BAOSHEREX (Baosteel-Shenghua high efficiency smelting reduction) ironmaking process for smelting molten iron by two-step method

A two-step method and molten iron technology, applied in the field of ironmaking, can solve the problems of high reducibility of iron ore, increase of raw material cost, shutdown treatment and other problems, so as to improve equipment utilization rate, increase production efficiency, and reduce the occurrence of sticking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

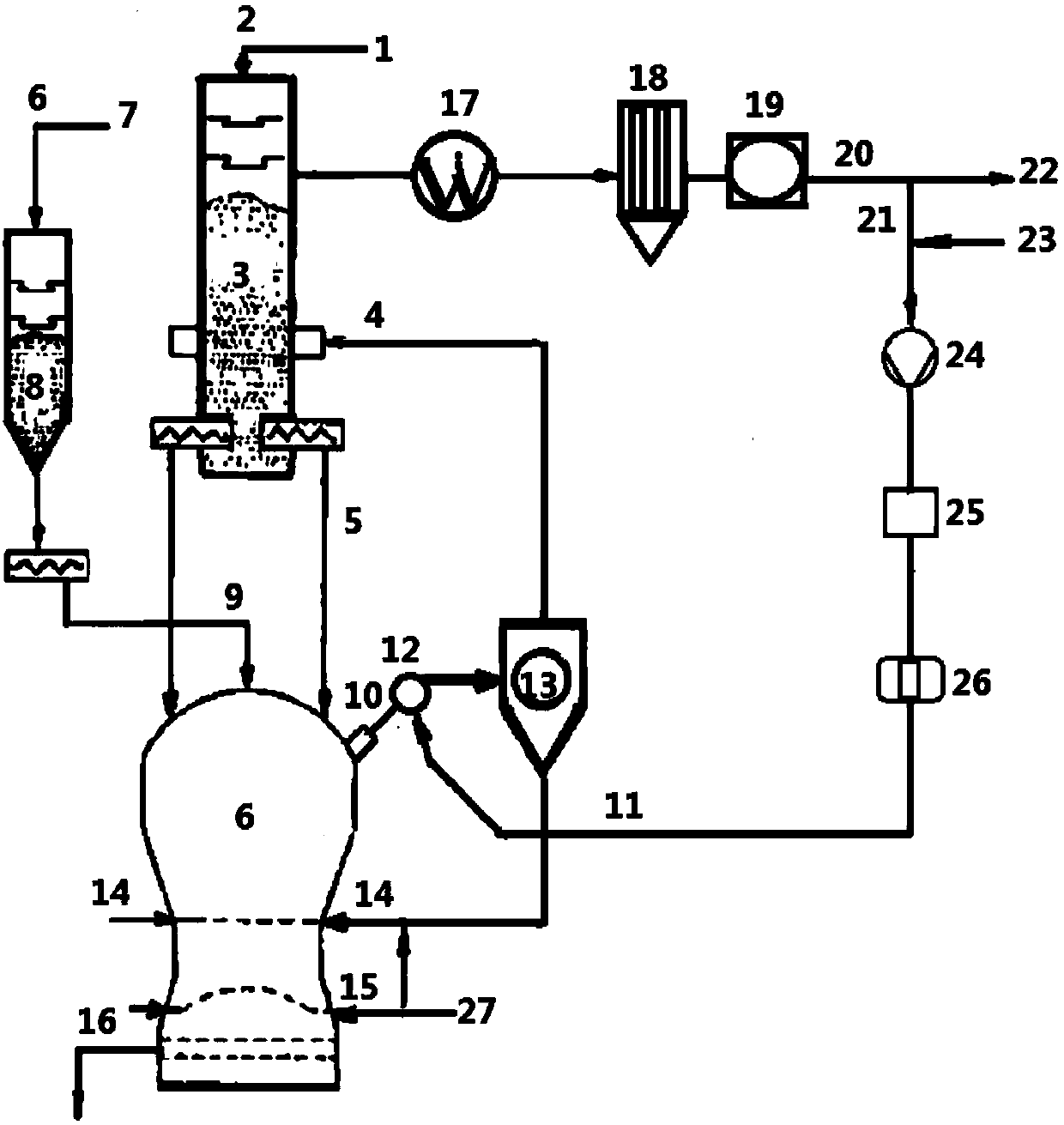

[0034] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0035] Take the BAOSHEREX ironmaking process where all iron-containing charge materials use oxidized pellets as an example.

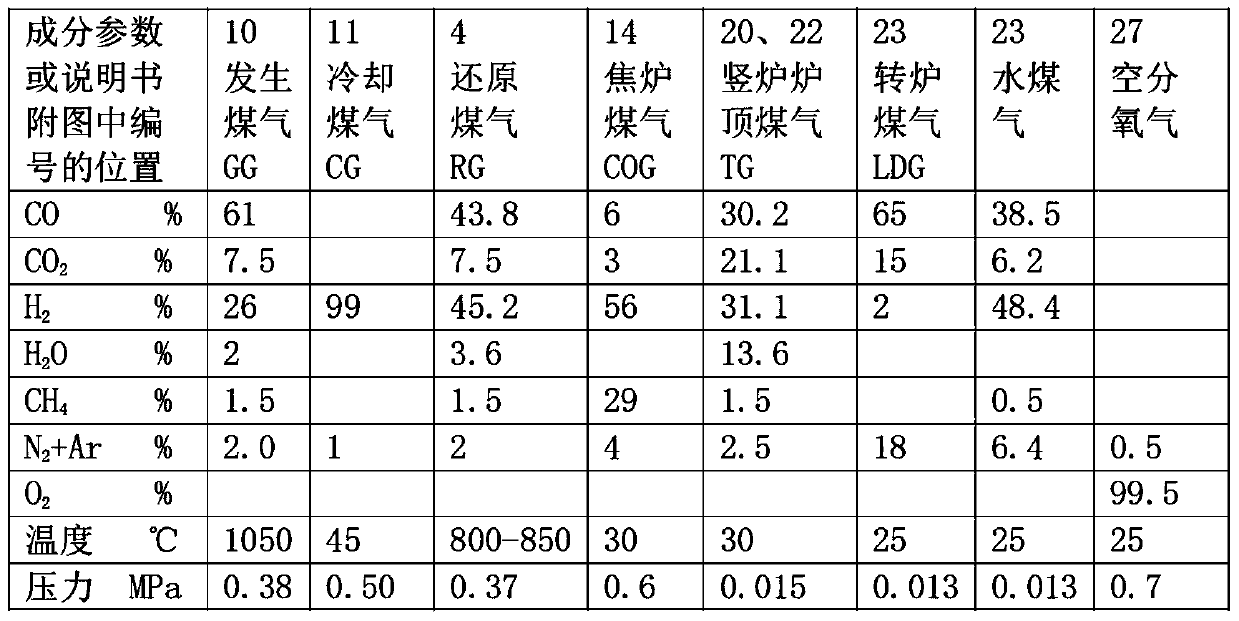

[0036] Oxidized pellets (1540kg / t iron, containing 65% TFe), coke (190kg / t iron, containing 85% fixed carbon), limestone (80kg / t iron) and Dolomite (110kg / t) and silica (9kg / t). Through the top charging system 2 of the shaft furnace, it is then loaded into the pre-reduction shaft furnace 3 according to the operating process. The charge moves from top to bottom by gravity, and the 1050°C high-temperature generated coal gas 10 generated by the melting and gasifier is combined with the pressurized and purified cold The coal gas 11 is mixed in the gas mixer 12, the temperature is adjusted to 800°C-850°C, and after being dedusted by the hot cyclone dust collector 13, it is used as the reduced gas 4 of the upper pre-reduction shaft fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com