Patents

Literature

1117results about How to "Reduce sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

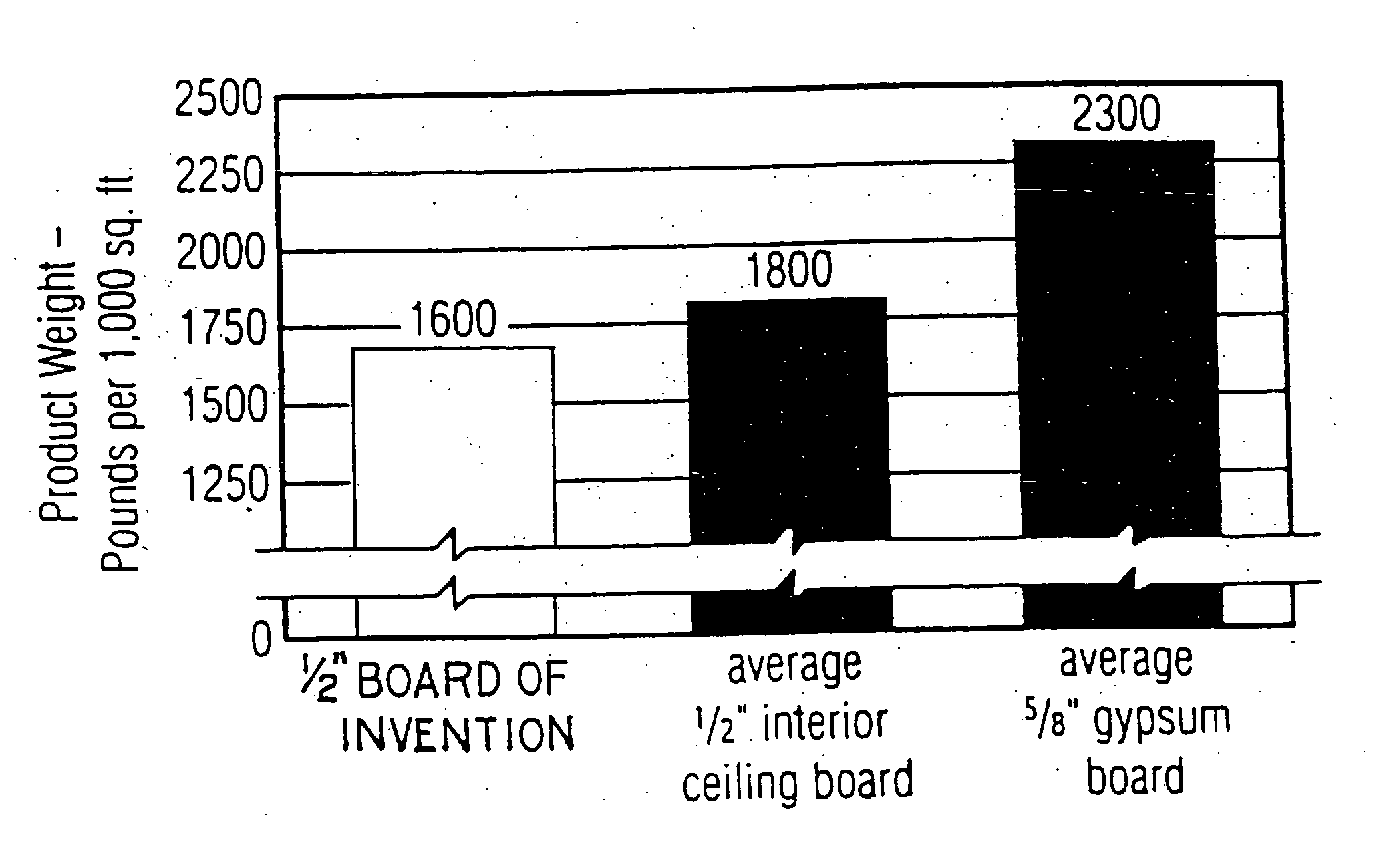

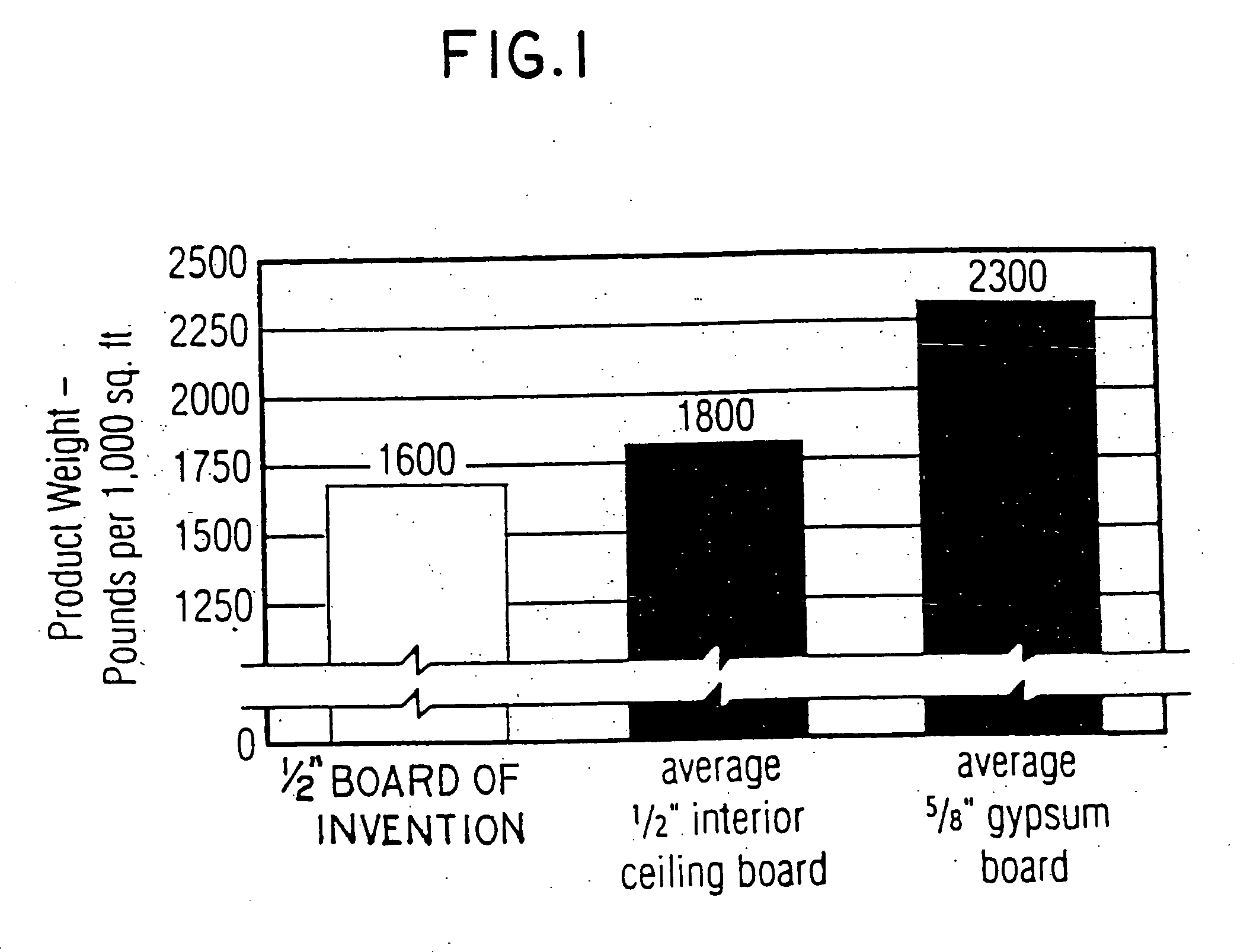

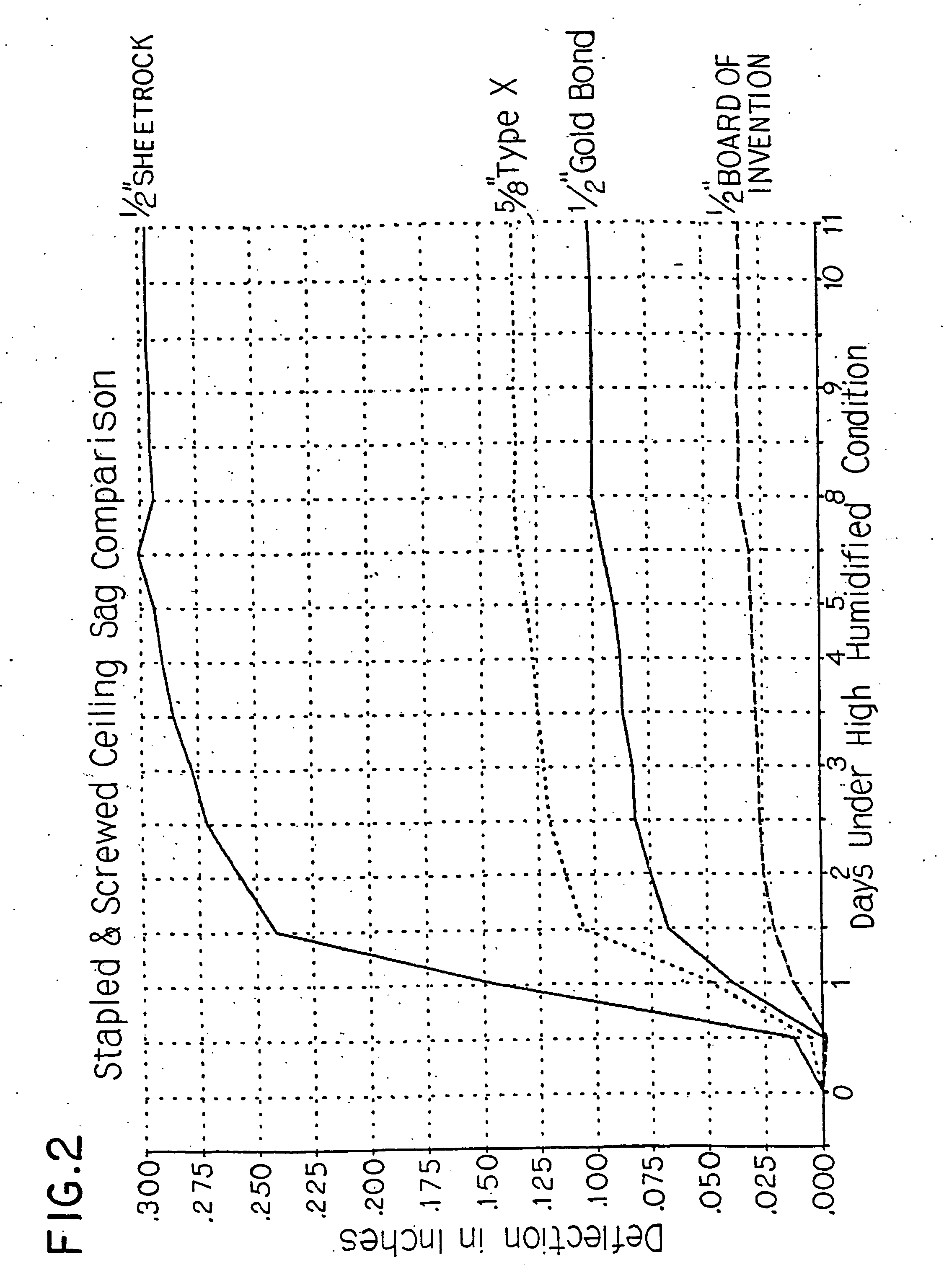

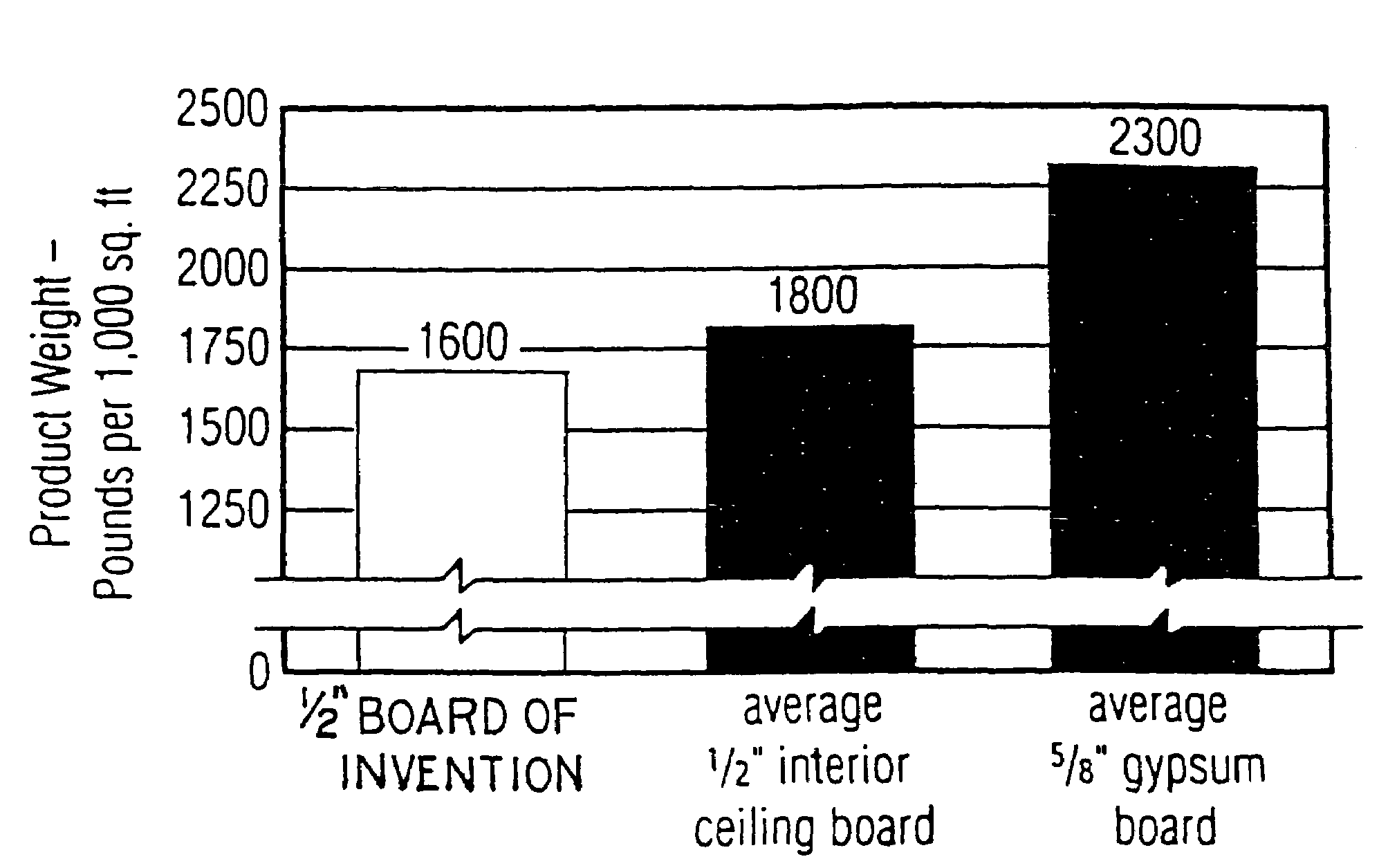

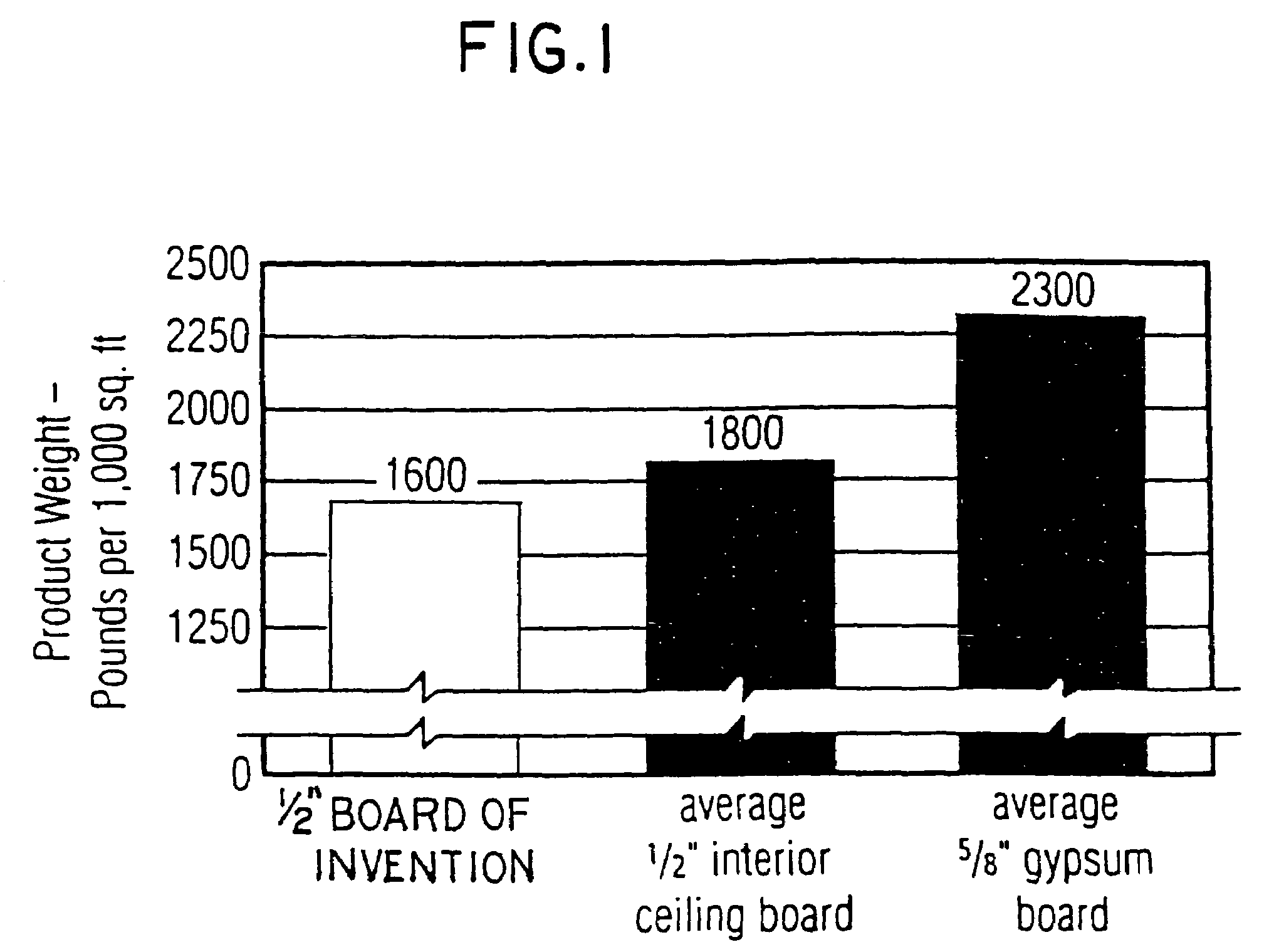

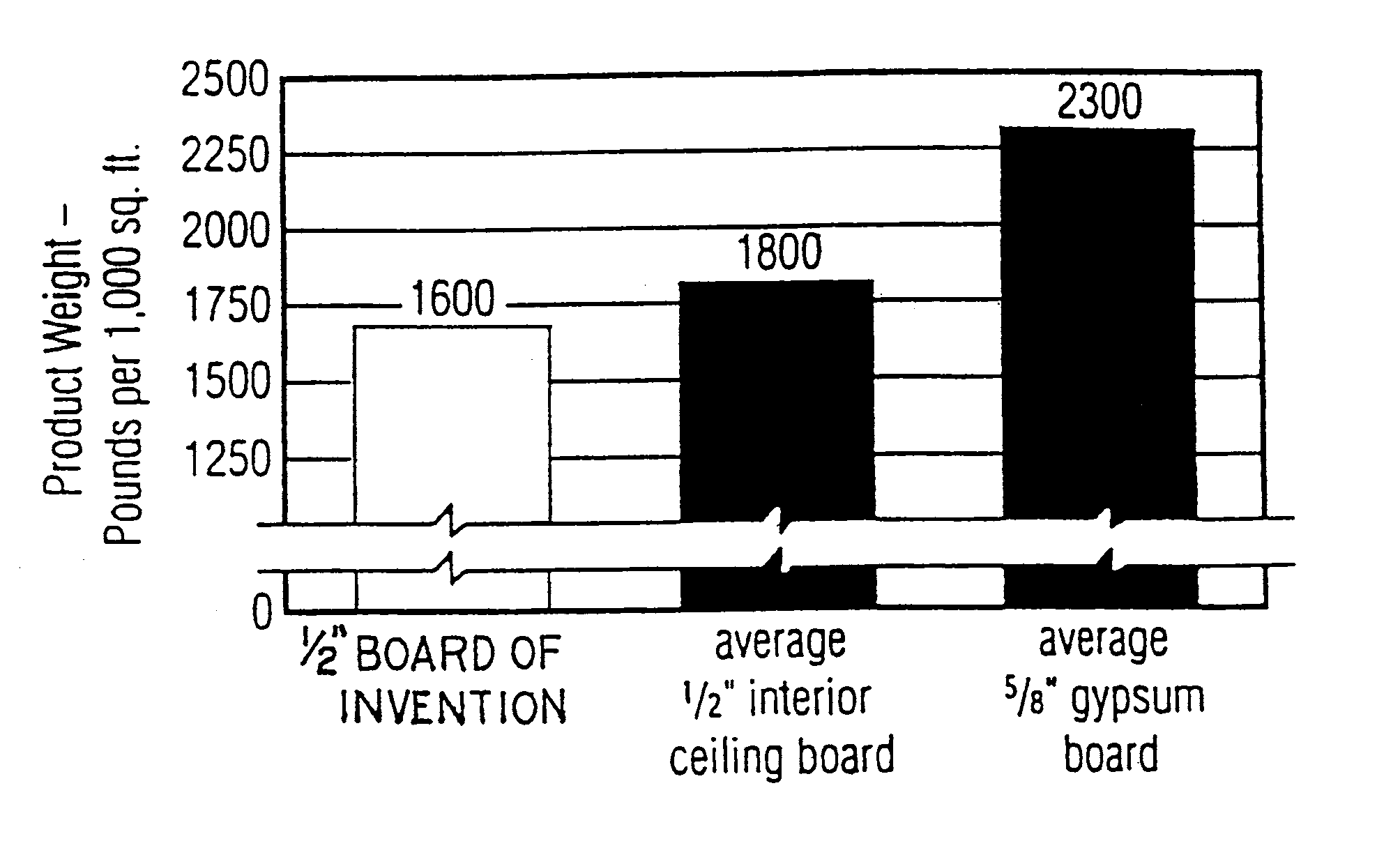

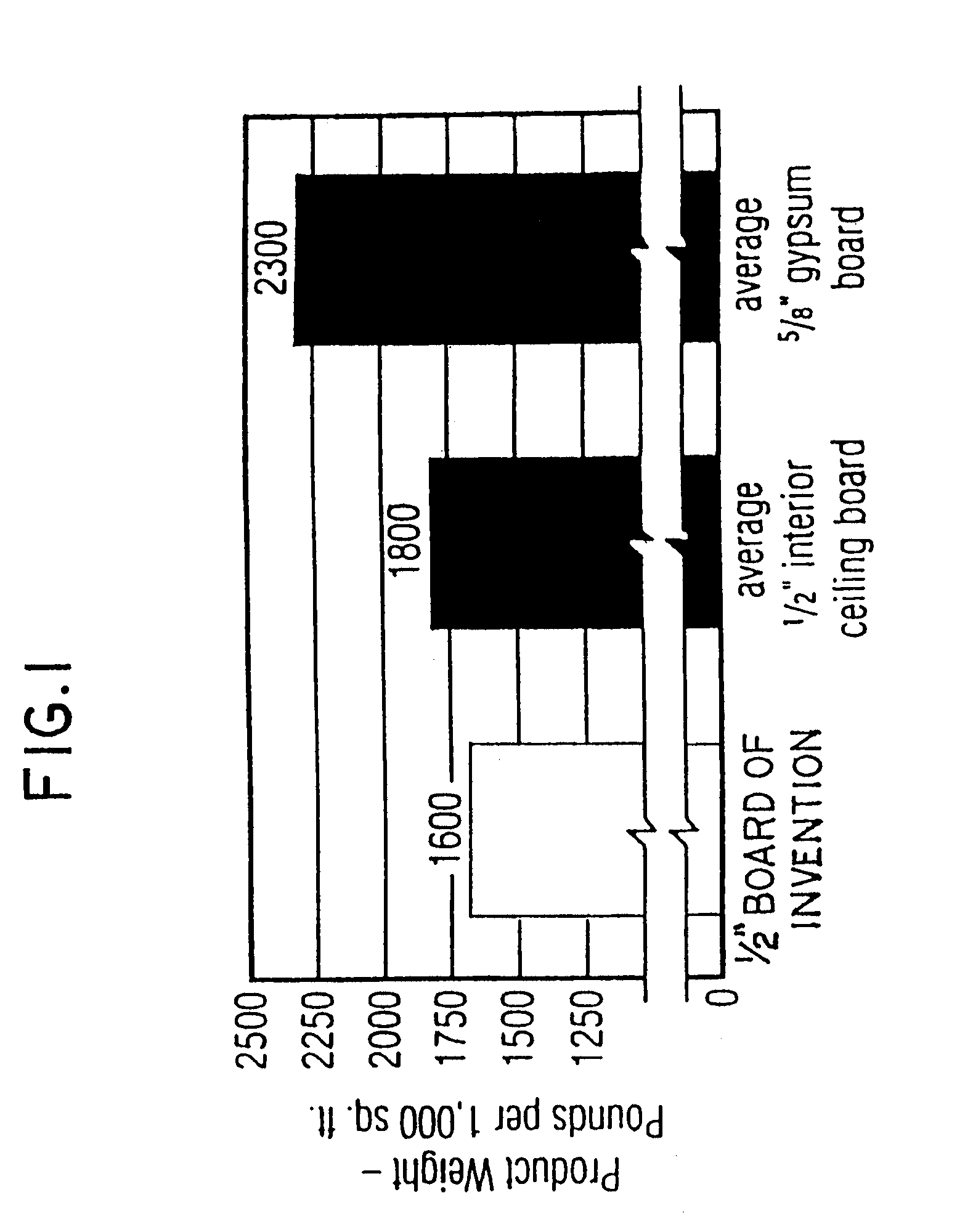

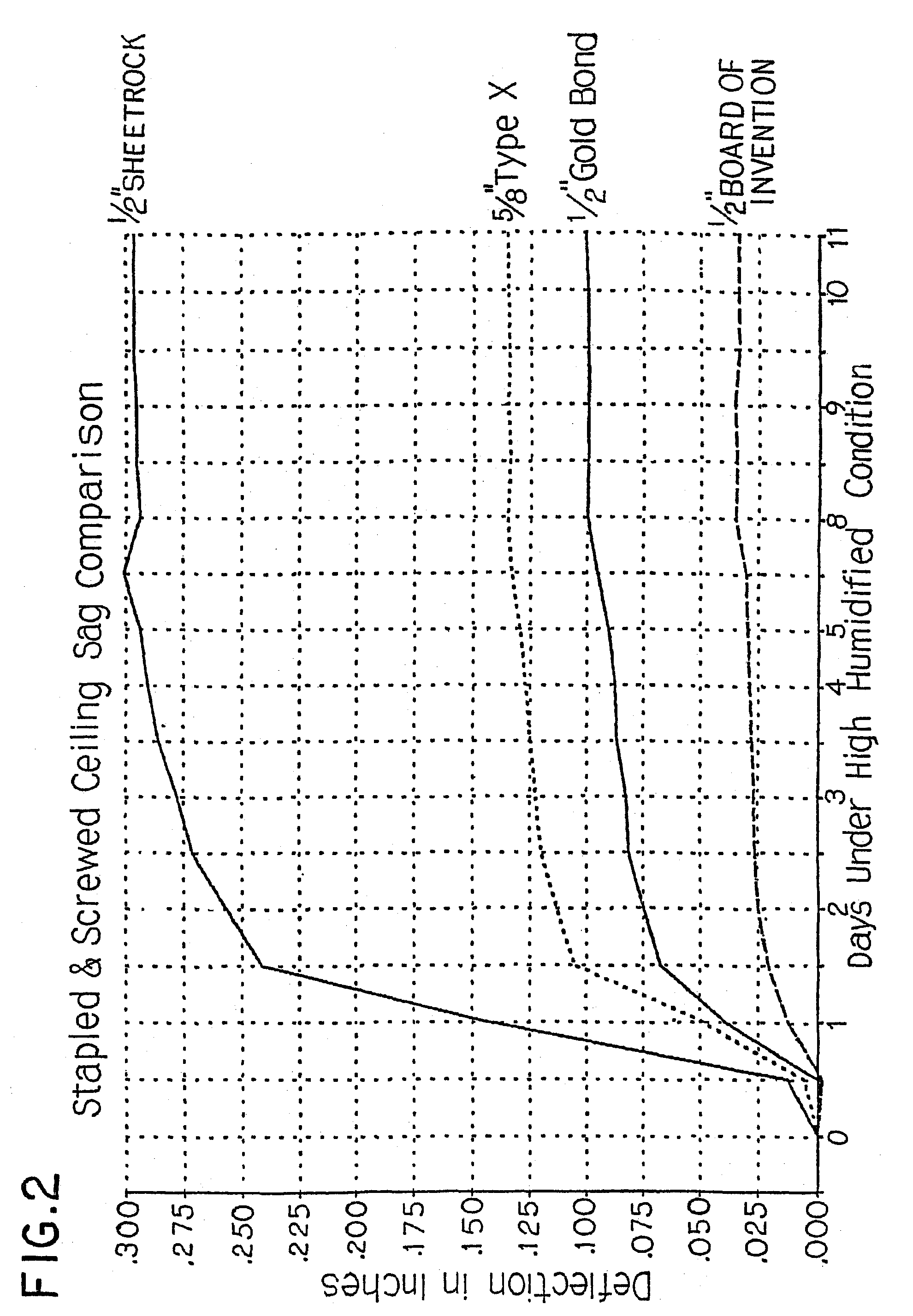

Gypsum-containing board and tile, and method for producing same

InactiveUS20050019618A1Improve the immunitySave a lot of costLiquid surface applicatorsConstruction materialO-Phosphoric AcidBrick

A method for producing a set gypsum-containing product comprising an interlocking matrix of set gypsum wherein said method comprises applying to said set gypsum one or more enhancing materials selected from the group consisting of phosphoric acid; condensed phosphoric acids, each of which comprises 2 or more phosphoric acid units; and salts or ions of condensed phosphates, each of which comprises 2 or more phosphate units, and monobasic salts or monovalent ions of orthophosphates.

Owner:UNITED STATES GYPSUM CO

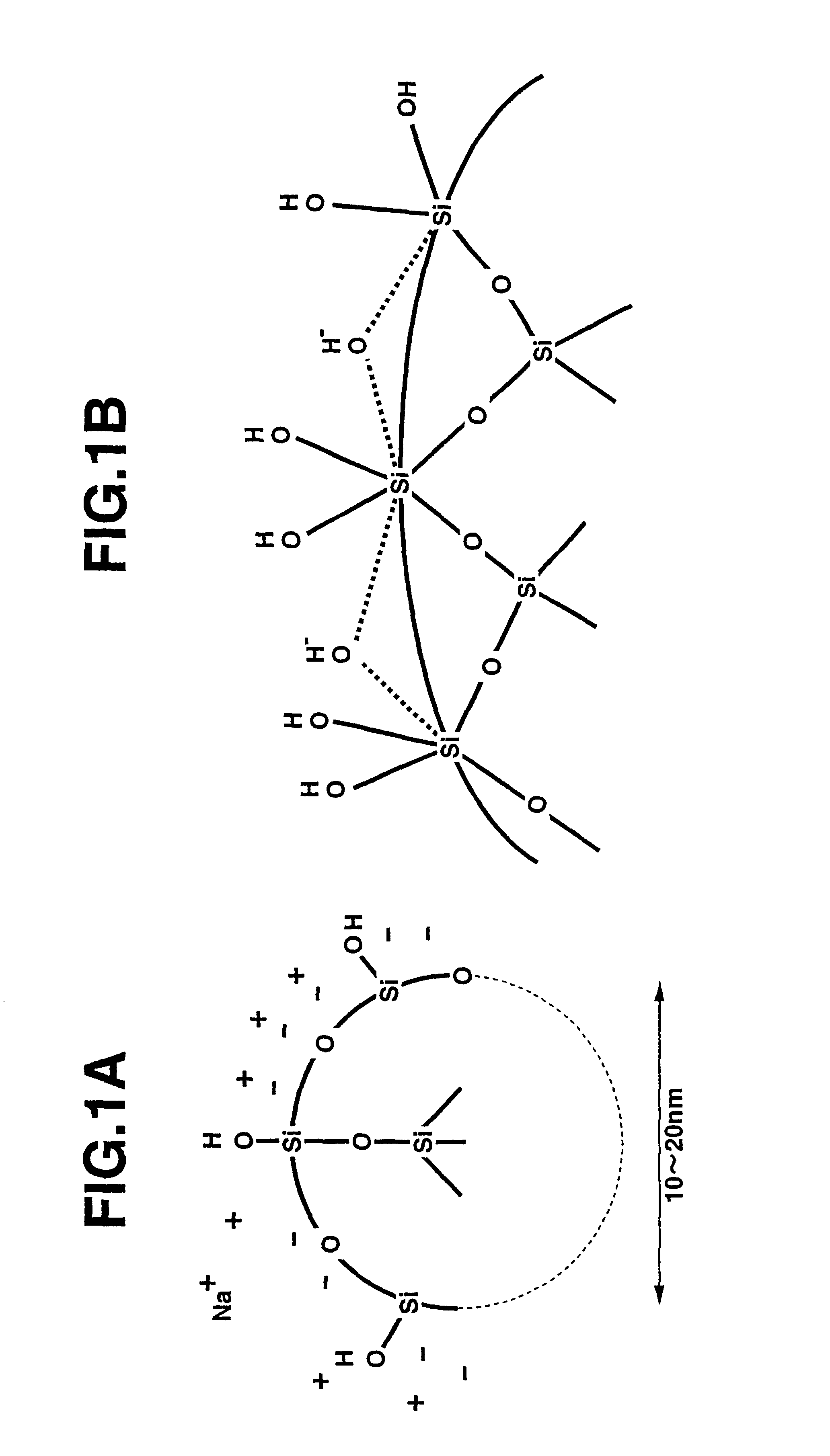

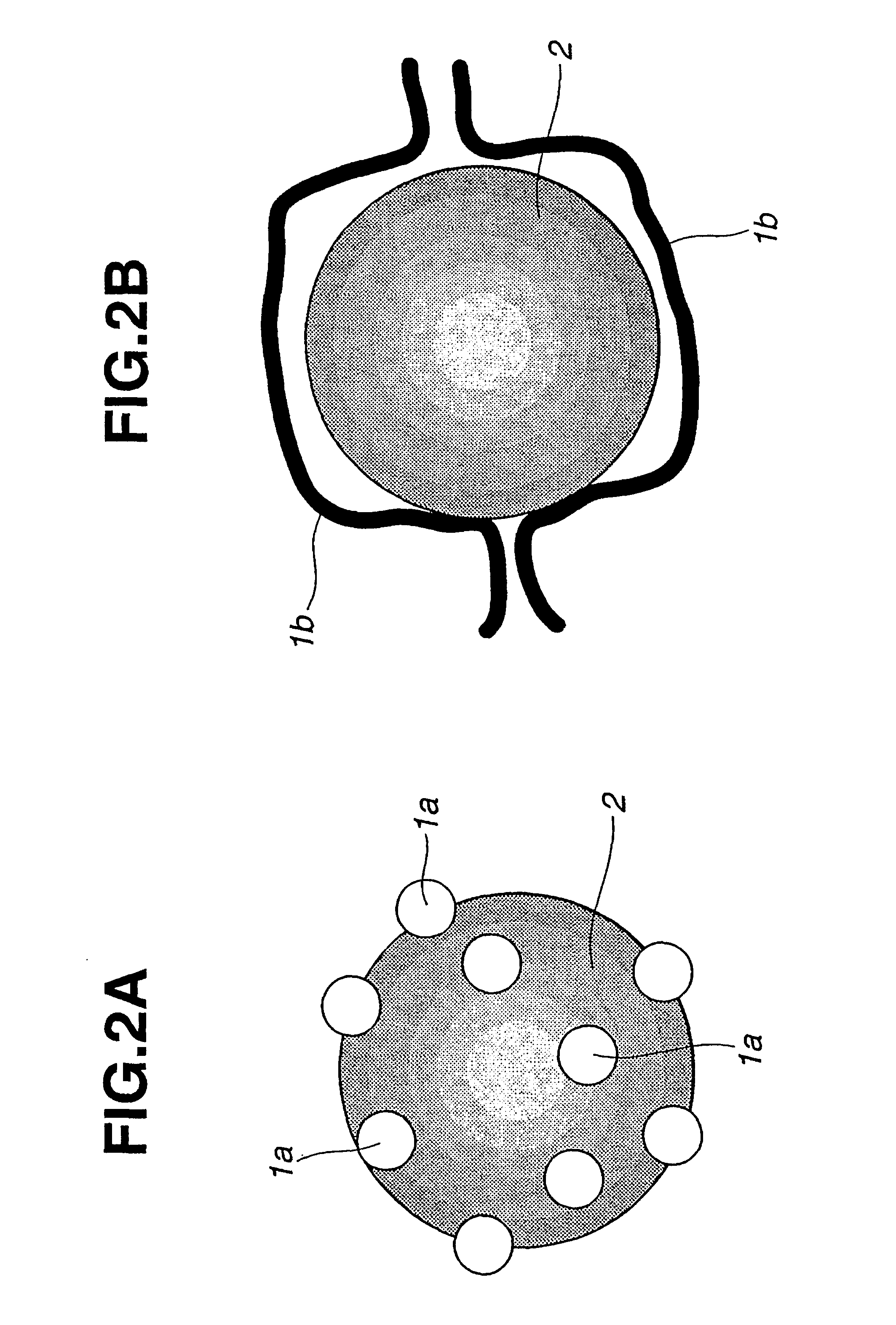

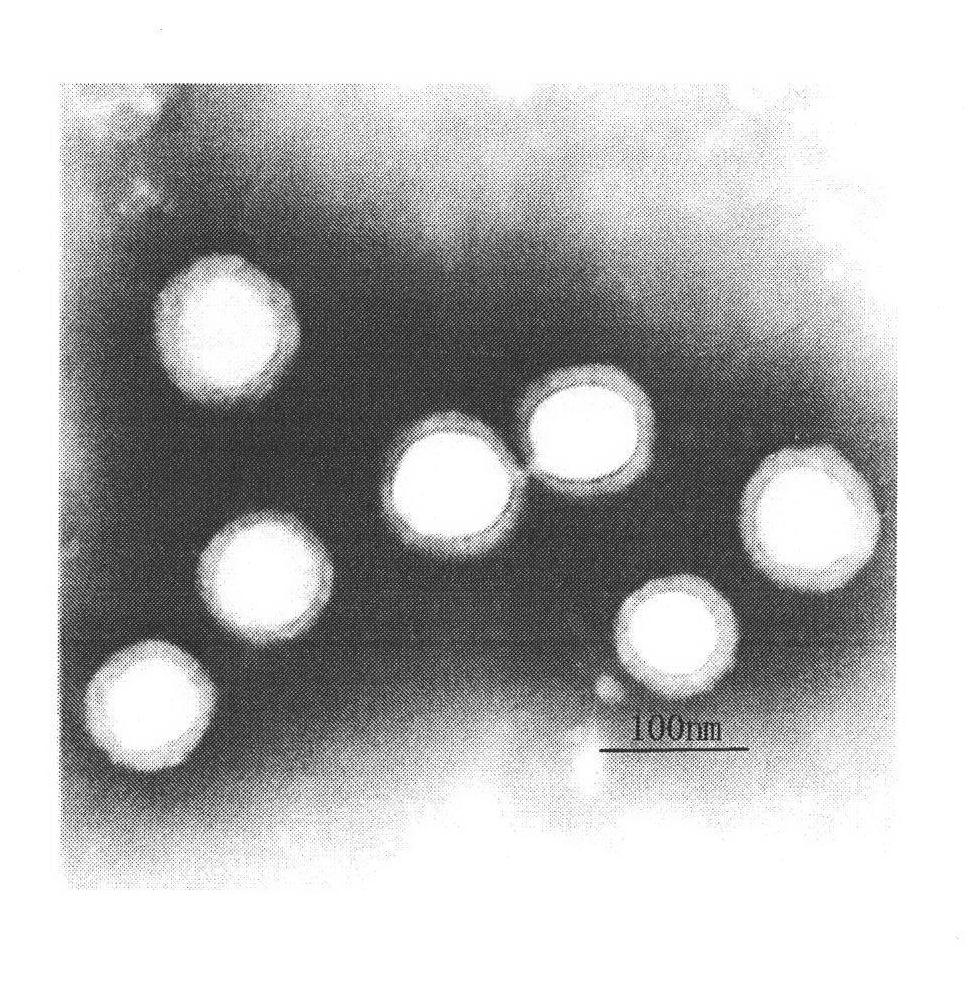

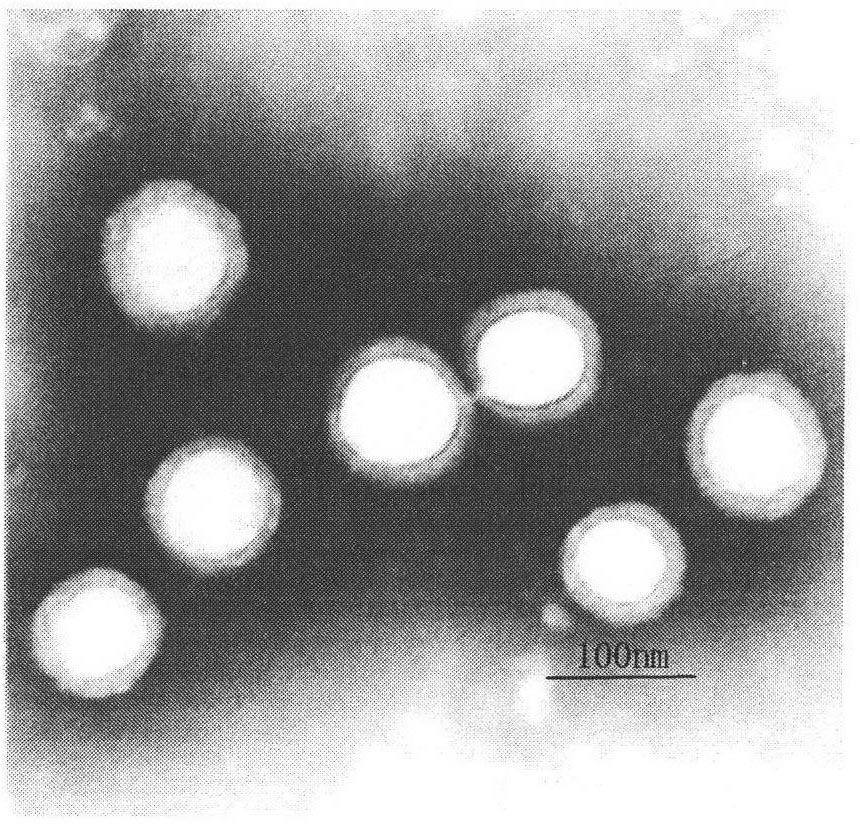

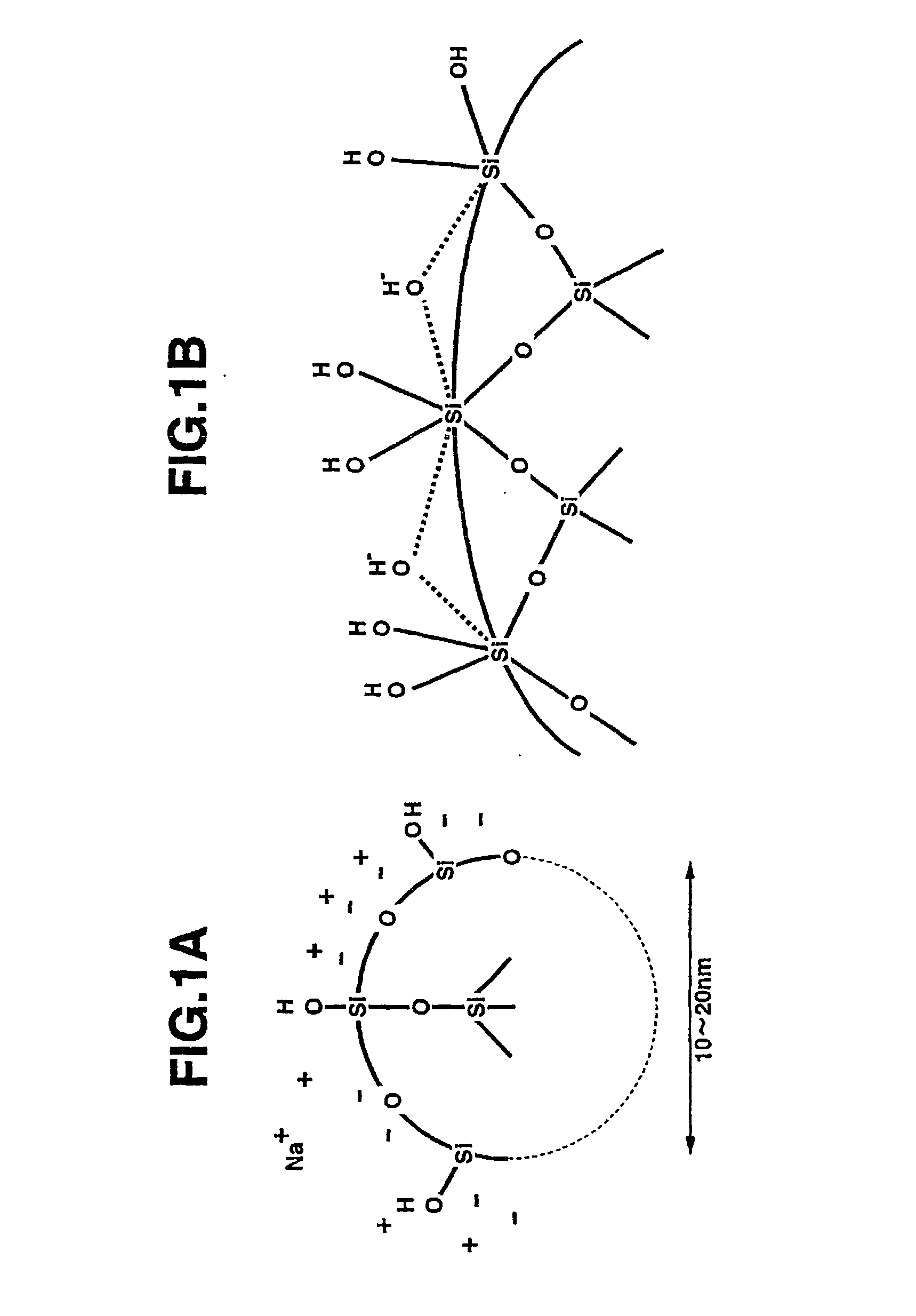

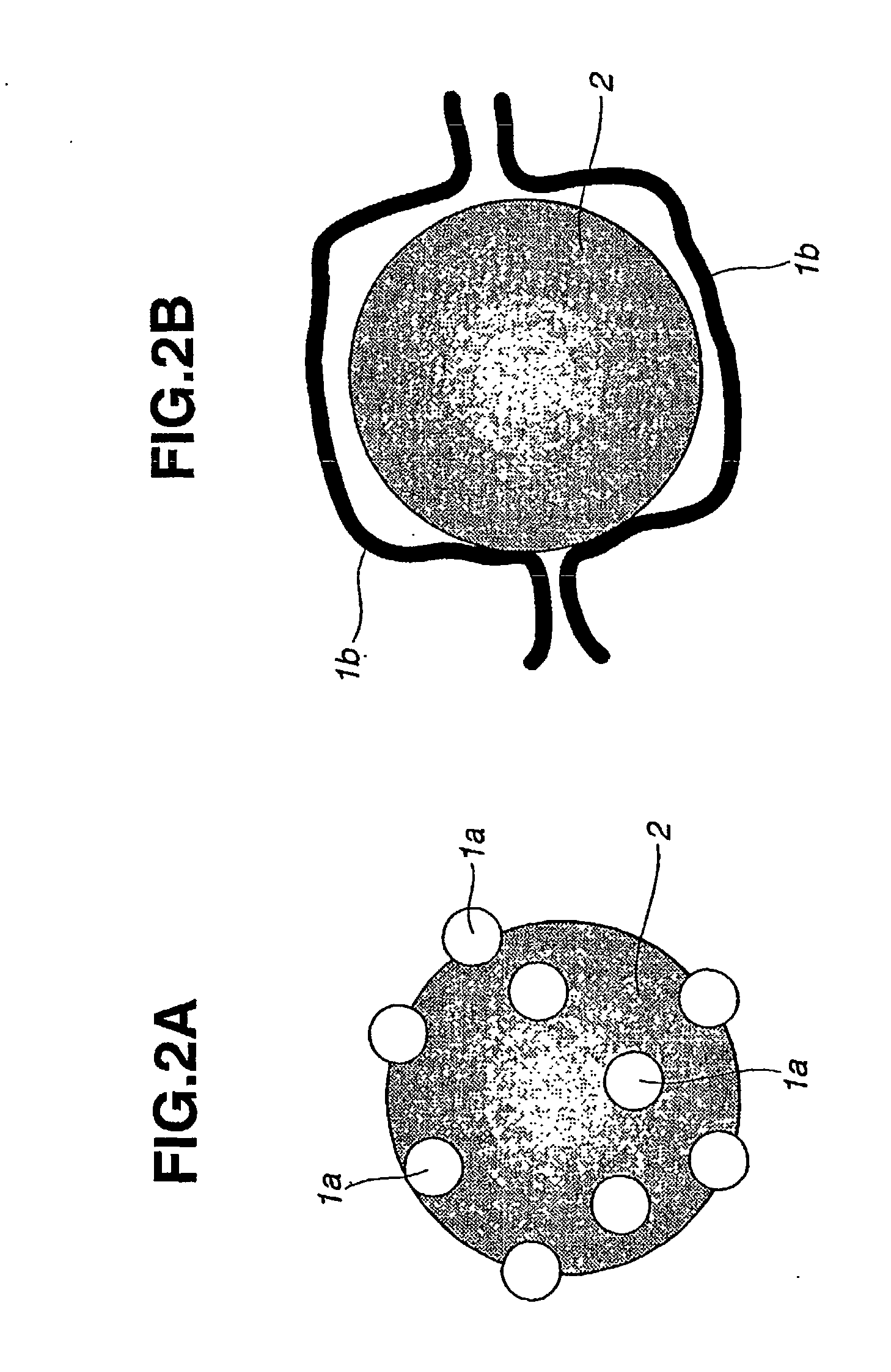

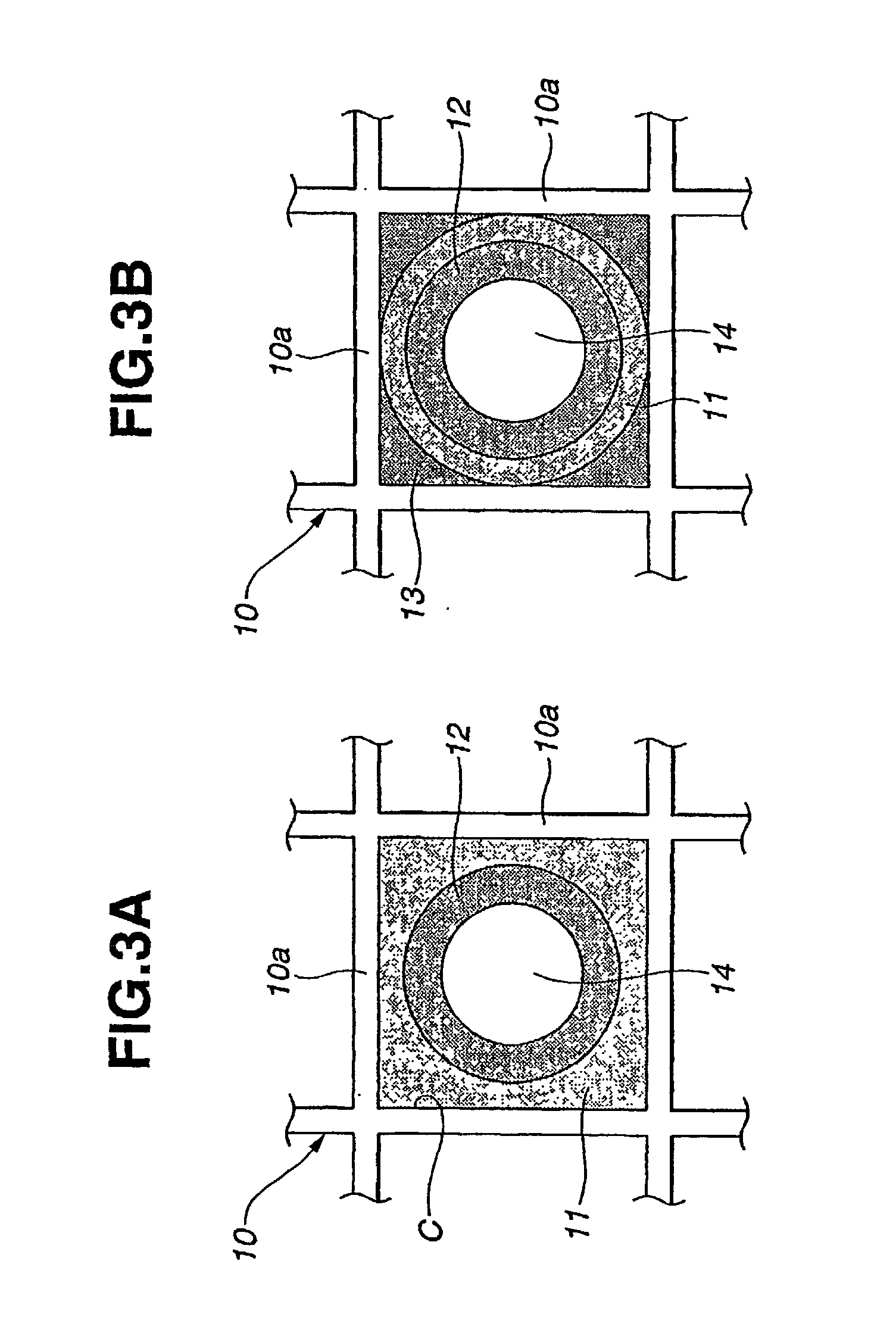

Exhaust gas purifying catalyst and method of producing same

InactiveUS6589901B2Improve heat resistanceReduce stickingInternal combustion piston enginesMolecular sieve catalystsColloidal silicaColloid

An exhaust gas purifying catalyst for exhaust gas discharged from an automotive internal combustion engine. The catalyst comprises a substrate over which a hydrocarbons adsorbing material layer is formed as a lower layer to absorb hydrocarbons contained in exhaust gas. The hydrocarbons adsorbing material layer contains zeolite and colloidal silica which has undergone firing. The colloidal silica is in a chain-like form and / or a spherical form before and after the firing. Additionally, a catalyst component layer is formed as an upper layer over the hydrocarbons adsorbing material layer. The catalyst component layer contains a catalyst metal.

Owner:NISSAN MOTOR CO LTD

Elastomeric laminate and elastomeric film

InactiveUS20110177735A1Improve heat resistanceImprove thermal stabilitySynthetic resin layered productsPaper/cardboard layered productsElastomerEngineering

An elastomeric laminate and an elastomeric film are provided. The elastomeric film can be a monolayer elastomeric film or a multilayer elastomeric film, wherein the monolayer elastomeric film includes an olefin-based elastomeric polymer and an effective polymer, and the multilayer elastomeric film when used as an alternative includes a first elastomeric member layer, and a second elastomeric member layer. The first elastomeric member layer includes at least one olefin-based elastomeric polymer, and at least one first draw down polymer. The second elastomeric member layer includes at least one elastomeric polymer and at least one second draw down polymer. The monolayer elastomeric film or the multilayer elastomeric film, and the elastic carrier are laminated together to form the elastomeric laminate.

Owner:CHENG KENNETH +1

Gypsum-containing board and tile, and method for producing same

InactiveUS7244304B2Increase resistanceHigh strengthLiquid surface applicatorsConstruction materialPhosphoric acidMonovalent ions

A method for producing a set gypsum-containing product comprising an interlocking matrix of set gypsum wherein said method comprises applying to said set gypsum one or more enhancing materials selected from the group consisting of phosphoric acid; condensed phosphoric acids, each of which comprises 2 or more phosphoric acid units; and salts or ions of condensed phosphates, each of which comprises 2 or more phosphate units, and monobasic salts or monovalent ions of orthophosphates.

Owner:UNITED STATES GYPSUM CO

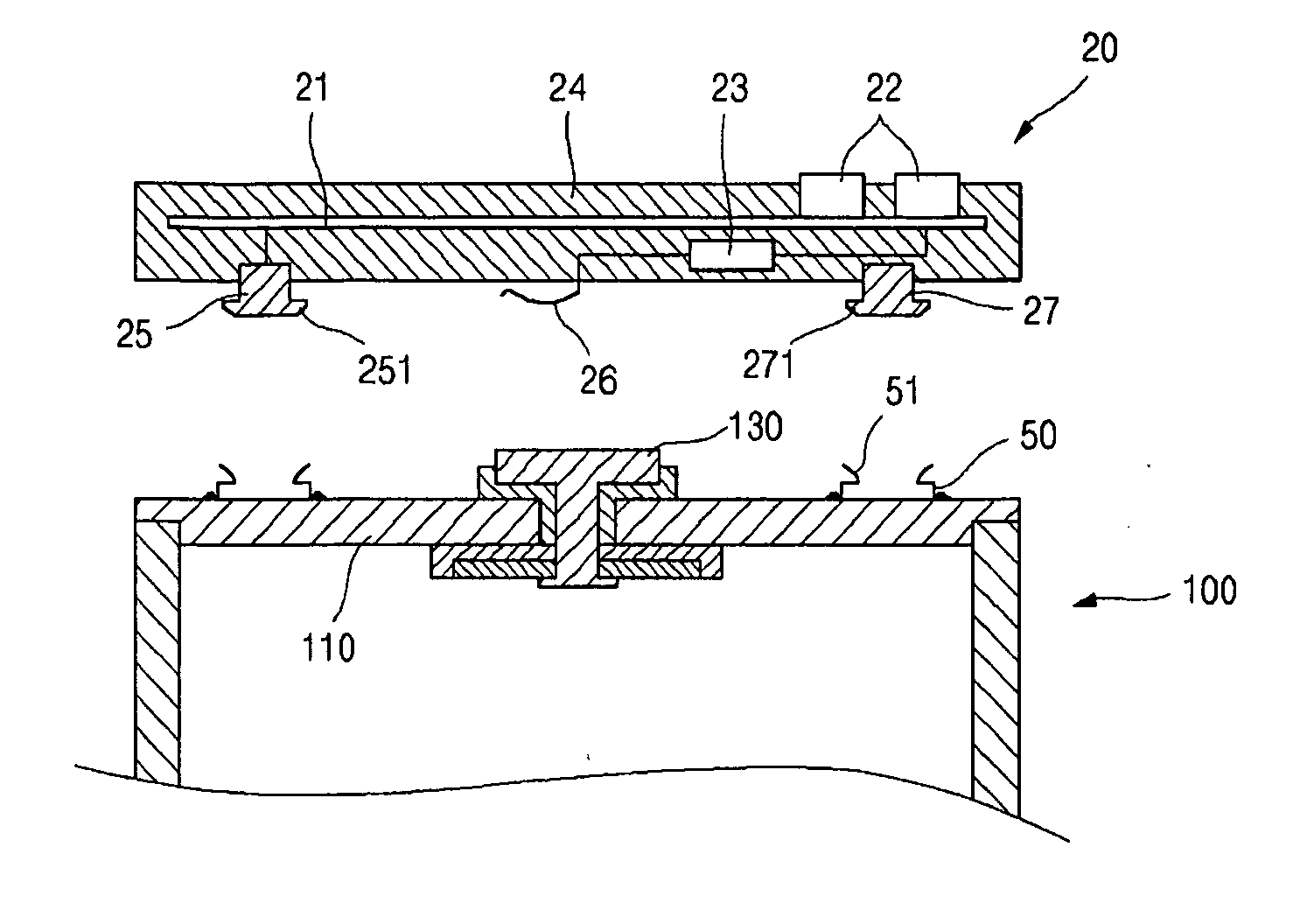

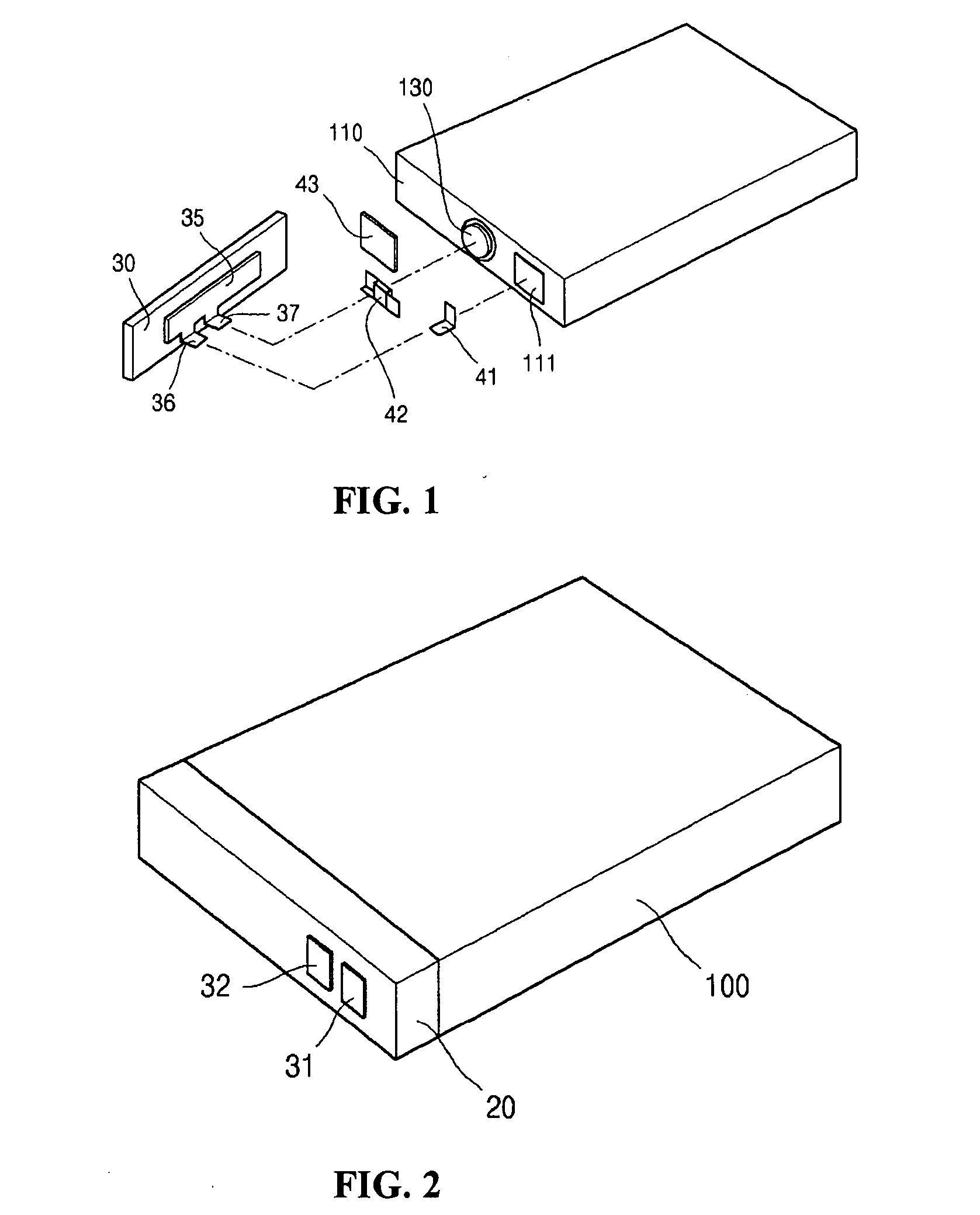

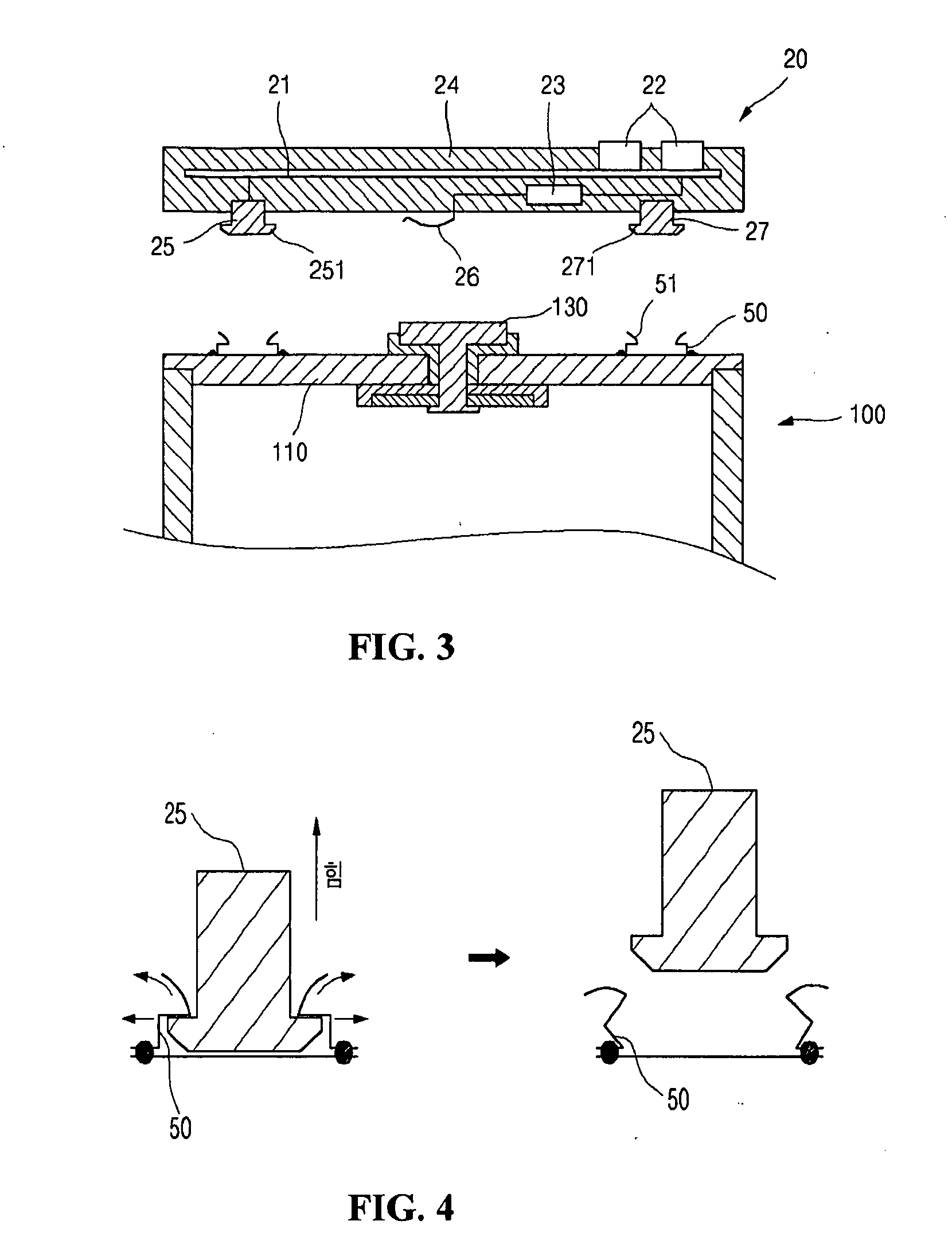

Rechargeable battery

InactiveUS20050175889A1Stable and simple mannerAvoid problemsFinal product manufacturePrimary cellsRechargeable cellMechanical bond

Disclosed is a rechargeable battery including: a bare cell composed of an electrode assembly including a negative electrode, a separator and a positive electrode, a container for housing the electrode assembly and an electrolyte, and a cap assembly for closing an opening of the container; and a safety device electrically coupled to an outer surface of the bare cell, wherein the safety device is coupled to the bare cell by being incorporated into a battery component part, and each of bonding surfaces of the bare cell and the battery component to be bonded to each other has a bonding parts capable of forming a mechanical bonding between the bare cell and the battery component. The rechargeable battery permits a safety device such as a protective circuit board and a bimetal device to be coupled to a bare cell in a stable and simple manner. Additionally, the mechanical bonding parts between the safety device and the bare cell can be separated so that the safety device such as a protective circuit board can be reused.

Owner:SAMSUNG SDI CO LTD

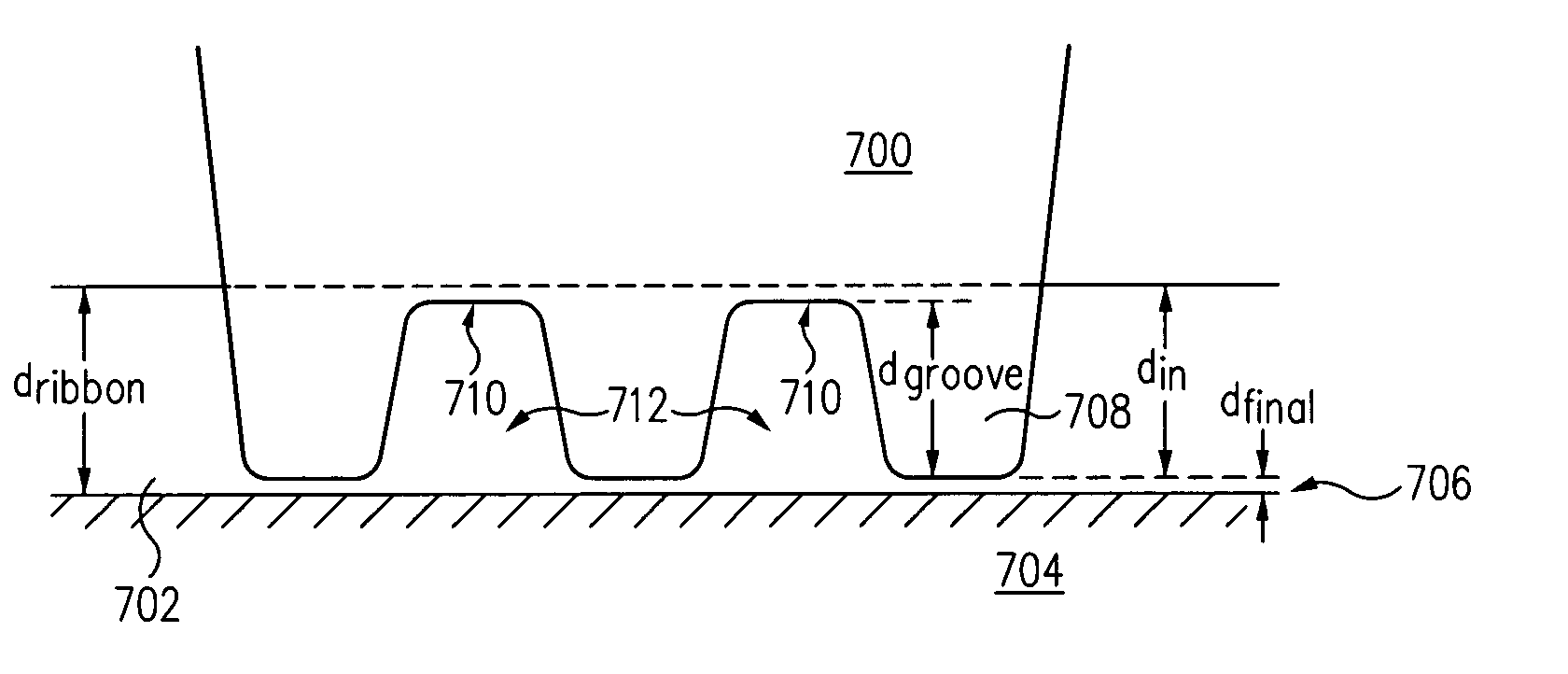

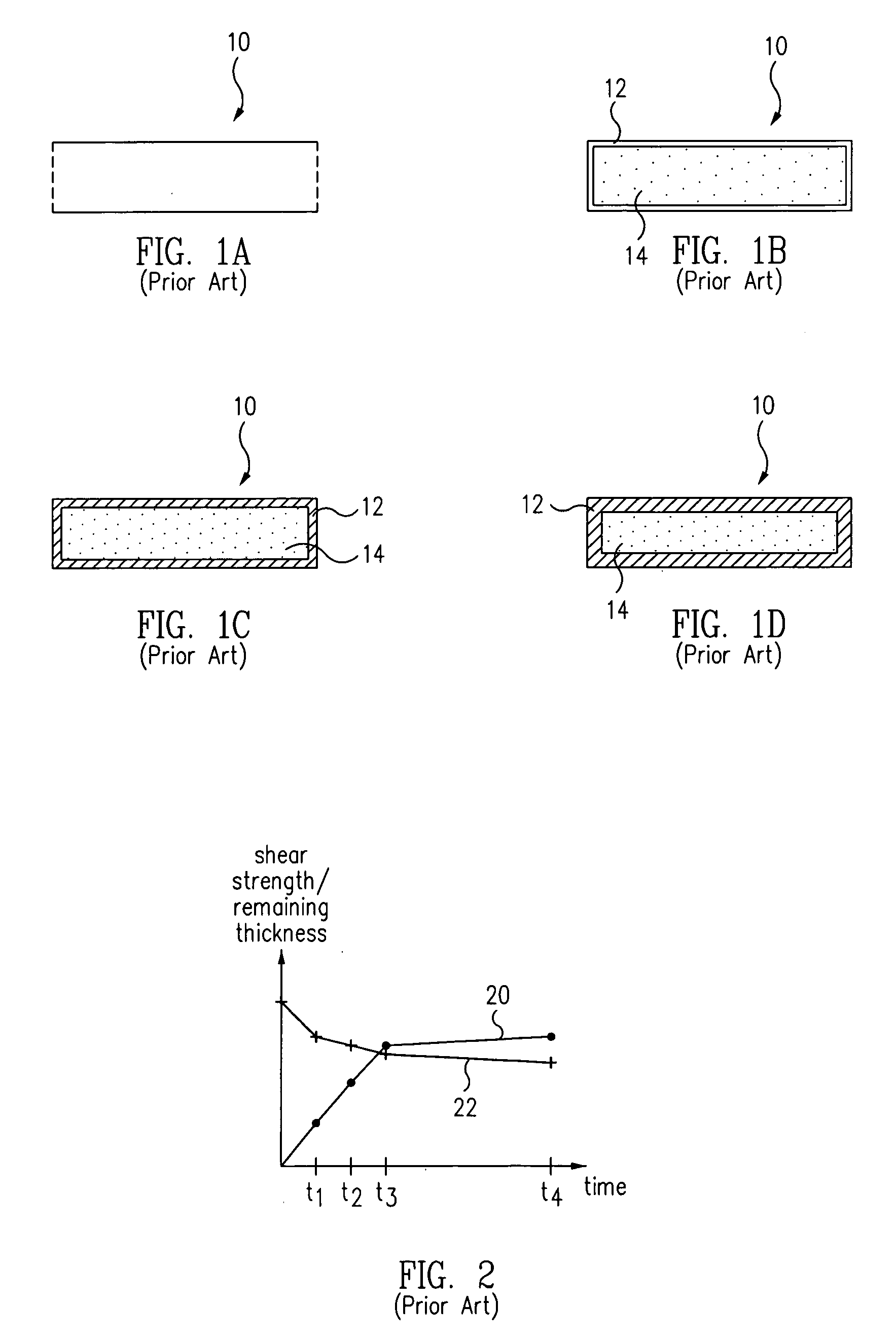

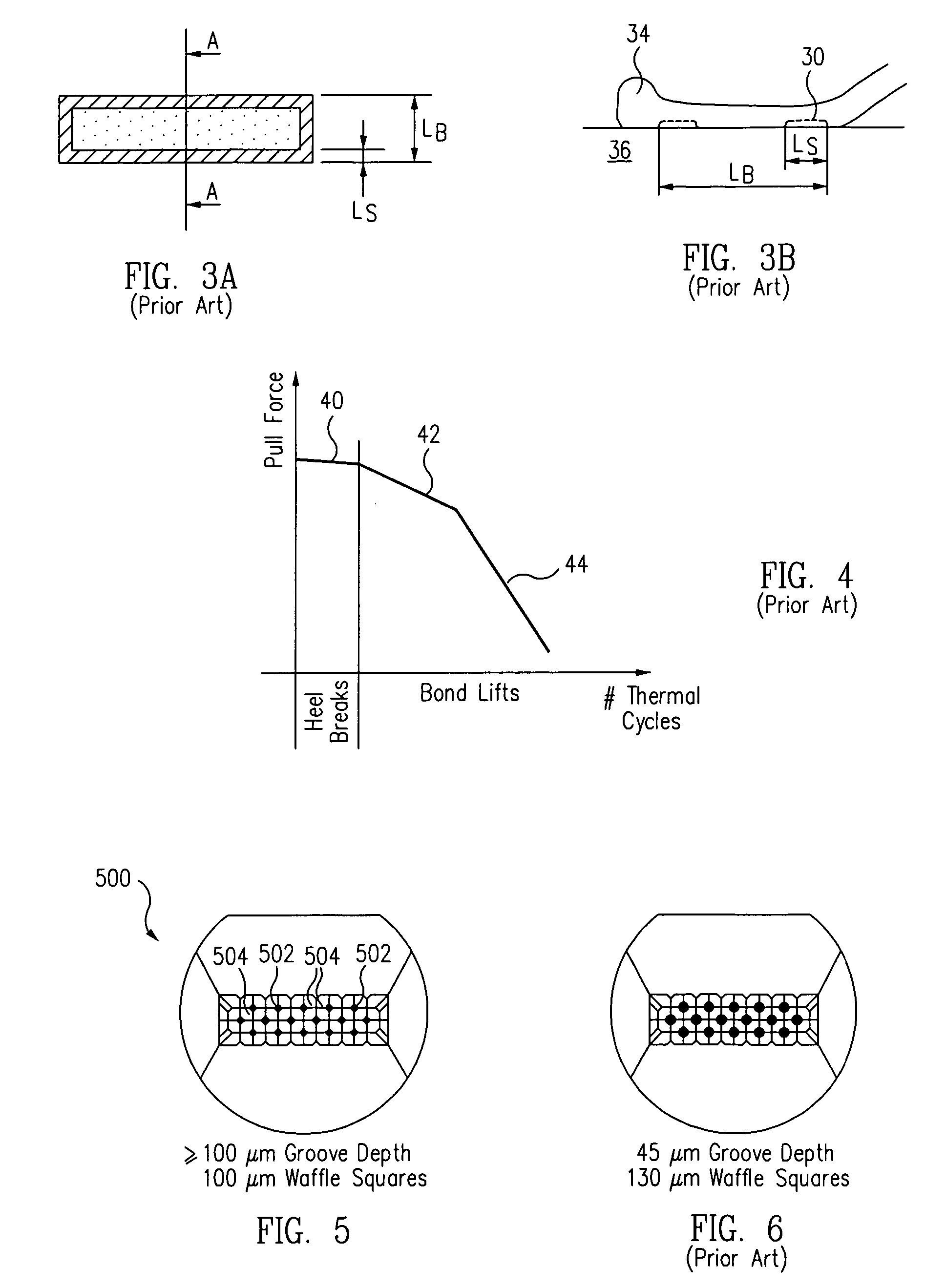

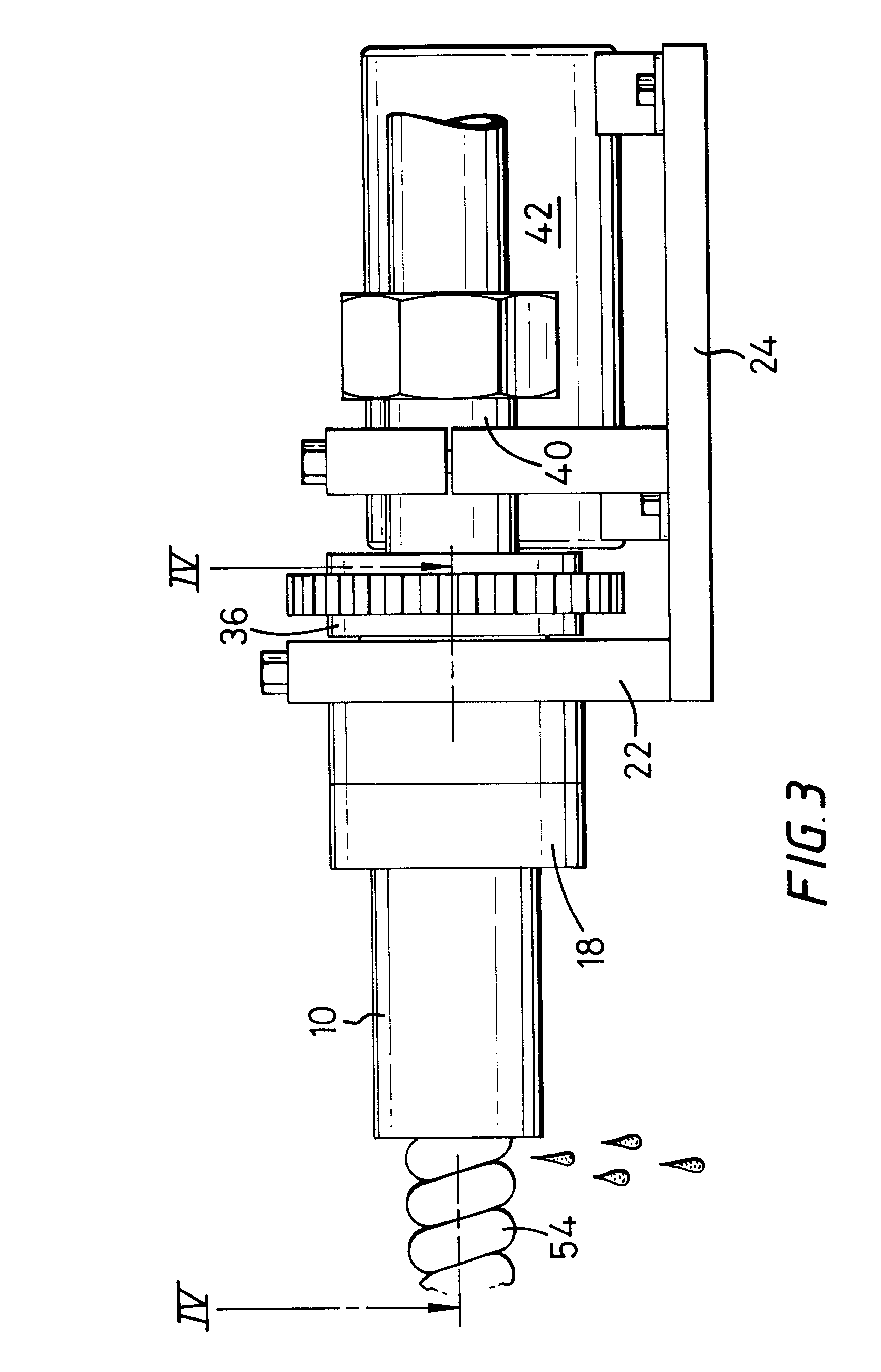

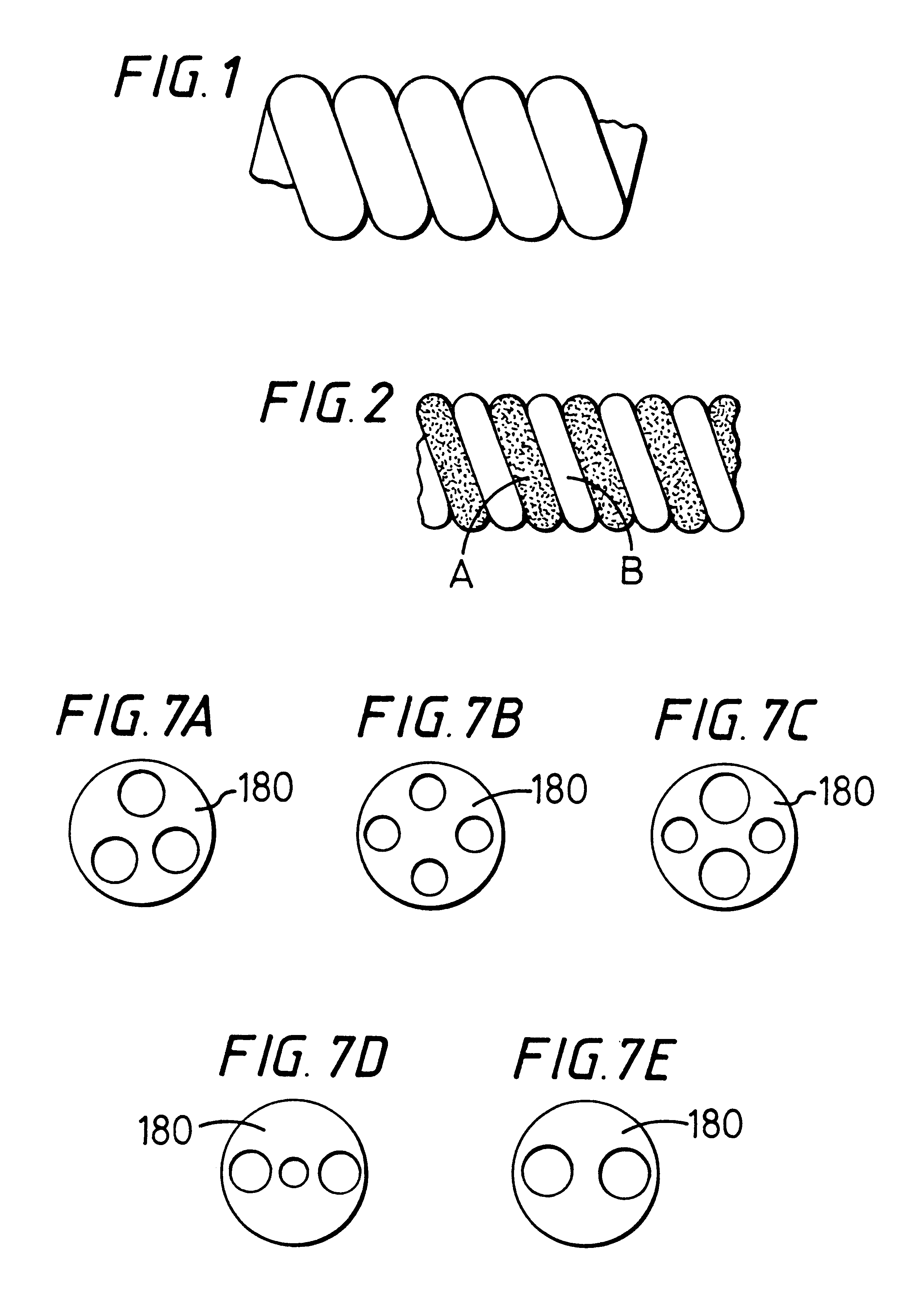

Ribbon bonding tool and process

InactiveUS20060163315A1High bonded areaLight strengthWelding/cutting auxillary devicesSolid-state devicesEngineeringMechanical engineering

Owner:ORTHODYNE ELECTRONICS

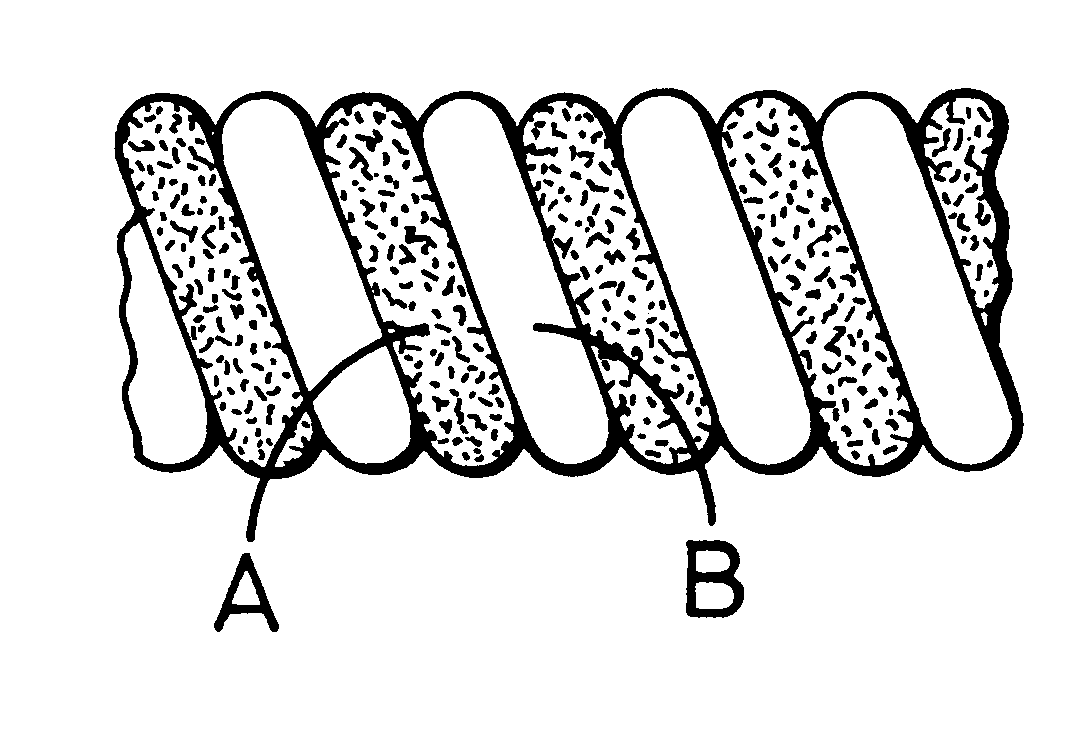

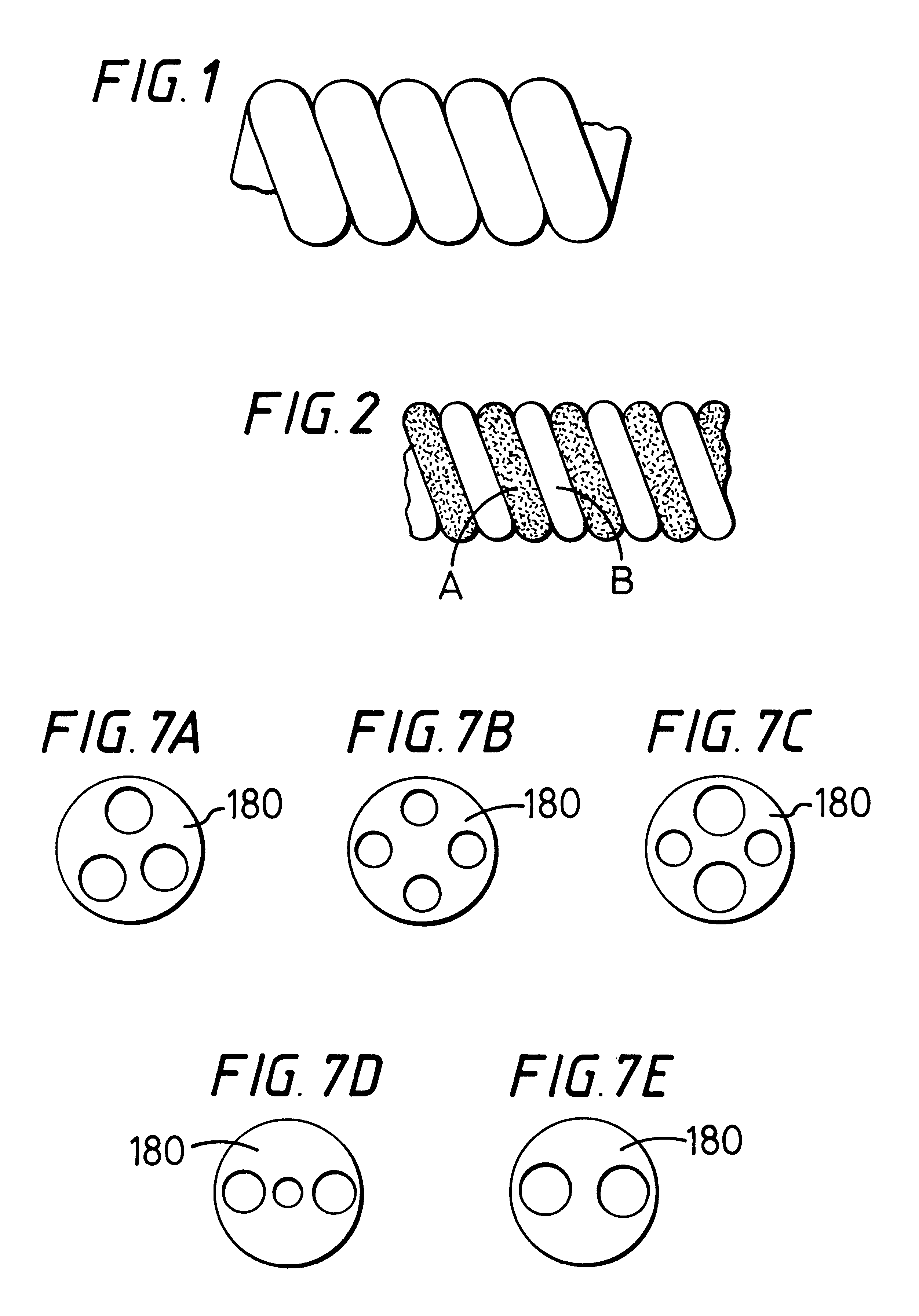

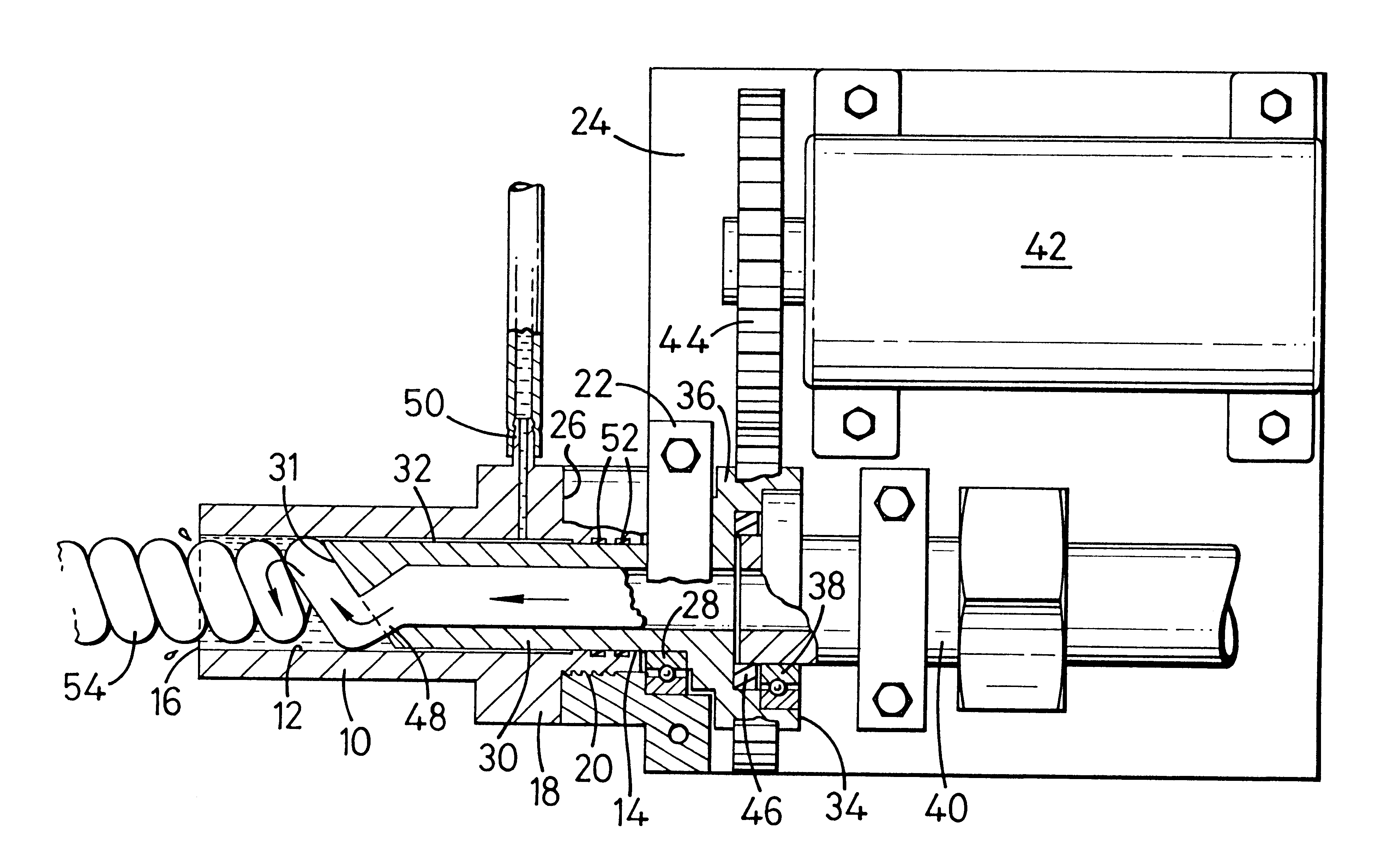

Helical food product

A food product comprising one or more plastic food substrates is formed into a helical configuration and coated with a fluid barrier agent to prevent reannealing of adjacent turns of the product. The fluid barrier agent may be an edible vegetable oil such, for example, as hydrogenated vegetable oil, Soya oil, rape oil, sunflower oil, safflower oil, peanut oil or a mixture of such oils. The product may define a single helix or a multiple helix, e.g. a double or triple helix.

Owner:BERNARD MATTHEWS FARMS

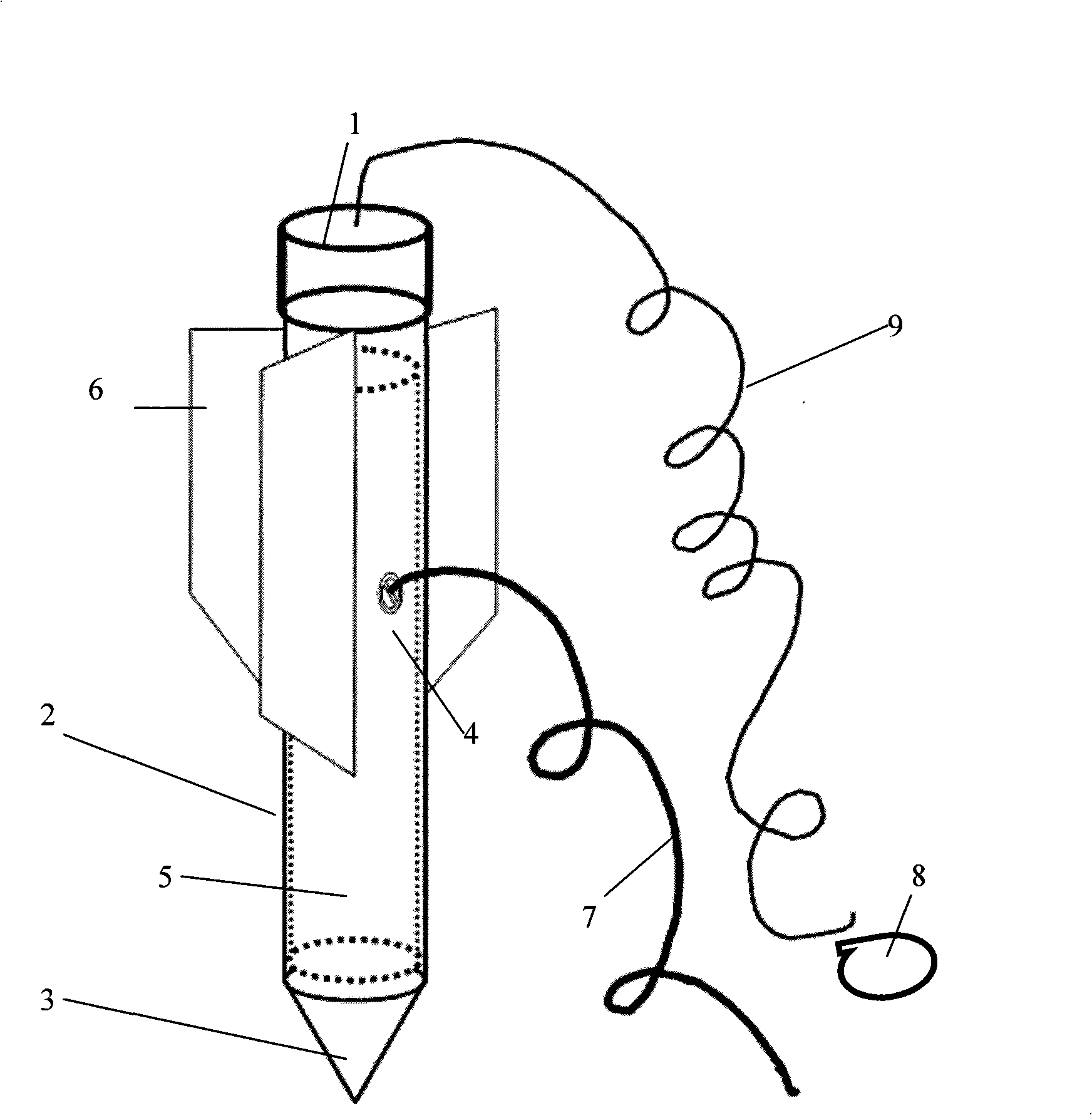

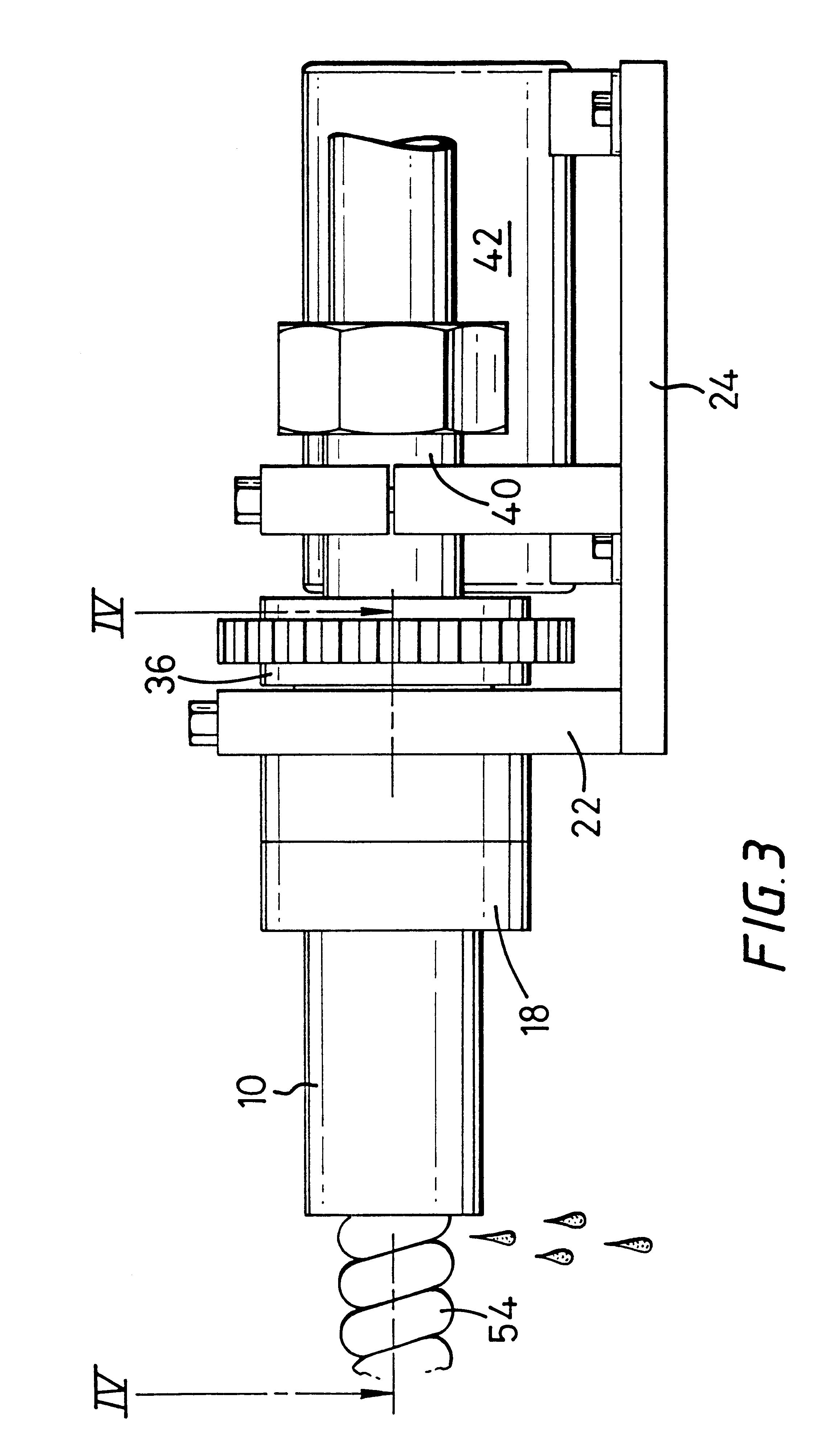

Power embedment anchor with high-frequency small amplitude vibration

The invention relates to a power embedment anchor with high-frequency micro-amplitude vibration in the ship and ocean engineering technical field. The embedment anchor comprises an anchor cover, an anchor shank, an anchor hammer, a lifting lug, a high-frequency micro-amplitude vibration device, a main fin, an anchor chain, a power source and a cable, wherein the anchor cover is arranged on the upper part of the anchor shank; the anchor hammer is arranged on the lower part of the anchor shank; the lifting lug is arranged on the surface of the outer wall of the anchor shank; the anchor chain is connected with the lifting lug; the high-frequency micro-amplitude vibration device is arranged inside the anchor shank; the main fin consists of two to four sheets which are uniformly and symmetrically arranged on the surface of the outer wall of the anchor shank; the power source supplies power to the high-frequency micro-amplitude vibration device through the cable; and the cable is connected with the power source and the high-frequency micro-amplitude vibration device through an outer cover. The embedment anchor has good holding power and underwater anchor weight ratio under different submarine sediment, can rapidly hold seabed, and is little in windlass tension needed in the process of raising anchors.

Owner:SHANGHAI JIAO TONG UNIV

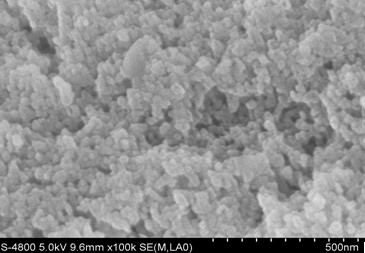

High solid phase content ceramic slurry for photo-curing 3D printing and preparation process of ceramic slurry

InactiveCN107129283AReduce surface tensionGood dispersionAdditive manufacturing apparatusSlurrySurface modification

The invention discloses high solid phase content ceramic slurry for photo-curing 3D printing, which comprises 75-90 parts by mass of inorganic ceramic powder and 10-25 parts by mass of organic liquid phase materials. The preparation process of the ceramic slurry comprises the following steps: firstly, carrying out modification treatment on the inorganic ceramic powder, and then adding the inorganic ceramic powder into the premixed organic liquid phase materials so as to be prepared into the high solid phase content ceramic slurry capable of being used for photo-curing 3D printing forming, wherein the modification treatment comprises a physical surface modification process or / and a chemical surface modification process. A ceramic green body prepared from the slurry can be sintered into a ceramic product with high compactness and high surface quality, thereby solving the problems of high contents of organic components, low compactness and poor surface quality of ceramic products, and the like in the prior art.

Owner:NANJING UNIV OF TECH +1

Gypsum-containing board and tile, and method for producing same

InactiveUS7758980B2Increase resistanceHigh strengthConstruction materialRecord information storageBrickSulfate

The invention provides a set gypsum-containing product having increased resistance to permanent deformation and a method for preparing it comprising forming a mixture of a calcium sulfate material, water, and an appropriate amount of one or more enhancing materials chosen from condensed phosphoric acids, each of which comprises 2 or more phosphoric acid units; and salts or ions of condensed phosphates, each of which comprises 2 or more phosphate units. The mixture is then maintained under conditions sufficient for the calcium sulfate material to form a set gypsum material.

Owner:UNITED STATES GYPSUM CO

Phosphogypsum based plastering gypsum

The invention discloses a phosphogypsum based plastering gypsum, and relates to a plastering material for a building wall. The phosphogypsum based plastering gypsum mainly comprises 75 to 95 percent of phosphogypsum based building gypsum, 1 to 3 percent of sierozem powder, 0.1 to 0.5 percent of retarder, 1.1 to 5.5 percent of composite water retention agent, 0.3 to 1 percent of ethylene-vinyl acetate copolymerized latex powder, and 0 to 20 percent of stuffing. The phosphogypsum based plastering gypsum effectively improves water retention property and lowers cost by adopting the combination of cellulose ether water retention agent and bentonite, effectively adjusts settling time and prolongs operable time by adopting the retarder, improves construction property, cohesive property and cracking resistance by doping the stuffing and the latex powder, and reduces adverse effects of impurities on the strength of plastering gypsum by adding the sierozem powder. The phosphogypsum based plastering gypsum has the advantages of good workability and construction property, long operable time, high breaking resistance, compression resistance and adhesion strength, good volume stability, good cracking resistance and lower cost, and can be used for a plastering layer of the building wall.

Owner:CHONGQING UNIV

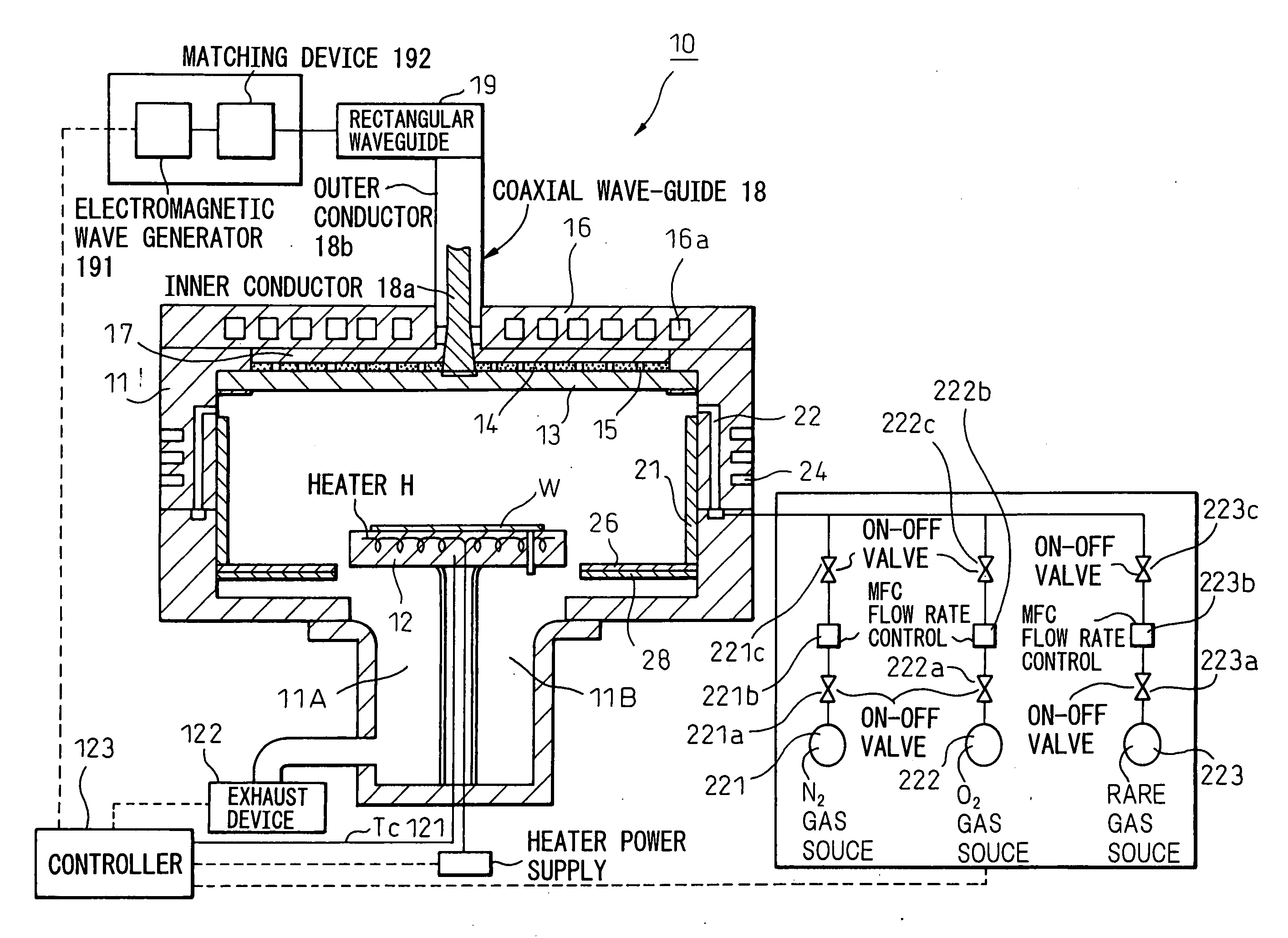

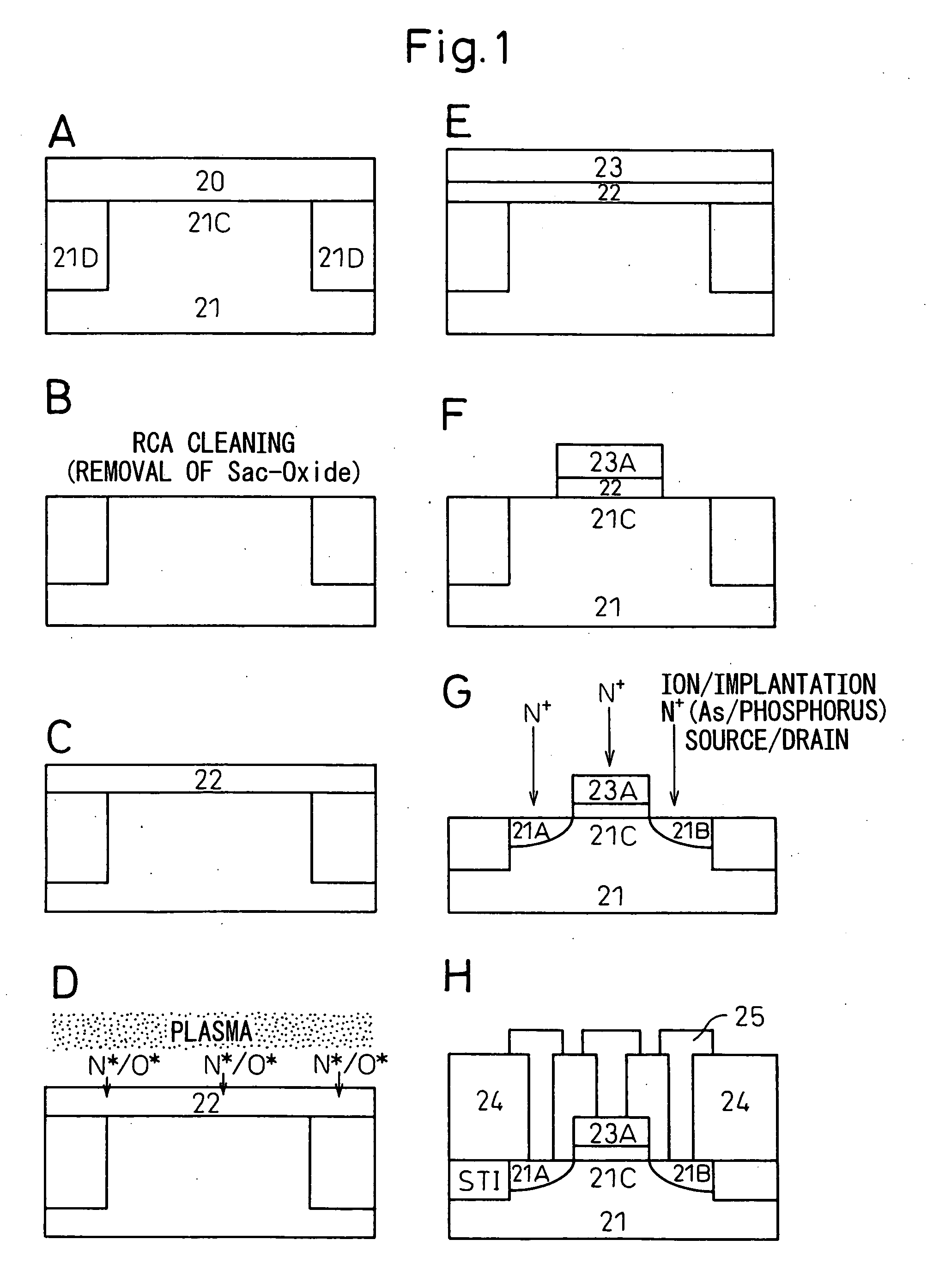

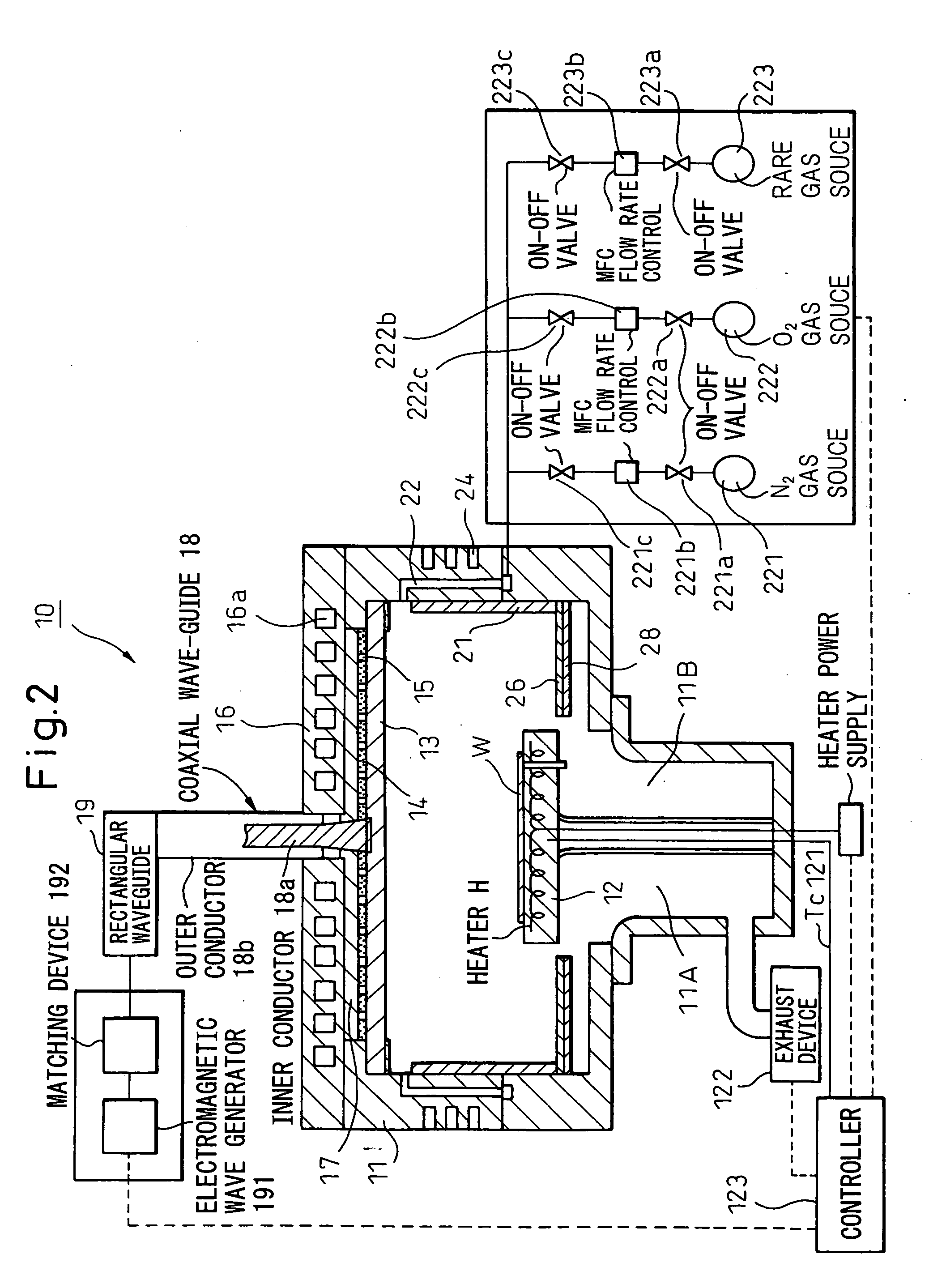

Method of modifying insulating film

ActiveUS20060199398A1Increased modificationShorten treatment timeTransistorSemiconductor/solid-state device manufacturingDangling bondMaterials science

An insulting film is modified by subjecting the insulting film to a modification treatment comprising a combination of a plasma treatment and a thermal annealing treatment. There is provided a method of enhancing the characteristic of an insulating film by improving deterioration in the characteristic of the insulating film due to carbon, a suboxide, a dangling bond or the like contained in the insulating film.

Owner:TOKYO ELECTRON LTD

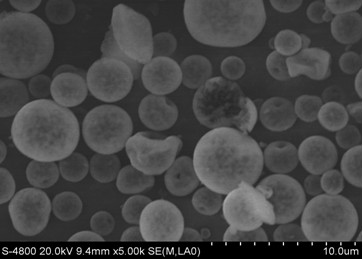

Preparation of nano silicone-acrylate core shell type composite latex for latex paints

InactiveCN101921360AThe polymerization process is stableGuaranteed yieldCoatingsChemistryWeather resistance

The invention relates to a preparation method of nano silicone-acrylate core shell type composite latex for latex paints. The preparation method solves the problem that latex paints prepared from the common latex is insufficient to meet the demands of people at the performance aspects of water resistance, weather resistance, pollution resistance and the like, and simultaneously reduces the restraint degrees of a region domain and a time and season domain for latex construction. In the preparation method, active organic silicon and acrylate monomers are mainly used as raw materials, and then the nano silicone-acrylate core shell type composite latex using polyacrylate as a core and using silicone-acrylate composite resin as a shell is synthesized by adopting a monomer pre-emulsifying process and a seed semi-continuous latex polymerization method, so that the preparation method has the advantages of stable polymerization process and convenient large-scale production. When used for preparing the latex paints of outer walls, the synthesized latex can greatly improve all performance of the latex paints, also solve the conflicts between the lowest film-forming temperature and film hardness and simultaneously realize the unification of the cost and the performance.

Owner:SHAANXI UNIV OF SCI & TECH

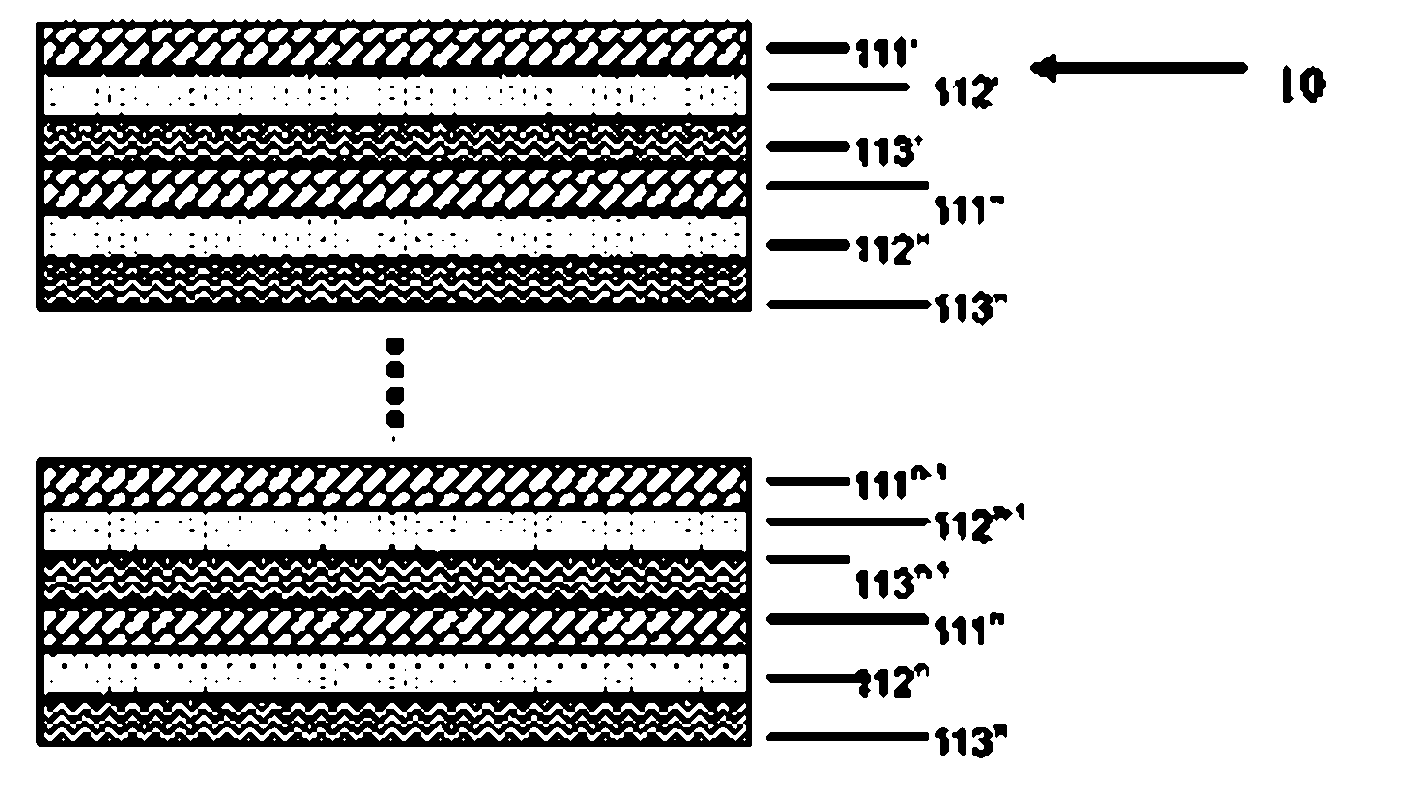

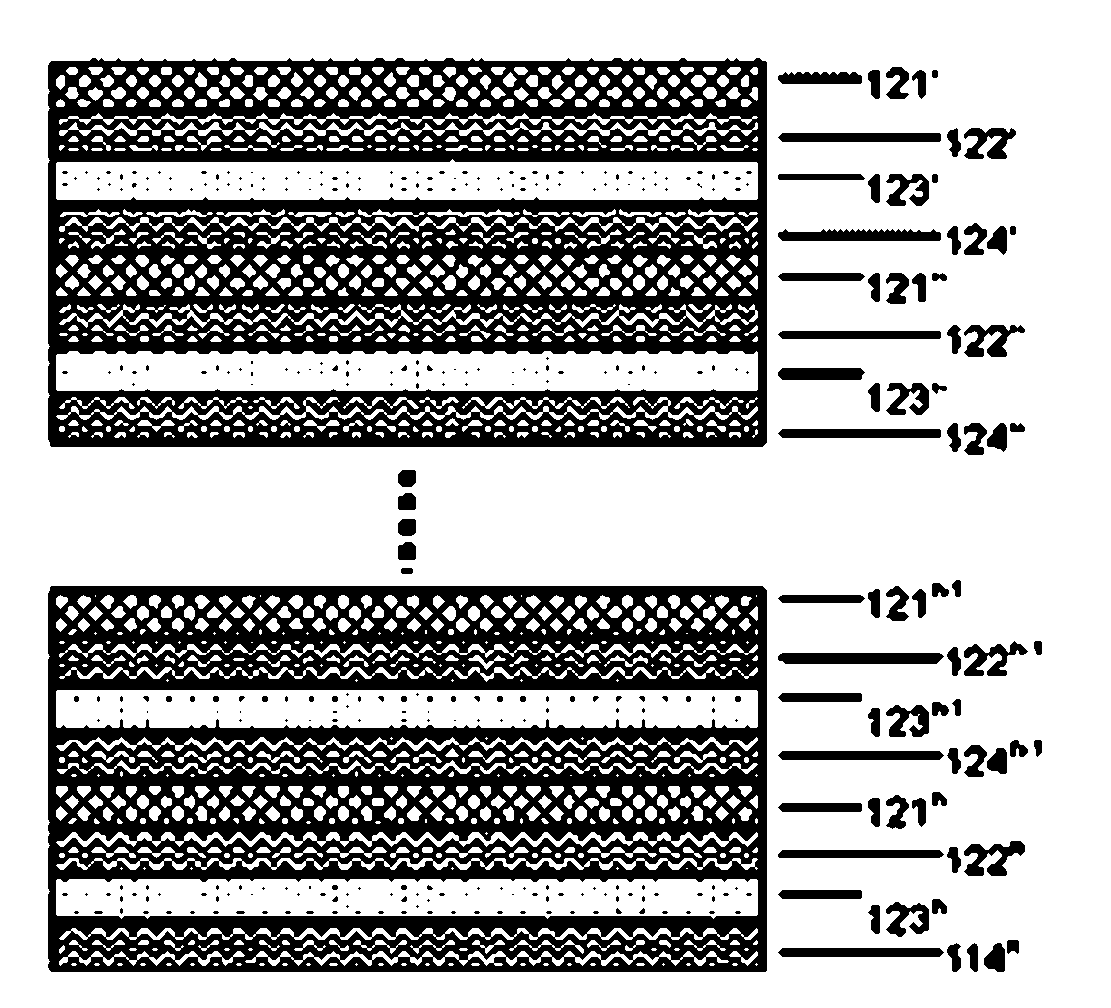

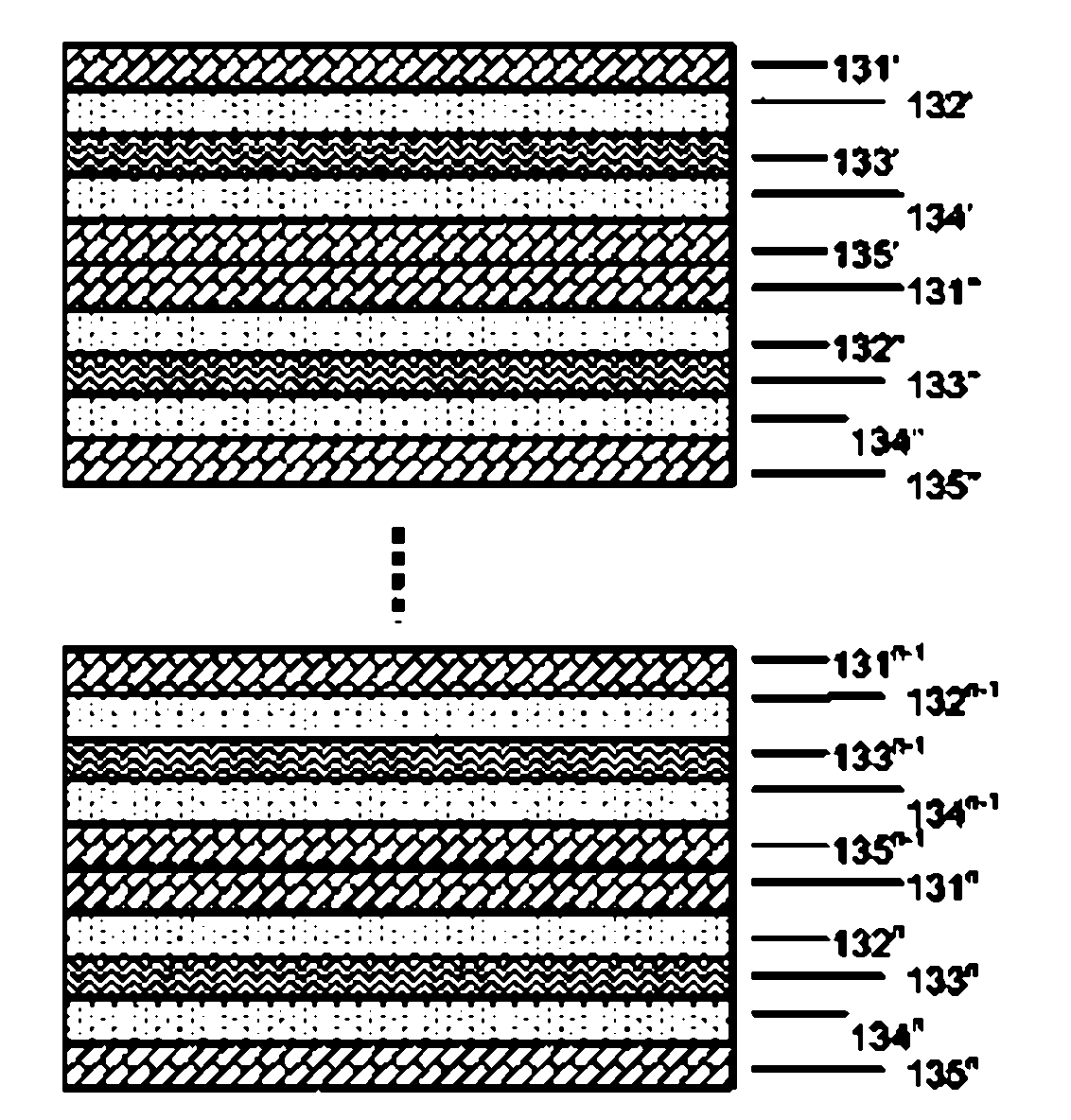

Barrier-property lapped polymer film packaging material

ActiveCN102001486AReduce dosageOne less contains at least dosageFlexible coversWrappersPolymer thin filmsEngineering

The invention discloses a barrier-property lapped polymer film packaging material comprising at least one layer-multiplied and coextruded lapped barrier compound layer. Each barrier compound layer comprises a plurality of repeating units which comprise at least two individual layers; each individual layer corresponds to one of two different polymers; at least one repeating unit of the lapped barrier compound layer at least comprises three individual layers; each of the individual layers corresponds to one of three different polymers; and at least one of the at least three polymers forms at least one barrier-property polymer part which can separate gas.

Owner:厦门天策材料科技有限公司

Method and apparatus for making an helical food product

Owner:BERNARD MATTHEWS FARMS

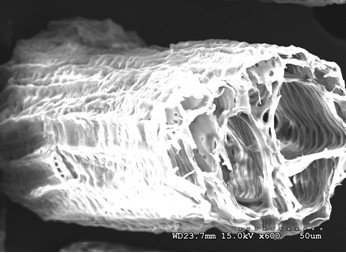

Short fiber food waste residue-based nano cellulose and preparation method thereof

InactiveCN102182089AFine granularityThe compactness of the crystal region is weakPretreatment with water/steamWashing/displacing pulp-treating liquorsFood additiveFiber

The invention relates to the field of processing of agricultural products, in particular to short fiber food waste residue-based nano cellulose and a preparation method thereof. The preparation method comprises three parts of pretreatment of short fiber food waste residues, acid hydrolysis of food residue fibers and homogenization. The nano cellulose prepared by the method has the granularity of 50-300nm, is short bar-shaped or microsphere-shaped and can be widely used for preparing a food additive or medicament excipient, and the like. In the method, acid hydrolysis is combined with high-pressure homogenization, thus the acid consumption and hydrolysis time are reduced, the granularity uniformity of the nano cellulose is improved; and the invention is suitable for mass production.

Owner:SOUTHWEST UNIV

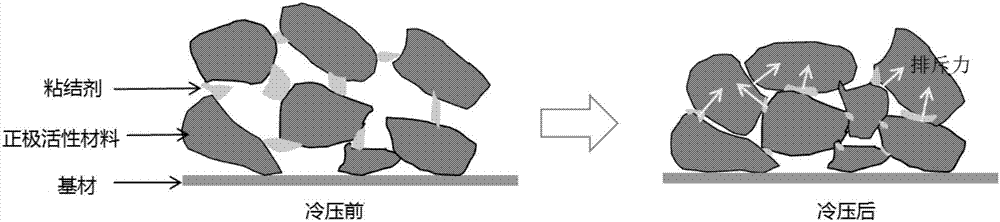

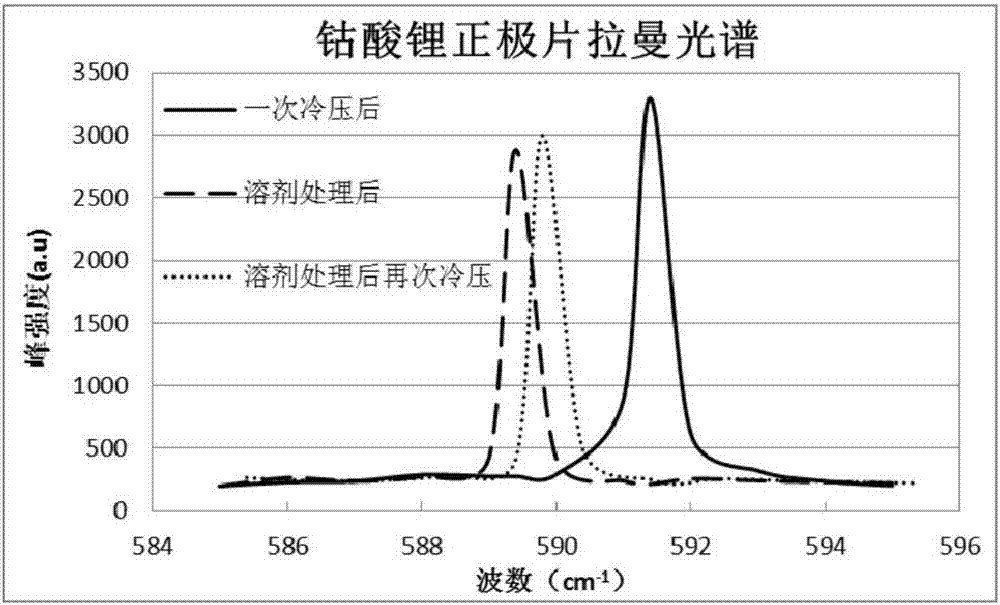

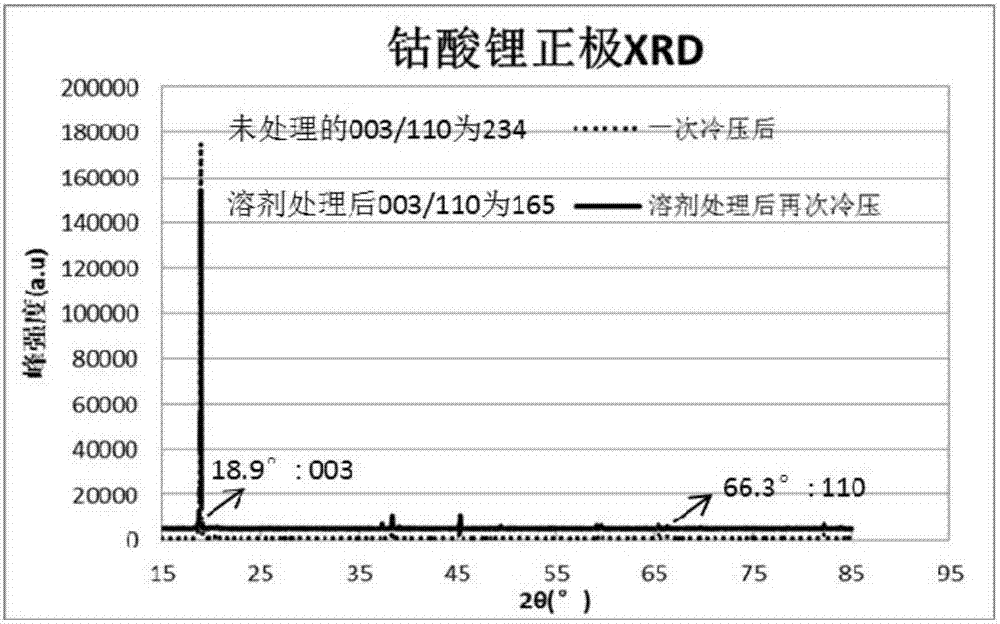

Lithium ion battery positive plate and manufacture method thereof

ActiveCN107403905AReduce stickingReduce thicknessSecondary cellsElectrode collector coatingSodium-ion batterySlurry

The invention discloses a manufacture method of a lithium ion battery positive plate. The manufacture method comprises the following steps: providing a positive current collector; preparing positive slurry containing an positive active material with a stratified-structured crystal form, uniformly distributing the positive slurry onto the positive current collector, drying, and carrying out primary cold pressing and slicing, so as to obtain a positive plate; carrying out infiltration on the positive plate by virtue of a solvent; and drying, and carrying out secondary cold pressing, so as to obtain the lithium ion battery positive plate. By carrying out infiltration on the positive plate which is subjected to primary cold pressing, residual stress of the positive plate can be effectively reduced, the expansion of the positive plate can be reduced, a lithium ion battery is thinned, and the energy density of the lithium ion battery is increased. The contact among particles of the positive active material is relatively close in a subsequent charging-discharging cycle process, and the cycle performance of the lithium ion battery is improved. Besides, the invention further discloses the lithium ion battery positive plate manufactured by the method and the lithium ion battery adopting the lithium ion battery positive plate.

Owner:NINGDE AMPEREX TECH

Method for producing bricks from silt and sludge

InactiveCN101830687AWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primary stirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

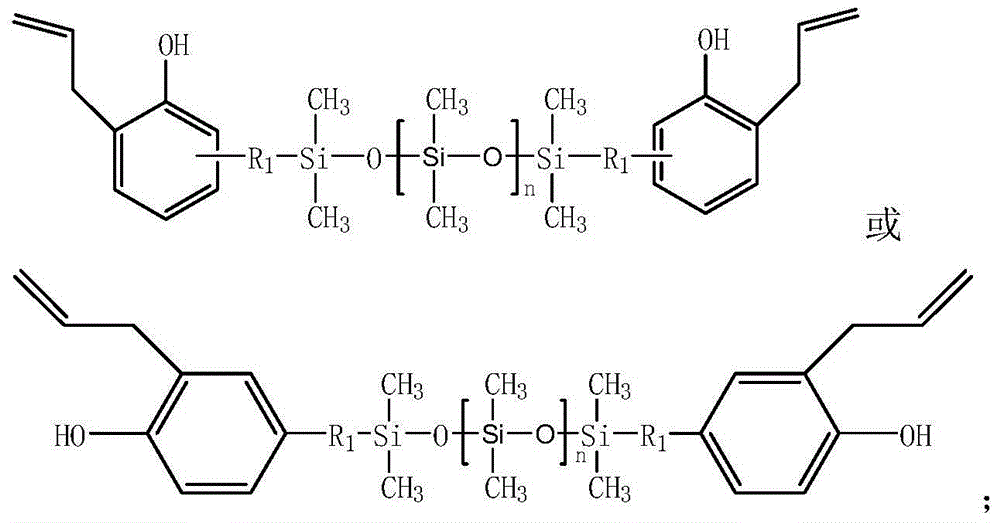

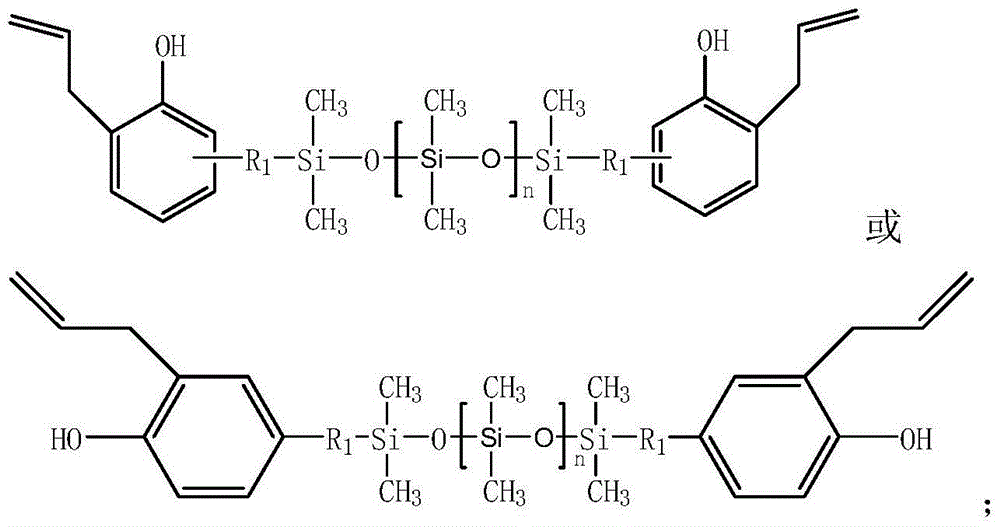

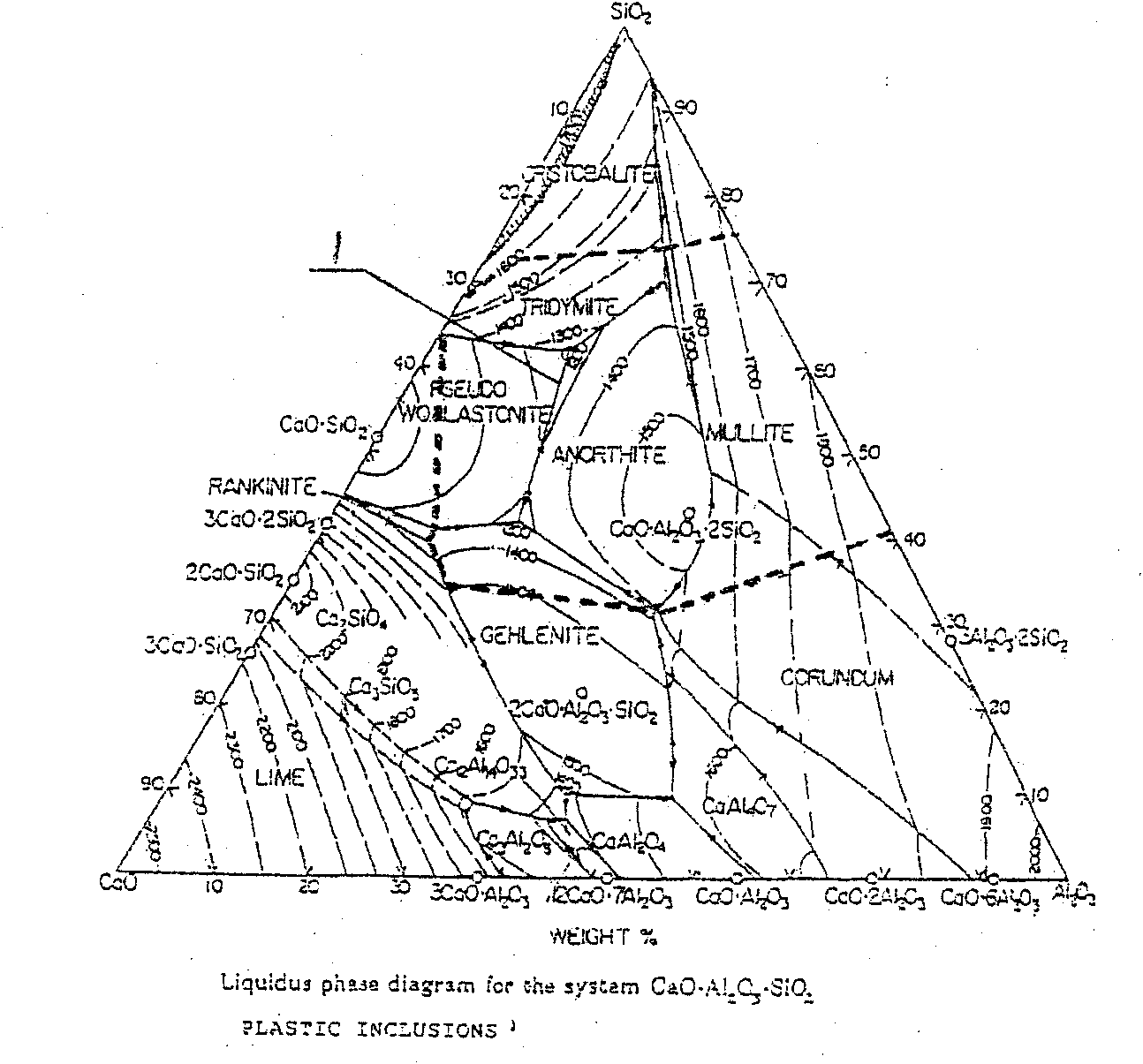

Resin composition and prepreg laminated board manufactured by employing same

InactiveCN104830059AImprove performanceGood thermal expansion performanceSynthetic resin layered productsMetal layered productsThermal expansionSilorane Resins

The invention discloses a resin composition which comprises the following solids by weight: (a) 100 parts of a bismaleimide resin prepolymer, (b) 5-80 parts of cyanate ester, (c) 0-50 parts of a flame retardant and (d) 0-65 parts of inorganic filler, wherein the bismaleimide resin prepolymer is obtained by carrying out reaction on an allyl compound and bismaleimide resin and the ratio of bismaleimide resin and allyl compound by weight is 100: (10-120). According to the resin composition disclosed by the invention, by adopting siloxane containing allyl at the tail end as a modifier of bismaleimide resin and limiting the content of siloxane in the modifier, unreacted siloxane resin is not generated in reaction, so that the advantages and characteristics of siloxane resin can be fully exerted and the interlaminar adhesive force at the high temperature is greatly improved. Moreover, the thermal expansion properties of the solids are optimized, so that the resin composition satisfies the requirements on high precision electronic substrate materials.

Owner:SHENGYI TECH SUZHOU

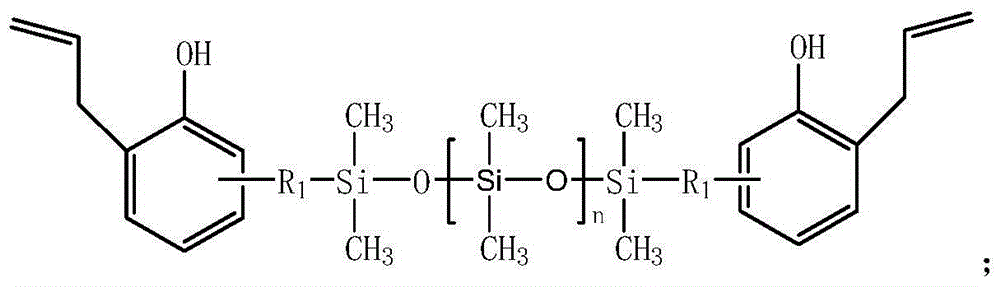

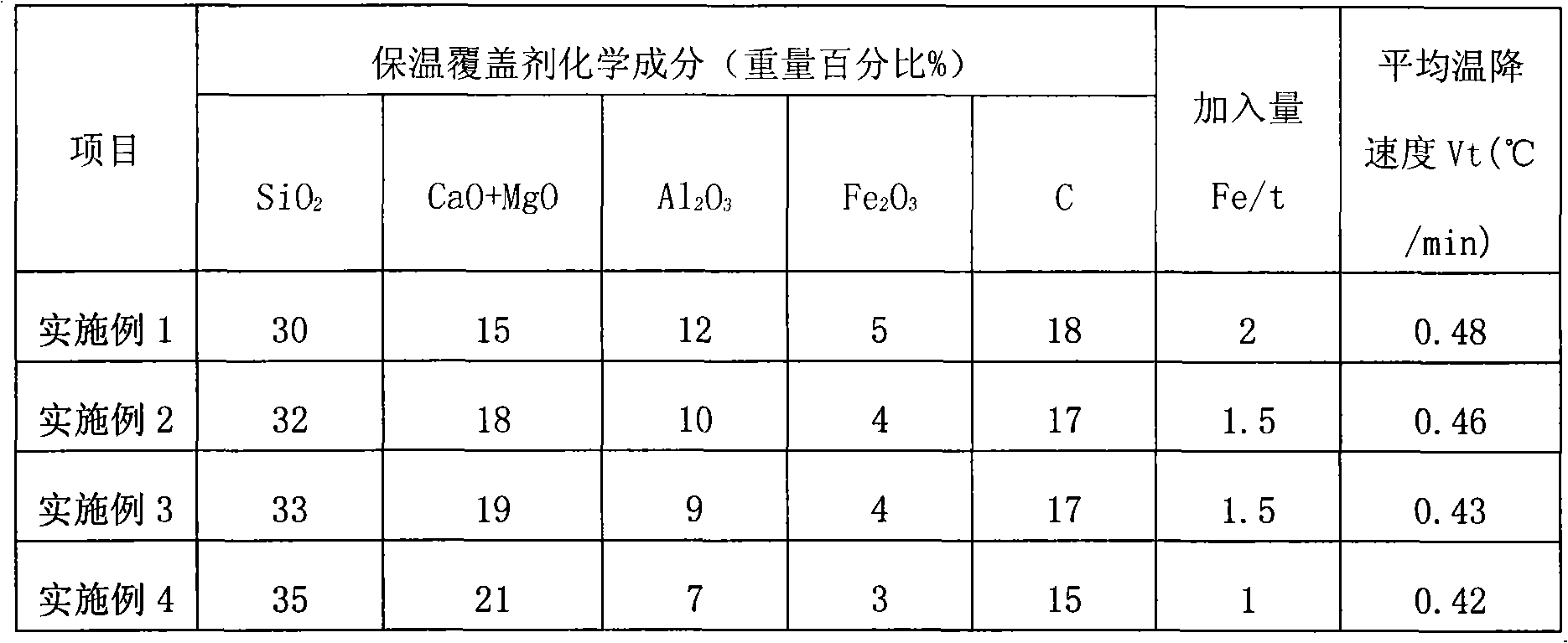

Granular heat-preserving covering flux for hot metal in steelmaking

InactiveCN101787413AConducive to slag cleaning operationImprove adsorption capacityProcess efficiency improvementSteelmakingImpurity

The invention discloses a granular heat-preserving covering flux for hot metal in steelmaking, and relates to a treatment agent added into a ladle for preserving heat on the surface of hot metal for steelmaking. The granular heat-preserving covering flux is characterized in that: the heat-preserving covering flux is prepared from expanded vermiculite, wollastonite, bauxite, iron ore concentrate and coke powder, and comprises the following components in percentage by weight: 30 to 35 percent of SiO2, 15 to 21 percent of (CaO+MgO), 7 to 12 percent of Al2O3, 3 to 5 percent of Fe2O3, 15 to 20 percent of C, and the balance of impurities; and the raw materials are ground, sieved, mixed, mixed and stirred, dried, cooled, and weighed and packaged at normal temperature and normal pressure. The granular heat-preserving covering flux has the advantages that: the granular heat-preserving covering flux has good slagability and spreadability, is conveniently adsorbed by inclusion, contains a heat-generating agent and an oxygen supplying agent so as to facilitate melting per se and reduce iron sticking and ladle sticking; the expanded vermiculite and the wollastonite regulate components of the heat-preserving covering flux, and have expanding and heat insulating functions, and good heat preservation property; the MgO regulates the alkalinity and reduces the adhesion of the heat-preserving covering flux with a ladle lining so as to facilitate cleaning slag in the ladle; and the heat-preserving covering flux is granular and greatly reduces dust pollution.

Owner:马鞍山中冶钢铁冶金高新技术有限公司

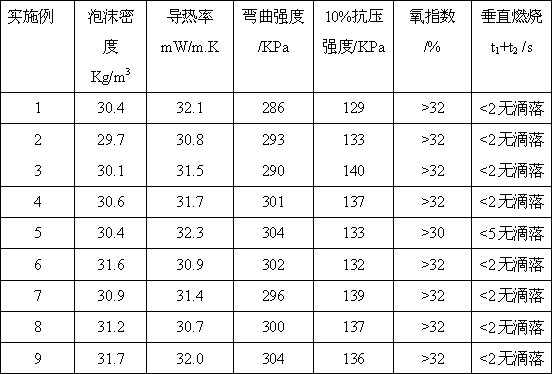

Preparation method of coated halogen-free flame-retardant foamable polystyrene

InactiveCN102977402AAvoid fireWith flame retardant functionNon-macromolecular adhesive additivesMacromolecular adhesive additivesBenzoyl peroxideThermal insulation

The invention belongs to the field of expandable polystyrene heat insulating materials, and particularly relates to a preparation method of coated halogen-free flame-retardant foamable polystyrene. The method comprises the following steps: adding polyvinyl alcohol and tricalcium phosphate into deionized water, and evenly mixing to obtain a mixed solution A; adding ammonium polyphosphate, melamine polyphosphate or PNP intumescent flame retardant into styrene, and adding benzoyl peroxide to obtain a mixed solution B; adding the mixed solution B into the mixed solution A to react, and adding a foaming agent to react to obtain halogen-free flame-retardant foamable polystyrene granules; and adding the prepared granules into a phenol formaldehyde resin or melamine resin binding agent containing small amounts of alkali silicate water solution and smoke inhibitor to carry out coating, thereby finally obtaining the coated halogen-free flame-retardant foamable polystyrene granules. The coated halogen-free flame-retardant foamable polystyrene has the advantages of excellent thermal insulation and heat shielding properties, and outstanding flame retardancy and smoke inhibition property, and can be used a flame-retardant architectural thermal insulation material.

Owner:LIAONING TECHNICAL UNIVERSITY

Exhaust gas purifying catalyst and method of producing same

InactiveUS20020198098A1Increase production costIncreased durabilityInternal combustion piston enginesMolecular sieve catalystsExhaust gasColloidal silica

An exhaust gas purifying catalyst for exhaust gas discharged from an automotive internal combustion engine. The catalyst comprises a substrate over which a hydrocarbons adsorbing material layer is formed as a lower layer to absorb hydrocarbons contained in exhaust gas. The hydrocarbons adsorbing material layer contains zeolite and colloidal silica which has undergone firing. The colloidal silica is in a chain-like form and / or a spherical form before and after the firing. Additionally, a catalyst component layer is formed as an upper layer over the hydrocarbons adsorbing material layer. The catalyst component layer contains a catalyst metal.

Owner:NISSAN MOTOR CO LTD

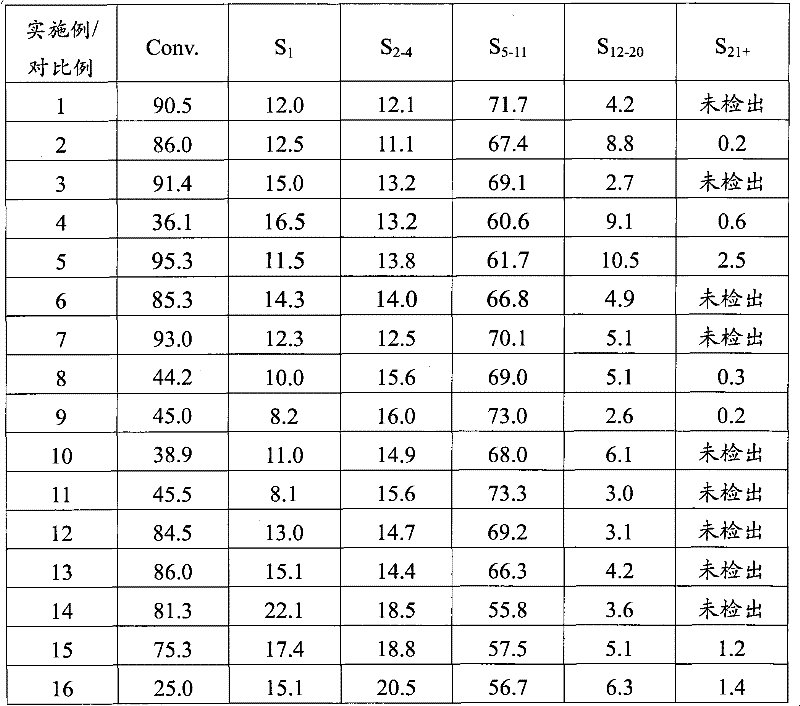

Catalyst for preparing high-quality gasoline fraction by virtue of syngas high selectivity and preparation method thereof

InactiveCN102211034AReduce stickingReduce pipe blockage and other problemsMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneMolecular sieve

The invention provides a catalyst for preparing a high-quality gasoline fraction by virtue of syngas high selectivity and a preparation method thereof. The catalyst comprises the following components in percentage by weight: 1-30% of metallic cobalt, 0.01-5% of assistant elements and the balance of molecular sieve. The catalyst has good selectivity to isoparaffin with 5-11 carbon atoms and quite low selectivity to the waxy hydrocarbons with more than 20 carbon atoms, so that the catalyst can be used for preparing high-quality gasoline fuels, and the catalyst carbon deposition can be avoided or obviously reduced. In addition, the invention further provides the preparation method of the catalyst.

Owner:WANHUA IND GRP

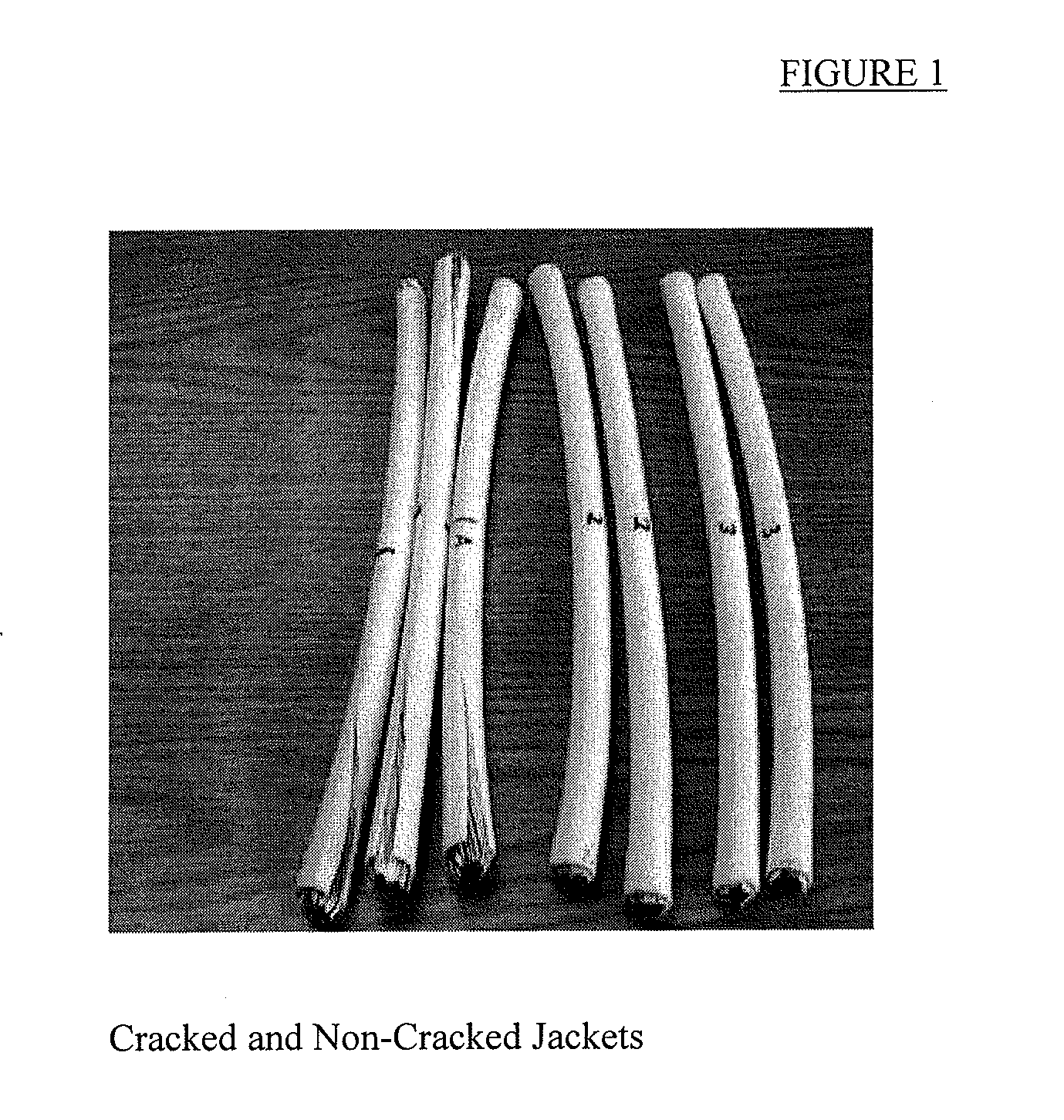

Crack-Resistant, Flame Retardant, Halogen-Free, Cable Assembly and Coating Composition

ActiveUS20100069545A1Affect adhesionImproved propertyLiquid surface applicatorsSpecial tyresMaleic anhydrideChemistry

Halogen-free, flame-retardant, crack-resistant, cable coatings are prepared from a composition comprising:A) 3 to 10 percent by weight of a low-melting temperature and medium to high grafted level maleic anhydride grafted polyethylene using a VLDPE base resin having density ranging from 0.86 to 0.91 g / cm3 and made with a single-site catalyst;B) 15 to 25% by weight of at least one EEA or EVA;C) 5 to 20% by weight of an a-olefin polymer; andD) 40 to 65% by weight of a flame retardant inorganic filler.

Owner:UNION CARBIDE CORP

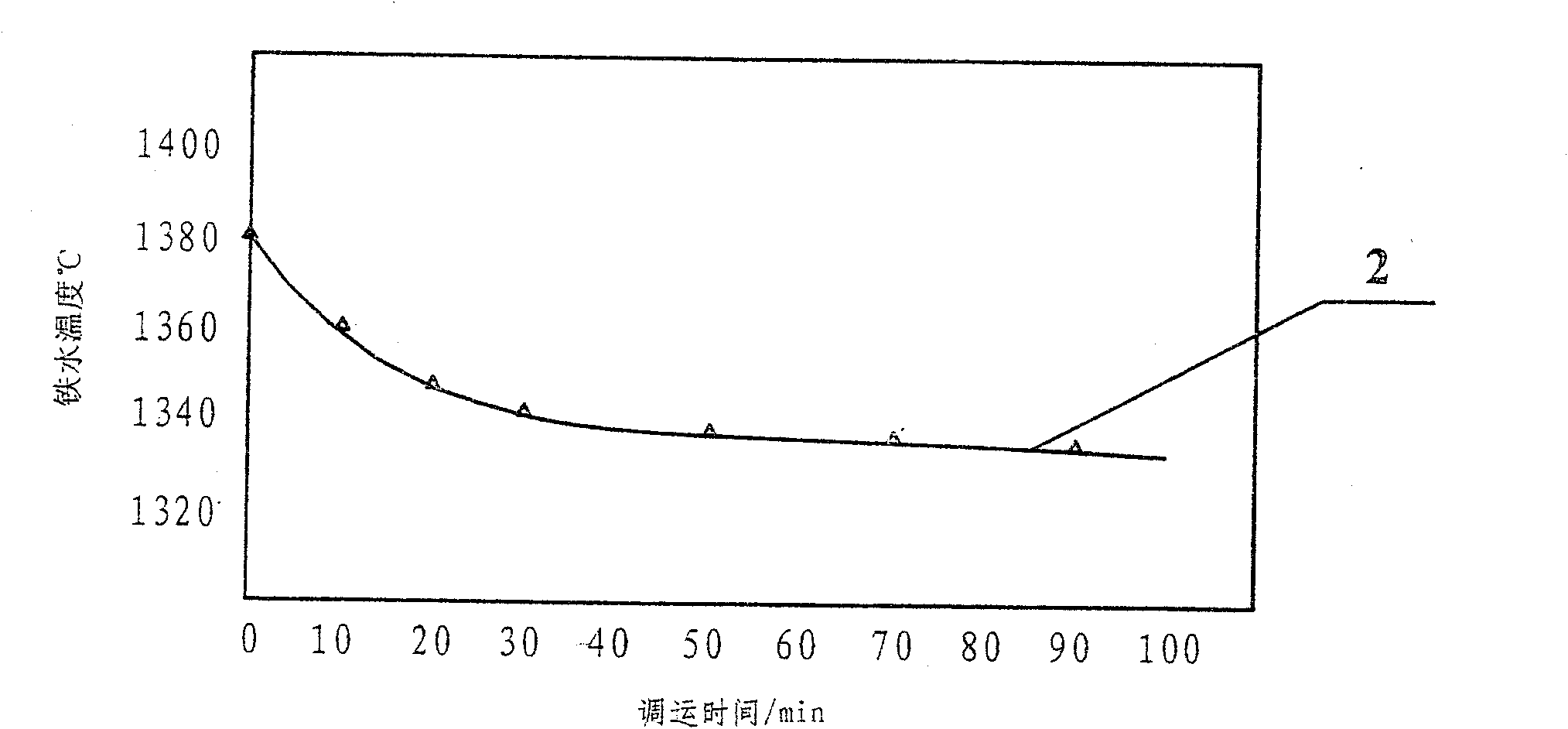

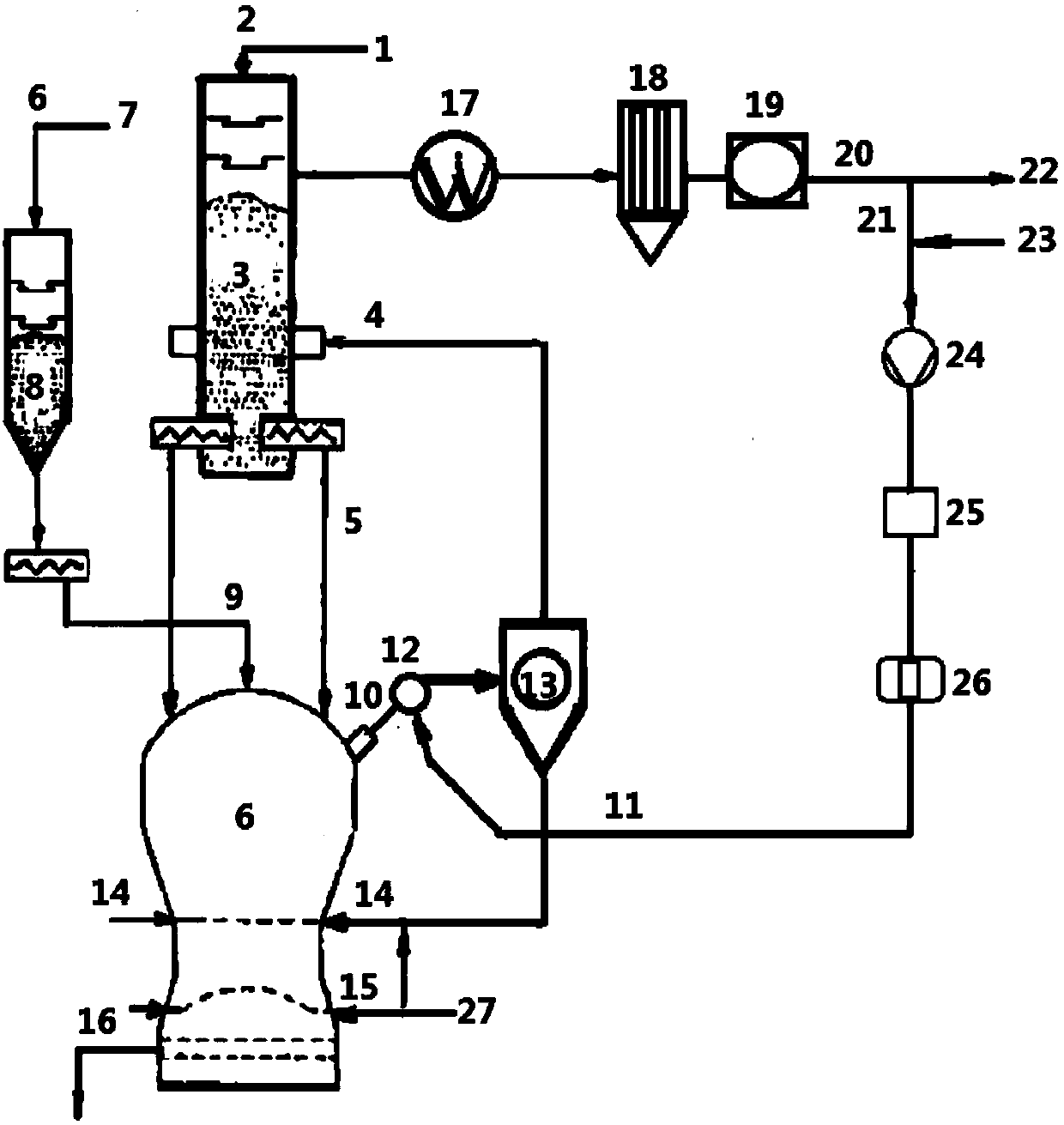

BAOSHEREX (Baosteel-Shenghua high efficiency smelting reduction) ironmaking process for smelting molten iron by two-step method

ActiveCN104212930AIncrease the amount of gasIncreased capacity to produce molten ironProcess efficiency improvementShaft furnaceThermal energySlag

The invention provides a BAOSHEREX (Baosteel-Shenghua high efficiency smelting reduction) ironmaking process for smelting molten iron by a two-step method, which belongs to the technical field of ironmaking. The steps of the process comprise vertical furnace type prereduction; and additional arrangement of a melt gasification furnace outside a vertical prereduction furnace: oxygen gas and pulverized coal are sprayed from oxygen gas tuyeres which are uniformly distributed in the middle part of a furnace cylinder of the melt gasification furnace, and generated heat meets the requirements of generating molten iron and furnace slag. In the BAOSHEREX ironmaking process, coal accounts for 80-85 weight percent of fuel, only oxygen gas containing 500-600m<3> / t of iron and carbon coke accounting for 15-20 weight percent of the fuel are used for producing high-quality hot molten iron at a temperature of 1350-1480 DEG C, pelletized water granulated slag and high-quality coal gas. The BAOSHEREX ironmaking process has the advantages of high yield, high efficiency, low energy consumption, low emission and low cost.

Owner:钢研晟华科技股份有限公司

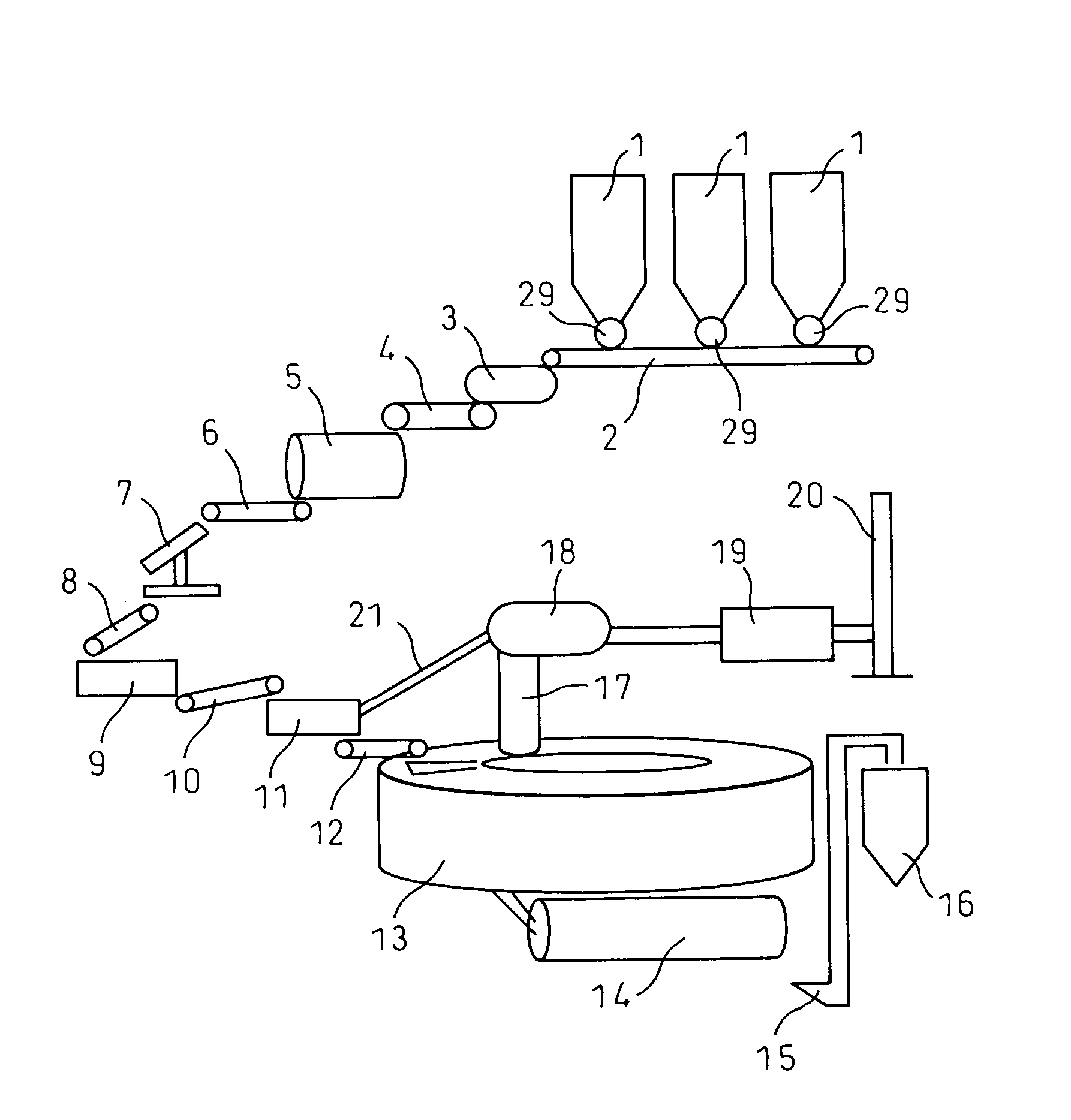

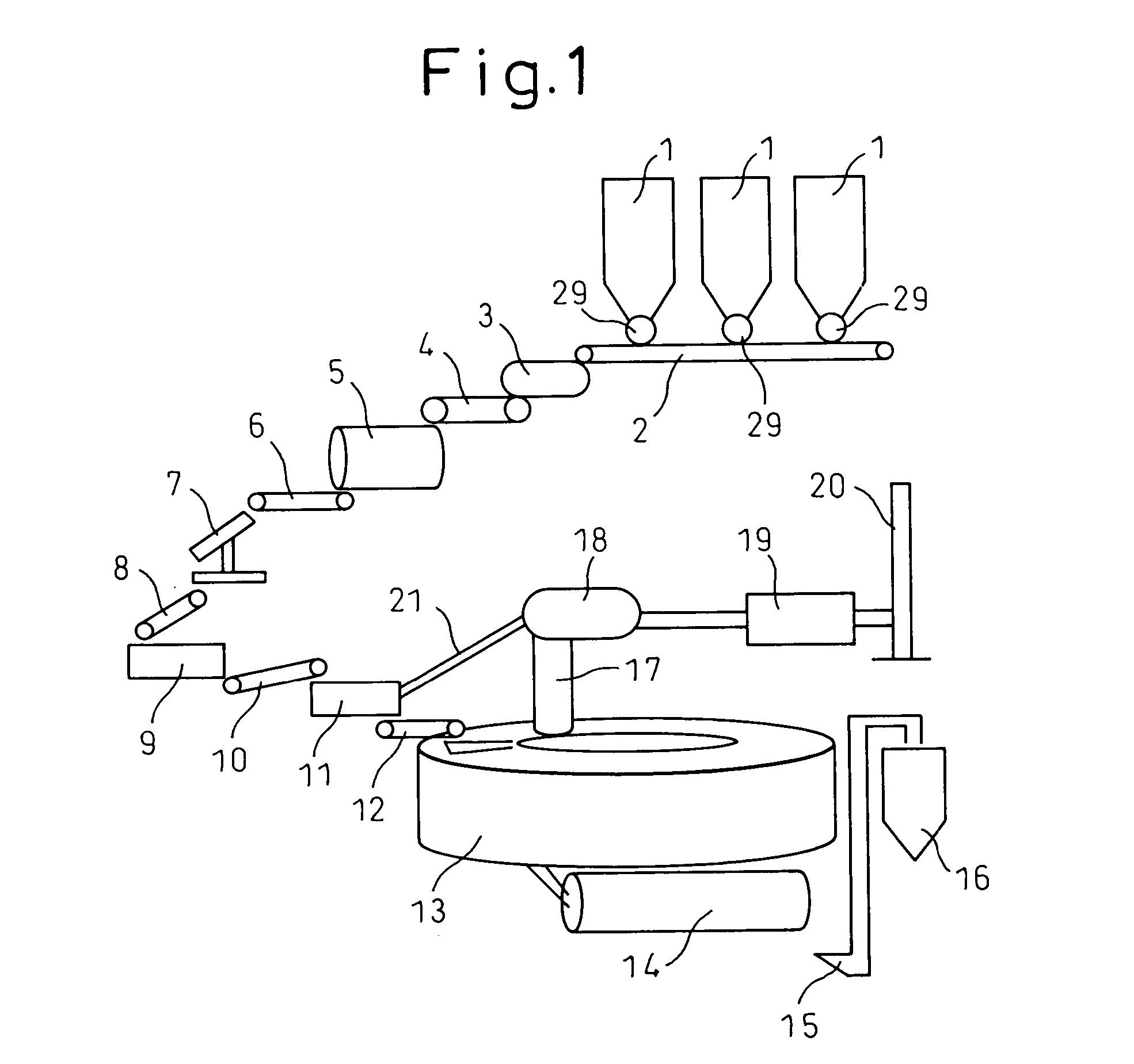

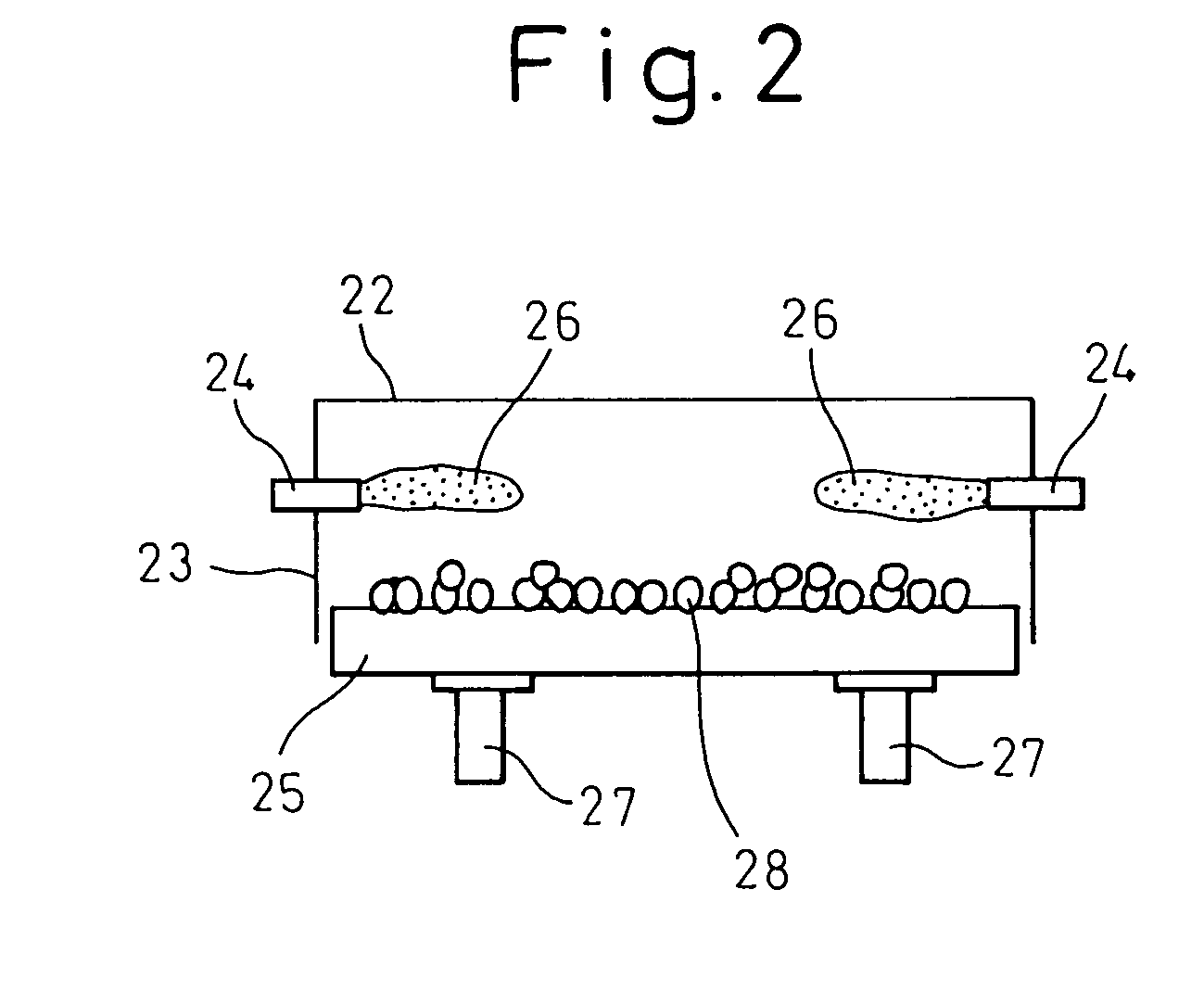

Metal oxide-containing green pellet for reducing furnace, method for production thereof, method of reduction thereof, and reduction facilities

InactiveUS20040020326A1High strengthHigh ratioBlast furnace componentsBlast furnace detailsOxideHigh intensity

The present invention provides a method and facility for preventing crumbling and powderization of green pellets when producing high strength green pellets using a powder feedstock and using the pellets in a rotary hearth reducing furnace and for efficiently reducing the same. It comprises kneading by a kneader 5 a feedstock of a powder of a fine particle size (20 to 80 wt % having size of not more than 10 mum) including a metal oxide and carbon-bearing powder fed from a feed storage tank 1 and producing green pellets by a pan type pelletized 7. The green pellets are screened by a pellet screen 9, then dried by a pellet dryer 11 and reduced by firing in a rotary hearth reducing furnace 13. At that time, the green pellets are continuously conveyed to prevent crumbling.

Owner:NIPPON STEEL CORP

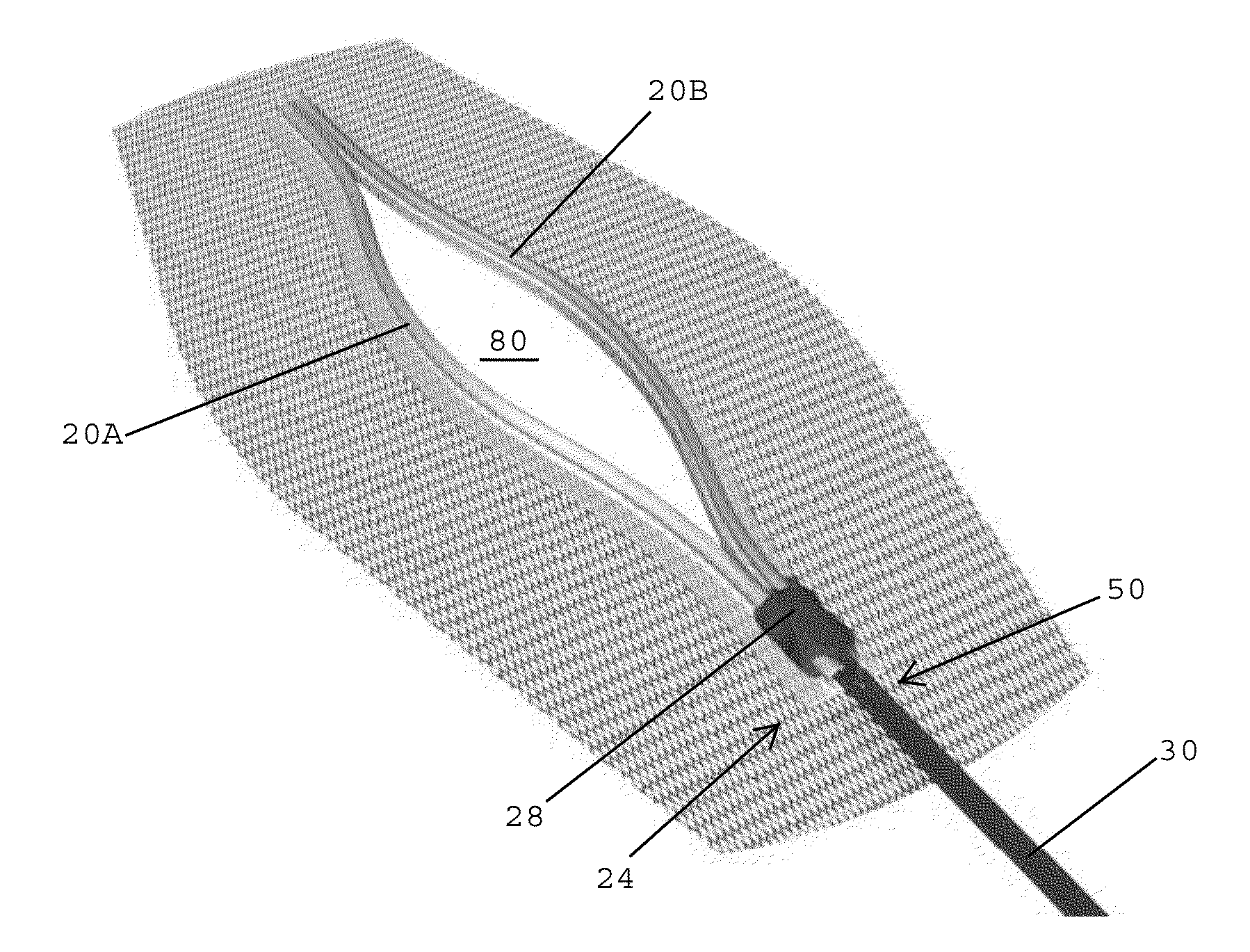

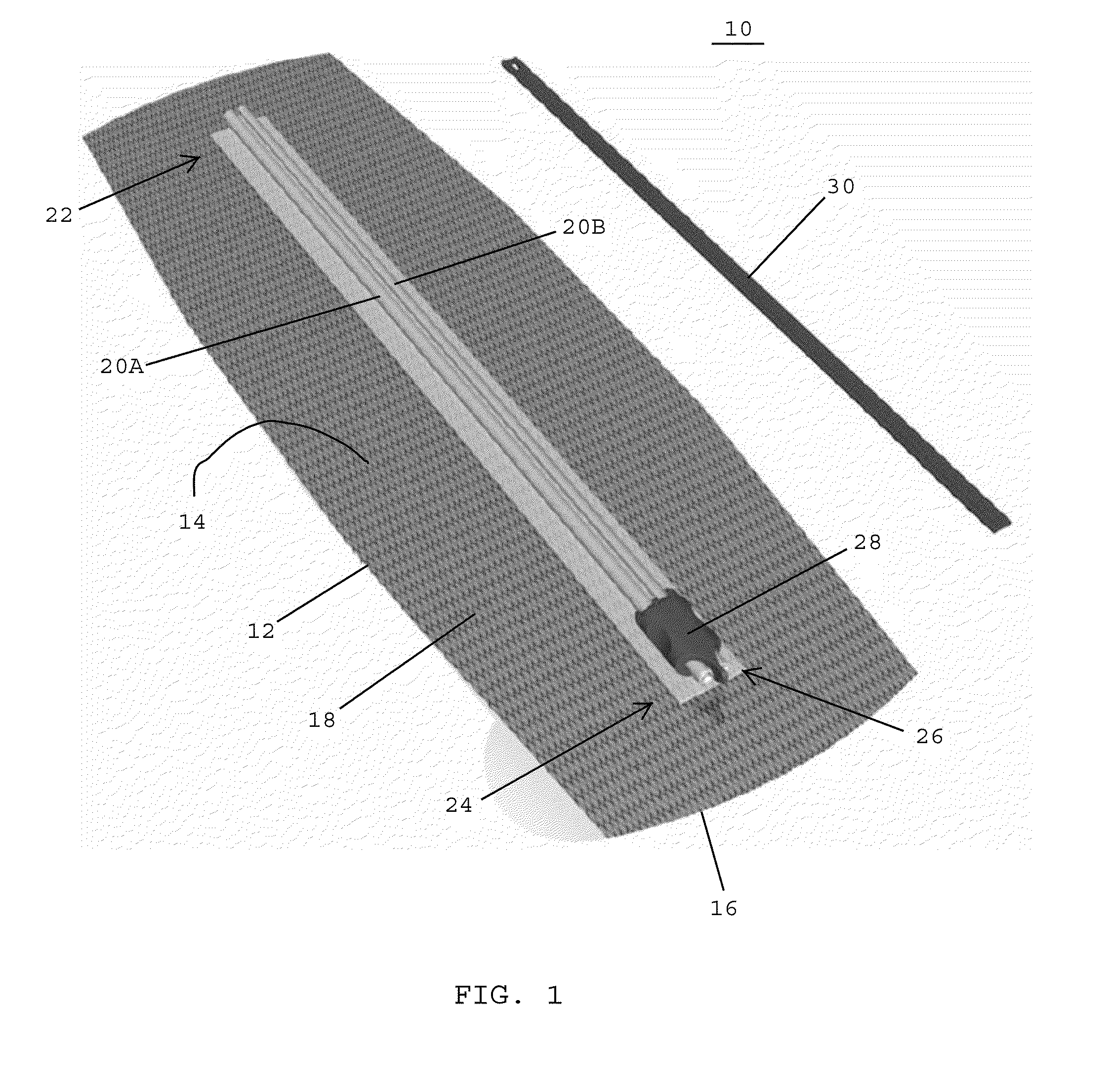

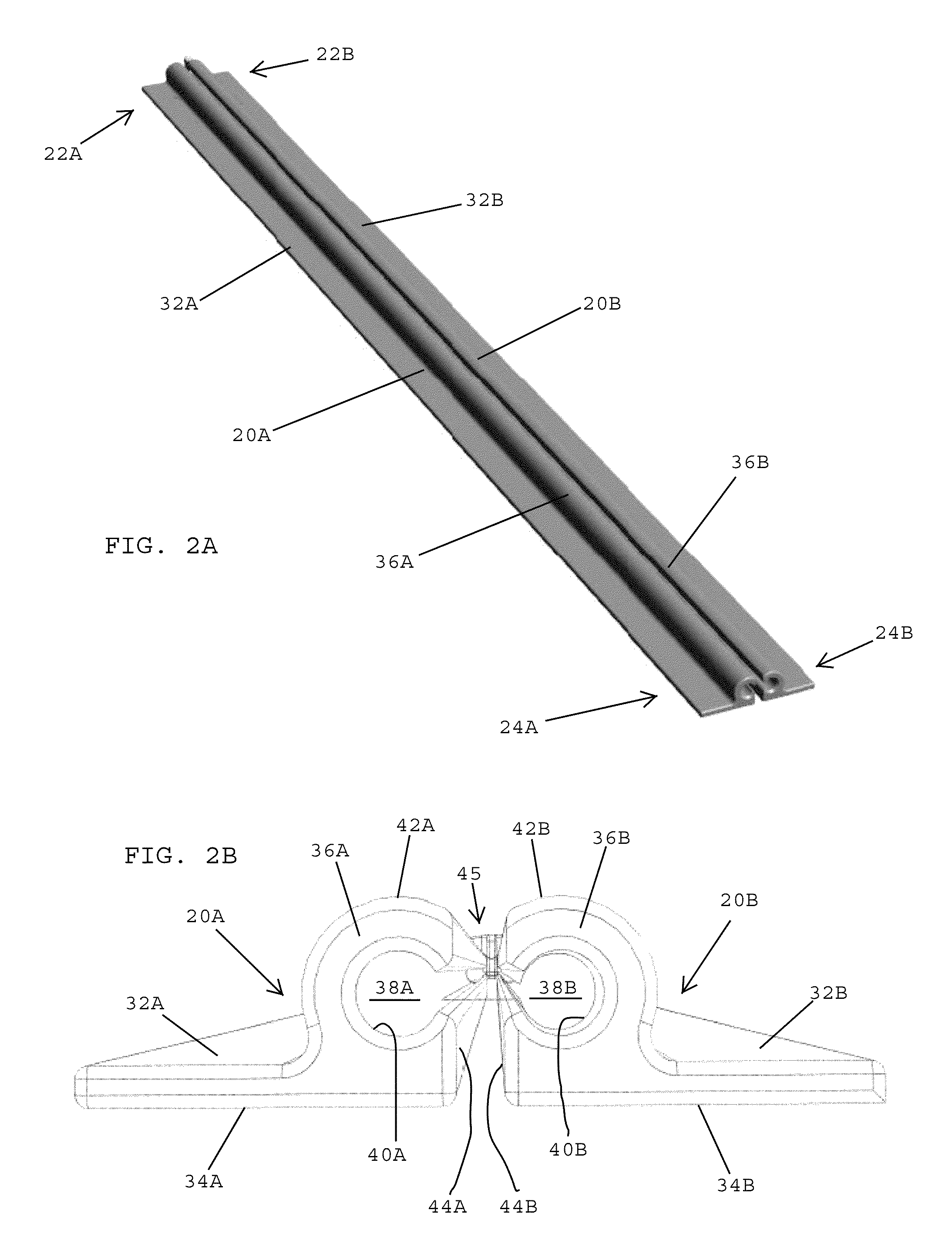

Incision guide and wound closure device and methods therefor

ActiveUS8777986B2Good adhesionEnabling visibilitySurgical veterinaryWound clampsAdhesiveHernia surgical mesh

An incision guide and wound closure device includes a surgical mesh having a top surface and a bottom surface, and first and second incision guides affixed to the top surface of the surgical mesh. The bottom surface of the mesh is adhered to tissue using clear or translucent adhesive. The first and second incision guides have opposing alignment surfaces that are adapted to guide a cutting instrument for making an incision through the mesh and into the tissue. The device has a closing element that is moveable along the length of the respective first and second incision guides for drawing the first and second alignment surfaces toward one another for closing the incision opening in the tissue.

Owner:ETHICON INC

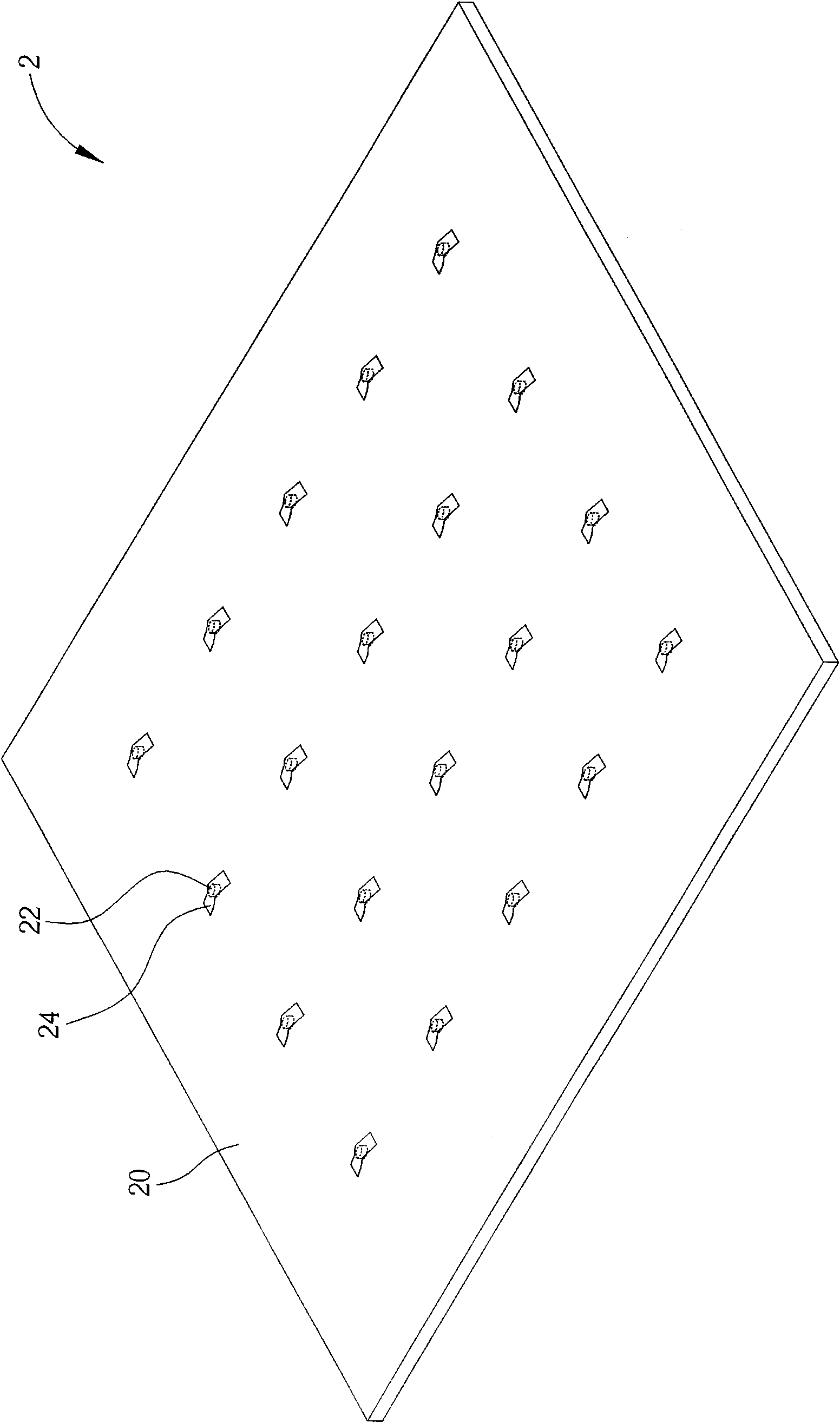

Implant for uteruses

The invention relates to the field of gynecological medical apparatus and instruments, in particularly to an implant for uteruses. The implant for the uteruses comprises a membrane (1). The implant for the uteruses has the advantages that problems of irritation influence on uteruses due to existing implants implanted in uterine cavities for a long time, poor uterine mucous membrane repair effects of conventional medicine, influence on the whole bodies of patients due to hormone medicine for oral administration and the like can be solved by the aid of the medicine to a great extent, and effects and individual degrees can be greatly improved during phased utilization.

Owner:吴江永元生物科技有限公司

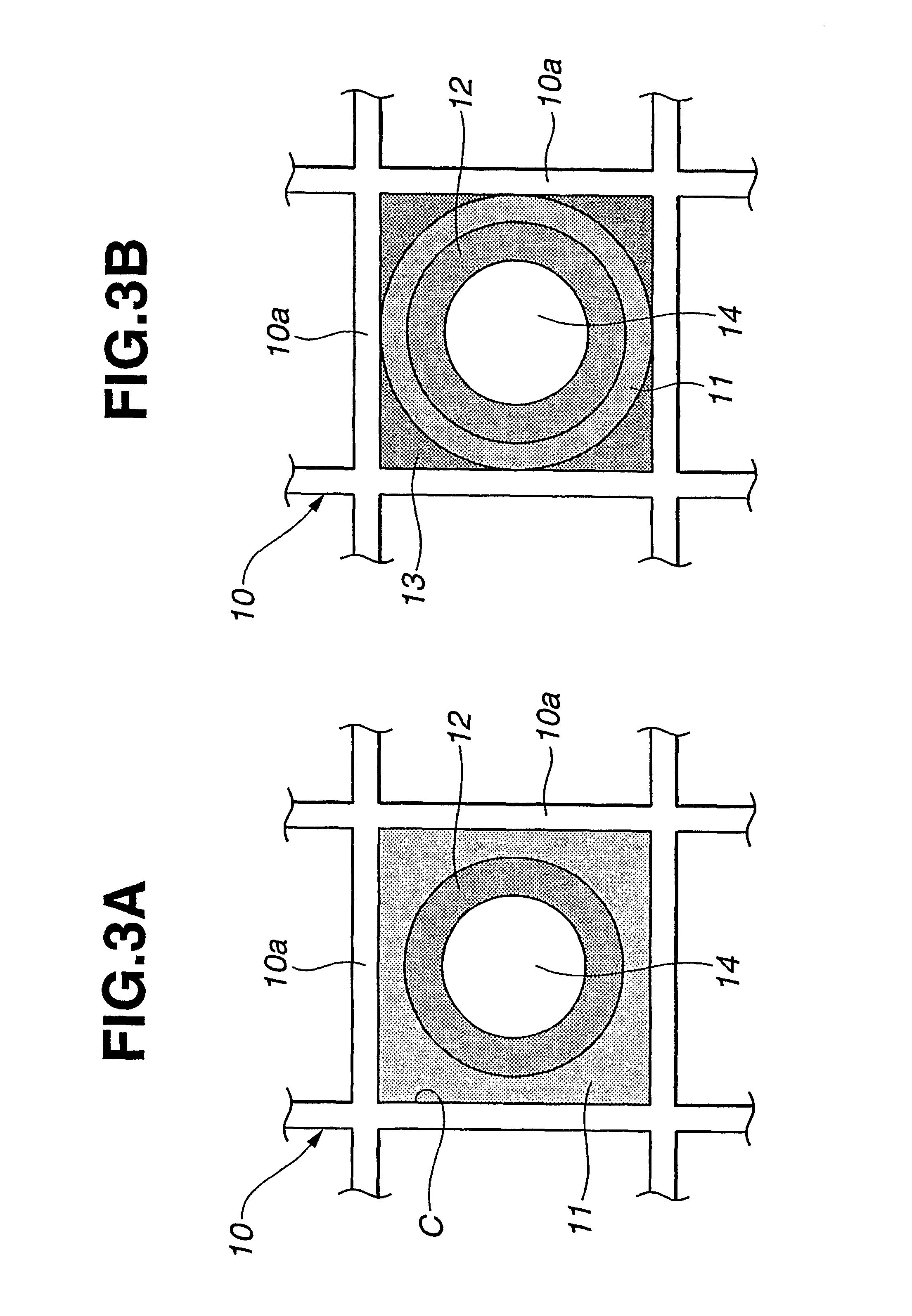

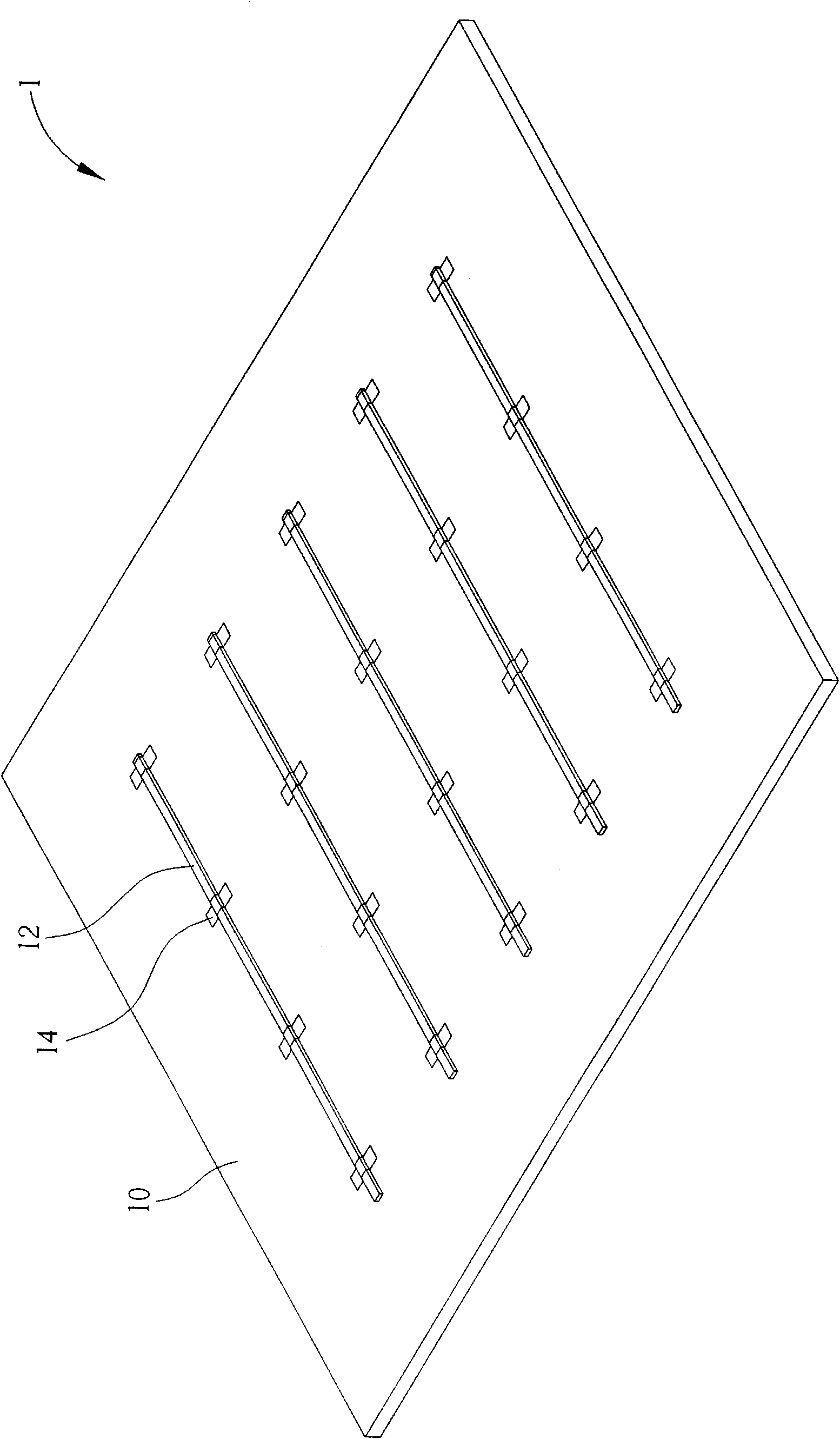

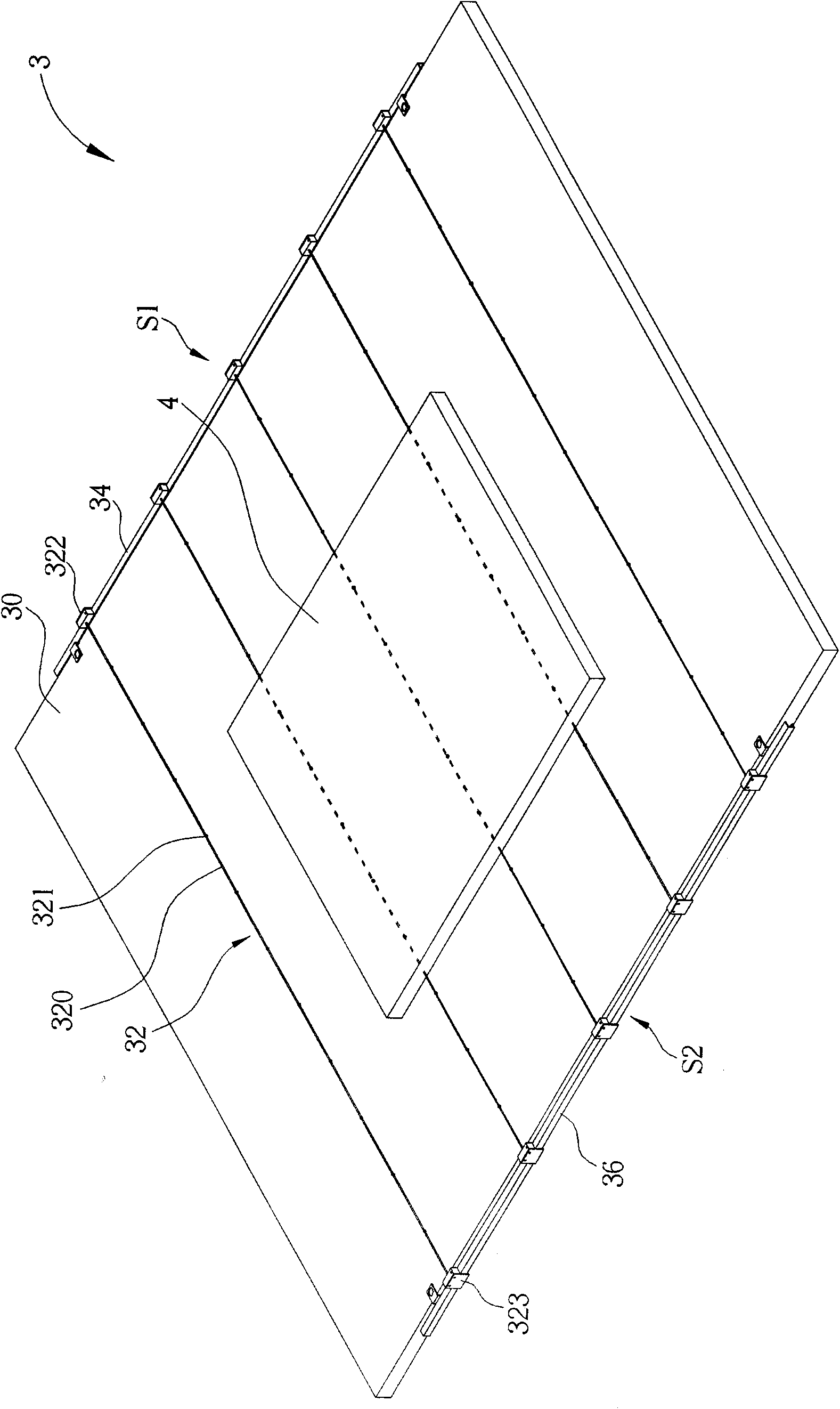

Baseplate support device

InactiveCN101807538AReduce stickingAvoid offsetSemiconductor/solid-state device manufacturingNon-linear opticsEngineeringPoint contact

The invention discloses a baseplate support device used for supporting a baseplate, which comprises a pedestal and a support structure, wherein the support structure is arranged on the pedestal, the support structure comprises a linear member and a plurality of spherical members, the spherical members are connected in series on the linear member, and the spherical members support the baseplate on the pedestal in the point-contact mode. By using the spherical members to support the baseplate on the pedestal in the point-contact mode, the invention can reduce the area in contact with the baseplate, and lower the possibility that the support structure is stuck to the baseplate at high temperature, thereby avoiding the deviation or the bad alignment of the baseplate.

Owner:AU OPTRONICS CORP

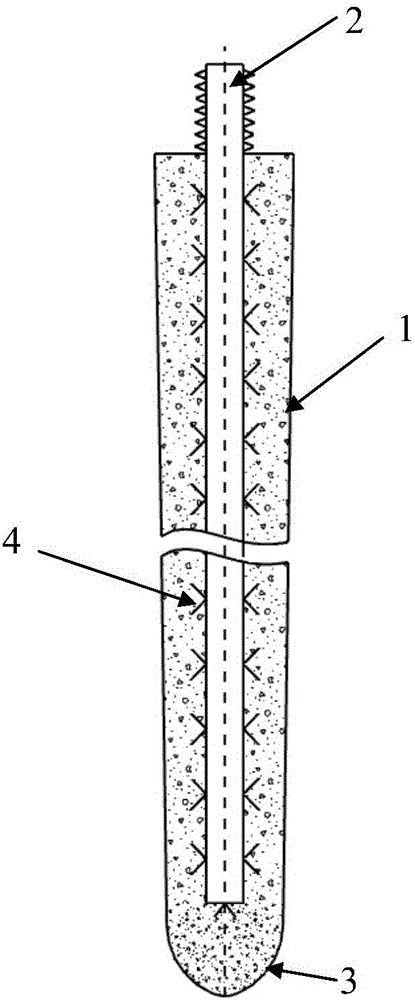

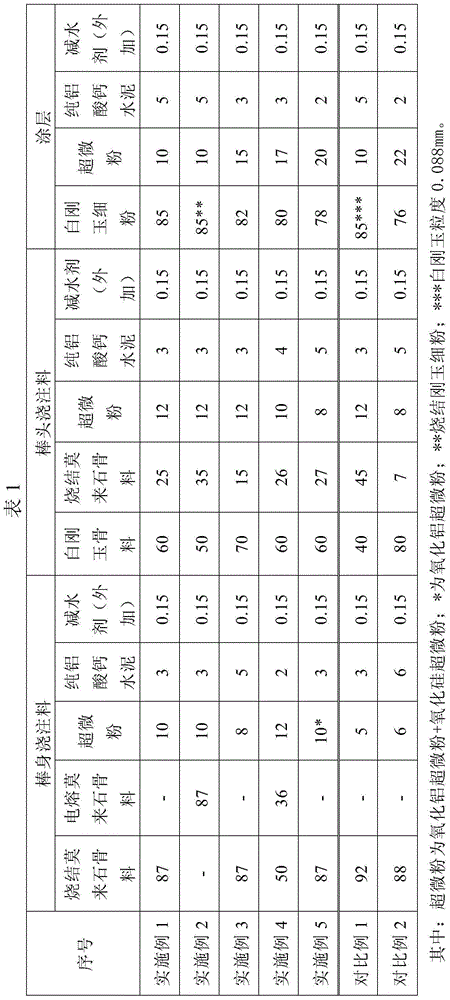

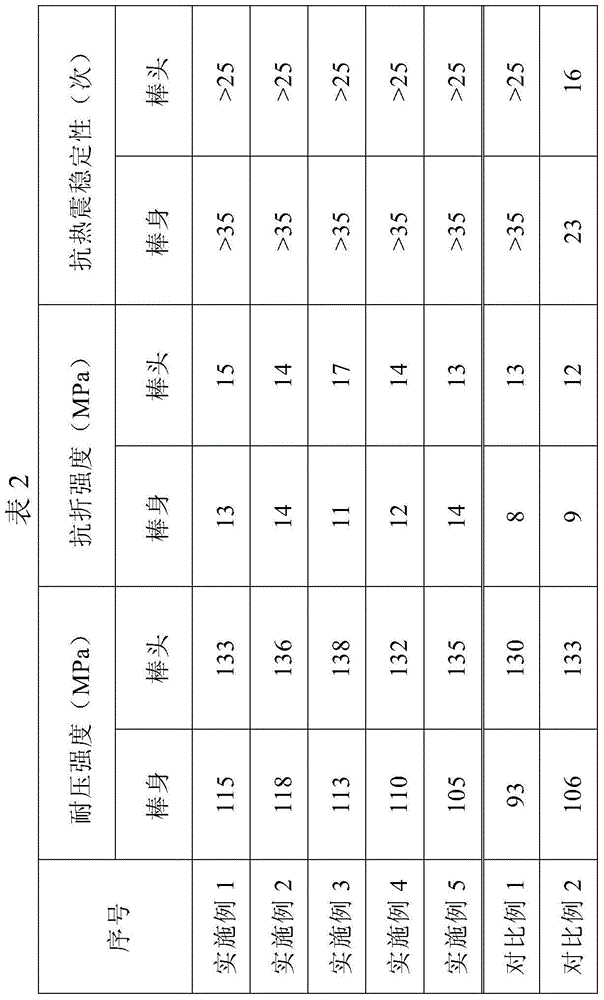

Continuous casting monolithic stopper and method of manufacture thereof

ActiveCN105753489AImprove thermal shock resistanceImprove erosion resistanceMelt-holding vesselsBrickMullite

The invention discloses a continuous casting monolithic stopper and a method of manufacture thereof.The monolithic stopper comprises a stopper body, a steel core inserted into the stopper body and a head connected to the lower end of the stopper body, the surface of the steel core is provided with an anchor, the surface of the monolithic stopper is coated with Al2O3 coating; the stopper body is made by casting castables comprising mullite, the head is made by casting castables comprising corundum and sintered mullite, and the monolithic stopper is manufactured by monolithic casting.The stopper obtained herein is good in monolithicity, is free of brick joint and head shedding problems of sleeve brick stoppers, has good thermal shock resistance, high strength and good resistance to molten steel scour erosion, is simple to manufacture and low in cost, and is suitable for stopping a tundish nozzle under low continuous casting, high-oxygen steel continuous casting and skid flow control.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com