Patents

Literature

220 results about "Caloric values" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Caloric Value of Food. the energy accumulated in food substances (proteins, fat, and carbohydrates); the energy value of foodstuffs, expressed in calories (cal) or kilocalories (kcal). The concept is used, for example, in the comparative evaluation of food products and in planning diets.

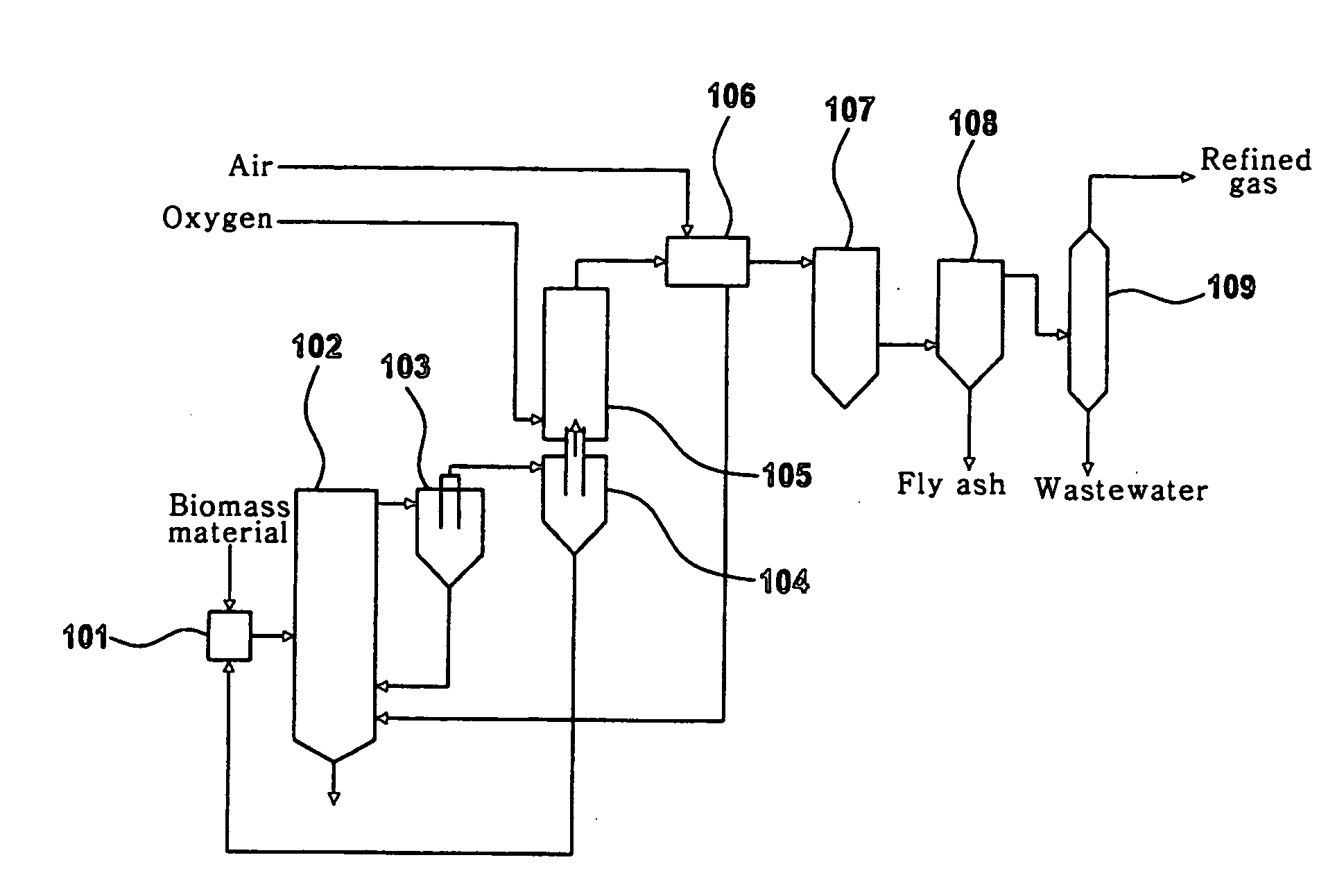

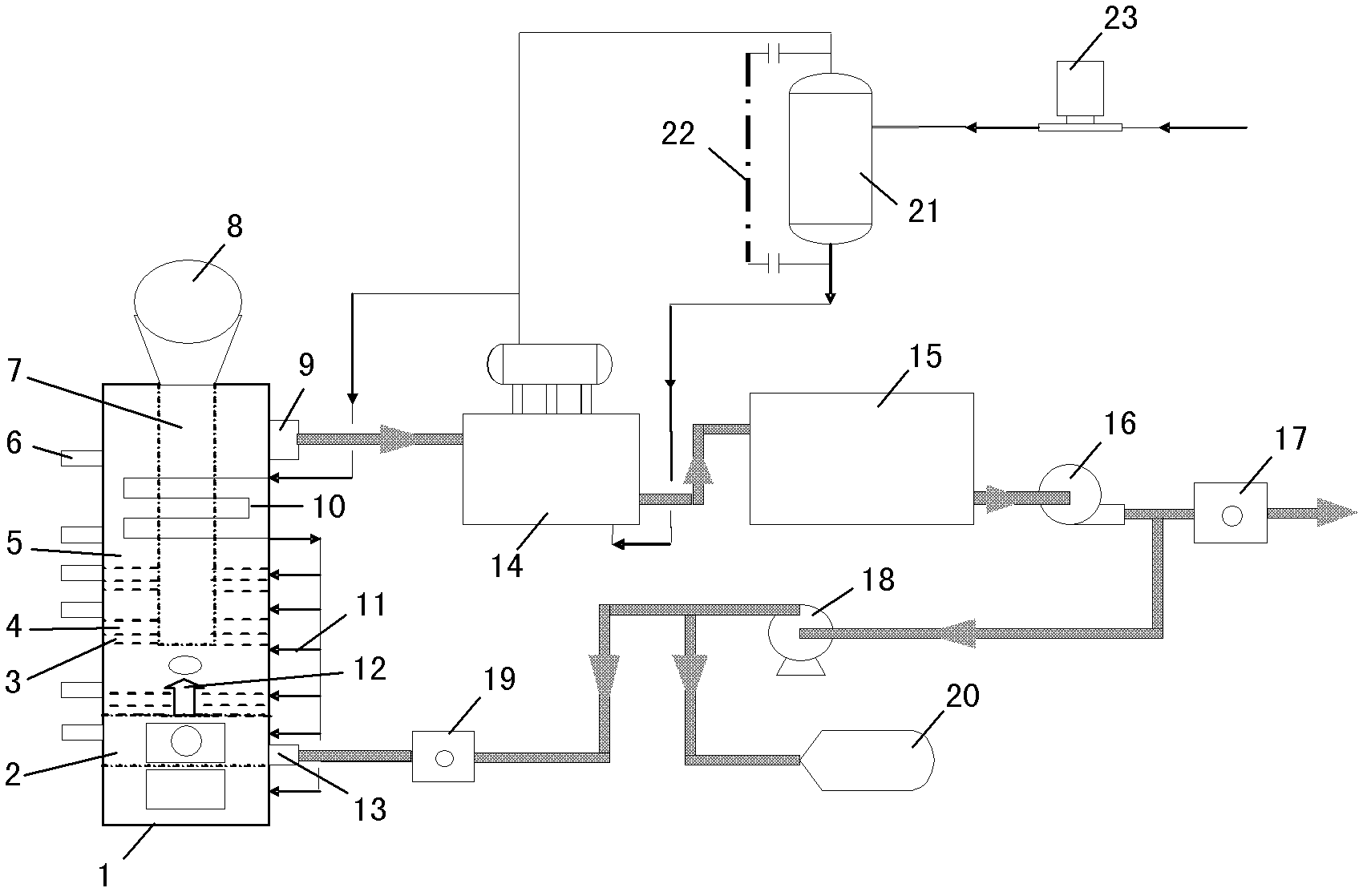

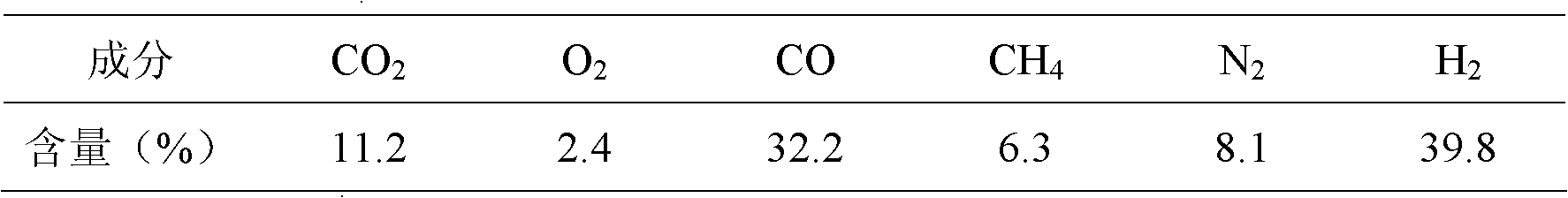

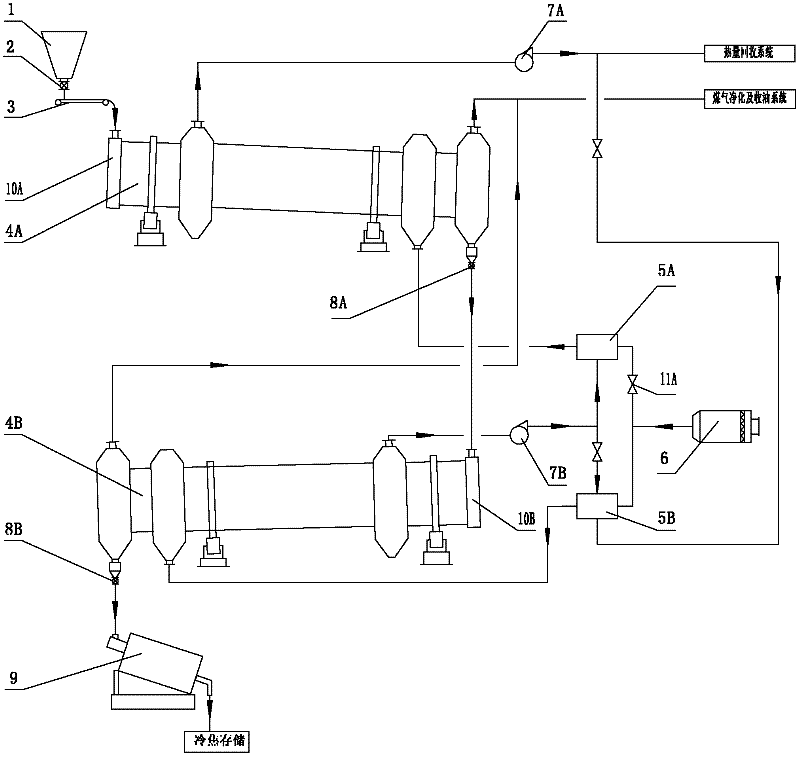

Apparatus of catalytic gasification for refined biomass fuel at low temperature and the method thereof

InactiveUS20070094929A1Low production costCompactCombustible gas catalytic treatmentLiquid hydrocarbon mixture productionCatalytic reformingFluidized bed

Disclosed is a gasification technique for converting biomass, which is difficult to treat, into clean gas fuel able to be burned in a cogeneration system. The gasification technique includes first stage fluidized-bed catalytic gasification, and second stage gasification of tar and catalytic reforming to convert nitrogen in tar, and HCN in a flammable gas into NH3, unlike conventional gasification techniques. In addition, since the temperature of a total gasification process is lower than a melting point of ash, powdery ash is generated and thus easily treated. Also, little heat is released due to the low process temperature, and therefore, a compact reactor may be designed to produce gas having a high caloric value. Further, the generated tar is recovered and reused in other processes, and the gas fuel contains a small amount of ammonia.

Owner:KOREA INST OF ENERGY RES

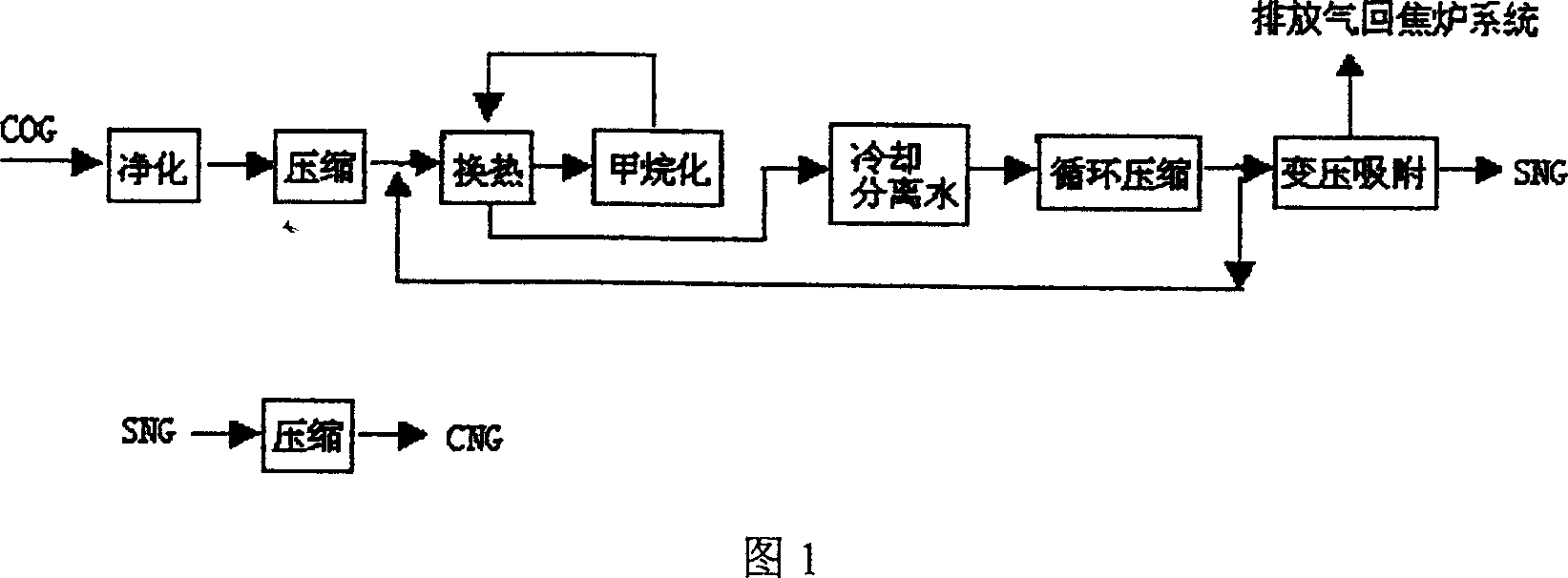

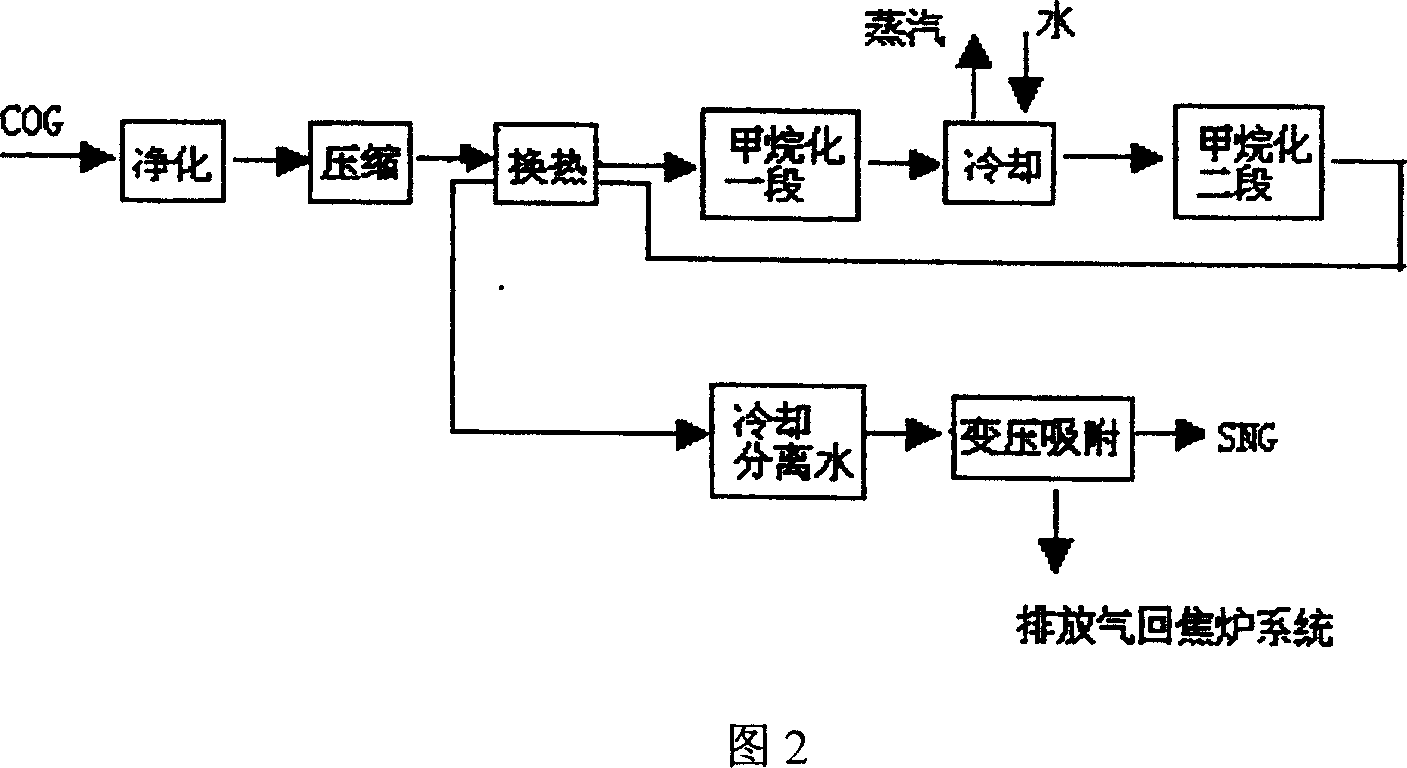

Method of preparing synthetic natural gas by coke oven gas

ActiveCN1919985AHigh calorific valueLow impurity contentGaseous fuelsCompressed natural gasMethanation

The invention discloses the method for producing natural gas with coking gas, comprising the following steps: purifying coking gas and removing benzene, naphthalene, hydrocarbon and sulphide, compressing, heat transferring, carrying out methanation reaction with catalyst, hydrogen in COG reacting with carbonic oxide and carbon dioxide to get methane; putting the mixture gas into pressure swing adsorbing device, and getting natural gas whose concentration is 90%. The natural gas has high caloric value, low impurity content.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

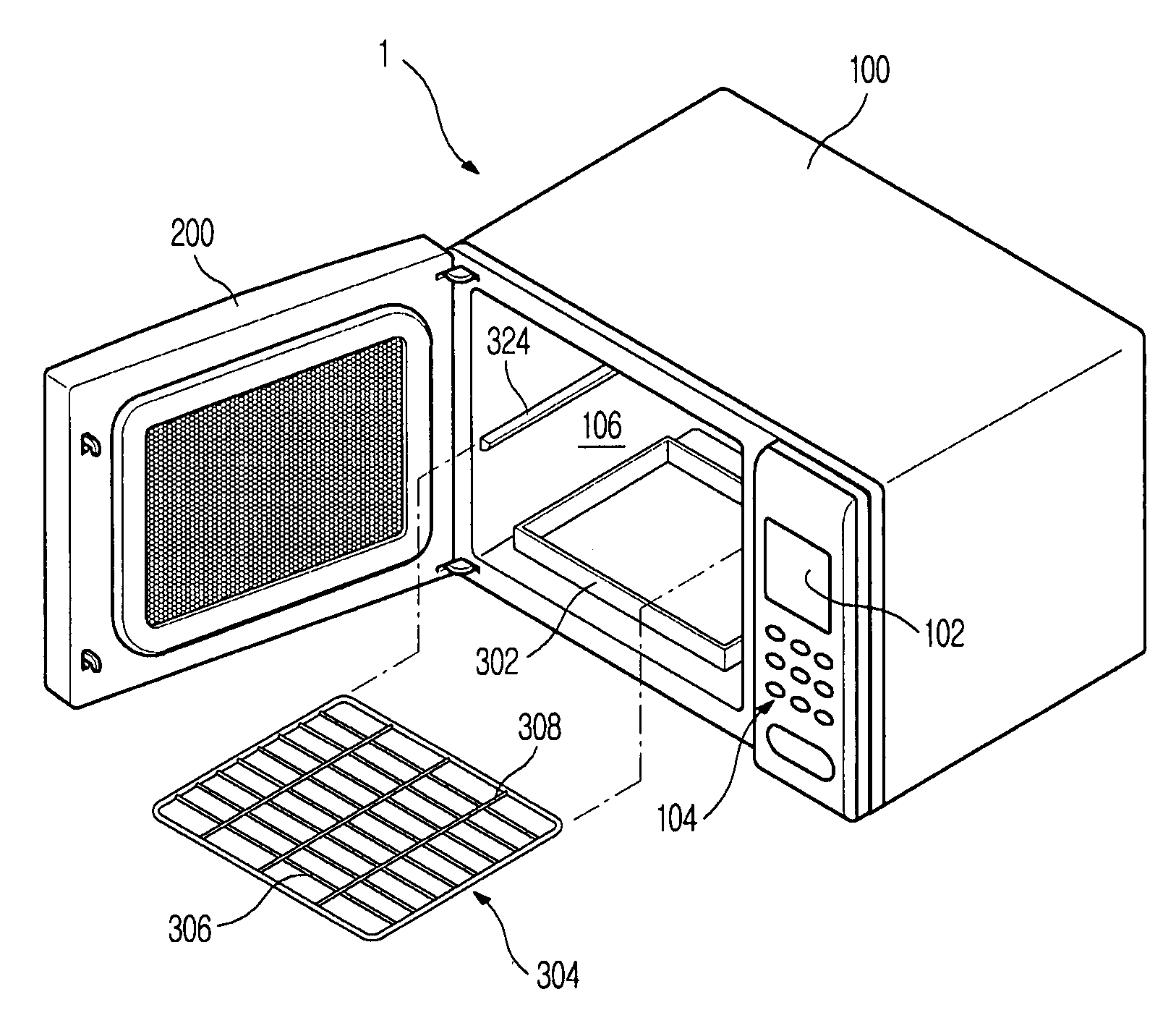

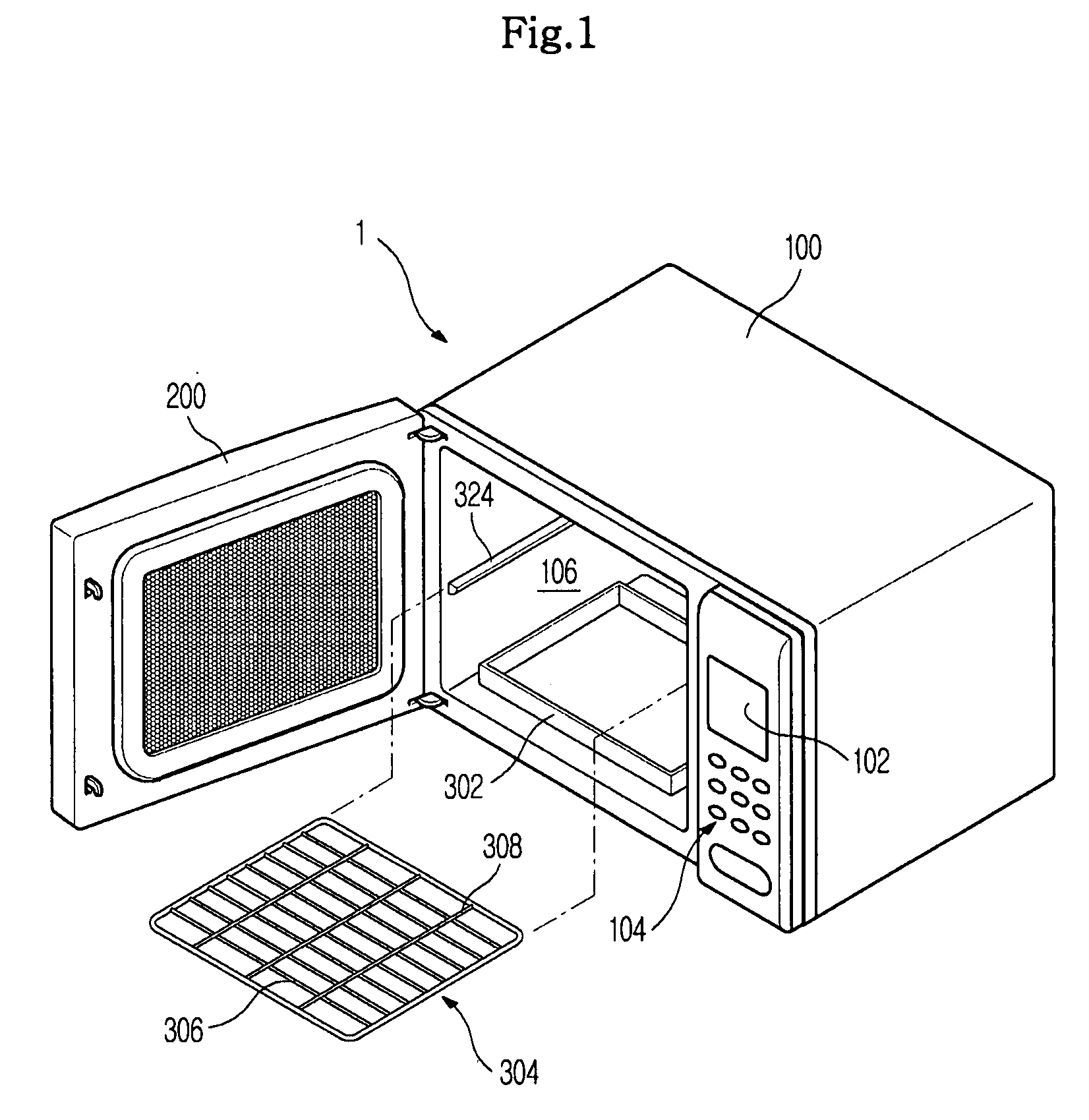

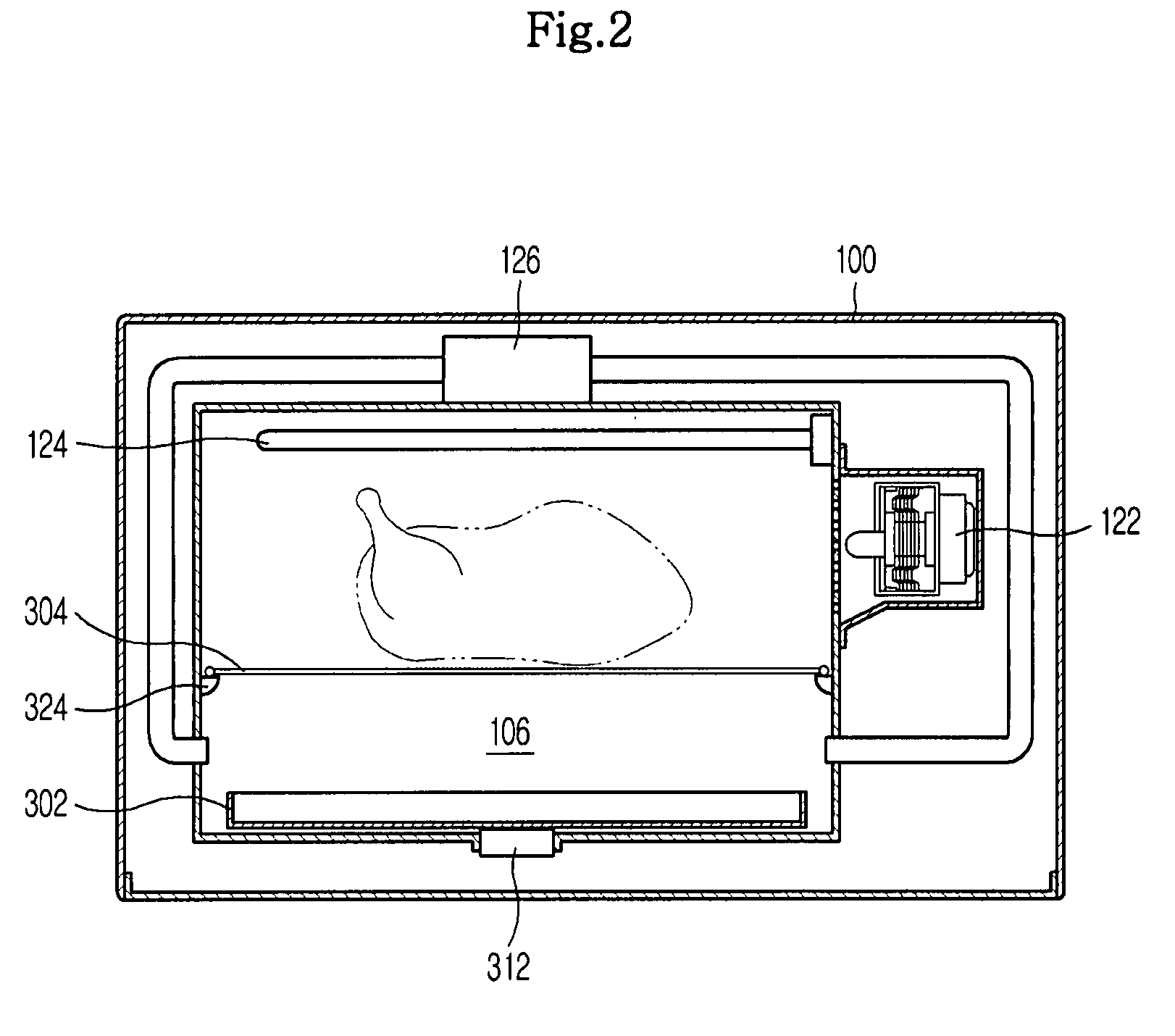

Cooking apparatus and method of displaying caloric information

InactiveUS20080102175A1Accurate informationDomestic stoves or rangesLighting and heating apparatusCaloric valuesEngineering

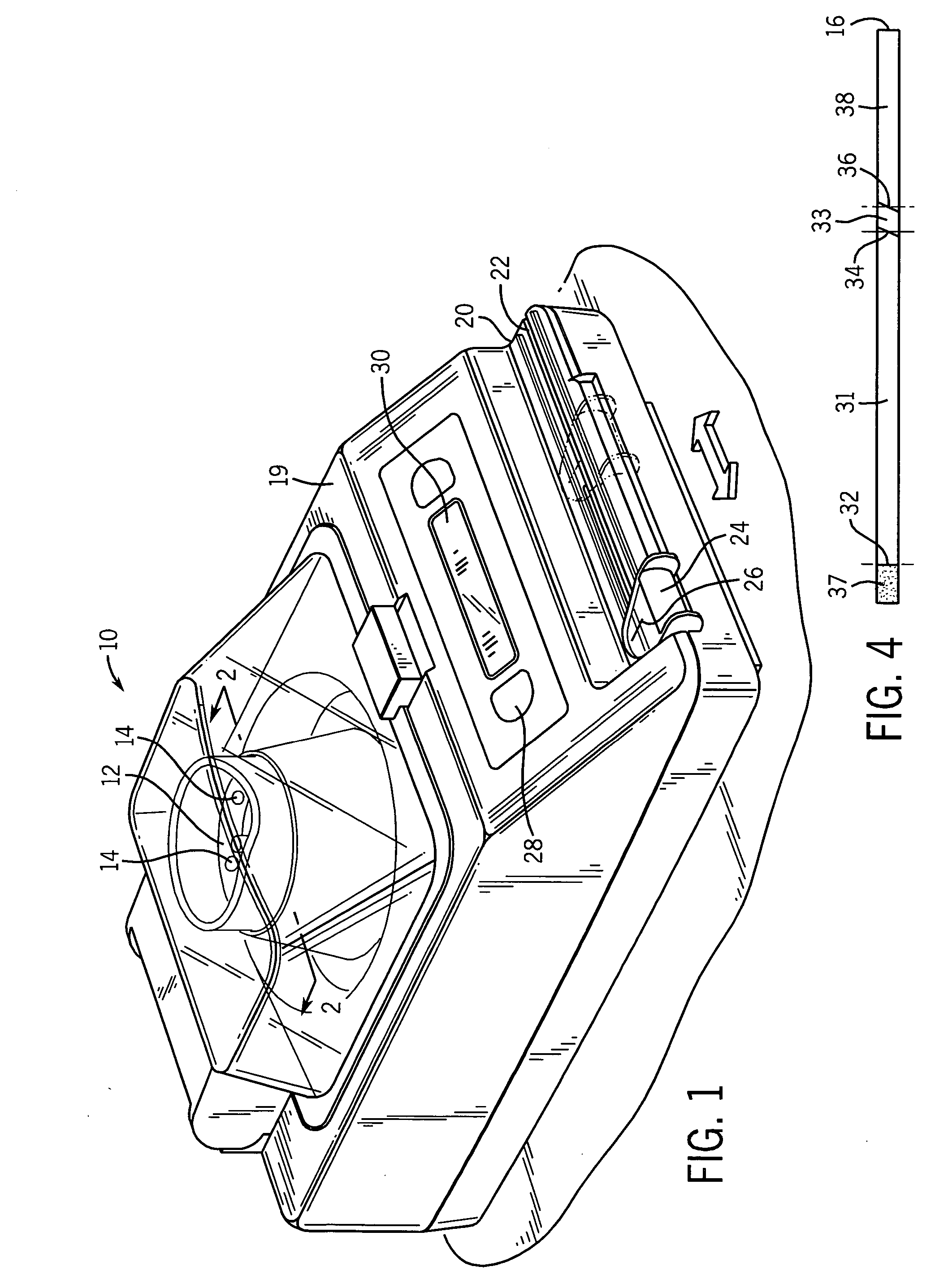

A cooking apparatus and method of displaying caloric information, capable of calculating fat removed by cooking in terms of caloric value, and displaying the removed caloric value information to a user. The cooking apparatus includes a main body having a cooking chamber and a display unit, a dripping tray placed in the cooking chamber to collects fat discharged from the food during a cooking operation of the cooking apparatus, at least one weight sensor detecting the weight of the dripping tray, and a controller calculating the weight of fat collected in the dripping tray, the weight of which is detected by the weight sensor for the dripping tray, in terms of caloric value, and displaying the calculated result on the display unit.

Owner:SAMSUNG ELECTRONICS CO LTD

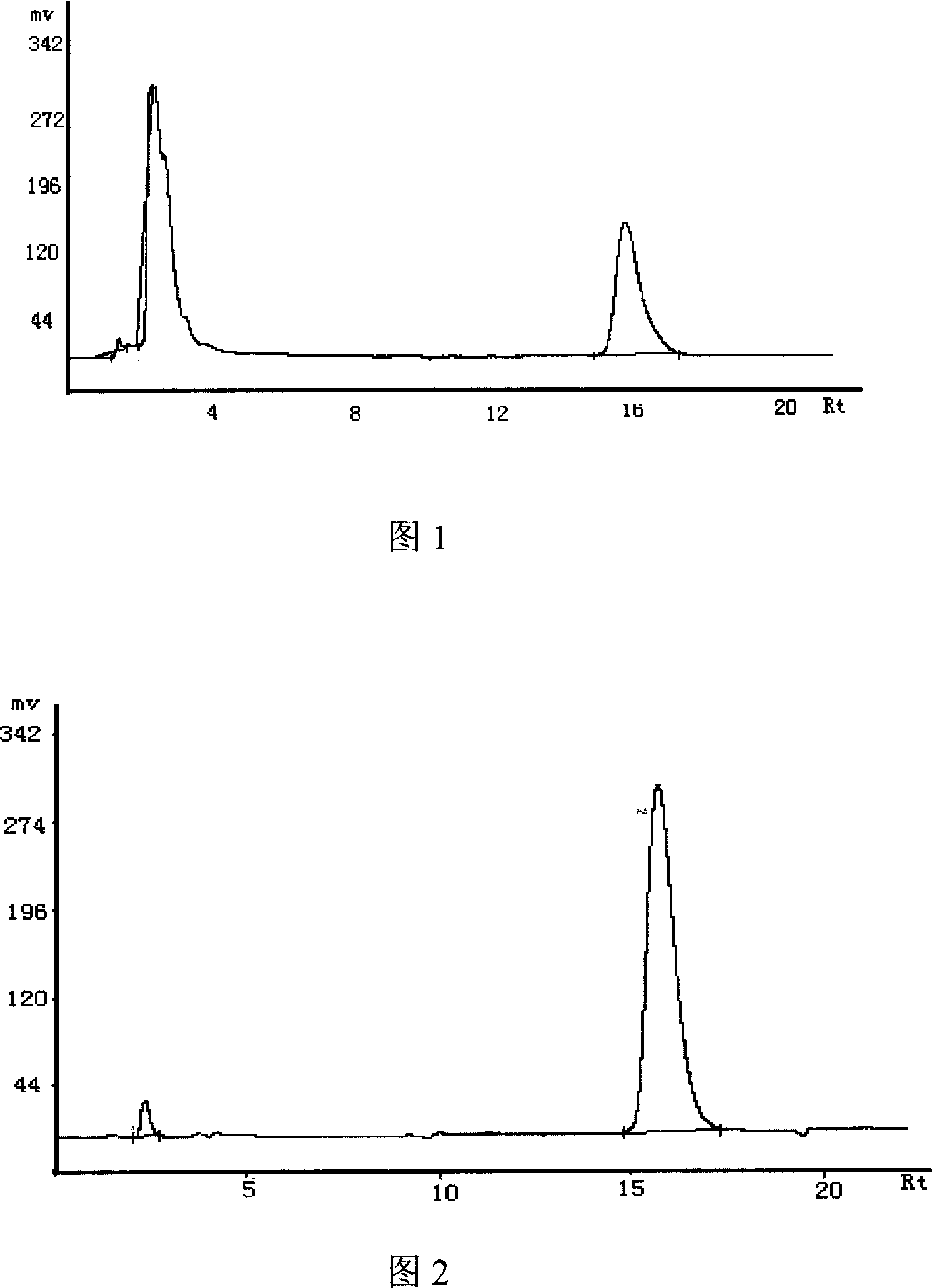

Method for preparing glycosides in high purity

InactiveCN101003552AImprove resource utilizationSimple extraction methodSugar derivativesSugar derivatives preparationCaloric valuesGlycoside formation

This invention discloses a method for extracting high-purity glucoside of Rubas suavissimus. The method comprises: extracting Rubas suavissimus with water or mixed solvents of water and ethanol under refluxing, adsorbing by resin, eluting, removing impurities by column chromatography, concentrating, drying to obtain powdery crude product, dissolving with absolute ethanol by heating, filtering, and crystallizing to obtain high-purity glucoside. The method is simple, and the product has such advantages as high purity and high sweetness. The glucoside can be used to produce high-sweetness healthcare products or drugs with low caloric value.

Owner:GUANGXI NORMAL UNIV

Personalized nutrition recipe device and method

InactiveCN103345591AEasy to useConvenient Meal PlanningSpecial data processing applicationsHealthy dietPersonalization

The invention discloses a personalized nutrition recipe device and method. According to the personalized nutrition recipe device and method, a reasonable nutrition intake of a user is calculated through personal basic information, the nutrition intake of the user is reasonably distributed into diet of each meal every day, and then a reasonable catering list is selected from a database in a matching mode according to the nutrition intake needed by the diet of each meal. The user achieves personalized catering through the selecting and editing of the catering list. When the user selects and edits the catering, the nutrition ingredient and caloric values are evaluated in real time, and assessment is provide for judging whether the catering is reasonable and healthy. After the catering of the user is finished, the personalized nutrition recipe method further stores the catering data, and history catering data are formed. According to the history catering data, the personalized nutrition recipe device and method analyzes food calories of the nutritional ingredient eaten by the user for a time period, and judges whether user diet is reasonable and healthy. The personalized nutrition recipe device and method achieves nutritional and healthy diet of the user through scientific management of the characterized catering for the user.

Owner:NANJING JKOM

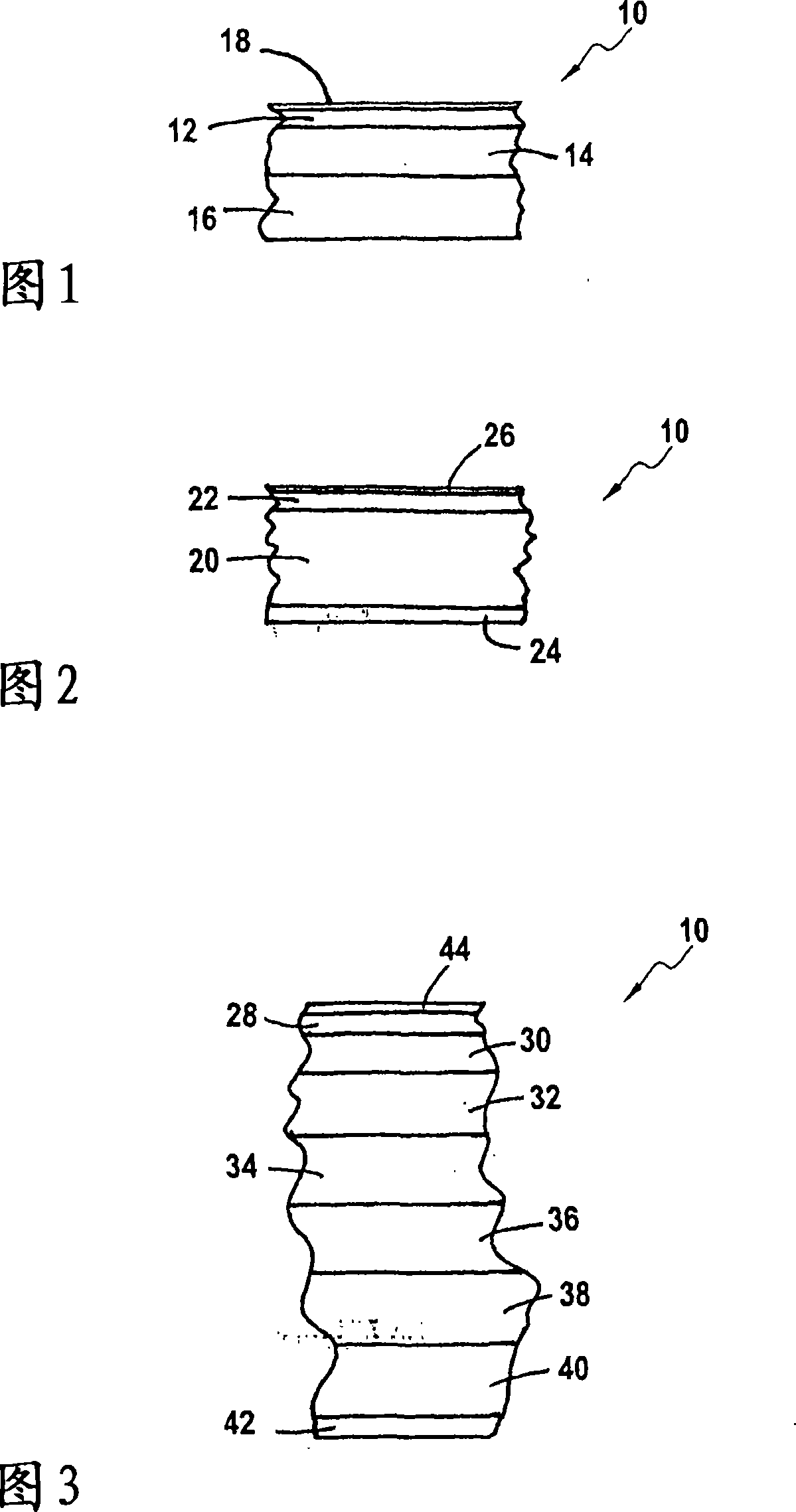

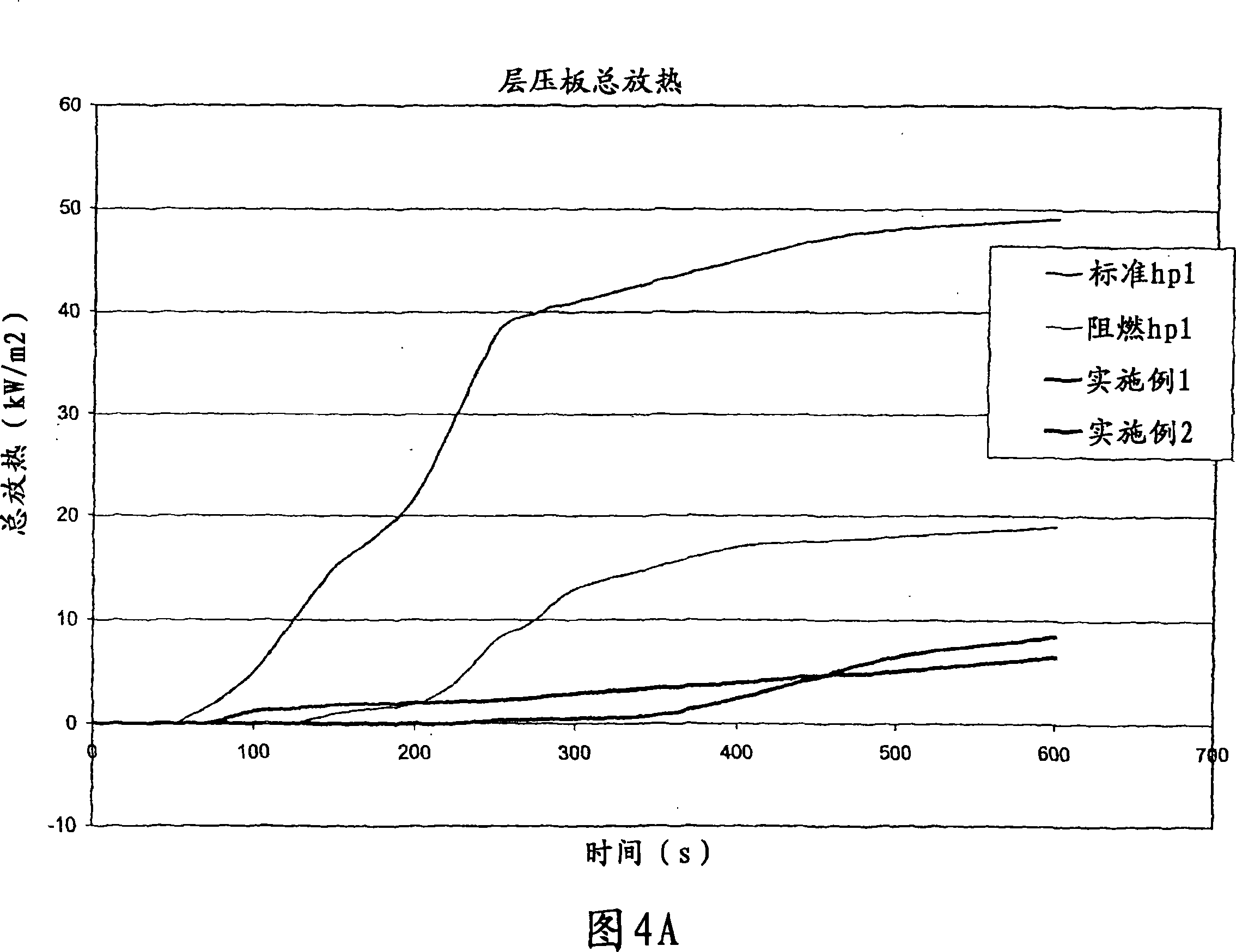

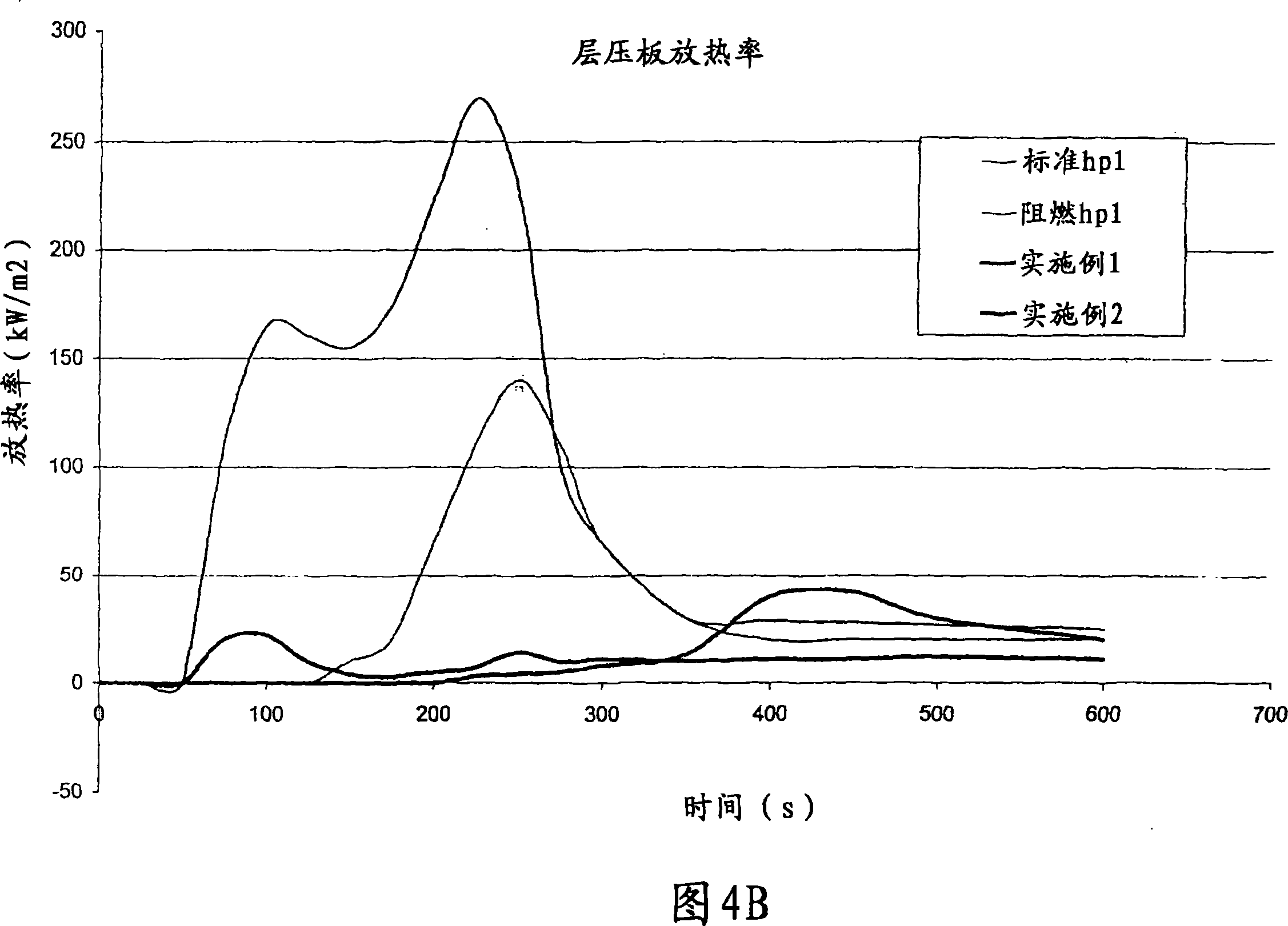

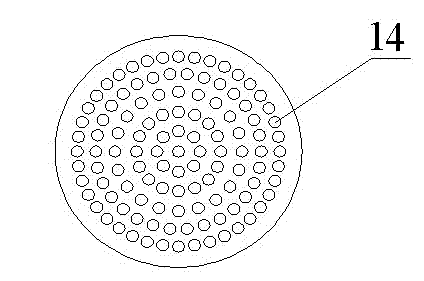

Non-combustible high pressure laminate

A high pressure laminate includes a first layer (12) of resin impregnated paper and at least one layer (14,16) of fiber reinforced veil. Each layer of fiber reinforced veil includes binder and filler. The laminate is characterized by having a caloric value of lower than 3.0 MJ / kg when tested in accordance with ISO 1716. A method for producing this high pressure laminate is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Method for the treatment of obesity, overweight and fluctuations in blood insuline and/or glucose levels

InactiveUS20030113310A1Low calorific valueLowering indexPeptide/protein ingredientsMetabolism disorderIntestinal structureBlood insulin

The present invention relates to a method of treating or preventing obesity, overweight, fluctuations in blood insulin levels and / or fluctuations in blood glucose levels in mammals. The method acording to the invention comprises the enteral administration to a mammal of an effective amount of a preparation containing an enzyme capable of converting an ingested carbohydrate or digestion product thereof into one or more absorbable components, wherein the total metabolic caloric value of the absorbable component(s) is less than the metabolic caloric value of the ingested carbohydrate or digestion product thereof. Thus the present invention effectively provides a method that allows complete digestion of ingested digestible carbohydrates whilst at the same time reducing the actual metabolic caloric value of said ingested carbohydrates. Another aspect of the invention relates to a pill for oral administration provided with an enteric coating and containing 25 to 10.000 IU glucose isomerase per gram.

Owner:NV NUTRICIA

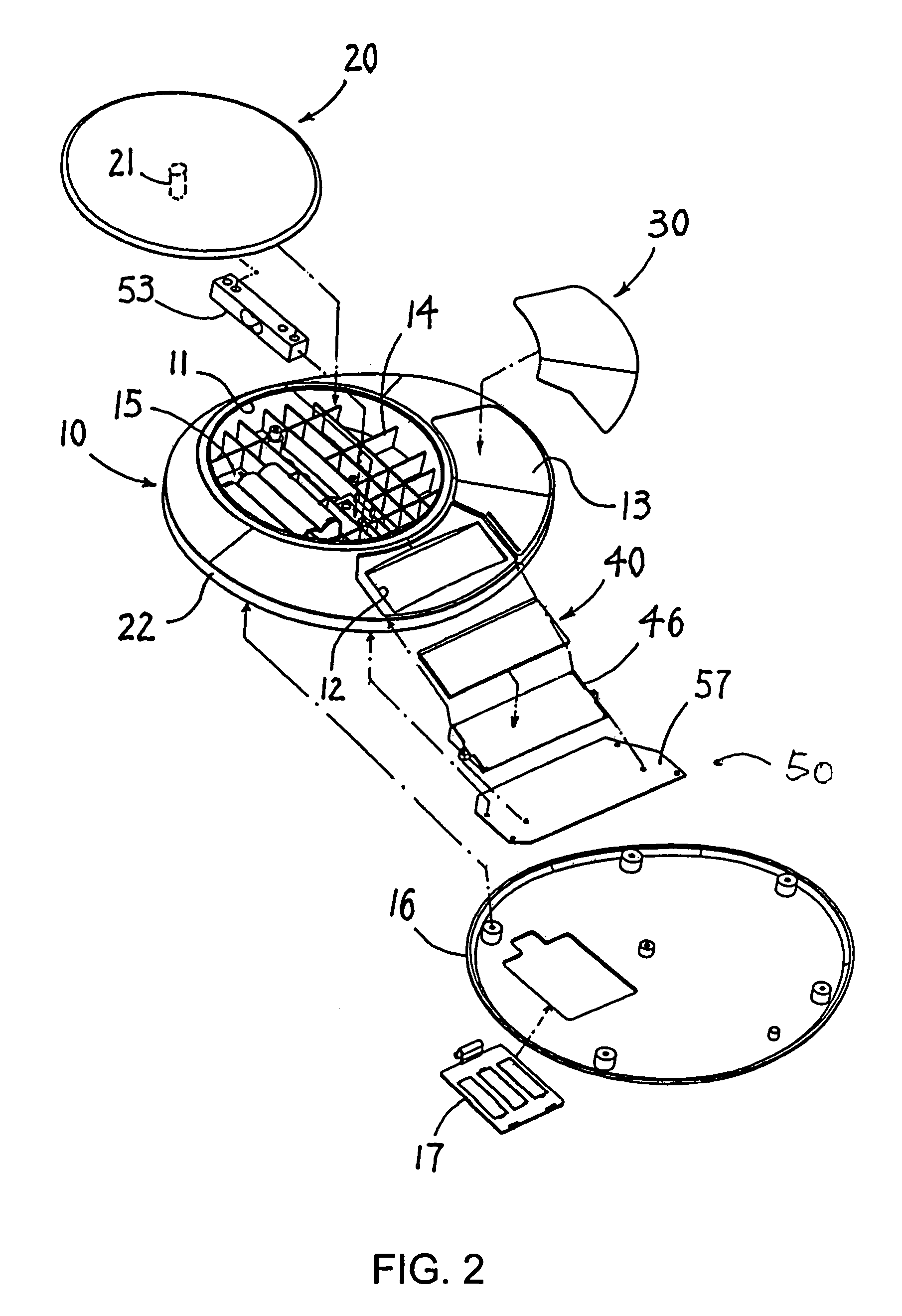

Apparatus and method for obtaining rapid creamatocrit and caloric content values of milk

InactiveUS20060013733A1Quick calculationFast contentSpecific gravity using centrifugal effectsTesting dairy productsFat contentLow volume

The invention relates to a centrifuge apparatus with a built-in sample tube reader and methods for rapidly obtaining measurements of creamatocrit, fat content and / or energy (caloric) content from low-volume fresh and frozen milk specimens.

Owner:SEPARATIONS TECH

Fish ball

The invention relates to fish ball. The fish ball is mainly made of, by weight, 100 parts of fresh fish flesh, 2-15 parts of synanthrin, 5-20 parts of cornstarch, 2.3-6.0 parts of egg white, 4.1-8.5 parts of flavoring agents, and 30-90 parts of drinking water. The fish ball has the advantages that the fish ball has low caloric value; the fish ball is capable of promoting growth of human colonic probiotics, inhibiting toxic fermentation products and increasing defecating frequency and excrement weight; excrement acidity can be increased, and colon cancer can be prevented; absorption of minerals such as calcium, magnesium and ferrum are promoted; physiological functions such as organism immunity are enhanced; and the fish ball can meet people's needs on traditional foods and modern people's needs on nutrition and health.

Owner:HENAN UNIV OF SCI & TECH

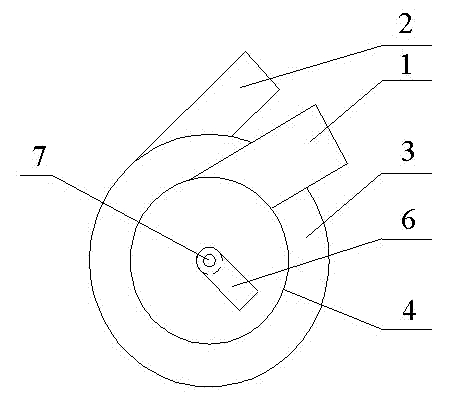

A Porous Media Burner Using Low Calorific Value Gas Fuel

InactiveCN102287819AImprove stabilityImprove combustion intensityIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberPorous medium

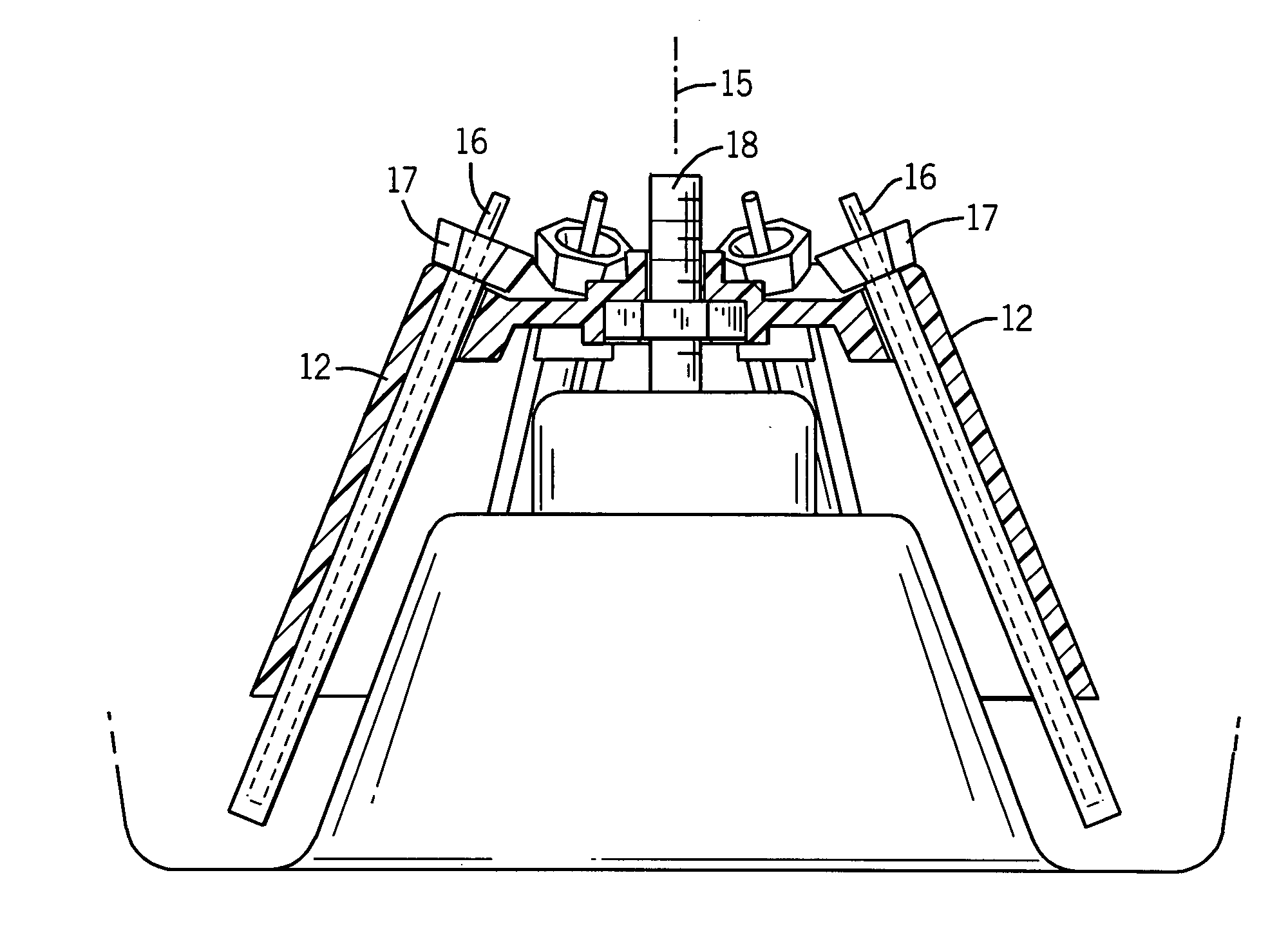

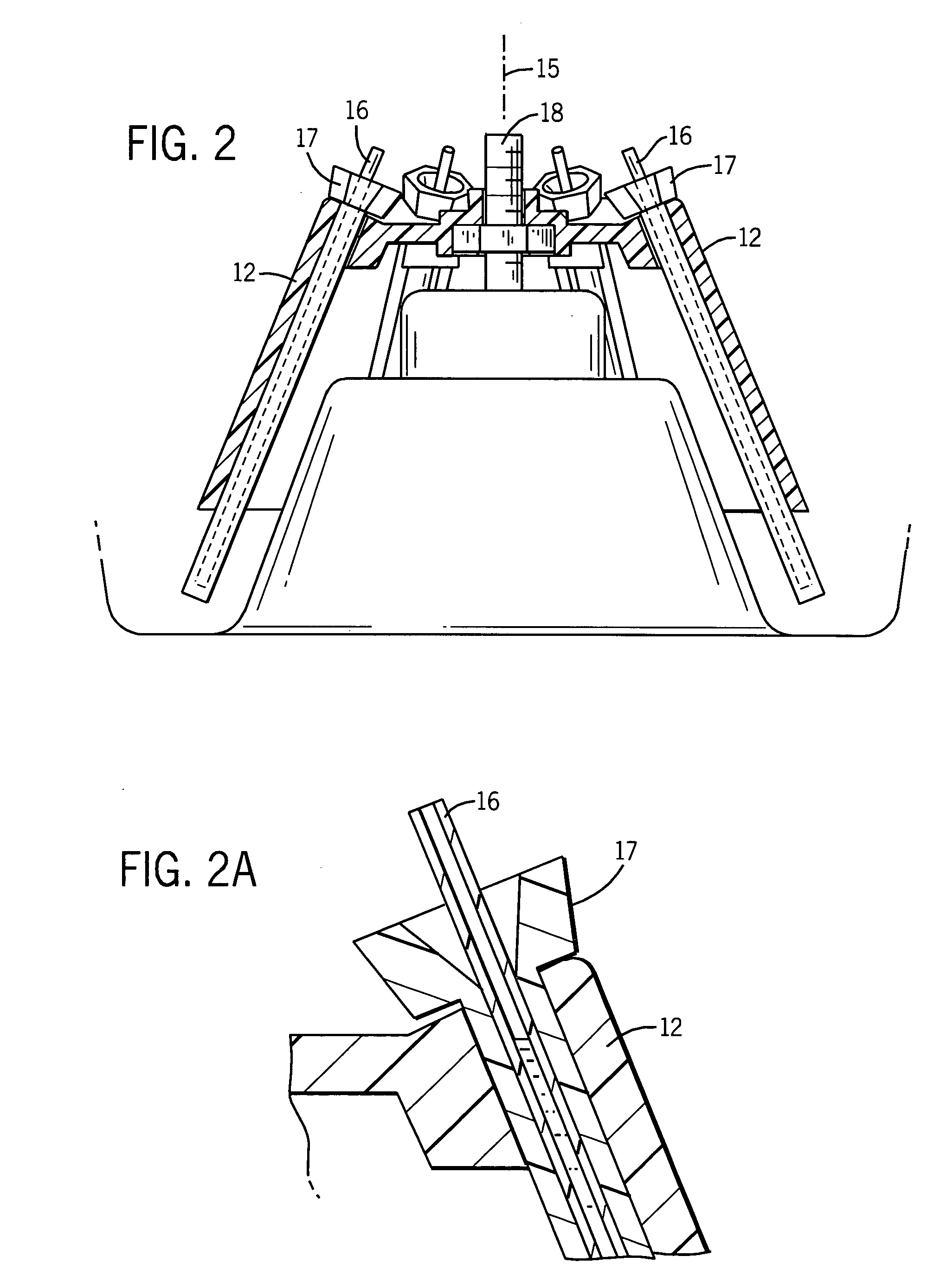

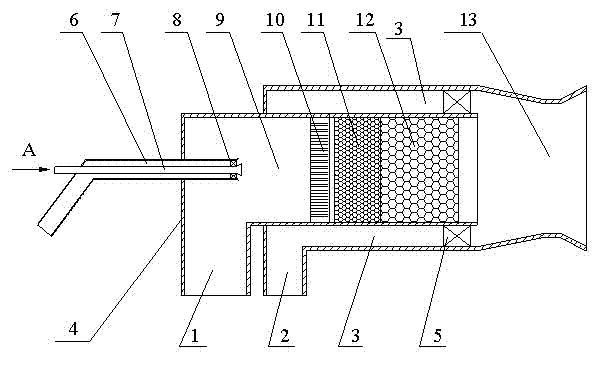

The invention discloses a porous medium combustor for a low-caloric-value gas fuel. The porous medium combustor comprises an oxygen-enriched conduit, an ignition air gun, a premixed combustion chamber, secondary air pipes and a combustor nozzle of which the central axes are coincident; the secondary air pipes are coaxially sleeved outside the premixed combustion chamber; air pipelines and fuel pipelines which circumferentially incline are correspondingly arranged on respective pipe walls of the secondary air pipes and the premixed combustion chamber; a mixing chamber, a mixed fuel gas uniformdistributor, a small porous medium and a large porous medium are sequentially arranged in the premixed combustion chamber along an airflow direction; air holes of the small porous medium and the large porous medium adopt a honeycomb arrangement structure; the oxygen-enriched conduit is coaxially sleeved outside the ignition air gun; and outlet ends of the oxygen-enriched conduit and the ignition air gun pass through a wall surface of the premixed combustion chamber and extend into the mixing chamber. By adopting the segmental type porous medium, the combustion stability of the low-caloric-value gas fuel can be obviously improved, the combustion intensity of the low-caloric-value gas fuel is enhanced, the combustion volume is reduced, the combustion efficiency is improved, and the discharge of pollutant can be effectively reduced.

Owner:CHINA JILIANG UNIV

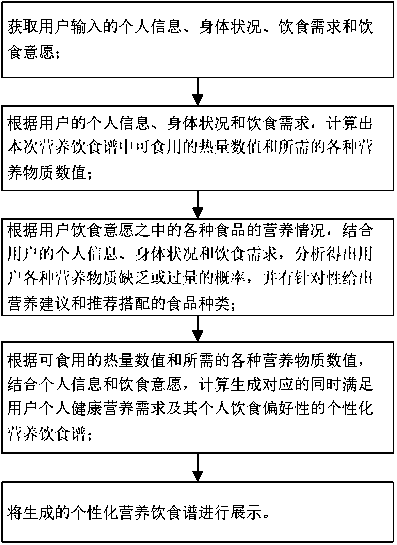

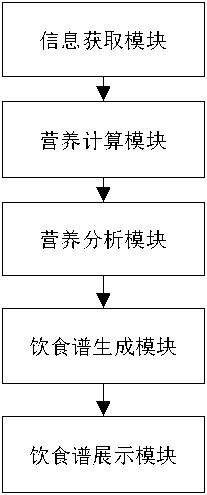

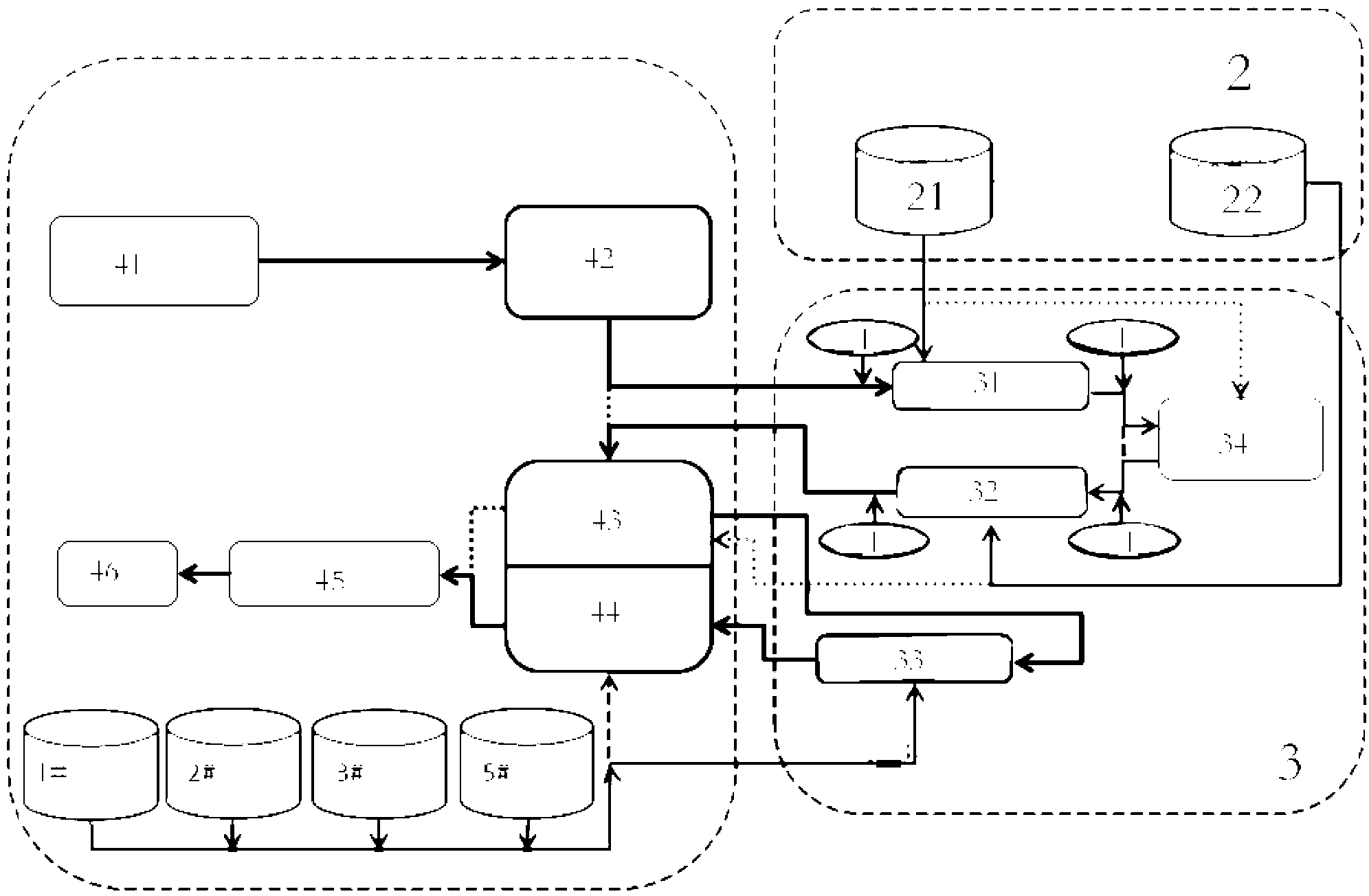

Personalized nutritional recipe recommendation method and system based on users' conditions

InactiveCN105512196ATake care of personal preferencesHigh feasibilityData processing applicationsSpecial data processing applicationsNutrition analysisPersonalization

The invention discloses a personalized nutritional recipe recommendation method and system based on users' conditions. The method comprises following steps: obtaining personal information, body conditions, diet requirements and diet wishes inputted by users; calculating edible caloric value and all needed nutriment values of the nutritional recipe this time; making analyses of probabilities of the users who lack or overeat nutrients; and calculating to generate personalized nutritional recipes of personal references. The system comprises an information acquisition module, a nutrition calculation module, a nutrition analysis module, a diet recipe generation module and a diet recipe display module. The personalized nutritional recipe recommendation method and system based on user's conditions have following beneficial effects: personalized nutrition recipes can be generated for different users; recipes easily satisfying the nutrition requirements can be automatically selected so that calculating difficulty and time are greatly minimized; through reasonable balance, personal preferences of users can be taken into consideration in order to effectively improve practicability of nutrition recipes; and the invention can be extensively applied to daily lives.

Owner:朱威

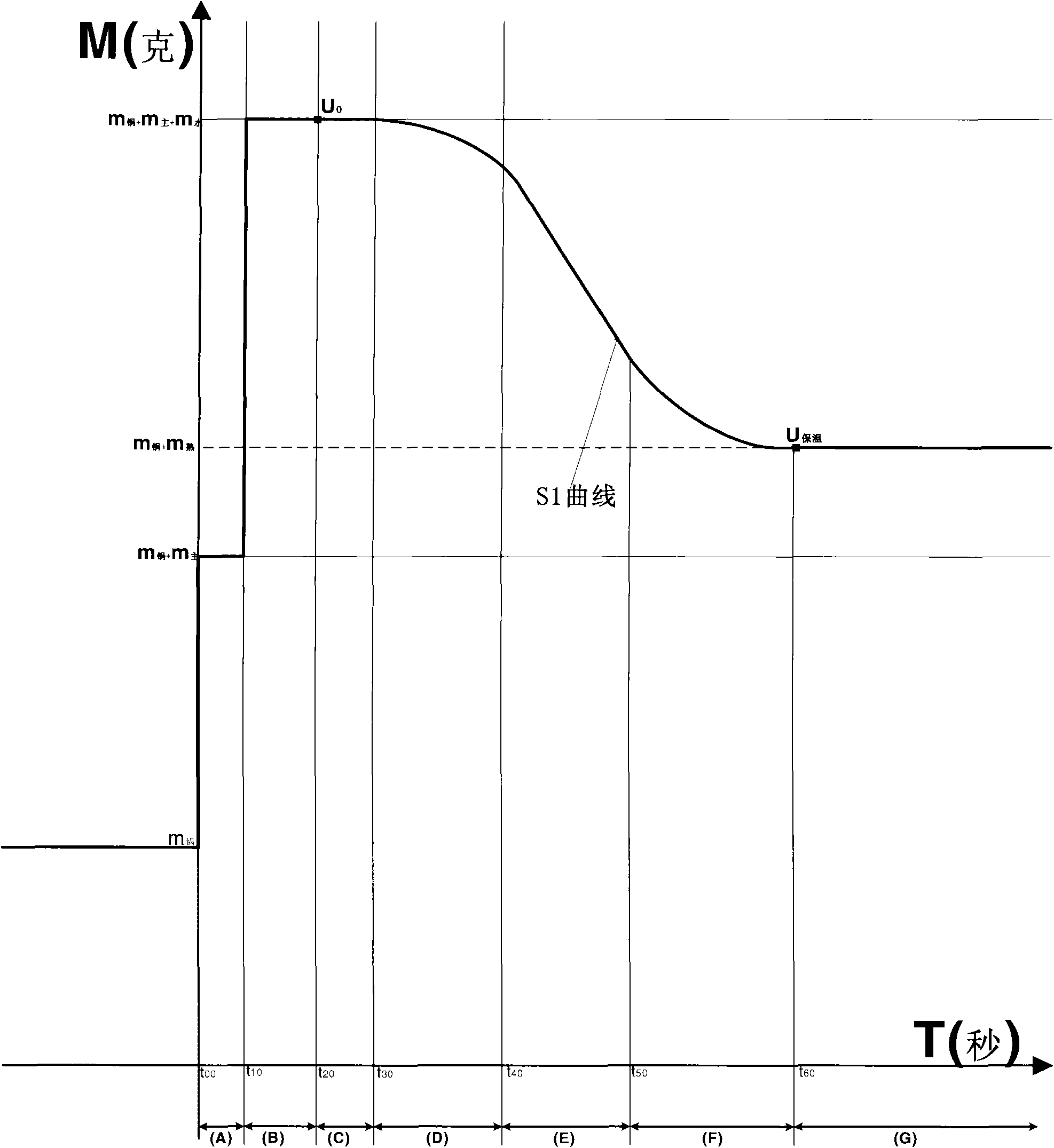

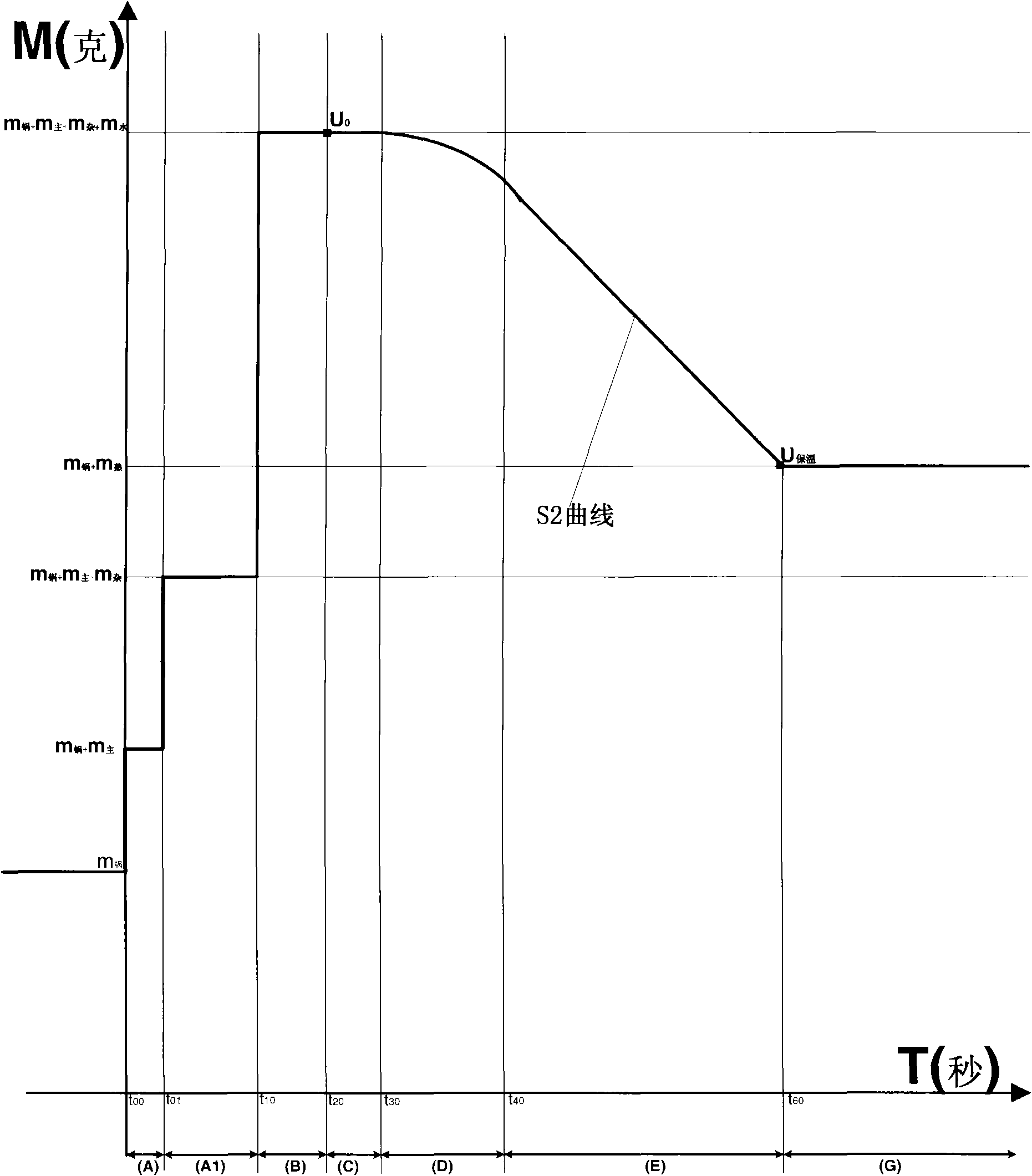

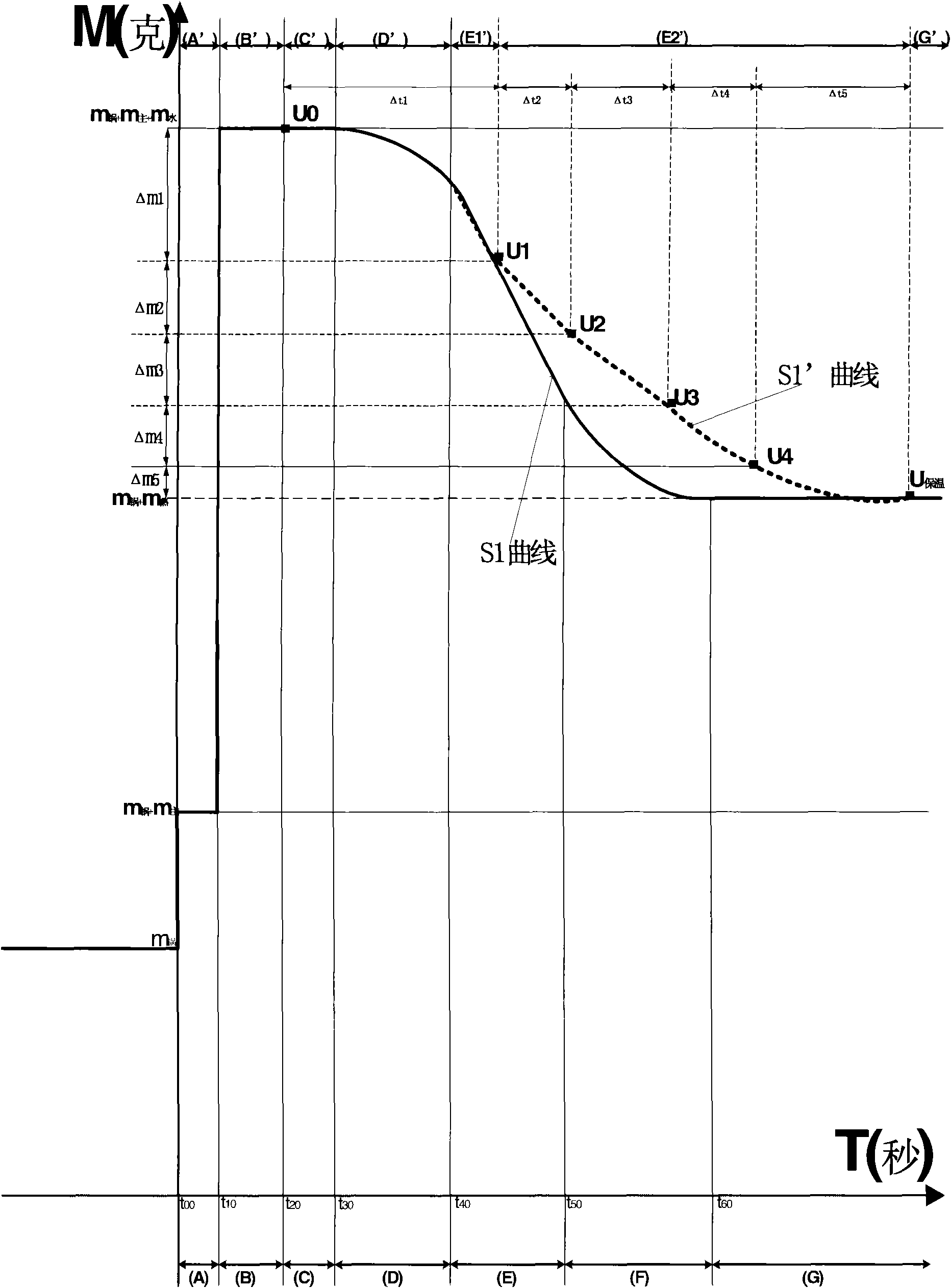

Gas stove with weighing function and weighing control method thereof

ActiveCN101936549AAchieve healthDomestic stoves or rangesLighting and heating apparatusCholesterolEdible oil

The invention discloses a gas stove with a weighing function and a weighing control method thereof. An electronic scale with the weighing function is additionally arranged below the stove tabletop of the gas stove and saves an experience database and a food information database in a cooking process so that the gas stove not only solves the problem that users fuzzily and inaccurately know how muchweight of water needs to be added to a certain weight of food, but also can feed back and intelligently adjust according to the tastes of the users to enable the next-time cooking tastes to be close to the taste demands of the users by designing the experience curve of heating power of a pressure cooker on the gas stove for the foods comprising rice, meat and the like on different weight points; and in addition, the gas stove enables the users to clearly and definitely know the total or per-capita intake caloric value, cholesterol content, protein content, fat content, mutual restraint between the foods, edible salt amount and edible oil amount of various foods in the cooking. Therefore, the invention realizes the standardization, automation, accuracy, intelligence and health of pressure cooker on the gas stove in the whole cooking process.

Owner:谢国华

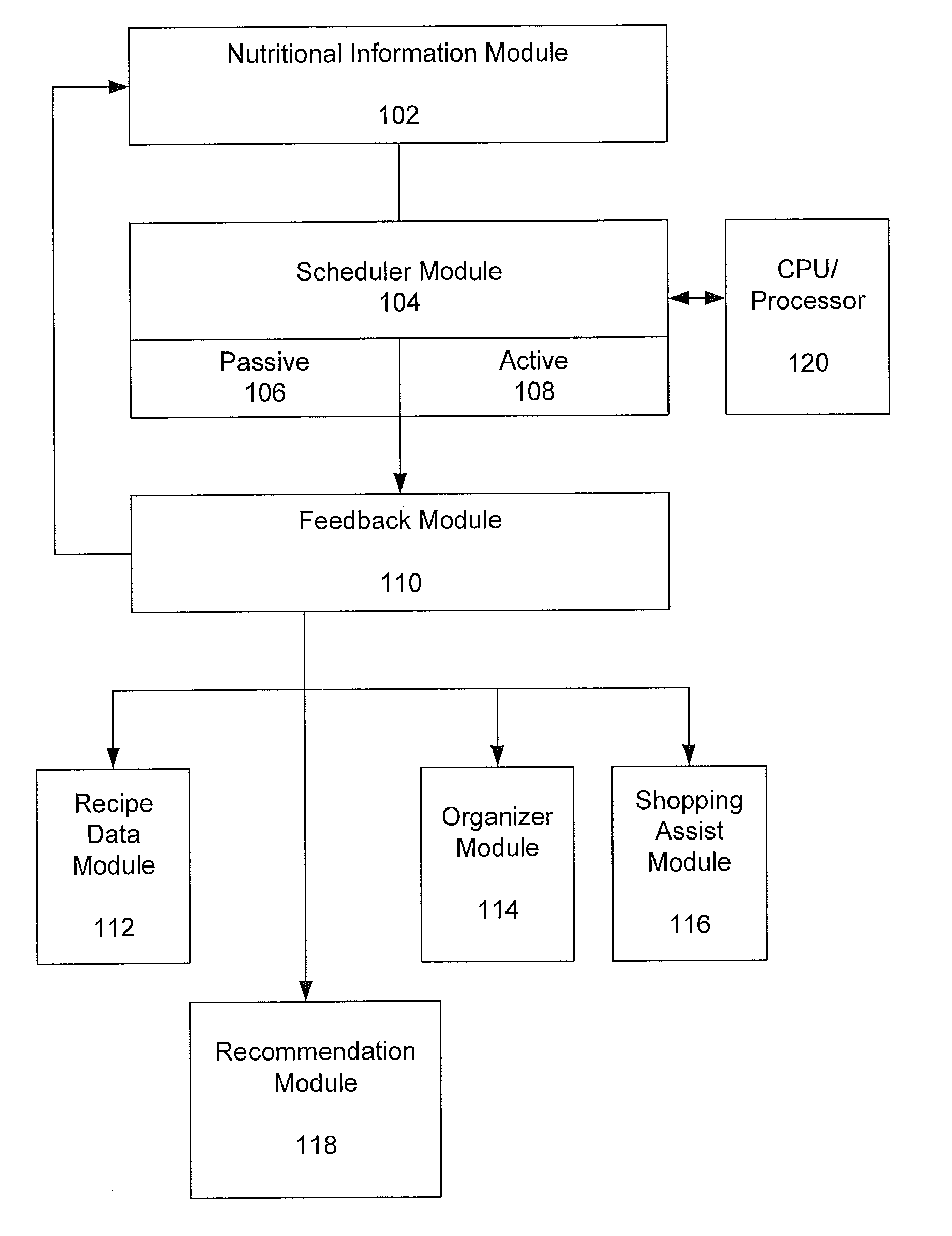

Food preparation system and method

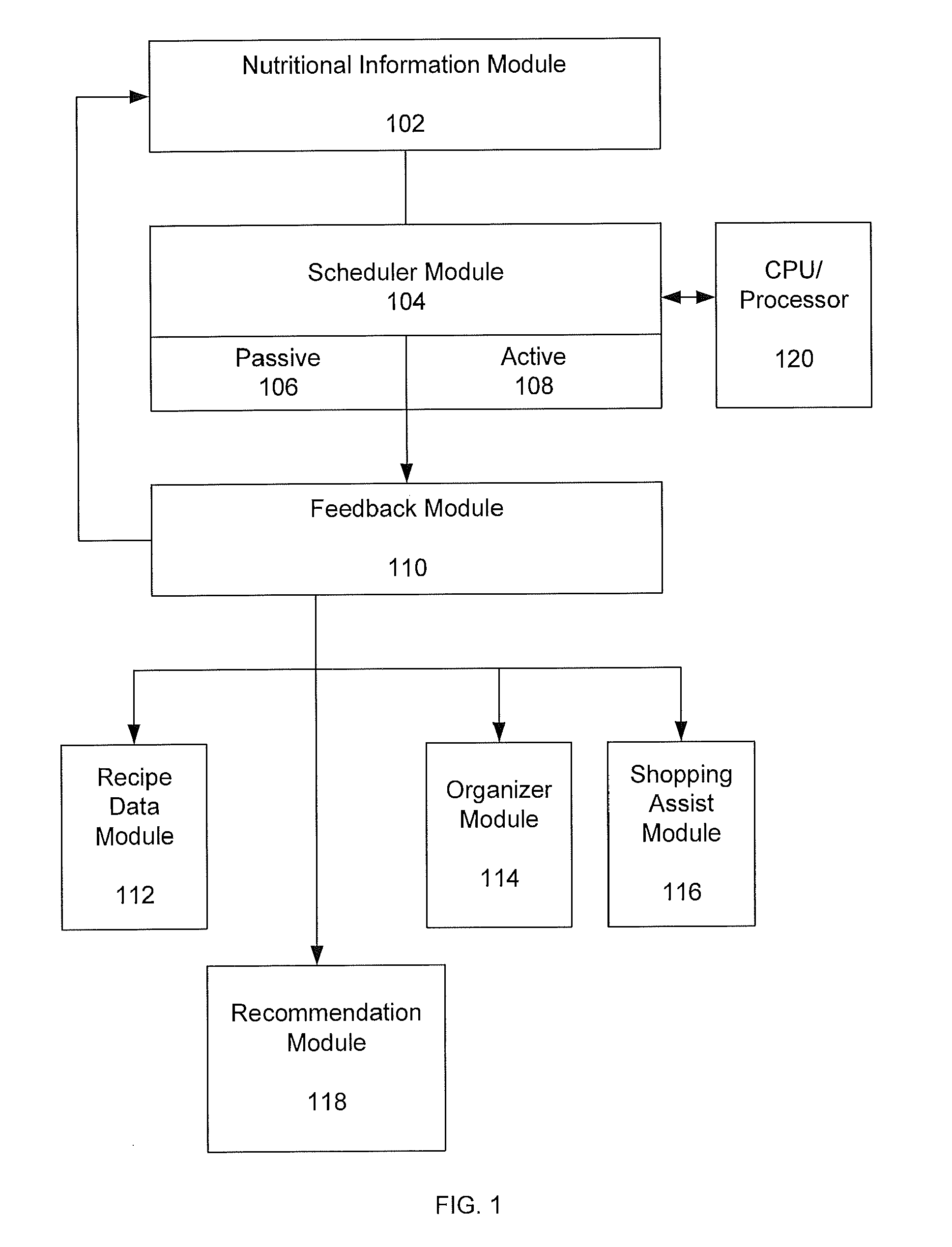

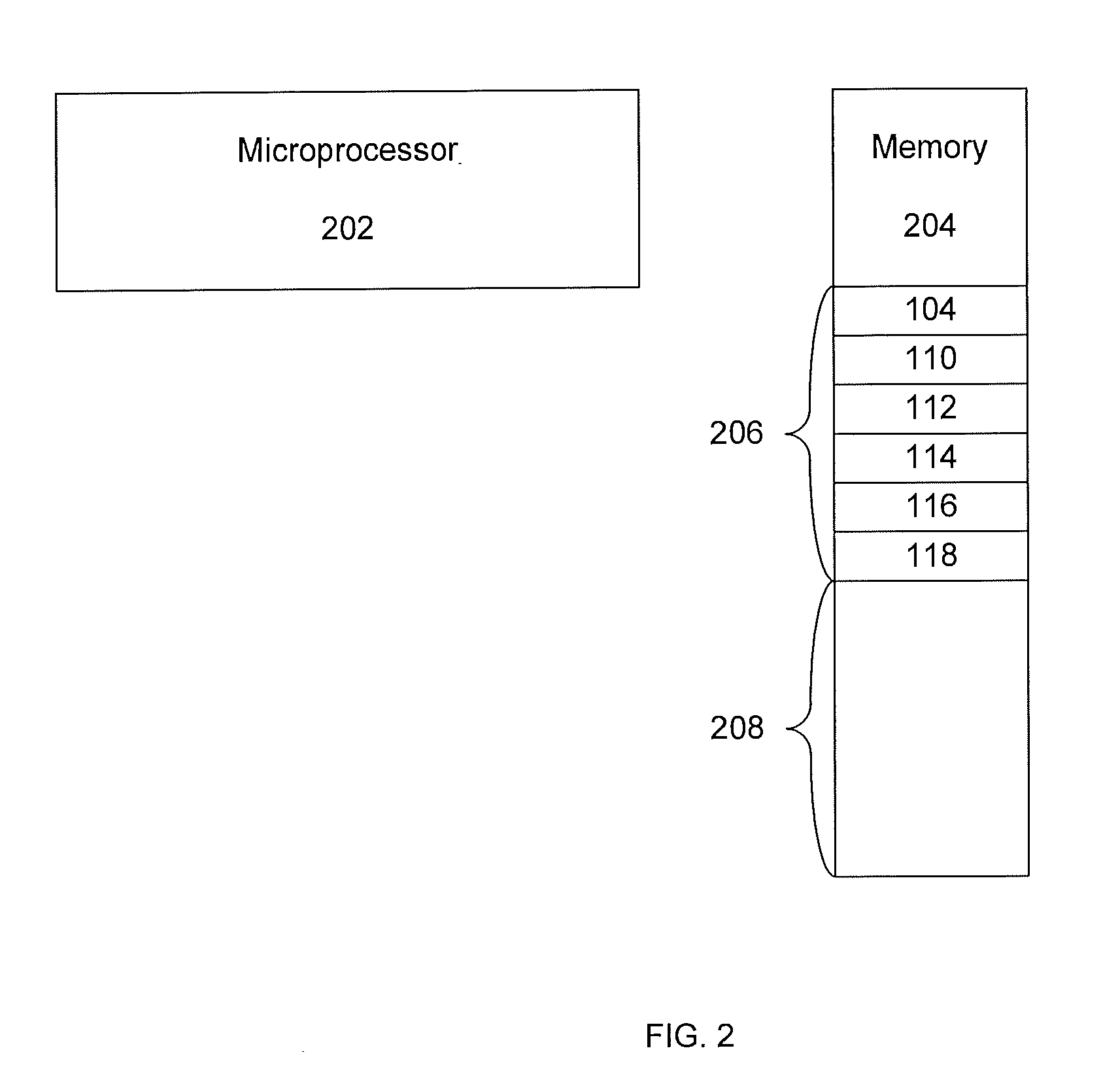

ActiveUS20110289044A1Easy to useNutrition controlFuzzy logic based systemsAdditive ingredientCaloric values

A system and method for the preparation of food is provided. The system utilizes a nutritional information module which allows nutritional information to be aggregated for an entire menu along with portion information and the ability to adjust serving weight by preferred caloric value for any individual recipe. The system also utilizes a scheduler module which compiles task information for any individual recipe items per paragraph. The schedule module may have any plurality of different task times including a passive task time and / or an active task time and may time stamp the time it takes to prepare any specific recipe. The schedule may compile cook information and store information in a memory bank for analysis of the individual cook's cooking style and cook time. Moreover, the system may also provide a feedback module which uses personal time co-efficients to predict how long it should take for any particular menu choice preparation. Additionally, the system may include any of a recipe data module, organizer module, shopping assistant modules and a recommendation module to help the individual cook decide of menu pairings for any particular recipe as well as source and purchase recipes, required ingredients, and required cookware and utensils.

Owner:HARRISON CHET

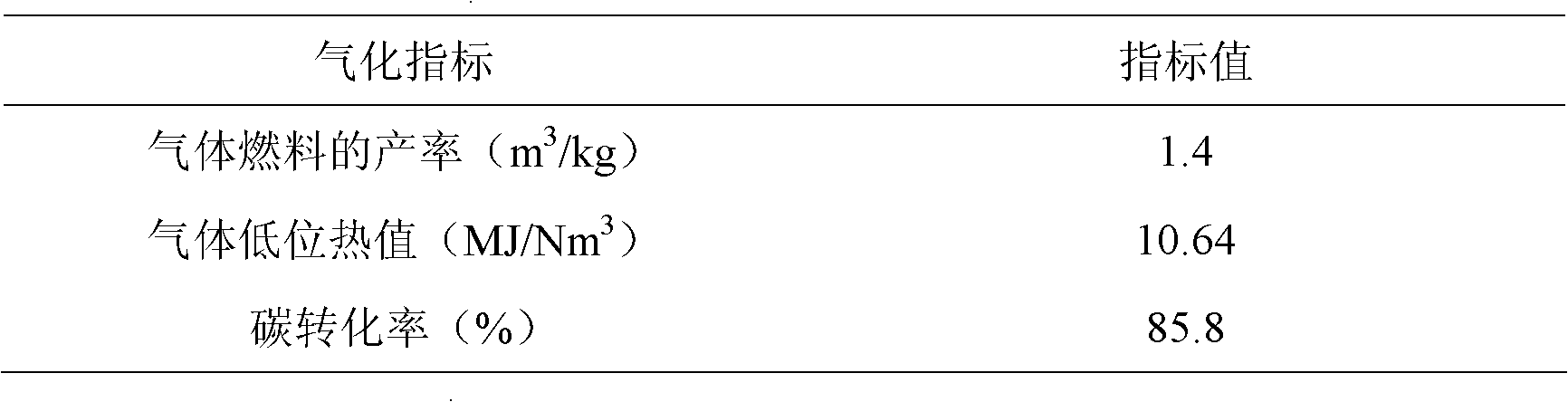

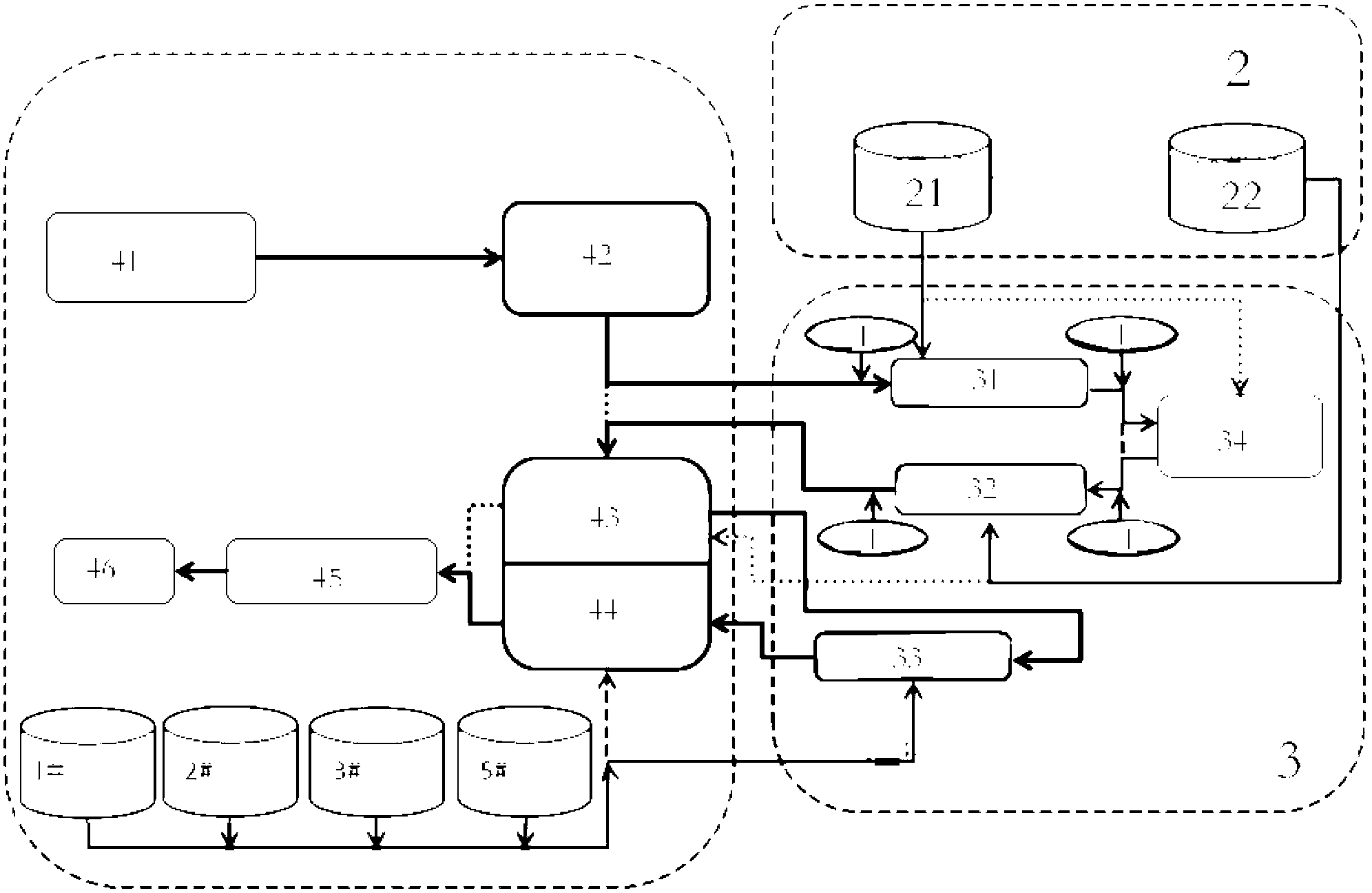

Intelligent conditioning system for deep dewatering of sludge

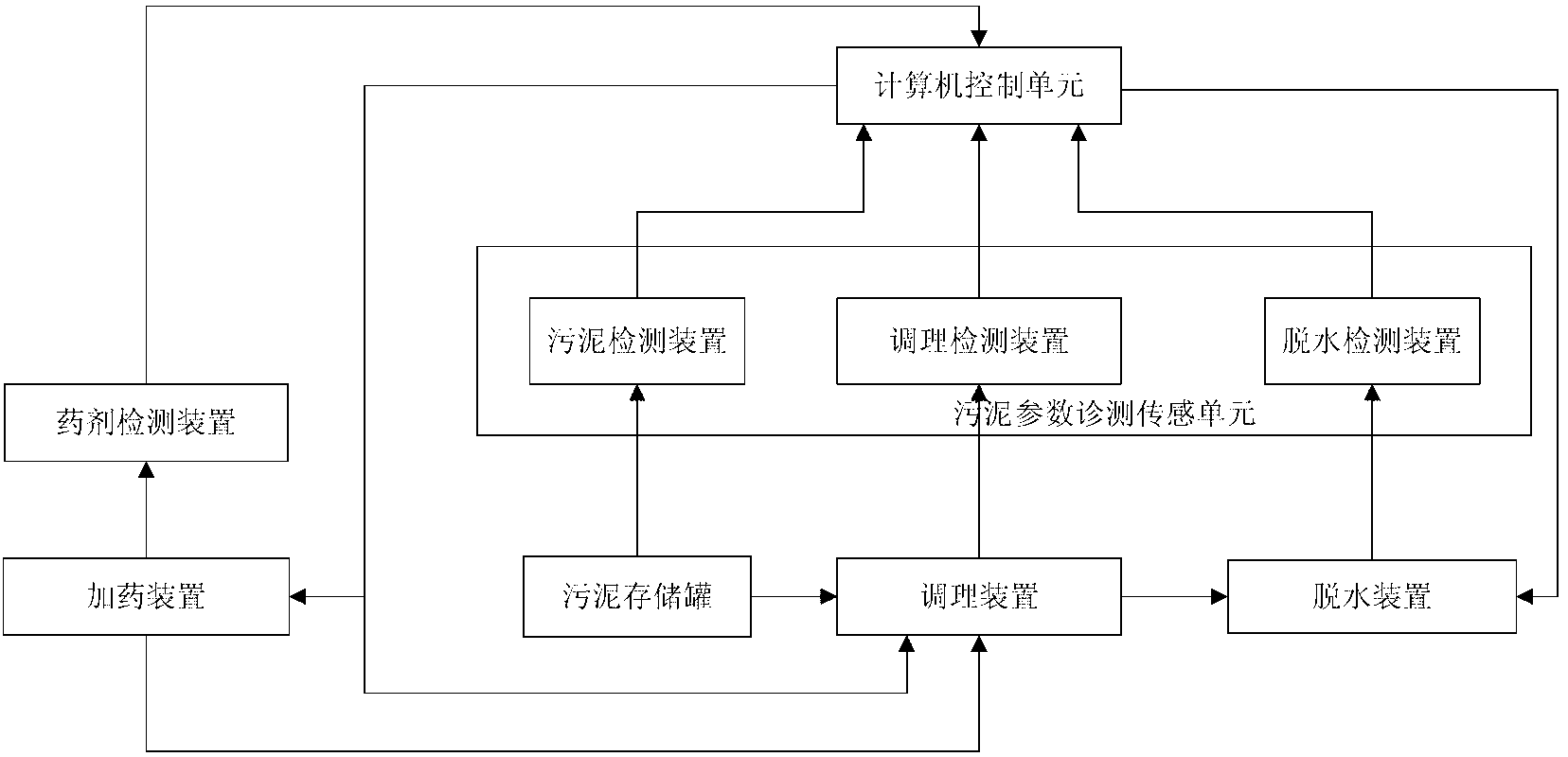

ActiveCN103241918ALower output qualitySludge treatment by de-watering/drying/thickeningSimultaneous control of multiple variablesChemical storageCaloric values

The invention discloses an intelligent conditioning system for deep dewatering of sludge, which comprises a dosing module, wherein the dosing module comprises an automatic dispensing system, a dosing system and chemical storage and throwing systems. According to the invention, an intelligent diagnosis system diagnoses each part in the reaction process of a sludge treatment device, and transmits the diagnosis result to a control unit; the control unit analyzes the diagnosis result, and controls the dosing system to perform dosing operation according to a control result; and through the treatment of the invention, the sludge moisture content is reduced from the originally 80-98% to 35-60%, the final sludge output mass is reduced by at least 50%, the sludge can still keep 70% or above (about 600-3000 kilocalories per kilogram) of the original organic caloric value after the sludge moisture content is reduced, and the sludge can be further treated by incineration and drying.

Owner:JIANGSU GREEN WAY ENVIRONMENTAL PROTECTION TECH

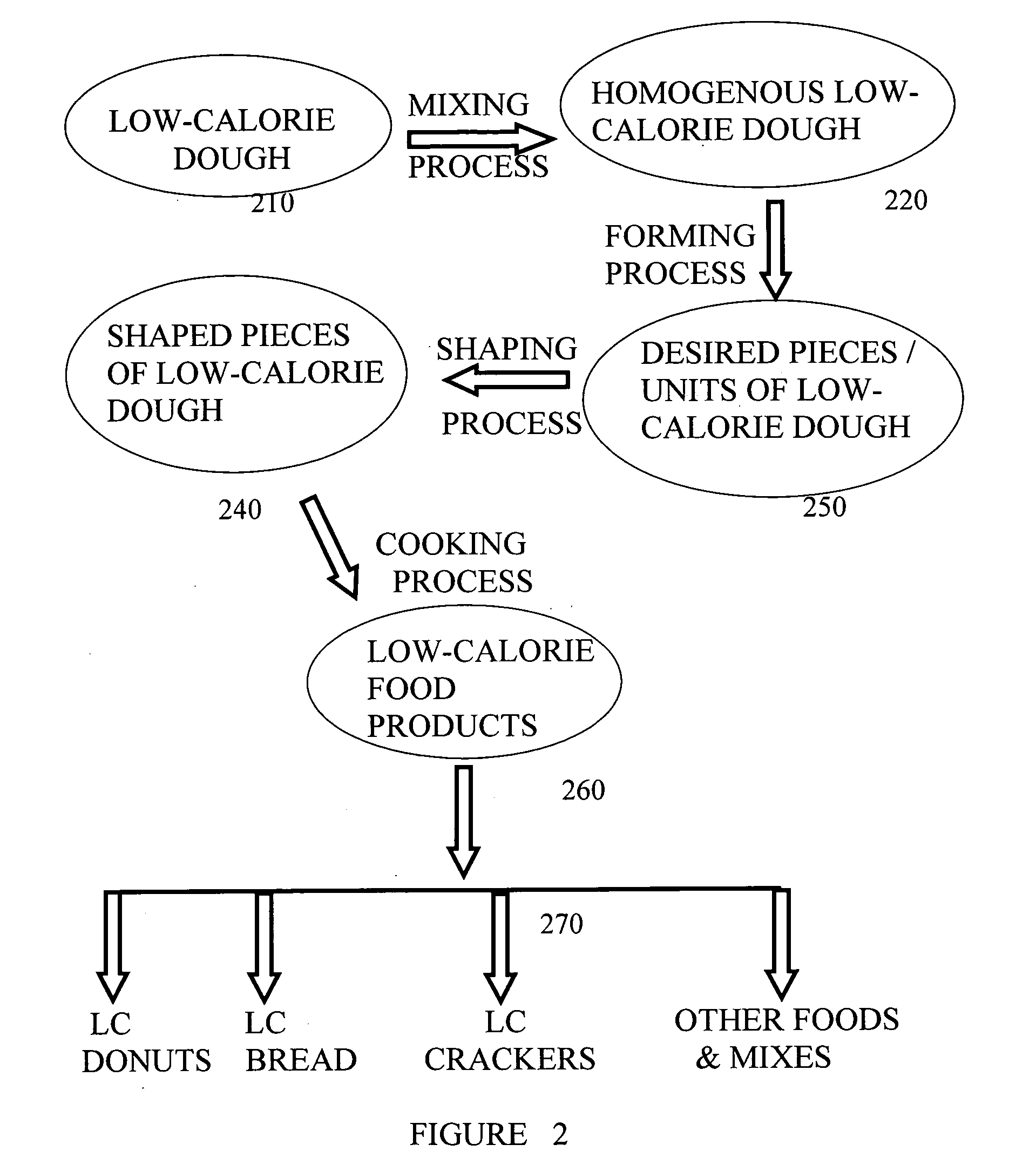

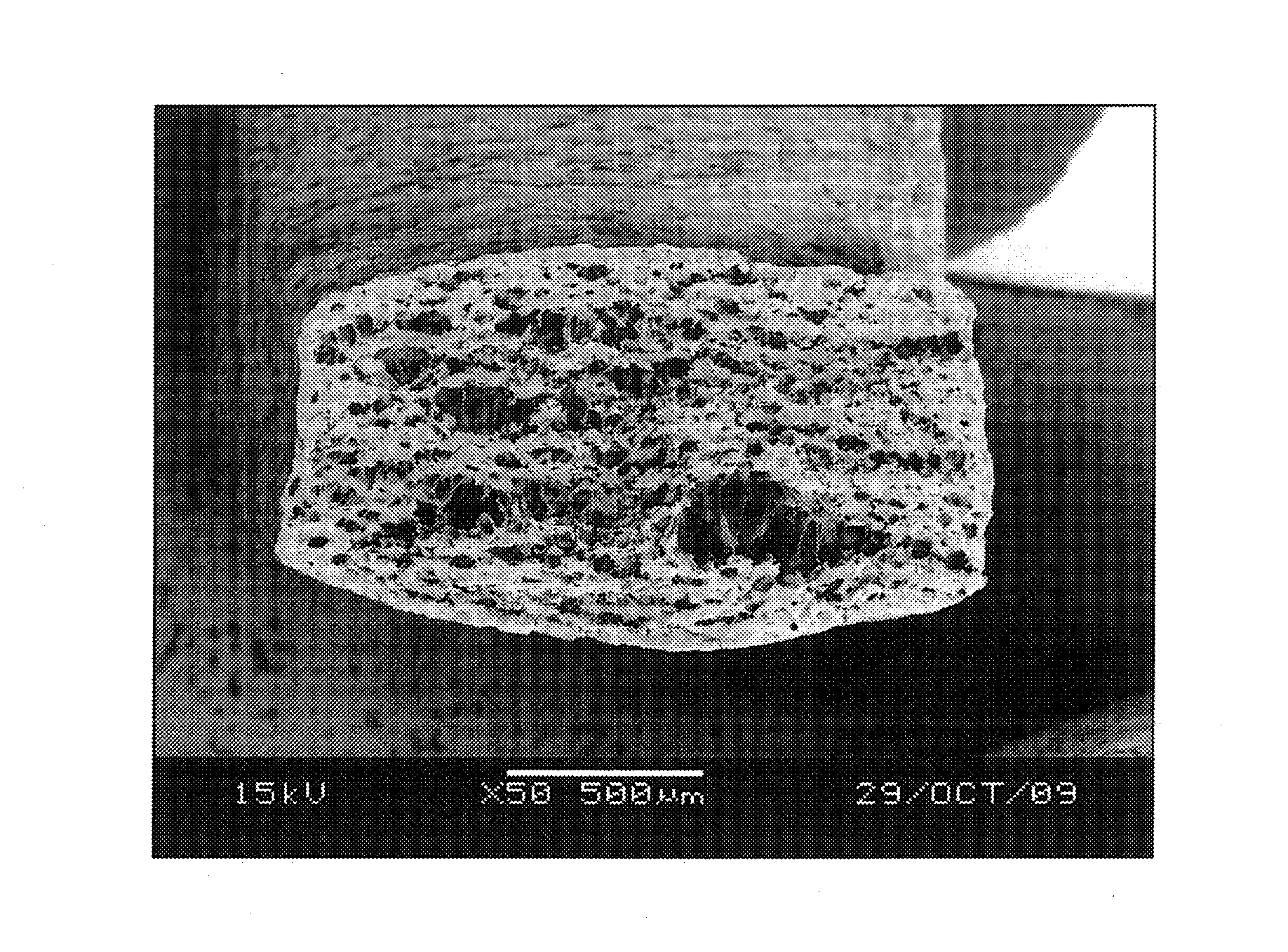

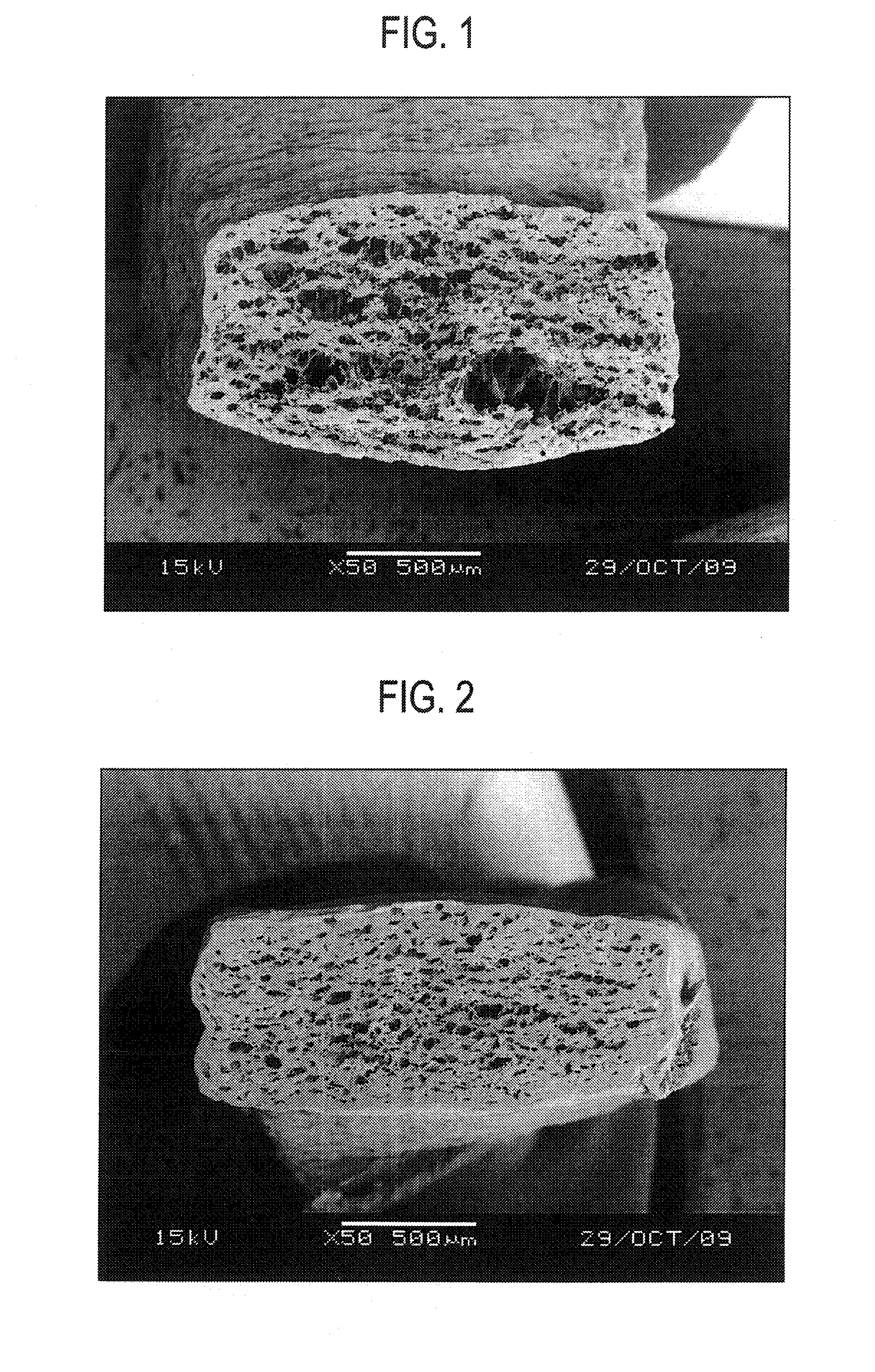

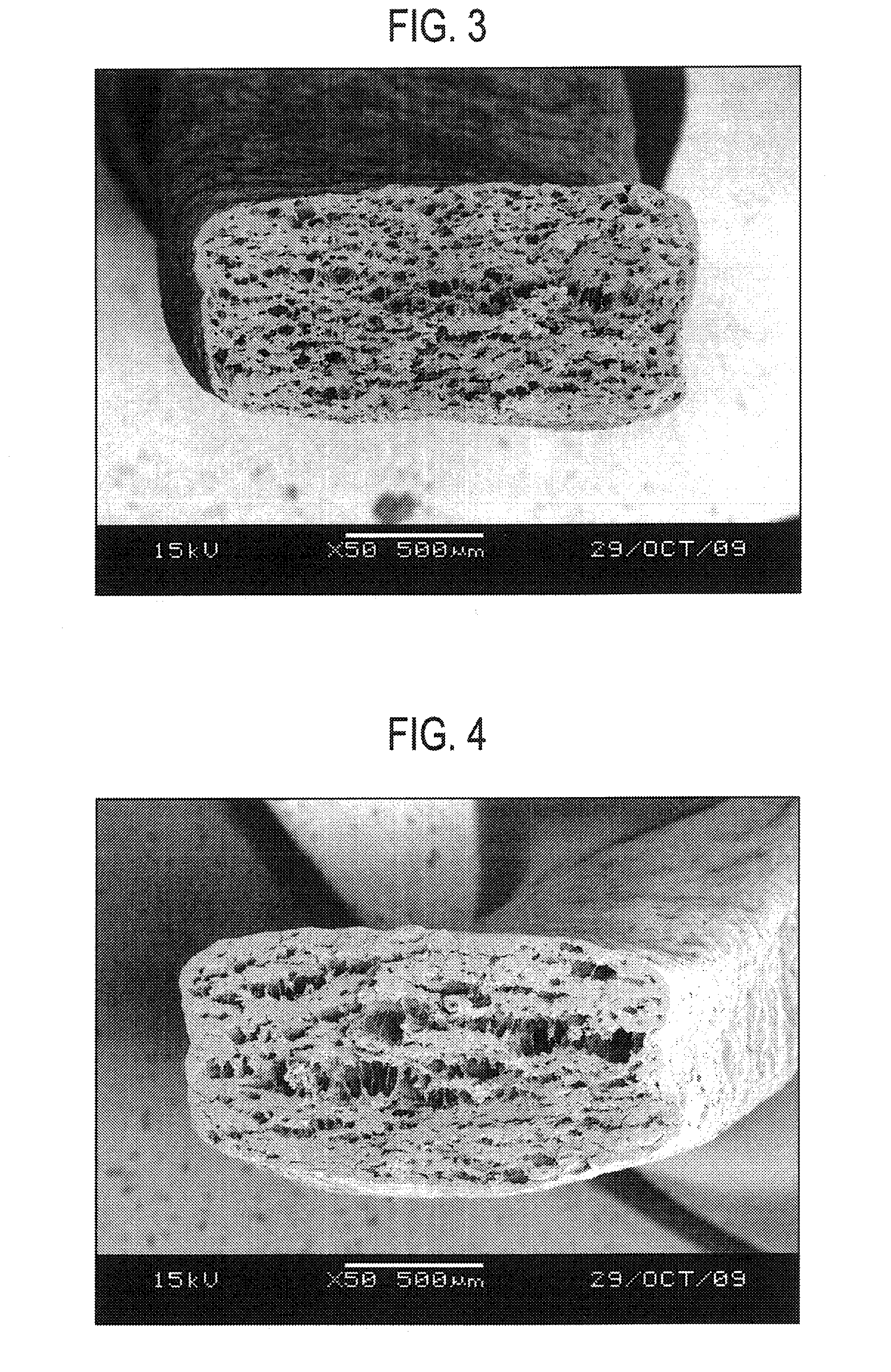

Low-calorie foods and process of making the same

InactiveUS20070259090A1Sufficiently deficient of caloriePalatableDough treatmentBaking mixturesCelluloseLow calorie

A novel dough-like mixture made using cellulose and hydrocolloid gums that can be used as a basis for forming a variety of low-calorie foods is disclosed. Methods for producing low-calorie and reduced-starch donuts, fillings, cookies, breads, and many other food products using this dough are also described. Erythritol-based reduced-sugar confectionery items and methods for their production and application, including use in reduced-calorie sweet-tasting bakery goods, are also disclosed. Many of the disclosed foods are low enough in caloric value to be termed “recreational solid foods,” with experiments showing that even ad libitum eating of them results in weight loss.

Owner:TECH ADVANCEMENT LABS

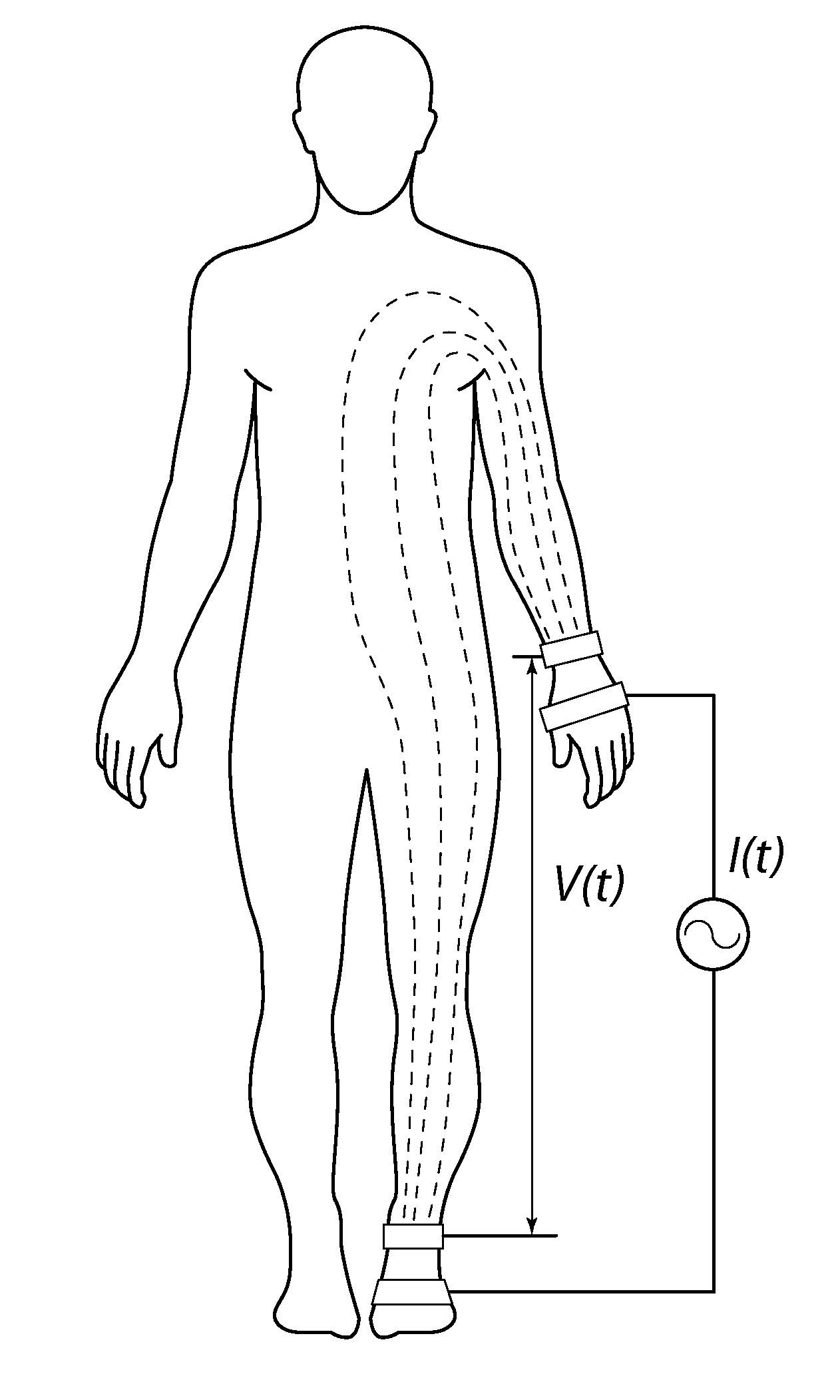

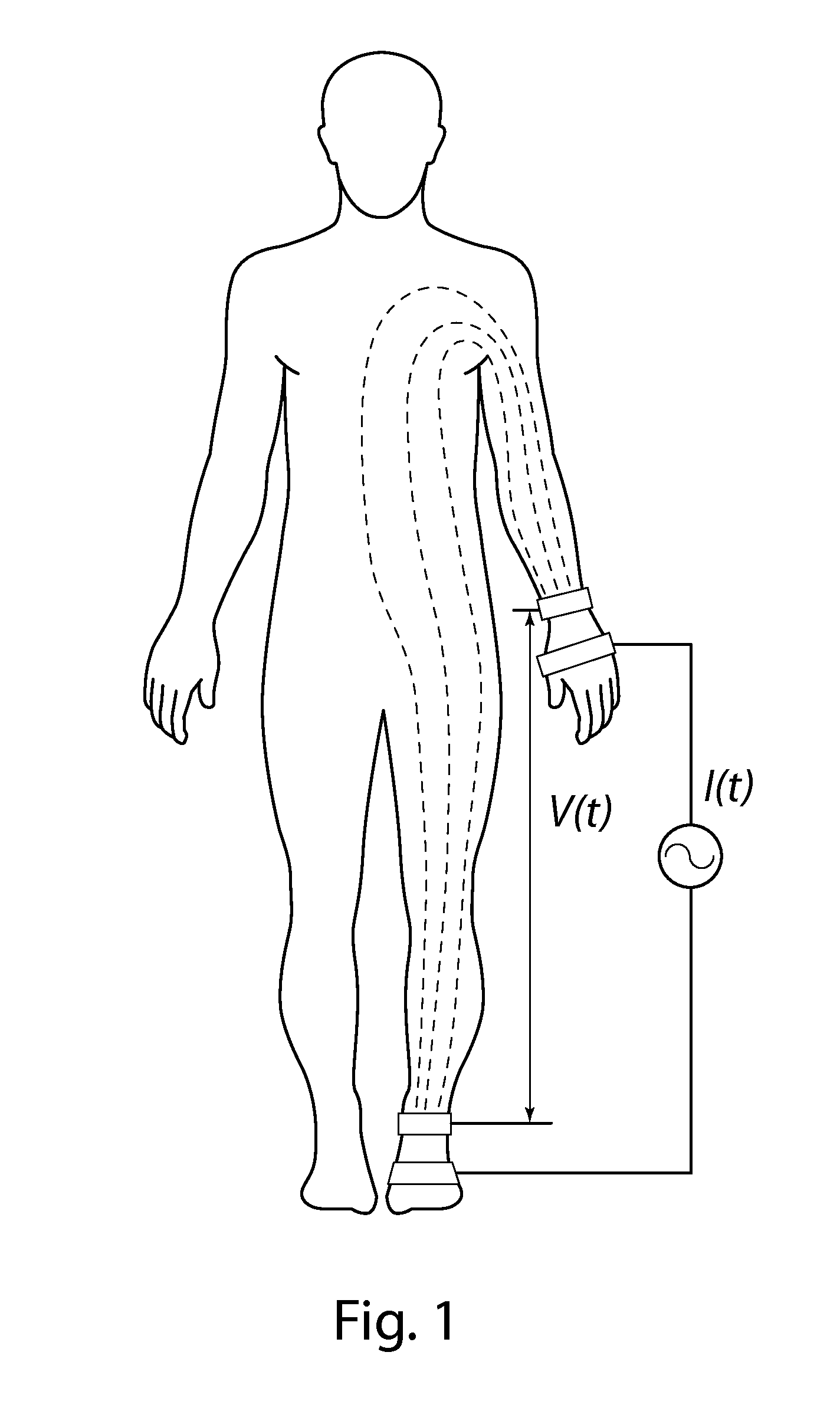

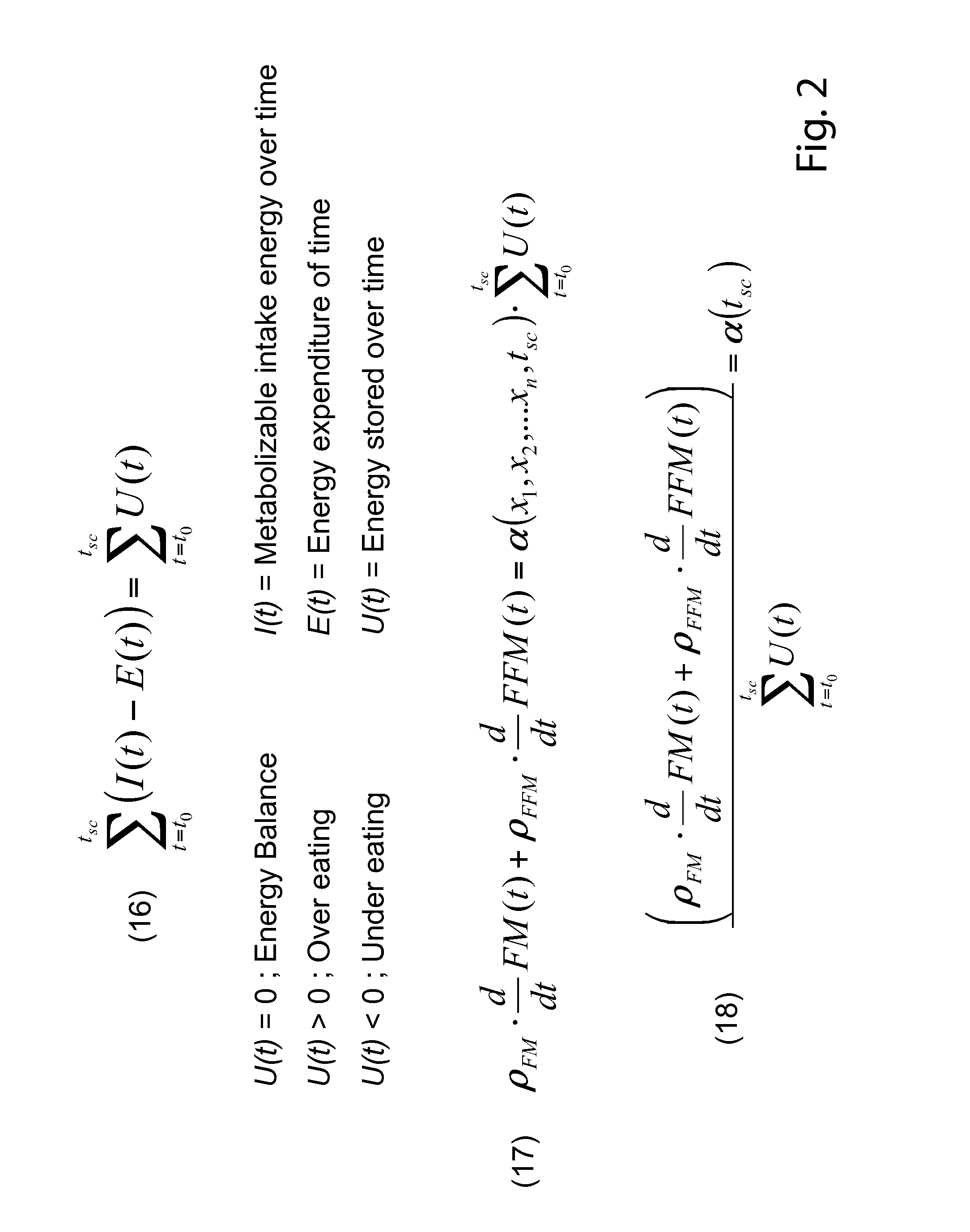

Systems and methods for determining caloric intake using a personal correlation factor

InactiveUS20140172314A1Nutrition controlDiagnostic recording/measuringCorrelation factorCaloric values

Systems and methods are provided for determining an individual's personal correlation factor and, using the personal correlation factor, determining the individual's caloric intake. A method for determining a personal correlation factor includes determining a body composition change over a calibration period, converting the body composition change to an equivalent energy value, and dividing the equivalent energy value by a net caloric value for the same calibration period, wherein the net caloric value includes a caloric expenditure less a caloric intake. A method for determining a subsequent caloric intake includes converting a body composition change to an equivalent energy value, dividing the equivalent energy value by the personal correlation value, and adding to this quotient the individual's caloric expenditure, wherein each step is performed using a processor.

Owner:ACCESS BUSINESS GRP INT LLC

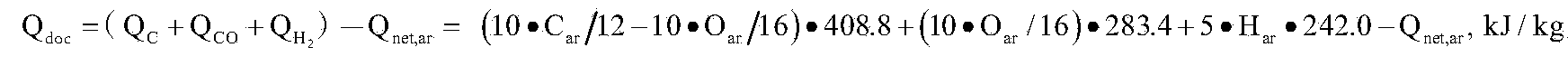

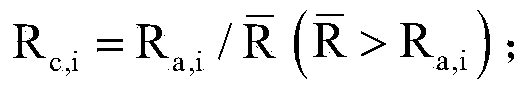

Establishment method of blast-furnace injected pulverized coal cost performance evaluation model

ActiveCN103952503ARealize optimal selectionLow cost performanceBlast furnace detailsAlternative fuelsCaloric values

The invention discloses an establishment method of a blast-furnace injected pulverized coal cost performance evaluation model, belonging to the technical field of blast furnace ironmaking, and solving the optimization and selection problems of blast-furnace injected pulverized coal. The model can be used for evaluating the cost performance of blast-furnace alternative fuels such as semi coke, carbocoal, biomass char, waste plastic and tires. A conception that pulverized coal can provide effective utilization caloric value for a blast furnace is proposed based on the combustion reaction behavior of pulverized coal in the blast furnace. Eight indexes influencing the real heat supply of coal powder and four indexes influencing the injection cost can be determined, and a blast-furnace injected coal / alternative fuel cost performance evaluation model can be established. The model is convenient to calculate, and has important guidance significance to the optimization and selection of the on-site blast-furnace injected coal. In addition, the model also can be used for changing corresponding indexes and evaluating other types of alternative fuels.

Owner:UNIV OF SCI & TECH BEIJING

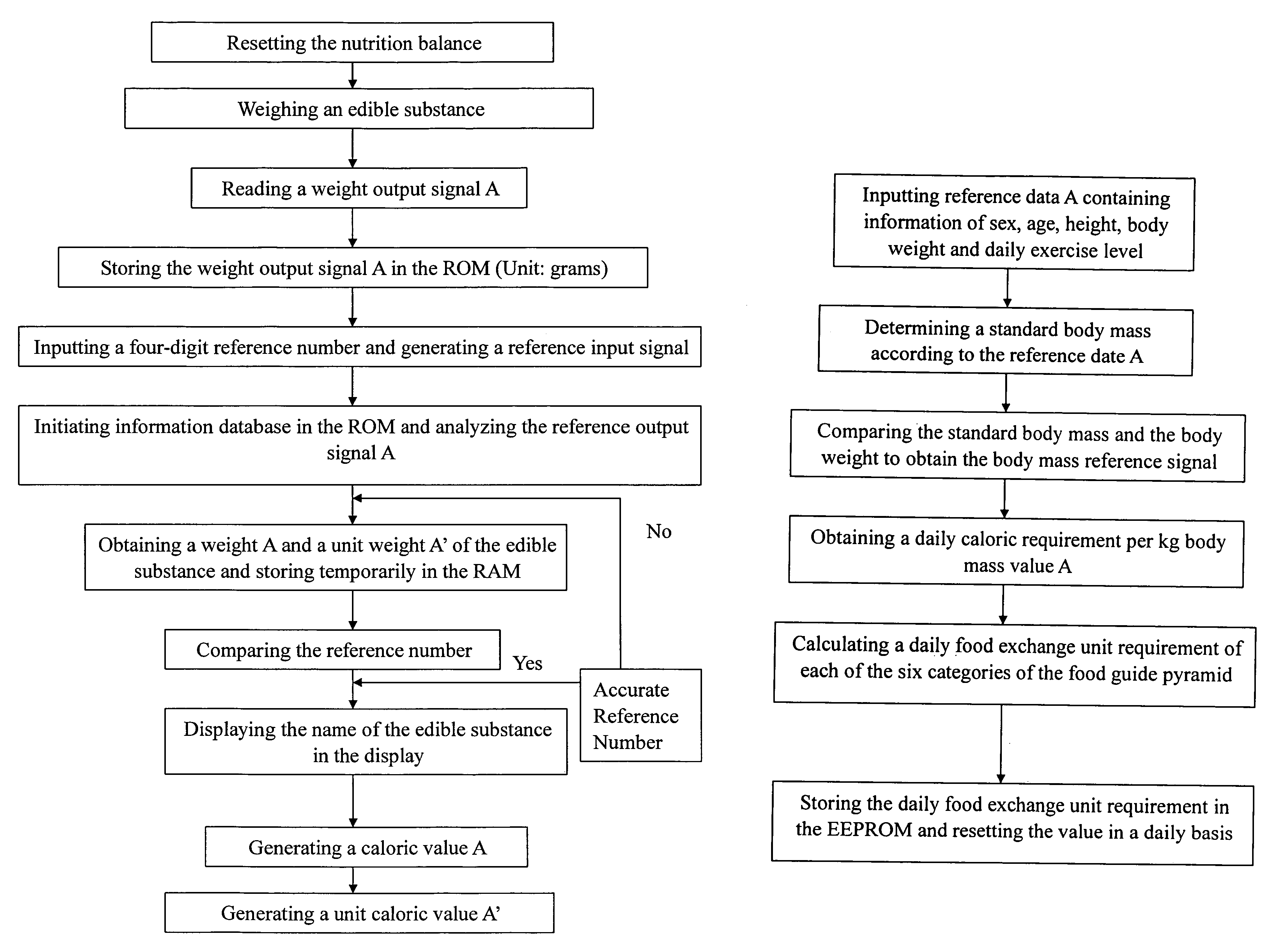

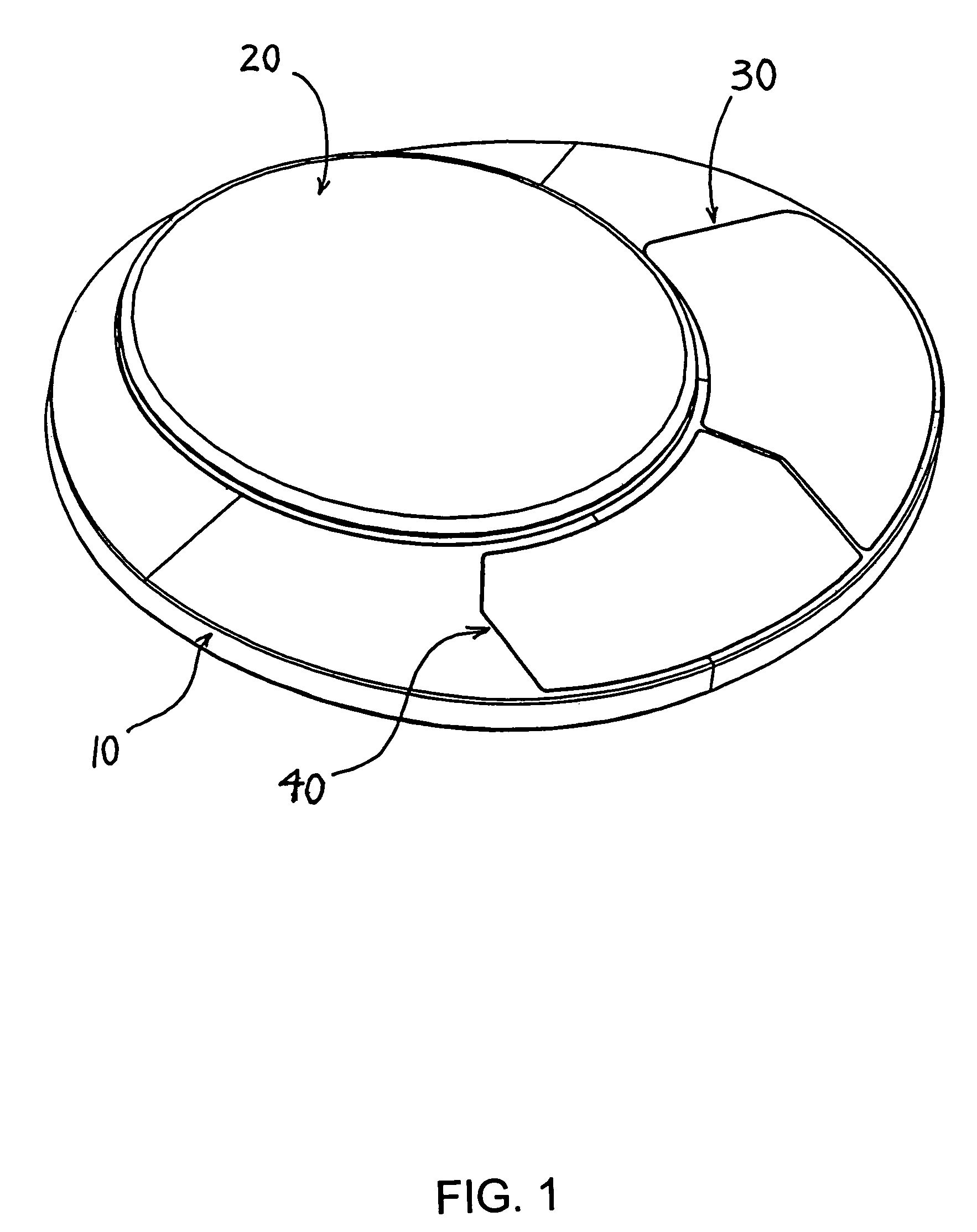

Diabetes mellitus nutritional balance for monitoring the food and nutritional intake

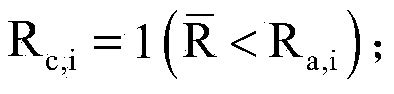

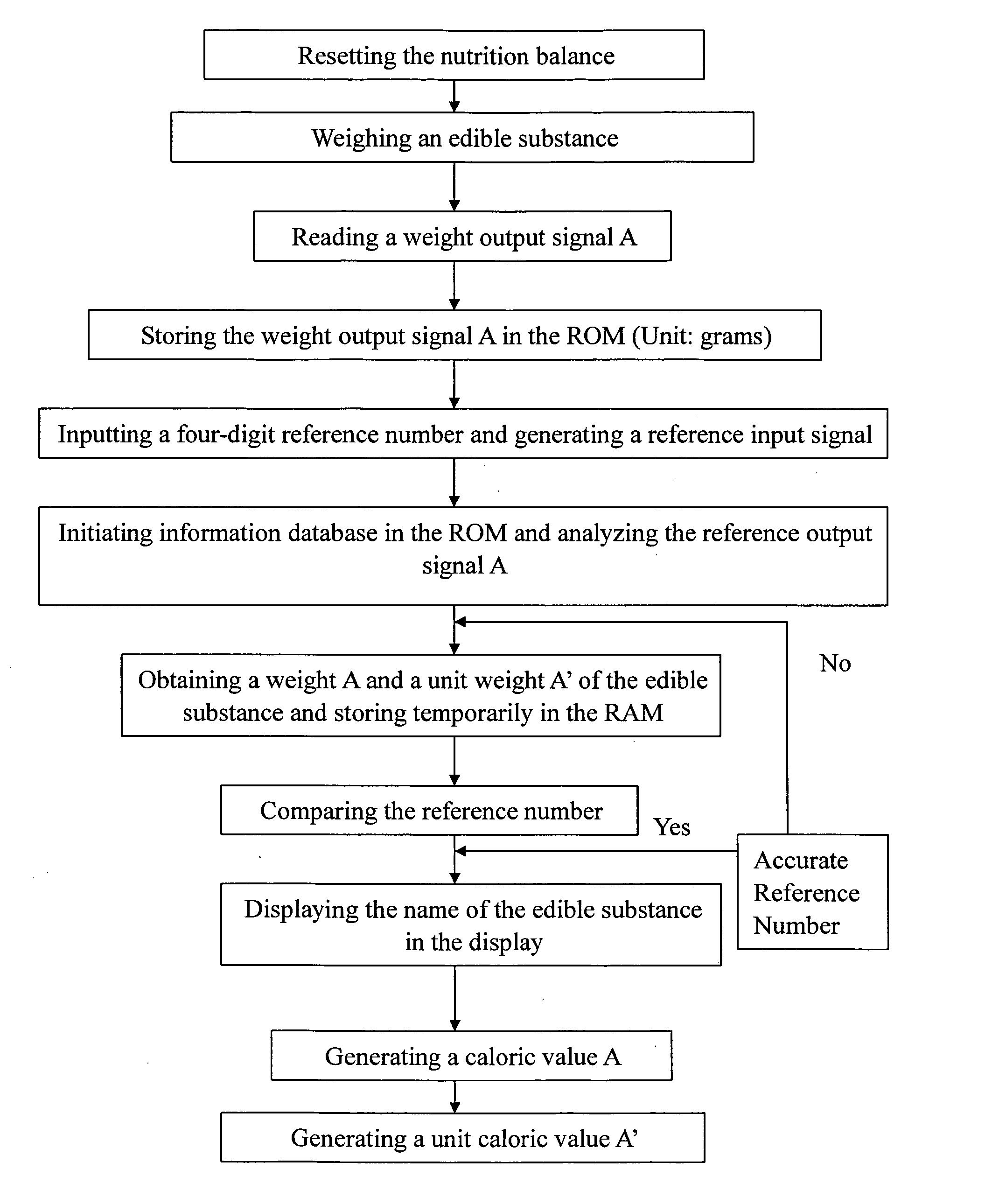

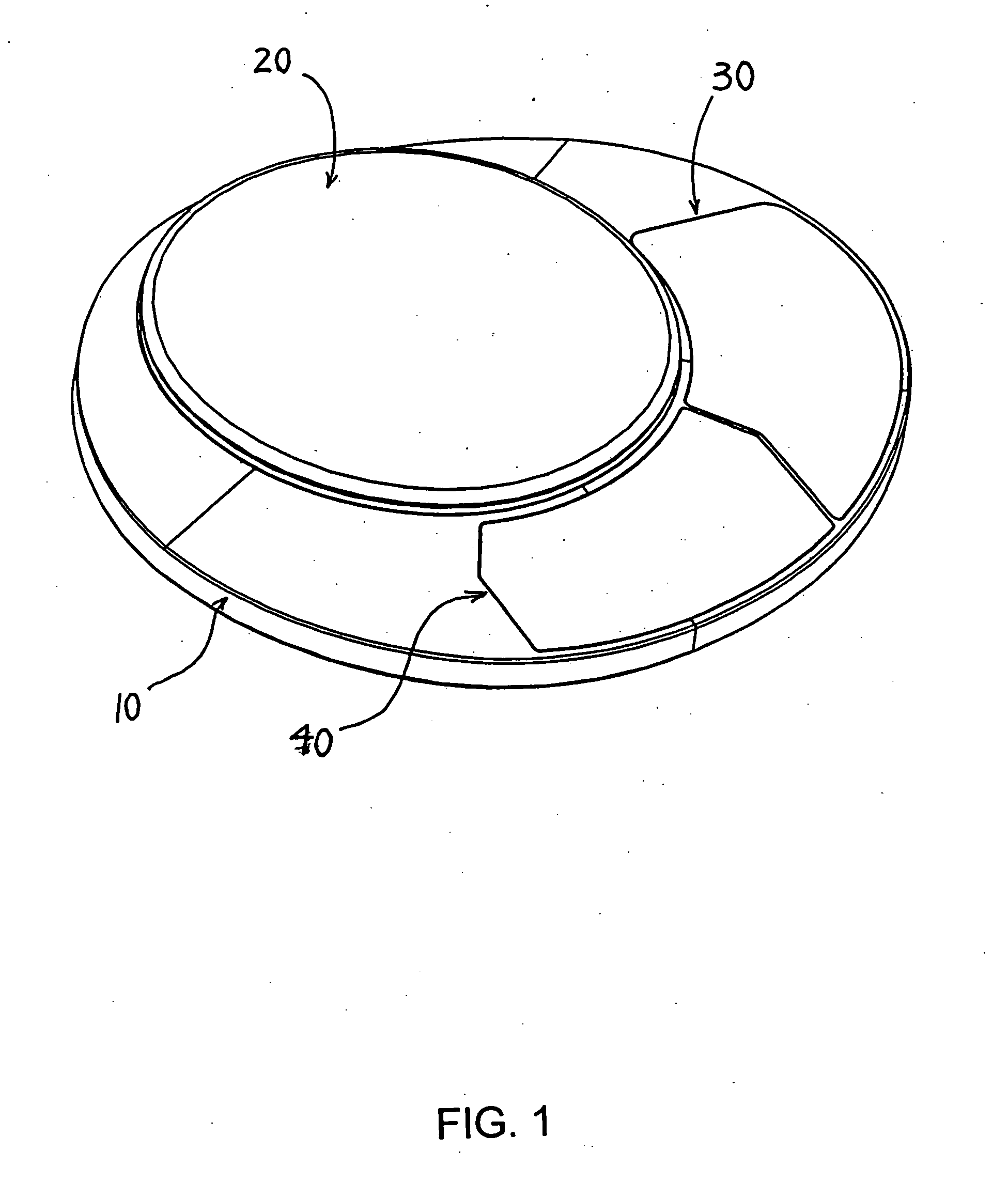

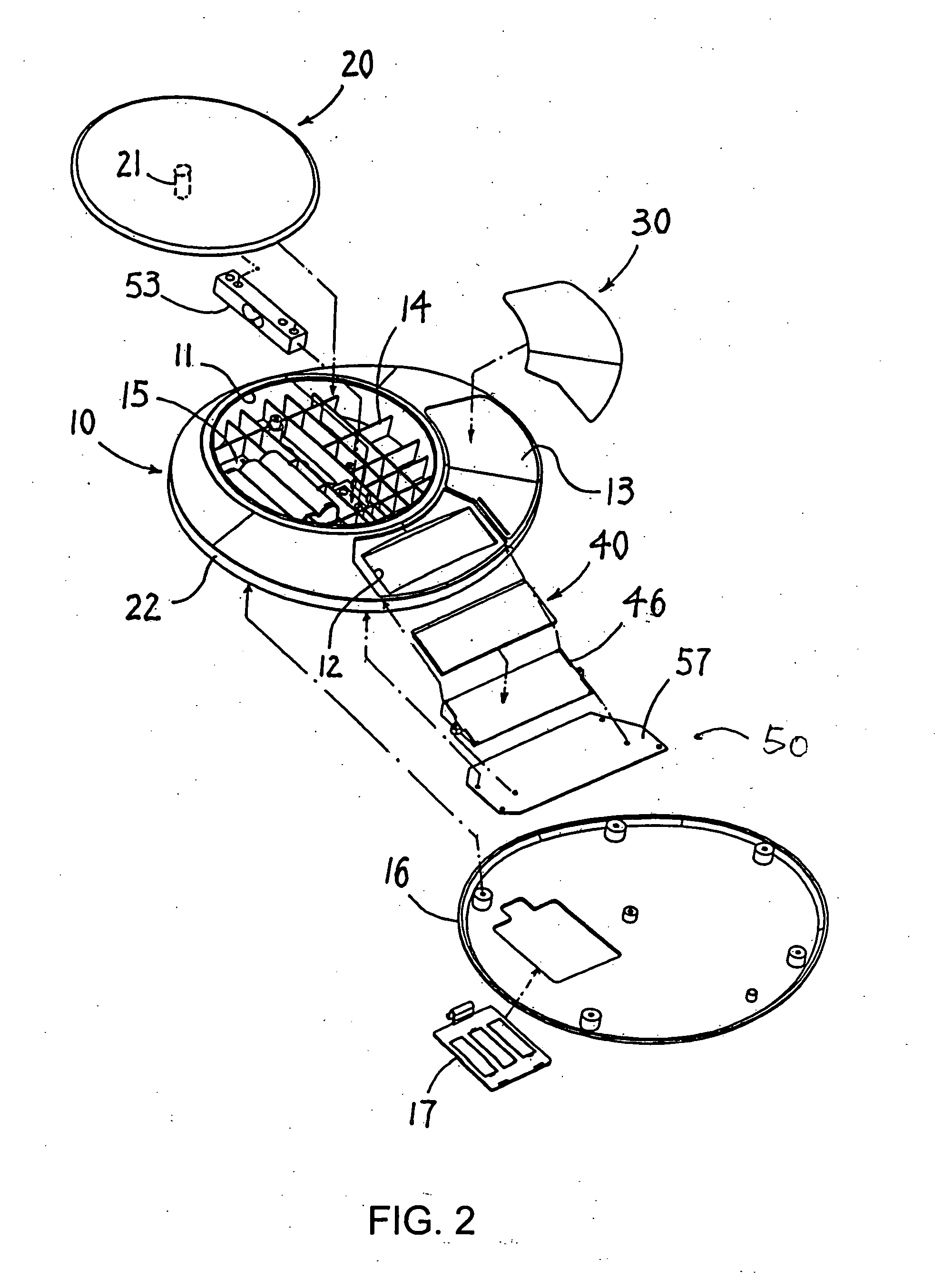

InactiveUS20050150696A1Limit total daily caloric intakeProvide controlSurgeryWeighing indication devicesControl systemNutrition

A nutrition balance for health control, especially for diabetics, to measure a weight and a caloric value of an edible substance, comprising a main body; a scale unit generating a weight signal while receiving the weight of the edible substance; a control unit comprising at least one input unit inputting a predetermined reference data and providing a reference data signal; a control system comprising a memory unit storing a predetermined balance database information and a controller, communicating with the memory unit, communicated with the scale unit to receive the weight signal and communicate with the input unit for receiving and storing the reference data signal to generating an output signal in response to the weight signal according to the reference data and the balance database information; and a display arrangement communicating with the control system to provide an output. The nutrition balance is for monitoring health and diet.

Owner:HYDRO GEAR PARTNERSHIP +1

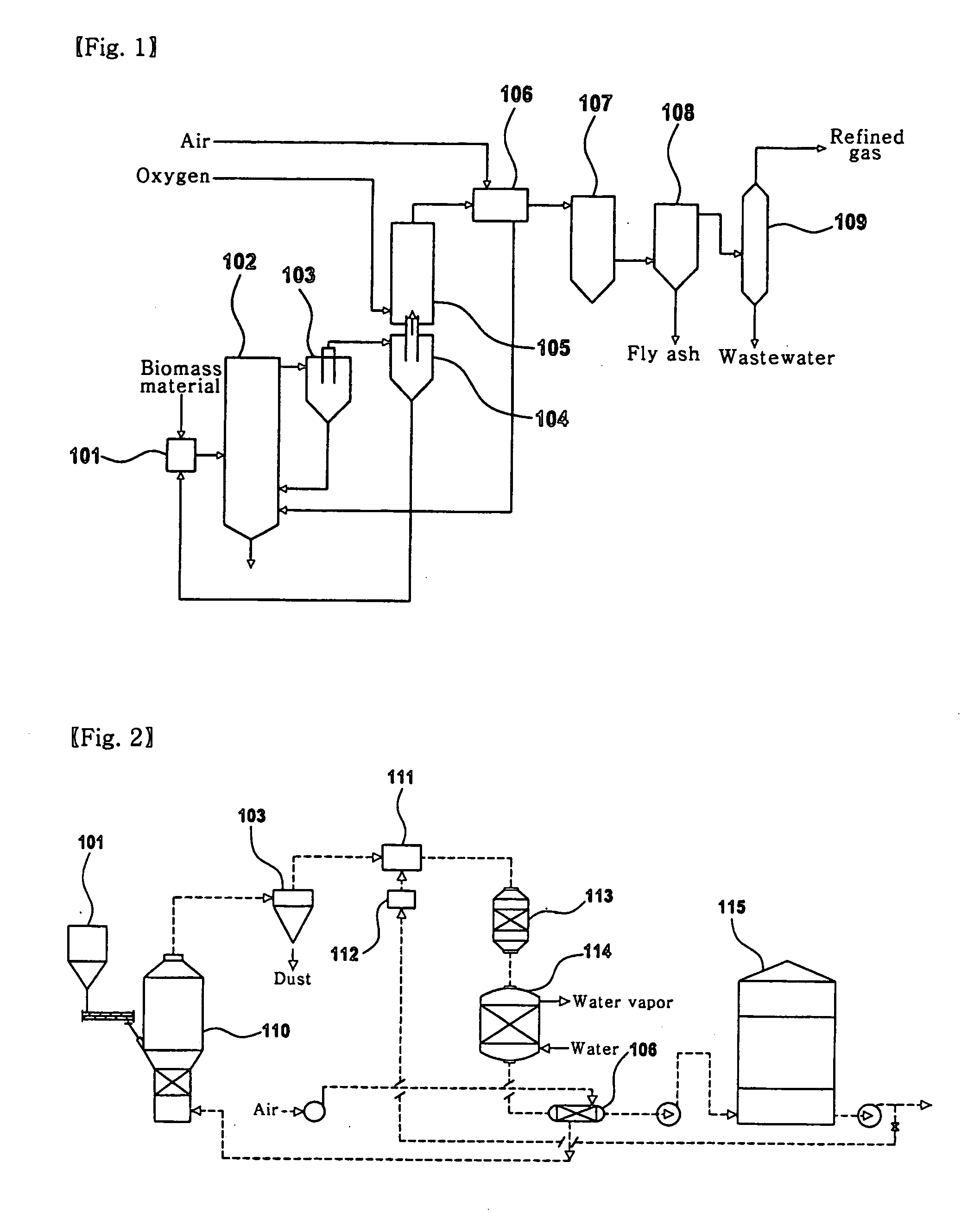

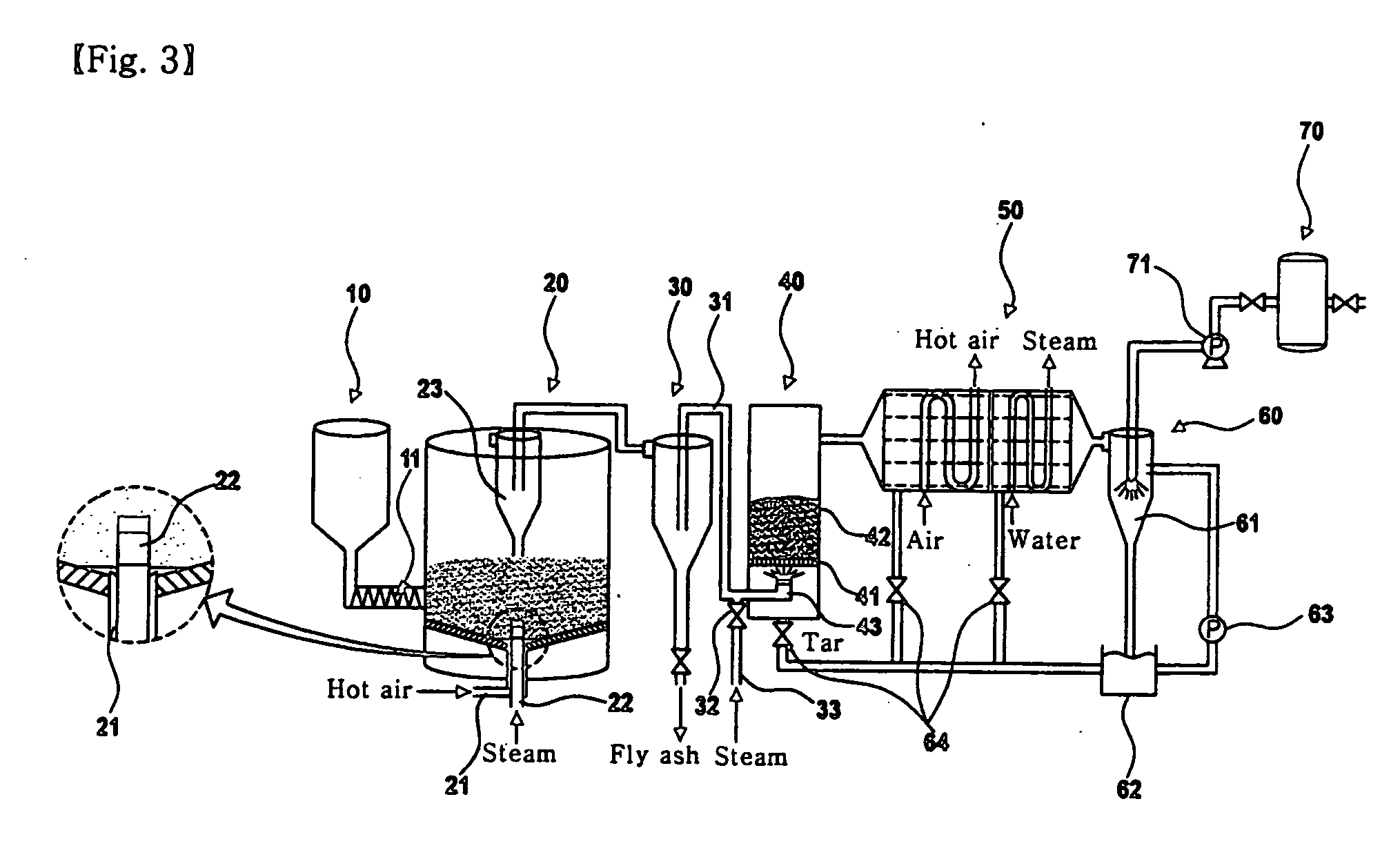

Method for self-heating pyrolysis gasification of biomass by gas backflow combustion

InactiveCN102643676AKeep warmImprove gasification efficiencyEnergy inputCombustible gas productionWater vaporSelf heating

A method for self-heating pyrolysis gasification of biomass by gas backflow combustion includes using air and steam as gasifying agent for pyrolysis gasification of the biomass in a pyrolysis gasifier, making the steam generated by a vaporizer into super-heated steam to compensate heat for the interior of the gasifier by waste heat of produced gas, allowing part of the produced gas to flow back into the gasifier to be combusted for supplying heat for gasification, removing tar by high-temperature pyrolysis, ensuring the whole gasifier to be under high temperature, and allowing gasification of biological pyrolytic carbon and cracking of the tar to tend to be through. By the method using the waste heat of combustible gas, part of the gas flows back to supply heat required by the biomass for pyrolysis gasification, interior high temperature of the gasifier is guaranteed, reaction is accelerated, and gasifying efficiency is improved. The produced combustible gas is low-tar gas with caloric value reaching 10MJ / Nm<3>, combustion is isolated from other reactions, and accordingly operation control is facilitated.

Owner:GUANGXI UNIV

Intelligent conditioning system for deep dewatering of sludge

ActiveCN103241921ALower output qualitySludge treatment by de-watering/drying/thickeningSludgeCaloric values

Owner:JIANGSU GREEN WAY ENVIRONMENTAL PROTECTION TECH

Method for producing instant noodles dried by hot air stream at high temperature

ActiveUS20110229613A1Moreish tasteMoreish textureFood preservationFood ingredient as taste affecting agentCaloric valuesFried noodles

A method for producing instant noodles dried by a high-temperature hot air stream, wherein the noodles have a moreish taste and texture similar to fried noodles and yet have a low caloric value. The method for producing instant noodles dried by a high-temperature hot air stream comprises: step (a) producing a noodle band from a noodle dough prepared by adding an edible oil to a noodle dough material containing a raw material flour, and then producing raw noodle strands from the noodle band, step (b) adhering an edible oil to the raw noodle strands, and then steaming the raw noodle strands to produce steamed noodles, step (c) forming a noodle block by packing a predetermined amount of the steamed noodles into a retainer, and step (d) swelling and drying the noodle block by blowing a hot air stream at a temperature of 120° C. to 160° C. onto the noodle block from above and below the retainer at a stream speed of 30 m / s to 70 m / s for a period of 3 to 15 minutes.

Owner:NISSIN YORK

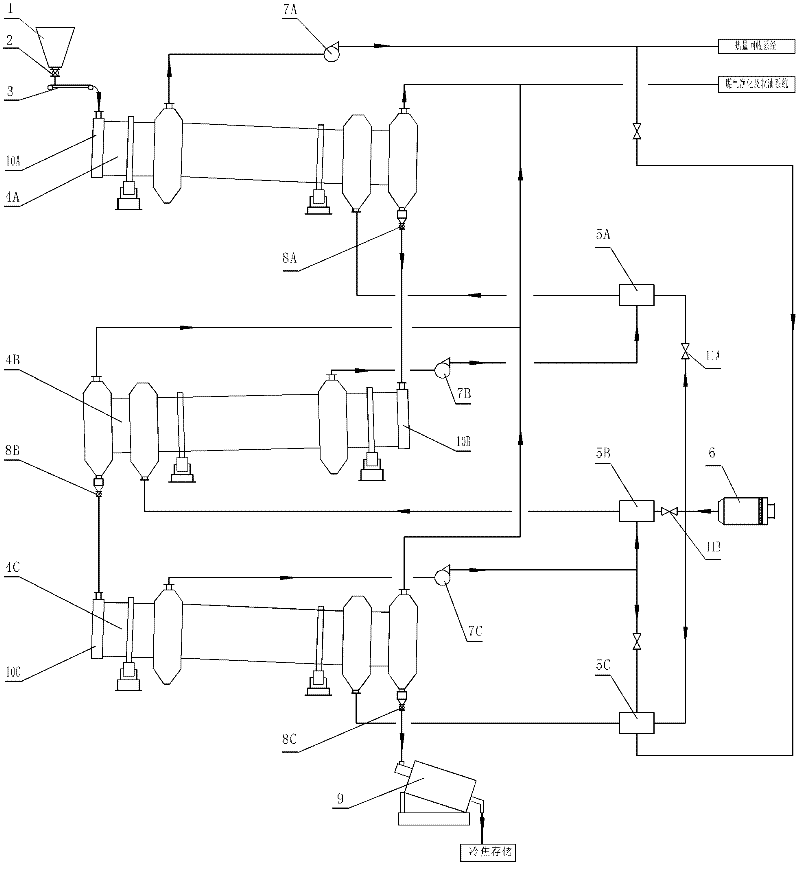

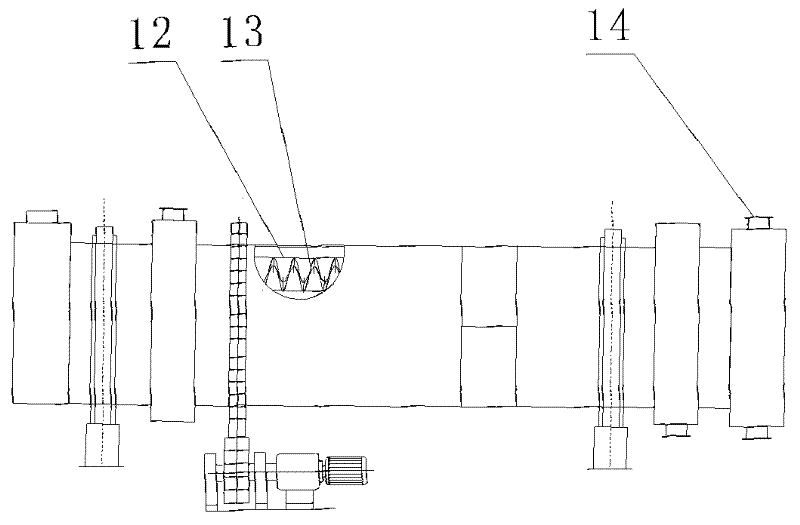

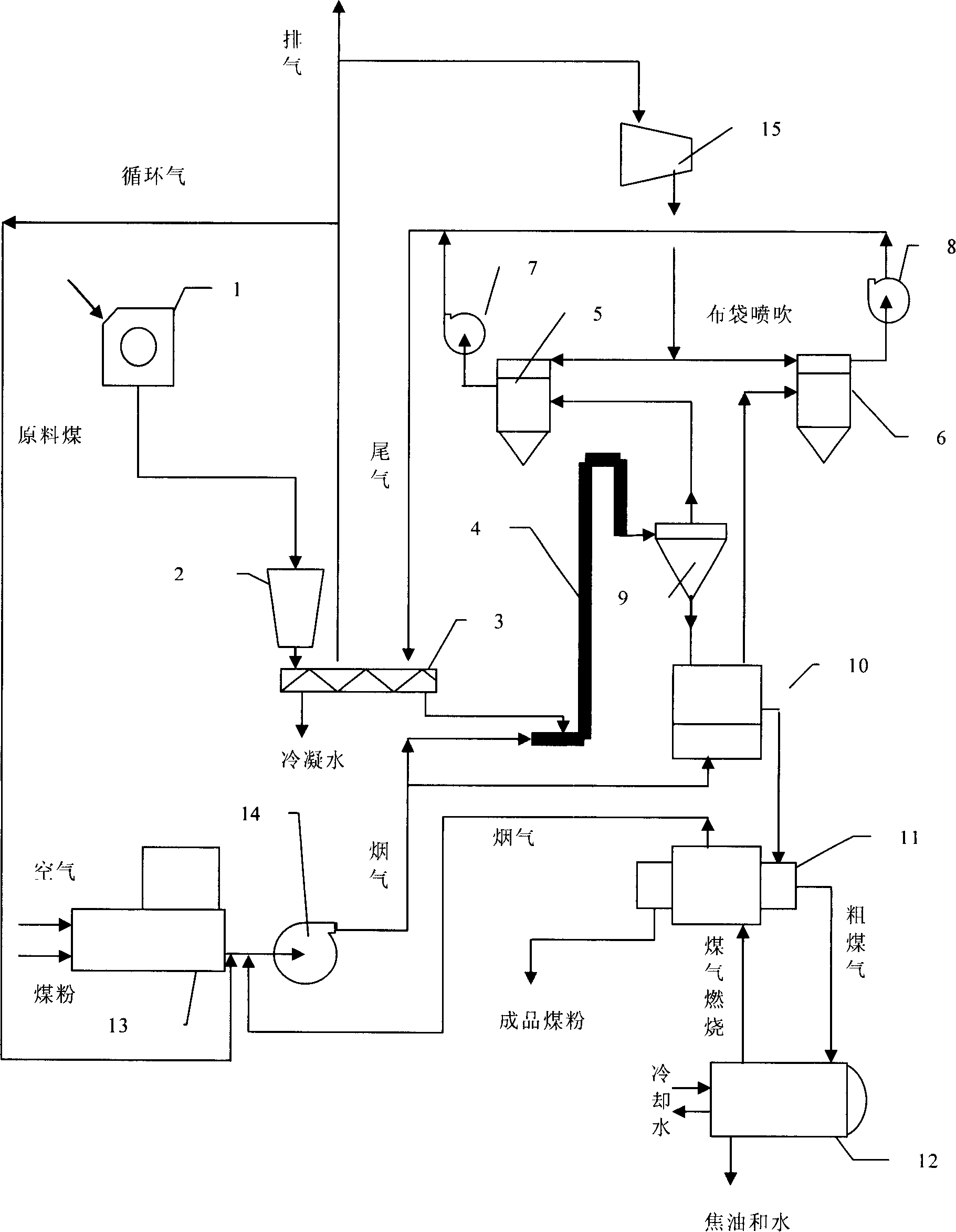

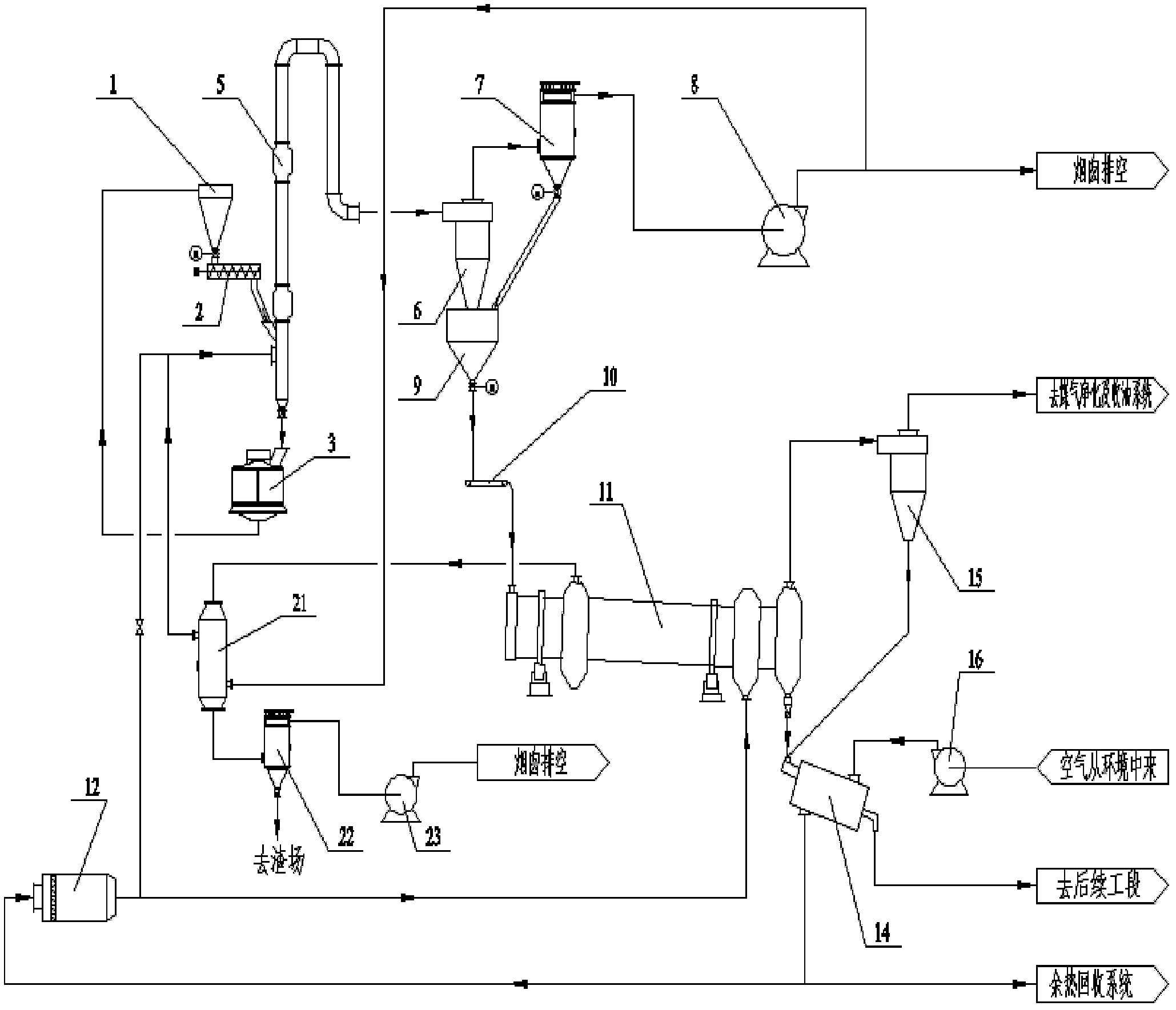

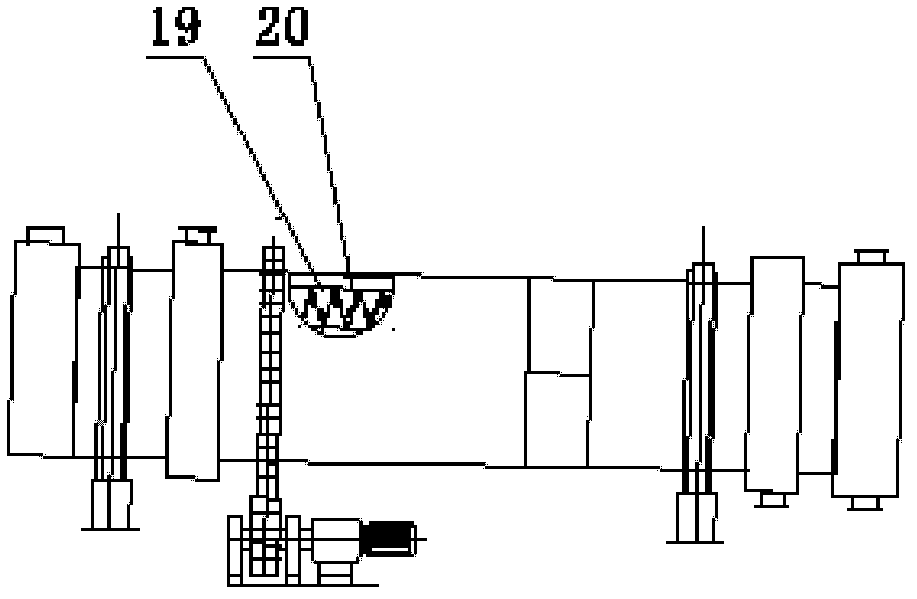

Multistage pulverized coal multiple-tube rotary low temperature dry distillation technology and system

ActiveCN102358841AEasy to handleIncrease the heat exchange areaIndirect heating destructive distillationSpecial form destructive distillationCaloric valuesHelical blade

The invention discloses a multistage pulverized coal multiple-tube rotary low temperature dry distillation technology and system. The multiple-tube rotary dry distillation machine multistage (two stages or more) series connection process is adopted to perform low temperature dry distillation on pulverized coal; a plurality of dry distillation tubes are arranged in the multiple-tube rotary dry distillation machine to disperse coal powder, a helical blade is arranged in each dry distillation tube to guide and disturb coal and reinforce the dry distillation effect and increase the dry distillation effective area, the technology has the advantages of large pulverized coal treatment capacity, large dry distillation gas treatment capacity, low tar and dust contents, high coal gas caloric value and the like; the chemical raw materials generated in the low temperature dry distillation process of bituminous coal and low-price pulverized coal can be recycled extremely, the comprehensive utilization rate of coal is increased; and semicoke powder and coal gas with high calorific value can be produced through the low temperature dry distillation of bituminous coal and low-price pulverized coal.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

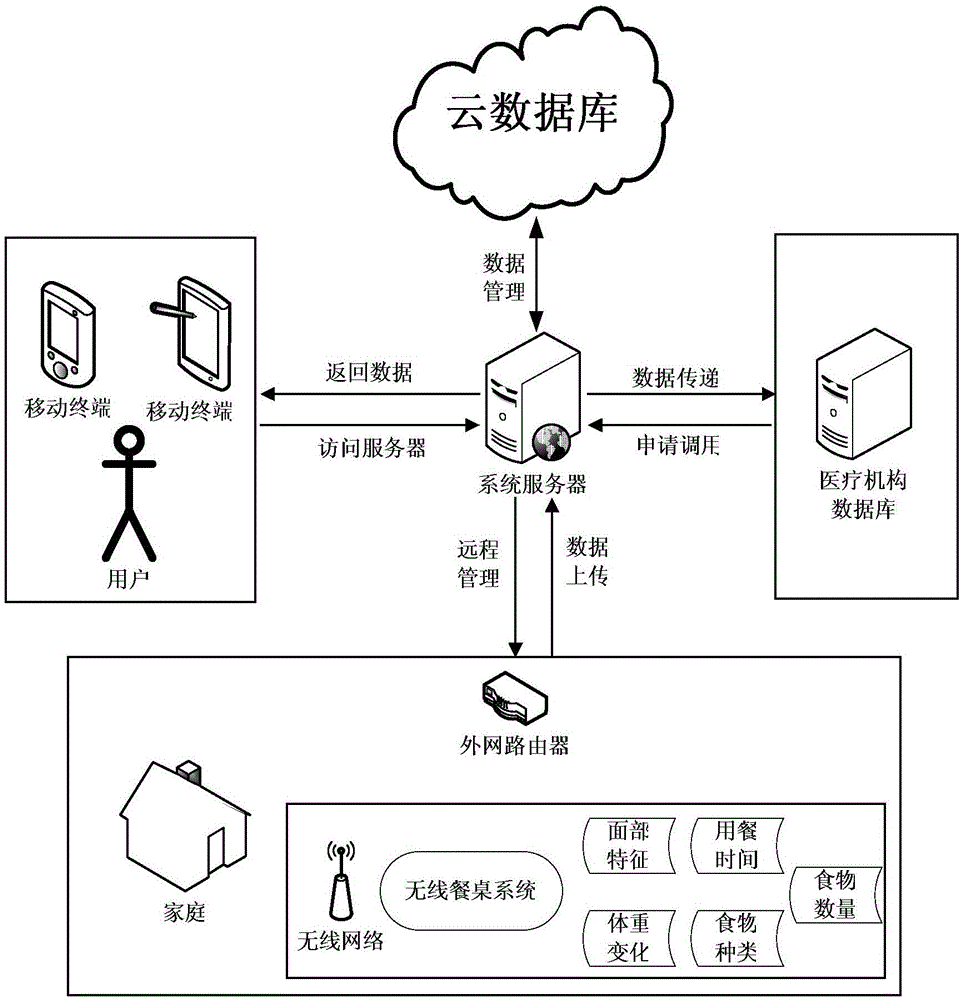

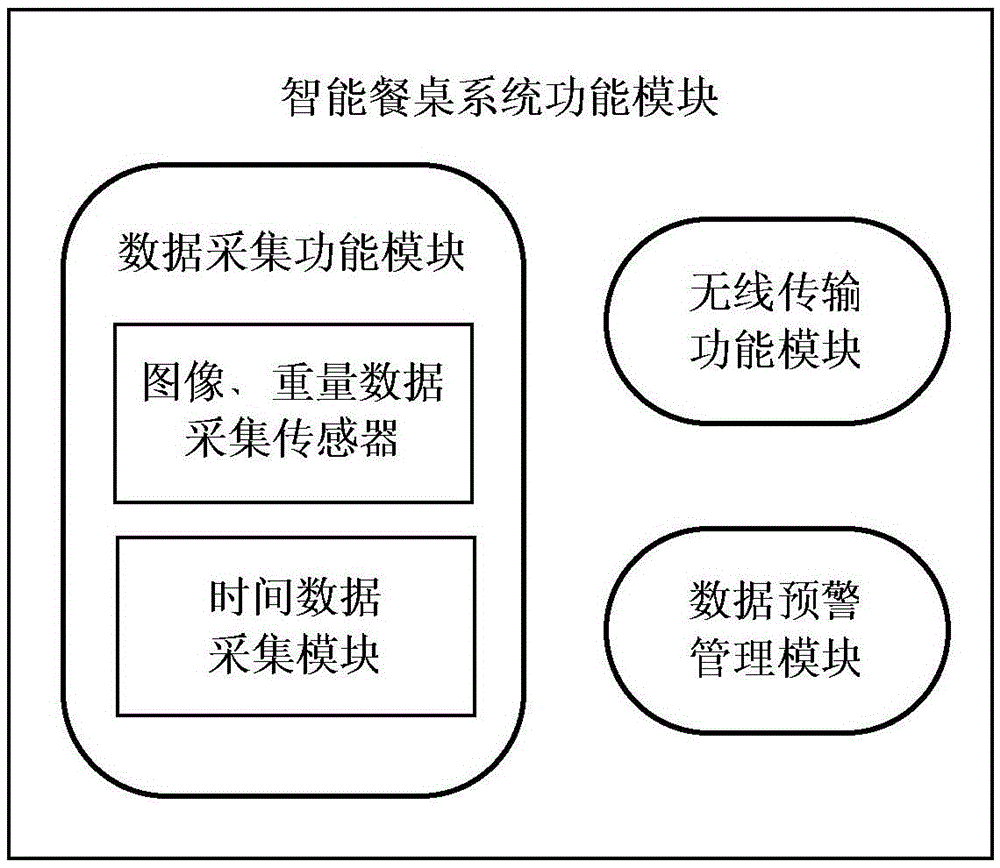

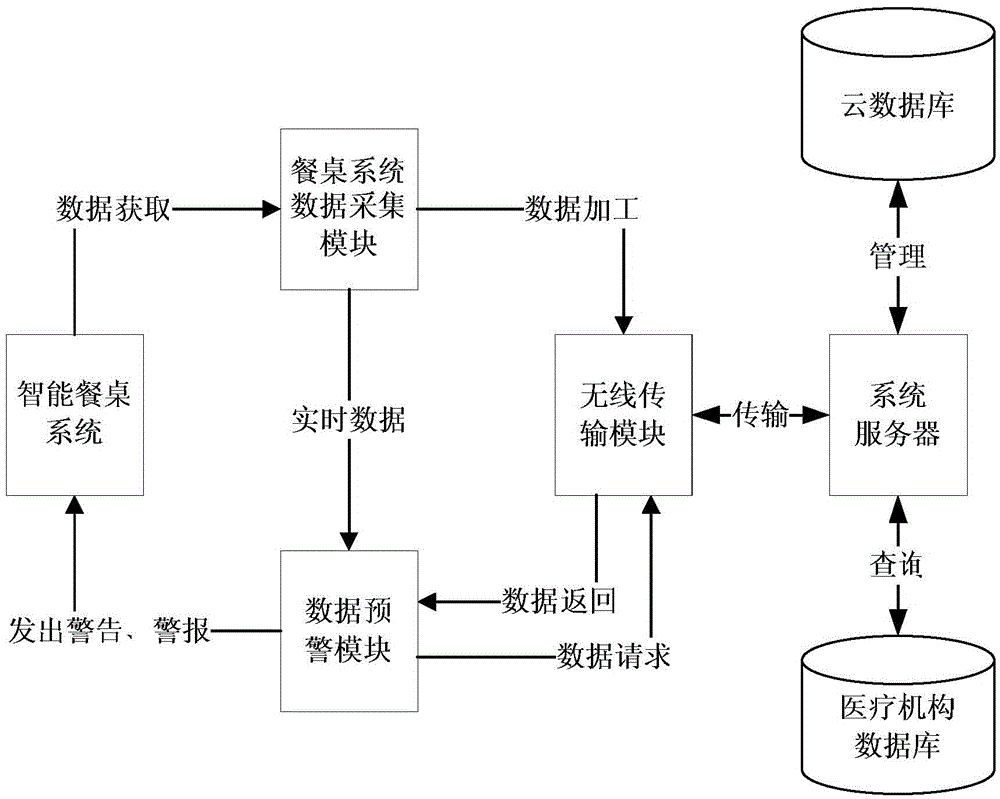

Intelligent dining table system and healthy diet control system based on Internet of Things

InactiveCN105468913AKnow your healthUnderstand the changing trendComputer-assisted diets prescription/deliverySpecial data processing applicationsHealthy dietWeight change

The invention provides an intelligent dining table system and a healthy diet control system based on the Internet of Things, relates to the technical field of software development of the healthy diet control system, and solves the problems that the existing dining table system is not integrated into the Internet of Things, thus the diet of a user cannot be supervised and controlled. A data acquisition module is used for performing image acquisition and weight acquisition, so as to acquire dining data of the user, including facial features, diet type and quantity, weight and dining time; a wireless transmission module is used for uploading the dining data to a system server and a medical institution database; a data early-warning management module is used for giving corresponding food type and quantity according to an expected caloric value set by the user, and also used for comparing weight change data of the user before and after dining with a long-term accumulated average value in a personal digital health file of the user, when the weight change data exceed the average value, then giving a warning, and if the dietary amount is under an exceeded state for a long time, then giving an early warning by the dining table system. According to the intelligent dining table system and the healthy diet control system based on the Internet of Things provided by the invention, the user can automatically acquire related data and an analysis report through an APP (Application).

Owner:HARBIN UNIV OF COMMERCE

Diabetes mellitus nutritional balance for monitoring the food and nutritional intake

InactiveUS7348500B2Limit total daily caloric intakeProvide controlSurgeryWeighing indication devicesNutritionControl system

A nutrition balance for health control, especially for diabetics, to measure a weight and a caloric value of an edible substance, comprising a main body; a scale unit generating a weight signal while receiving the weight of the edible substance; a control unit comprising at least one input unit inputting a predetermined reference data and providing a reference data signal; a control system comprising a memory unit storing a predetermined balance database information and a controller, communicating with the memory unit, communicated with the scale unit to receive the weight signal and communicate with the input unit for receiving and storing the reference data signal to generating an output signal in response to the weight signal according to the reference data and the balance database information; and a display arrangement communicating with the control system to provide an output. The nutrition balance is for monitoring health and diet.

Owner:HYDRO GEAR PARTNERSHIP +1

Sludge fermentation dehydration drying method

ActiveCN101007695ALow calorific valueSpeed up fermentationSludge treatment by de-watering/drying/thickeningClimate change adaptationCaloric valuesFilter press

The invention discloses a ferment dewater drying method of sludge, which comprises the following steps: inputting sludge with moisture percentage at 90-97% into tempering groove; adding Fe3+ with 0.5-1.5% and Ca2+ or chemical materials to stir and mix 8-16min; tempering evenly; injecting modified sludge into plate filter press; keeping 30-70min at 1.5Mpa-2.5Mpa; descending moisture percentage of sludge to about 55-65%; introducing sludge of being pressed to sludge fermentation tank through band carrier; blowing air through the bottom with volume of blast at 4500-5000m3 / h; accelerating speed of fermentation to dry water from sludge. The invention can drop caloric value of sludge.

Owner:SWISON CREATIVE ENVIRONMENTAL SOLUTIONS CO LTD

Method for preparing additive of vehicle fuel in MSO~M90, R80~E90 alcohol group

This invention discloses a method for preparing additive for M80-M90 or E80-E90 alcohol-based automobile fuel. When 10-20 parts of the additive is added into 80-90 parts of methanol or ethanol, alcohol-based automobile fuel can be obtained, which can be used as a substitute for gasoline without the need for adjusting or replaing present engines. The alcohol-based automobile fuel has comparable power to commercialized leadless gasoline. Besides, a fuel energizer is added into the additive, which can convert methanol whose caloric value is 49% of leadless gasoline into automobile fuel with high power.

Owner:HEILONGJIANG JIANYE FUEL

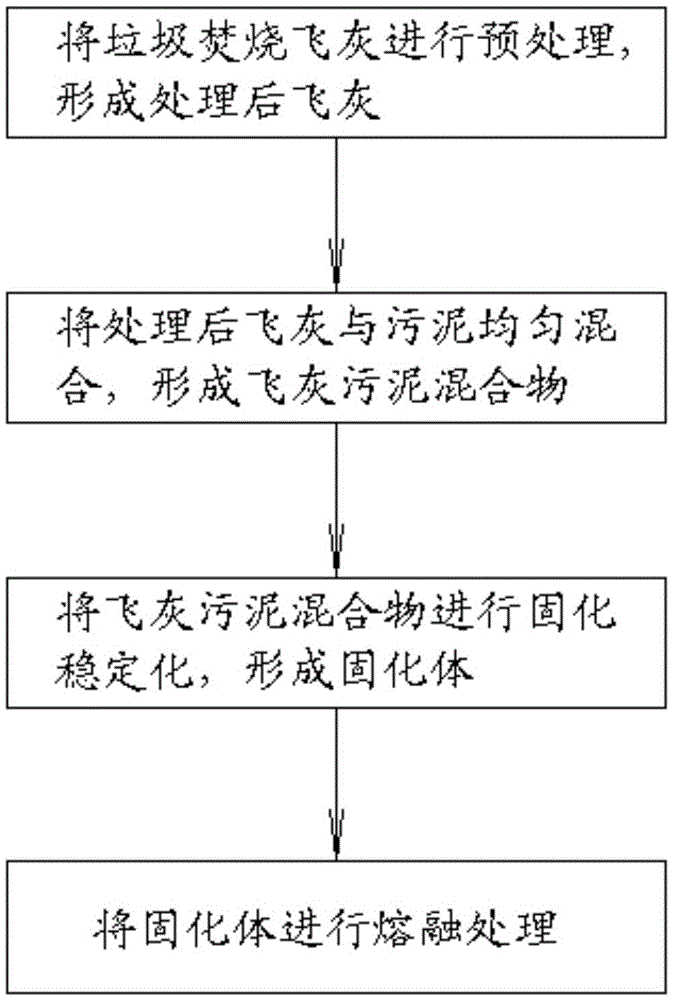

Melting treatment method for waste incineration flying ash

ActiveCN105562423AReduce volatilityPrevent volatilizationSolid waste disposalResource utilizationCaloric values

The invention relates to a melting treatment method for waste incineration flying ash, and belongs to the technical field of environmental engineering. The treatment method comprises the following steps of carrying out pretreatment on the waste incineration flying ash to form treated flying ash; uniformly mixing the treated flying ash with sludge to form a mixture of the flying ash and the sludge; carrying out solidification and stabilization on the mixture of the flying ash and the sludge to form a solidified body; and carrying out melting treatment on the solidified body. The treatment method can effectively solve the problems that the caloric value in the flying ash is relatively low, and heavy metals in the flying ash are liable to volatilize, so that pipeline blockage in a flying ash conveying process is avoided; and the melting treatment method is good in treatment effect, is low in cost, is free from secondary pollution, and is high in resource utilization.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

Low water content high heating value coal dust and its preparing method and device

ActiveCN101168693AImprove hydrophobicityLess suctionDrying solid materials with heatBiofuelsFluidized bed dryingCaloric values

The invention provides pulverized coal with low water content and high caloric value, and the manufacturing method and the device thereof. The method comprises the following steps that low metamorphic pulverized coal is pulverized into pulverized coal with particle diameter less than 6 mm; and the pulverized coal obtained is dried in a pneumatic dryer and / or a fluidized bed dryer until the water content is lower than 3 percent. The invention also provides pulverized coal with low water content and high caloric value, and the manufacturing method and the device thereof, wherein, the method further comprises that the pulverized coal dried is heated to be up to 150 to 460 DEG C in a heat reactor which is operated continuously, and the pulverized coal is discharged after staying for 10 to 80 minutes.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

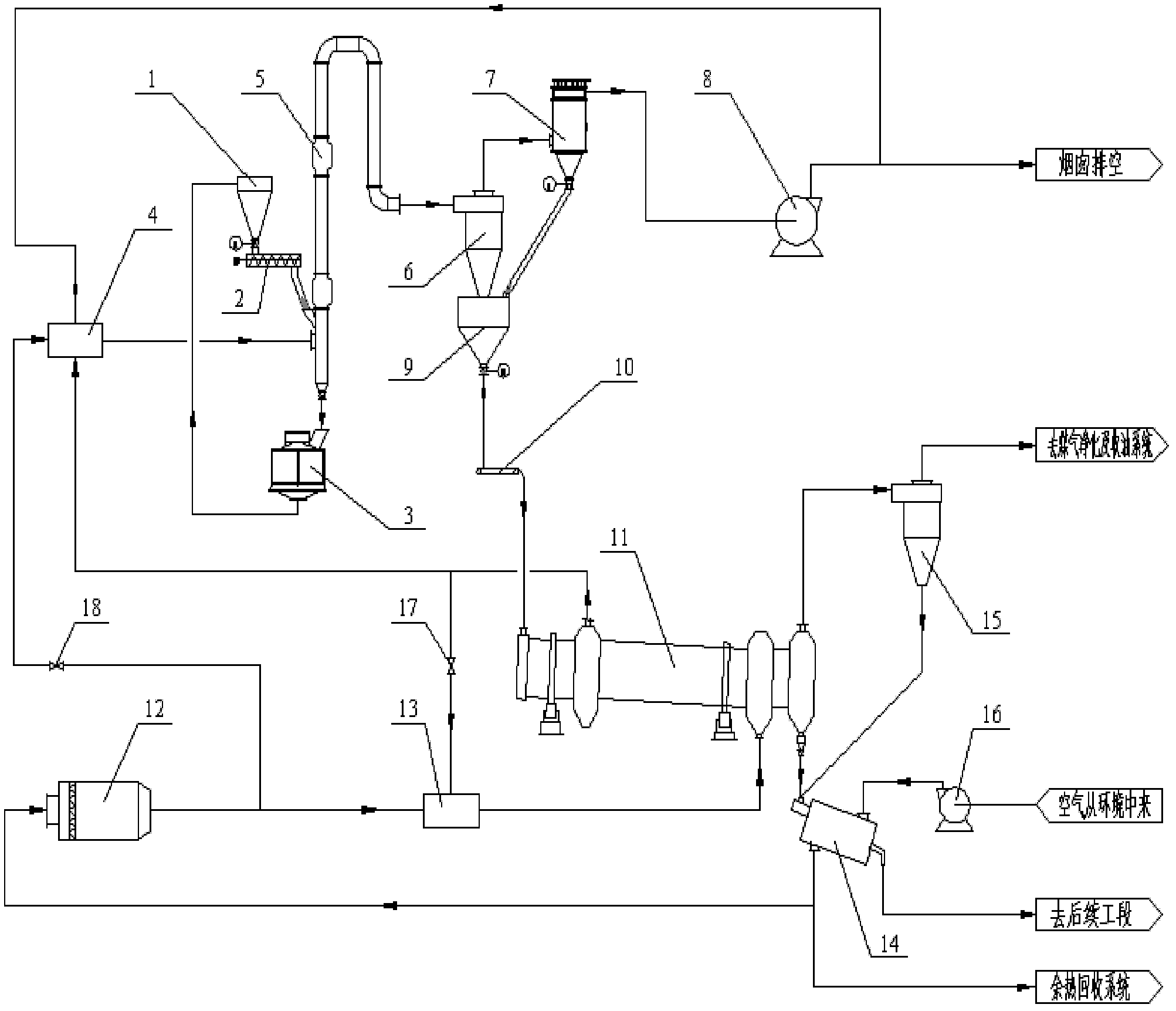

Quality-improving technique combining low-rank coal pneumatic drying with multi-tube revolving destructive distillation and system for same

ActiveCN102433142AEasy dischargeLow investment costCoke quenchingEnergy inputHigh energyCoking wastewater

The invention discloses a quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and a system for the same, wherein the technique comprises a coal flow and a hot smoke flow, and both of the coal flow and the hot smoke flow comprise a drying process and a destructive distillation process which are connected with each other; the system comprises a gas flow drying system and a multi-tube revolving destructive distillation system which are connected with each other. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention realize a cascade efficient utilization for a high-temperature smoke, and increase the energy utilization rate of the whole system. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention have the advantages of high energy utilization rate, safe and stable system, small treatment capacity for destructive distillation gas, small treatment capacity for coking wastewater, high yield of tar, high calorific value of coal gas etc. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention also can recover chemical raw materials such as coal tar generated during a low-rank coal low-temperature destructive distillation process, and increase the comprehensive utilization rate of coal. Via the technique, a powdery or granular semicoke which is low in volatile matter, high in low caloric value and good in stability is produced by a quality-improving technique using a low-rank coal low-temperature destructive distillation. The technique is suitable for producing a civil or industrial coal gas with a medium caloric value by a quality-improving technique using a low-rank coal low-temperature destructive distillation.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Method for deep dewatering sludge

InactiveCN106542718AConstant organic contentConstant sludge calorific valueSludge treatment by de-watering/drying/thickeningFiberBurn treatment

The invention provides a method for deep dewatering sludge. Dewatering is conducted through plate-frame pressure filtration type sludge dewatering equipment. The method comprises the steps of 1 equipment inspecting, 2 preparing of a polymeric flocculant and a dewatering auxiliary, 3 sludge extracting, 4 dewatering auxiliary and polymeric flocculant adding, dispersing and reacting, 5 sludge pump working, 6 pressure filtration dewatering, 7 sludge discharging, 8 parameter recording and 9 equipment cleaning. According to the method, the adopted polymeric flocculant is a cationic organic polymeric flocculant with a long chain structure, the chain has many active cationic groups which can neutralize negative charges on sludge particles and bond multiple sludge particles simultaneously, and therefore dewatering is promoted; the dewatering auxiliary is high-activity plant fiber and can change and increase the sludge floccule structure and construct a net-shaped skeleton. The water content of the sludge dewatered through the method is lower than 60%, the organic matter contents and the sludge caloric values of the sludge before and after dewatering basically keep invariable, subsequent drying and burning treatment is promoted, and the significant governance advantages are achieved.

Owner:上海广神生态环保科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com