Method for preparing sulfoethyl-carboxymethyl-crosslinked starch based wallpaper adhesive

A technology of cross-linking starch and carboxymethyl, applied in the directions of starch-derived adhesives, adhesive types, etc., can solve the problems of unstable performance and slow drying speed of starch-based adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

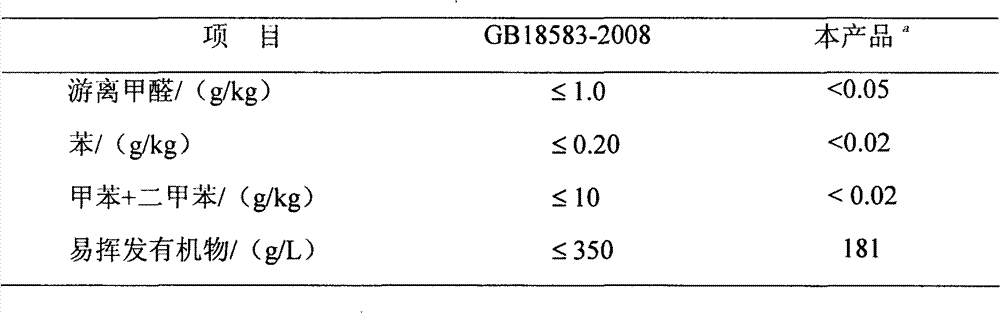

Benefits of technology

Problems solved by technology

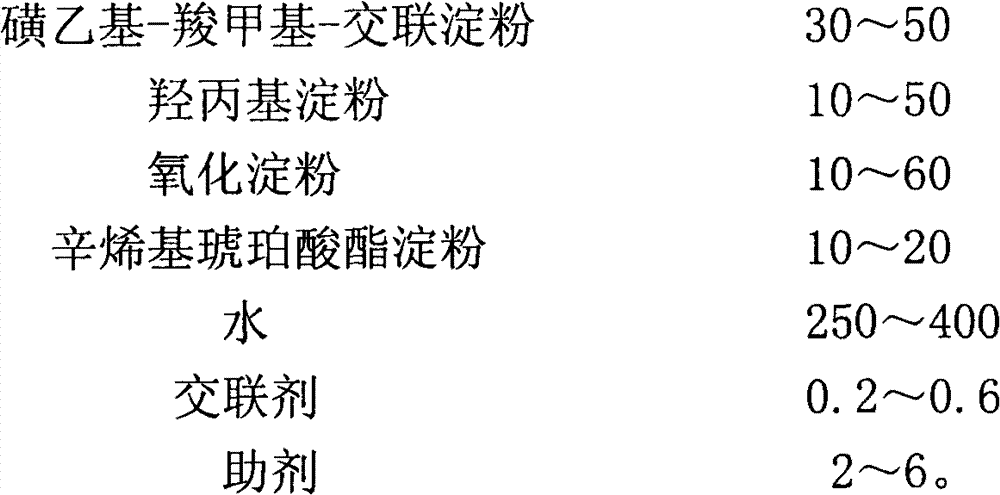

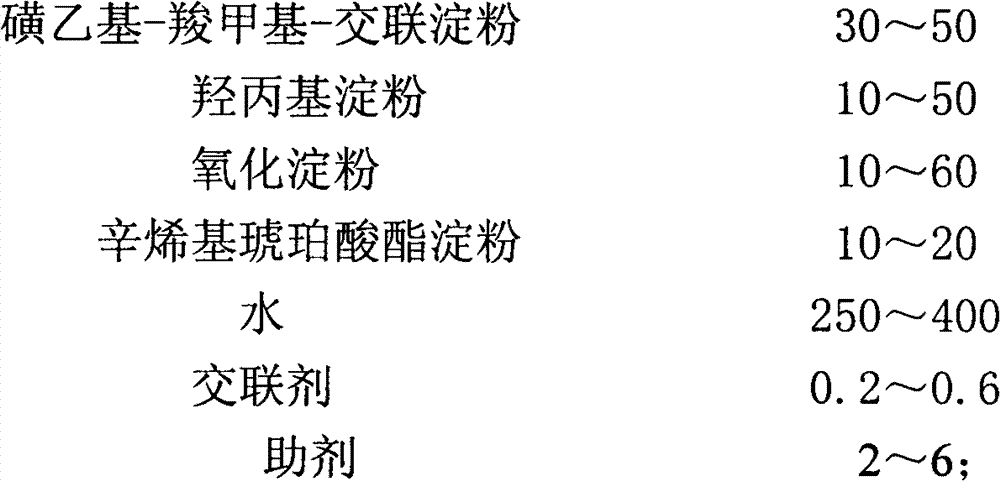

Method used

Image

Examples

Embodiment 1

[0033] (1). Add 340Kg of water to the mixing tank, and add 50Kg of hydroxypropyl starch, 40Kg of oxidized starch, and 10Kg of octenyl succinate in turn while stirring, so that the substances are evenly dispersed;

[0034] (2). Add 30Kg of sulfoethyl-carboxymethyl-cross-linked starch into the above-mentioned slurry mixing kettle, and stir for 15 minutes to disperse the added substances evenly;

[0035] (3). Raise the temperature to 60°C, add 0.6Kg of sodium tetraborate, and stir for 50 minutes;

[0036] (4). Cool down to room temperature, add 4Kg of additives, and stir until uniform;

[0037] (5). Filter with 80 meshes to obtain the wallpaper glue product.

Embodiment 2

[0039] (1). Add 300Kg of water to the mixing tank, and add 40Kg of hydroxypropyl starch, 20Kg of oxidized starch, and 15Kg of octenyl succinate in turn while stirring, so that the substances are evenly dispersed;

[0040] (2). Add 40Kg of sulfoethyl-carboxymethyl-cross-linked starch into the above-mentioned slurry mixing kettle, and stir for 10 minutes to disperse the added substances evenly;

[0041] (3). Heat up to 70°C, add 0.4Kg of sodium tetraborate, and stir for 60 minutes;

[0042] (4). Cool down to room temperature, add 3Kg of additives, and stir until uniform;

[0043] (5). Filter with 80 meshes to obtain the wallpaper glue product.

Embodiment 3

[0045] (1). Add 250Kg of water into the mixing tank, and add 10Kg of hydroxypropyl starch, 30Kg of oxidized starch, and 10Kg of octenyl succinate in turn while stirring, so that the substances are evenly dispersed;

[0046] (2). Add 50Kg of sulfoethyl-carboxymethyl-cross-linked starch into the above-mentioned slurry mixing kettle, and stir for 15 minutes to disperse the added substances evenly;

[0047] (3). Raise the temperature to 75°C, add 0.4Kg of sodium tetraborate, and stir for 60 minutes;

[0048] (4). Cool down to room temperature, add 2Kg of additives, and stir until uniform;

[0049] (5). Filtering with a 100-mesh screen to obtain the wallpaper glue product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com