Patents

Literature

33results about How to "High hot and cold intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing cold-bonded pellets from iron containing sludge by compound adhesive

InactiveCN101775489AReduce the amount of non-ferrous materialsReduce pollutionCelluloseSodium Bentonite

The invention relates to a method for preparing cold-bonded pellets from sludge containing iron by an compound adhesive, belonging to the technical field of adhesives for metallurgical ironmaking. The method of the invention comprises the following concrete steps: adopting the compound adhesive of an inorganic adhesive and an organic adhesive, wherein the organic adhesive in the compound adhesive comprises the following raw materials: vinyl acetate, acroleic acid, sodium cellulose glycolate, polyvinyl alcohol, polyisobutylene, molasses and coal tar; and the inorganic adhesive comprises the following raw materials: bentonite, calcium oxide, basic sodium silicate, sodium chloride, talcum powder and light calcium carbonate. When the organic adhesive and the inorganic adhesive in the adhesive are prepared, the components are proportioned and controlled strictly in a proper order, so that the defects of one adhesive singly used can be avoided, and the compound adhesive has good caking property on the iron containing sludge. The method of the invention recycles iron from iron containing sludge and changes waste into resources, thereby reducing pollution of storage and transport on the environment, and saving the energy consumption in the sintering and high furnace production.

Owner:TONGJI UNIV

Dry powder briquette adhesive, briquette including adhesive and preparation method of briquette

The invention relates to a dry powder briquette adhesive, which is made by mixing the following raw materials in parts by weight: 40 to 85 parts of bentonite, 10 to 50 parts of oxidized starch, 0.1 to 5 parts of sodium chlorides, 0.1 to 1 part of polyvinyl alcohol, 0.1 to 5 parts of sodium carbonate, 1 to 10 parts of calcium oxides and 0.5 to 10 parts of sodium carboxymethylcellulose. The invention also relates to a briquette including the adhesive and a preparation method thereof. By using the dry powder briquette adhesive, the briquette including the adhesive and the preparation method thereof, the disadvantages that a briquette adhesive has a large addition amount and a briquette is low in cold and hot strength and poor in heat stability, and the like in the prior art are solved.

Owner:河北东慈环保科技有限公司

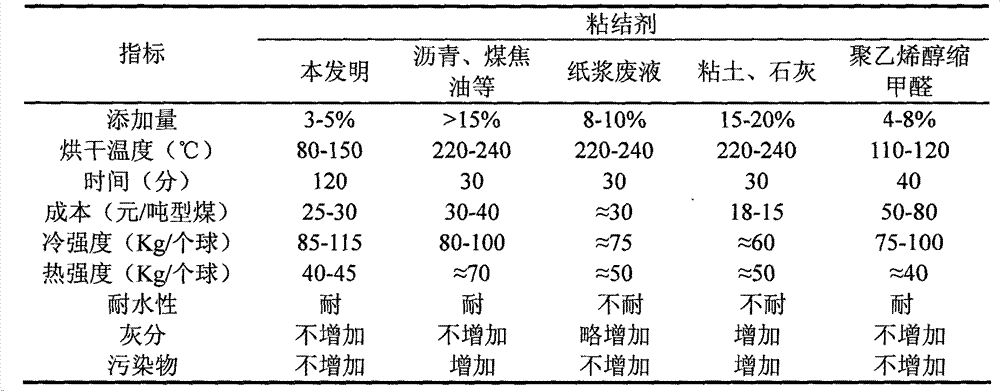

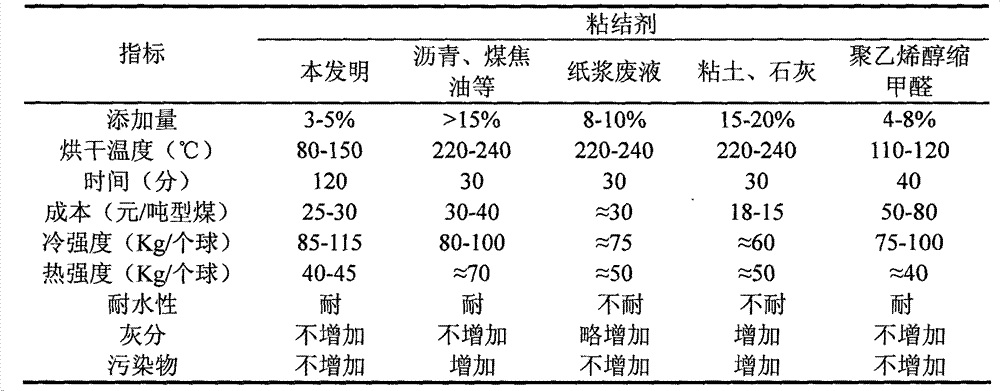

Novel waterproof compound coal binder

InactiveCN103710065AImprove adhesionConvenient and cheap sourceSolid fuelsSodium BentoniteEconomic benefits

The invention discloses a novel waterproof compound coal binder mainly used for the molding production of industrial gasification briquette from pulverized anthracite. The binder comprises bentonite, starch, extraordinary resin, cement and an organic polymer material. The binder has the advantages of low consumption, simple preparation technology, low cost, no secondary pollution, and suitableness for various coals. Molded gasification briquette processed in the invention has high cold and hot strengths (a cold compression strength of 85-115kg / ball and a hot compression strength of 40-45kg / ball, has a strong binding power and a good waterproof property, so the binder has a good economic benefit and application prospect.

Owner:ZHENGZHOU UNIV

Low-smoke-intensity and high-sulfur fixation adhesion agent

InactiveCN103215096AHigh hot and cold intensityImprove waterproof performanceSolid fuelsSlagPolyethylene glycol

The invention discloses a low-smoke-intensity and high-sulfur fixation adhesion agent. The adhesion agent consists of the following components in parts by weight: 30-40 parts of magnesium oxychloride cement, 10-20 parts of bentonite, 20 parts of steel furnace waste slag, 5 parts of graphite gangue, 2 parts of trisodium phosphate, 8 parts of sodium silicate, 3 parts of a solidification agent, 7 parts of a hardening agent and 5 parts of polyethylene glycol. The low-smoke-intensity and high-sulfur fixation adhesion agent provided by the invention has the advantages of low smoke blackness and good sulfur fixation performance; moreover, combustion performance of briquette coal cannot be changed, no calorific value is not reduced, briquette coal has good waterproofness, cold and hot strength is high and mechanical performance is good.

Owner:徐祥兵

High-strength waterproof deck binder and preparation method thereof

ActiveCN105754495AWell mixedBond firmlyNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceBitumen emulsion

The invention discloses a high-strength waterproof deck binder and a preparation method thereof.The binder is made by mixing components A, B and C according to a weight ratio of 1:1:1.5; the component A comprises, according to parts by weight: 100 parts of emulsified asphalt, 60-75 parts of EVA (ethylene-vinyl acetate copolymer), 20-30 parts of hydroxypropyl acrylate, 5-8 parts of hydroxyethyl acrylate, 0.2-2 parts of polytetrafluoroethylene, and 2-7 parts of an amine curing agent; the component B comprises, according to parts by weight: 40-45% of bentonite, 3-4% of starch, 1-3% of special resin, 6-9% of an organic polymer material, and 40-50% of asphalt-cement; the component C is made by mixing the following materials according to percent by weight: 10-40% of white cement, 5-20% of mica powder, 5-20% of ash calcium powder, 5-15% of silica fume powder, 10-40% of quartz sand, 0.1-0.7% of dispersible emulsion powder, 0.1-0.5% of organosilicon powder, 0.1-0.5% of lignin, and 0.1-0.4% of polypropylene fiber; the quartz sand is 20-80 in mesh.

Owner:江苏文昌新材料科技有限公司

High viscosity briquette waterproof composite binder

InactiveCN105296045AImprove molding rateImprove cohesionSolid fuelsEconomic benefitsThermal stability

The invention discloses a high viscosity briquette waterproof composite binder, which includes the following raw materials by weight: 350-400 parts of pregelatinized starch, 400-450 parts of magnesium oxide, 100-150 parts of fly ash, 50-100 parts of red mud, 6-8 parts of soda ash, and 4-6 parts of polyacrylamide. The binder provided by the invention has viscosity of greater than or equal to 20000Mpa.s, granularity of 200-mesh up to 85%, a moisture content of less than or equal to 10% and a pH value of 8.5-9.0. The briquette provided from the binder provided by the invention not only has strong waterproof performance, but also has the advantages of flammability, good thermal stability, high cold-hot strength, high reaction activity, high thermal efficiency and environmental protection, also has the advantages of wide raw material sources, low cost, simple preparation process and the like, has very good social, ecological and economic benefits, and is easy to realize large-scale production.

Owner:GUANGXI JINZHUANGJIN ENERGY SAVING TECH

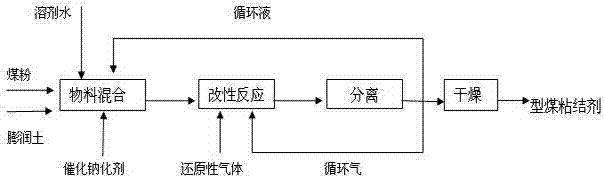

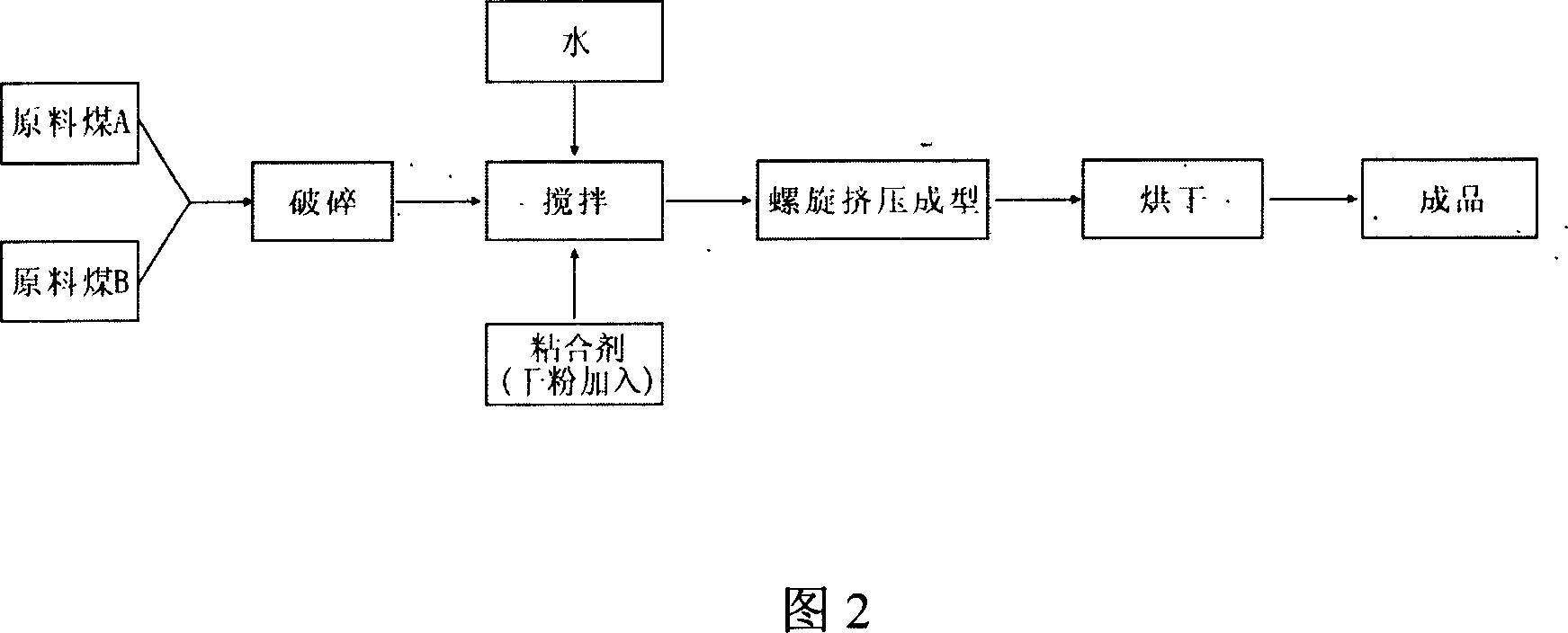

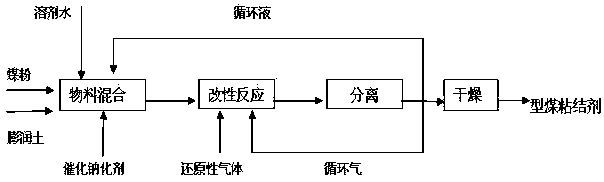

Method for preparing briquette binder

ActiveCN103113949AEasy to operateWill not increase the contentSolid fuelsCoal briquetteSocial benefits

The invention relates to a method for preparing a briquette binder. According to the method, pulverized coal and bentonite are taken as master batches and are matched with water as a solvent and a catalytic sodium agent so as to react at a high temperature and a high pressure for preparation of the briquette binder. The method has the advantages of obviously improving the coking property of coal briquette, being simple in technology and simple in operation and having obvious economic and social benefits. Raw materials are wide in source and have low cost.

Owner:TAIYUAN UNIV OF TECH

Coke quenching method for solid powder and materials therefor

The invention discloses a coke quenching method and material of solid powder, which comprises the following steps: pouring red coke in the coke quenching car powder to blend evenly; dissipating heat; putting coke and coke quenching powder into sieving equipment when the coke temperature is below 200 Deg C; finishing coke quenching.

Owner:何相华

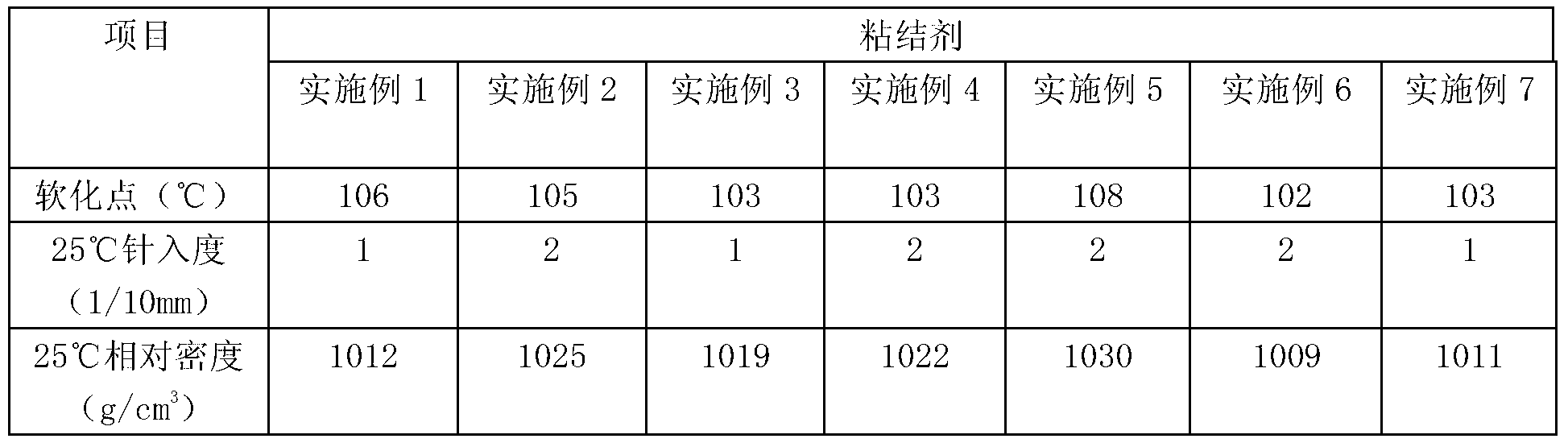

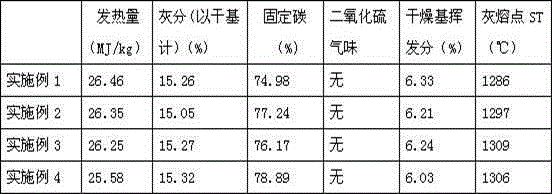

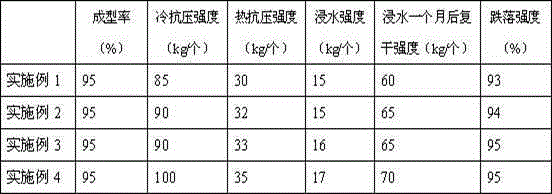

Technology of sodium-based serial composite modified briquette for gasification

InactiveCN102786996AHigh hot and cold intensityImproved hot and cold intensitySolid fuelsFixed-bed gasificationThermal stateCompressive strength

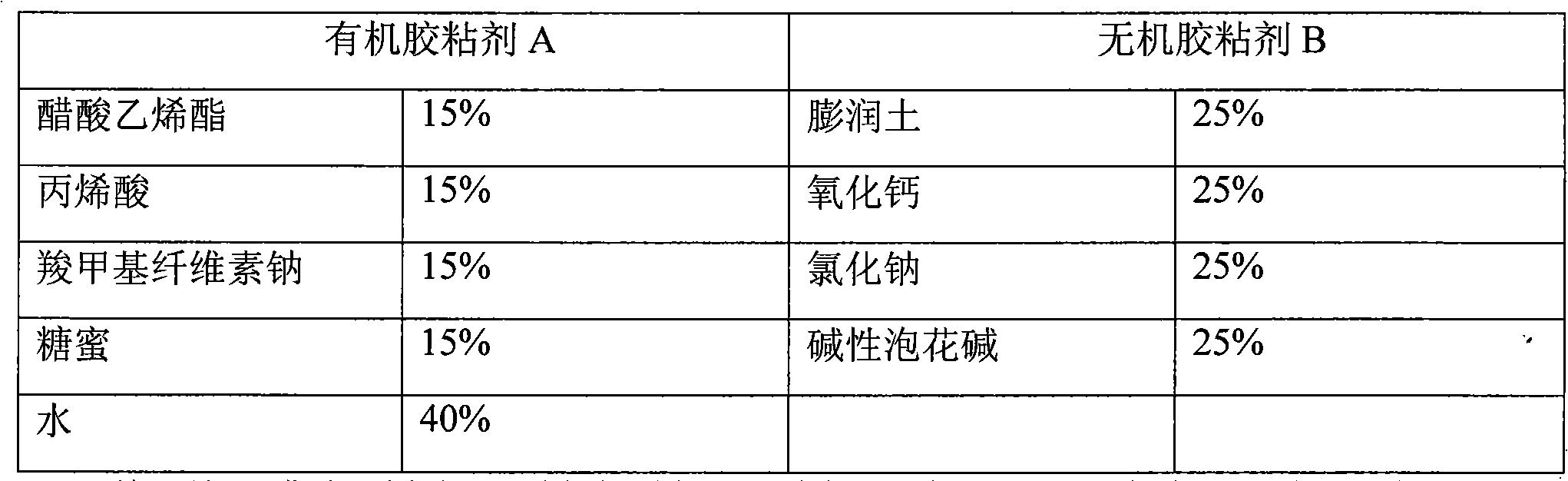

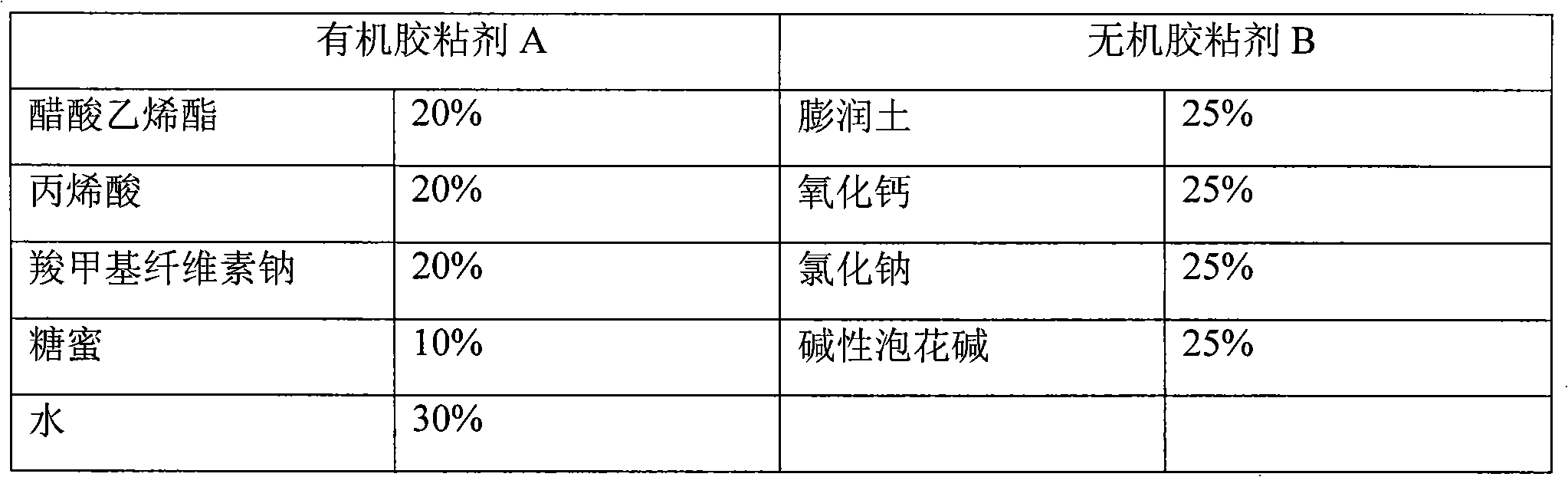

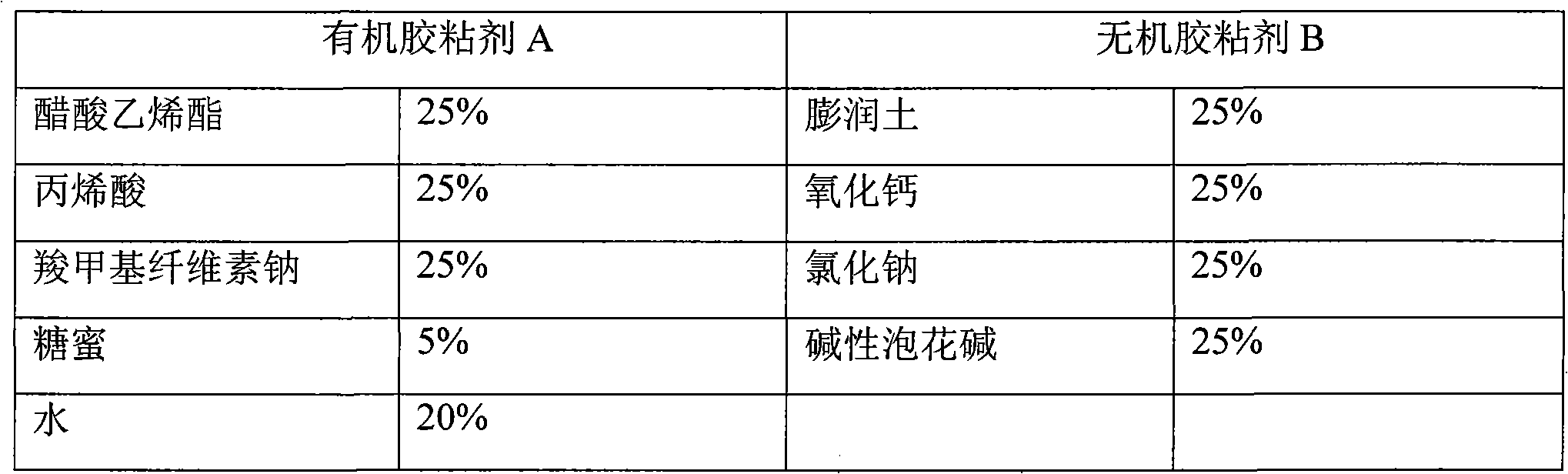

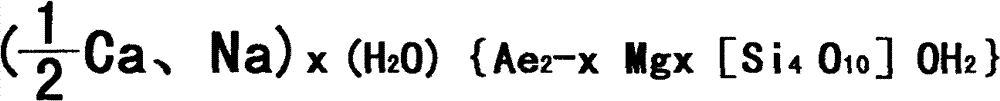

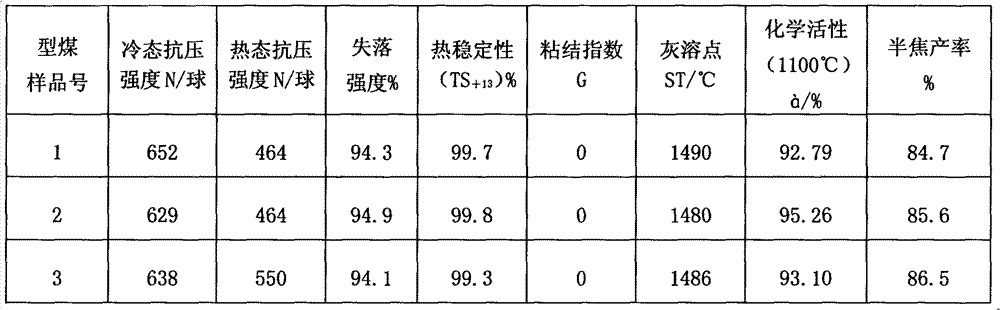

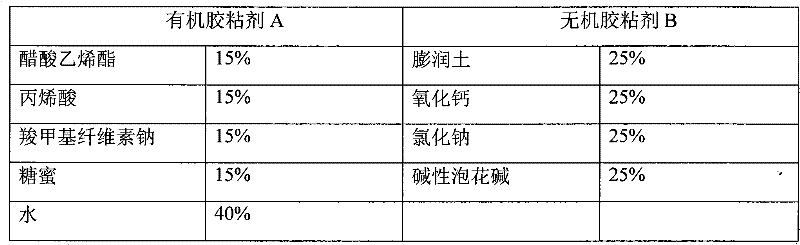

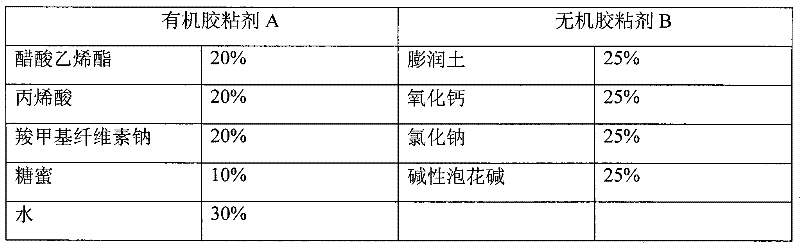

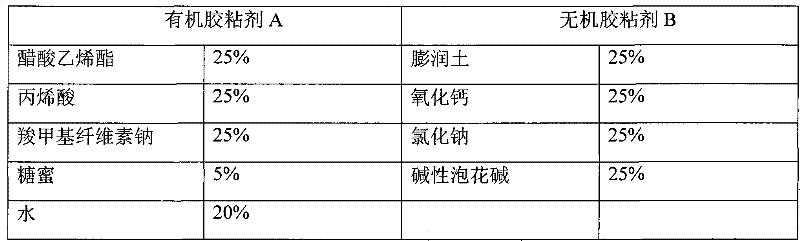

The invention discloses technology of sodium-based serial composite modified briquette special for gas stoves. The technology is established through optimization and screening based on multiple-batch and long-period industrial tests. Preparation of a two-component binder is the core technology of the invention; the binder comprises a sodium-based organic binder component (NR1) and a sodium-based inorganic binder component (NR2) which are respectively prepared through modification of organic matter and inorganic matter which are widely distributed, rich in reserve, and low in price. Before powder coal shaping, the (NR1) and (NR2) components are mixed with the powder coal according to a certain proportion based on the coal quality conditions; after procedures of kneading, shaping, and consolidation, a gasification briquette product is processed, which has cold-state compressive strength of not less than 600 N / ball, thermal-state compressive strength of not less than 400 N / ball, thermal stability of more than 99%, an ash fusion point ST of more than 1400 DEG C, a bonding index G tending to be zero, and chemical activity of more than 90%. Practice confirms that the special briquette produced by the sodium-based two-component composite binder is far better than Datong lump coal commonly used by people with respect to gasification performance. The popularization and application of the technology of the invention can not only relieve the situation of few product and high price for commercial lump coal, but also increase the value of powder coal processing, greatly reduce fuel cost for briquette users, and the technology of the invention is innovative technology with long development prospects.

Owner:李长安 +2

Low rank pulverized coal pyrolysis oil extraction process

InactiveCN105273732AReduce dust generationReduce generationSpecial form destructive distillationCoal pyrolysisAdhesive

The invention discloses a low rank pulverized coal pyrolysis oil extraction process. The process includes: taking 100 parts of low rank pulverized coal, 10-15 parts of a 0.5%-2% organic binder, and 8-15 parts of strong adhesive pulverized coal as the raw materials, and mixing the material evenly, and extruding the mixture into block coal on briquetting equipment; drying the block coal, then putting it into a pyrolysis furnace, conducting air isolation heating at 550-650DEG C, recovering the volatile and performing condensation and cooling so as to obtain gas phase coal gas, a tar, water and tar residue mixture, and solid semicoke, separating the tar, water and tar residue to obtain tar, tar residue and water; and adding the each time separated tar residue into the raw material of follow-up oil extraction process to be used as an auxiliary adhesive for briquetting of low rank pulverized coal. Therefore, the a lot of powder of low rank coal can be utilized efficiently, and the tar yield is significantly increased.

Owner:CHINA UNIV OF MINING & TECH

Environment-friendly clean coal for civil use and preparation method thereof

InactiveCN106085538AGet rid of dependenceRaw materials are easy to getSolid fuelsChemical productsBriquette

The invention provides environment-friendly clean coal for civil use and a preparation method thereof. The environment-friendly clean coal is prepared from, by weight, 80%-94% of semi coke, 5%-20% of shaped coal binder and 3%.-17% of shaped coal additive. The environment-friendly clean coal has the advantages that on the condition that a coal chemical product of semi coke which is low in cost is utilized, and a compound type binder and an efficient multifunctional additive taking a by-product of an agricultural product of straw as the main material is added, the use cost of the clean coal is reduced to the maximum extent.

Owner:北京奥洁鼎森新能源科技有限公司

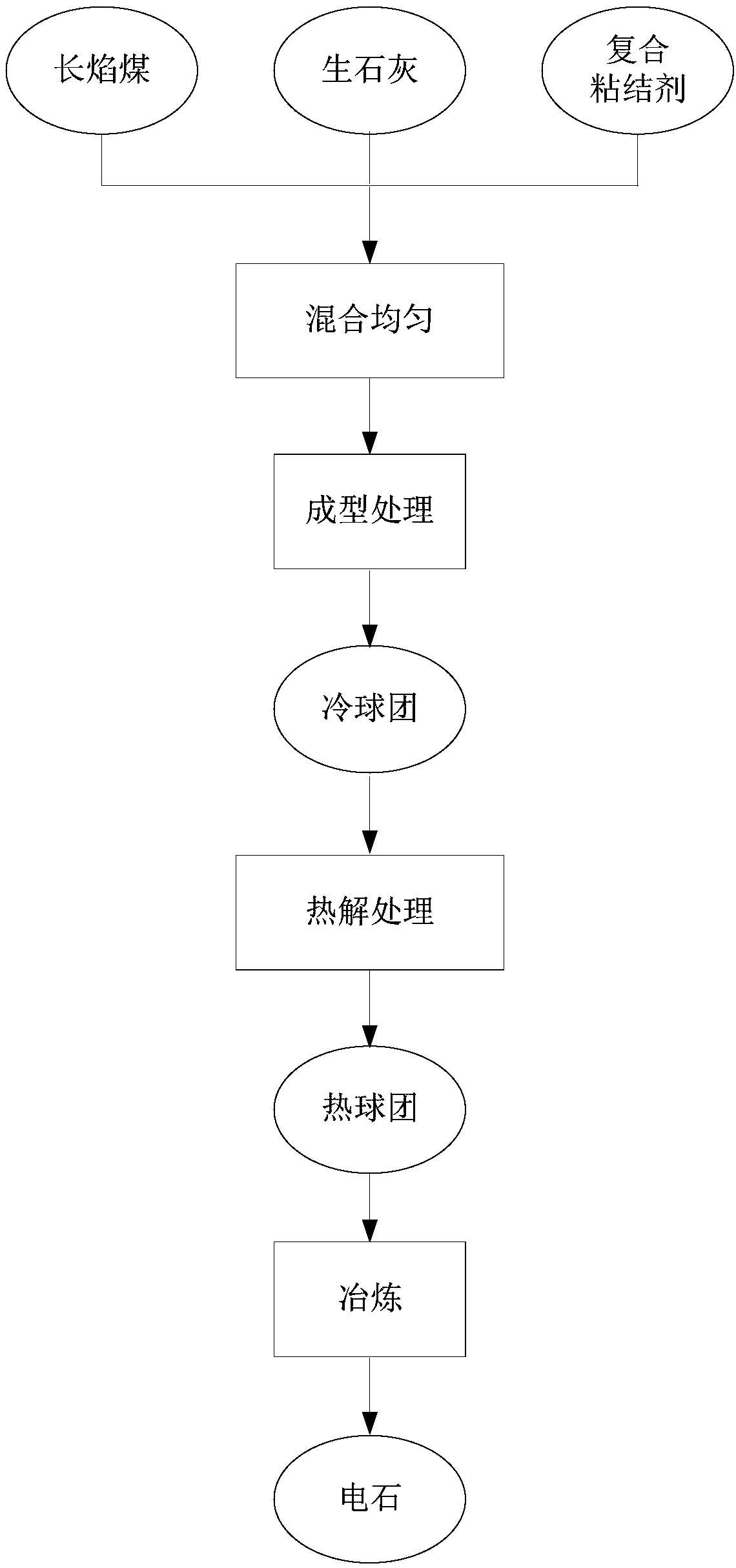

Adhesive used for preparing cold bond pellets from Ramsbottom carbon powder, preparation method and use method thereof

The invention belongs to the technical field of an adhesive used for metallurgy, in particular to an adhesive used for preparing cold bond pellets from Ramsbottom carbon powder, a preparation method and a use method thereof. The adhesive is prepared from the following ingredient in percentage by weight: 3 to 5 percent of aluminium oxide, 5 to 10 percent of sodium silicate, 3 to 10 percent of polyving akohol, 0.5 to 1 percent of crylic acid, 0.5 to 1 percent of calcium oxide and the balance of water, and the weight sum of the ingredients is 100 percent. The method comprises the following steps: firstly, grafting modified polyving akohol through crylic acid; then, adding other ingredients; and finally, preparing the adhesive through high-speed mixing. During the preparation of the pellets, the mixing proportion with the Ramsbottom carbon is controlled at a value about 1 / 20. The invention is suitable for small blast furnace iron manufacture, and can be used for replacing parts of coke in industries such as metallurgical furnace charge, chemical engineering coal gas raw materials, calcium carbide production raw materials and the like.

Owner:TONGJI UNIV

10mm-below granular oil shale cold-pressing sphere and method for oil refining by adopting same

InactiveCN102618308AHigh mechanical strengthUnbreakableLiquid hydrocarbon mixture productionSpecial form destructive distillationMagnesium phosphateAdhesive

The invention discloses a 10mm-below granular oil shale cold-pressing sphere and a method for oil refining by adopting the same. The oil shale cold-pressing sphere is prepared by adding adhesives with weight percentage of 8-15 percent into 10mm-below granular oil shale, wherein the adhesives comprise the following components in percentage by weight: 10-30 thousandth of humic acid calcium, 20-40 thousandth of kaolin, 0.5-1 thousandth of magnesium phosphate, and the balance water. The method comprises the following steps of: feeding the oil shale cold-pressing sphere into a gas retort, cushioning and falling through two layers of baffles, increasing steps of heat supplying carried out by a central heat supply device in the gas retort and the like so as to carry out dry distillation to obtain an oil gas mixture, and carrying out oil refining through an oil recovery system and the like. The oil shale cold-pressing sphere has good resistance to high temperature and high mechanical strength, and is not easy to crush; the production period of the gas retort is effectively prolonged, and the working efficiency is improved; and the cold-pressing sphere is adopted for oil refining, so that the co-combustion amount is high, the heat stability is good, the hot and cold strength is high, the dry distillation effect is good, the oil extraction rate is higher, the pollutant emission is less, the space is saved, the secondary pollution is avoided, and the cost is low.

Owner:于炳正

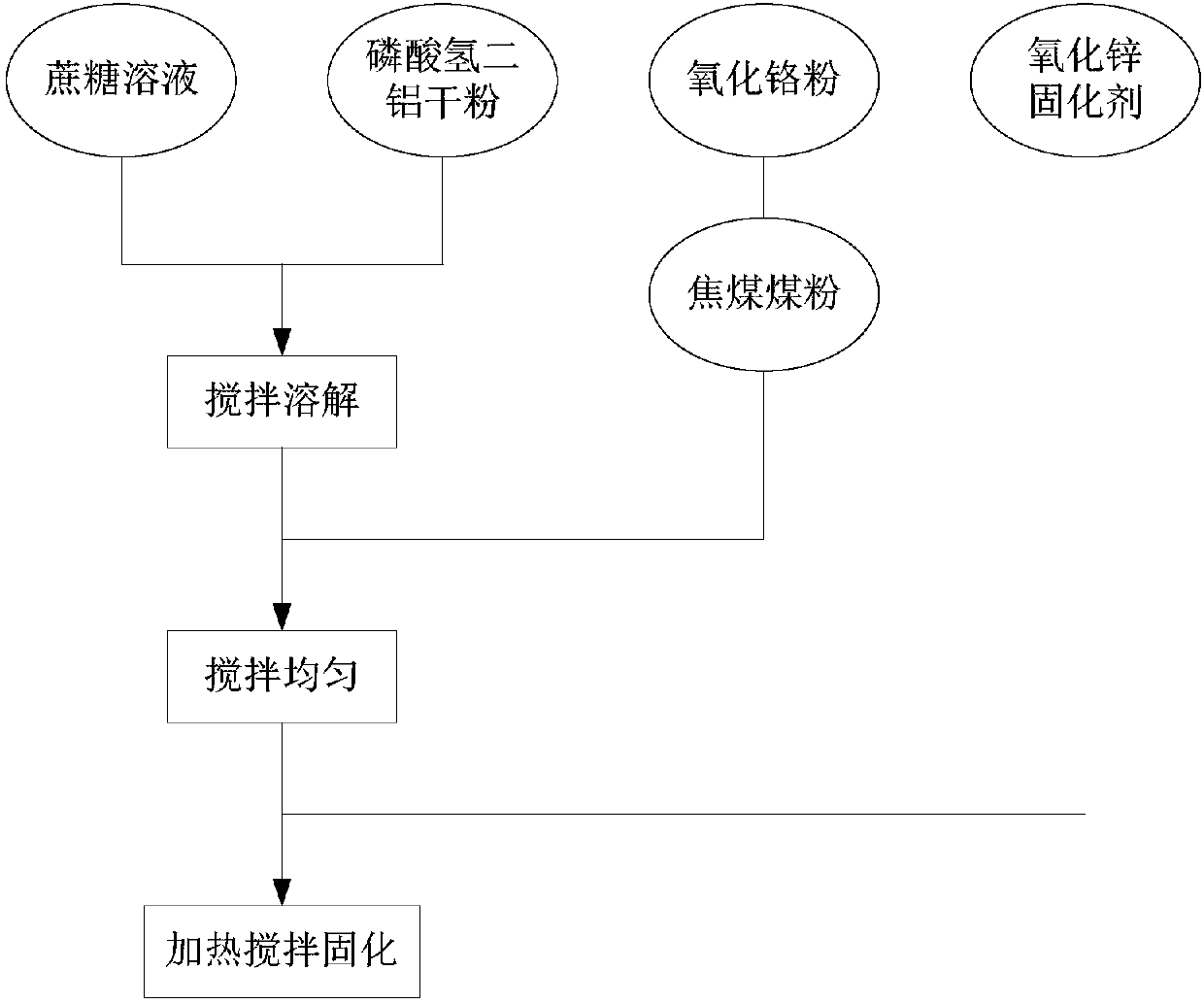

Composite adhesive and preparation method and application thereof

InactiveCN107915228ARaw materials are cheap and easy to getSimple preparation processCalcium carbideHydrogen phosphateAdhesive

The invention discloses a composite adhesive, which is prepared from the following components in parts by weight: 100 parts of 30wt% sucrose solution, 20-30 parts of dialuminum hydrogen phosphate drypowder, 5-10 parts of chromic oxide dry powder, 20-30 parts of pulverized coking coal and 3-5 parts of a zinc oxide curing agent. The composite adhesive can simultaneously improve the cold and hot strength of long flame coal and quick lime pellets. The invention also discloses a preparation method of the composite adhesive and a method for preparing high-quality calcium carbide by utilizing the composite adhesive.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

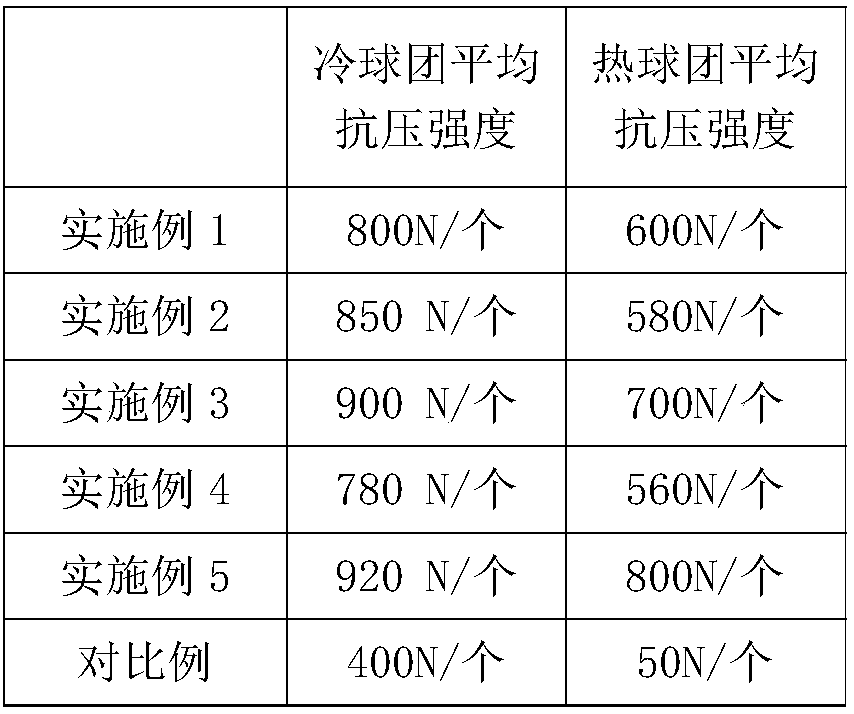

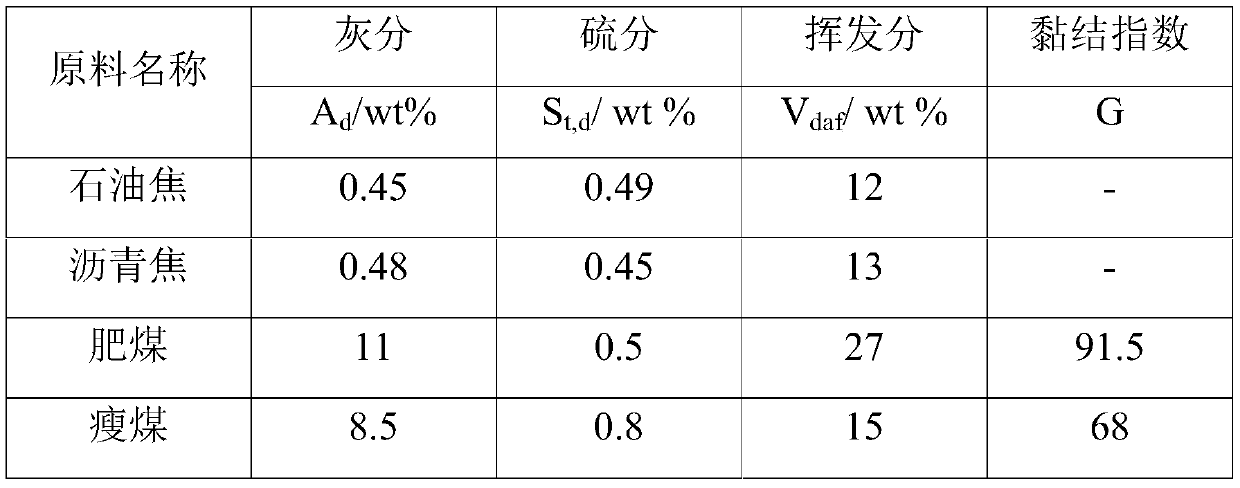

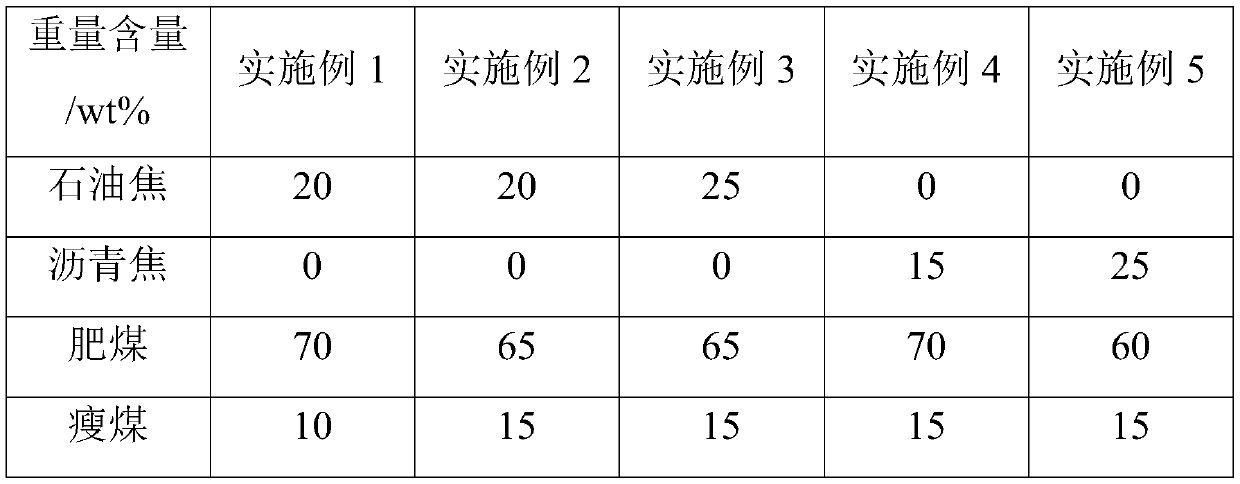

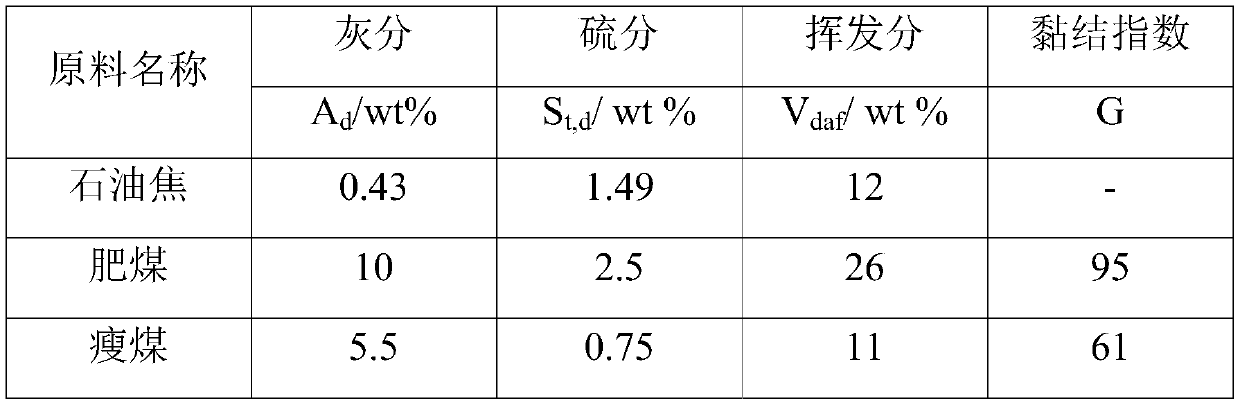

Formed coke and preparation method and application thereof

InactiveCN111575033AHigh lumpinessHigh hot and cold intensitySpecial form destructive distillationCoke ovenBriquette

The invention relates to the field of coal chemical industry, in particular to formed coke and a preparation method and application thereof. The preparation method of the formed coke comprises the following steps: (1) pressing mixed coal obtained by mixing raw materials to obtain formed coal; based on the total weight of the raw materials, the raw materials comprise 15-25 wt% of coke powder, 60-70wt% of fat coal and 5-15 wt% of lean coal; and (2) putting the formed coal into a coke oven at room temperature, heating the coke oven from room temperature to 1050-1200 DEG C at a rate of 6-10 DEG C / h, and carrying out destructive distillation at 1050-1200 DEG C for 350-400 hours to obtain the formed coke. The formed coke obtained in the invention has the advantages of few internal cracks, largelumpiness, high thermal strength and low ash content so that the formed coke has a wide application prospect.

Owner:山西沁新能源集团股份有限公司

Metallurgical pellet binding agent and process for pressing pellets by using same

The invention relates to a metallurgical pellet binding agent which can reach the strength required by metallurgy, and a process which can improve the qualification rate of the metallurgical pellet products, simplify the technical process and reduce the cost and presses the pellet products by using the binding agent. The metallurgical pellet binding agent comprises the following raw materials: 1.435 kilos of blue vitriol, 0.5 kilo of red vitriol, 221 kilos of sodium silicate, 110.5 kilos of water, which are heated and mixed evenly. 425# Portland cement accounting for 3-8 percent of the metallurgical raw materials is added, and the metallurgical pellet binding agent is obtained. The metallurgical raw materials and the 425# Portland cement are mixed in a stirrer in terms of fixed quantity according to a proportion of 1:0.03-0.08. The rest raw materials of the binding agent, which account for 3-8 percent of the added 425# Portland cement, are sprayed in the mixture material. Pellets are obtained by means of pressing in a ball press. The pellets are maintained and dried and then can be placed into a furnace for use. The metallurgical pellet binding agent has the advantages of low binding cost and high pellet strength, is economical and practical and can bind different metallurgical scraps together, particularly iron concentrate powder and pulverized coal, so as to press and shape the metallurgical pellets satisfying the metallurgical requirement.

Owner:新疆吉泰低阶煤利用研究有限责任公司

Composite adhesive containing coal iron powder pellets

The invention relates to a composite adhesive containing coal iron powder pellets, which comprises 30-50% of modified ammonium humate, 5-15% of starch, 40-60% of flux and other components. The adhesive is added in the form of dry powder, the adding way is simple and easy to control, the adding amount is 4-6%, and the adhesive has broad resources of raw materials, low cost, no introduction of alkali metal elements which are harmful to the iron-making technology, high cold and hot strength of the molded pellets and high thermal stability of higher than 90%, and is conductive to reducing the melting point for iron-making by smelting reduction. The composite adhesive can meet the needs of large-scale production and easy popularization.

Owner:田原宇

Novel waterproof compound coal binder

InactiveCN103710065BImprove adhesionConvenient and cheap sourceSolid fuelsEconomic benefitsAnthracite

The invention discloses a novel waterproof compound coal binder mainly used for the molding production of industrial gasification briquette from pulverized anthracite. The binder comprises bentonite, starch, extraordinary resin, cement and an organic polymer material. The binder has the advantages of low consumption, simple preparation technology, low cost, no secondary pollution, and suitableness for various coals. Molded gasification briquette processed in the invention has high cold and hot strengths (a cold compression strength of 85-115kg / ball and a hot compression strength of 40-45kg / ball, has a strong binding power and a good waterproof property, so the binder has a good economic benefit and application prospect.

Owner:ZHENGZHOU UNIV

High-strength bridge deck waterproof adhesive and preparation method thereof

ActiveCN105754495BWell mixedBond firmlyNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveBridge deck

The invention discloses a high-strength waterproof deck binder and a preparation method thereof.The binder is made by mixing components A, B and C according to a weight ratio of 1:1:1.5; the component A comprises, according to parts by weight: 100 parts of emulsified asphalt, 60-75 parts of EVA (ethylene-vinyl acetate copolymer), 20-30 parts of hydroxypropyl acrylate, 5-8 parts of hydroxyethyl acrylate, 0.2-2 parts of polytetrafluoroethylene, and 2-7 parts of an amine curing agent; the component B comprises, according to parts by weight: 40-45% of bentonite, 3-4% of starch, 1-3% of special resin, 6-9% of an organic polymer material, and 40-50% of asphalt-cement; the component C is made by mixing the following materials according to percent by weight: 10-40% of white cement, 5-20% of mica powder, 5-20% of ash calcium powder, 5-15% of silica fume powder, 10-40% of quartz sand, 0.1-0.7% of dispersible emulsion powder, 0.1-0.5% of organosilicon powder, 0.1-0.5% of lignin, and 0.1-0.4% of polypropylene fiber; the quartz sand is 20-80 in mesh.

Owner:江苏文昌新材料科技有限公司

Method for preparing briquette binder

ActiveCN103113949BEasy to operateWill not increase the contentSolid fuelsCoal briquetteSocial benefits

The invention relates to a method for preparing a briquette binder. According to the method, pulverized coal and bentonite are taken as master batches and are matched with water as a solvent and a catalytic sodium agent so as to react at a high temperature and a high pressure for preparation of the briquette binder. The method has the advantages of obviously improving the coking property of coal briquette, being simple in technology and simple in operation and having obvious economic and social benefits. Raw materials are wide in source and have low cost.

Owner:TAIYUAN UNIV OF TECH

A metallurgical pellet adhesive and a process for pressing pellets using the adhesive

The invention relates to a metallurgical pellet adhesive capable of achieving the strength required for smelting and a process for pressing pellet products using the adhesive which can improve the qualified rate of metallurgical pellet products, simplify the process and reduce costs. Including the following raw materials: 1.435 kg of blue vanadium, 0.5 kg of red sail, 221 kg of sodium silicate, 110.5 kg of water, heated and mixed evenly; 425# ordinary cement is added at 3-8% of the metallurgical raw materials to become a metallurgical pellet binder. Mix metallurgical raw materials and 425# ordinary cement quantitative feeding in a mixer, the ratio is 1:0.03-0.08, spray the rest of the adhesive raw materials in the mixed raw materials, and the ratio is 3-3% of the amount of 425# ordinary cement 8%, and finally pressed into pellets in a briquette machine, and after curing and drying, it can be put into the furnace for use. It has the advantages of low bonding cost, high pellet strength, economical and practical, and can bond different metallurgical wastes, especially iron concentrate powder and coal powder, to form metallurgical pellets that meet smelting requirements.

Owner:新疆吉泰低阶煤利用研究有限责任公司

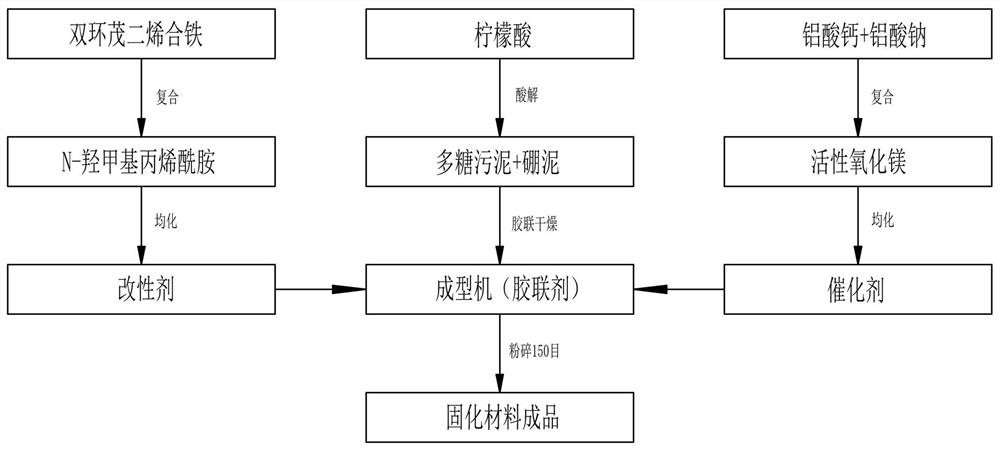

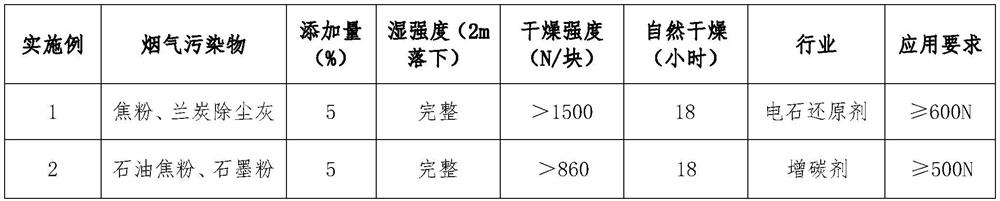

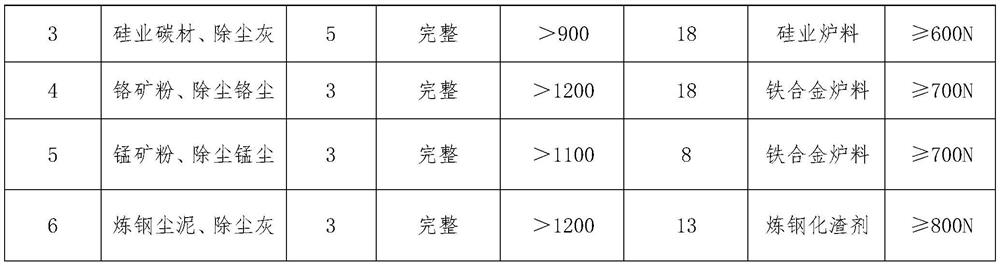

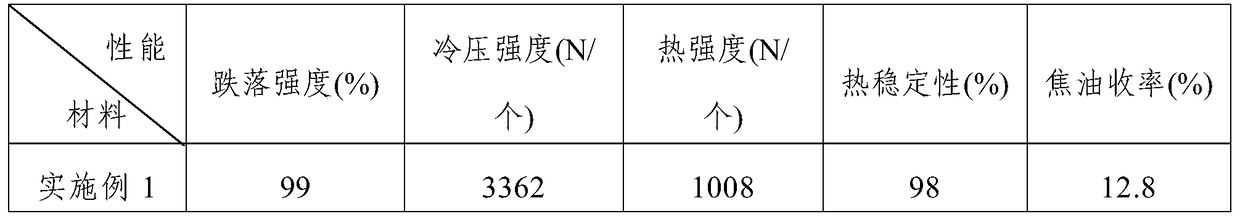

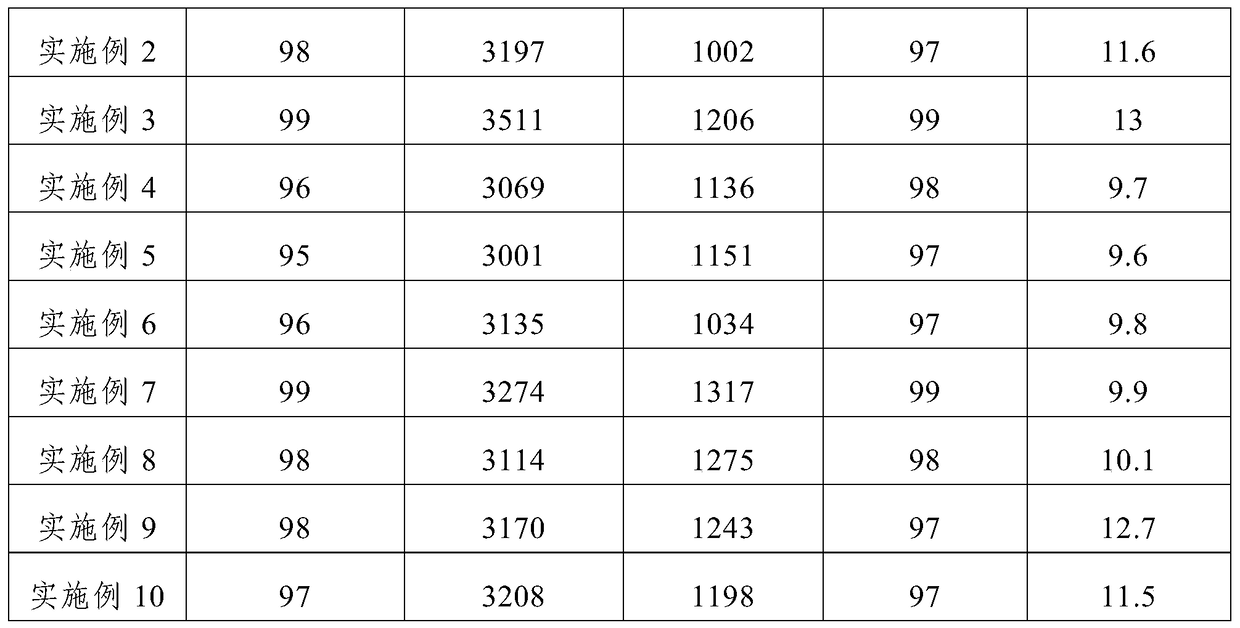

Industrial flue gas solid waste recycling drying-free curing material and application

ActiveCN114477859AAchieve protectionSolve processingProcess efficiency improvementPtru catalystSludge

The invention relates to an industrial flue gas solid waste recycling drying-free curing material and application, and effectively solves the technical problems that the existing pollution treatment method affects the air permeability of a sintered material layer and the strength of sintered ore and cannot be recycled and reused for application, and the curing material is prepared from the following raw materials in percentage by weight: 40-50% of a forming agent, 5-10% of a modifier and 40-50% of a catalyst. Wherein the forming agent consists of polysaccharide sludge, boric sludge and citric acid; the modifying agent is prepared from N-hydroxymethyl acrylamide and dicyclopentadienyl iron; the catalyst is composed of sodium aluminate, calcium aluminate and active magnesium oxide. The material is used for industrial flue gas solid waste solidification treatment, industrial flue gas purification solid waste can be directly solidified into block mass particles through a forming device, the block mass particles can be used as auxiliary materials or raw materials for smelting after being naturally solidified for 8-18 h, and therefore industrial flue gas pollution treatment and solid waste recycling application are achieved.

Owner:河南北斗众创高新技术研究院有限公司 +2

A dry powder briquette binder, a briquette containing the binder and a method for preparing the briquette

The invention relates to a dry powder briquette binder, which is prepared by mixing the following raw materials in parts by weight: 40-85 parts by weight of bentonite, 10-50 parts by weight of oxidized starch, 0.1-5 parts by weight of sodium chloride, polyvinyl alcohol 0.1-1 parts by weight, 0.1-5 parts by weight of sodium carbonate, 1-10 parts by weight of calcium oxide and 0.5-10 parts by weight of sodium carboxymethylcellulose. The present invention also relates to a briquette comprising the above-mentioned binder and a preparation method thereof. The invention solves the disadvantages of the prior art, such as large addition amount of briquette binder, low hot and cold strength of briquette, poor thermal stability and the like.

Owner:河北东慈环保科技有限公司

Briquette and production method thereof

The invention discloses a briquette and a production method thereof. The briquette is prepared from the following raw materials in parts by mass: 1-1.5 parts of slack coal, 0.5-1 part of fine coal, 0.1-0.5 part of gelatin, and 0.1-0.5 part of basic zinc carbonate. Through adoption of the briquette and the production method thereof, the comprehensive utilization ratio of coal powder is improved; the briquette is enabled to have high hot and cold intensity, further, less adhesive is used, and post-combustion solid wastes are reduced.

Owner:攀枝花市观诚工贸有限公司

A kind of composite biomass briquette binder and its preparation method and application

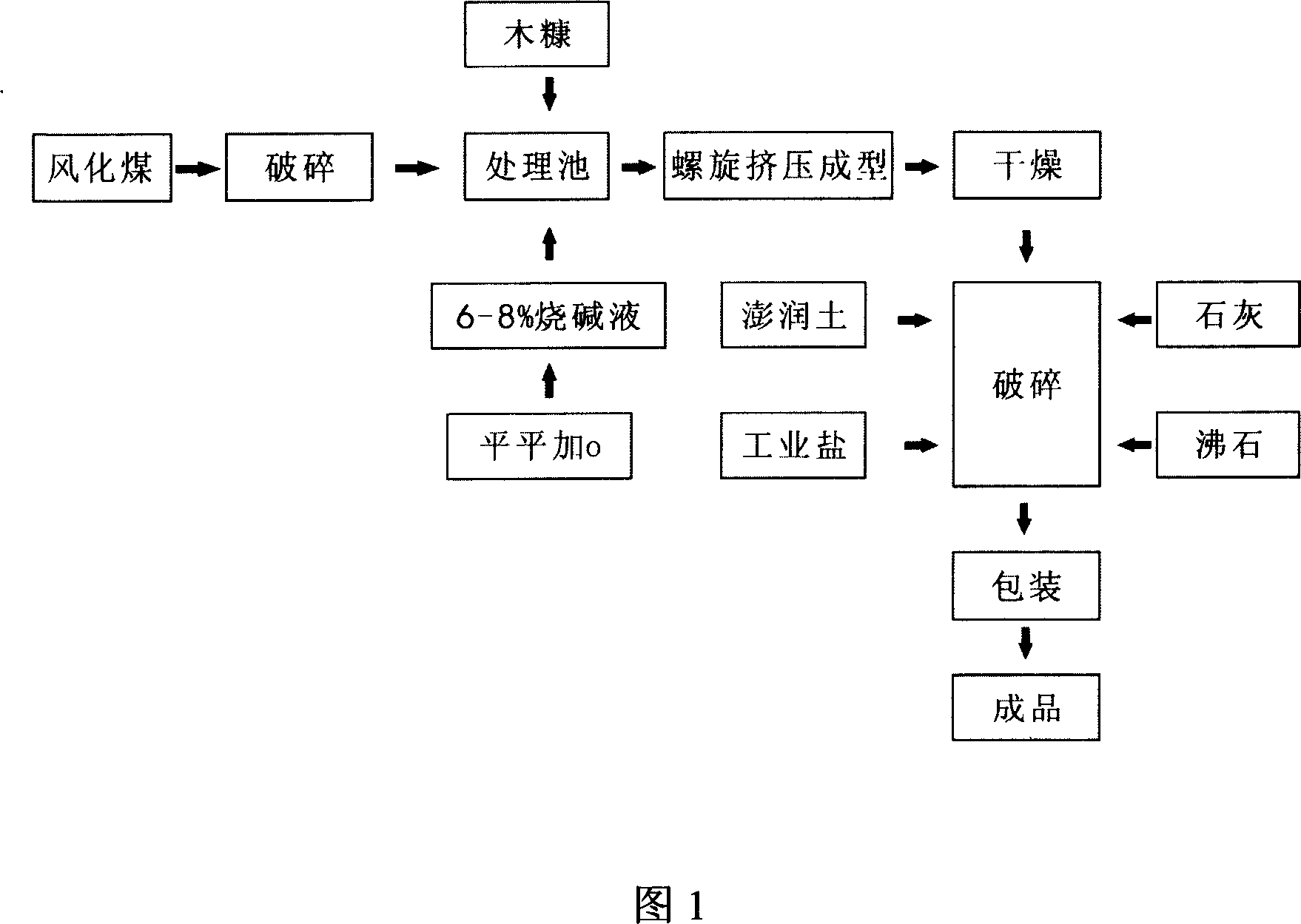

ActiveCN104877727BImprove adhesionIncrease cold strengthCoke ovensSolid fuelsSodium BentoniteBriquette

The invention discloses a composite biomass briquette binder, which is prepared from the following raw materials in parts by weight: 1 part of sunflower straw, 10 to 20 parts of sodium hydroxide solution, 0.3 to 0.4 parts of bentonite, and 1 to 2 parts of emulsified asphalt or 1 part of sunflower straw, 10 to 20 parts of sodium hydroxide solution, 0.3 to 0.4 parts of bentonite, 0.3 to 0.4 parts of sodium humate, and 0.6 to 2.2 parts of modified starch; in addition, the invention also discloses a composite A preparation method of a biomass briquette binder and an application of the composite biomass briquette binder in preparing pyrolysis briquettes. The invention uses sunflower stalks as the main raw material, and when the prepared composite biomass briquette binder is used to prepare briquettes for pyrolysis, it can not only make the briquettes have good cold and hot strength, but also can significantly improve the thermal efficiency of the briquettes. The tar yield during solution is simple, and the preparation method is simple and environmentally friendly.

Owner:SHAANXI COAL & CHEM TECH INST +1

Briquette binder and briquette manufacturing method

InactiveCN102504906AHigh hot and cold intensityGood moisture resistance and water resistanceSolid fuelsWaste based fuelBriquetteDomestic animal

The invention relates to a briquette binder and a briquette manufacturing method. Domestic animal blood or blood powder is compounded with organic wastewater containing natural polymers, using amount of the domestic animal blood is 7% to 15% of weight of coal, using amount of the blood powder is 10% of the weight of the coal, and using amount of the organic wastewater is 4% to 6% of the weight of the coal. The briquette binder and the briquette manufacturing method are characterized in that the domestic animal blood is performed anti-coagulation and antiseptic treatment, namely an anticoagulant occupying 0.48% to 2% of weight of the blood and an antiseptic occupying 0.4% to 0.6% of the weight of the blood are added.

Owner:XIAN RUIJINYUAN ENERGY TECH

A method suitable for preparing cold-set pellets from iron-containing sludge using composite adhesives

InactiveCN101775489BReduce the amount of non-ferrous materialsReduce pollutionSludgeCarvacryl acetate

Owner:TONGJI UNIV

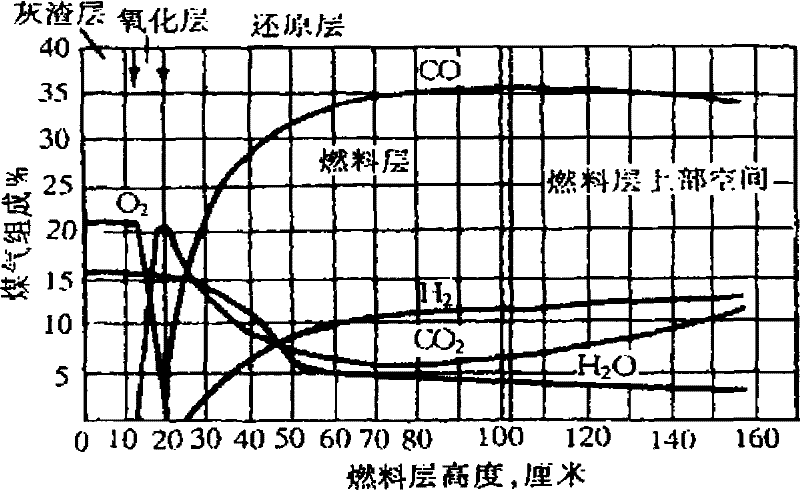

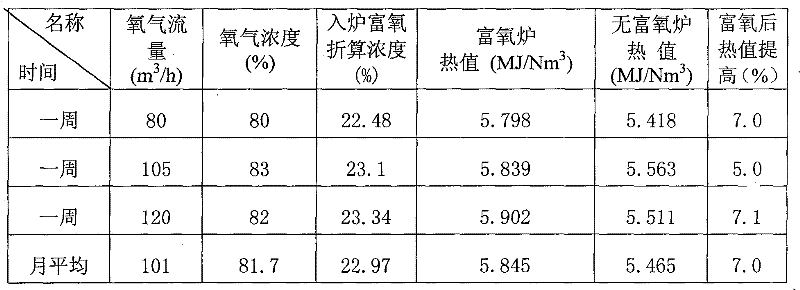

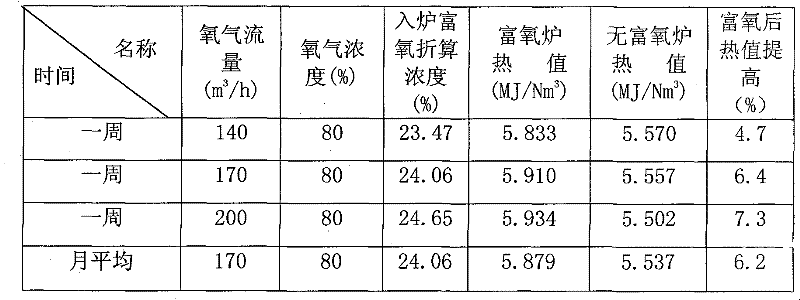

Oxygen-enriched gas producing method for hybrid gas furnace

ActiveCN101250438BHigh calorific valueReduce carbon contentChemical industryCombustible gas productionSocial benefitsNitrogen

The invention provides an oxygen-enriched gas making method for a mixed gas producer furnace, which comprises the following steps: lowering the content of inactive gas nitrogen through improving the concentration of useful components oxygen in gasifying agent, improving gasification intensity and coal utilization ratio of a producer furnace, assuring the optimum gasifying agent oxygen concentration scope which is 24.0%-25.5% when a TG-3m or II-3m type mixed coal gas producer furnace is producing gas in oxygen-enriched. The method of the invention can effectively improve mixing producer furnace calorific value of gas, gasification intensification and efficiency, lower slab carbon content, achieve the purpose of saving energy and reducing emission, and has considerable economic and social benefits.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

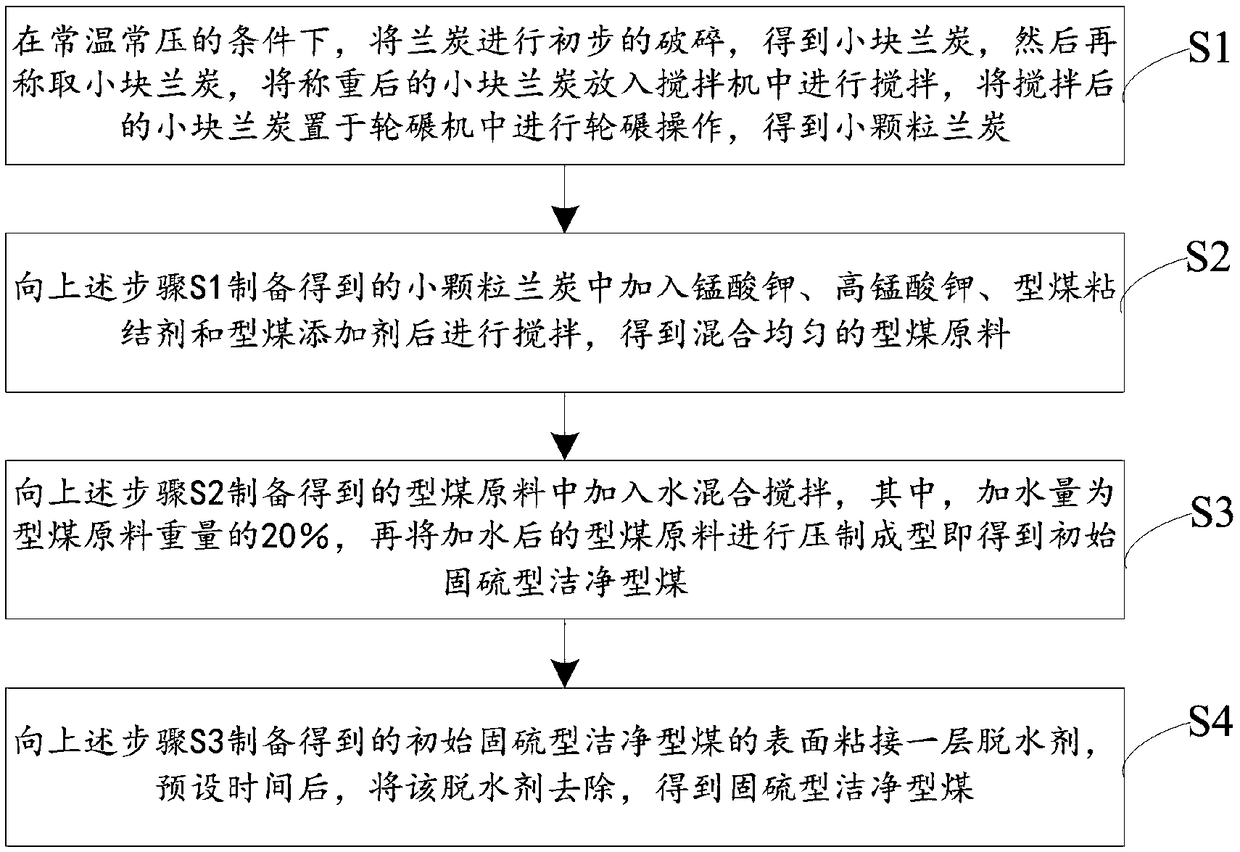

Sulfur-fixing type clean coal briquette and preparation method thereof

The invention provides a sulfur-fixing type clean coal briquette which contains the following components by weight percent: 73%-80% of semi-coke, 4%-6% of coal briquette binder, 2%-3% of dehydrating agent, 0.3%-3% of coal briquette additive, 1%-2% of potassium manganate and 1%-3% of potassium permanganate, wherein the coal briquette additive is a mixture of potassium nitrate, potassium chloride, quick lime, sodium chloride and potassium perchlorate.

Owner:宁夏兴顺煤业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com