of oxidized starch

The invention relates to a high efficiency clean production method for oxidized starch. The technical problem to be solved by the invention is to carry out the production of the oxidized starch under the conditions of continuous fluidization without waste discharge, shorten the reaction time and reduce the energy consumption. The preparation method comprises: premixing and activating an oxidant and an activating catalyst in advance; and continuously metering and mixing the premixed and activated oxidant and the activating catalyst and the crude starch at a high speed, continuously inputting the mixed material into a pipeline reactor with a packing auger, and carrying out the pipeline reaction at 20 to 80 DEG C for 20 to 100 minutes so as to continuously obtain the oxidized starch crude product. The water content in the reaction system is 12 to 35 percent.

Owner:HANGZHOU PAPERMATE SCI & TECH

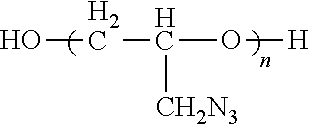

Resin Modified Starch Adhesive And Preparation Method Thereof

The present disclosure provides a resin modified starch adhesive. The resin modified starch adhesive comprises, by weight, 100 parts of a dry starch, 300-500 parts of deionized water, 20-40 parts of an epoxy resin, 5-10 parts of an azido polyether, 1-2 parts of 3, 5-diamido-1, 2, 4-triazole, 1-3 parts of a cyanoacrylate, 5-10 parts of sodium hypochlorite solution, 3-8 parts of sodium tripolyphosphate, 2-5 parts of hydrotalcite, 3-8 parts of kaolin and 1-4 parts of sodium sulfate. The starch adhesive is prepared by modifying an oxidized starch emulsion with an epoxy resin modified by the azido polyether to introduce reactive functional groups and water-resisting five-membered ring structures, thus the shear strength and the water resistance of the adhesive are greatly improved.

Owner:HONGSHENG TECH BEIJING CO LTD

Method for preparing etherification-oxidation-grafting multiple-modified starches

The invention discloses a method for preparing etherification-oxidation-grafting multiple-modified starches. The method comprises the following steps: using native starch as a raw material, adding an etherifying agent, an oxidizing agent and a composite catalyst, and completing etherification and oxidation reaction with one step by adopting a microwave semidry method; using the obtained etherified and oxidized starch as a raw material, adding an initiating agent, a basic catalyst and a composite vinyl monomer, and carrying out graft copolymerization reaction by adopting an open system method in a microwave reactor. The three modification methods of etherification, oxidation and grafting are organically combined, and a variety of reactive groups are grafted in the molecular structure of starch, the method enhances the advantages and avoid weaknesses and has complementary advantages. By regulating a process formula, the method can obtain a series of multiple-modified starches with different ratios of reactive groups and different grafting ratios. The multiple-modified starches have various good characteristics of carboxymethyl-etherified and / or hydroxyalkyl-etherified, oxidized and grafting starches and can be applied to the fields of papermaking, food, textile, daily chemical industry, polymeric flocculants, super absorbent materials, oilfield chemical materials, biodegradable mulch film and plastics and the like.

Owner:GUANGXI UNIV FOR NATITIES

Original-taste chicken steak and processing method thereof

The invention discloses an original-taste chicken steak and a processing method thereof. According to pickling materials, chicken breast is pickled with the pickling materials and then is coated with powder; pulp is coated and then the powder is coated; the powder for coating is wheat meal, potato starch, corn starch, oxidized starch, table salt, ground white pepper, garlic powder, sodium hydrogen carbonate, sodium carboxymethylcellulose and sodium alginate; and the pulp for coating comprises 3 parts of the table salt, 18 parts of the corn starch, 0.8 part of carrageenan, 0.5 part of a compound moisture retaining agent, 0.5 part of soybean oil, 1 part of egg white and 76.2 parts of water. According to the method, ingredients and additives are accurately selected and matched; the product processed by the method has low oil content and good water retaining property; and the outer-layer wrap is crispy and the inner-layer meat is delicious. The guarantee period of the product is increased by 5-15 days when being compared with that of similar products; the water retaining property is good, the oil content is low, the mouth feel is good and the taste of the chicken breast is improved; the appetite of people is improved and the eating convenience is increased; and by virtue of powder coating and oil frying processes, the product has a crispy taste when people eat.

Owner:LIAOCHENG DONGDA FOOD

Dry powder briquette adhesive, briquette including adhesive and preparation method of briquette

The invention relates to a dry powder briquette adhesive, which is made by mixing the following raw materials in parts by weight: 40 to 85 parts of bentonite, 10 to 50 parts of oxidized starch, 0.1 to 5 parts of sodium chlorides, 0.1 to 1 part of polyvinyl alcohol, 0.1 to 5 parts of sodium carbonate, 1 to 10 parts of calcium oxides and 0.5 to 10 parts of sodium carboxymethylcellulose. The invention also relates to a briquette including the adhesive and a preparation method thereof. By using the dry powder briquette adhesive, the briquette including the adhesive and the preparation method thereof, the disadvantages that a briquette adhesive has a large addition amount and a briquette is low in cold and hot strength and poor in heat stability, and the like in the prior art are solved.

Owner:河北东慈环保科技有限公司

Preparation method of oxidized starch

InactiveCN102443070ALow gelatinization temperatureImprove liquidityWater-repelling agents additionFibre treatmentOxidizing agentPotassium permanganate

The invention discloses a preparation method of oxidized starch. Corn starch, sulfuric acid, sodium hydroxide, potassium permanganate and sodium borate are used as main raw materials, and the oxidized starch is prepared via crude starch pretreatment, oxidation, pasting and complexation. The mass parts of the raw materials of the oxidized starch are: 100-110 parts of the corn starch, 11-12 parts of the sulfuric acid, 60-70 parts of the potassium permanganate, 36-40 parts of the sodium hydroxide, 95-105 parts of the sodium borate and 260-280 parts of water. The potassium permanganate is used as an oxidant, and the prepared oxidized starch has the advantages of low gelatinization temperature, good fluidity, white color and good film-forming performance.

Owner:NANTONG XIYUN TRADE

One-step method of preparing oxidated carboxymethyl starch sodium from sweet potato starch

The invention discloses a preparing method of sodium starch carboxymethyl oxide based on sweet potato starch, wherein the oxidant is 30% hydrogen peroxide; the alkalizer is sodium hydroxide; the etherifying agent is monochloroacetic acid; the solvent is anhydrous alcohol; these reactions are proceeded in the same reactor simultaneously.

Owner:NANCHANG UNIV

Preparation technology of oxidized hydroxypropyl starch

The invention discloses a preparation technology of oxidized hydroxypropyl starch. The preparation technology is characterized by comprising the following steps: S1, preparing starch milk; S2, performing a hydroxypropylation reaction on propylene oxide; S3, oxidizing hydroxypropyl starch; and S4, performing centrifugation, washing, oven drying, smashing and screening to obtain the oxidized hydroxypropyl starch. The oxidized hydroxypropyl starch prepared by the preparation technology has the characteristics of high whiteness, low gelatinization temperature, low paste viscosity, good freeze-thawstability, high transparency and the like, and has common characteristics of oxidized starch and hydroxypropyl starch. By controlling the usage amount of propylene oxide and the hydroxylation time, the content of hydroxypropyl in the starch can be increased, and the oxidized hydroxypropyl starch has strong freeze-thaw stability, and high transparency, salt resistance and acid resistance; and at the same time, after the hydroxylation is finished, oxidation of the starch is continued, and by controlling the usage amount of an oxidant and the oxidation temperature, the content of carboxyl in thestarch can be effectively increased, and the oxidation efficiency can be improved.

Owner:临泉县金禾面粉有限公司

Preparation method and application of oxidized starch

InactiveCN102718878AComply with clean and environmentally friendly production requirementsImprove smoothnessWater-repelling agents additionPaper coatingBursting strengthFiber

The invention provides oxidized starch, a preparation method thereof and application. The preparation method of the oxidized starch includes the steps: (1) under the condition of mixing, spraying catalyst solution into the starch, spraying oxidants and increasing the temperature to reach 30-50 DEG C; (2) after mixing the starch every 15 minutes within an hour, spraying residual oxidants to react for 4-8 hours; and (3) cooling the starch, adding neutralizers until the pH (potential of hydrogen) of a system is 6-8, crushing the starch, and screening the starch by a screen with 90-120 meshes to obtain the oxidized starch. The weight of the sprayed oxidants accounts for 30-60wt% of the overall weight of oxidants, catalysts are sodium hydroxide or potassium hydroxide, and the oxidants are hydrogen peroxide. The oxidized starch can be used for gluing the surface of paper, continuous and uniform films are formed on the surface of a paper sheet, oil resistance and scratch resistance of the paper sheet can be improved, and smoothness and glossiness of the paper sheet are improved. When the oxidized starch is used for internal sizing, paste can be uniformly and adsorbed on fibers, and the bursting strength and the folding resistance of the paper are improved.

Owner:新乡市东升新材料有限公司 +1

Process for the oxidation of starch

A process for the oxidation of starch to obtain carbonyl-substituted starch using V, Cr, Mn, Fe, Co or Cu, wherein Fe and / or Cu are preferred as catalyst. The oxidation of the starch proceeds in quasi-dry form by spraying the dry starch with solutions containing hydrogen peroxide and / or the catalyst and mixing the moistened powder. Oxidized starch containing up to approx. 10 carbonyl groups per 100 glucose units is obtainable.

Owner:DEGUSSA AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com