High efficiency and clean production method of oxidized starch

A technology of oxidized starch and a manufacturing method, which is applied in the field of efficient and clean manufacturing of continuous fluidized oxidized starch, can solve the problems of increasing production cost, waste water pollution, reducing product yield and the like, and achieves low production cost, less investment, and reaction time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

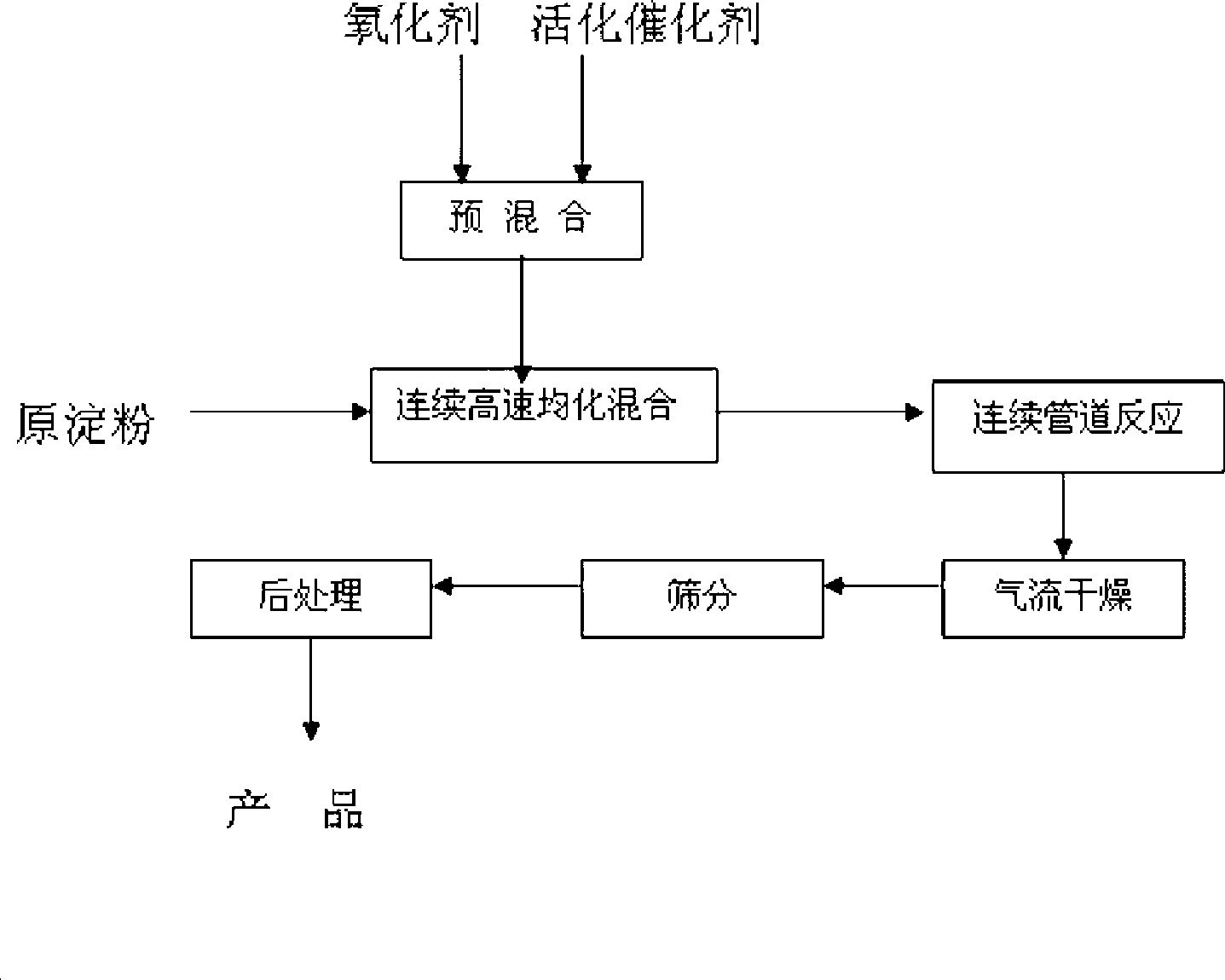

Image

Examples

Embodiment 1

[0016] This example oxidized starch efficient and clean manufacturing method (continuous fluidized manufacturing method), adopts cornstarch and potassium permanganate (its consumption is 1.5% of starch) as the proportioning raw materials, selects NiSO 4 To activate the catalyst, it was used in an amount of 30 ppm by weight of cornstarch.

[0017] Catalyst NiSO 4 Dissolve in water to prepare a 5% aqueous solution, then mix the oxidizing agent and the catalyst according to the above ratio, and then mix and homogenize with corn starch continuously and rapidly for 15 minutes in a coulter-type closed device with a rotation speed of 800 rpm.

[0018] The mixed and homogenized material continuously and evenly enters the pipeline reactor with an auger. The material is reacted at 65°C for 30 minutes, and the moisture content of the reaction system is 20%. The viscosity of the primary product of oxidized starch is continuously obtained at about 200mpa. s (BROOKFIELD viscosity, concentr...

Embodiment 2

[0020] As operating according to Example 1, the reaction temperature is controlled at 60°C, the starch adopts potato starch and sodium peroxide (its consumption is 5% of the starch) as raw materials, and CuCl is selected. 2 When it is a catalyst, when its consumption is 40ppm of potato starch, the viscosity of the first product of potato oxidized starch obtained is about 10mpa.s (BROOKFIELD viscosity, concentration 5%, 90°C).

Embodiment 3

[0022] As operating according to Example 1, the reaction temperature is controlled at 70°C, the starch adopts cornstarch and persulfuric acid (its consumption is 3% of the starch) as the proportioning raw materials, and selects FeSO 4 And when CaO (weight part 2:1) is catalyzer, when its consumption is 70ppm of cornstarch, the viscosity that obtains corn oxidized starch first product is about 50mpa.s (NDJ-1 viscosity 60rpm / l No. rotor, concentration 10%, 70°C), the carboxyl content is about 0.09.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com