Novel combined cement clinker roasted and waste heat generation system and technique

A cement clinker and waste heat power generation technology, which is applied in the field of cement clinker calcination and power generation systems with waste heat, can solve the problems of insufficient heat exchange, low material dispersion, and low clinker output, so as to achieve economic benefits and improve clinker production. material quality, targeted results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

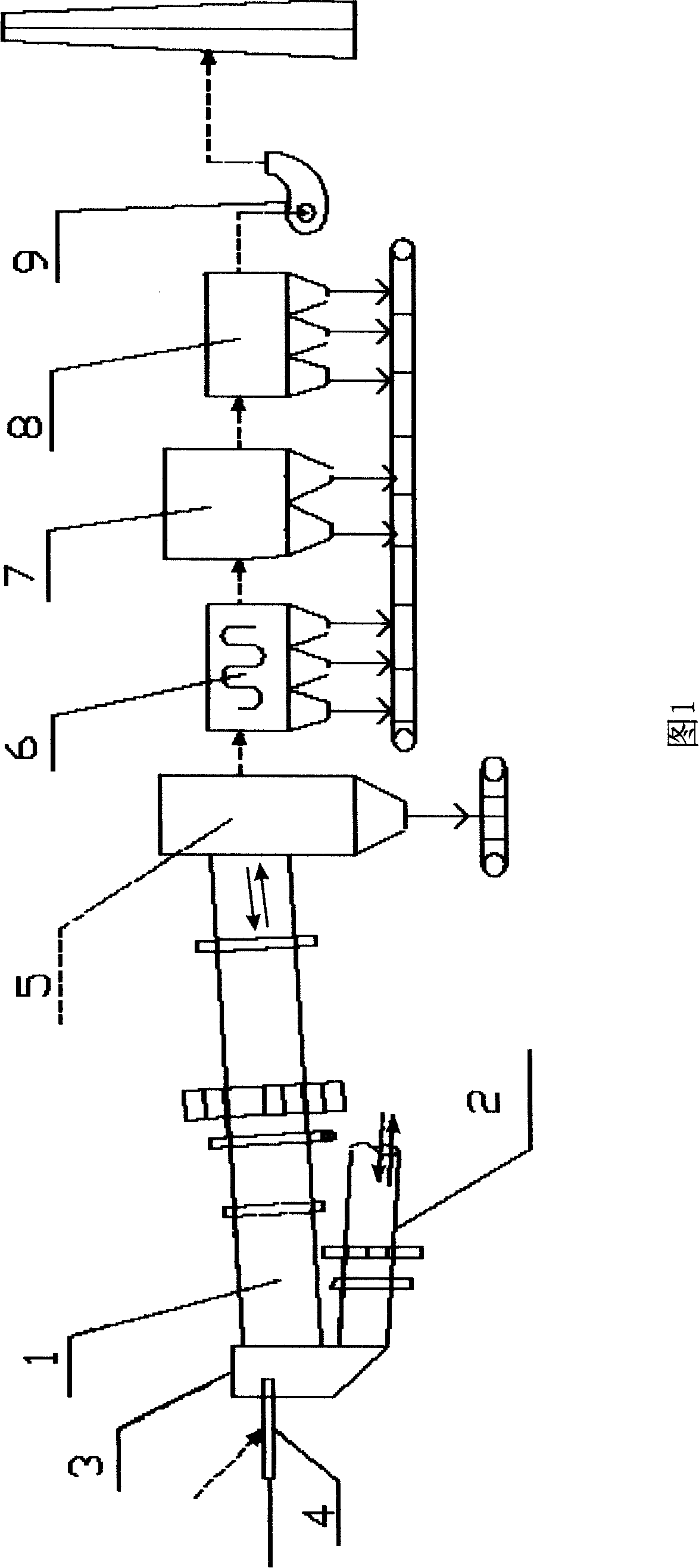

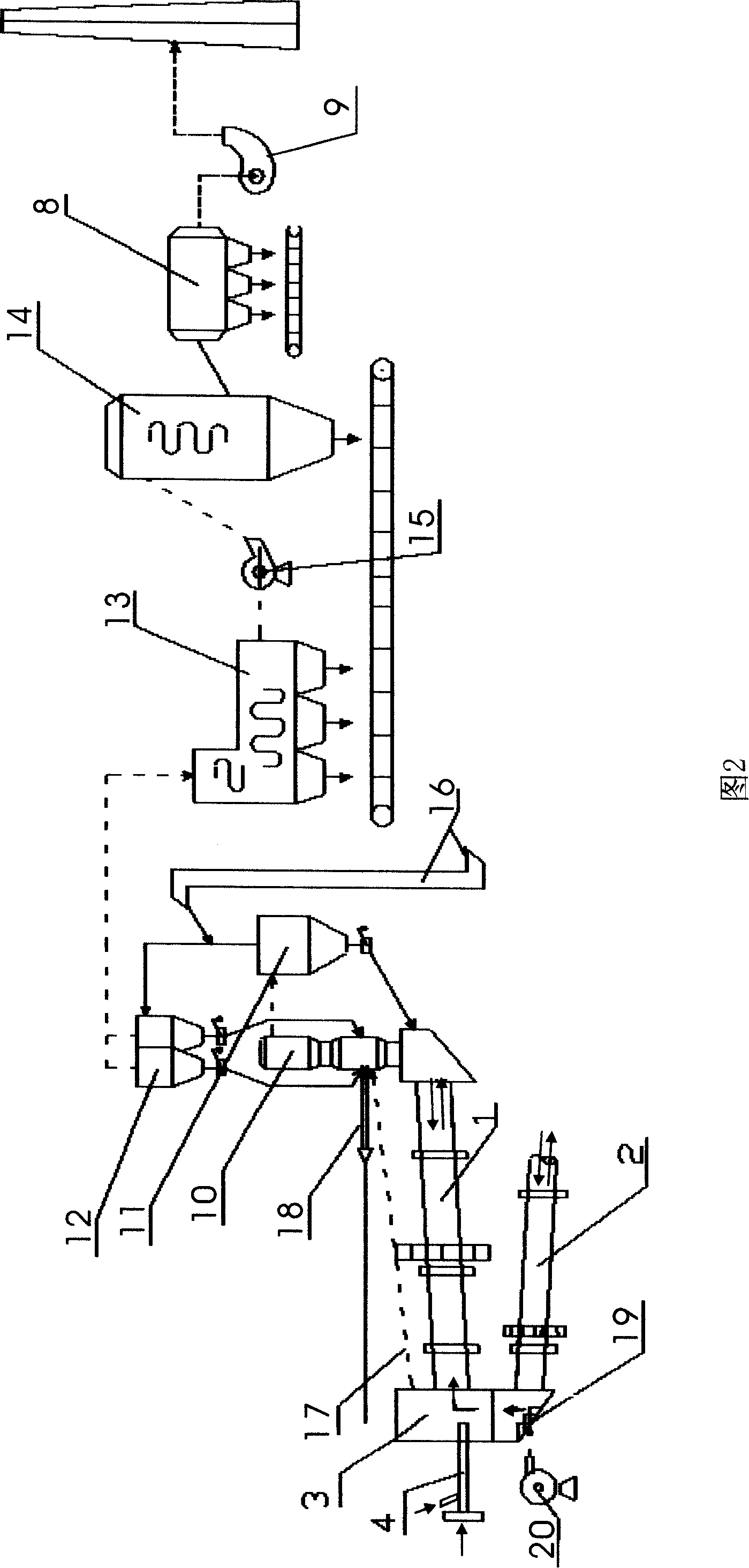

[0024] As shown in Fig. 2, the cement clinker calcining of the present invention and band waste heat power generation system are composed of rotary kiln (1), single cylinder cooler (2), kiln head cover (3), burner (4) , D-D type decomposition furnace (10), new waste heat boiler (13), high-voltage electric precipitator (8), etc., the bottom of the kiln hood (3) is connected with an inflatable beam grate plate device (19), which is connected with The single cylinder cooling machine (2) is connected, and several high-pressure blowers (20) are arranged beside the device; the upper part of the kiln head cover (3) is connected with a tertiary air duct (17); the middle end of the kiln head cover (3) is connected The burner (4), the other end is connected with a rotary kiln (1) which has been shortened and has a shrinkage at the tail, and the top of the tail of the rotary kiln (1) is connected with a D-D type calciner (10), and the D-D type calciner (10 ) is provided with a calciner b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com