Patents

Literature

387 results about "Gasoline fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petrol, also known as Gasoline, is a transparent fuel derived from crude oil and is used as fuel in internal combustion engines.

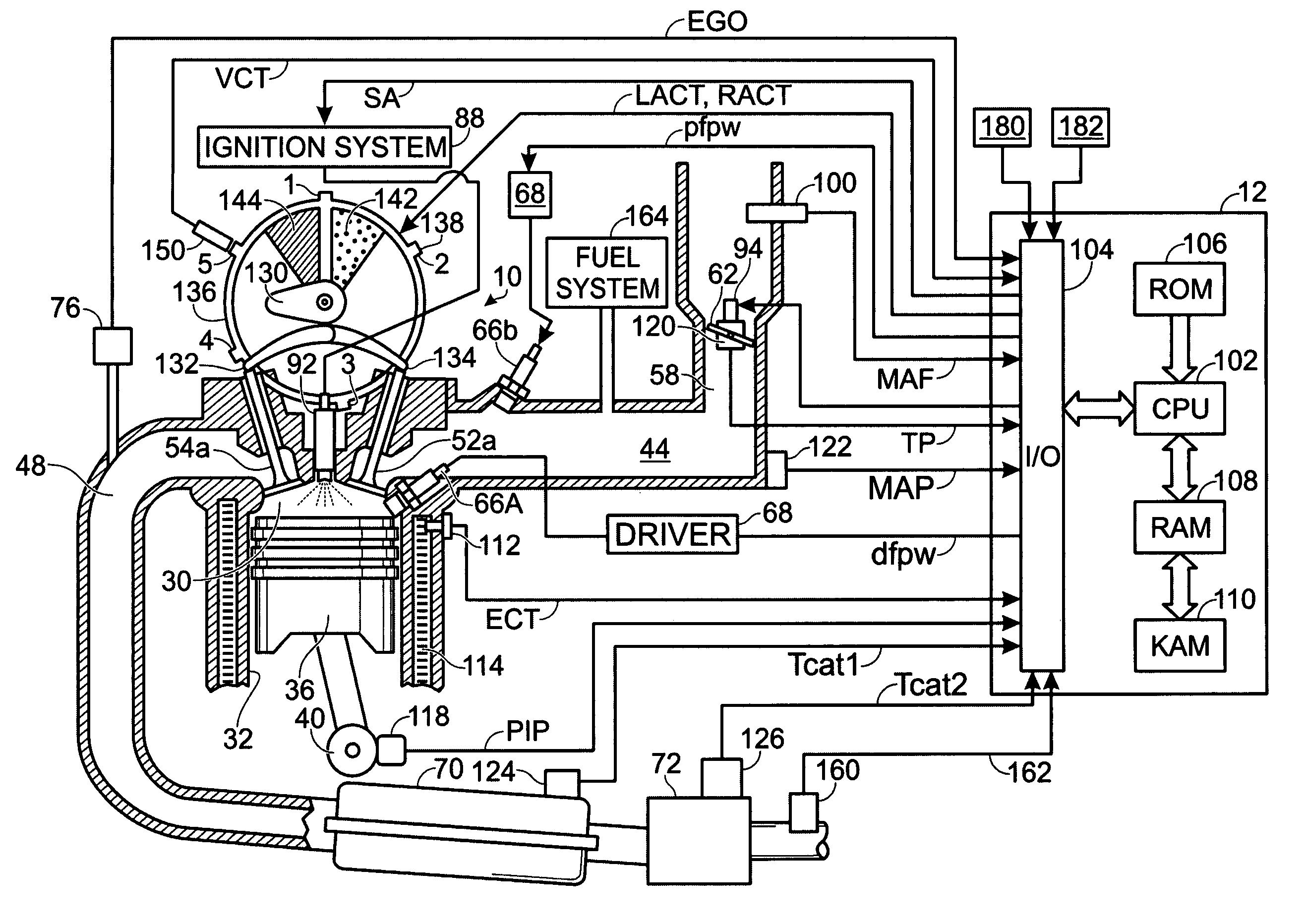

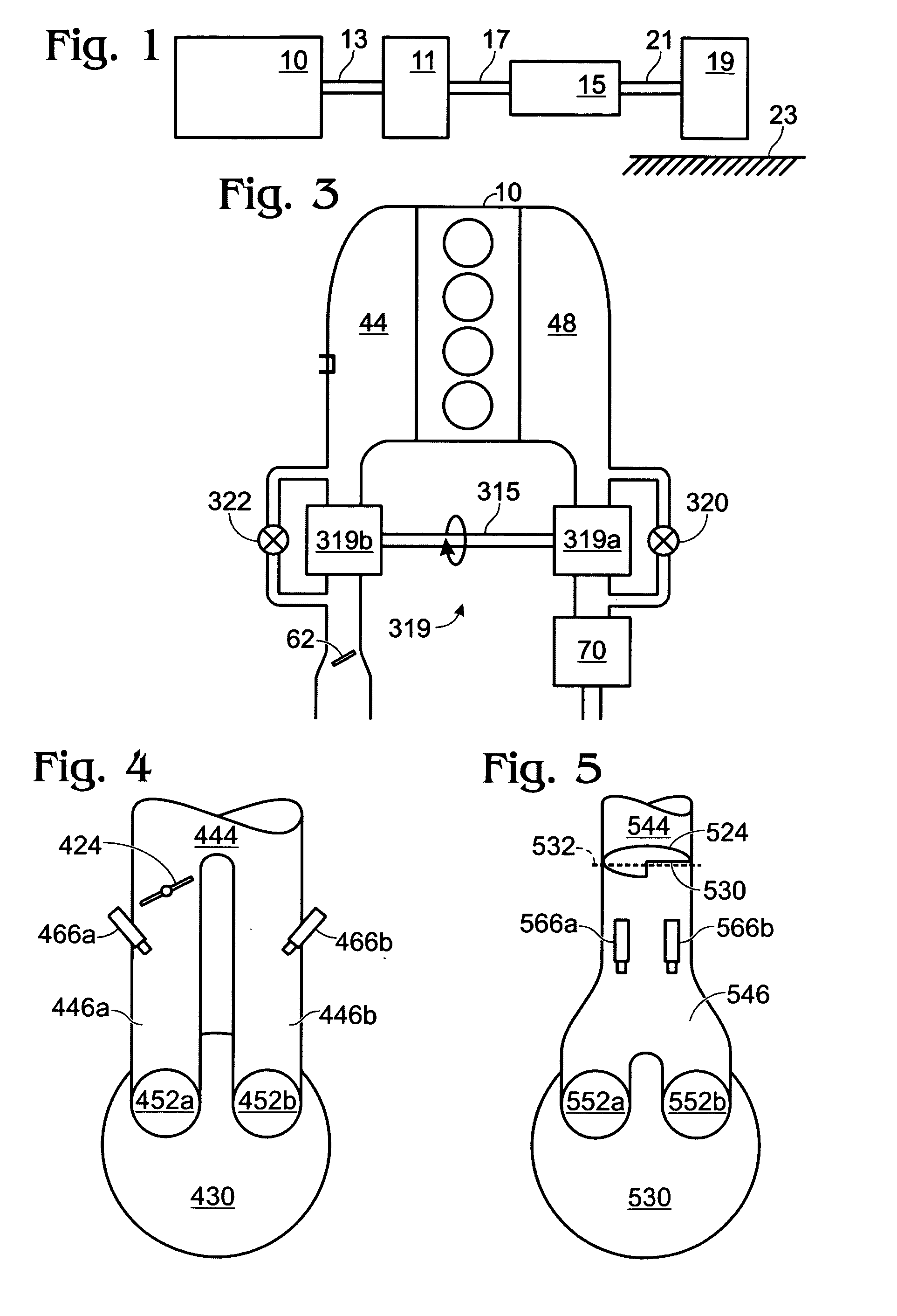

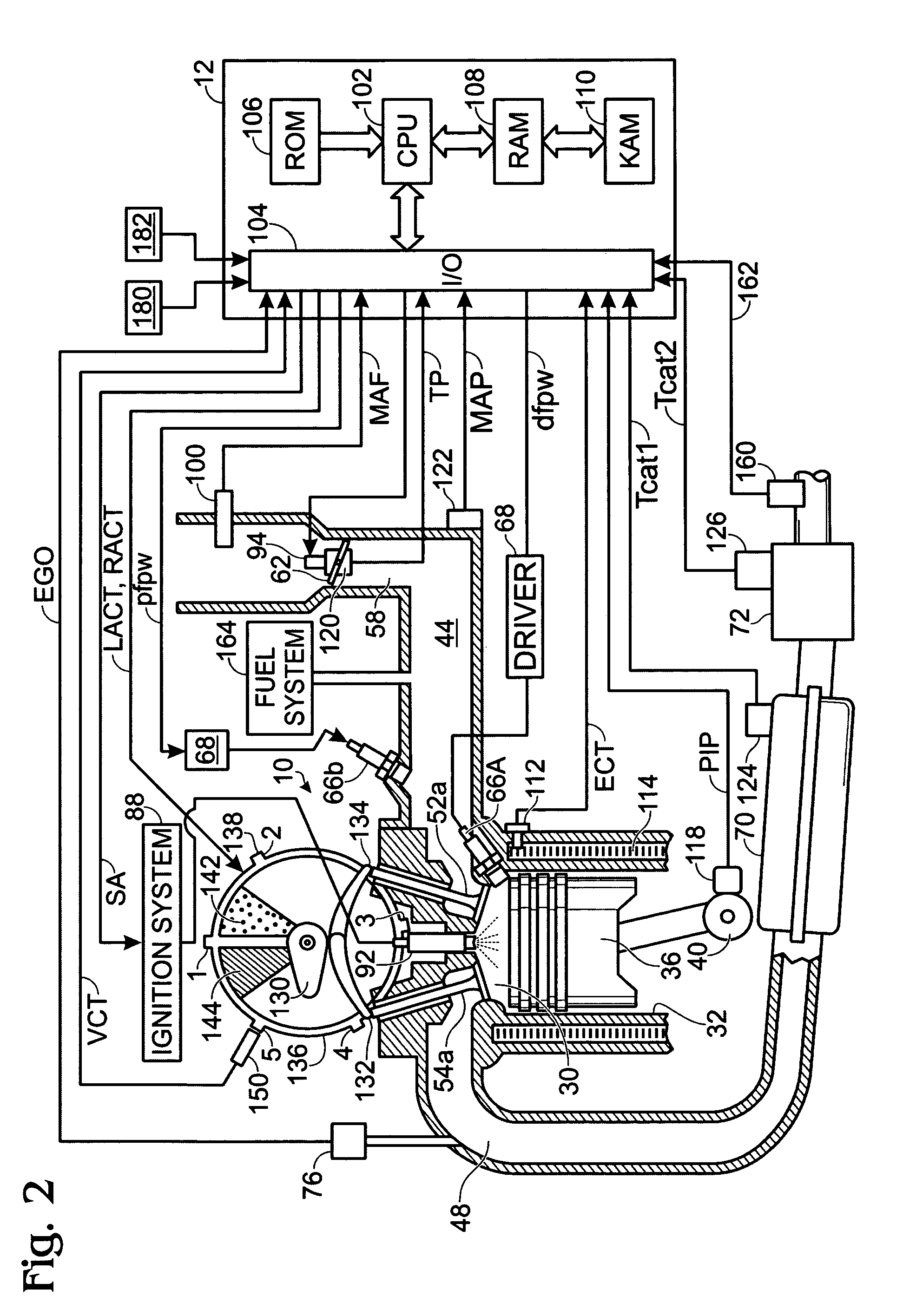

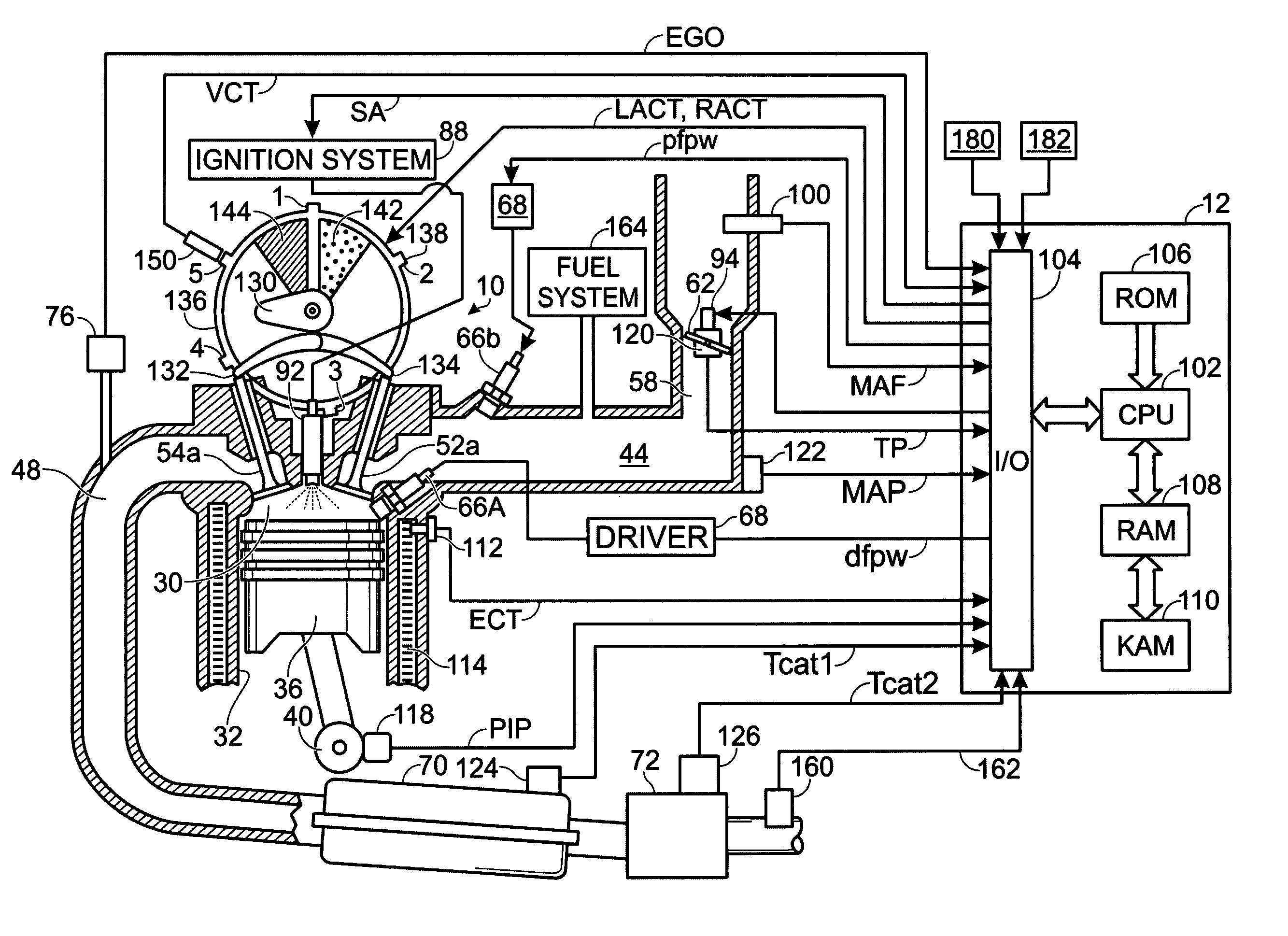

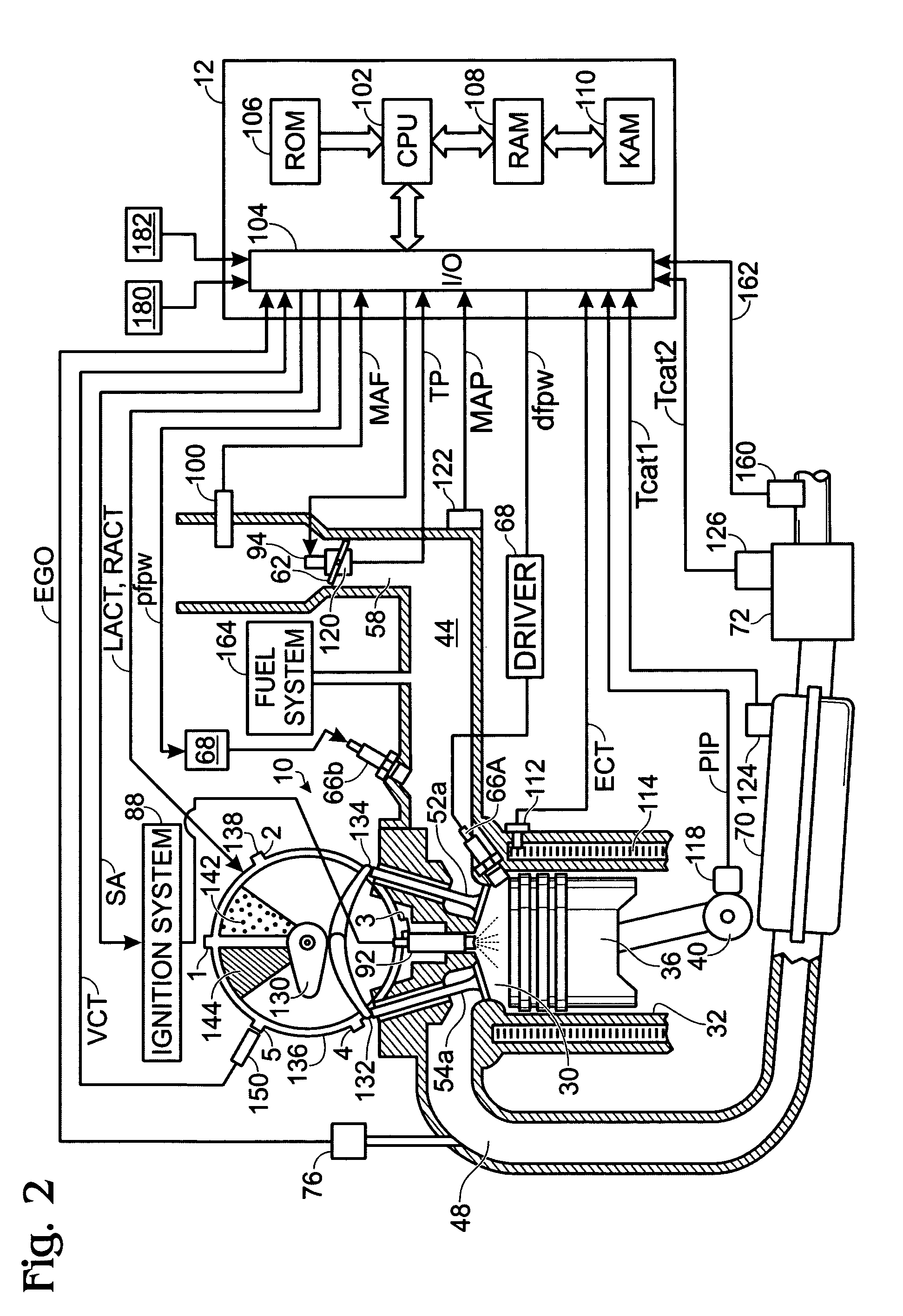

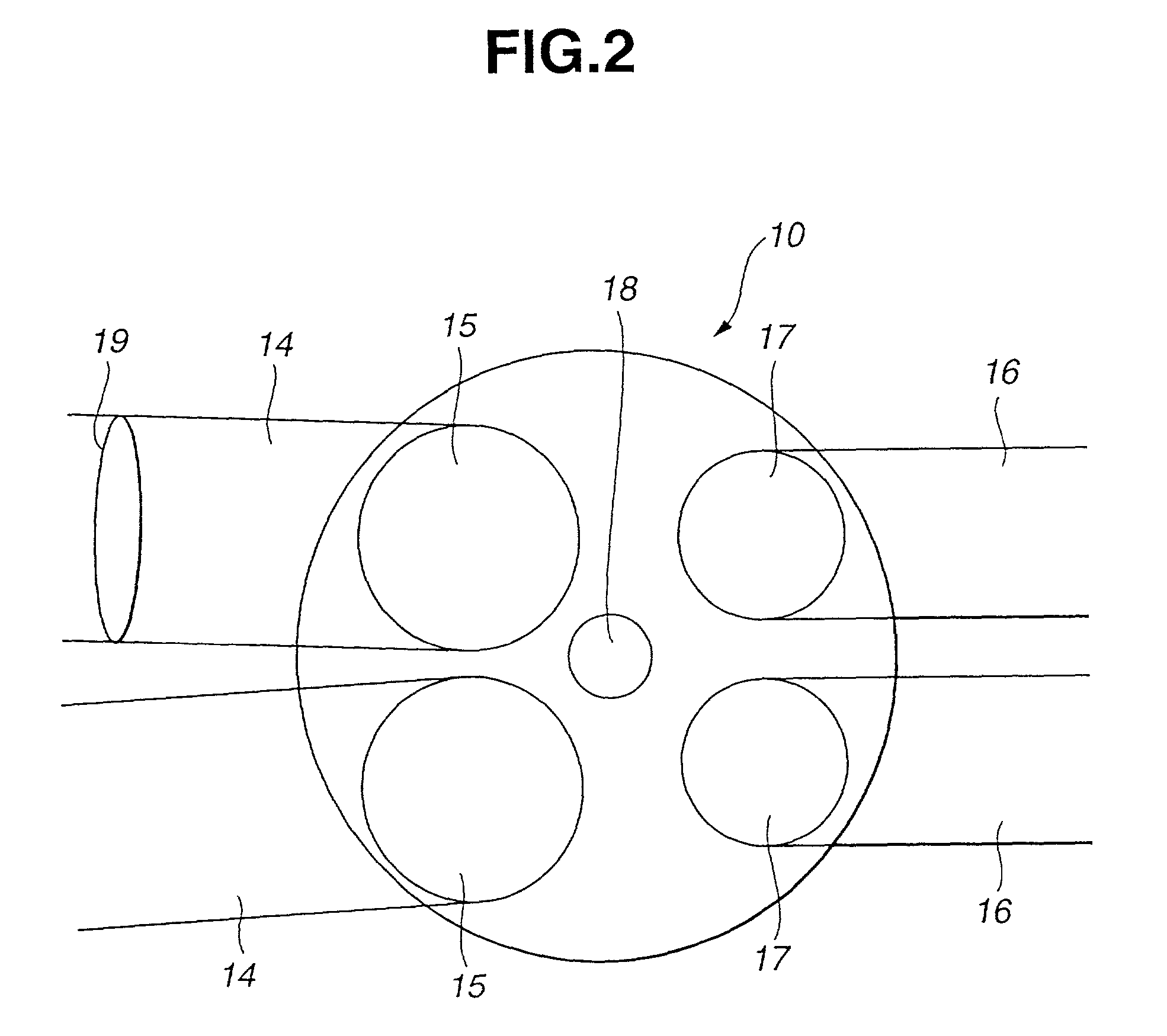

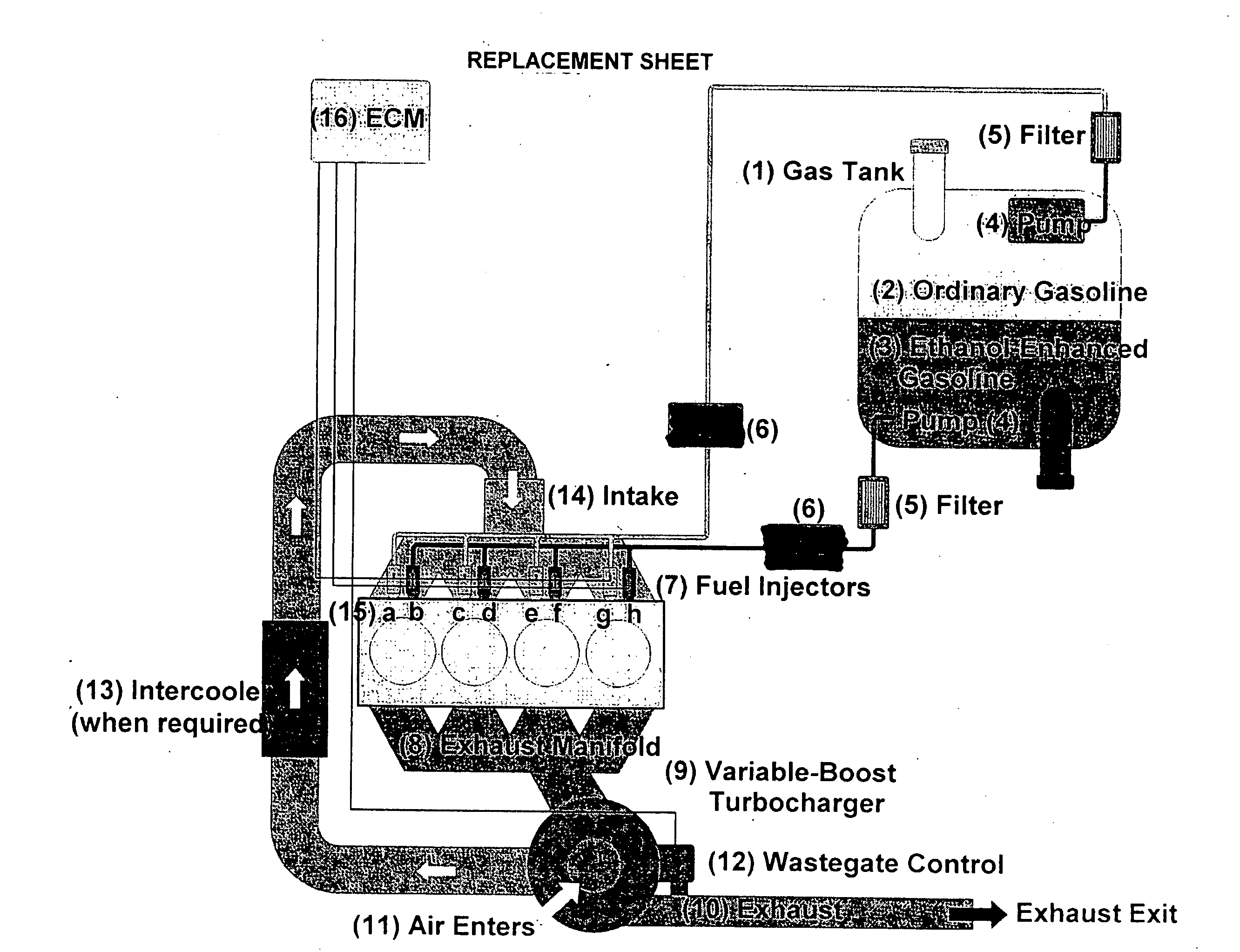

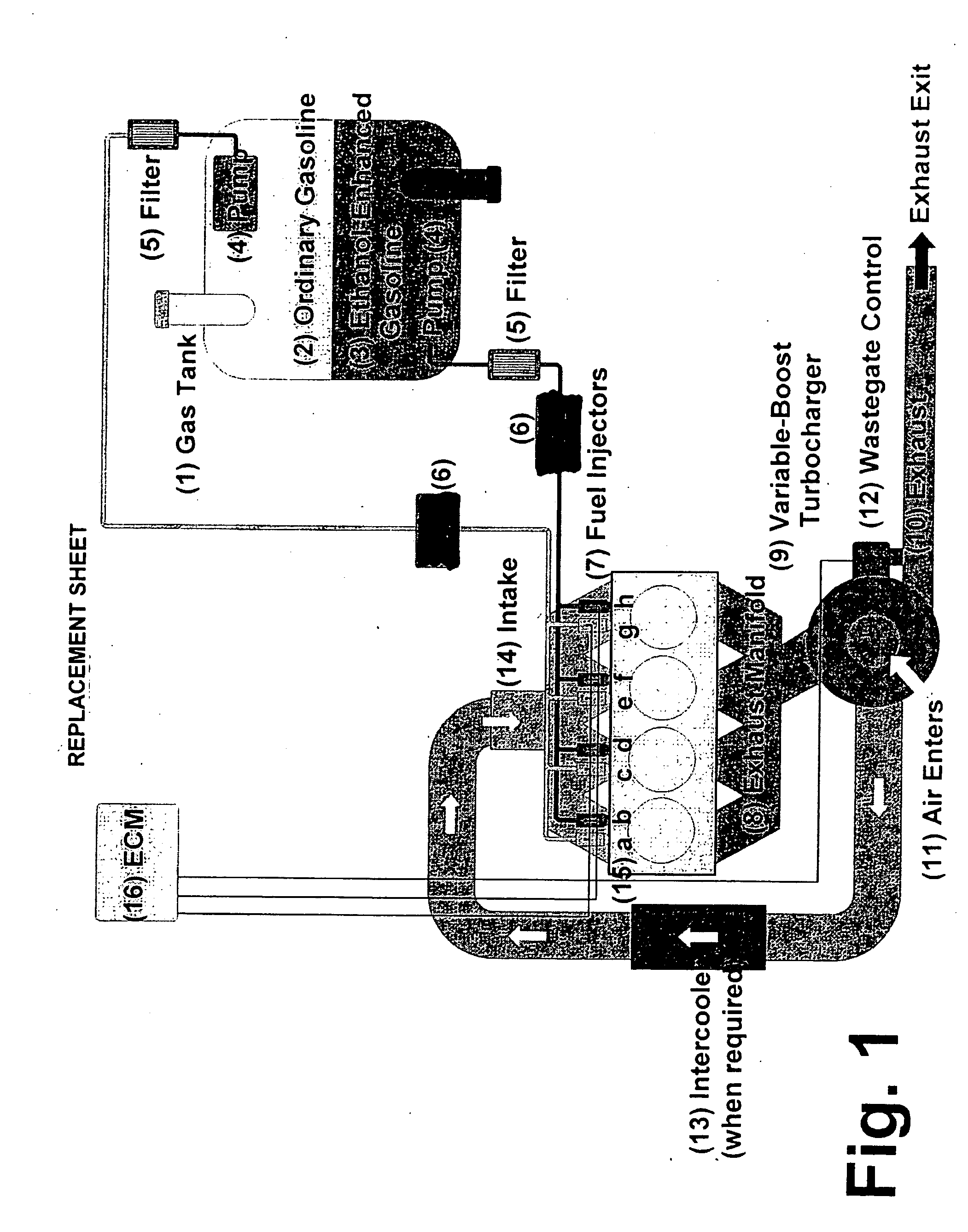

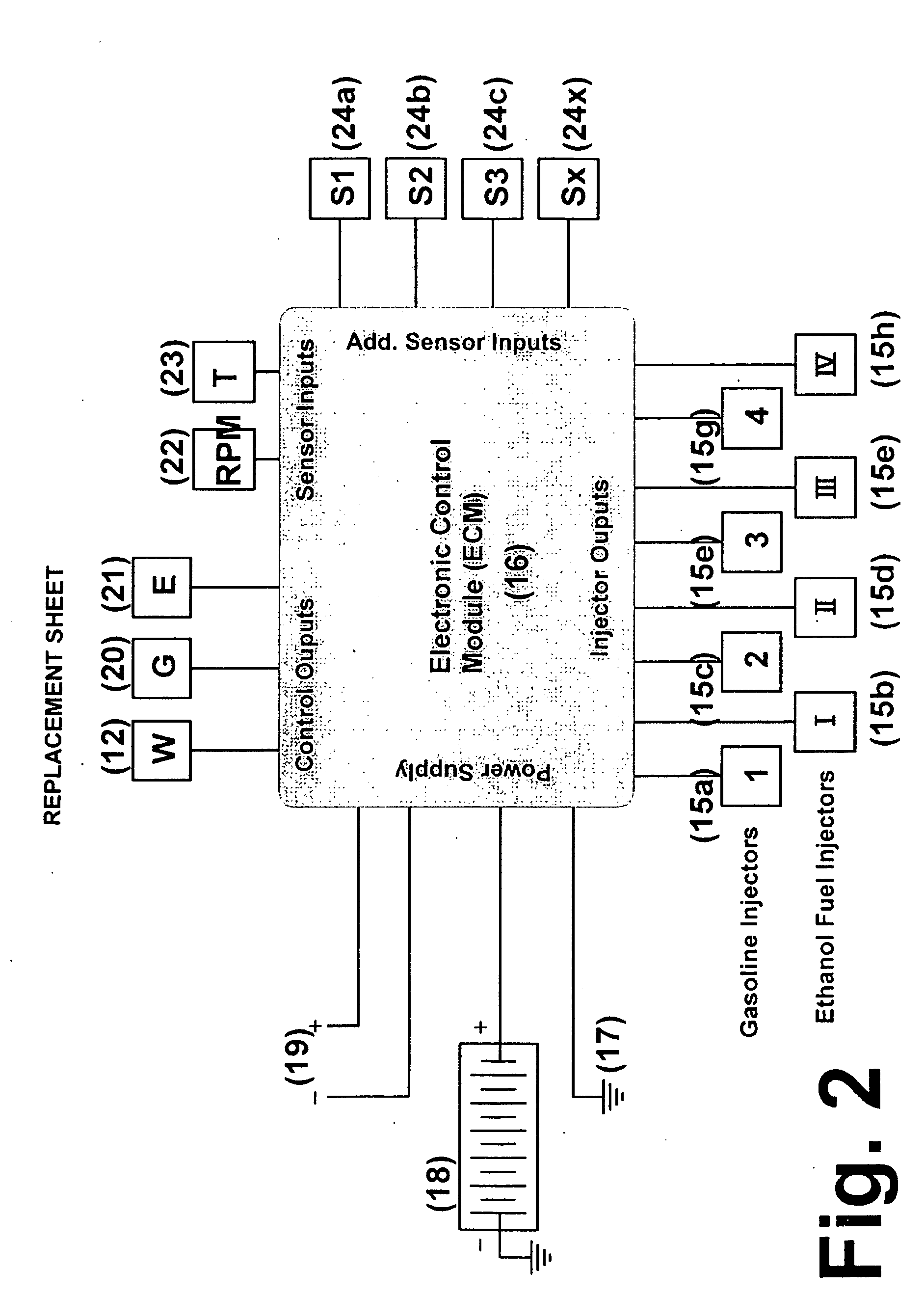

Engine with water and/or ethanol direct injection plus gas port fuel injectors

Owner:FORD GLOBAL TECH LLC

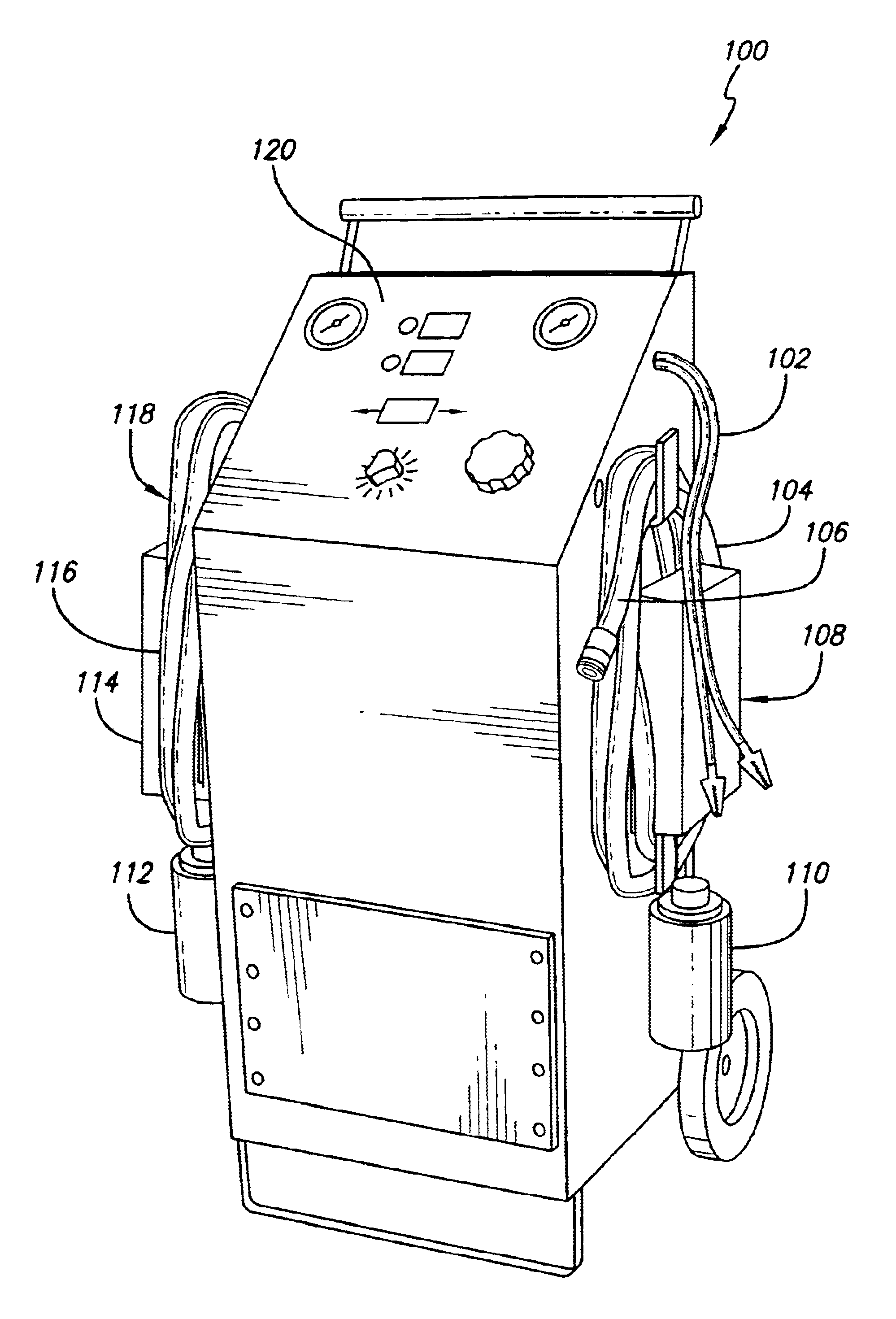

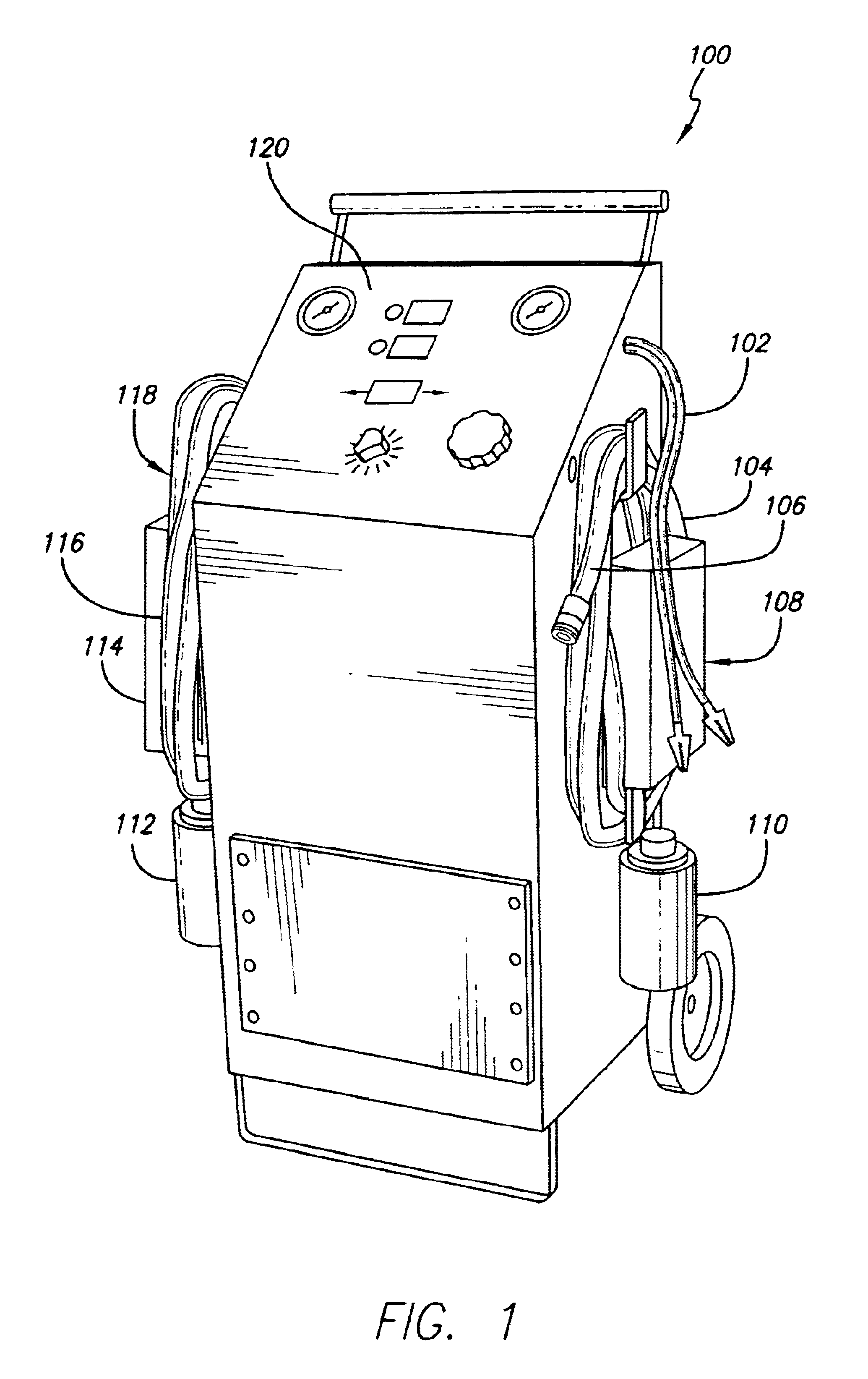

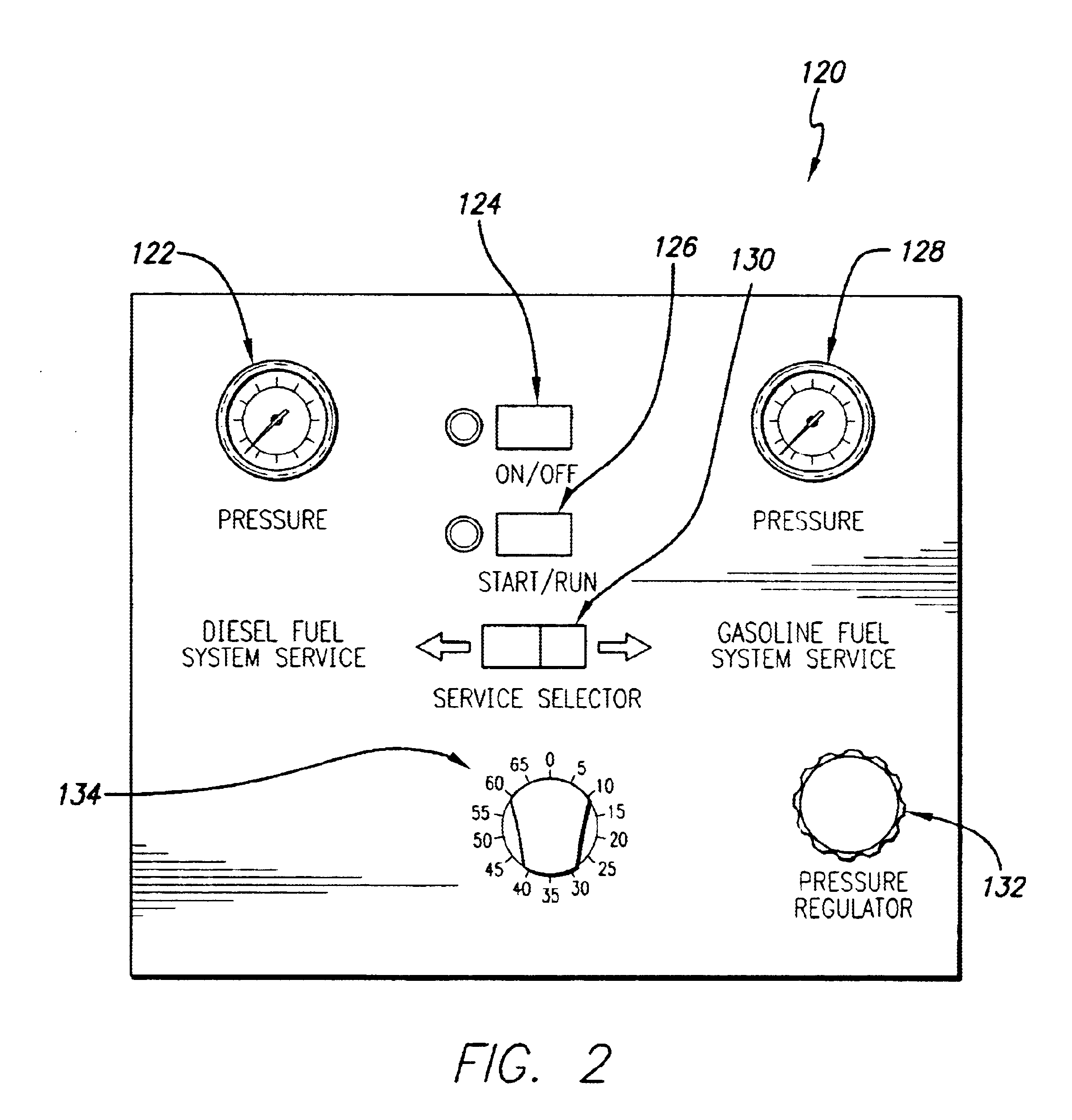

Automatic fuel system cleaner

An apparatus and method for cleaning either a diesel or a gasoline fuel system. The automatic fuel cleaner apparatus comprises a diesel service portion and a gasoline service portion. The diesel and gasoline service portions each includes a return hose having a first end capable of being coupled to a fuel line outlet of the fuel system. Each service portion further includes a detergent reservoir having an input connected to the return hose. Each service portion also includes a pump having an input connected to an output of the detergent reservoir. The diesel and gasoline service portions each further includes an output hose having a first end connected to a pump output and a second end capable of being coupled to a fuel line inlet. The gasoline service portion also comprises a pressure regulator connected to the output of the gasoline pump.

Owner:CPS PROD CANADA

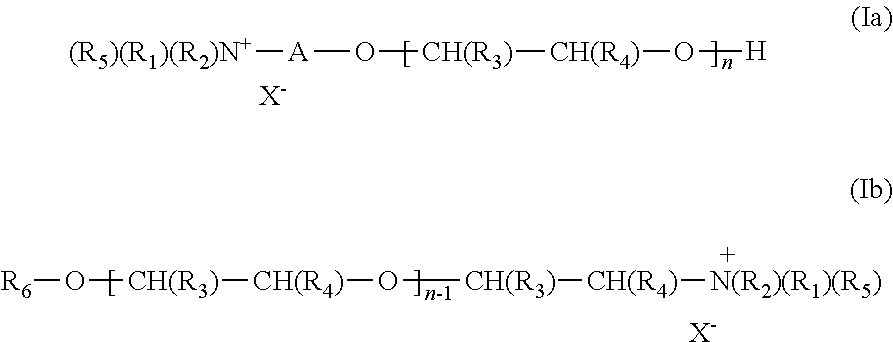

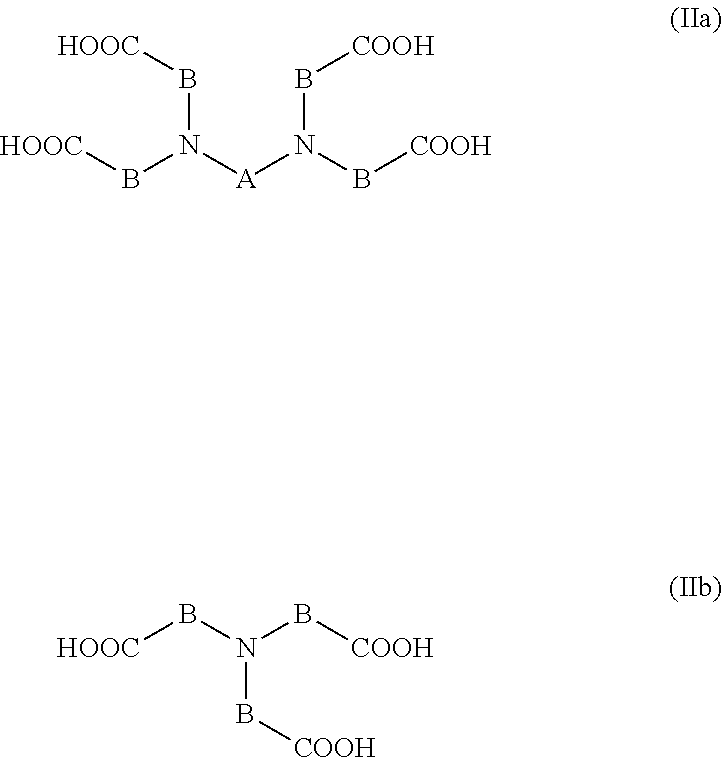

Quaternized polyether amines and their use as additive for fuels and lubricants

InactiveUS20130225463A1Organic compound preparationLiquid carbonaceous fuelsGasoline fuelCommon rail

The present invention relates to novel quaternized polyetheramines and to the preparation thereof. The present invention further relates to the use of these compounds as a fuel and lubricant additive. More particularly, the invention relates to the use of these quaternized nitrogen compounds as a fuel additive for reducing or preventing deposits in the injection systems of direct injection diesel engines, especially in common rail injection systems, for reducing the fuel consumption of direct injection diesel engines, especially of diesel engines with common rail injection systems, and for minimizing power loss in direct injection diesel engines, especially in diesel engines with common rail injection systems. The invention also provides additive packages comprising these polyetheramines; and fuels and lubricants additized therewith. The invention further relates to the use of these quaternized nitrogen compounds as an additive for gasoline fuels, especially for improving the intake system cleanliness of gasoline engines.

Owner:BASF AG

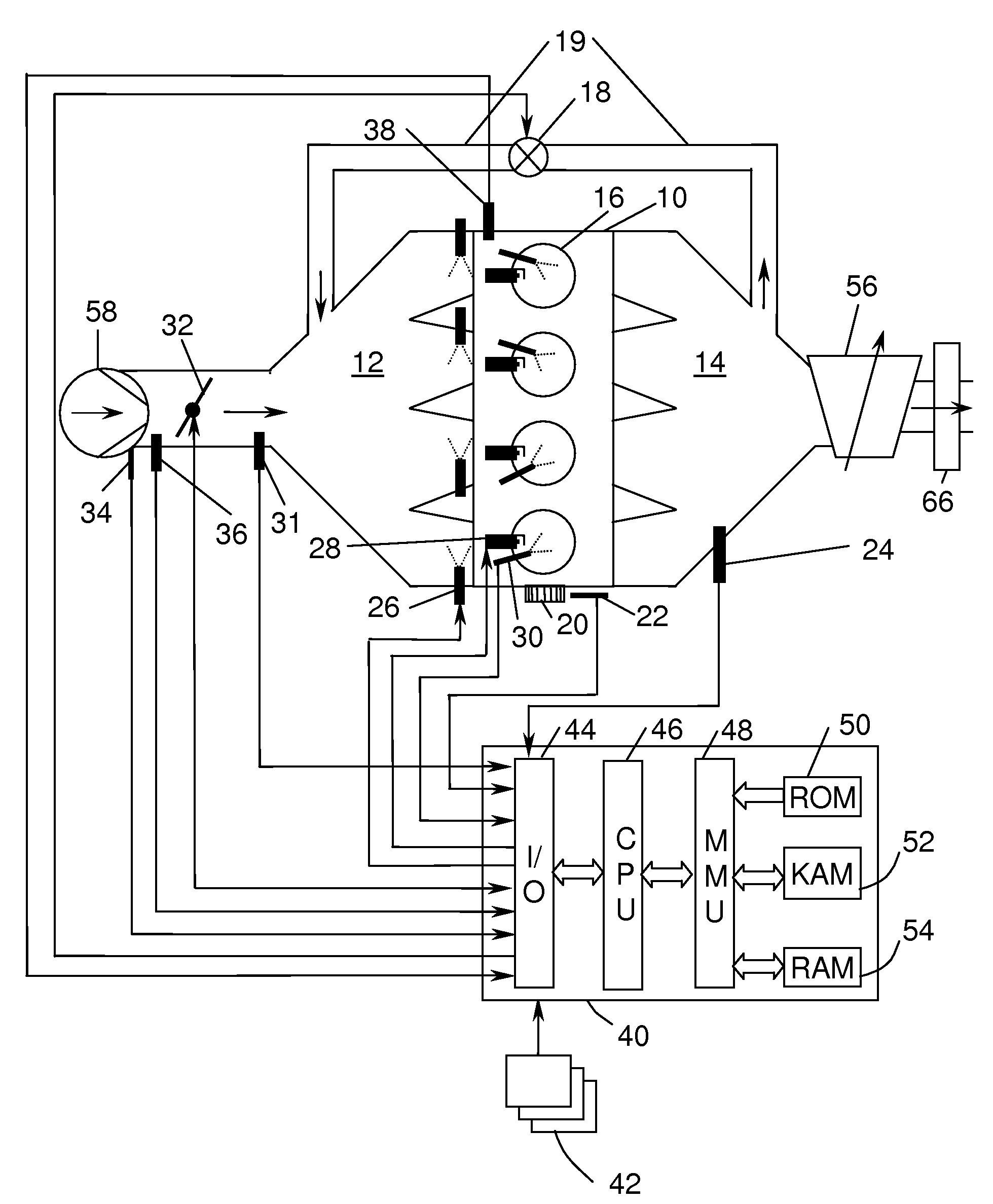

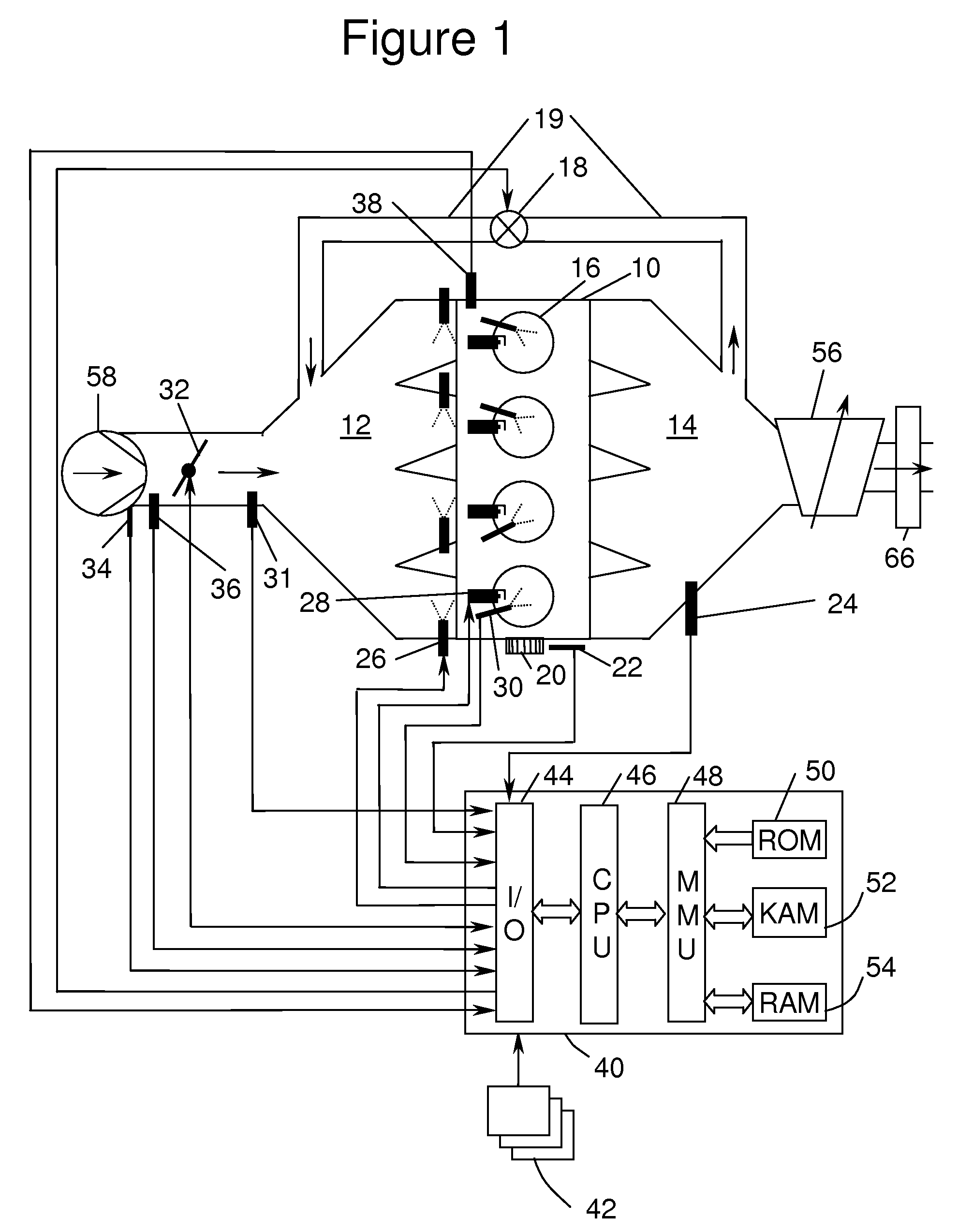

Engine with water and/or ethanol direct injection plus gas port fuel injectors

Owner:FORD GLOBAL TECH LLC

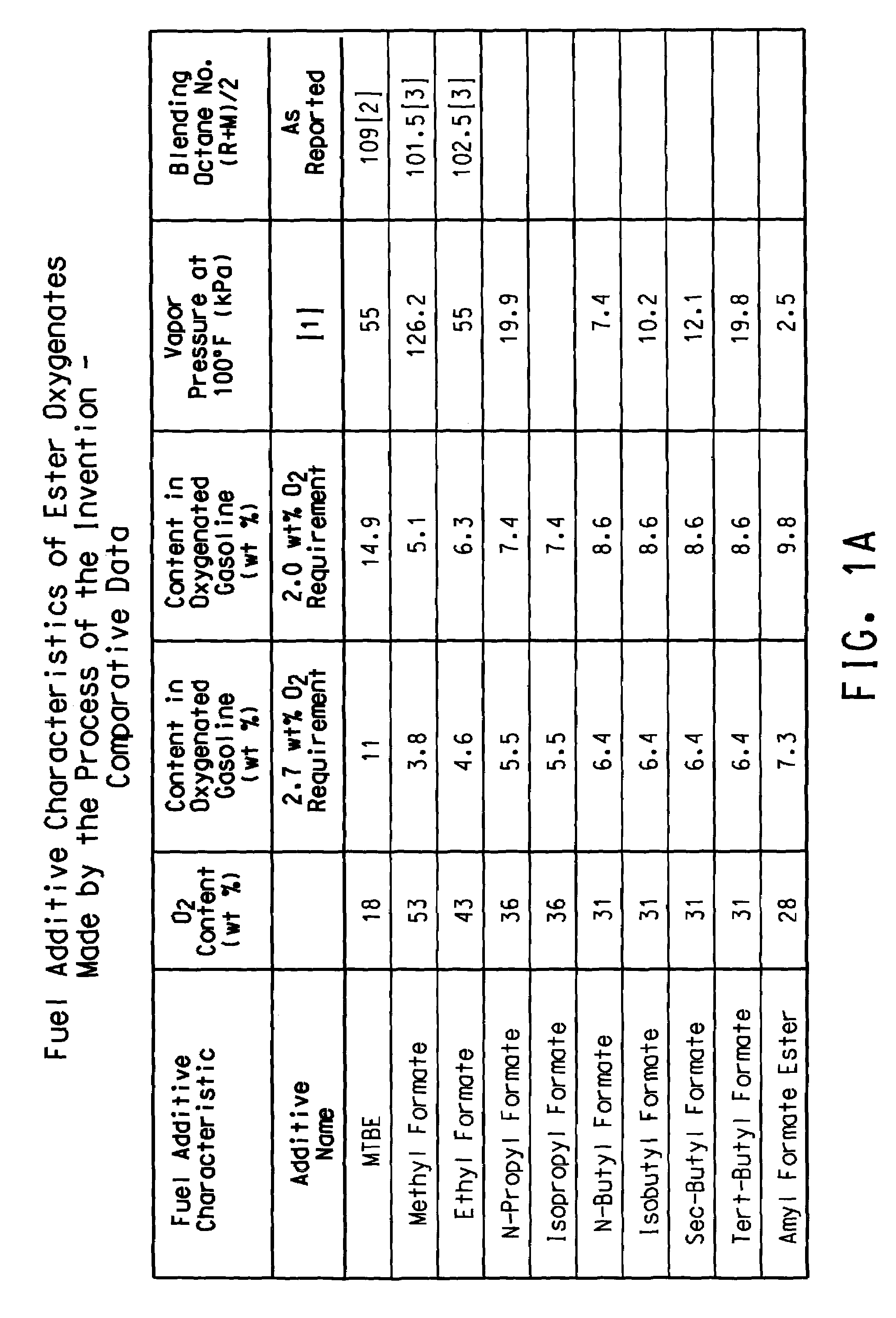

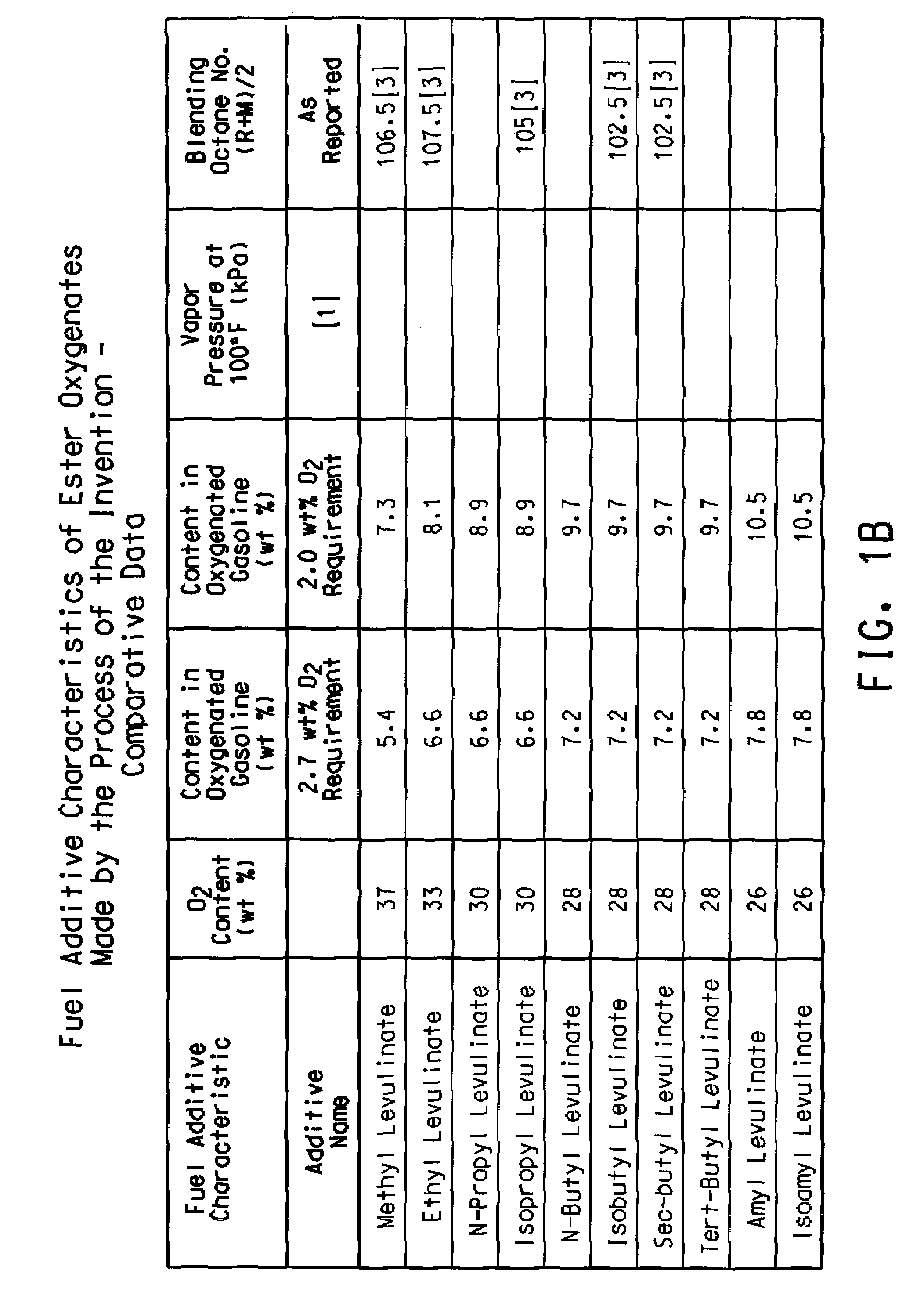

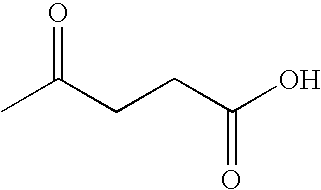

Preparation of levulinic acid esters and formic acid esters from biomass and olefins

This invention relates to a process for producing a mixture of levulinic acid esters and formic acid esters from biomass and olefins, and the composition prepared therefrom. This invention also relates to usage of the mixture of these esters as fuel and as fuel additives for gasoline fuel, diesel fuel, and biofuel.

Owner:EI DU PONT DE NEMOURS & CO

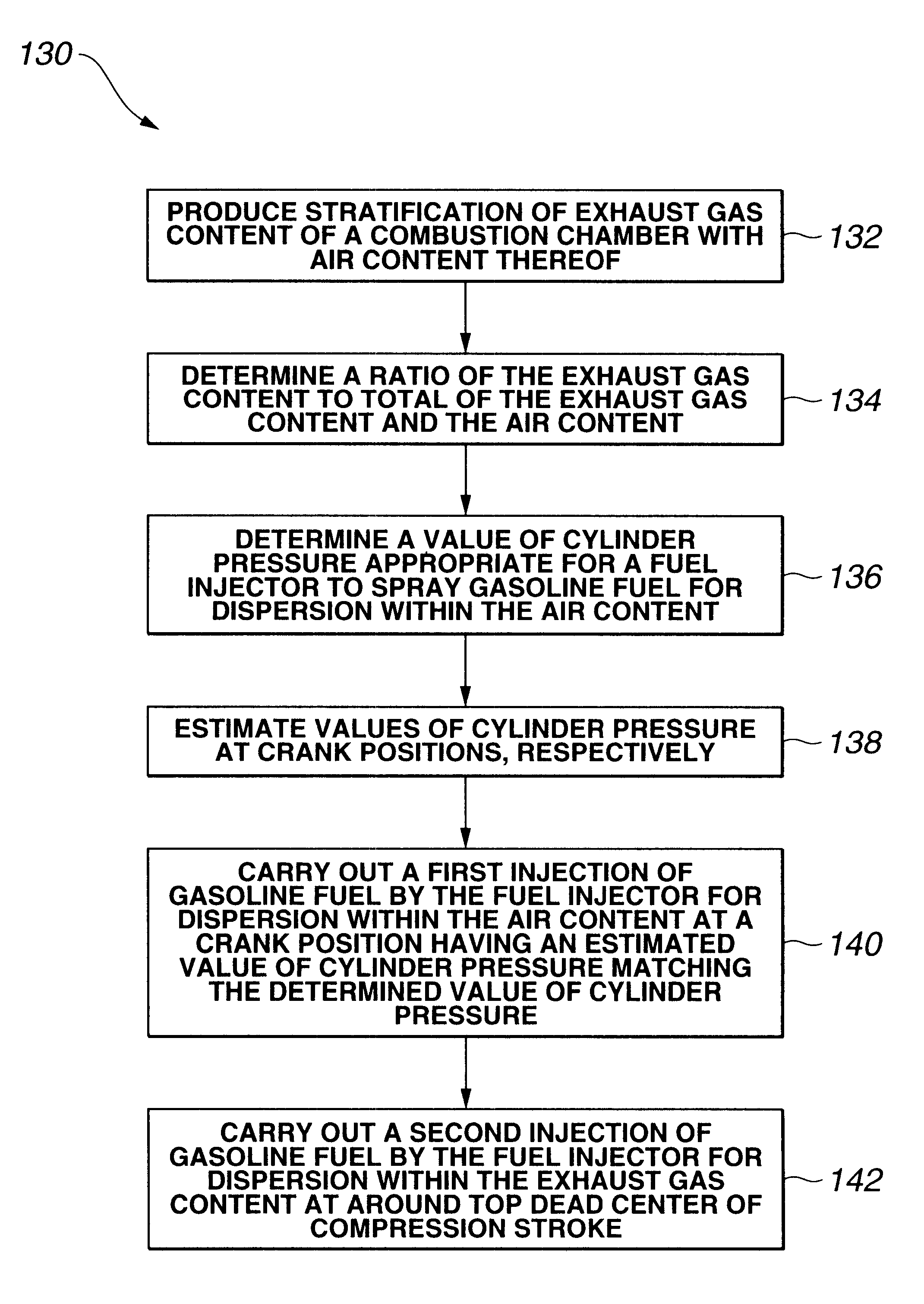

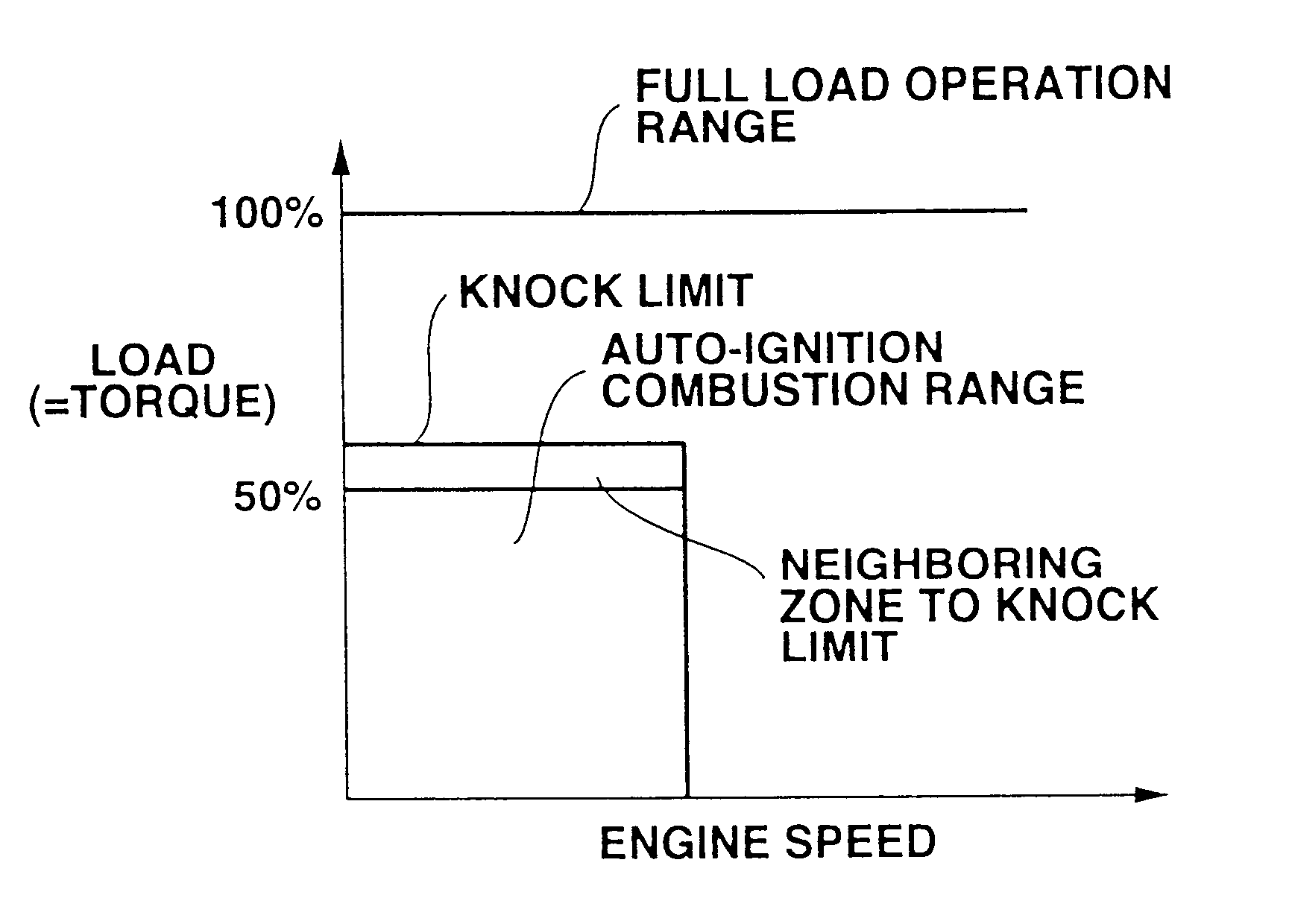

Controlled auto-ignition lean burn stratified engine by intelligent injection

A system and method for widening auto-ignition range of a lean burn internal combustion engine employs stratified charge of exhaust gas content and air content. A fuel injection system carries out a first injection of gasoline fuel for dispersion within the air content, and a second injection of gasoline fuel for dispersion within the exhaust gas content. This intelligent injection of gasoline fuel accomplishes auto-ignition of gasoline fuel within the exhaust gas content over extended range of engine speed and load.

Owner:NISSAN MOTOR CO LTD

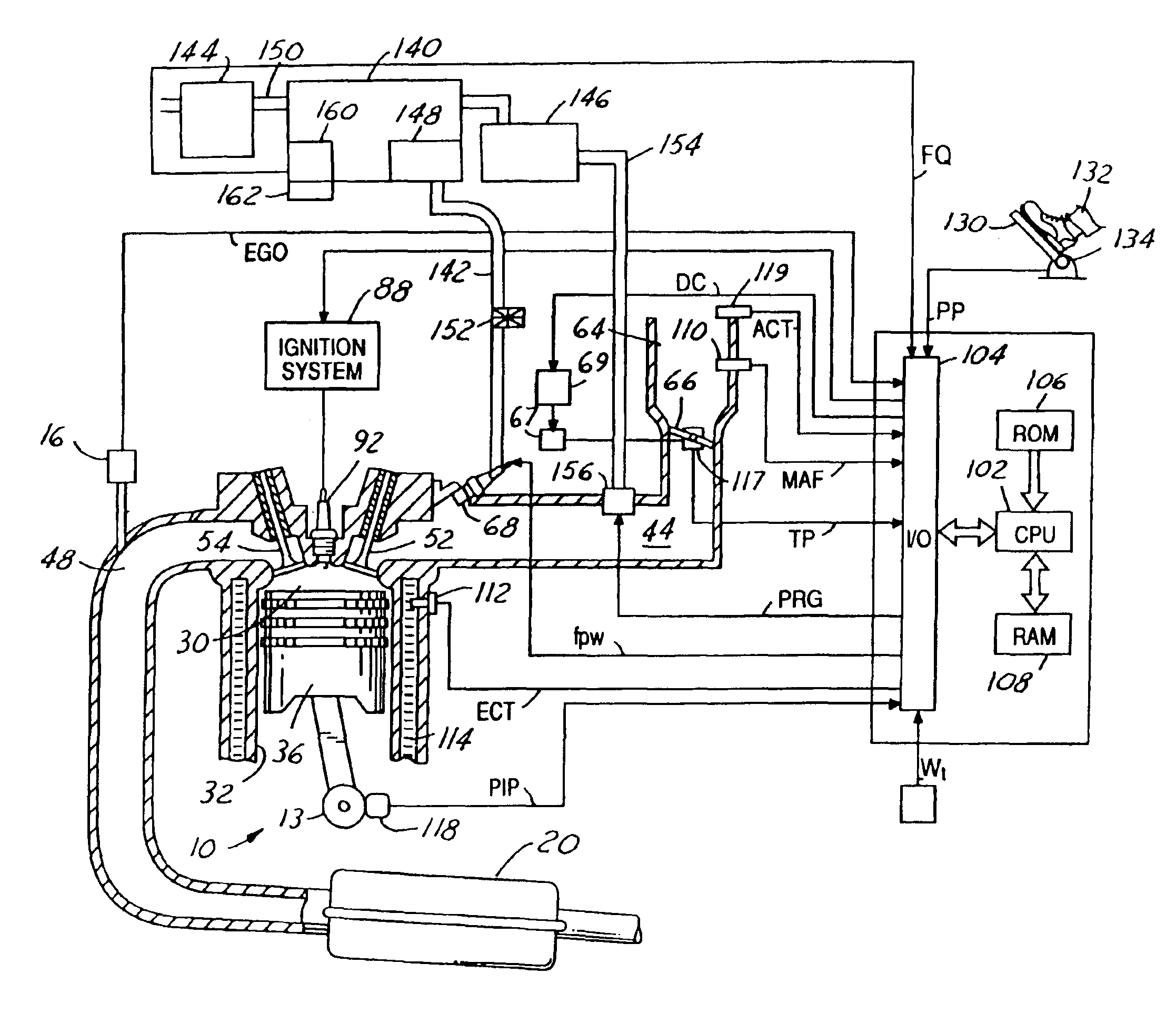

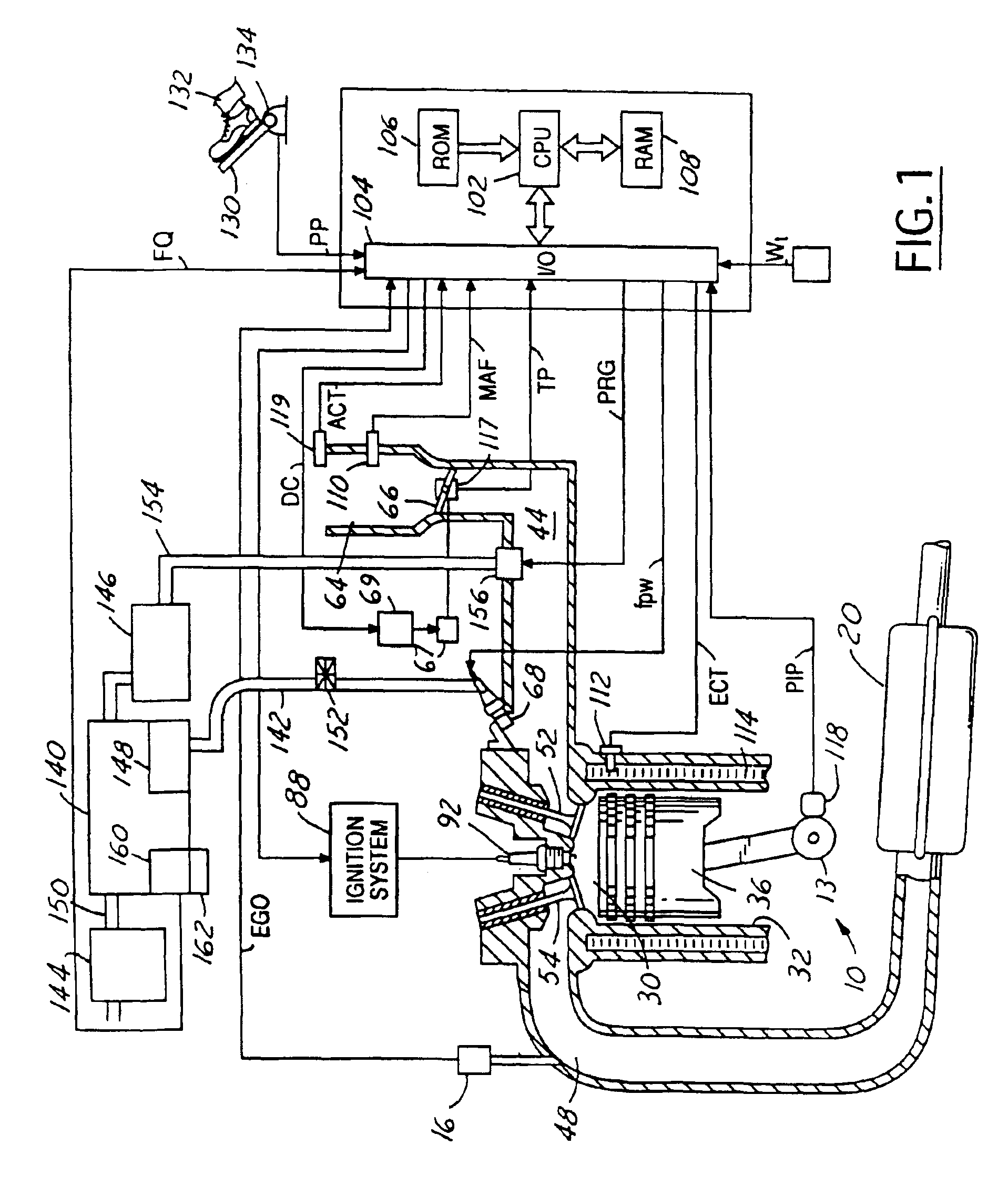

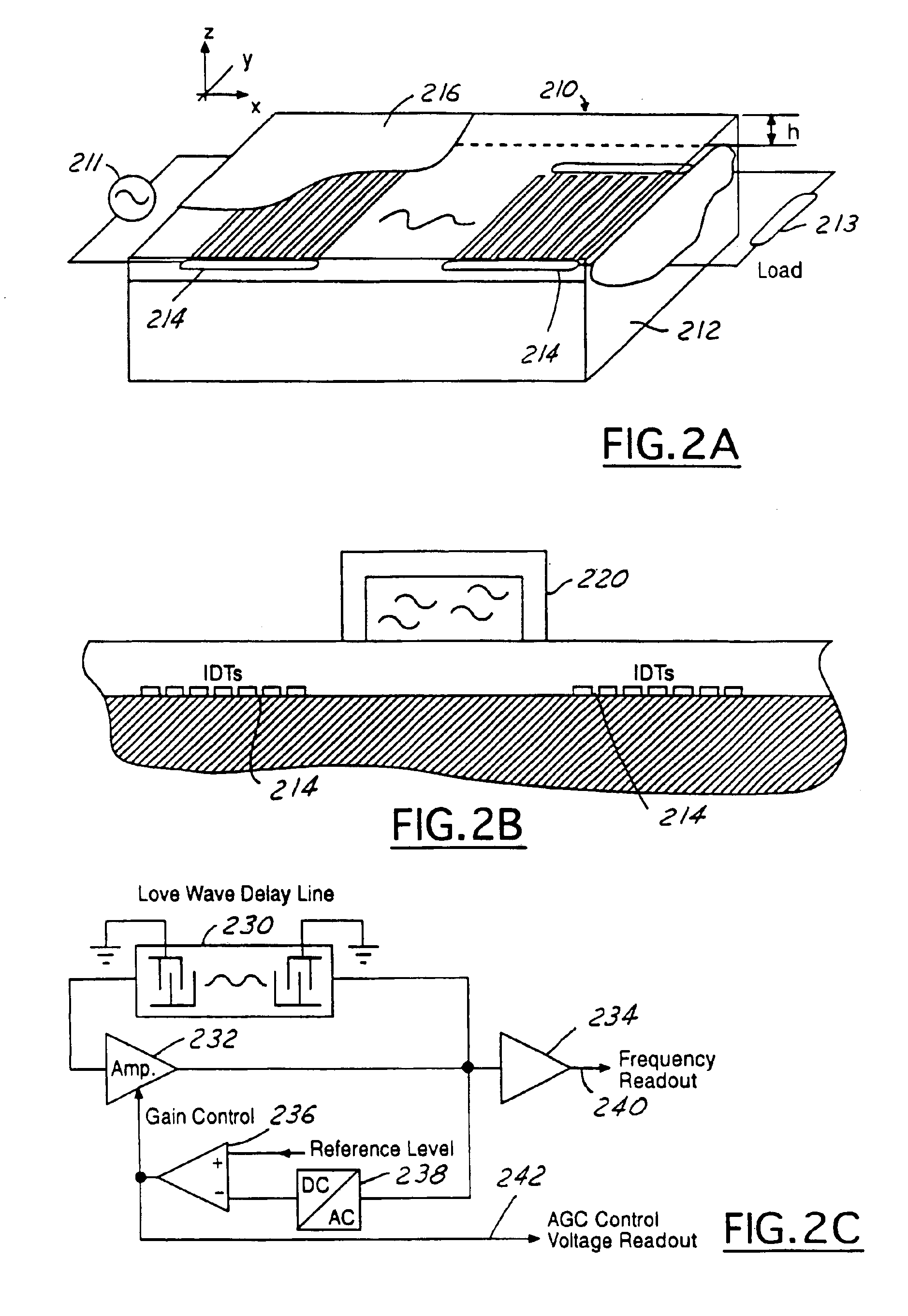

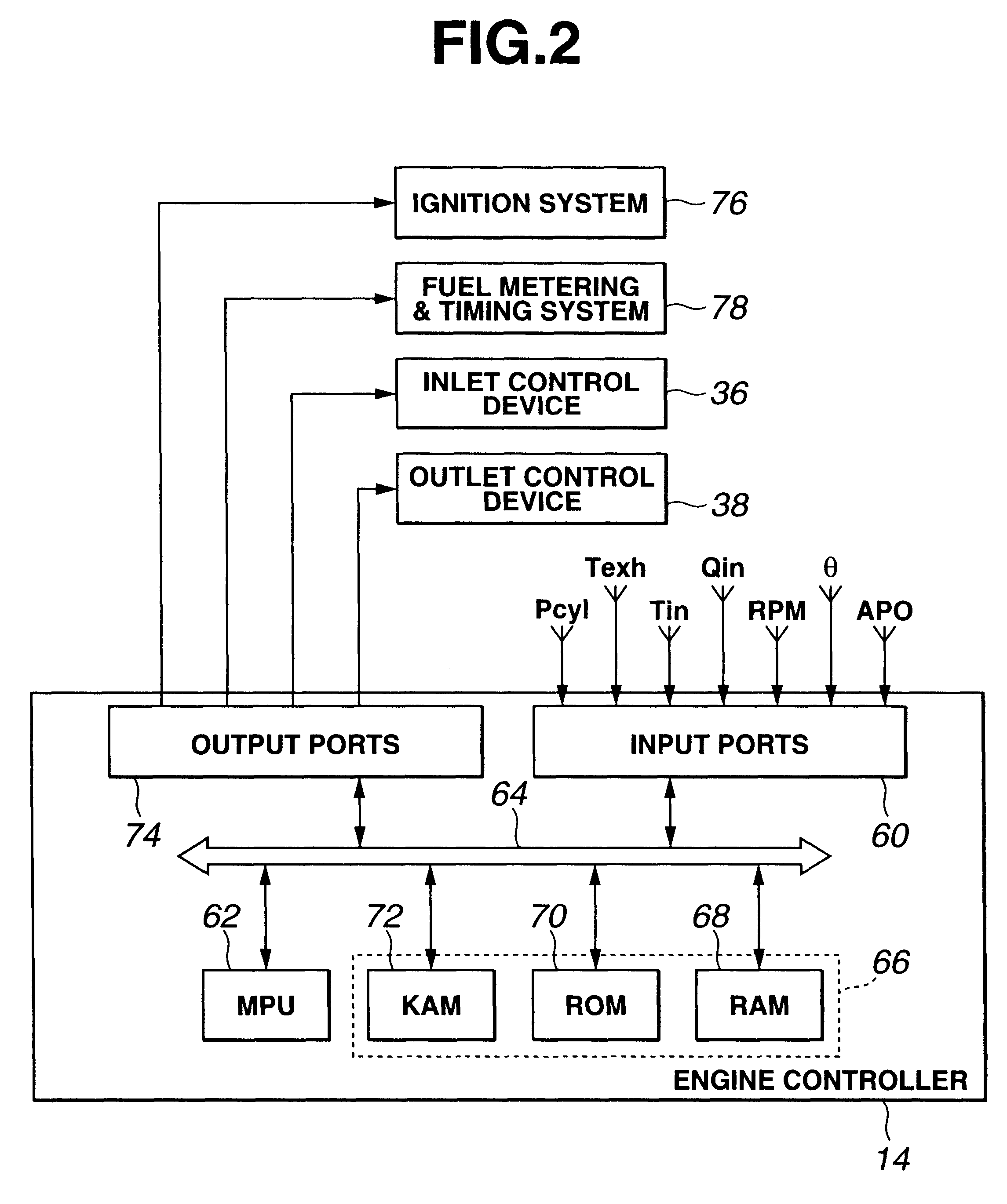

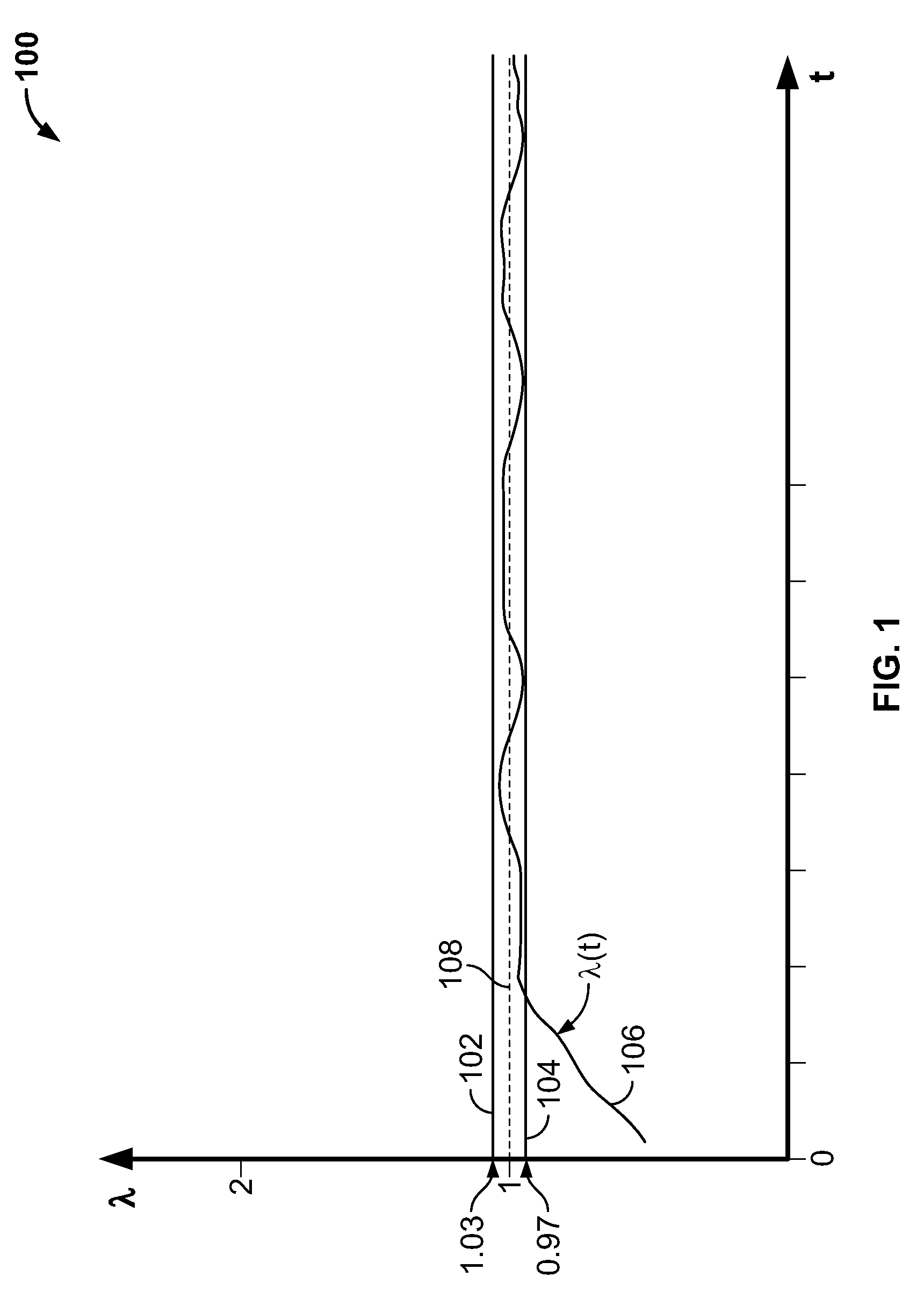

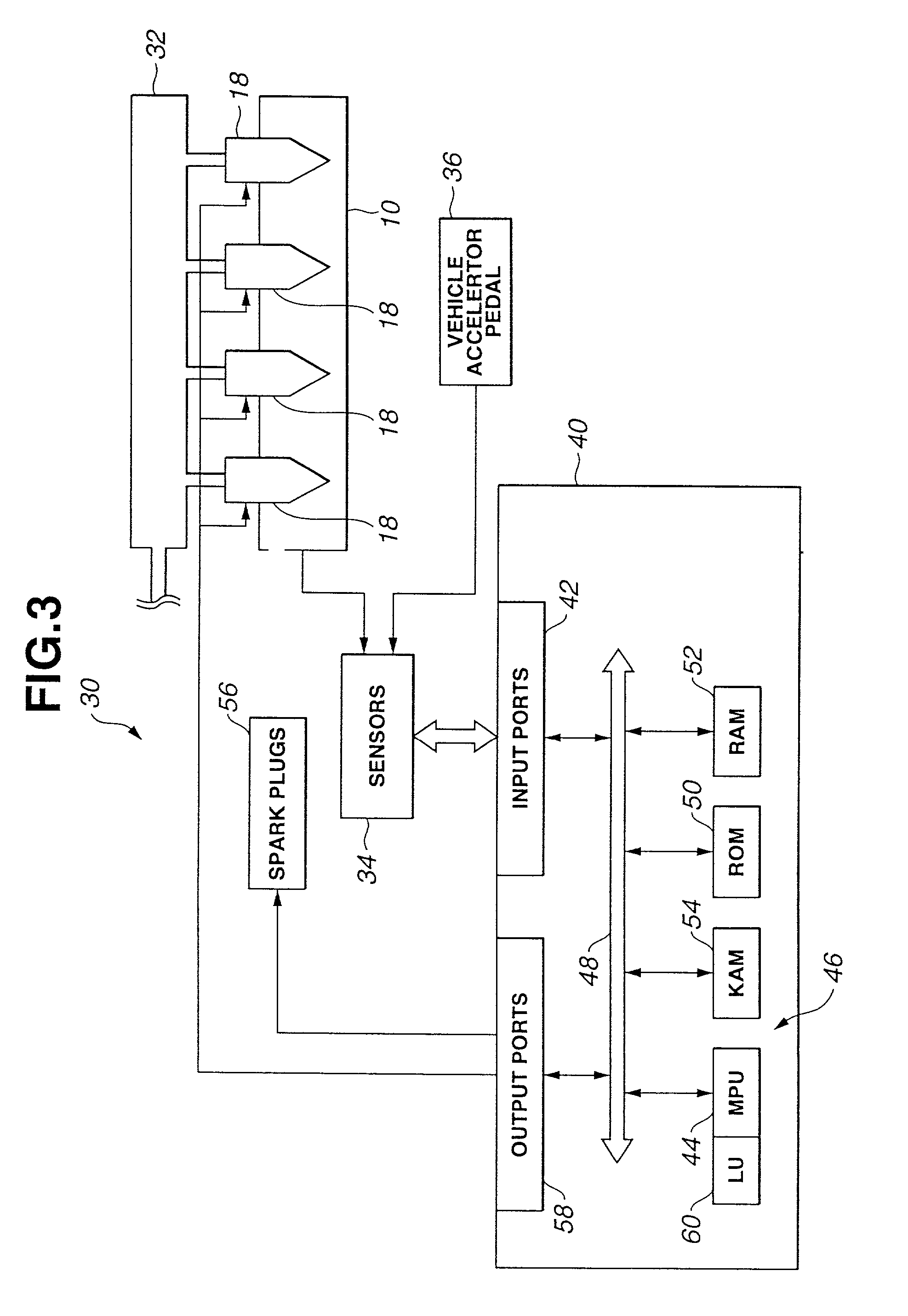

Engine control with fuel quality sensor

InactiveUS6935311B2Improved cold-start emissionImprove driveabilityElectrical controlInternal combustion piston enginesGasoline fuelFuel quality

A system is described using a fuel quality sensor for controlling various aspects of engine operation. In particular, an acoustic wave sensor is utilized to measure viscosity and density of gasoline fuels. This measurement is utilized to predict engine combustion quality during an engine start. Based on the prediction, the method adjusts engine operating parameters (such as fuel injection amount and ignition timing) to achieve improved vehicle driveability and engine combustion.

Owner:FORD GLOBAL TECH LLC

Auto-ignition combustion management in internal combustion engine

InactiveUS6401688B2High densityElectrical controlCombustion enginesCombustion chamberTop dead center

Owner:NISSAN MOTOR CO LTD

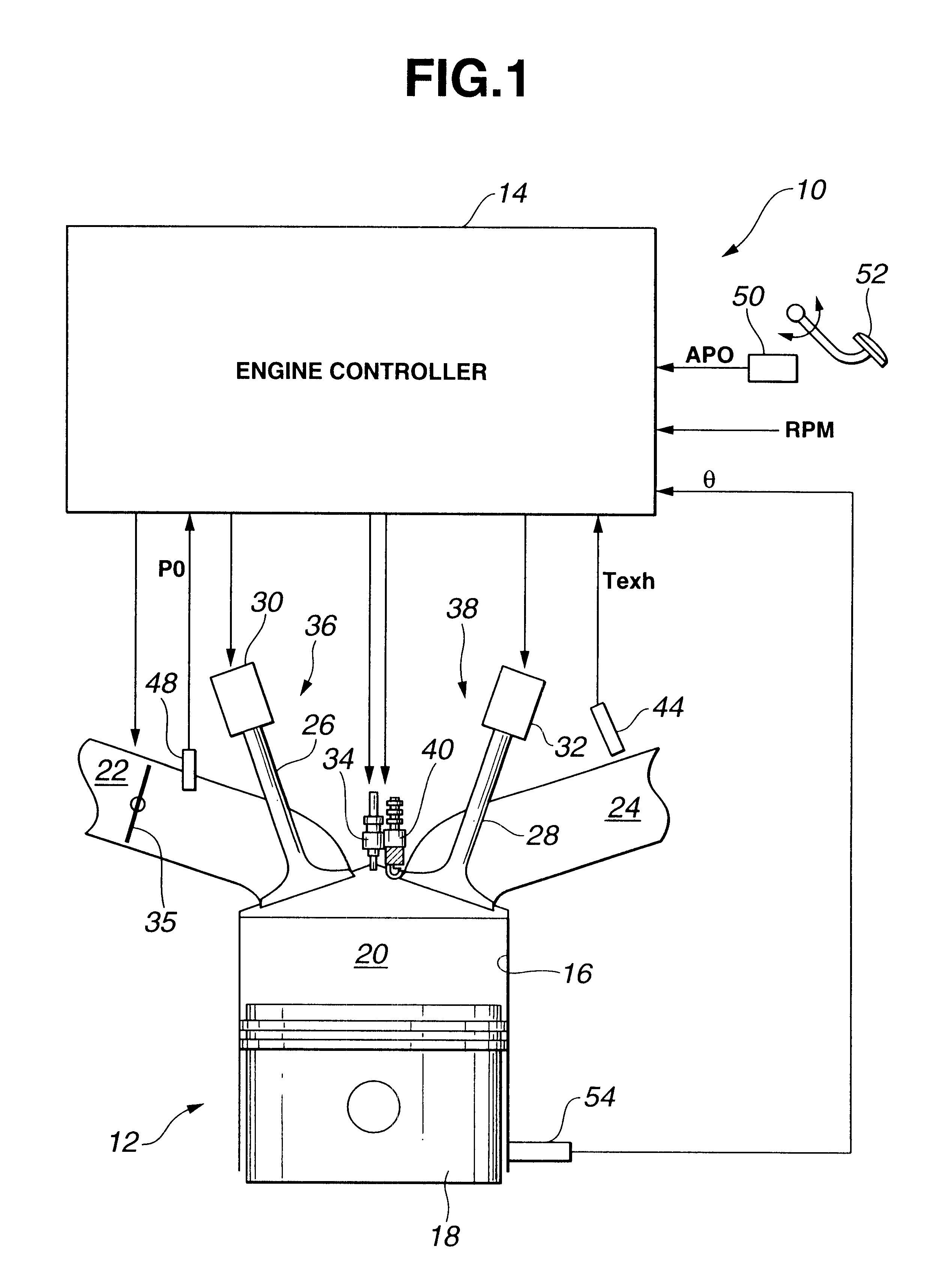

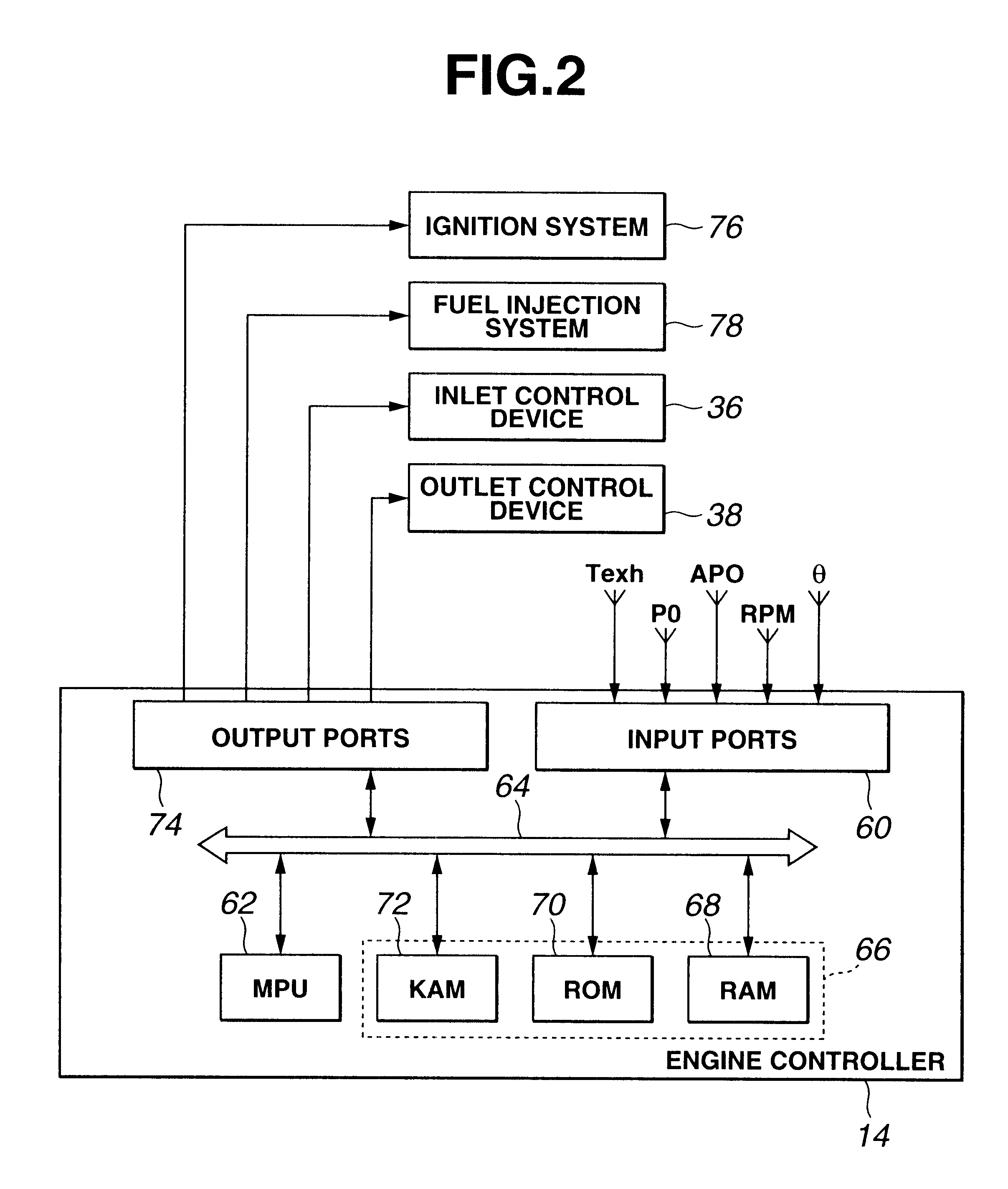

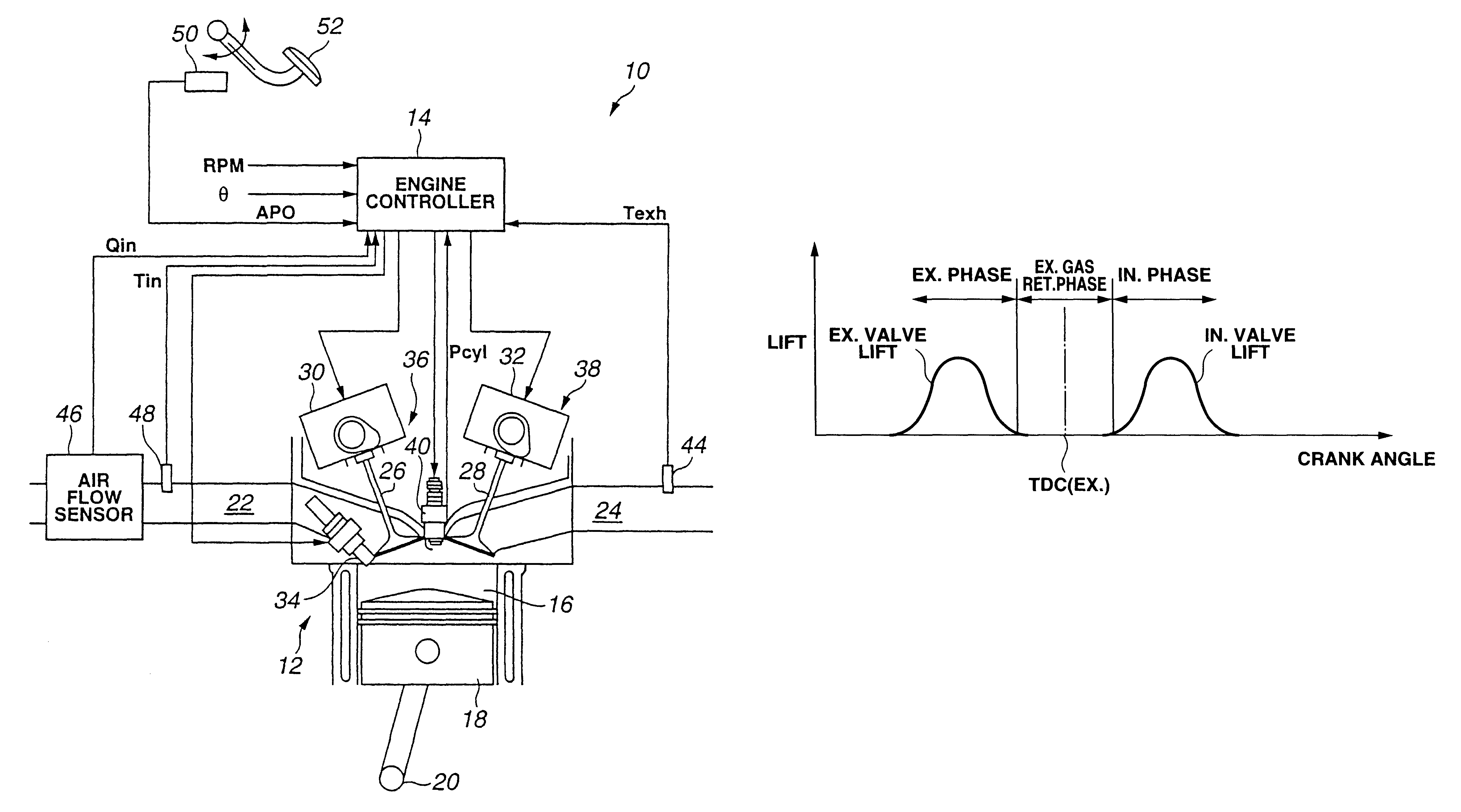

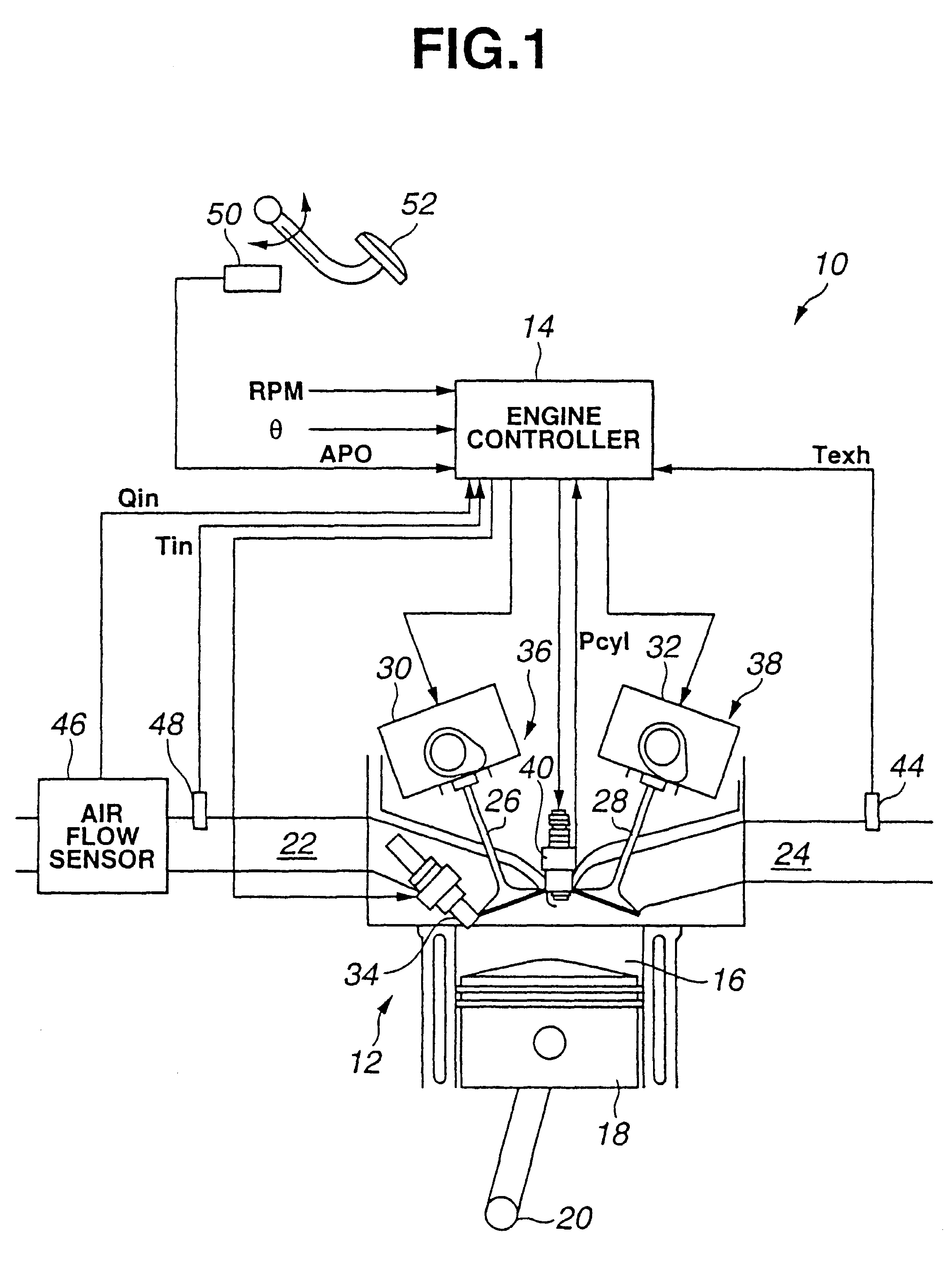

Auto-ignition of gasoline engine by varying exhaust gas retaining duration

A system and method controls auto-ignition of gasoline fuel within a cylinder of an internal combustion engine by varying an exhaust gas retaining duration. A generator provides a parameter indicative of combustion event within the cylinder. An engine controller adjusts an inlet control device and an outlet control device to retain exhaust gas for subjecting the retained exhaust gas to compression. In order to vary duration of the exhaust gas retaining phase, closing timing of the outlet control device is varied based on the parameter.

Owner:NISSAN MOTOR CO LTD

Fuel compositions and methods thereof

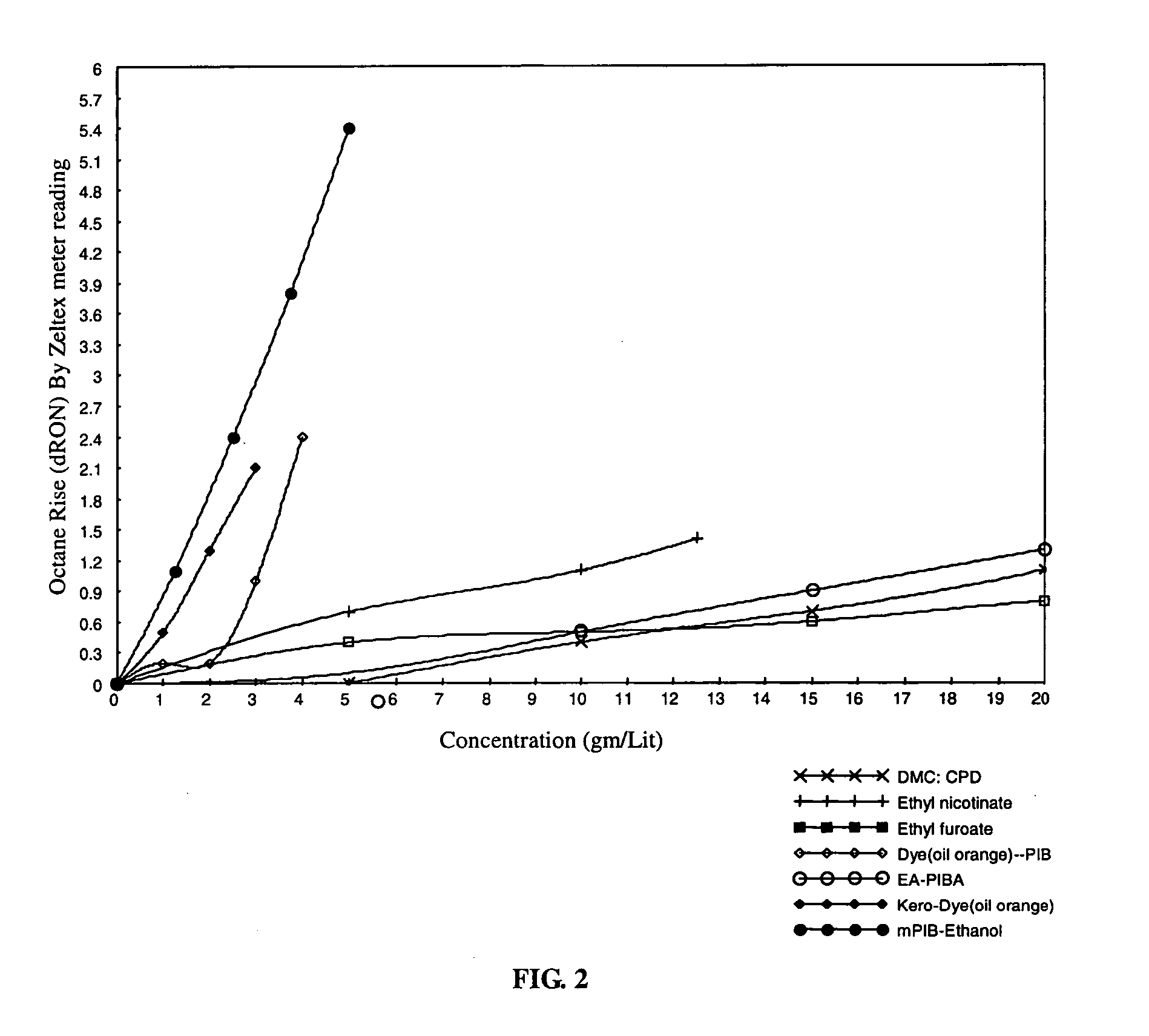

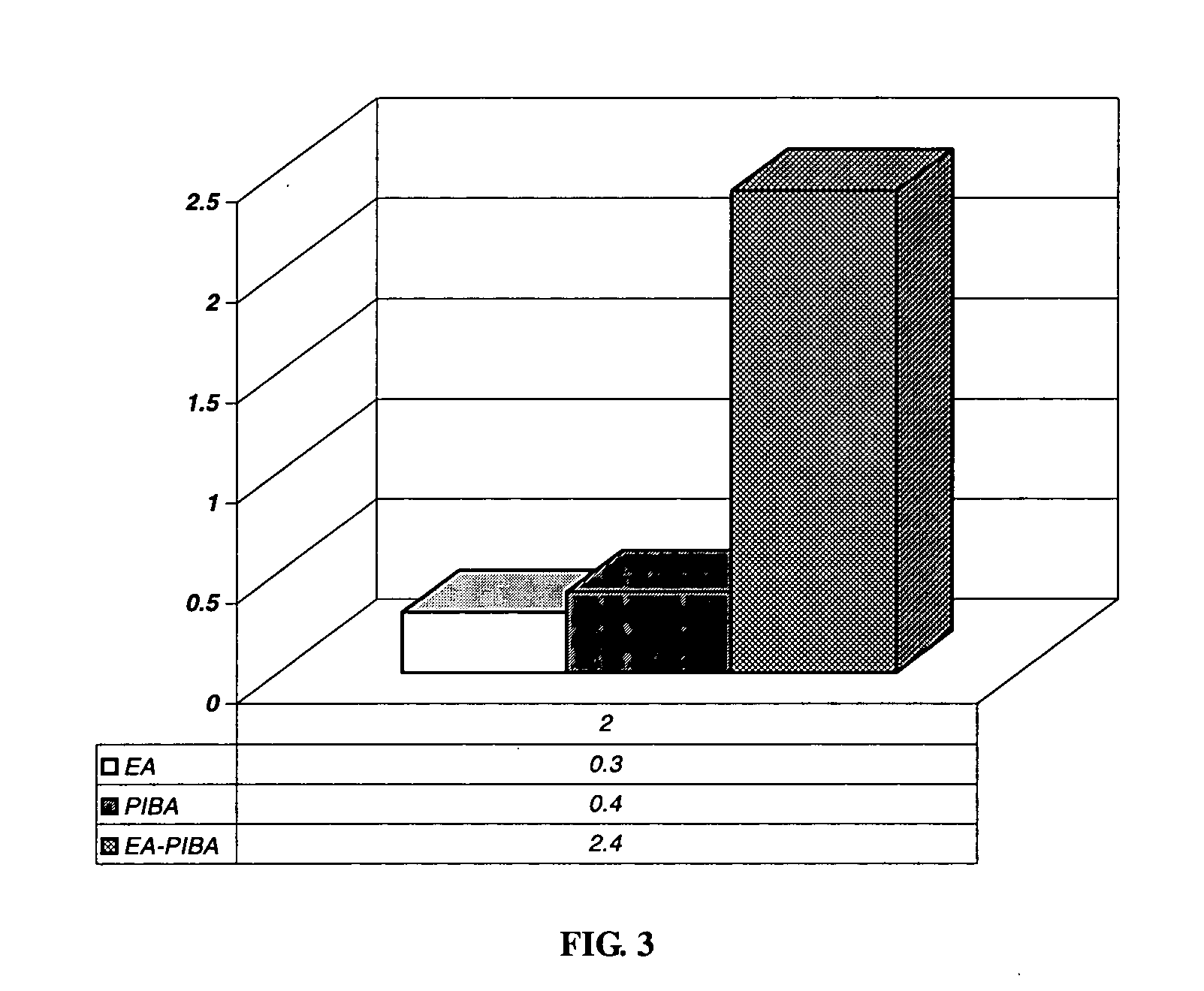

InactiveUS20050229479A1Increasing octane indexImprove propertiesLiquid carbonaceous fuelsFuel additivesGasoline fuelEngineering

Anti-knock gasoline fuel compositions are provided including anti-knock additives and mixtures thereof. The octane quality of fuel for an internal combustion engine improved with the anti-knock additives.

Owner:OCTANE IP L L C

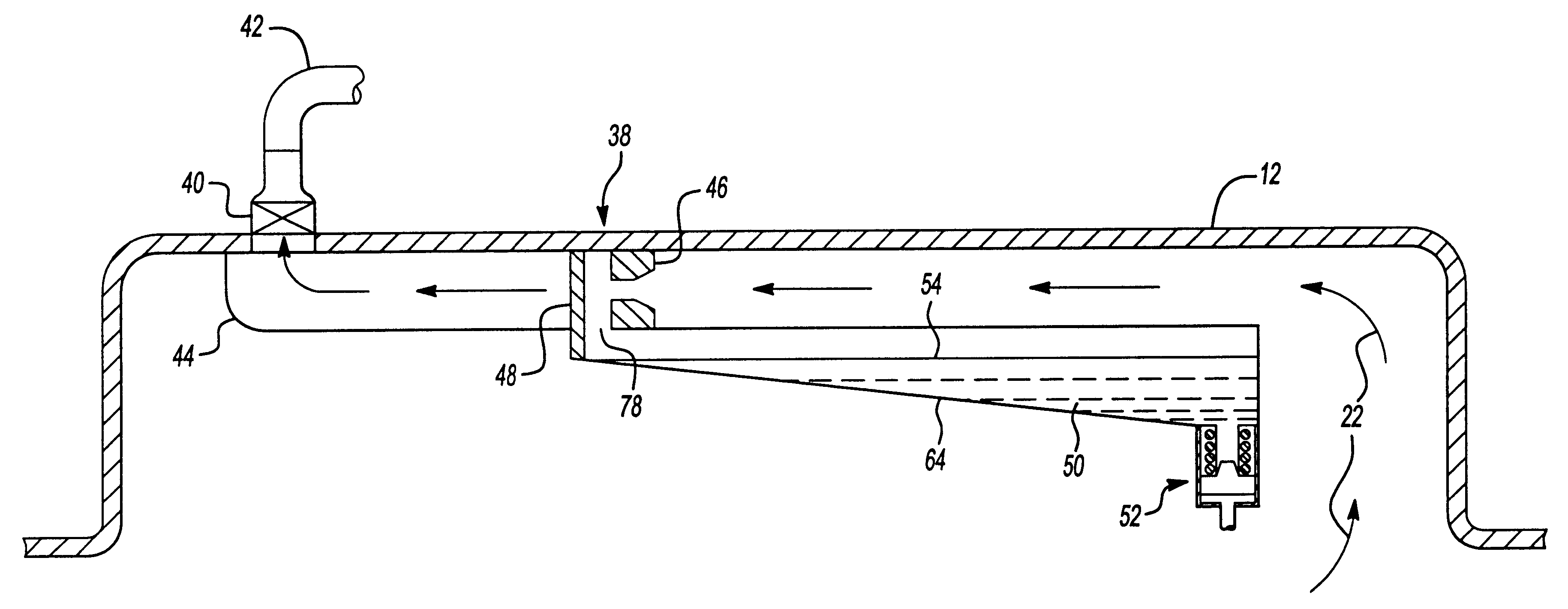

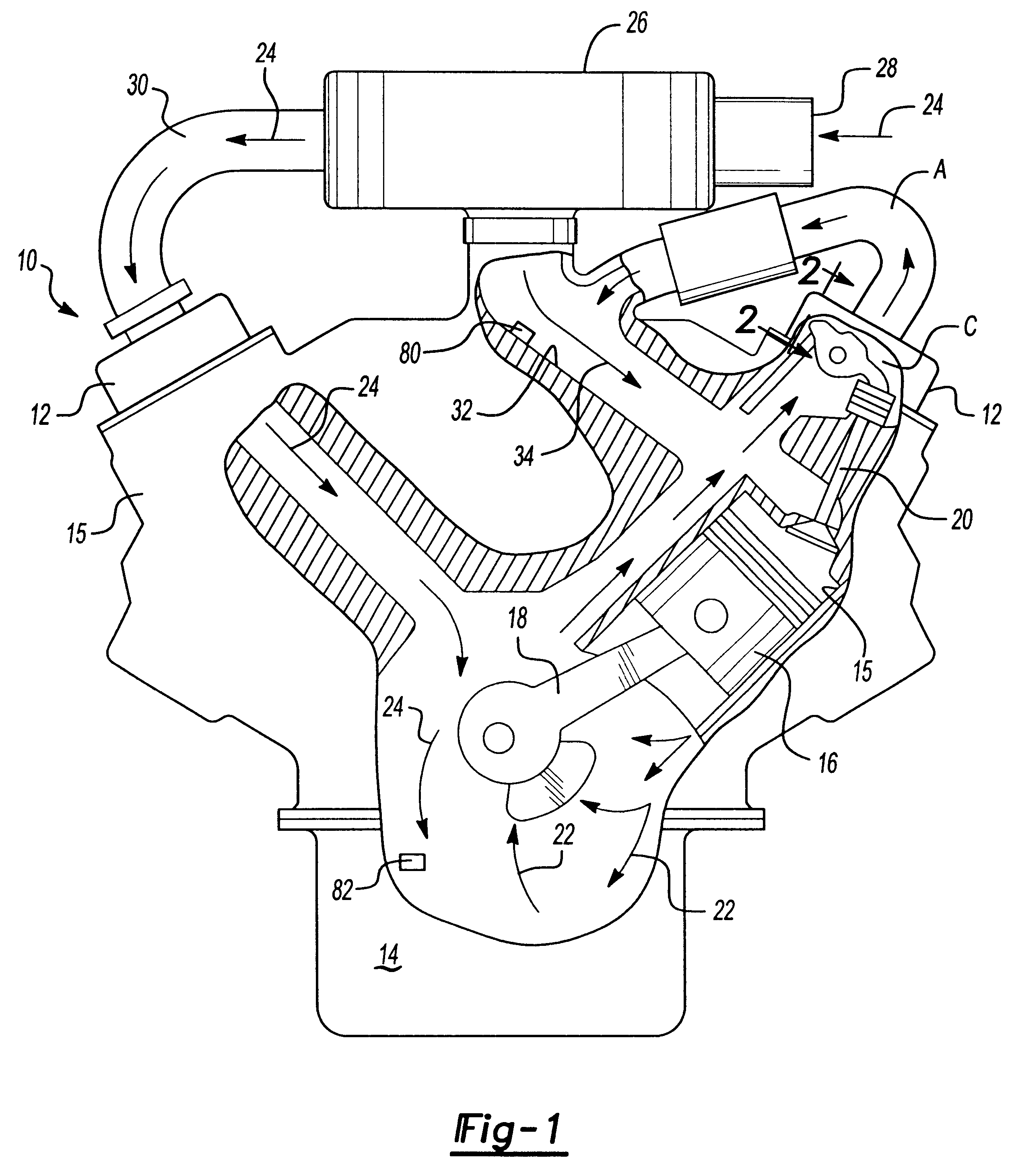

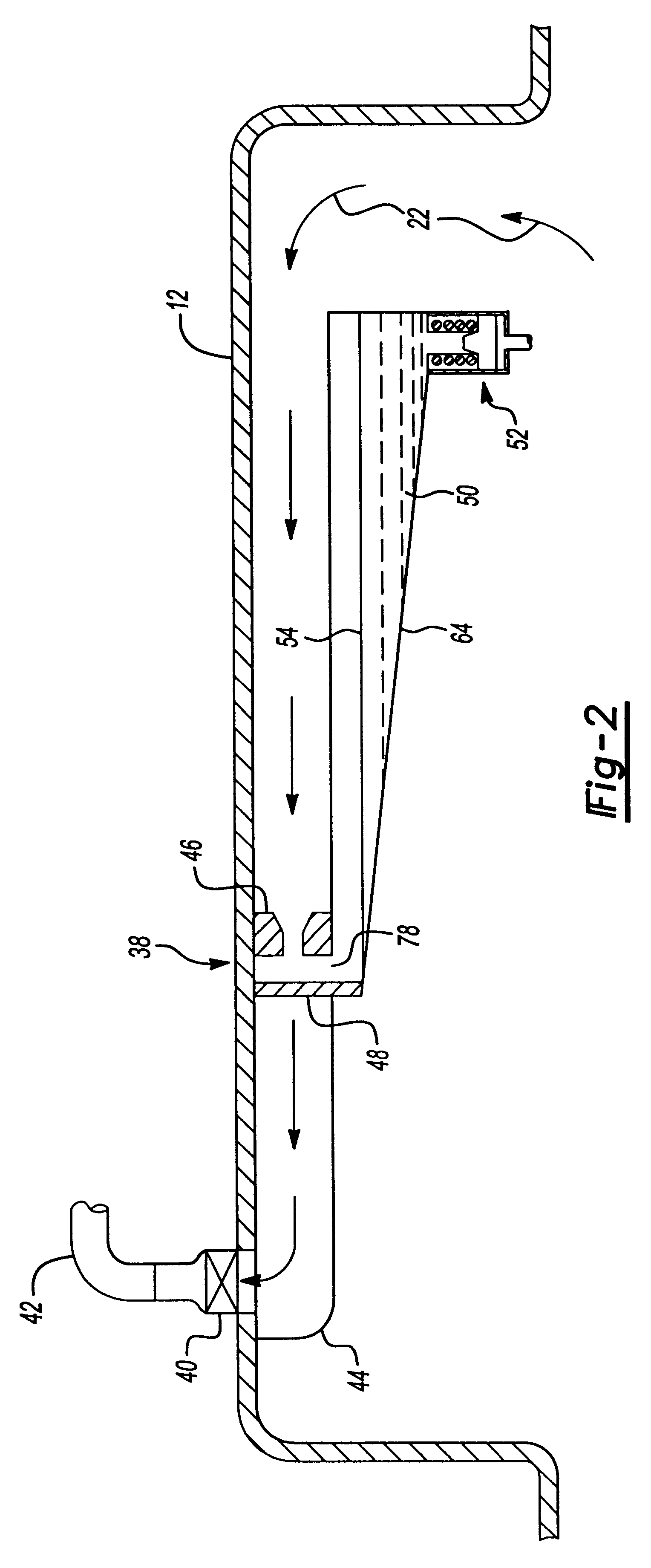

Crankcase bypass system with oil scavenging device

InactiveUS6435170B1Internal combustion piston enginesNon-fuel substance addition to fuelRe entryVacuum pressure

An engine crankcase bypass system includes a scavenging mechanism for the collection and removal of oil entrained in engine bypass gases that include unburned gasoline fuel and water vapors. The improved bypass system, designed to replace a standard PCV (positive crankcase ventilation) system, senses manifold and crankcase vacuum pressures, and via utilization of either an electronic or mechanical valve provides continuous adjustments of bypass gas flows for the maintenance of a constant gas flow sufficient to exceed normal engine bypass flow rates. A deflector system positioned in a flow stream is designed to extract and separate oil vapor from unburned gasoline fuel and water vapors entrained in the bypass gases. The oil is collected and drained to a temporary reservoir for subsequent re-entry into the oil sump of the engine. The fuel and water vapors are immediately returned to the intake manifold of the engine for reburning of the fuel.

Owner:MAHLE ENGINE COMPONENTS USA

Universal Synthetic Gasoline Fuel Conditioner Additive, Method and Product-by-Process

ActiveUS20100269404A1Reduce premature mechanical wearReduce failureLiquid carbonaceous fuelsAdditivesGasoline fuelEngineering

A process of producing a universal synthetic based gasoline fuel additive that cleans the fuel system including valves surface, lubricates the fuel pump, injectors and valves while allowing for a clean and more efficient burn. A major portion will consist of (a) Alfa-Olefins, (b) 2-propanol (c) Hydrolsomerized High VI HT Base Oils, (d) Dimethyl Ketones, (e) Low Flash Mineral Spirits, (f) Low Aromatic Solvent, (g) Isomer Reformate, (h) Solvent Activated Dye. In a preferred embodiment, this universal synthetic gasoline conditioner additive for improving lubrication comprises: alpha-olefins comprising from 5 to 30 percent thereof, by weight; low odor aromatic solvents comprising from 3 to 27 percent thereof, by weight; 2-Propanol comprising of 3 to 30 percent thereof, by weight; and at least one a base oil comprising from 0.50 to 15 percent thereof, by weight; wherein: the percentages by weight are specified in relative proportion to one another.

Owner:BESTLINE INT RESEACRH

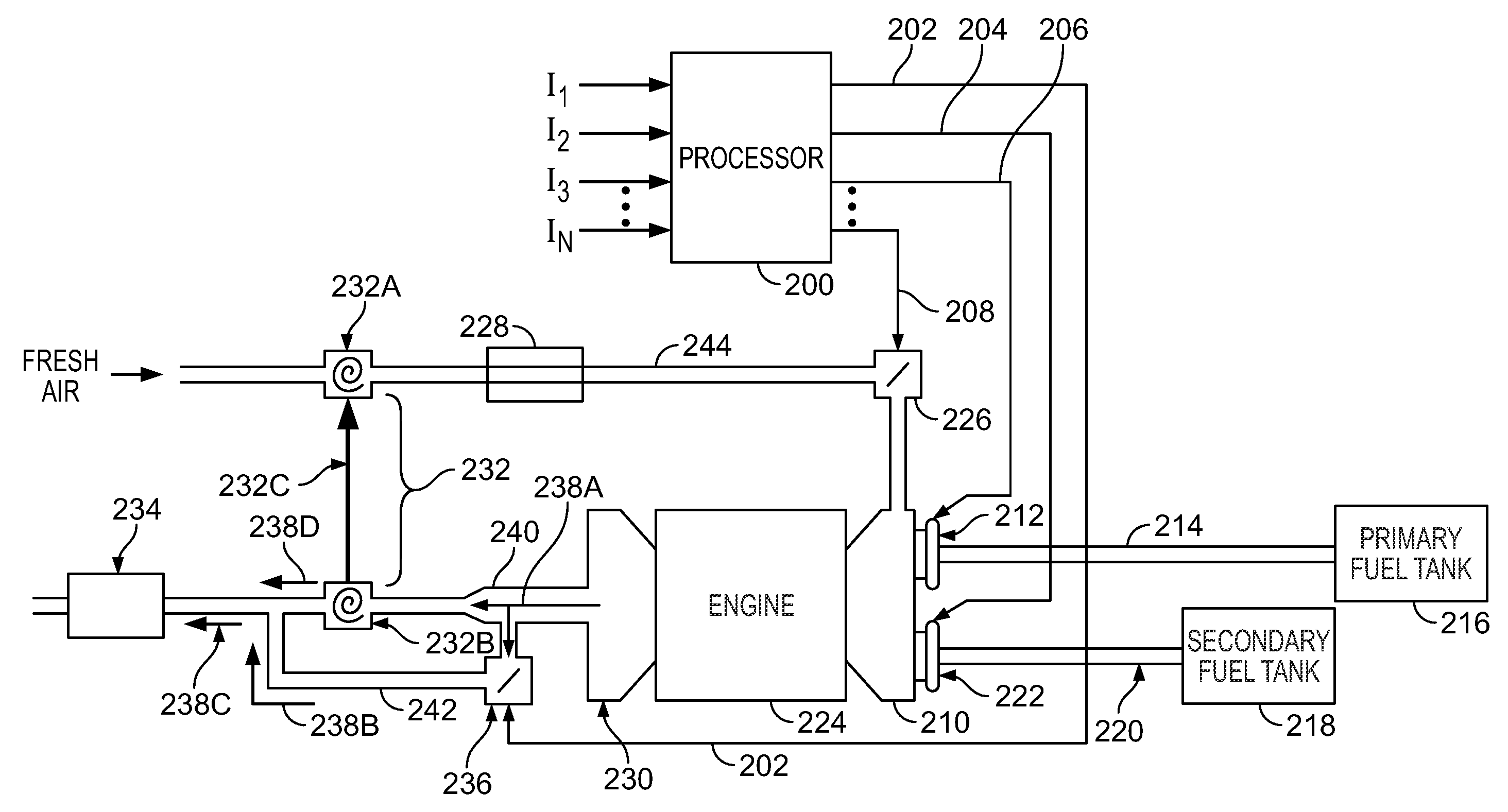

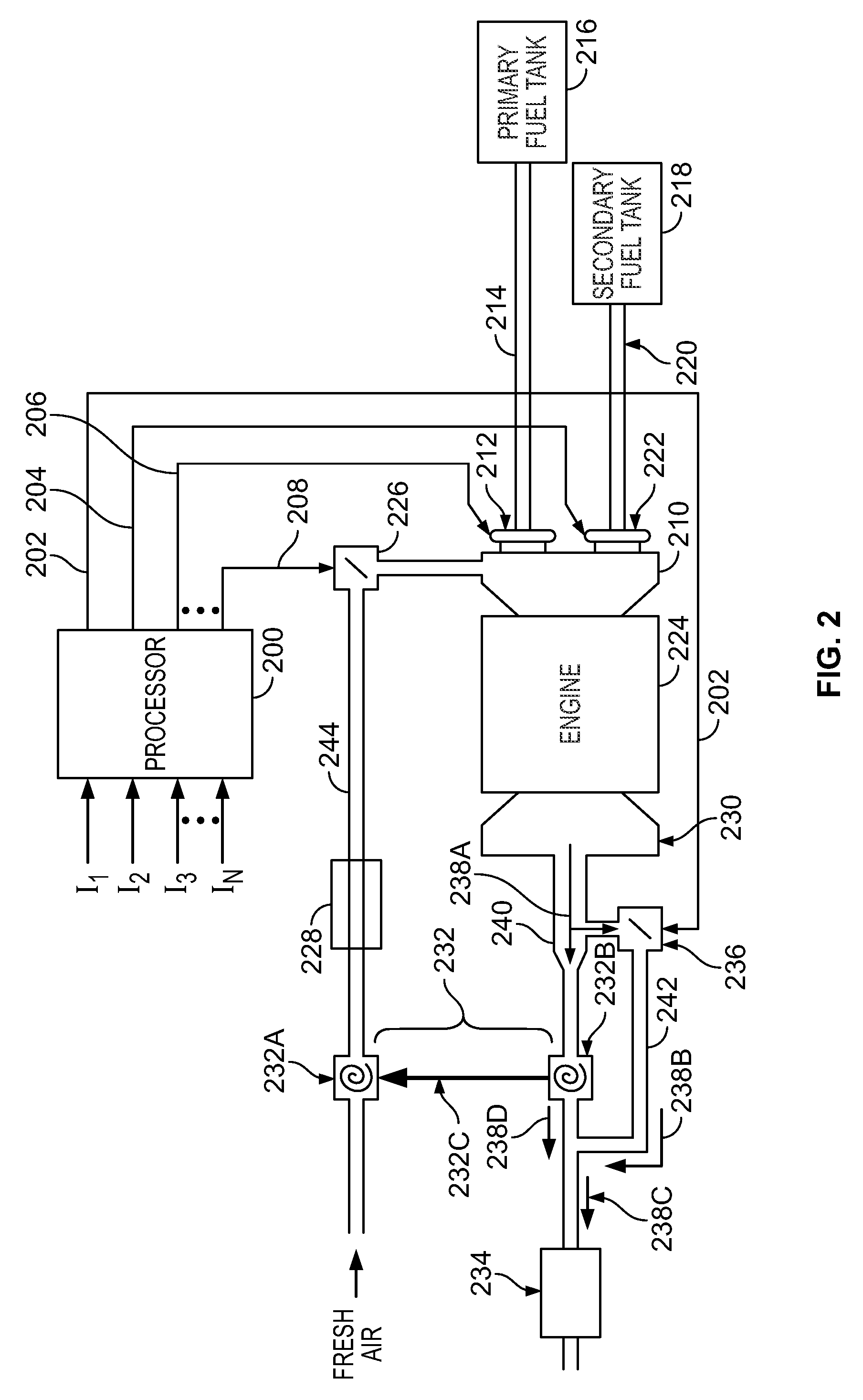

Bi-fuel engine with variable air fuel ratio

ActiveUS20110301826A1Reduce the temperatureReduction tendencyElectrical controlInternal combustion piston enginesGasoline fuelHydrogen fuel

A conventional gasoline engine is retrofitted to operate as a bi-fuel engine calibrated to burn Hydrogen gas as a primary fuel and gasoline as a secondary fuel at various acceptable air fuel ratios while avoiding forbidden air fuel ratios. The engine is preferably operated to burn Hydrogen fuel in a charged mode and in a lean mode at certain acceptable air fuel ratios where relatively very little NOx emissions occur. When additional power or acceleration is requested, processor controlled fuel injectors are operated to inject relatively small amounts of gasoline into the engine resulting in a fuel mixture that prevents increases in NOx emissions as the processor controls the engine to operate at a stoichiometric air fuel ratio where a catalytic converter is best able to reduce harmful emissions into the environment. The injection of the secondary liquid gasoline fuel to the gaseous Hydrogen fuel the temperature of the fuels significantly reduces or eliminates backfiring tendency of the engine. The engine has a safety feature in that the Hydrogen fuel is shut off if a leakage of Hydrogen is detected. The engine then operates with gasoline fuel used as a backup fuel.

Owner:H2 IP INVESTMENTS LTD

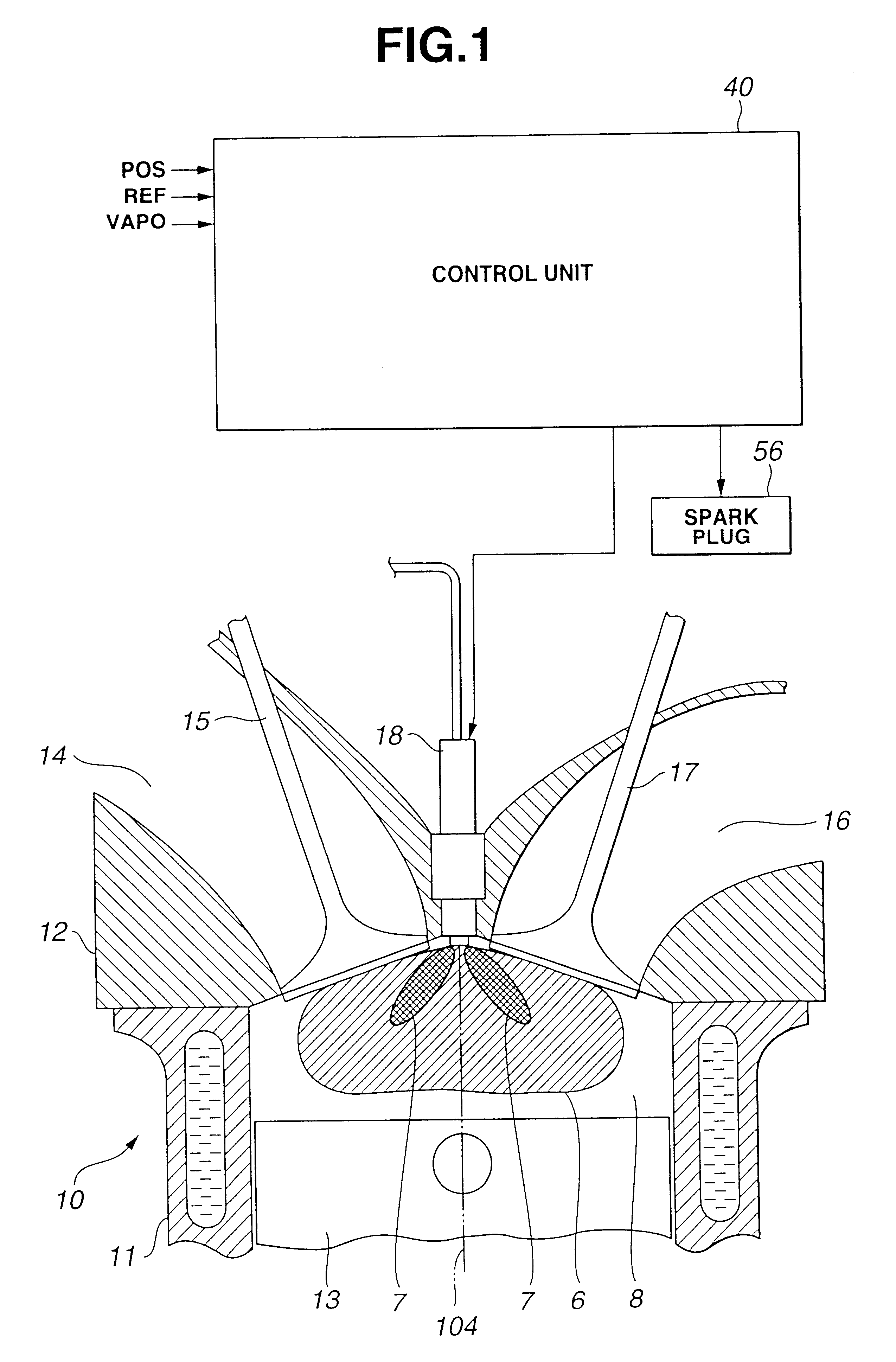

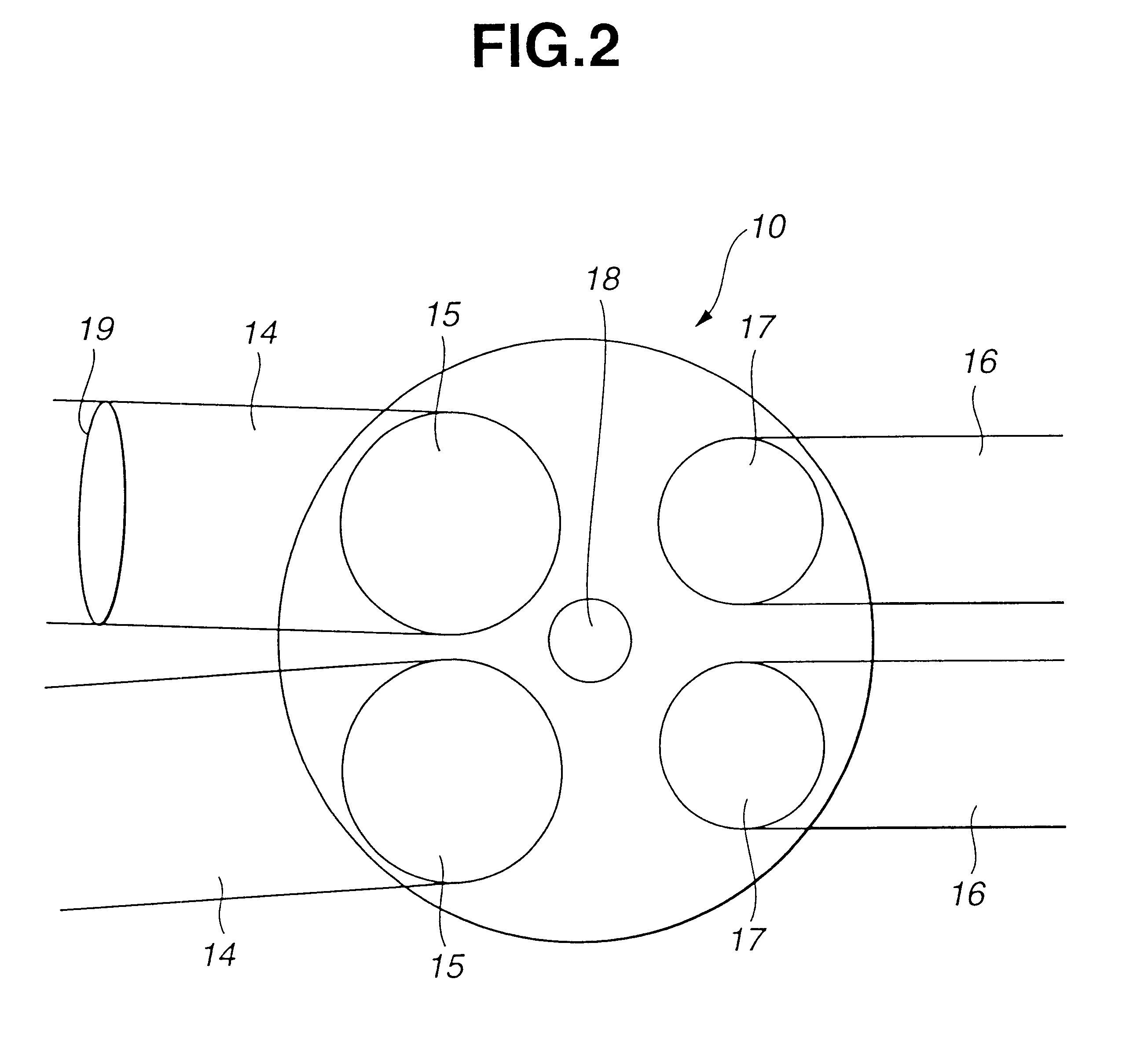

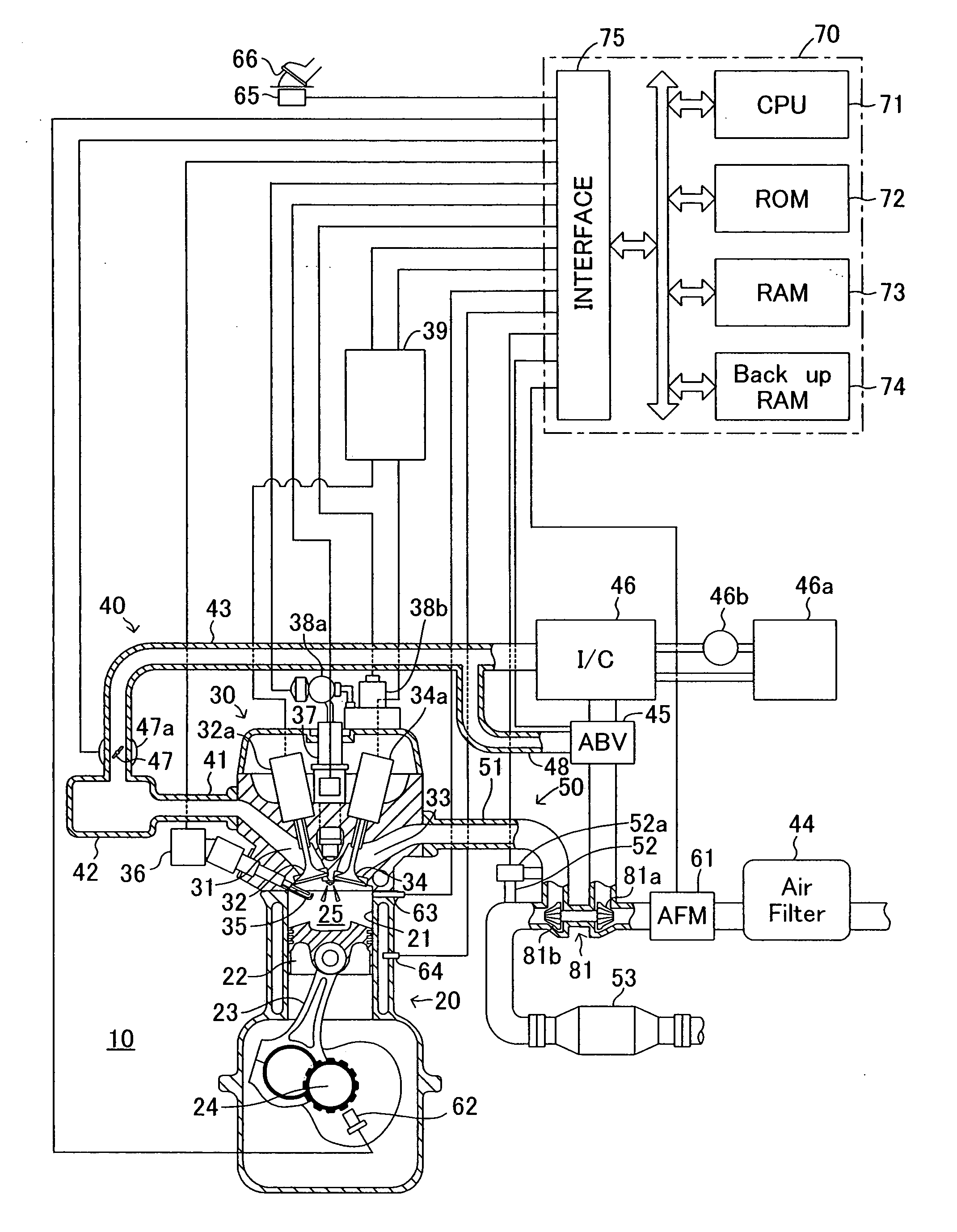

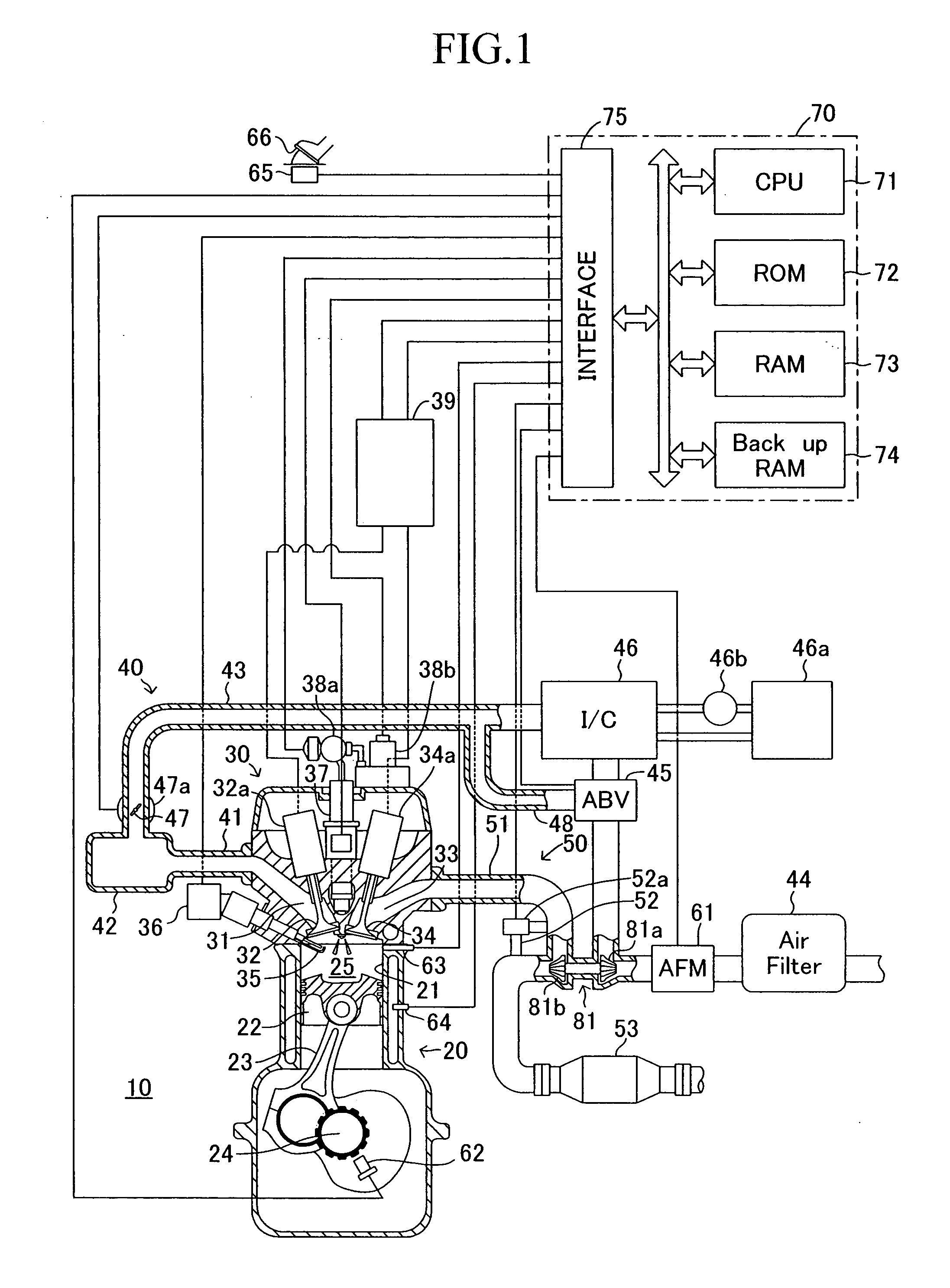

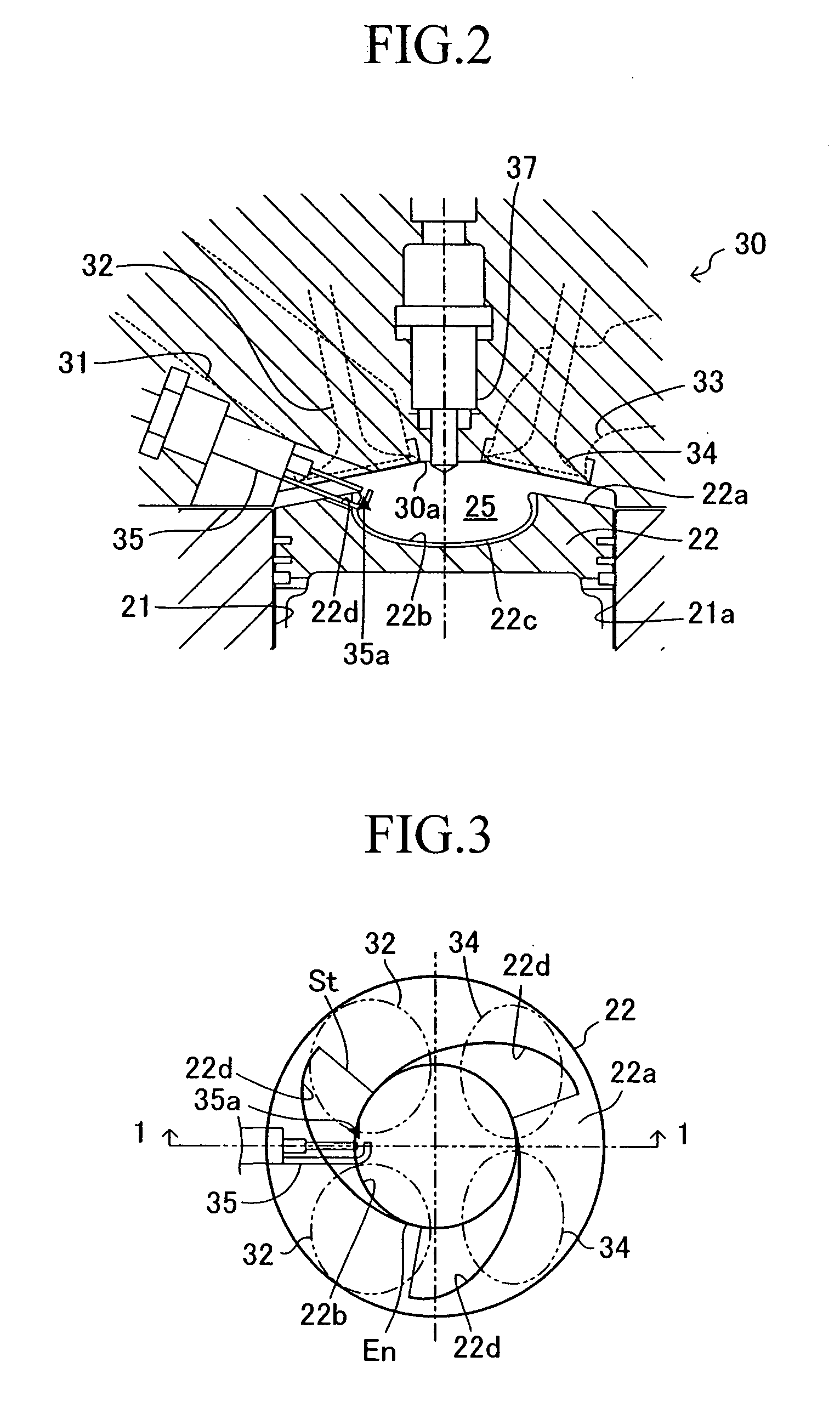

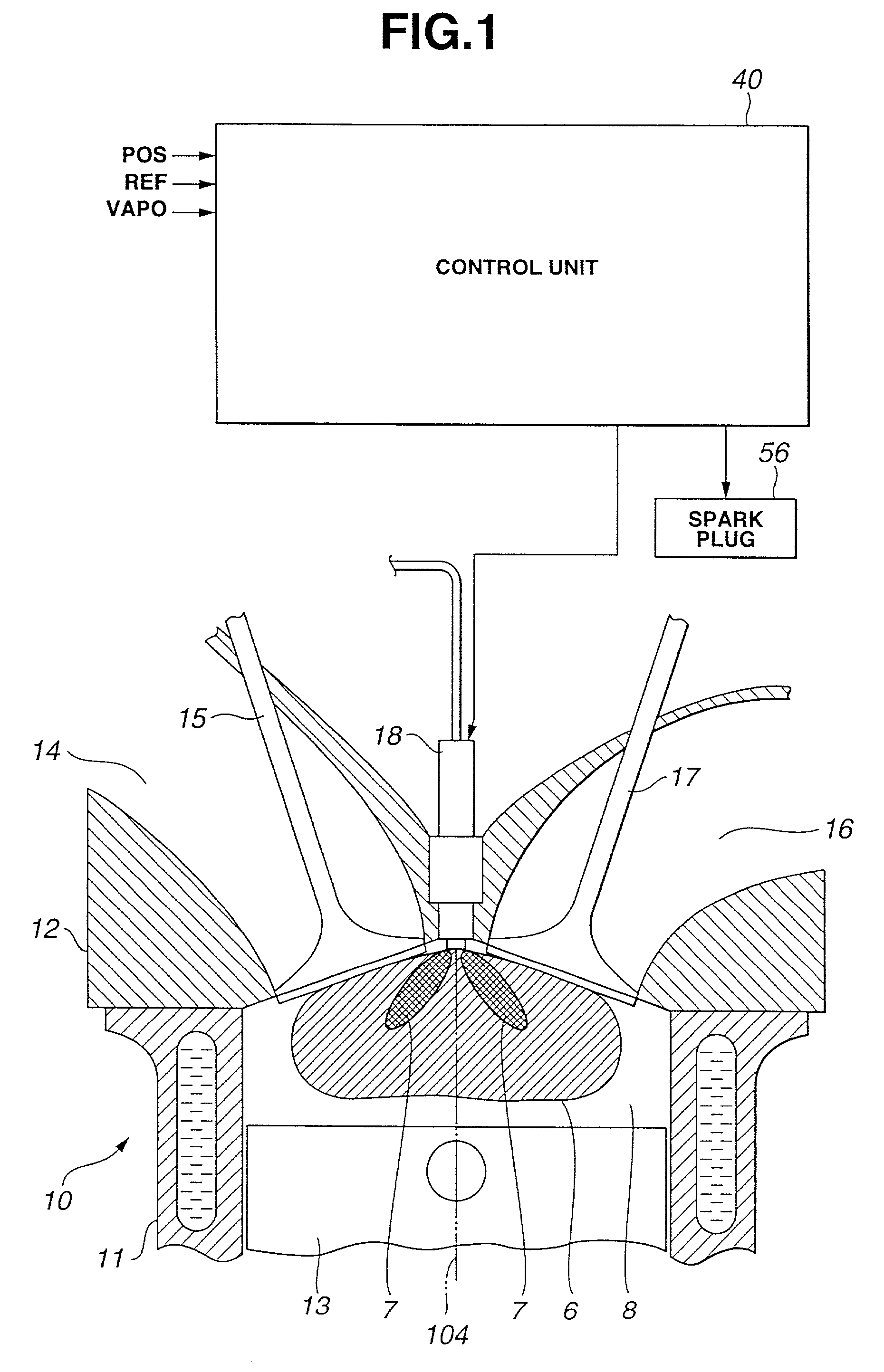

Internal Combustion Engine

ActiveUS20080275621A1Stably carry-outDegradation of combustionElectrical controlInternal combustion piston enginesCombustion chamberGasoline fuel

An internal combustion engine 10 includes a fuel injection valve 37 for injecting a gasoline fuel into a combustion chamber 25, and a spark plug 35. When the internal combustion engine is operated in a light-load region, the fuel is injected at an early and / or middle stage of an intake strode, whereby a homogeneous air / fuel mixture is formed and compressed to thereby perform a premixed-charge compression auto-ignition operation in which the fuel is auto-ignited and combusted. When the internal combustion engine is operated in a middle-load region, a spark-ignition combustion operation is performed. When the internal combustion engine is operated in a high-load region, air taken into the combustion chamber is compressed, and the fuel is injected into the compressed air, thereby performing a diffusion combustion operation in which the fuel is diffusion-combusted.

Owner:TOYOTA JIDOSHA KK

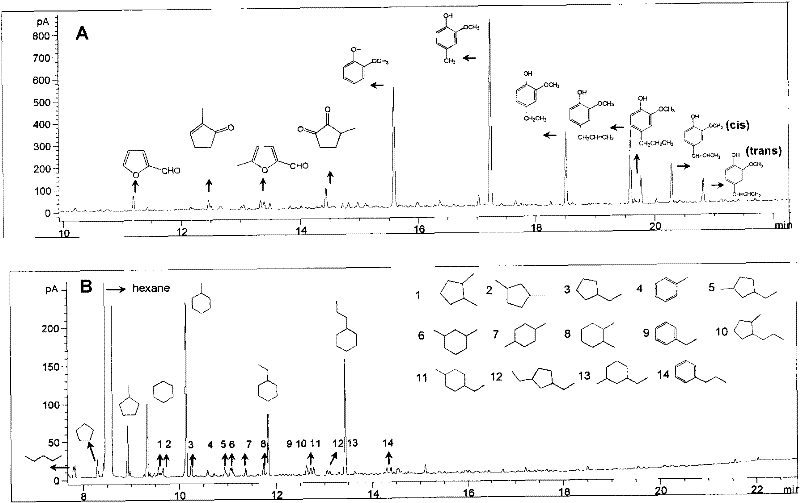

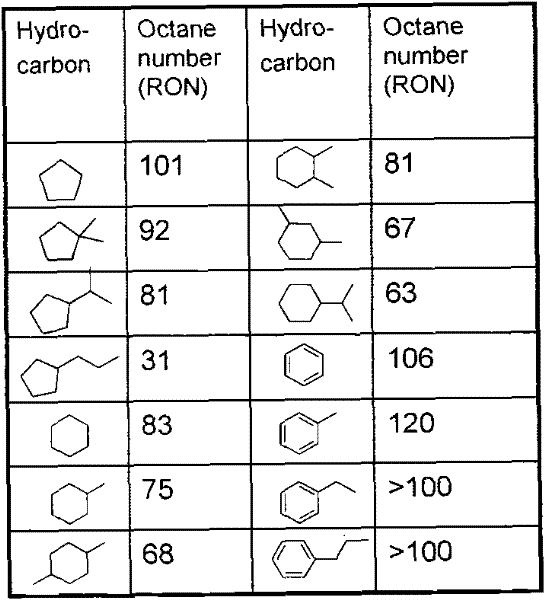

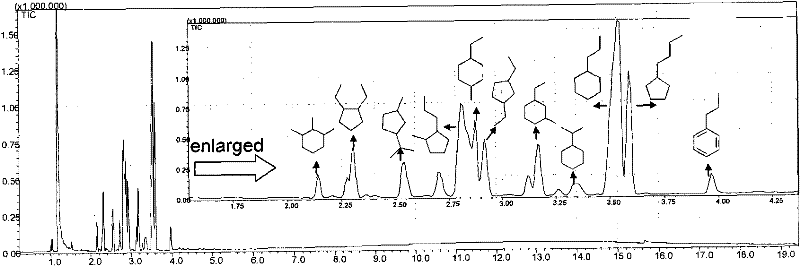

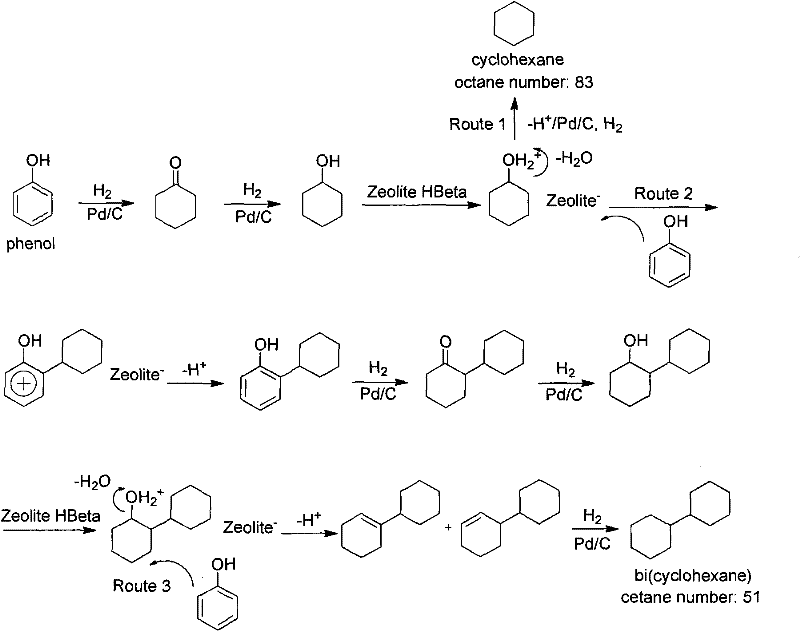

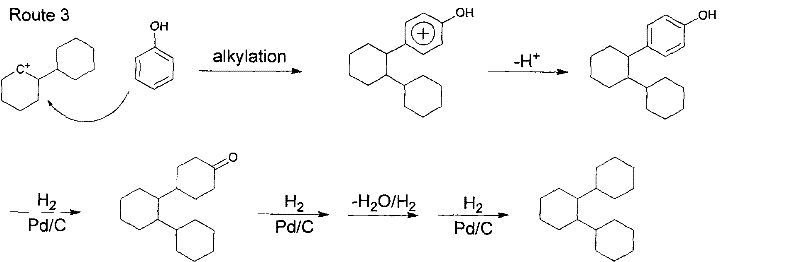

Method for preparing high-quality gasoline from cracking biological oil

InactiveCN102676201ASimple methodWay to save energyLiquid hydrocarbon mixture productionBio-feedstockFuranCellulose

The invention discloses a method for preparing high-quality gasoline from cracking biological oil and relates to the technical field of hydrocarbon fuel preparation. According to the method, crude biological oil, lignocellulose, xylogen, phenolic monomer derived from the xylogen or / and lignin of the xylogen, cellulose, and a furan compound derived from the cellulose are used as raw materials. Under the catalytic action of Ni / HMFI catalyst, the hydrocarbon fuel is obtained through one-step hydrogenation deoxidizing conversion. Most of hydrocarbon products in obtained refined biological oil belong to the range of naphthenic hydrocarbon and aromatic hydrocarbon, does not contain sulphur and nitrogen, and belongs to high-octane high-quality clean gasoline fuel. The method has the advantage of being economical (source of the raw materials is wide and cost is low), simple in process, environment-friendly and easy to industrialize and the like. The catalyst is low in cost, efficient and easy in mass production, and products have significant application requirements. The method plays an important role in the field of replacement of fossil energy by biomass energy in the future, and is wide in application prospects.

Owner:赵晨

Corrosion inhibitor compositions for oxygenated gasolines

ActiveUS20130227878A1Good storage stabilityReduce corrosionLiquid carbonaceous fuelsFuel additivesCarbon numberAlcohol

This invention relates to corrosion inhibitor additive combinations giving long acting performance in oxygenated gasoline blends comprising either low carbon number (<3) or high carbon number (greater than or equal to 4) alcohols or mixtures thereof and adapted for use in fuel delivery systems and internal combustion engines. The invention also is concerned with a process for conferring anti-corrosion properties to oxygenates in gasoline fuel mixtures wherein the oxygenate comprises biologically-derived butanol.

Owner:GEVO INC +1

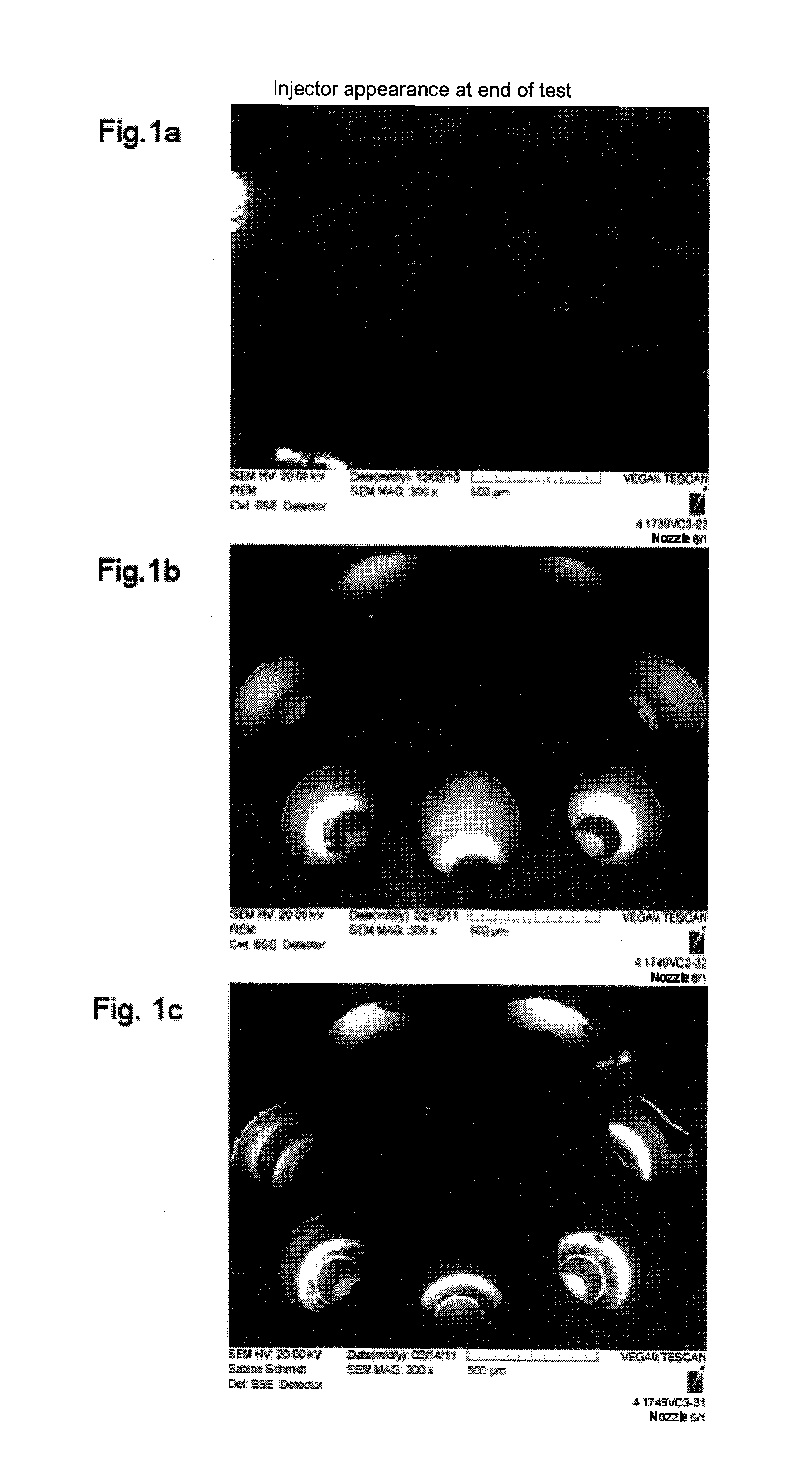

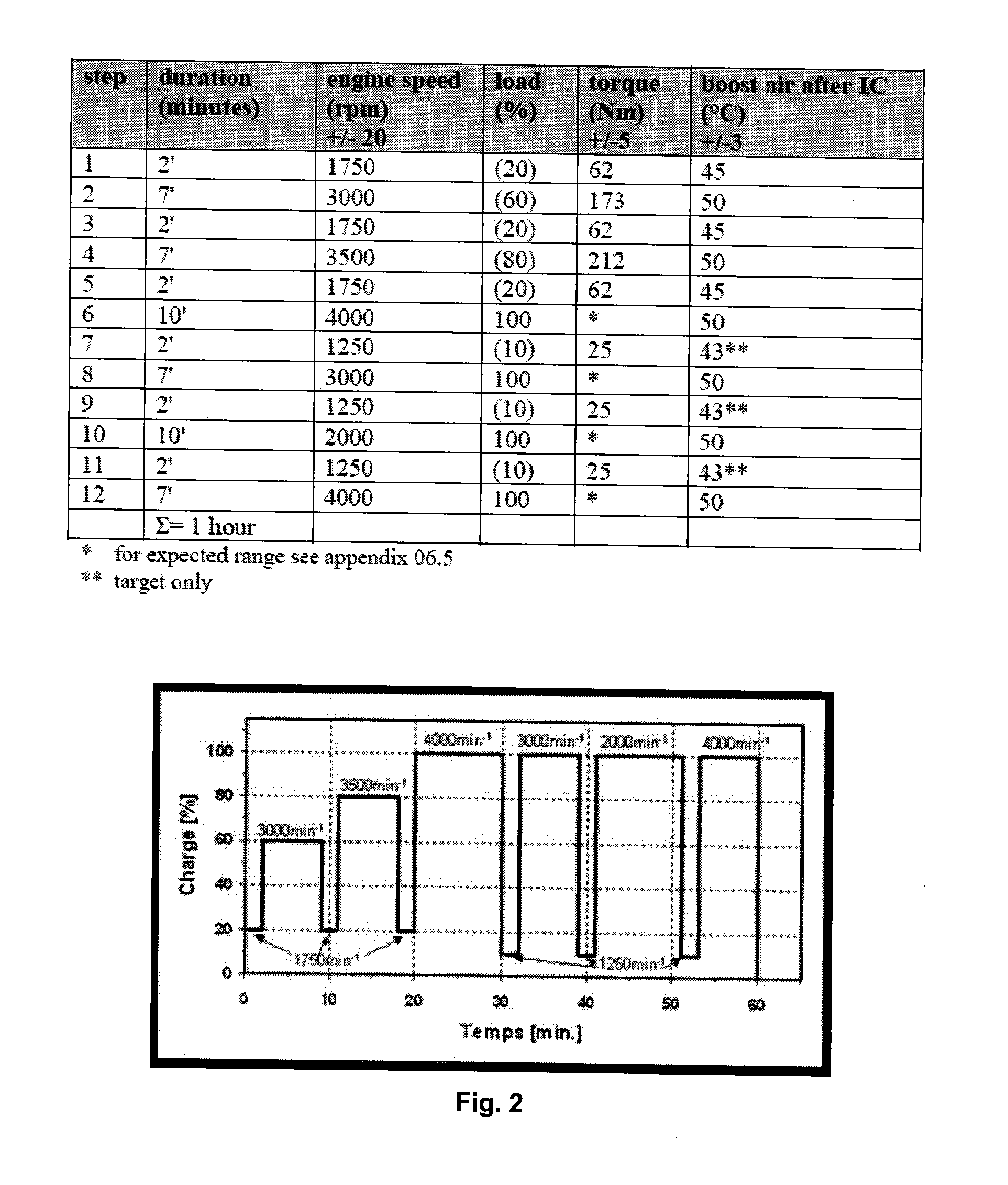

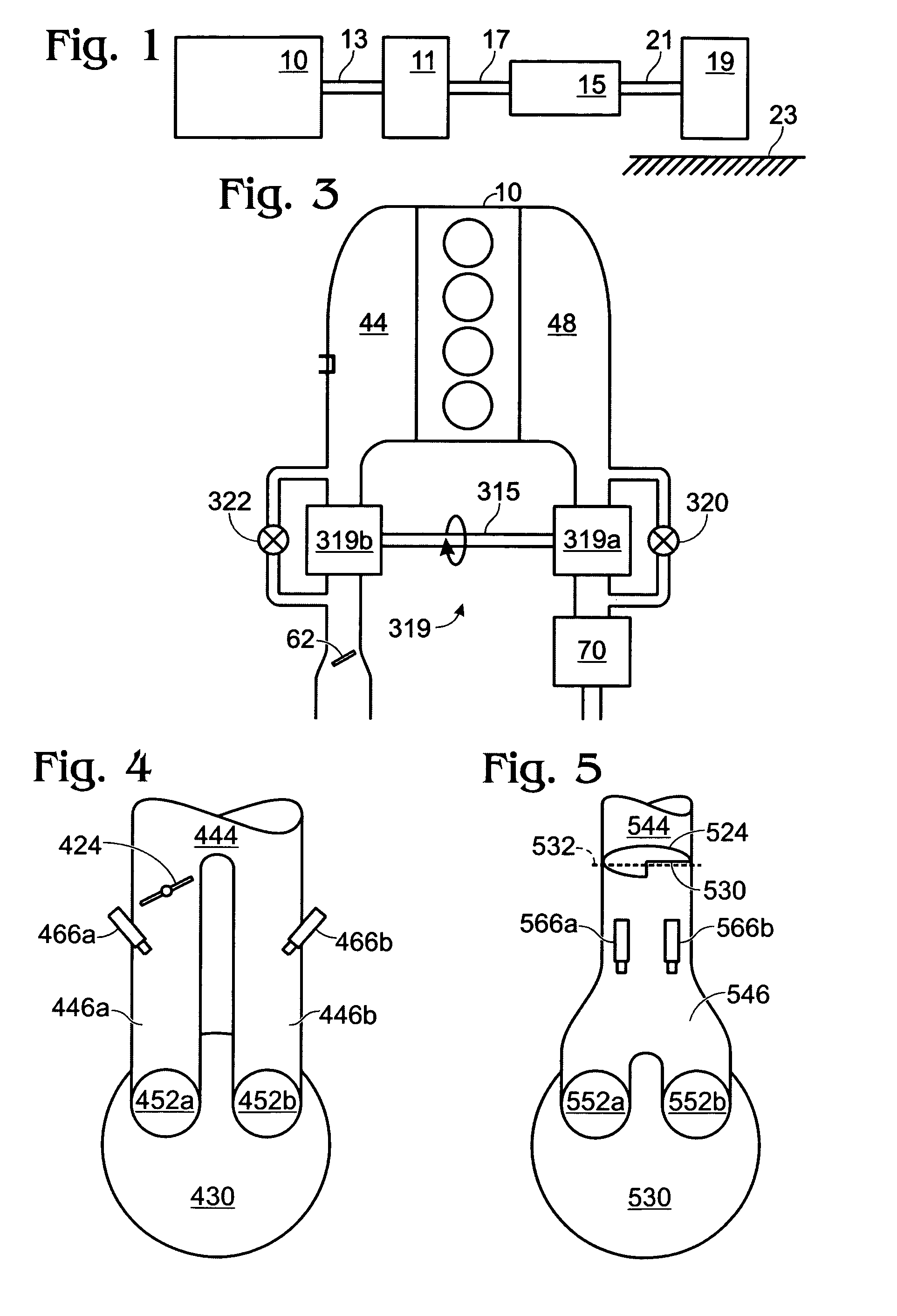

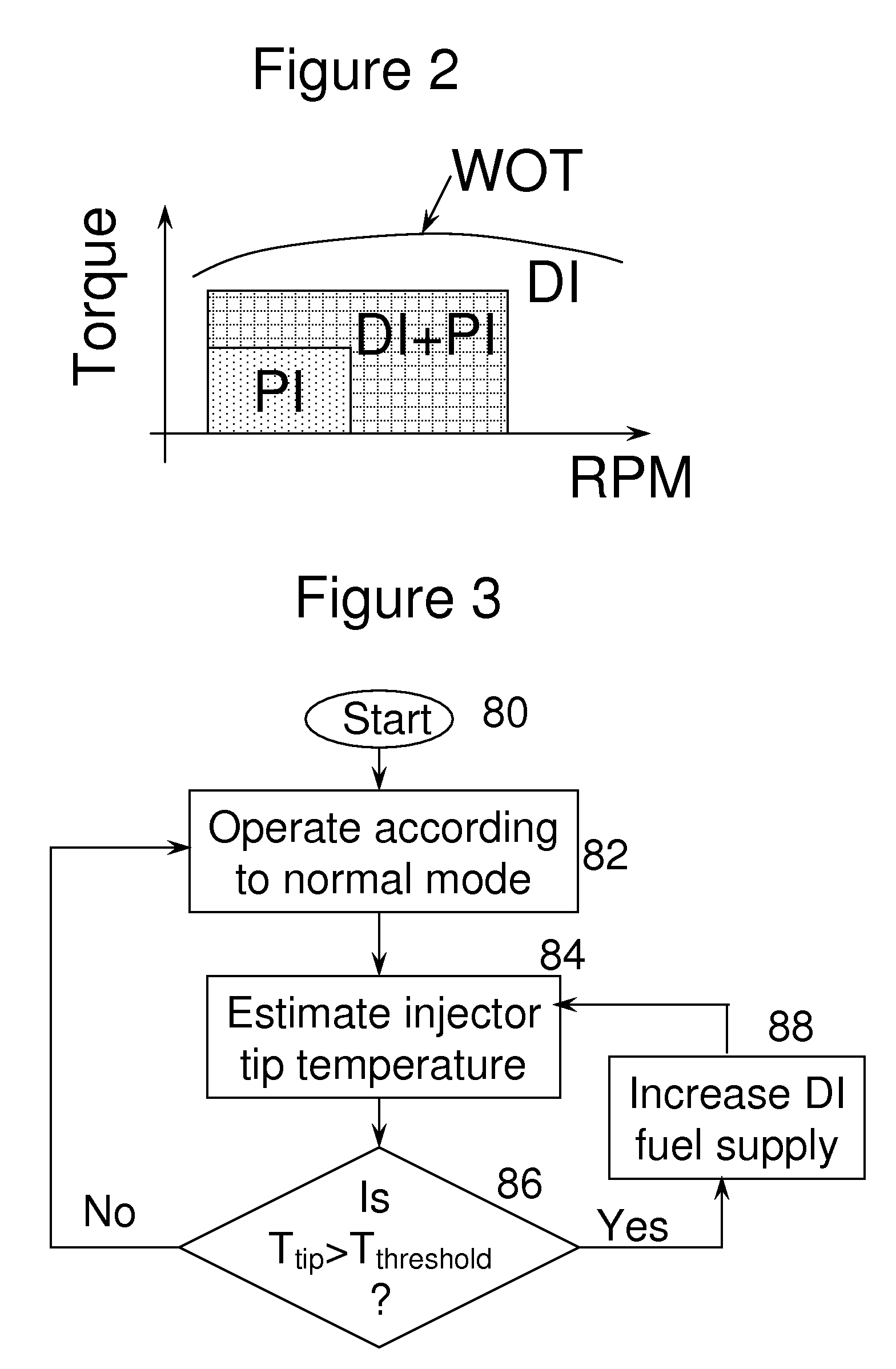

Method and System to Mitigate Deposit Formation on a Direct Injector for a Gasoline-Fuelled Internal Combustion Engine

InactiveUS20090090332A1Reduced deposit formationInhibition formationElectrical controlInternal combustion piston enginesGasoline fuelExternal combustion engine

In an internal combustion engine having both a port injector and a direct injector supplying fuel to a cylinder of the engine, a method is disclosed for avoiding deposit formation on and / or inside the tip of the direct injector. The tip temperature is estimated. When the tip temperature exceeds a threshold temperature at which deposits are formed, the amount of fuel delivered by the direct injector is increase.

Owner:FORD GLOBAL TECH LLC

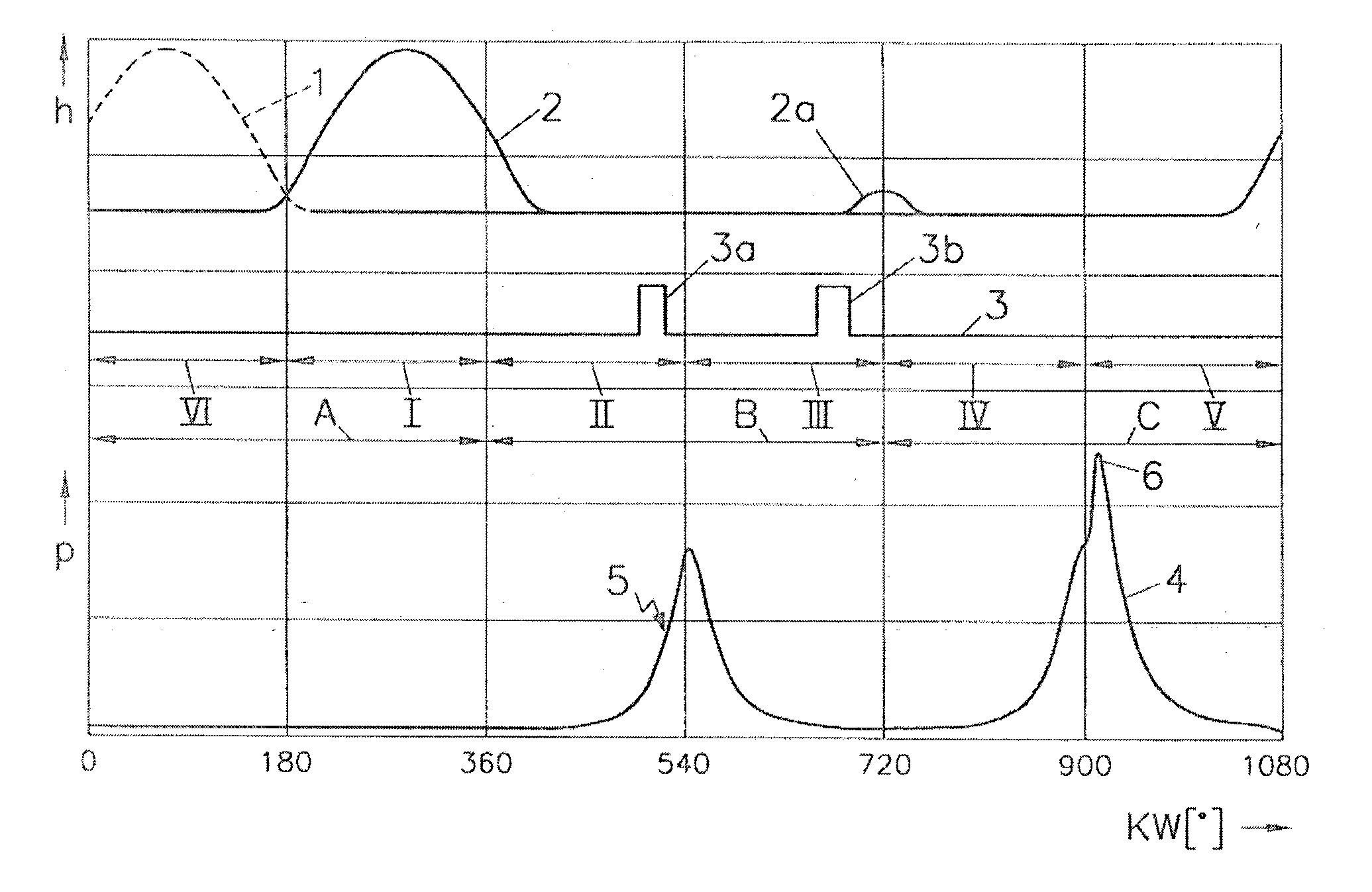

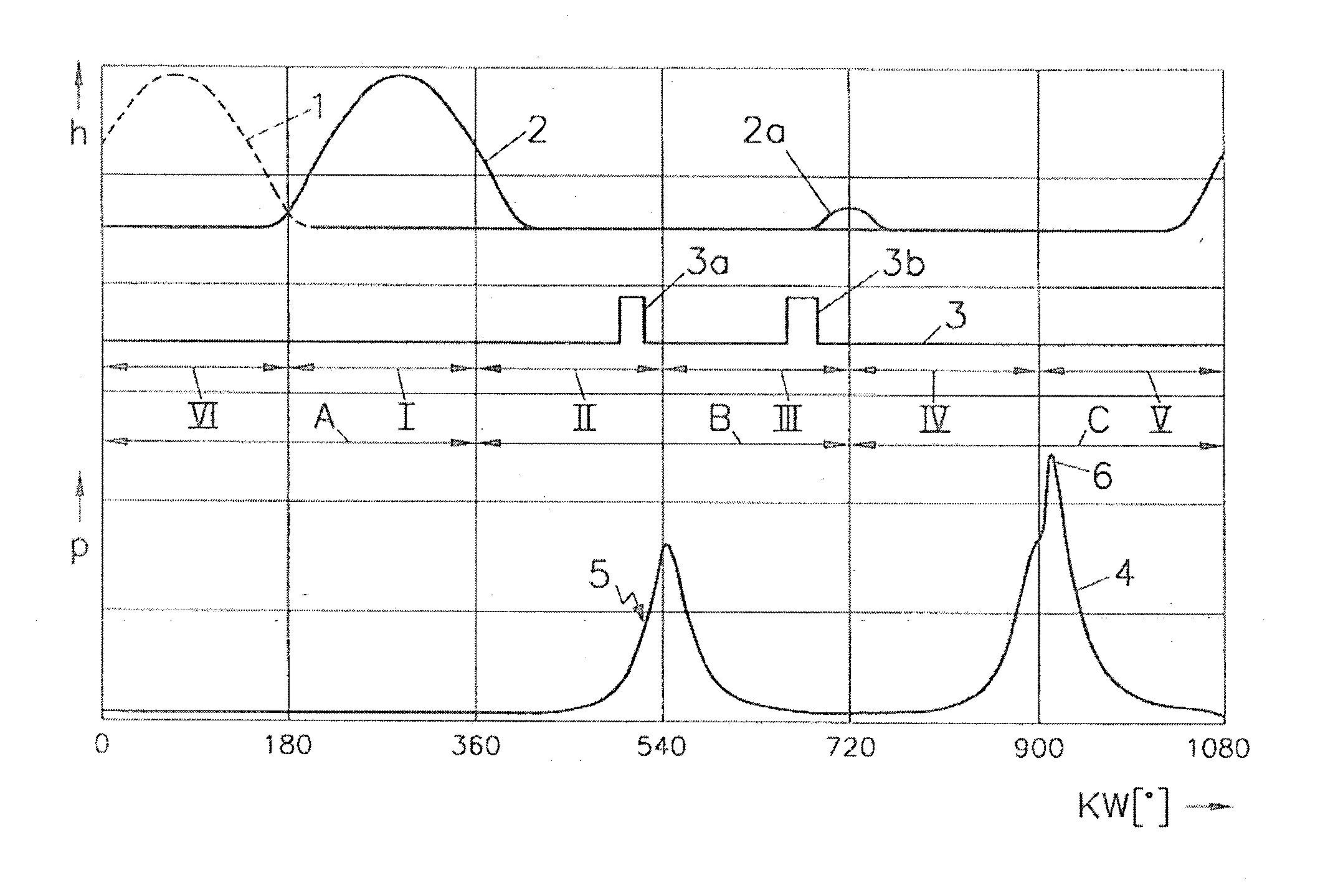

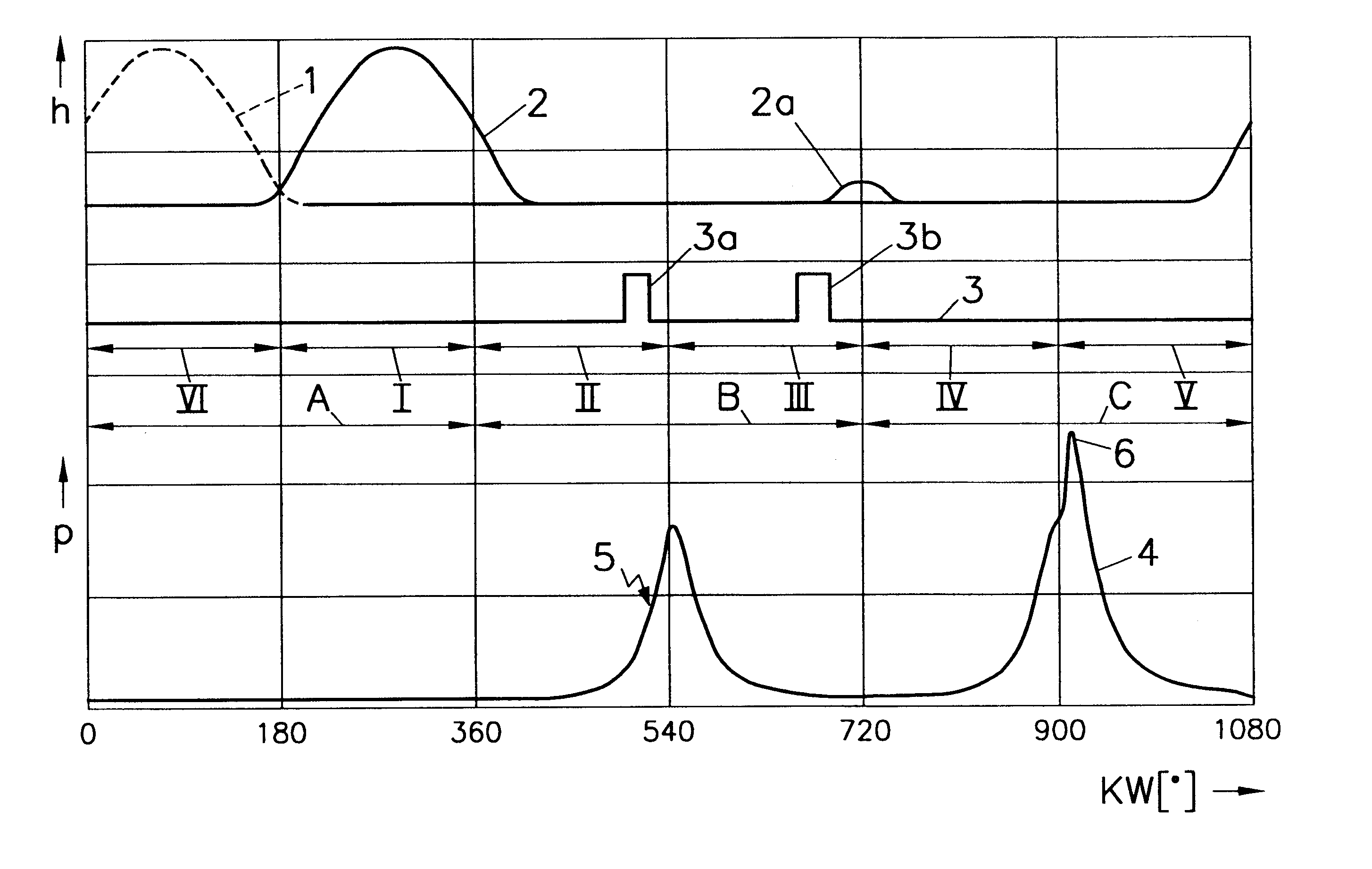

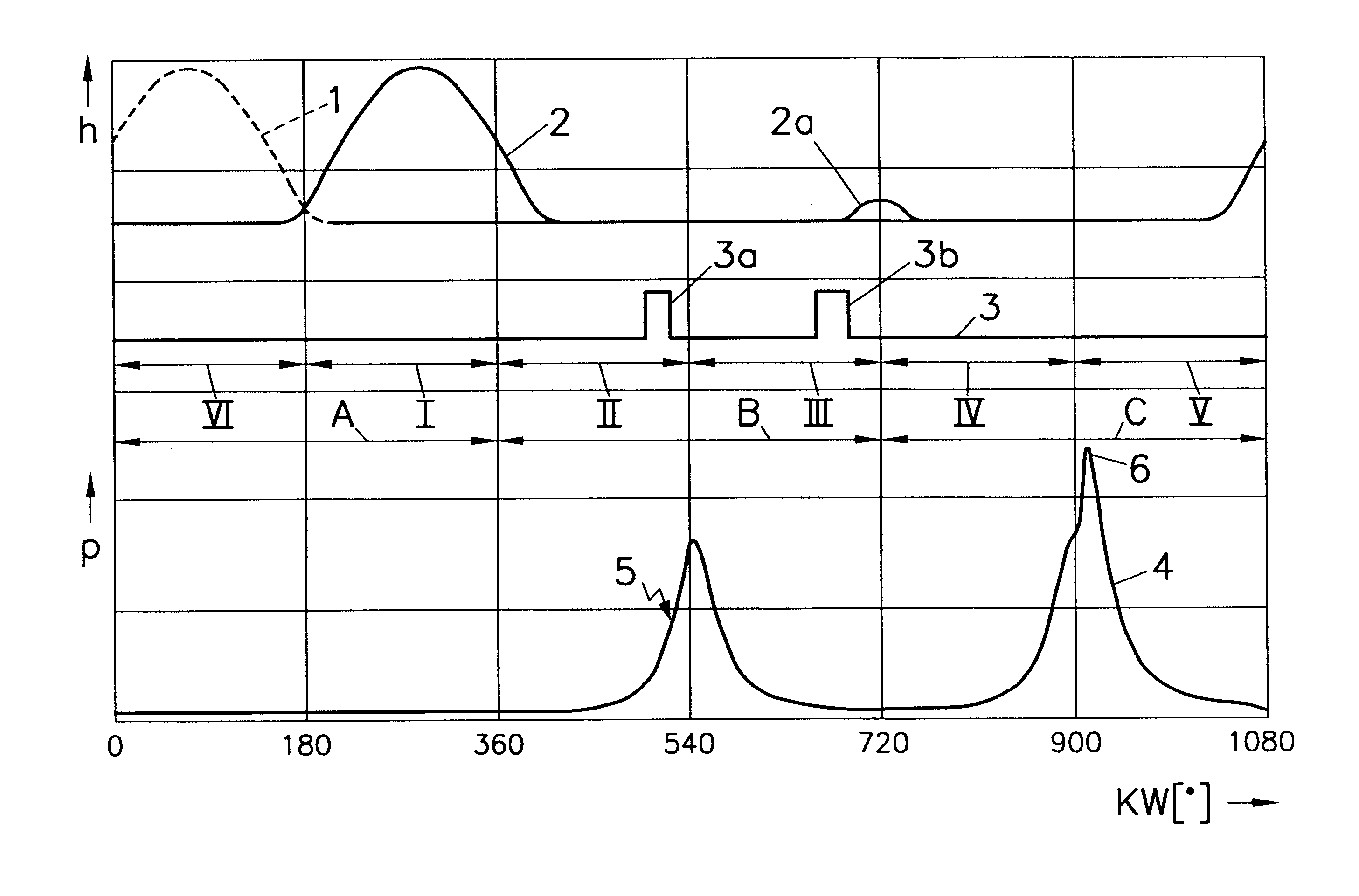

Method of operating an internal combustion engine

InactiveUS20040123822A1Reduce lossHigh consumption potentialCombustion enginesExternal combustion engineGasoline fuel

The invention relates to a method of operating an internal combustion engine with a six-stroke process involving the following sequence of events: 1<st >stroke (I): air intake into the combustion chamber, 2<nd >stroke (II): compression of the air and injection (3a) of a first fraction of gasoline fuel into the combustion chamber, 3<rd >stroke (III): first working stroke after first ignition (5) of the mixture, said ignition (5) being initiated by an ignition device, 4stroke (IV): new compression of the contents of the combustion chamber, 5stroke (V): second working stroke after second ignition (6) of the fuel-air mixture contained in the combustion chamber, 6stroke (VI): expulsion of the exhaust gases from the combustion chamber, a second fraction of gasoline fuel being injected (3b) prior to the second ignition (6). In order to achieve the lowest possible fuel consumption and low emissions in an internal combustion engine it is suggested that the second fraction of gasoline be injected (3b) during the third stroke (III), preferably during the second half of the third stroke (III), that an at least almost homogeneous fuel-air mixture be formed in the combustion chamber prior to the second ignition (6) and that the second ignition (6) occurs by compression ignition of said homogeneous fuel-air mixture.

Owner:AVL LIST GMBH

Auto-ignition combustion management in internal combustion engine

InactiveUS20010022168A1High densityElectrical controlCombustion enginesCombustion chamberTop dead center

An enhanced auto-ignition in a gasoline internal combustion engine, comprises a fuel injector directly communicating with said combustion chamber for spraying gasoline fuel. The fuel injector sprays a first injection quantity of gasoline fuel into a combustion chamber at first fuel injection timing, which falls in a range from the intake stroke to the first half of the compression stroke, thereby to form air / fuel mixture cloud that becomes a body of mixture as the engine piston moves from the first fuel injection timing toward a top dead center position of the compression stroke, and the fuel injector sprays a second injection quantity of gasoline fuel into the body of mixture at second fuel injection timing, which falls in the second half of the compression stroke, forming mixture cloud that is superimposed on a portion of said body of mixture, thereby to establish the cylinder content wherein the density of fuel particles within the superimposed portion is high enough to burn by auto-ignition at an ignition point in the neighborhood of the piston top dead center position of the compression stroke, causing temperature rise and pressure, which initiate auto-ignition of the fuel particles within the remaining portion of said body of mixture.

Owner:NISSAN MOTOR CO LTD

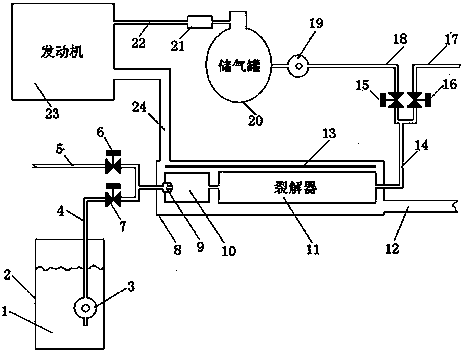

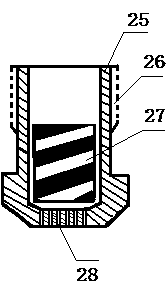

Hydrogen engine system

InactiveCN103352777AAvoid poisoningAvoid failureInternal combustion piston enginesNon-fuel substance addition to fuelCatalytic reformingAlcohol

A hydrogen engine system is a low-carbon engine system which takes hydrogen-enriched gas produced by using alcohol cracking as fuel. The hydrogen engine system comprises a fuel storage tank and a fuel conveying device, a fuel heating gasifying and cracking device, a hydrogen-enriched gas compressor and an exhaust discharging pipe, wherein the fuel storage tank is connected with the fuel conveying device and then connected to the fuel heating gasifying and cracking device; fuel passes through the hydrogen-enriched gas compressor and is then input into an automobile engine to do work; the fuel heating gasifying and cracking device is installed inside a high-temperature chamber formed by an exhaust discharging device. The hydrogen engine system rarely changes an original gasoline-fueled automobile, keeps a function that the original automobile uses gasoline as fuel, and has unchanged dynamic performance; when an engine is started through cold start and no alcohol is supplied or a storage battery is low in power in the running process, common gasoline can be still used for driving the automobile or heating up a cracker to reach heat and temperature which are required by catalytic reforming hydrogen production, so that the hydrogen engine system has a good development prospect.

Owner:GUANGXI DIKAI SCI & TECH

Universal synthetic gasoline fuel conditioner additive, method and product-by-process

ActiveUS7931704B2Improve the lubrication effectReduce failureLiquid carbonaceous fuelsAdditivesGasoline fuelKetone

A process of producing a universal synthetic based gasoline fuel additive that cleans the fuel system including valves surface, lubricates the fuel pump, injectors and valves while allowing for a clean and more efficient burn. A major portion will consist of (a) Alfa-Olefins, (b) 2-propanol (c) Hydroisomerized High VI HT Base Oils, (d) Dimethyl Ketones, (e) Low Flash Mineral Spirits, (f) Low Aromatic Solvent, (g) Isomer Reformate, (h) Solvent Activated Dye. In a preferred embodiment, this universal synthetic gasoline conditioner additive for improving lubrication comprises: alpha-olefins comprising from 5 to 30 percent thereof, by weight; low odor aromatic solvents comprising from 3 to 27 percent thereof, by weight; 2-Propanol comprising of 3 to 30 percent thereof, by weight; and at least one a base oil comprising from 0.50 to 15 percent thereof, by weight; wherein: the percentages by weight are specified in relative proportion to one another.

Owner:BESTLINE INT RESEACRH

Power modulated, dual fuel, small displacement engine control system

InactiveUS20090076705A1Improve fuel economyEmission reductionElectrical controlInternal combustion piston enginesAlternative fuelsDetonation

An engine capitalizes on the advantages of alternative fuels such as ethanol, E-85, and other alcohols, with a small displacement engine, two cylinders or more, and at least a divided fuel tank or alternatively two tanks. An electronic engine control module selects the fuel for operating conditions and delivers the fuel through separate injection systems. The module selects unleaded gasoline for starting, light load and light cruising conditions. Upon greater demands for engine power, the module adds or switches entirely to a secondary fuel such as alcohol, ethanol, E-85 or other ethanol / gasoline blends and reduces or eliminates the introduction of gasoline fuel. The secondary fuel provides more power than unleaded gasoline, thus reducing the engine displacement required for operating a vehicle under a variety of loads. The present invention seeks a substantial engine power increase, reduction in engine detonation, improved cold starting, re-evaluation of turbochargers, a decrease in gasoline consumption, and gasoline as the default fuel.The engine control system allows a small and efficient engine to deliver increased power upon demand over conventional automotive engines. The system modulates boost pressure when using a secondary fuel for operations at an increased power level. The power level increase occurs from the combination of lower stoichiometric, or higher octane, fuel and increased dynamic intake pressures. The system maintains engine power as low, with little or no intake boost pressure, and the gasoline, 85 octane minimum, is delivered through injectors. When higher power is demanded, the system increases boost pressure, at intake, while a secondary power fuel (ethanol, E-85, alcohol and the like), is injected.

Owner:COLESWORTHY ROBERT L +1

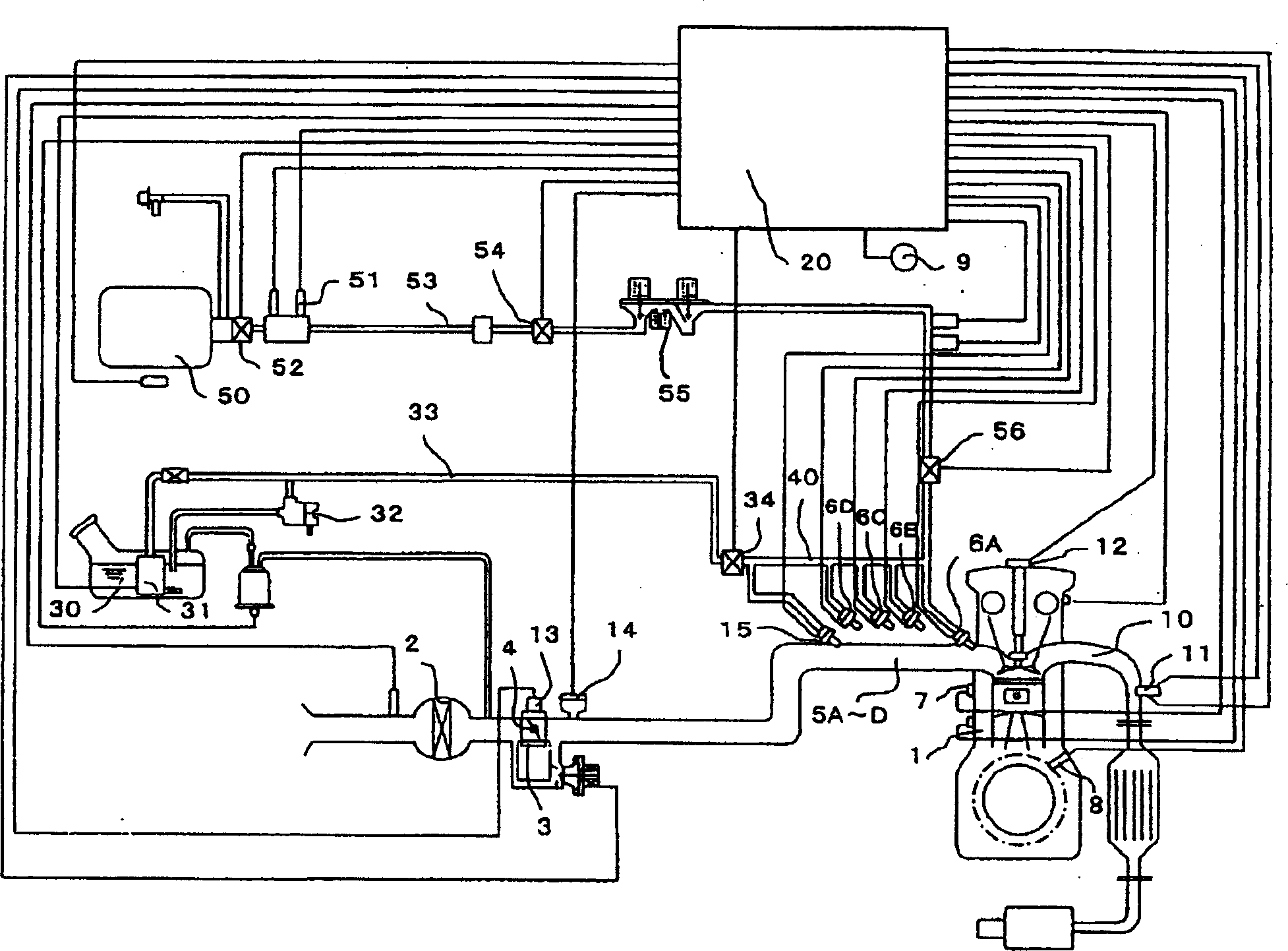

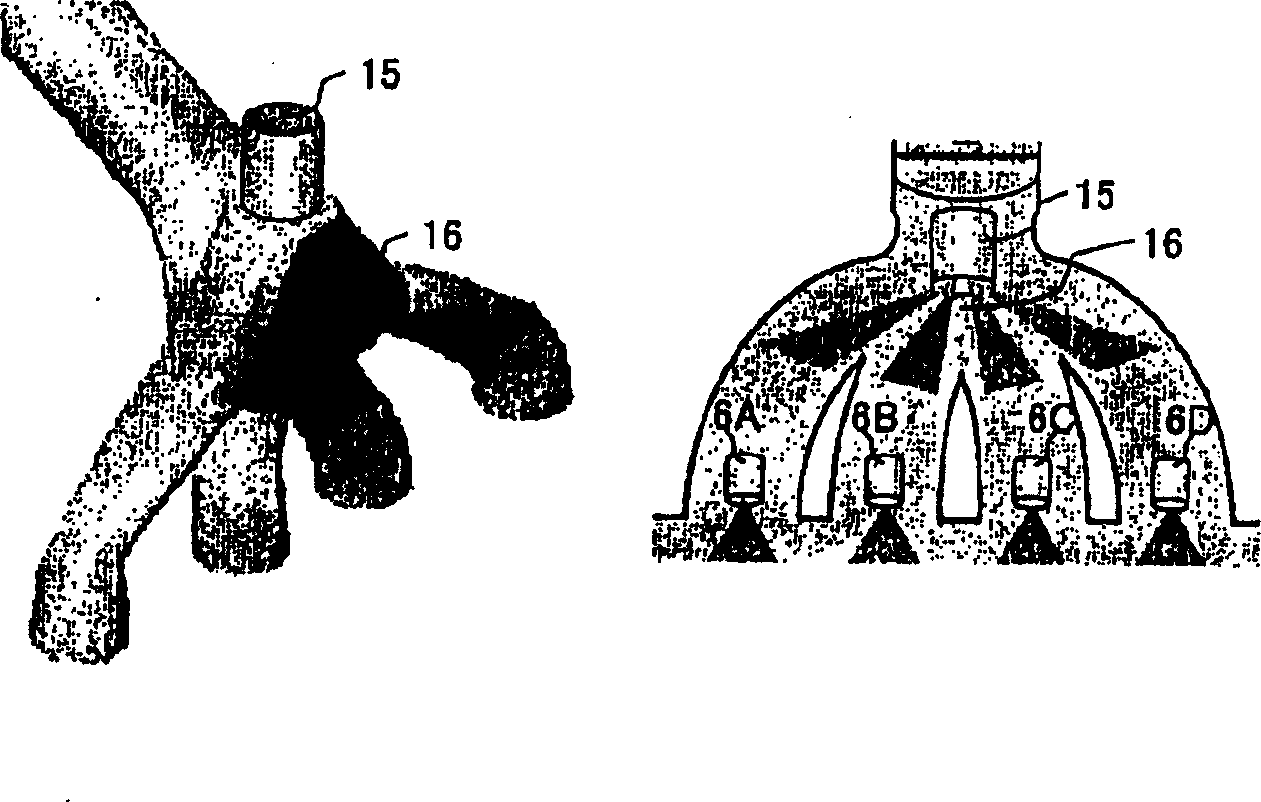

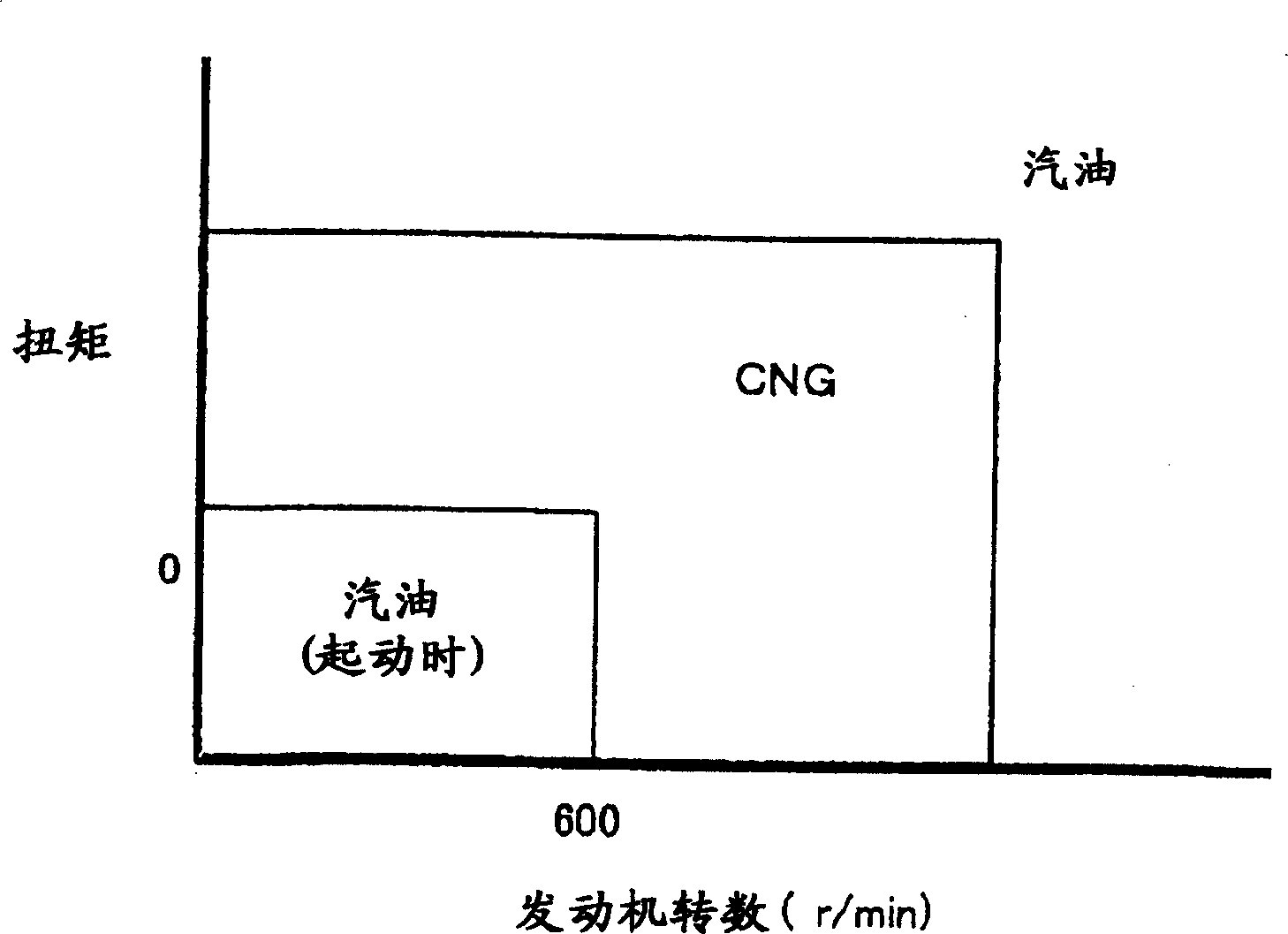

Fuel injection control method and device of double-fuel internal-combustion engine

A bi-fuel internal combustion engine is intended for suppressing consumption of gasoline fuel and reducing exhaust emissions; under ordinary operations, a CNG fuel emitting smaller amounts of NOx, HC, CO, and the like as compared with a gasoline fuel, is used as a supply fuel to reduce the exhaust emissions; in this case, a fuel injection device is required for each of the two types of fuel, that is, the gasoline fuel and the CNG fuel and the problem is torque change and fluctuation occurring when the fuel is switched from gasoline to CNG, or vice versa. Control is provided for correcting a fuel injection quantity, an intake air quantity, and ignition timing when the type of fuel supplied to the engine is switched from one type to another. A single fuel injector is used as both an injector of gasiform fuel and an injector of liquid fuel.

Owner:HITACHI LTD

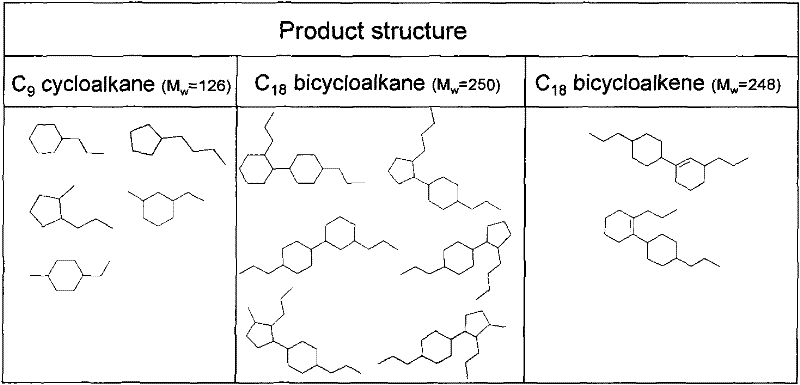

Method for preparing high-quality gasoline and diesel oil from lignin pyrolysis oil

InactiveCN102676202AWide variety of sourcesLow costLiquid hydrocarbon mixture productionBio-feedstockAlkaneGasoline fuel

The invention discloses a method for preparing high-quality gasoline and diesel oil from lignin pyrolysis oil, and belongs to the technical field of preparation of liquid fuel. The method comprises the steps of using lignin pyrolysis oil, crude biological oil, lignin, phenolic monomer and / or dipolymer derived from the lignin as materials, and converting the materials into C6-C9 gasoline and C10-C20 diesel oil hydrocarbon fuel with adjustable ratio under the catalytic action of Ni-based or Pd-based catalyst loaded on a molecular sieve, wherein the major ingredients of the obtained gasoline are C6-C9 cycloalkanes and aromatic hydrocarbons and belong to clean gasoline fuel with high octane value and high quality; while the major ingredients of the diesel oil are C12-C20 bicyclic alkanes, the cetane number is between 51-60, and the diesel oil does not contain polycyclic aromatic compound or sulphur or nitrogen and belongs to the clean high-quality diesel fuel. The method disclosed by the invention has the advantages of wide material source, low cost, clever reaction process, efficient coupling, simple and green process, easiness of industrialization, large product requirement, very broad application prospect and the like.

Owner:赵晨

Method of operating an internal combustion engine

InactiveUS6758174B1Improve efficiencyEmission reductionCombustion enginesExternal combustion engineGasoline fuel

The invention relates to a method of operating an internal combustion engine with a six-stroke process involving the following sequence of events:1<st >stroke (I): air intake into the combustion chamber,2<nd >stroke (II): compression of the air and injection (3a) of a first fraction of gasoline fuel into the combustion chamber,3<rd >stroke (III): first working stroke after first ignition (5) of the mixture, said ignition (5) being initiated by an ignition device,4stroke (IV): new compression of the contents of the combustion chamber,5stroke (V): second working stroke after second ignition (6) of the fuel-air mixture contained in the combustion chamber,6stroke (VI): expulsion of the exhaust gases from the combustion chamber,a second fraction of gasoline fuel being injected (3b) prior to the second ignition (6).In order to achieve the lowest possible fuel consumption and low emissions in an internal combustion engine it is suggested that the second fraction of gasoline be injected (3b) during the third stroke (III), preferably during the second half of the third stroke (III), that an at least almost homogeneous fuel-air mixture be formed in the combustion chamber prior to the second ignition (6) and that the second ignition (6) occurs by compression ignition of said homogeneous fuel-air mixture.

Owner:AVL LIST GMBH

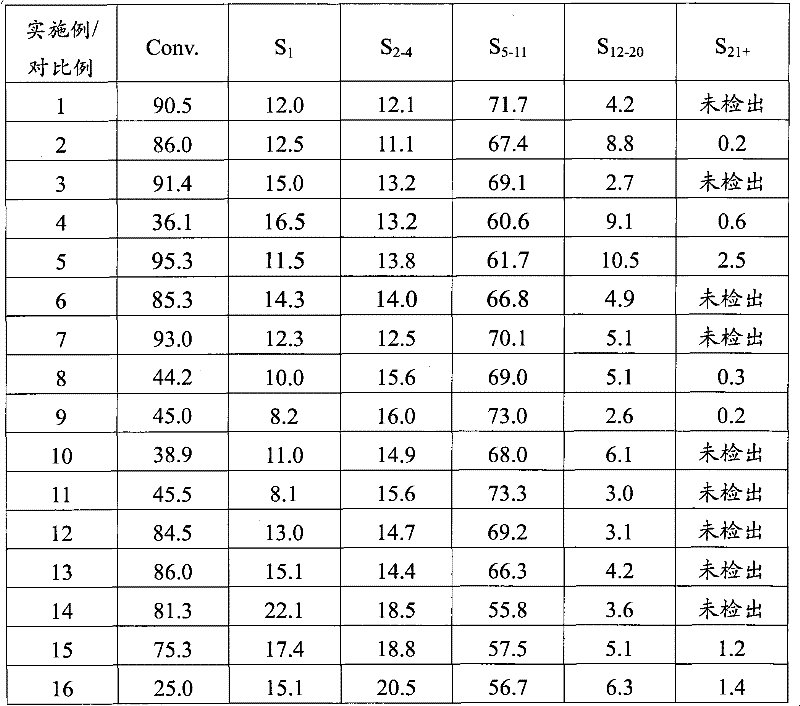

Catalyst for preparing high-quality gasoline fraction by virtue of syngas high selectivity and preparation method thereof

InactiveCN102211034AReduce stickingReduce pipe blockage and other problemsMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneMolecular sieve

The invention provides a catalyst for preparing a high-quality gasoline fraction by virtue of syngas high selectivity and a preparation method thereof. The catalyst comprises the following components in percentage by weight: 1-30% of metallic cobalt, 0.01-5% of assistant elements and the balance of molecular sieve. The catalyst has good selectivity to isoparaffin with 5-11 carbon atoms and quite low selectivity to the waxy hydrocarbons with more than 20 carbon atoms, so that the catalyst can be used for preparing high-quality gasoline fuels, and the catalyst carbon deposition can be avoided or obviously reduced. In addition, the invention further provides the preparation method of the catalyst.

Owner:WANHUA IND GRP

Copolymers as additives for fuels and lubricants

Novel uses of copolymers for removing and / or reducing the level of deposits in the fuel system and / or injection system of direct injection diesel and / or gasoline engines are provided. What is provided is the use of particular copolymers as fuel additive or lubricant additive; to processes for preparation of such additives, and fuels and lubricants added therewith, such as, more particularly, as a detergent additive; to use of these copolymers for reducing the level of or preventing deposits in the fuel systems and especially the injection systems of direct injection diesel engines, especially in common rail injection systems, for reducing the fuel consumption of direct injection diesel engines, especially of diesel engines with common rail injection systems, and for minimizing power loss in direct injection diesel engines, especially in diesel engines with common rail injection systems; and as an additive for gasoline fuels, especially for operation of DISI engines.

Owner:BASF AG

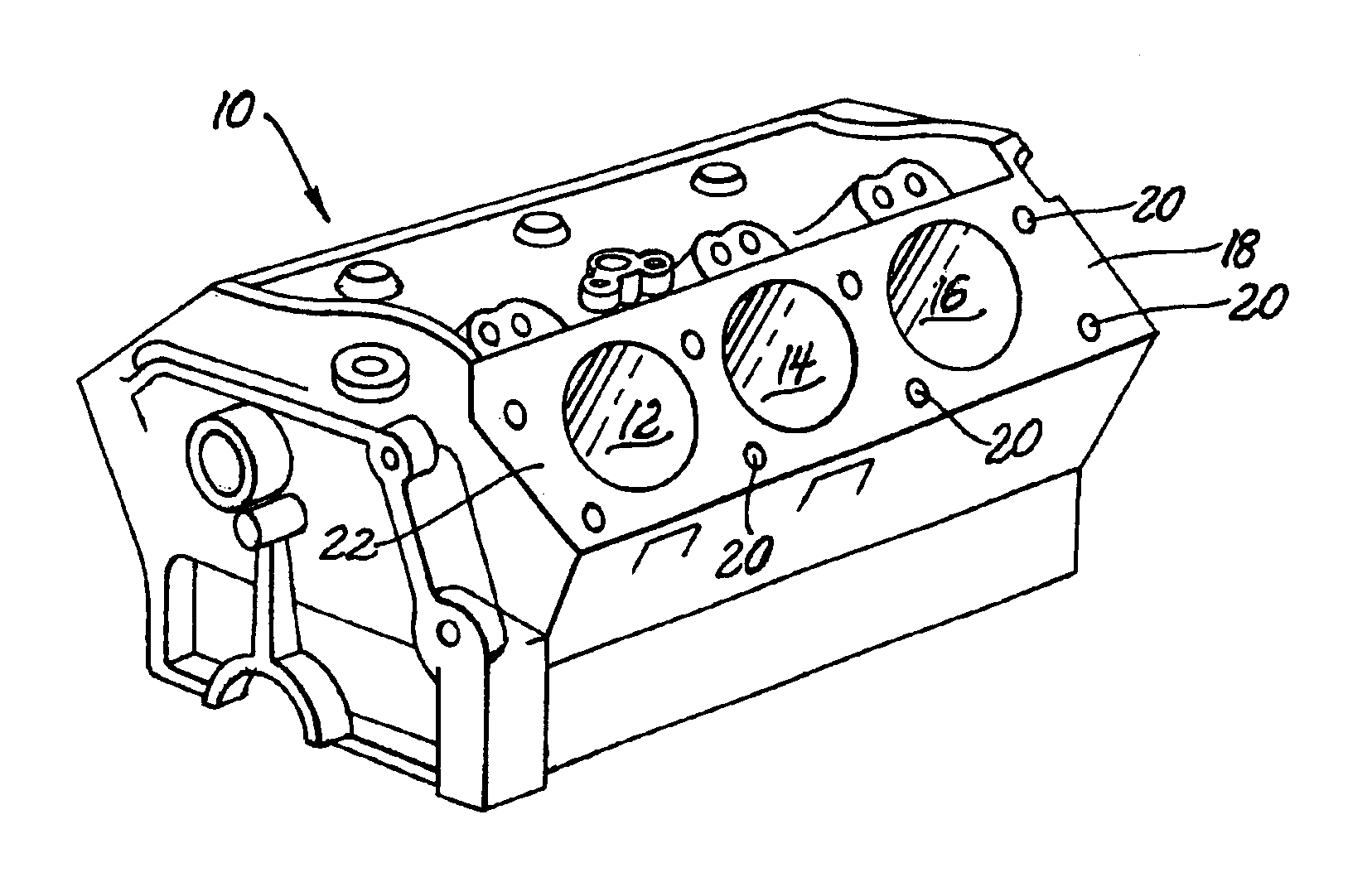

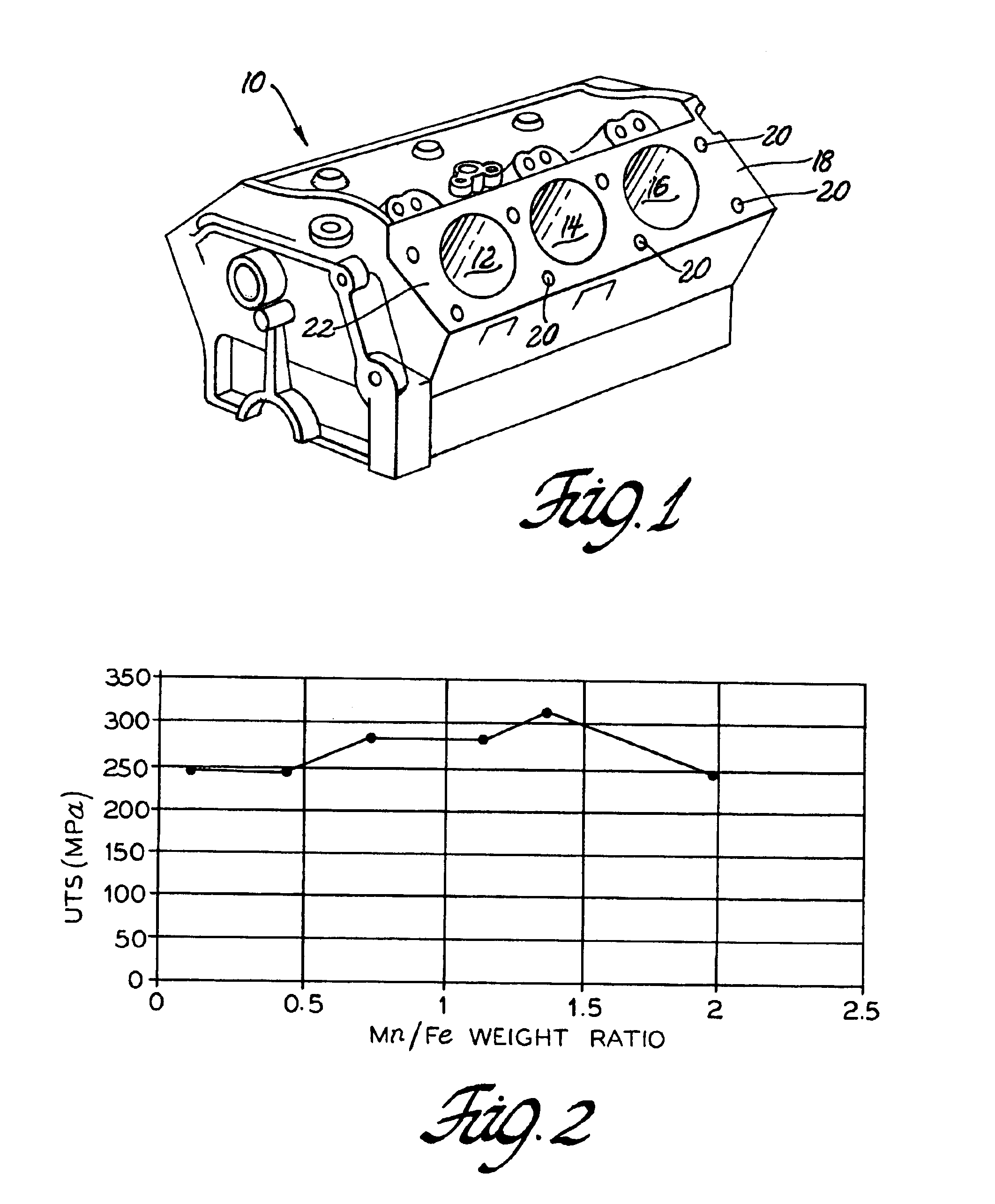

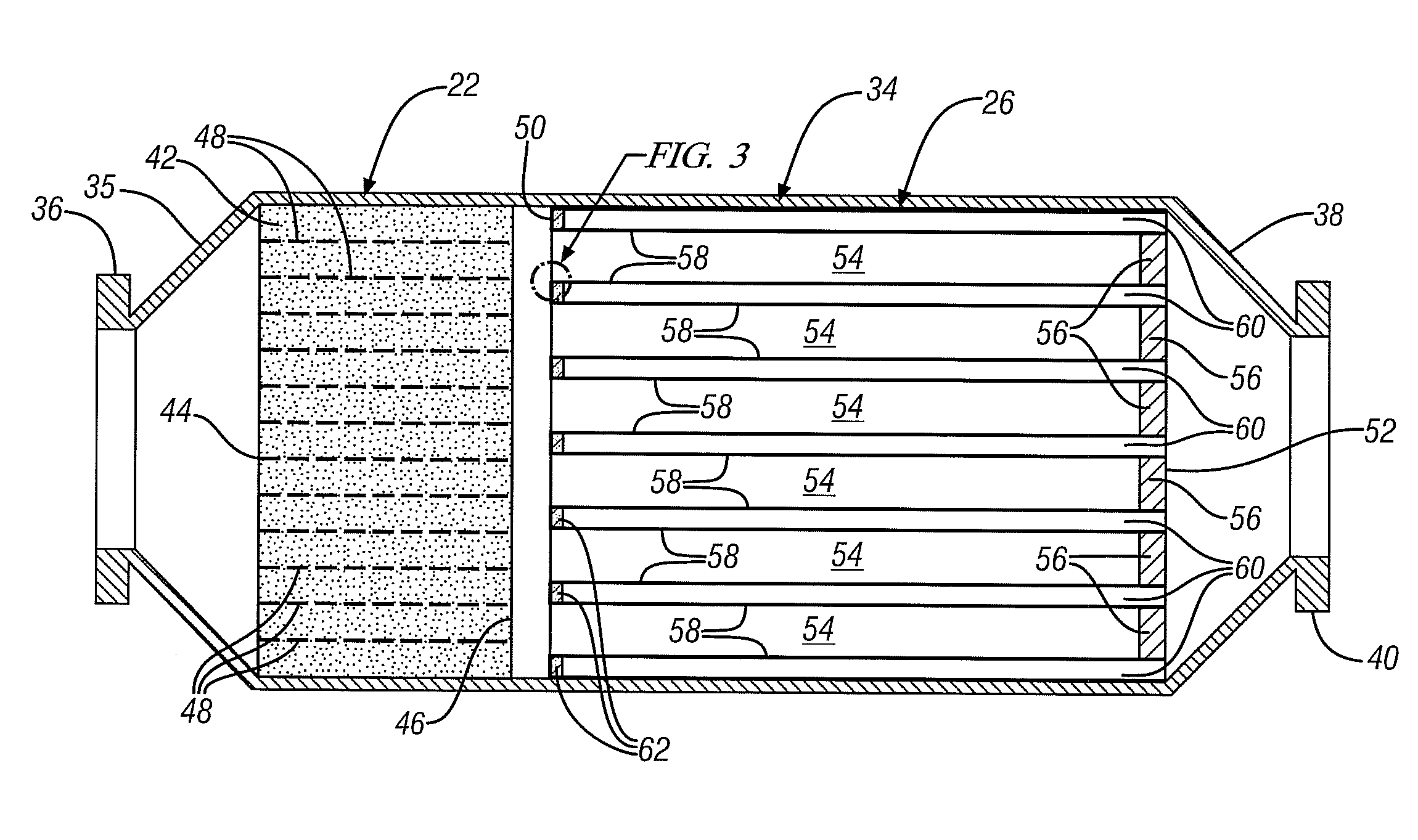

Aluminum alloy for engine blocks

An aluminum alloy is disclosed that is suitable for casting and machining cylinder blocks for engines, especially gasoline fuel engines for automotive vehicles. The casting has the strength and wear resistance to piston / seal scuffing for such engines. The alloy comprises, by weight, 9.5 to 12.5% silicon, 0.1 to 1.5% iron, 1.5 to 4.5% copper, 0.2 to 3% manganese, 0.1 to 0.6% magnesium, 2.0% max zinc, 0 to 1.5% nickel, 0.25% maximum titanium, up to 0.05% strontium and the balance aluminum, where the weight ratio of manganese to iron is 1.2 to 1.75 or higher when the iron content is equal to or greater than 0.4% and the weight ratio of manganese to iron is at least 0.6 to 1.2 when the iron content is less than 0.4% of the alloy.

Owner:GM GLOBAL TECH OPERATIONS LLC

Hydrocracking process selective for improved distillate and improved lube yield and properties

ActiveUS20120080357A1Treatment with plural serial cracking stages onlyMolecular sieve catalystsGasoline fuelLubricant

This invention relates to a process involving hydrocracking of a feedstream in which a converted fraction can exhibit relatively high distillate product yields and maintained or improved distillate fuel properties, while an unconverted fraction can exhibit improved properties particularly useful in the lubricant area.In this hydrocracking process, it can be advantageous for the yield of converted / unconverted product for gasoline fuel application to be reduced or minimized, relative to converted distillate fuel and unconverted lubricant. Catalysts and conditions can be chosen to assist in attaining, or to optimize, desirable product yields and / or properties.

Owner:EXXON RES & ENG CO

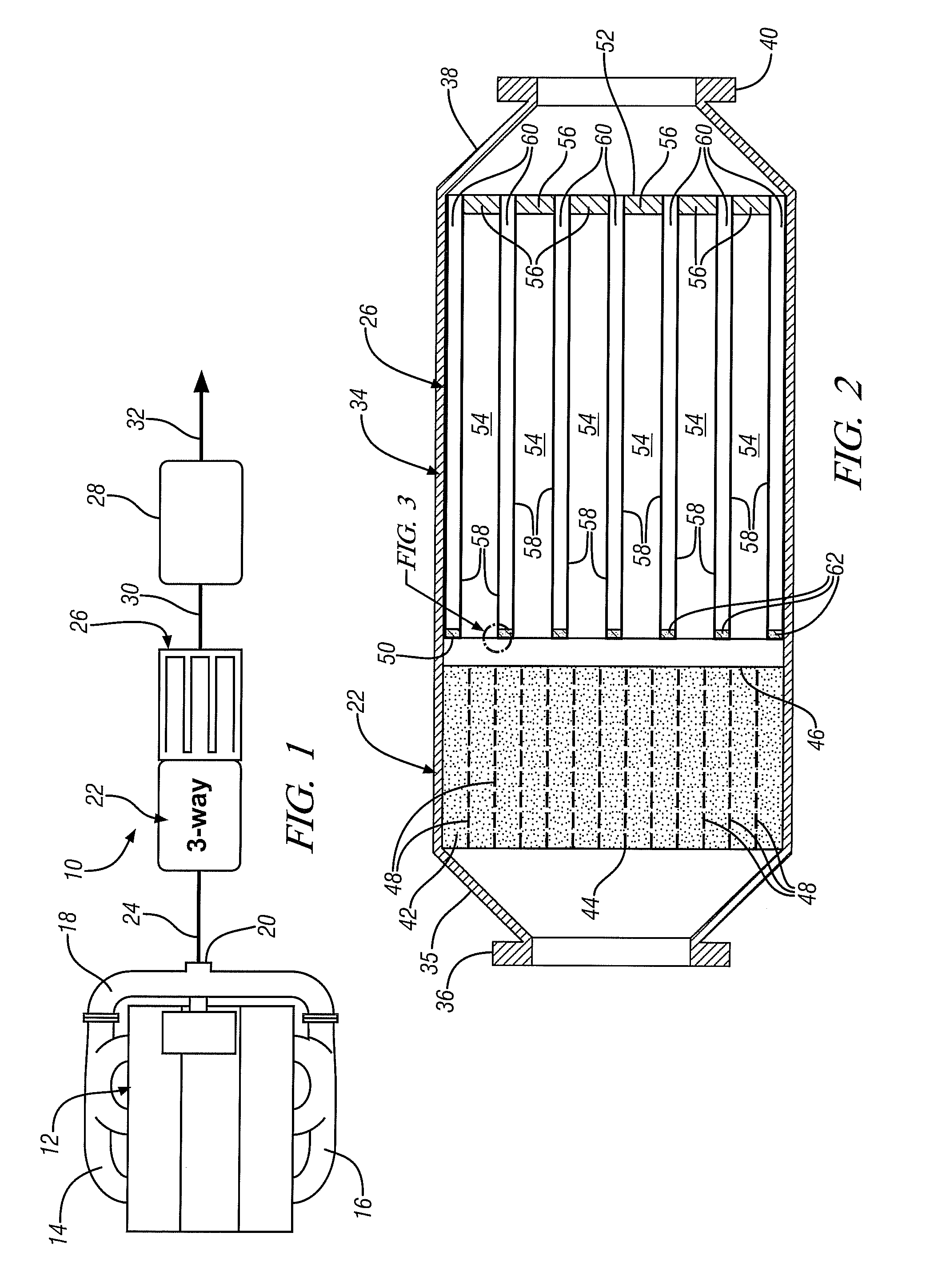

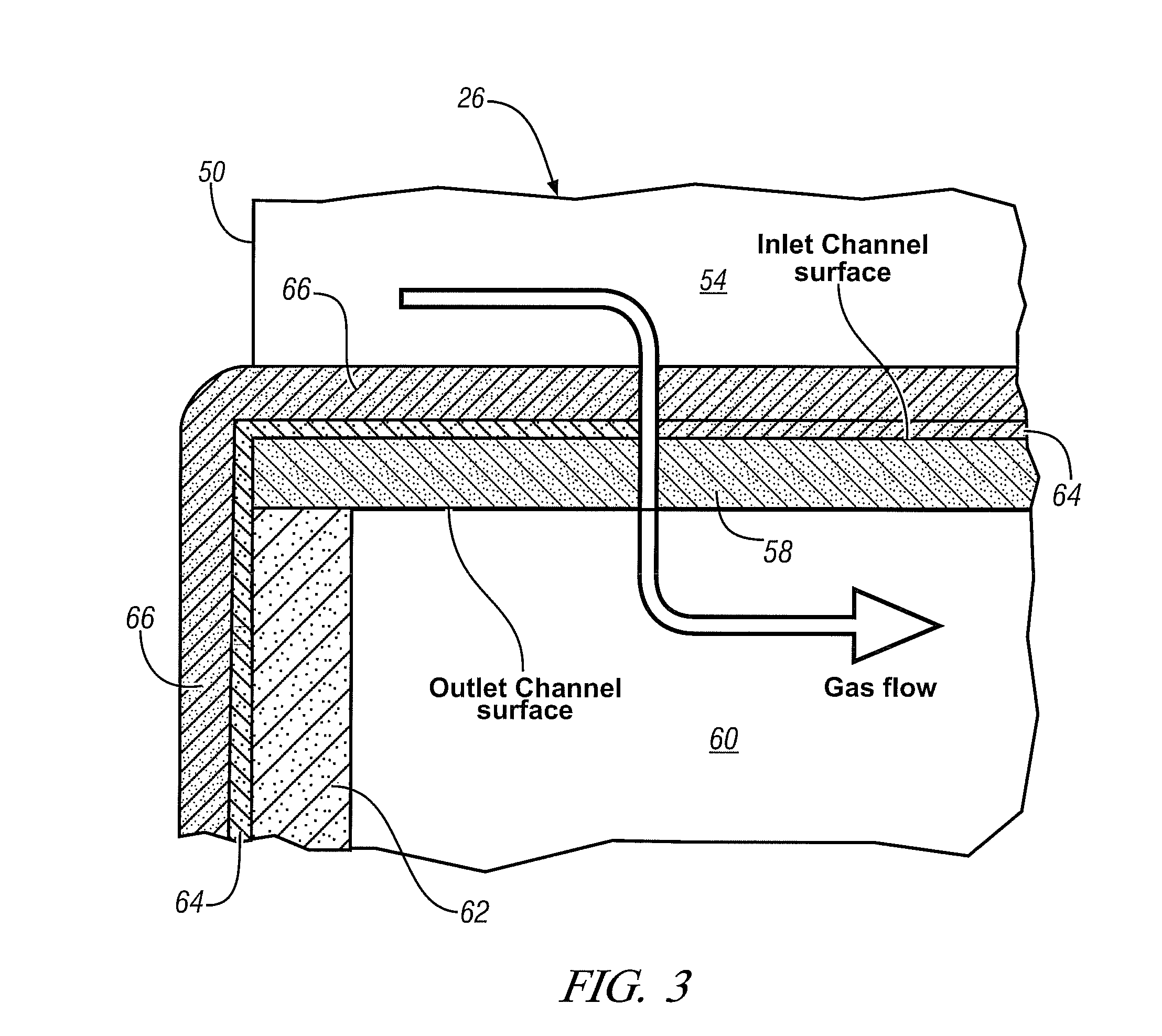

Exhaust particulate management for gasoline-fueled engines

InactiveUS20110120089A1Less catalystReduce frequency and likelihoodGas treatmentInternal combustion piston enginesParticulatesInlet channel

A thin layer of low mean-pore-size filter material that permanently accommodates the accumulation of exhaust particulates (as soot or a soot cake) is carried on a porous ceramic support. The supported filter material is closely coupled with the exhaust manifold of the engine, for the purpose of passive regeneration of stored particulates, and removes particulate matter from the exhaust which is directed through the filter layer and ceramic support. The oxygen content of the exhaust oxidizes the particulate matter on the filter material. In a preferred embodiment, a thin layer of the filter material is supported on inlet channel walls of a wall flow-through ceramic filter body to remove the particles from the exhaust. The filter body comprises an upstream exhaust gas flow inlet face with openings to a plurality of inlet channels and a downstream face with a like plurality of openings from outlet channels. The inlet channels are closed at the downstream face and the outlet channels are closed at the inlet face. So the exhaust stream enters the inlet channels and flows through the filter layers and supporting channel walls to an outlet channel. The filtered exhaust stream exits the outlet end of the filter body and is combined into an exhaust passage downstream of the filter body for further treatment as may be necessary.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com