Modified starch adhesive and method for preparing same

A starch adhesive and modification technology, which is applied in the direction of starch-derived adhesives, adhesives, monocarboxylate copolymer adhesives, etc., can solve the problems of insignificant improvement of bond strength, poor fluidity of the system, and steric hindrance Increase and other problems, achieve significant water resistance shear strength, increase shear strength, and improve water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare oxidized starch emulsion and polyvinyl acetate emulsion according to the preparation method of modified starch adhesive in the patent of the present invention in advance. Add an appropriate amount of polyvinyl acetate and epoxy resin to the oxidized starch emulsion, add an appropriate amount of tertiary amine catalyst, filler, defoamer, preservative, etc., and stir rapidly for 20 minutes to obtain the sample.

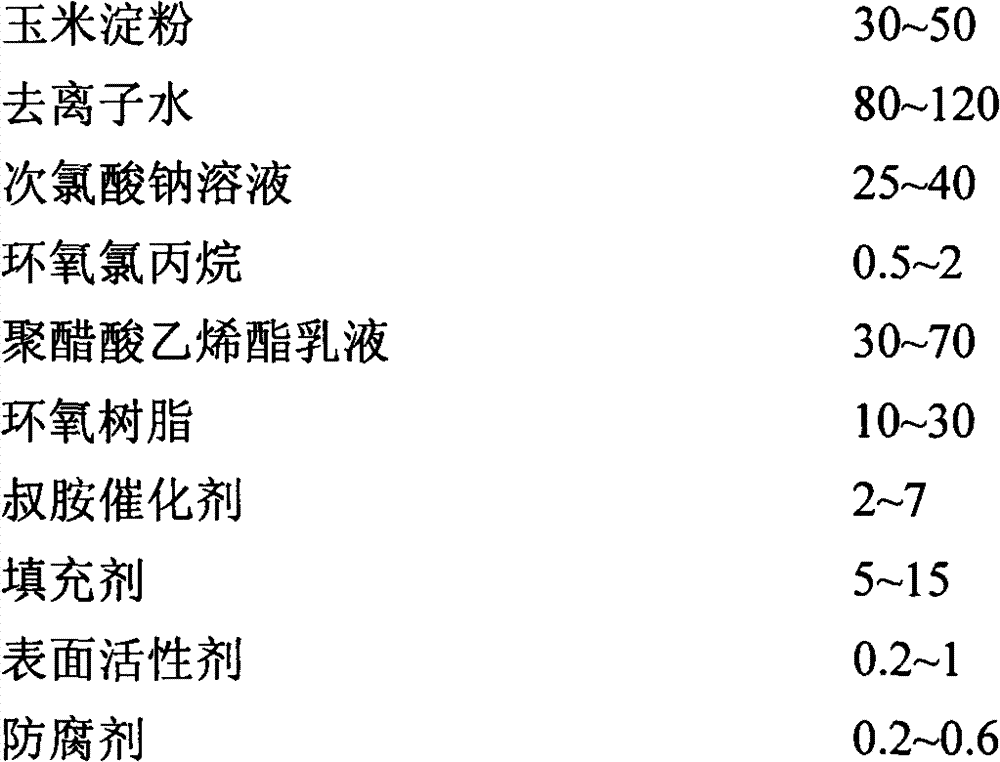

[0033] Each component and its mass parts are as follows:

[0034]

Embodiment 2

[0036] Raw material pretreatment and modified starch glue preparation method are the same as embodiment 1.

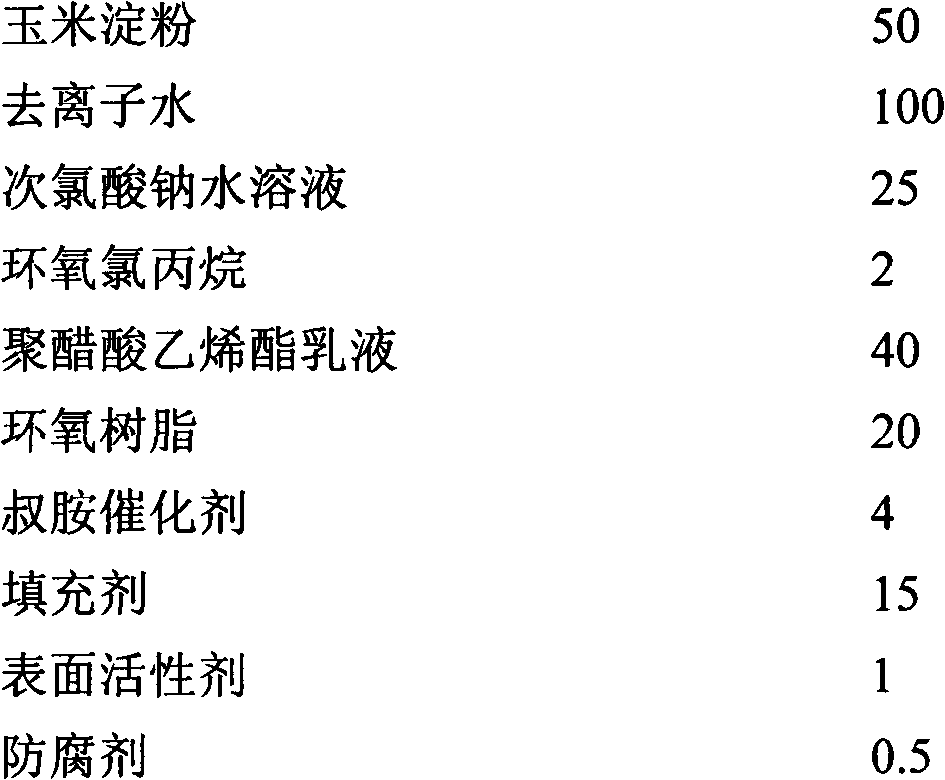

[0037] Each component and its mass parts are as follows:

[0038]

Embodiment 3

[0040] Raw material pretreatment and modified starch glue preparation method are the same as embodiment 1.

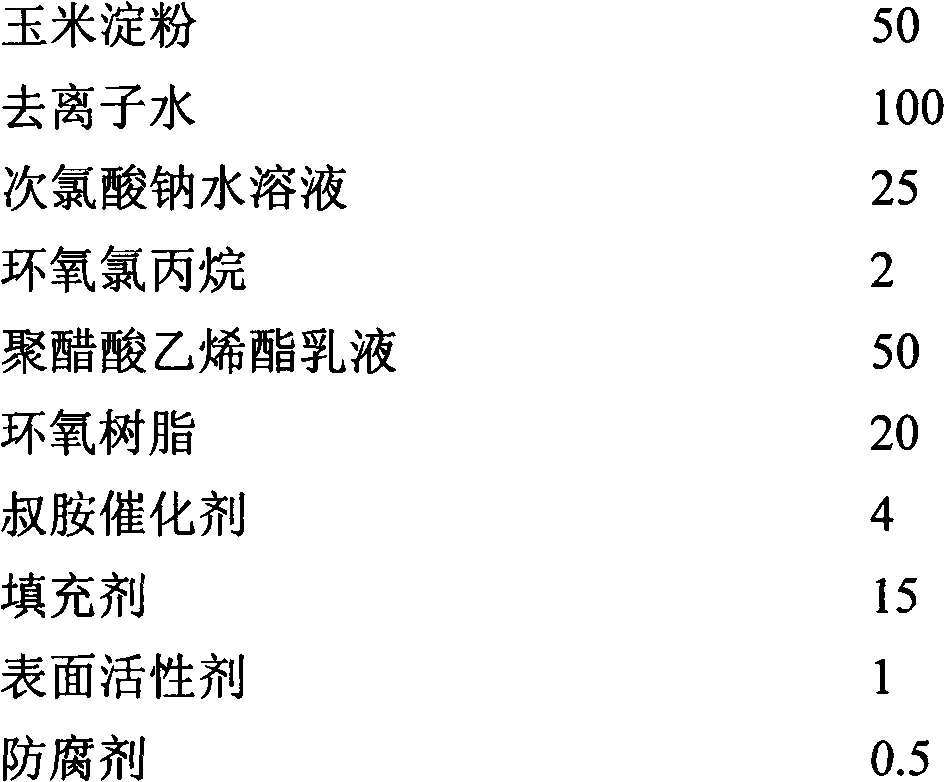

[0041] Each component and its mass parts are as follows:

[0042]

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com