Non-combustible high pressure laminate

A technology of laminated boards and fire-resistant layers, applied in the field of high-pressure laminated boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

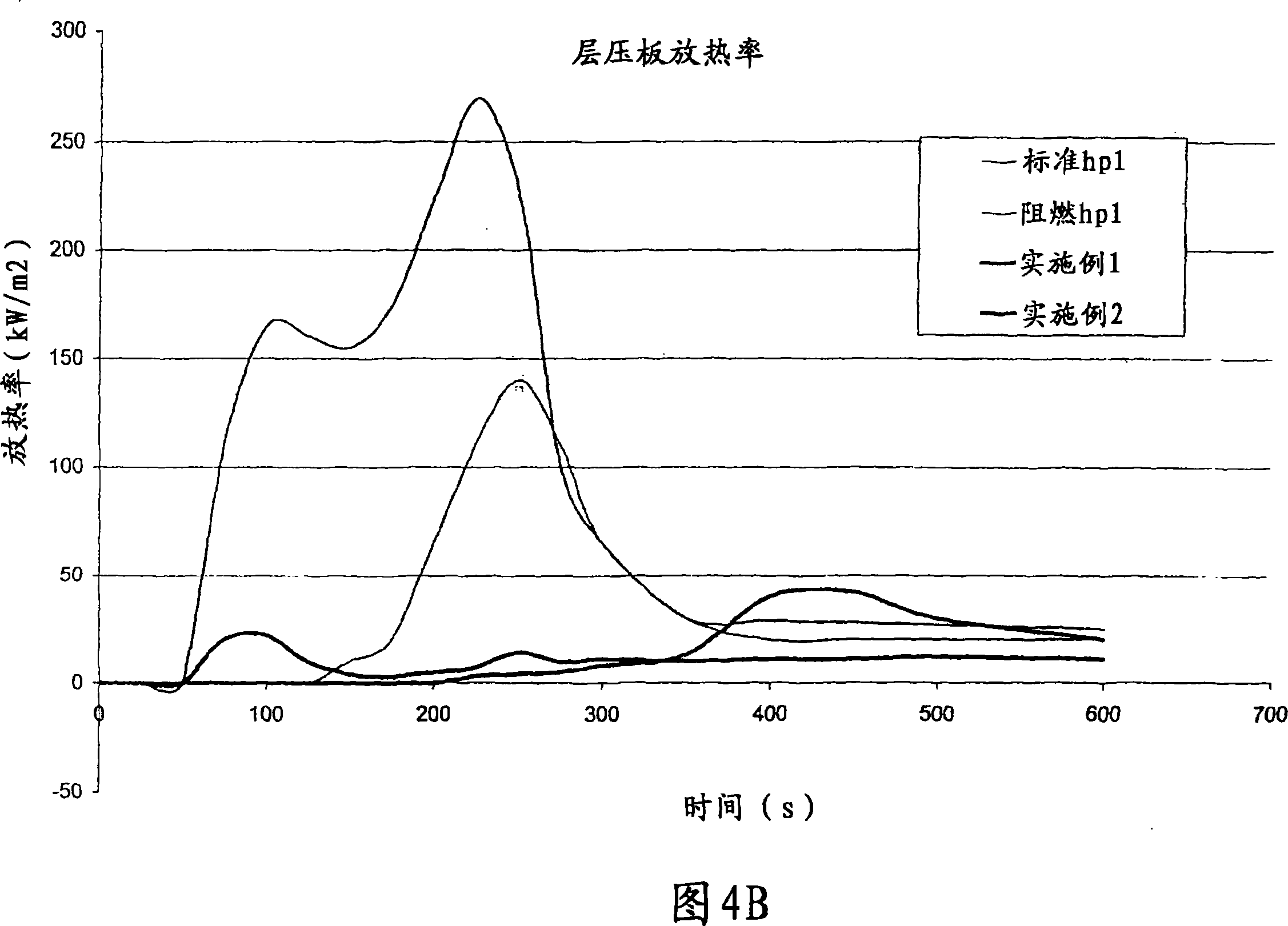

Embodiment 1

[0060] Five samples of the high pressure laminates of the present invention were prepared. In a first example (Example 1), five layers of fiber reinforced glass curtains were sandwiched between two layers of melamine formaldehyde impregnated decorative paper.

[0061]The glass fiber used in this glass curtain is E-glass with a fiber diameter of 11 microns and a length of 10 mm. Each glass curtain has 100g / m 2 weight per unit area. The glass curtain included polyvinyl alcohol binder at a content of 16% by weight.

[0062] The decorative paper layers each have a 160 g / m 2 weight per unit area, including 80g / m 2 Basis weight paper and 80g / m 2 Melamine formaldehyde resin.

[0063] The stacked layers of glass curtains were then impregnated with a formulation of secondary binder and filler comprising 21 wt% phenol formaldehyde, 26 wt% calcium carbonate and 53 wt% aluminum hydroxide. The final glass curtain weight is 1000g / m 2 .

[0064] at 100kg / cm 2 The stacked layers wer...

Embodiment 2

[0066] The glass fiber used in the product of Example 2 is E-glass with a fiber diameter of 13 microns and a length of 11 mm. The glass curtains each have a 50g / m 2 The weight per unit area and the polyvinyl alcohol binder are included at a content of 14 wt%.

[0067] The stacked layers of glass curtains were impregnated with a formulation of secondary binder and filler of 15 wt% melamine formaldehyde, 20 wt% calcium carbonate and 65 wt% aluminum hydroxide. The final glass curtain weight is 900g / m 2 .

[0068] at 50kg / cm 2 The stacked layers of the product of Example 2 were pressed together at a temperature of 145° C. for 20 minutes to prepare a laminate with a thickness of 3 mm.

[0069] Further examples 3, 4 and 5 of the invention are given together with examples 1 and 2 in table 1 below. In addition, for comparison, the table also includes corresponding measurements for representative prior art HPL (standard HPL) and prior art FR-HPL (flame retardant HPL) products. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com