High viscosity briquette waterproof composite binder

A binder and high-viscosity technology, applied in the field of binders, to achieve the effect of improving molding rate, reducing production cost, and strong waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

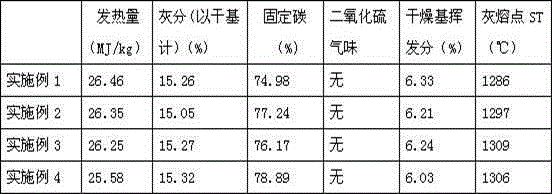

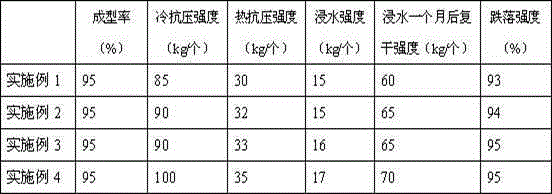

Examples

Embodiment 1

[0027] Its preparation method comprises the following steps:

[0028] In parts by weight, weigh 350 parts of pregelatinized starch, 400 parts of magnesium oxide, 120 parts of fly ash, 60 parts of red mud, 6 parts of soda ash and 4 parts of polyacrylamide, and put each component into a pulverizer to pulverize to 150 mesh, then add each component into a mixer, and stir for 20 minutes at a rotating speed of 80r / min to obtain a high-viscosity molded coal waterproof composite binder.

[0029] Example 2

Embodiment 2

[0031] The preparation method comprises the following steps:

[0032] In parts by weight, weigh 420 parts of magnesium oxide, 350 parts of pregelatinized starch, 100 parts of fly ash, 80 parts of red mud, 6 parts of soda ash and 5 parts of polyacrylamide, and put each component into a pulverizer to pulverize to 200 mesh, then add each component into a mixer, and stir for 15 minutes at a rotating speed of 100r / min to obtain a high-viscosity molded coal waterproof composite binder.

[0033] Example 3

Embodiment 3

[0035] The preparation method comprises the following steps:

[0036] In parts by weight, weigh 380 parts of pregelatinized starch, 420 parts of magnesium oxide, 150 parts of fly ash, 50 parts of red mud, 7 parts of soda ash and 5 parts of polyacrylamide, and put each component into a pulverizer to pulverize to 250 mesh, then add each component into a mixer, and stir for 10 minutes at a speed of 120r / min to obtain a high-viscosity molded coal waterproof composite binder.

[0037] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com