Catalyst for preparing high-quality gasoline fraction by virtue of syngas high selectivity and preparation method thereof

A high-selectivity, gasoline fraction technology, applied in the field of Fischer-Tropsch synthesis catalyst and its preparation, achieves the effects of flexible source, improved selectivity and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

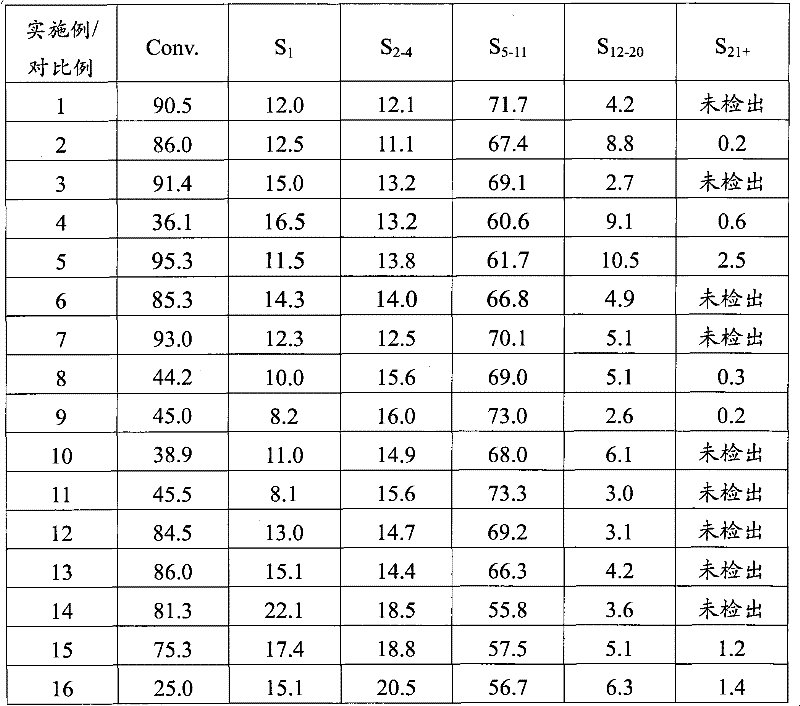

Examples

Embodiment 1

[0050] Weigh 0.085g NaNO 3 , add 100ml H 2 In O, the preparation concentration is 0.01mol L -1 NaNO 3 aqueous solution. Weigh 8.0 g of MOR molecular sieve with a silicon-aluminum ratio of 12 (manufactured by Nankai University Catalyst Factory, NKF-12) into the above solution, and stir at 30° C. for 20 min. Filter, wash with deionized water, and dry at 100°C for 5h. Weigh 5.0g of treated molecular sieves and add to a concentration of 1.0mol L -1 Ammonium nitrate aqueous solution, stirred at 50°C for 1h, washed with deionized water, dried at 100°C for 15h, and calcined at 500°C for 5h in an air atmosphere to obtain a molecular sieve carrier, denoted as MOR-0.01 M.

[0051] Weigh 0.8856g Co(NO 3 ) 2 ·6H 2 O was dissolved in 25ml deionized water to form a cobalt nitrate solution, and then 0.0165g RuCl was added 3 ·3H 2 O, after stirring and dissolving, weigh 2.0g MOR-0.01M molecular sieve and add it to the above solution. Stir at room temperature for 10 h, let stand fo...

Embodiment 2

[0056] Weigh 0.085g NaNO 3 , add 100ml H 2 In O, the preparation concentration is 0.01mol L -1 NaNO 3 aqueous solution. Weigh 8.0 g of Beta molecular sieve (manufactured by Catalyst Factory of Nankai University, NKF-6) with a silicon-aluminum ratio of 25 and add it to the above solution, and stir at 30° C. for 30 min. Filter, wash with deionized water, and dry at 100°C for 5h. Weigh 5.0g of treated molecular sieves and add to a concentration of 1.0mol L -1 Ammonium nitrate aqueous solution, stirred at 50°C for 1h, washed with deionized water, dried at 100°C for 15h, and calcined at 500°C for 5h in an air atmosphere to obtain a molecular sieve carrier, denoted as Beta-0.01 M.

[0057] Weigh 0.8856g Co(NO 3 ) 2 ·6H 2 O is dissolved in 20ml of deionized water to make cobalt nitrate solution, then add 0.0781g KNO 3 , after stirring and dissolving, weigh 2.0g Beta-0.01M molecular sieve and add it to the above solution. Stir at room temperature for 4h, let stand for 10h, ...

Embodiment 3

[0062] Weigh 0.085g NaNO 3 , add 100ml H 2 In O, the preparation concentration is 0.01mol L -1 NaNO 3 aqueous solution. Weigh 8.0 g of ZSM-5 molecular sieve (manufactured by Catalyst Factory of Nankai University, NKF-5) with a silicon-aluminum ratio of 38 and add it to the above solution, and stir at 30° C. for 30 min. Filter, wash with deionized water, and dry at 100°C for 5h. Weigh 5.0g of treated molecular sieves and add to a concentration of 1.0mol L -1 Ammonium nitrate aqueous solution, stirred at 50°C for 2h, washed with deionized water, dried at 100°C for 15h, and calcined at 500°C for 5h in an air atmosphere to obtain a molecular sieve carrier, denoted as ZSM-5 -0.01M.

[0063] Weigh 1.6605g Co(NO 3 ) 2 ·6H 2 O was dissolved in 30ml of deionized water to form a cobalt nitrate solution, and then 0.0674g of NaNO was added 3 , after stirring and dissolving, weigh 2.0g ZSM-5-0.01M molecular sieve and add it to the above solution. Stir at room temperature for 4h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com