Patents

Literature

44results about How to "Improve clinker quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

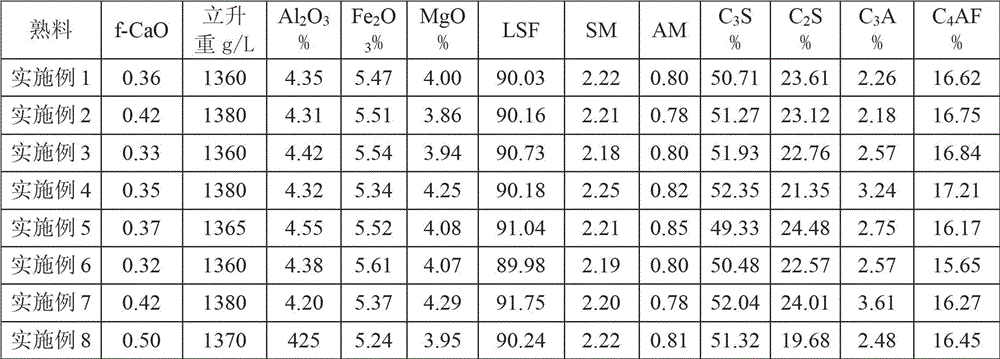

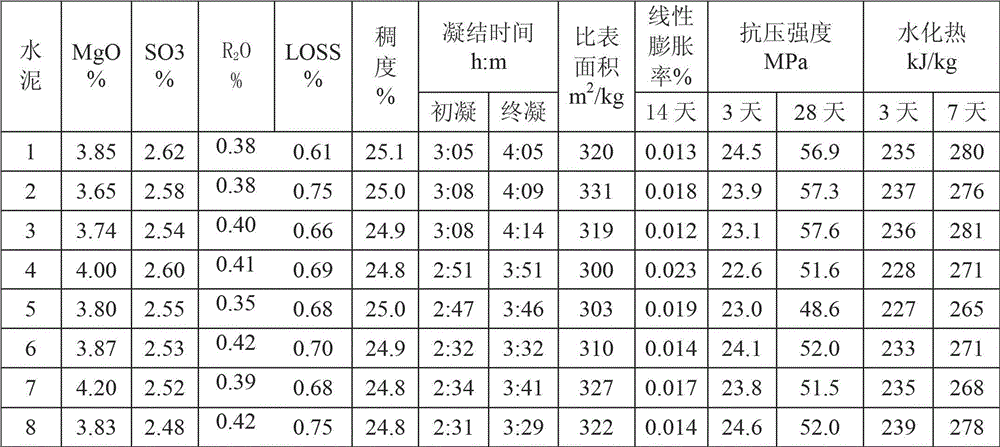

Micro-expansive moderate-heat Portland cement and production method thereof

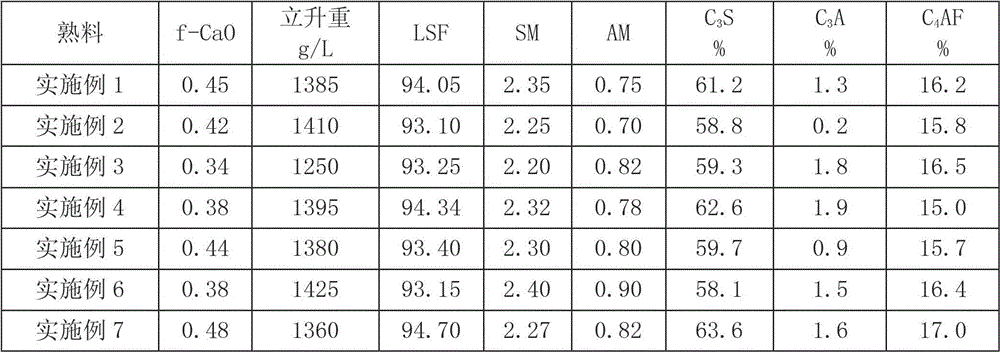

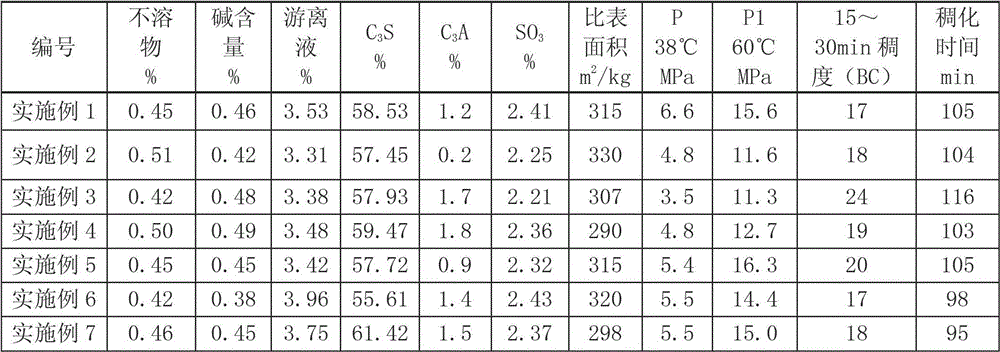

InactiveCN102976641AHigh strengthHeat of hydration controlClinker productionHigh magnesiumPortland cement

The invention discloses a micro-expansive moderate-heat Portland cement and a production method thereof. The cement contains micro-expansive moderate-heat Portland cement clinker and gypsum in a weight ratio of 92:8-98:2, and also comprises grinding aid which accounts for 0-0.1 wt% of the sum of micro-expansive moderate-heat Portland cement clinker and gypsum. The raw meal of the micro-expansive moderate-heat Portland cement clinker is prepared from the following raw materials in percentage by weight: 65-80% of calcium raw material, 5-20% of silicon correction raw material, 5-15% of iron correction raw material and 3-10% of magnesium correction raw material. The micro-expansive moderate-heat Portland cement clinker is prepared by the following steps: grinding the raw meal, dehydrating the slurry, drying and crushing the filter cake, and firing to obtain the clinker. By adopting the low-aluminum high-iron high-magnesium low-saturation-ratio formula, the invention effectively controls the hydration heat of cement, displays the micro-expansive property, and can compensate the volume shrinkage in the concrete cooling process, thereby reducing or avoiding cracks.

Owner:GUANGXI YUFENG CEMENT

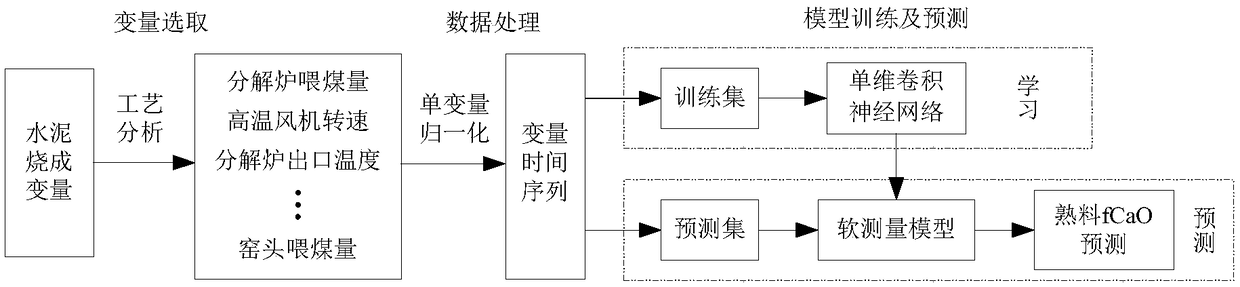

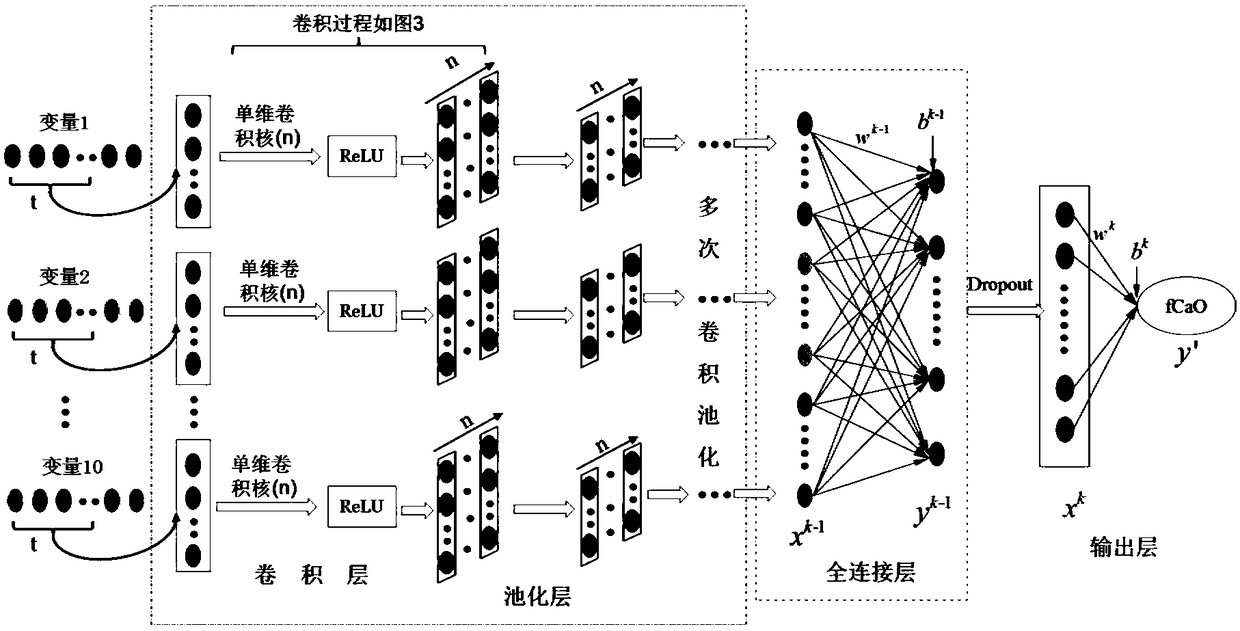

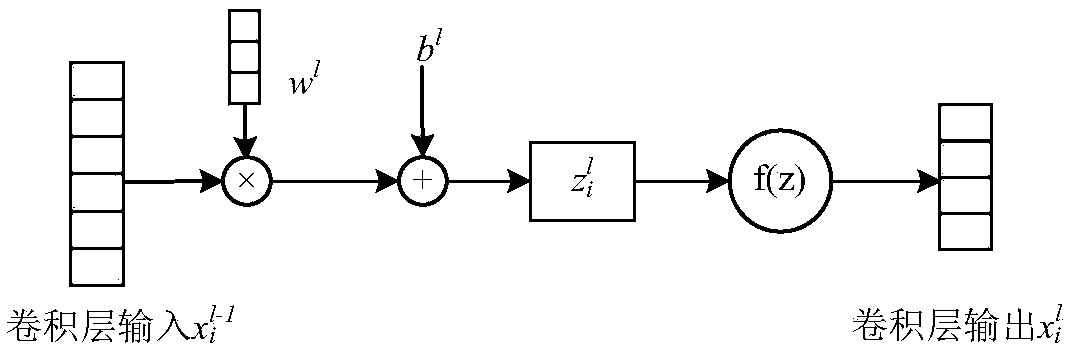

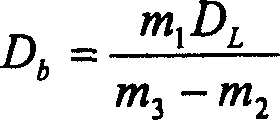

Soft measurement method of free calcium of cement clinker

ActiveCN109147878AAvoid delayReduce computationCheminformatics data warehousingCheminformatics programming languagesSupervised trainingMulti variable

The invention discloses a soft measurement method of free calcium of cement clinker. The method comprises the following steps: selecting 10 variables as auxiliary variables for clinker fCaO soft measurement according to a cement process, inputting the time sequence, serving as a model, of each variable, and performing normalization processing on the time sequence of each selected variable; according to the characteristic of the time sequence in the cement sintering process, establishing a clinker fCaO soft measurement model based on a multi-variable time sequence convolutional neural network,determining an initial parameter of an MT-CNN model and performing forward-direction training on the network; performing supervised training by utilizing error reverse fine adjustment, optimizing weight w and bias b in the MT-CNN by correcting the error, and predicting the cement clinker fCaO in real time by utilizing the trained MT-CNN model. Calculation of time delay between each variable and the clinker fCaO is avoided and the calculation quantity needed by time sequence matching is reduced; the convergence speed, the precision and the generalization ability of the model are improved; and the fCaO content of the cement clinker can be predicted well, the quality of the cement clinker can be improved and the production energy consumption can be reduced.

Owner:YANSHAN UNIV

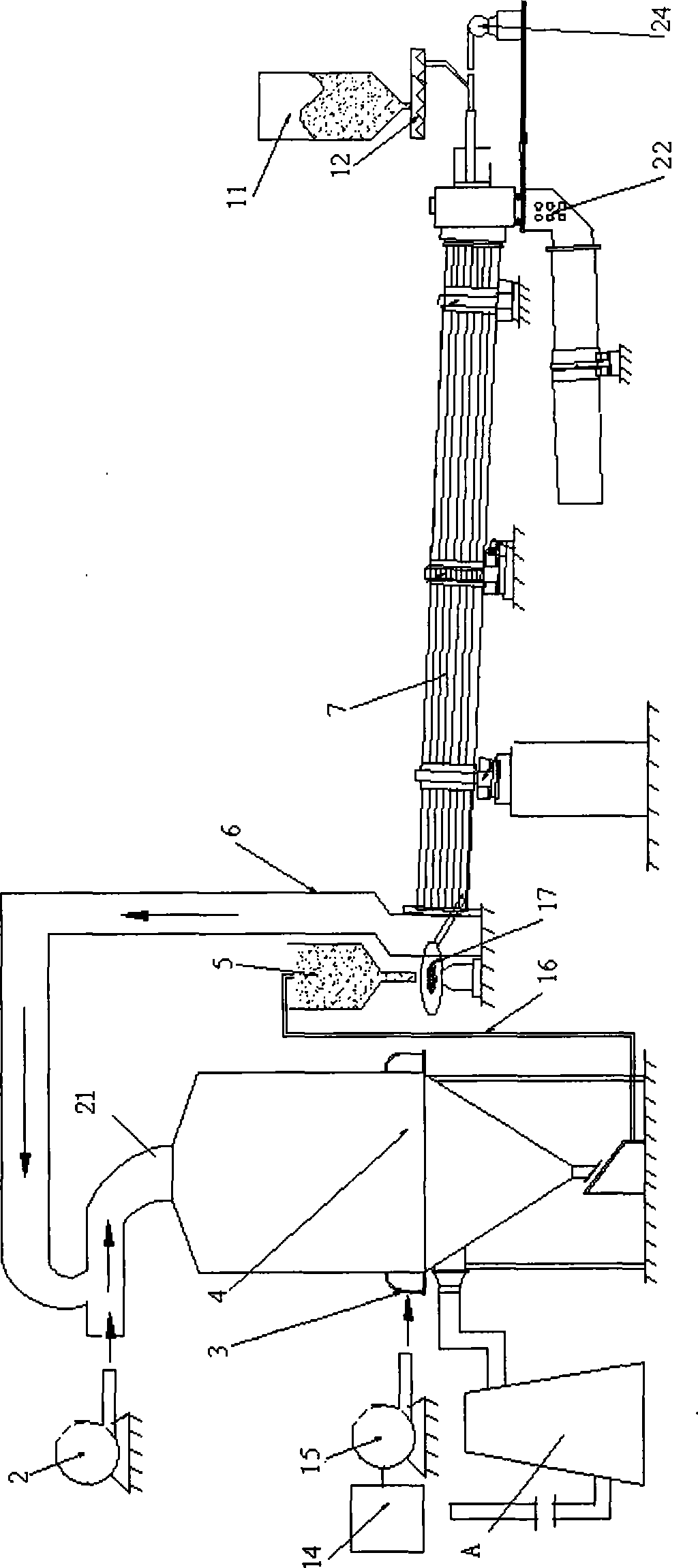

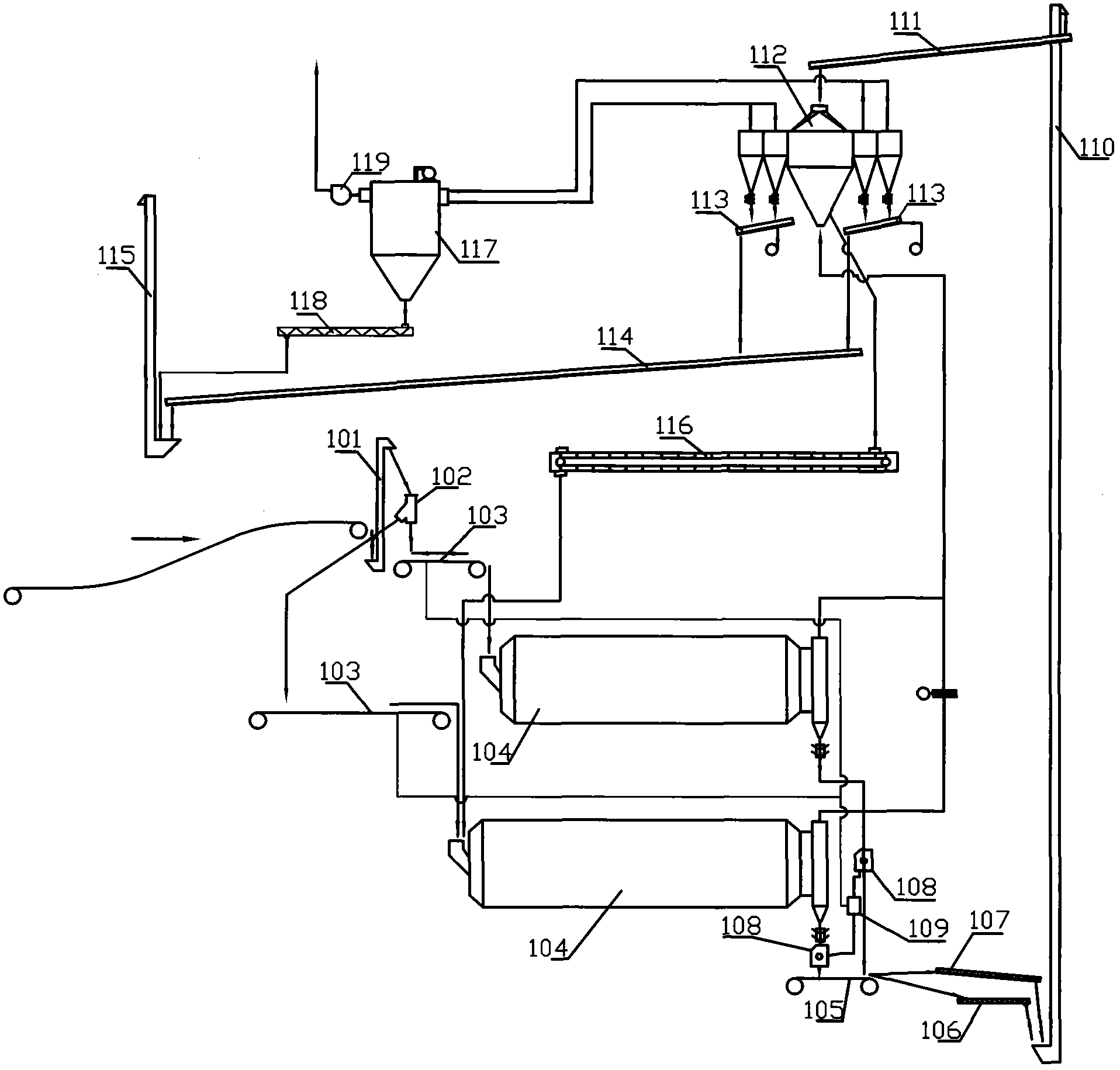

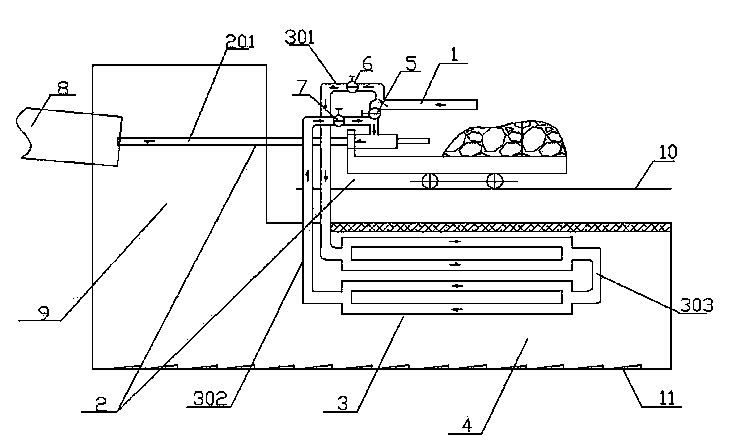

Dry sintering method and apparatus for aluminum oxide clinker

InactiveCN101462755AHigh trafficImprove thermal efficiencyChemical industryAluminium oxide/hydroxide preparationSlurryMoisture

The invention relates to a method for sintering an alumina clinker by a drying method. The method comprises that: raw slurry is dried in a drying tower to obtain dry raw materials with the moisture content rate of between 3 and 5 percent, and then the dry raw materials are mixed with kiln dust by weight percentage of 9 : 1-7 : 3 to be sintered in a kiln to obtain qualified clinkers. A sintering device comprises an air heater, a slurry drying device, a dry material silo, a kiln tail hood, a kiln body, a powdered coal silo, a powdered coal screw machine, a dry raw material conveyor, a disc feeding machine, a feed opening and a blower. The slurry drying device is provided with the dry raw material conveyor which delivers dry materials into the dry material silo arranged above the disc feeding machine; the slurry drying device is provided with a hot air pipe which is connected with the air heater and one end of the kiln tail hood respectively; and the other end of the kiln tail hood is positioned in a dry material feeding opening on the tail of the kiln body. The method has the advantages of simple process method, convenient operation, energy conservation and high taste of the sintered clinker and is favorable for stabilizing the thermal regulation of a rotary kiln. The device can effectively improve the productivity and the service life of the rotary kiln, is applicable to industrialized production, can be used for matching with the prior rotary kilns with various models, and can replace the process flow for producing the alumina by the prior sintering method.

Owner:湖南中大冶金设计有限公司

Preparation method of magnesium calcium clinker

InactiveCN1903769APromoting rational and efficient comprehensive utilizationHigh purityCarbonationCalcium magnesium

The present invention relates to a preparation method of calcium-magnesium clinker. Said method includes the following steps: using magnesite and limestone as raw material, soft burning at 800-100deg.C, cooling, hydration, ball-grinding and wet mixing, filtering, carbonating, drying, forming and calcining at 1600-1900deg.C so as to obtain the invented calcium-magnesium clinker.

Owner:NORTHEASTERN UNIV

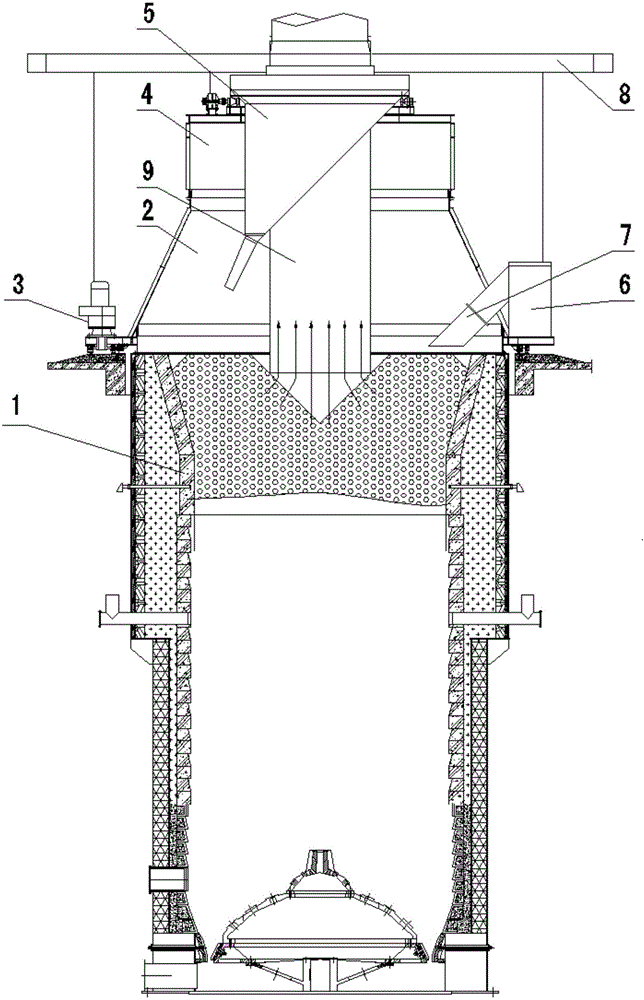

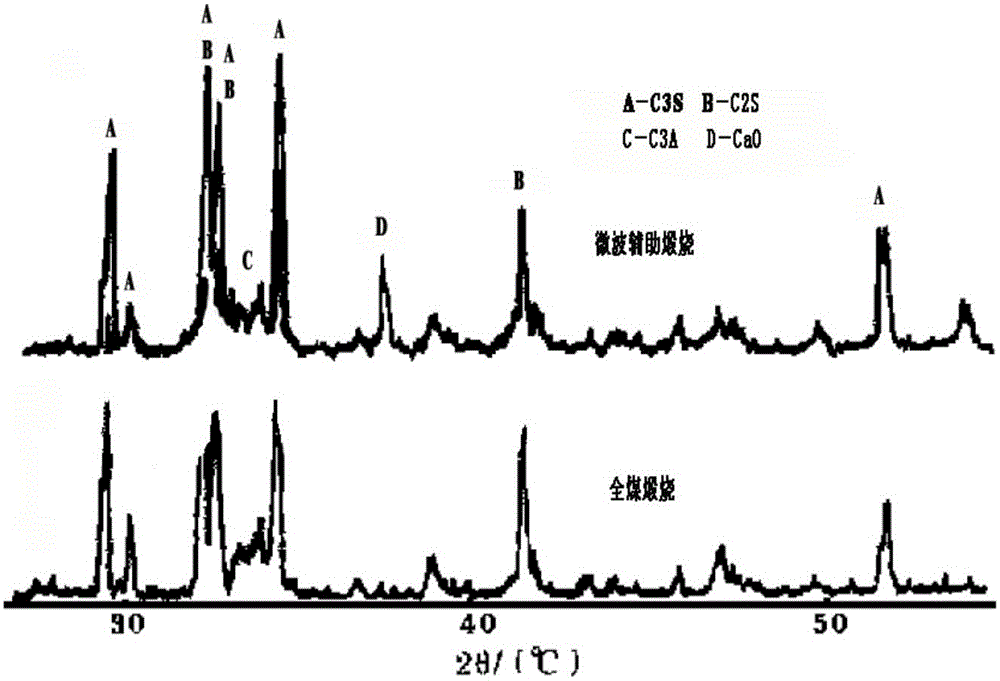

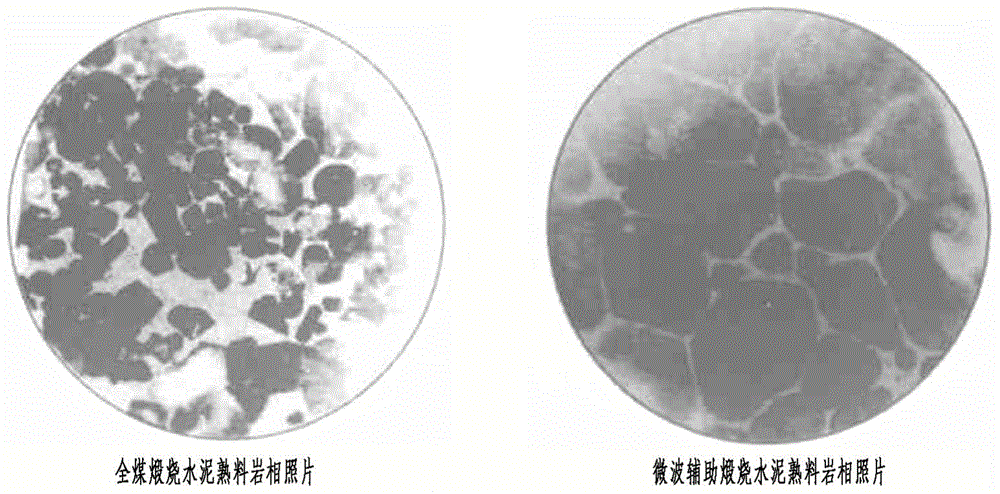

Microwave kiln for assisting in cement clinker calcination and microwave calcination method thereof

ActiveCN104457217AUniform radiationAdjustable speedRotary drum furnacesWaste heat treatmentThermodynamicsProcess engineering

The invention discloses a microwave kiln for assisting in cement clinker calcination. The microwave kiln for assisting in cement clinker calcination comprises a kiln body and further comprises a rotary kiln cover, a driving mechanism, a fixed kiln cover, a distributing device, a microwave generator and a waveguide tube, wherein a draught fan is installed on the bottom of the kiln body, and the rotary kiln cover is installed on the kiln mouth of the kiln body. According to the microwave kiln for assisting in cement clinker calcination, microwave field radiation is even; the rotary kiln cover is arranged, the waveguide tube and the microwave generator are installed on the rotary kiln cover and rotate along with the rotary kiln cover, and a microwave field which is large in coverage area and even in microwave radiation is formed gradually in the kiln body by microwaves emitted by the microwave generator during rotation; in addition, an annular power supply slide wire and the driving mechanism are arranged, the rotating speed of the rotary kiln cover can be adjusted through the driving mechanism, and thus the microwave field can be adjusted.

Owner:张雪华

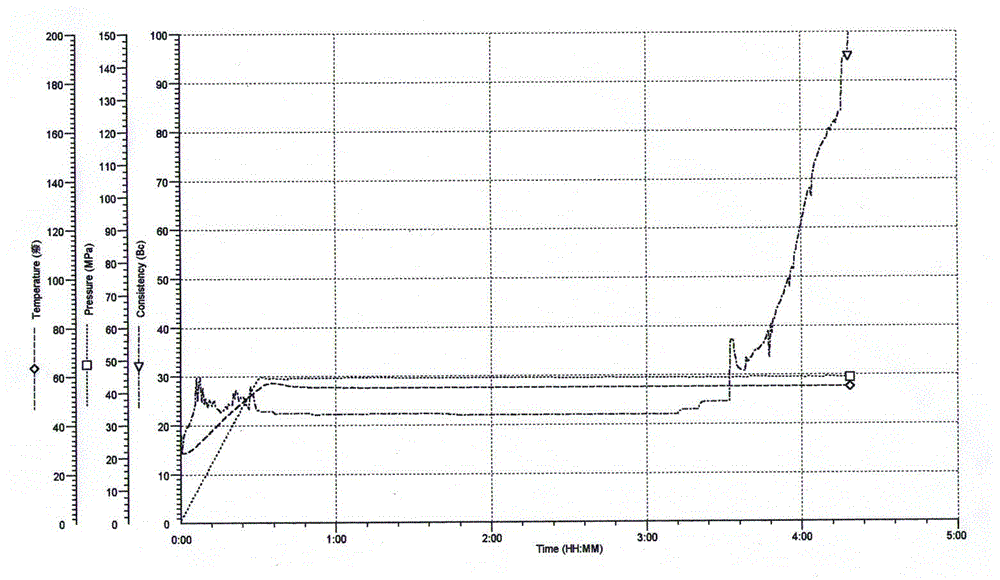

G-class oil well cement and processing technology thereof

ActiveCN104986975AImprove grindabilityIncreased raw mill outputDrilling compositionDecompositionCalcination

The invention provides a method for producing high-quality G-class oil well cement with gangue as a siliceous material. The method specifically comprises the following steps that the gangue is used as the siliceous material for dosing, a raw material is obtained through grinding, preheating decomposition, high-temperature calcination and cooling are conducted, so that oil well clinker is obtained, the oil well clinker and gypsum are ground together, and then oil well cement is obtained. After the method is implemented, the raw materials except limestone are waste residues, and therefore the coal consumption of clinker calcination is greatly reduced. The grinding yield of the raw material is greatly increased, energy sources are greatly saved, emission of CO2 is reduced, energy conservation and emission reduction are achieved, and the method accords with the national energy conservation and emission reduction environmental-protection concept; by the adoption of the scheme, the waste residues, such as the gangue, coal ash and mining barren rock are consumed greatly, and environmental pollution is reduced; besides, production cost can be reduced, and economic benefits can be increased.

Owner:GEZHOUBA SONGZI CEMENT

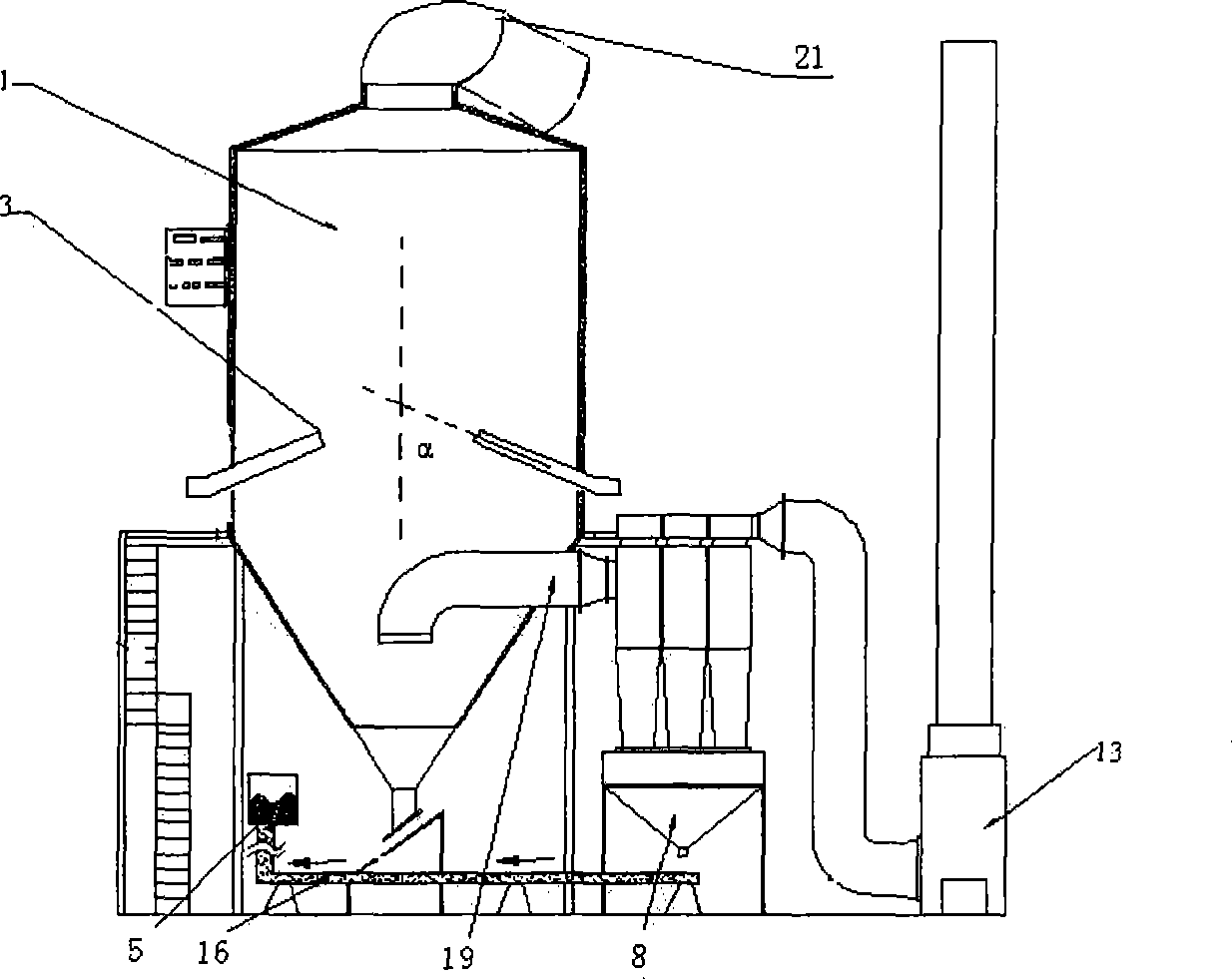

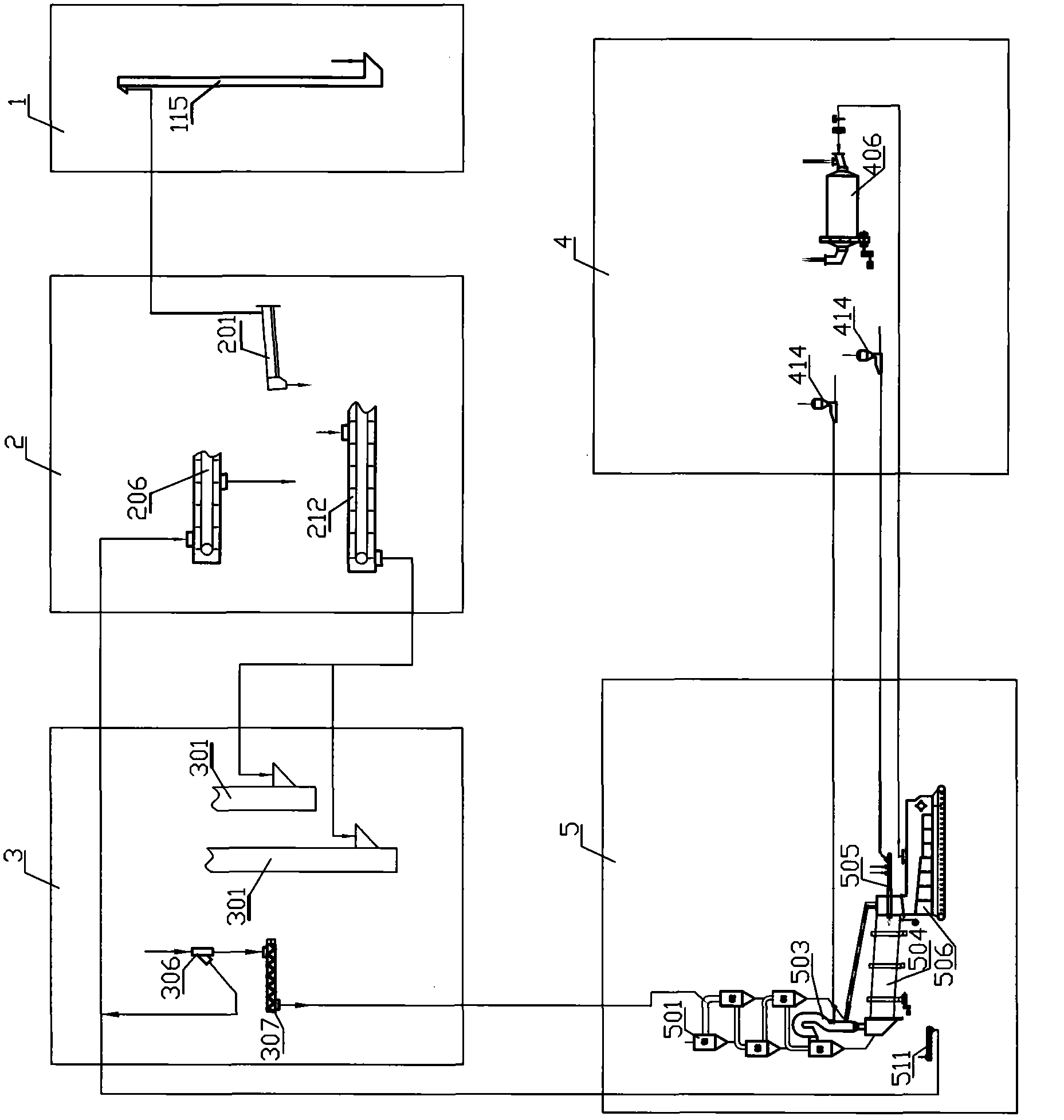

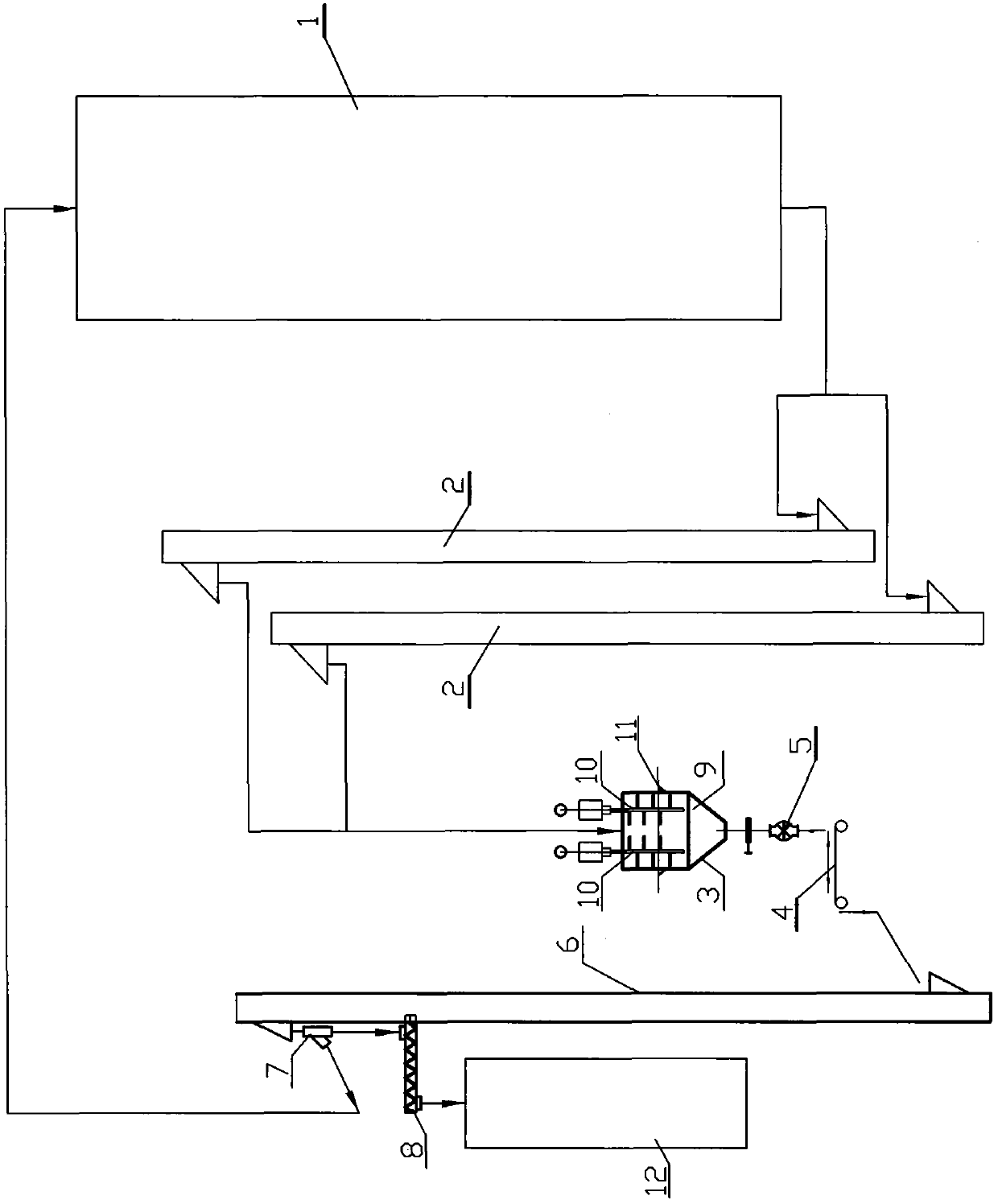

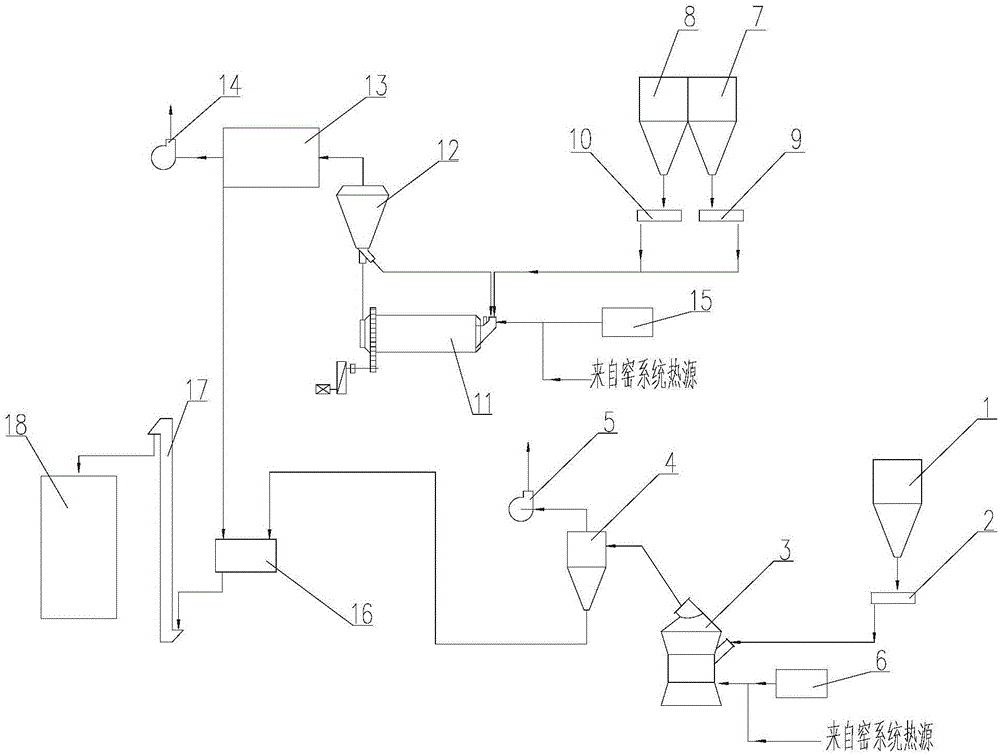

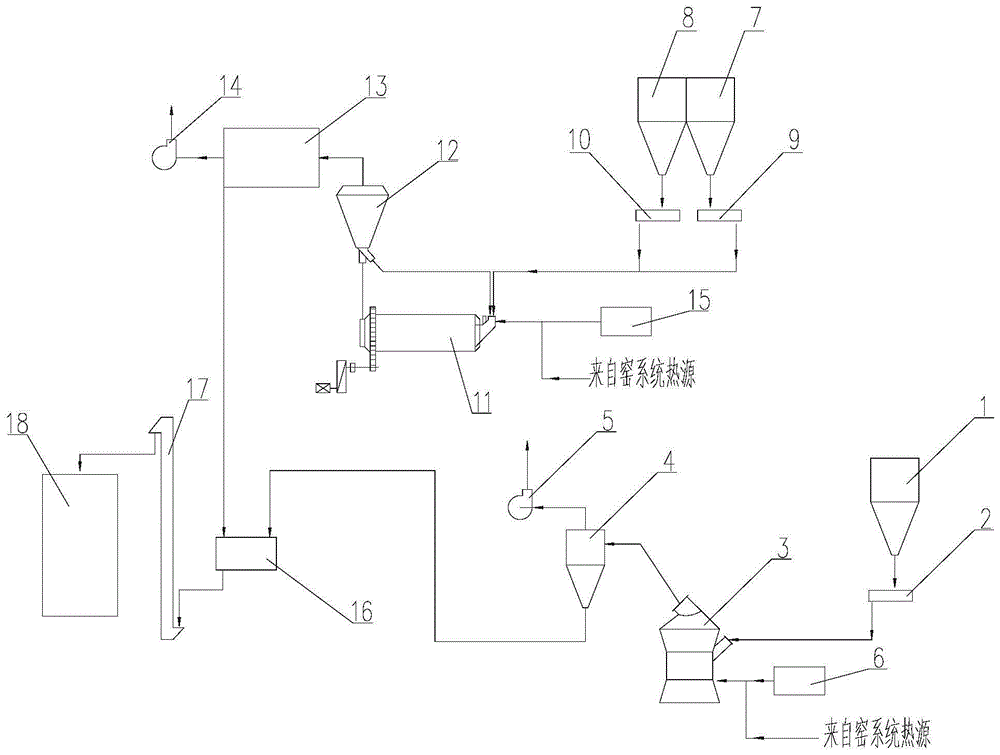

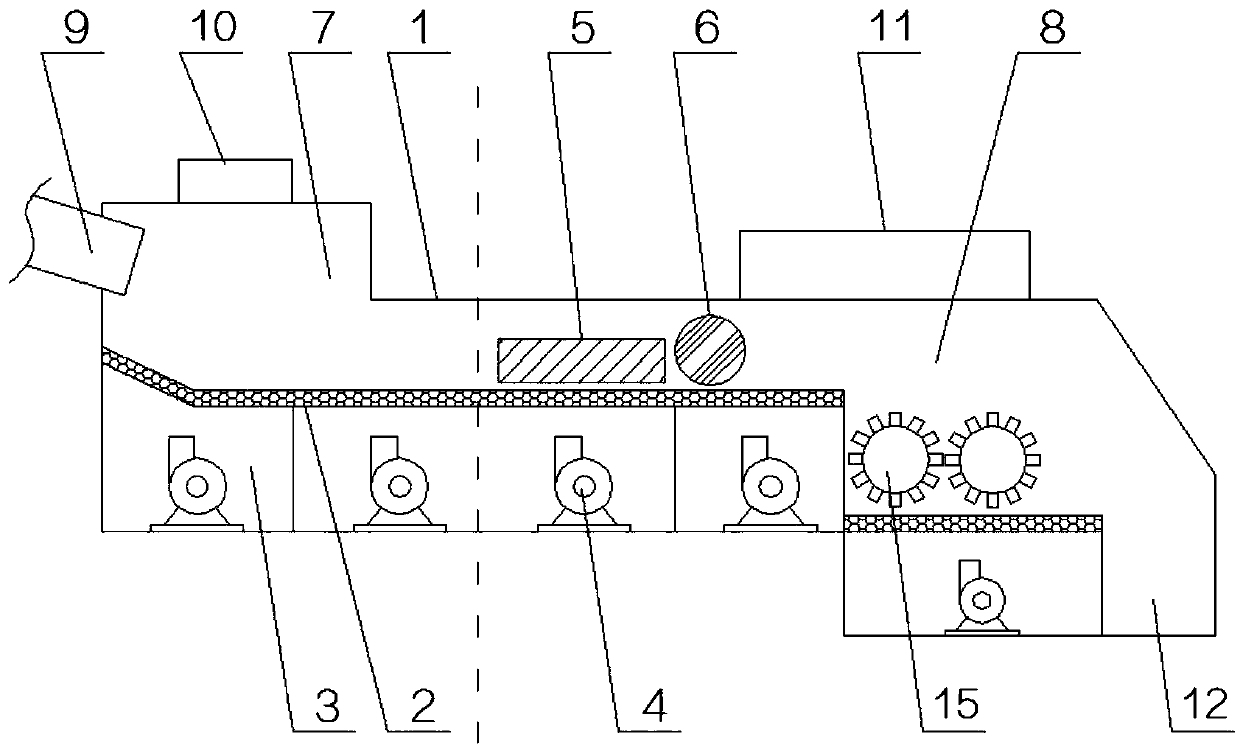

Energy-saving and environment-friendly cement clinker preparation system

ActiveCN103351106AUniform and stable qualityQuality improvementClinker productionDecompositionScrew conveyor

The invention discloses an energy-saving and environment-friendly cement clinker preparation system, which includes a raw material preparation system, a raw material homogenization system, a fed raw material conveying system, a cement and pulverized coal preparation system and a cement clinker calcination system, wherein a material outlet of a loading bucket elevator is connected with a material inlet of a raw material homogenization air conveying chute; a material outlet of an unloading chain conveyer is connected with material inlets of two unloading bucket elevators respectively; a material outlet of a raw material feeding spiral conveyer is connected with a material inlet of a preheater; a material outlet of a spiral pneumatic conveying pump is connected with a material inlet of a decomposition furnace; a material outlet of another spiral pneumatic conveying pump is connected with a material inlet of a four-passage pulverized coal combustion device; a hot air outlet of an air-beam type grate cooler is connected with an air inlet of an air-swept coal mill; one material outlet of an electric tee scraper-trough conveyer and a material outlet of a kiln tail dust collection spiral conveyer are both connected with a material inlet of a re-homogenization loading chain conveyer. The system has the advantages as follows: the yield of the clinker is increased, the energy consumption is lowered, the emission is reduced, the quality of the clinker is improved, and the quality of the cement is stable.

Owner:INNER MONGOLIA MENGXI CEMENT CO LTD

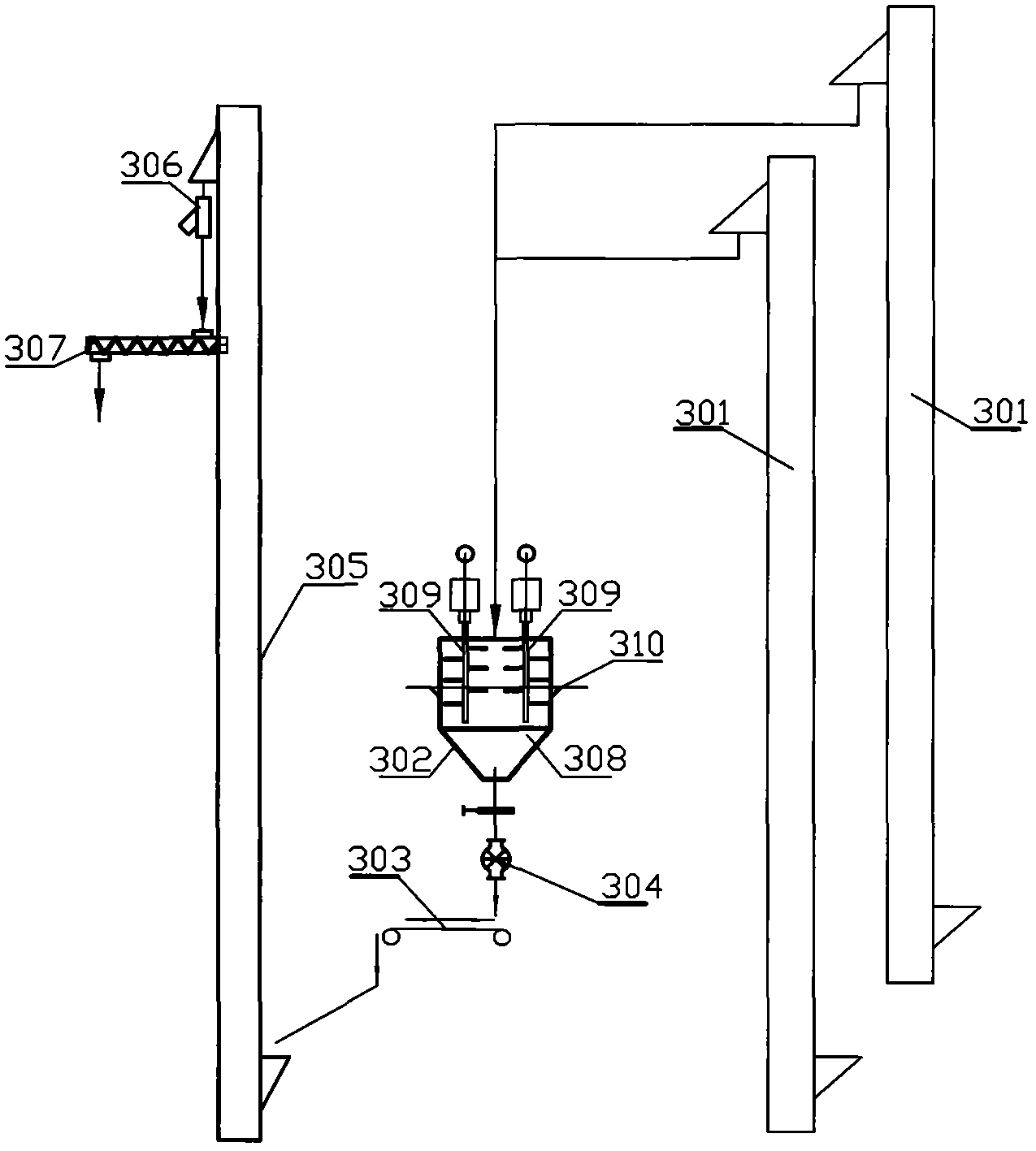

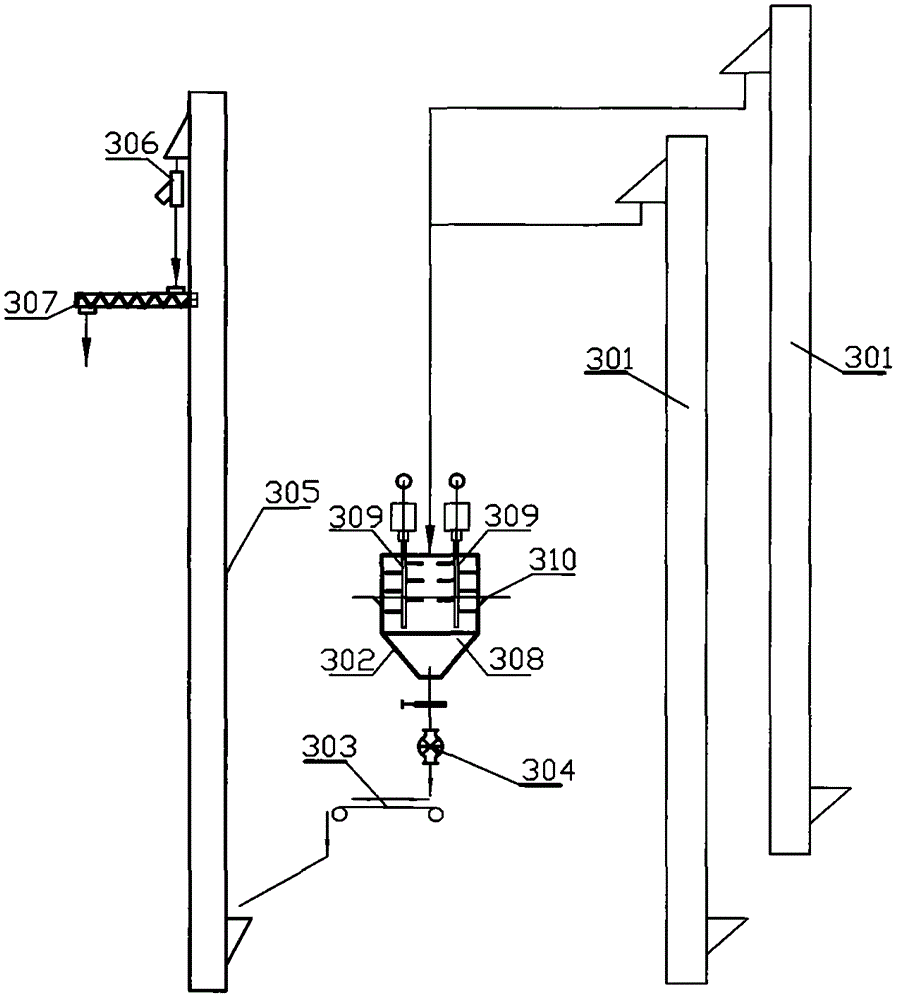

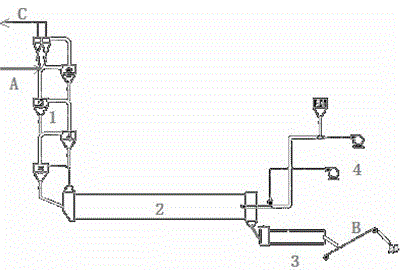

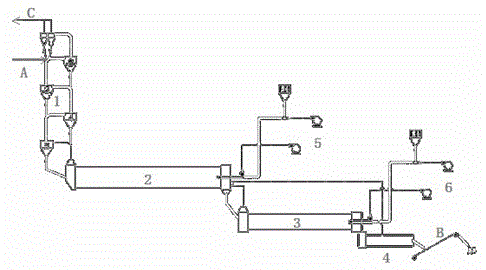

Cement raw meal conveying system

InactiveCN103387121AImprove homogenizationHigh strengthMechanical conveyorsImpellerAdditive ingredient

The invention discloses a cement raw meal conveying system, which comprises a homogenization silo, two hopper type lifting machines, a raw meal homogenization measuring cabin, a speed regulating and quantitative feeding machine, an impeller feeding machine, a steel wire twisted lifting machine, an electric equal tee valve and a spiral conveyor. The system has the advantages that by adopting a double-hopper lifting machine to lift raw meal, the capability of homogenization is improved, a spiral stirring device and a load sensor are additionally mounted on a raw meal cabin, the phenomena of a full cabin and the blockage of conveying pipelines are eliminated, the homogenization function on the raw meal is improved again, and the homogenization degree of the raw meal is improved; after the system is used, the problem of fluctuation in raw meal ingredients is thoroughly solved, and the quality of ripe meal is greatly promoted; and the overall raw meal conveying system forms a self-circulation system, once material blockage or a fault occurs in a preheater, raw meal in the conveying device can be timely circulated back to the raw meal homogenization silo, and as long as the position of the homogenization silo premits, the raw meal preparation system is not required to be shut down for long due to the fault of the preheater.

Owner:INNER MONGOLIA MENGXI CEMENT CO LTD

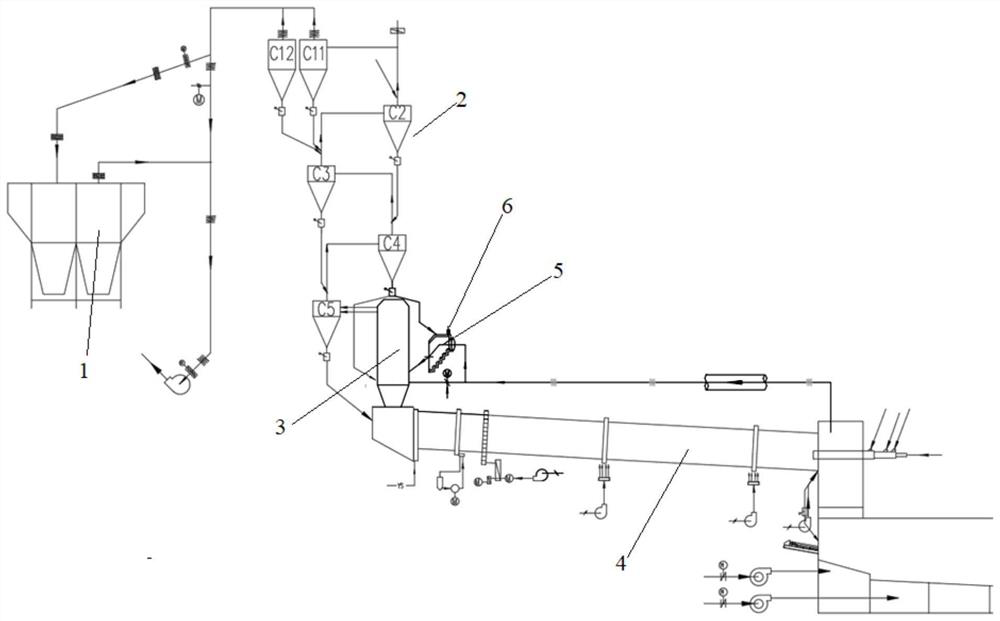

System and method for achieving green denitration by means of dry process production process

PendingCN110170239ASave coalLess investmentNitrous oxide captureDispersed particle separationCycloneProcess equipment

The invention discloses a system and a method for achieving green denitration by means of a dry process production process. The system comprises a multi-stage cyclone barrel, a decomposing furnace, afeed-end chamber, a rotary kiln and a grate cooler, wherein a denitration chamber is arranged on the lower part of the decomposing furnace, a spraying and scattering integrated machine is arranged inthe decomposing furnace, a spraying and scattering denitrator which sprays and scatters steam and pulverized coal simultaneously is arranged in the denitration chamber, the feed-end chamber is arranged below the denitration chamber and is communicated with the rotary kiln, the grate cooler at the head of the rotary kiln is provided with a secondary air taking hood and a tertiary air taking hood, the tertiary air taking hood is connected to the grate cooler and a tertiary air hose, and the air outlet of the tertiary air hose is communicated with the decomposing furnace. By combining characteristics of a cement production process, the system optimizes the process design and the process equipment, and reduces generation of NOX fundamentally by means of process measures based on efficient highquality production, so that green denitration is achieved.

Owner:山东泰溥节能环保科技有限公司

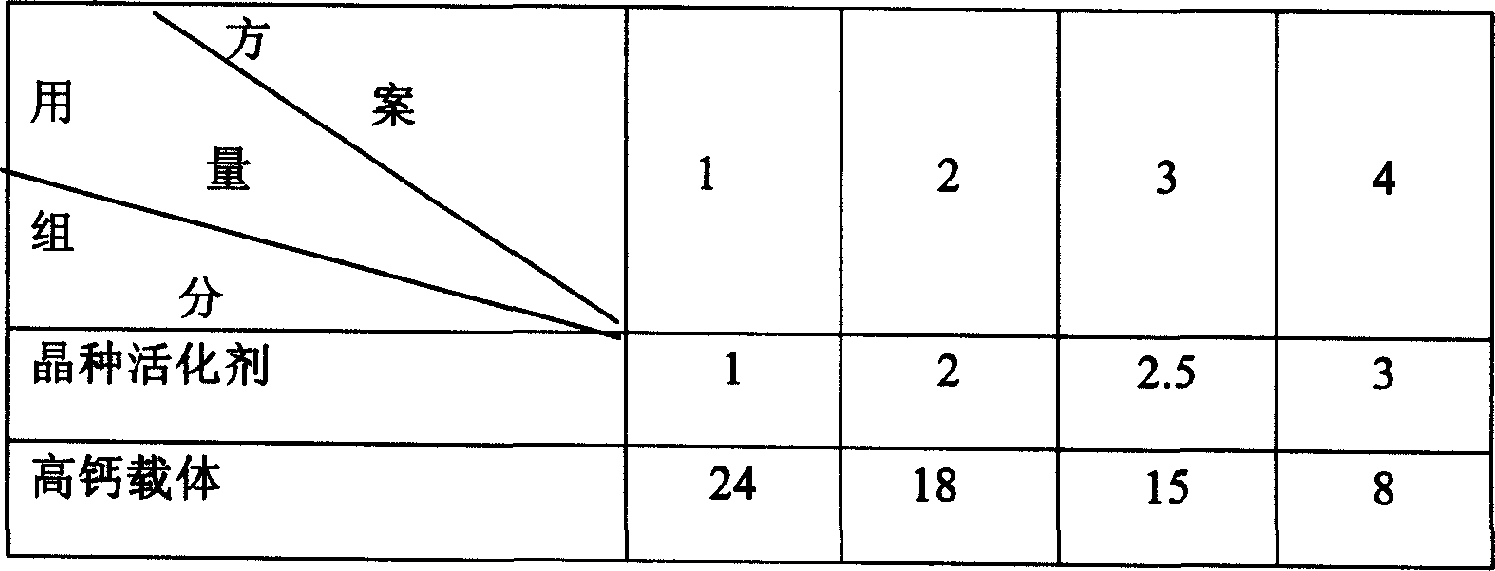

Highly active cement mineral forming promoter

The invention relates to high activity cement mineral forming accelerating agent applied to produce new type dry method cement. It is made up of seed crystal activating agent and high calcium carrier, and their proportioning by weight respectively are from one portion to three portion, and from eight portion to twenty four portion. The constituent and weight content of the seed crystal activating agent is from forty percent to eighty percent of the slag, the mineralizing agent is from twenty percent to sixty percent. The main effects of the accelerating agent supplied by the invention are that it obviously appear the seed crystal and mineralizing action, can greatly improve the raw material inflammability, reduce the fire temperature, broaden the fire range, increase the C3S content and activity of the clinker, so that increase the output and quality, as well as save resource and energy source, reduce the environment loading, and possess better economic and social benefit.

Owner:WUHAN UNIV OF TECH

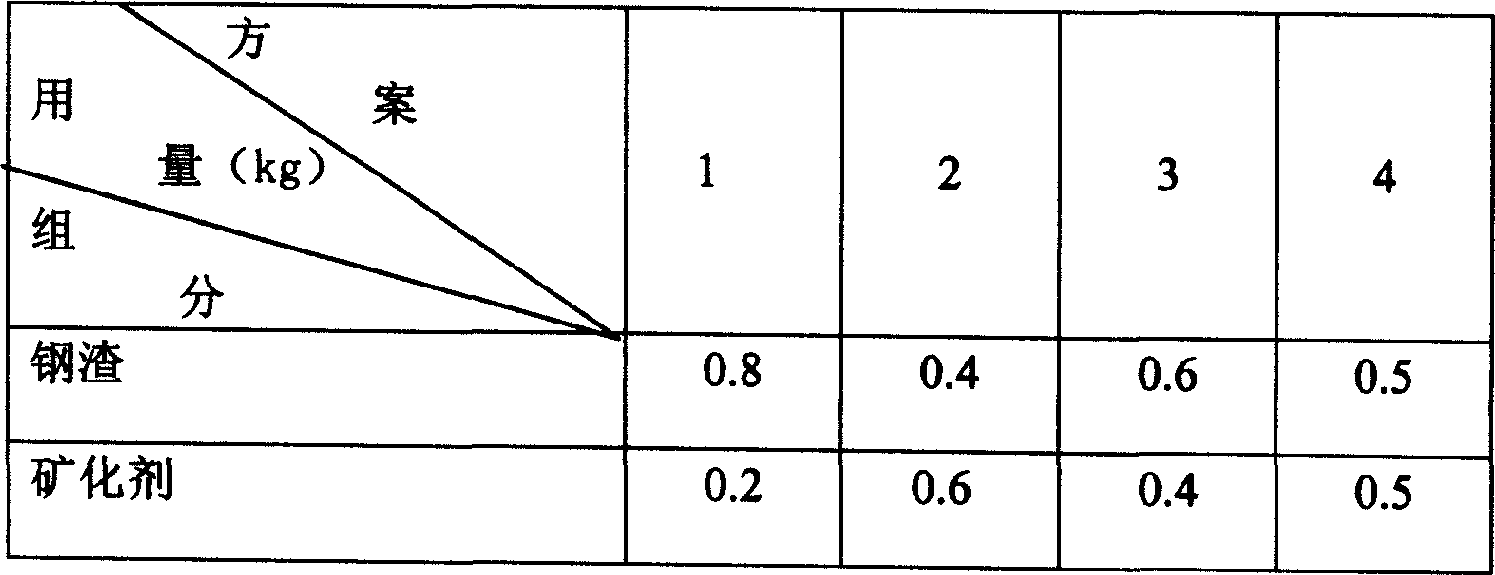

Thermal technology for making acid from gypsum as well as device

ActiveCN105152141AReduce heat lossReduce dosageSulfur compoundsClinker productionRotary kilnFlue gas

The invention discloses a thermal technology for making acid from gypsum. According to the thermal technology, a raw gypsum material which does not contain a reducing agent is dried and dehydrated by a dehydration furnace firstly, the raw material after drying and dehydration is preheated by a multi-level preheater, at least part of the preheated raw material is fed into a prereduction furnace, and the residual part is fed into a rotary kiln; the prereduction furnace reduces 20%-35% calcium sulfate into calcium sulfide, a hot raw material discharged from the prereduction furnace is fed into the rotary kiln, calcium sulfide and calcium sulfate react in the rotary kiln to generate sulfur dioxide and calcium oxide, sulfur dioxide enters an acid making procedure along with flue gas exhausted from the rotary kiln, calcium oxide and other components in the raw gypsum material are calcined into cement clinker in the rotary kiln and then discharged from the kiln, and the cement clinker is cooled and output. The invention further discloses a device for applying the thermal technology. Heat consumption of a gypsum acid-making system is reduced, the use amount of the reducing agent is reduced, the quality of clinker is improved, and the concentration of sulfur dioxide in the acid-making flue gas is increased, so that the investment and operation costs of a flue gas acid-making system are reduced.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

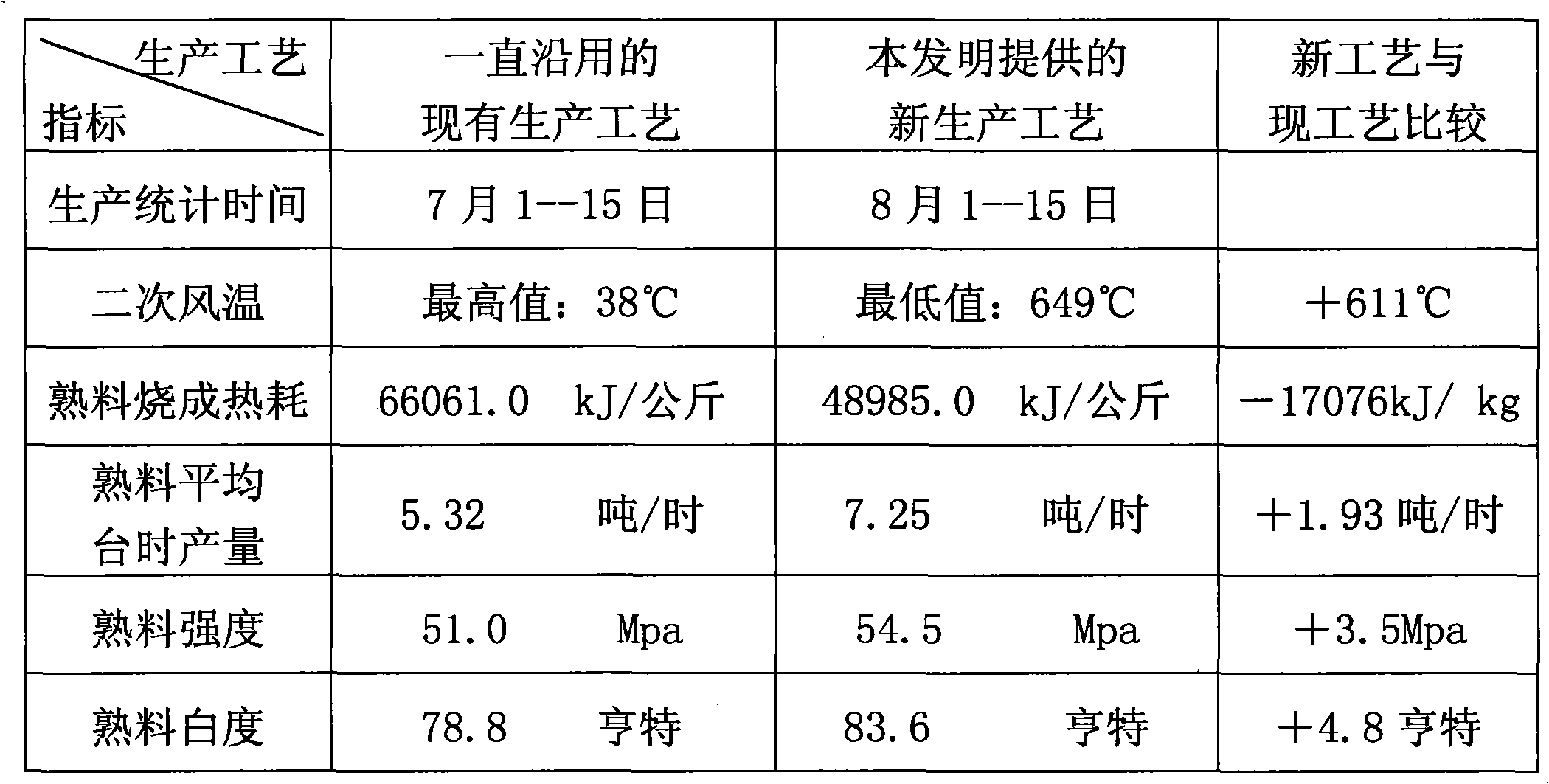

Cooling bleaching production technique of white portland cement clinker

The invention relates to a cooling bleaching production technique of white silicate cement clinker, comprising the following steps: discharging calcined high-temperature white silicate cement clinkerfrom a kiln, conveying the clinker into an air heat exchanger for 5-500 seconds of bleaching by wind cooling; delivering the hot air that conducts heat exchange with the high-temperature clinker intoa clinker calcining kiln so as to be used as secondary combustion air; and transferring the clinker bleached by the air heat exchanger into a normal spray-type or soak-type cooling bleaching machine for spray-type or soak-type cooling bleaching until the clinker is cooled down to the temperature of 20-100 DEG C. Compared with the existing production technique, the white silicate cement clinker isbeneficial to decreasing the heat consumption for calcining the clinker, and promoting the sufficient combustion of fuels, thus improving the calcining yield of the kiln; besides, two times of coolingbleaching with different media is beneficial to improving the quality of the white cement clinker.

Owner:吴飞龙

A kind of G grade oil well cement and its processing technology

ActiveCN104986975BImprove grindabilityIncreased raw mill outputDrilling compositionDecompositionCoal

The invention provides a method for producing high-quality G-class oil well cement with gangue as a siliceous material. The method specifically comprises the following steps that the gangue is used as the siliceous material for dosing, a raw material is obtained through grinding, preheating decomposition, high-temperature calcination and cooling are conducted, so that oil well clinker is obtained, the oil well clinker and gypsum are ground together, and then oil well cement is obtained. After the method is implemented, the raw materials except limestone are waste residues, and therefore the coal consumption of clinker calcination is greatly reduced. The grinding yield of the raw material is greatly increased, energy sources are greatly saved, emission of CO2 is reduced, energy conservation and emission reduction are achieved, and the method accords with the national energy conservation and emission reduction environmental-protection concept; by the adoption of the scheme, the waste residues, such as the gangue, coal ash and mining barren rock are consumed greatly, and environmental pollution is reduced; besides, production cost can be reduced, and economic benefits can be increased.

Owner:GEZHOUBA SONGZI CEMENT

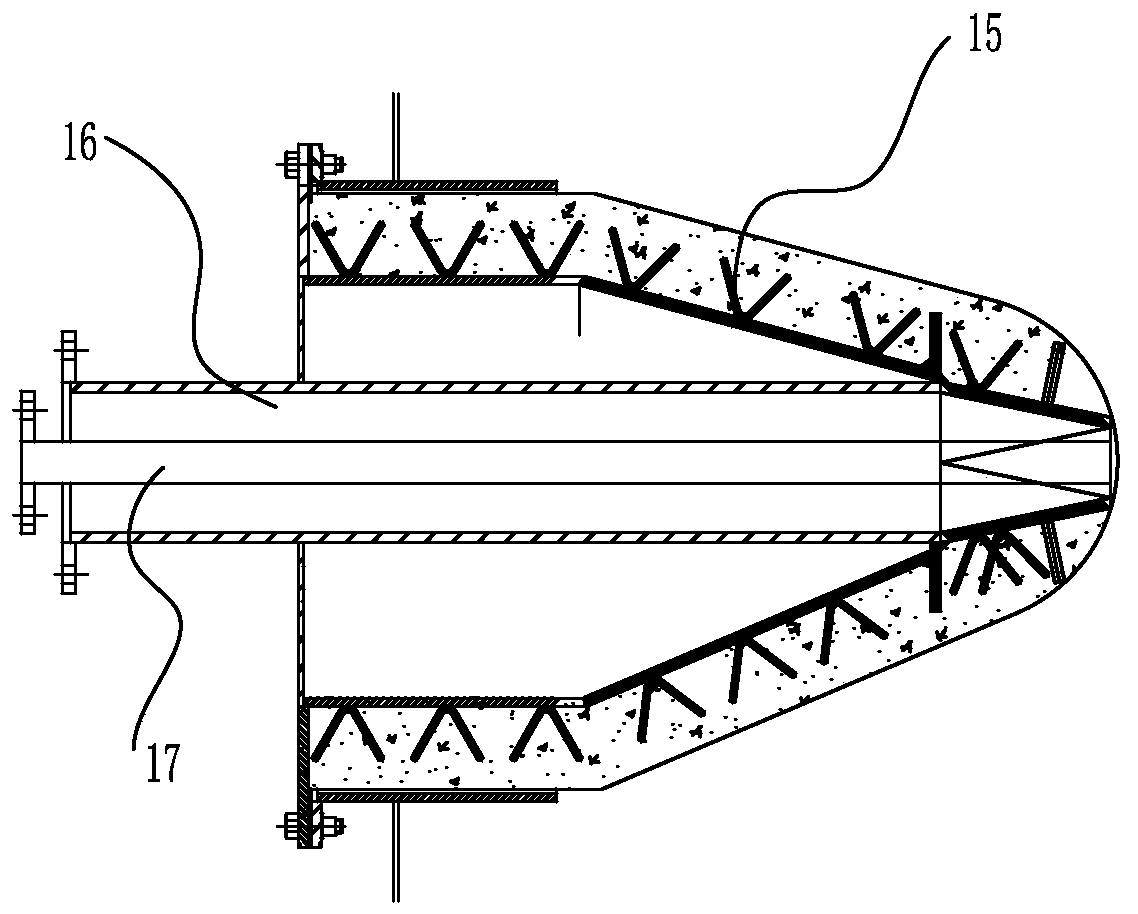

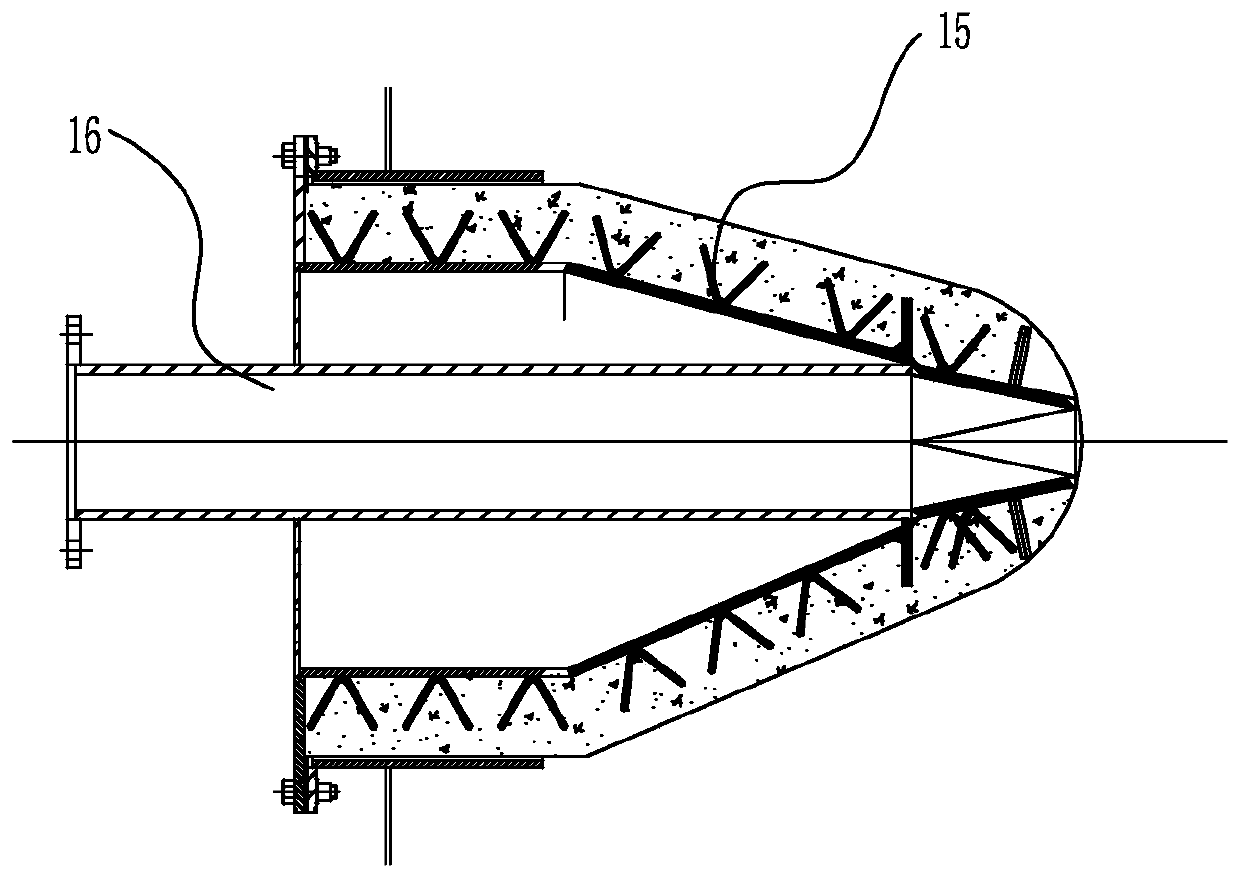

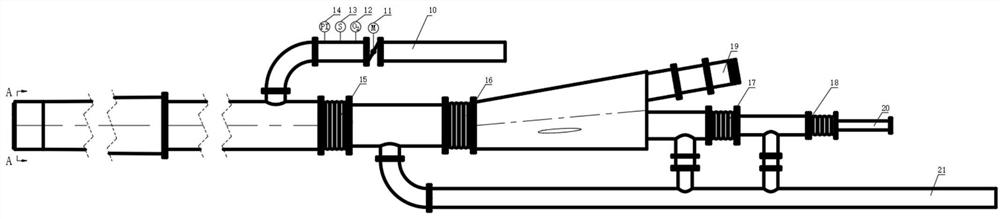

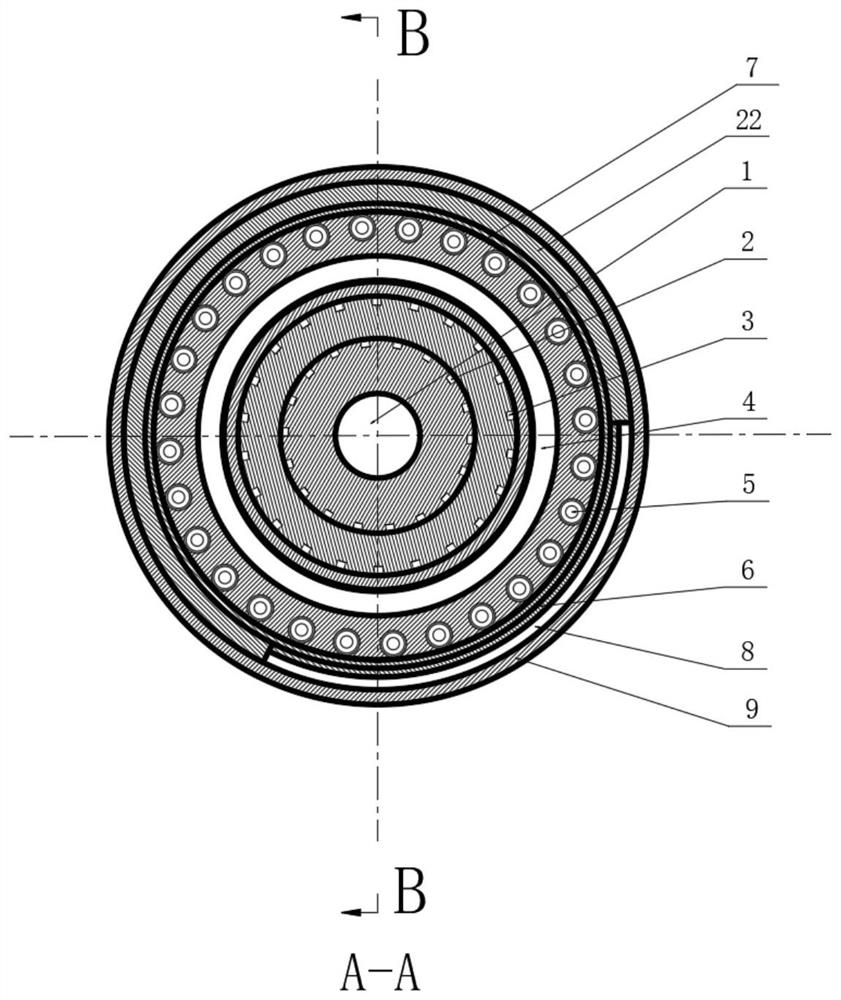

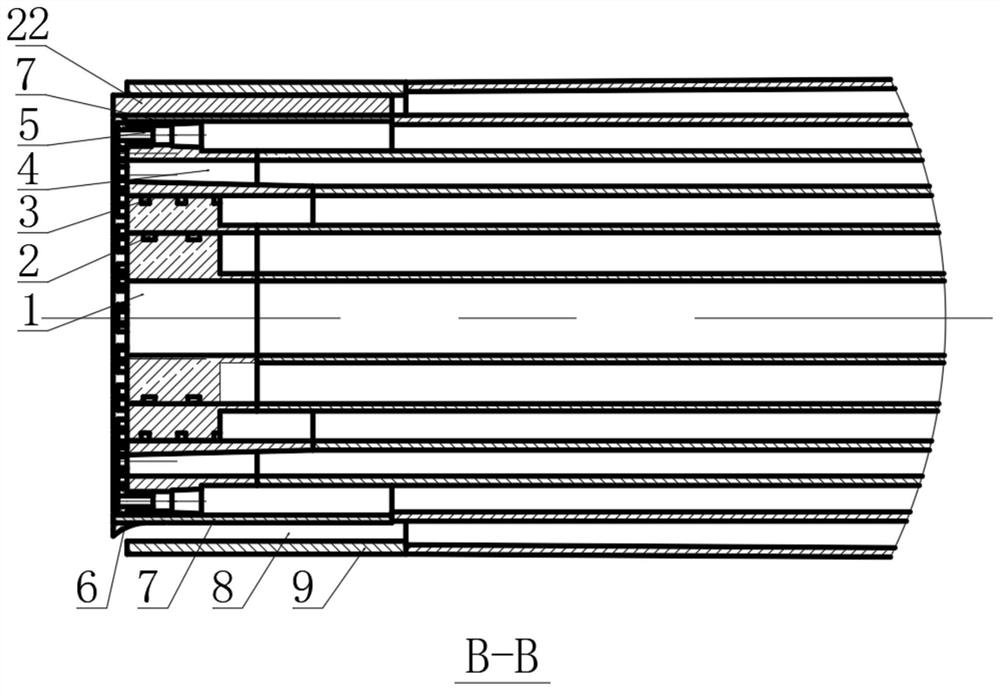

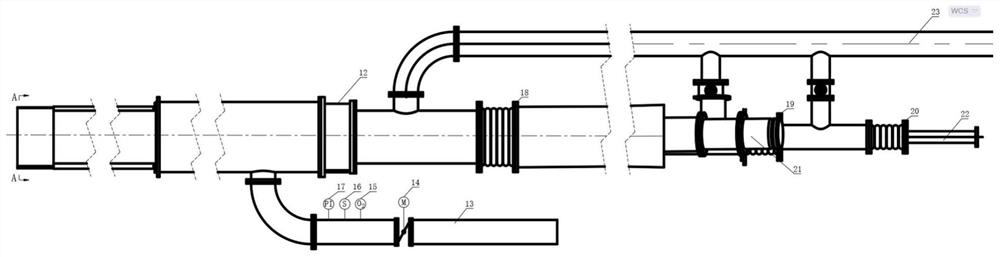

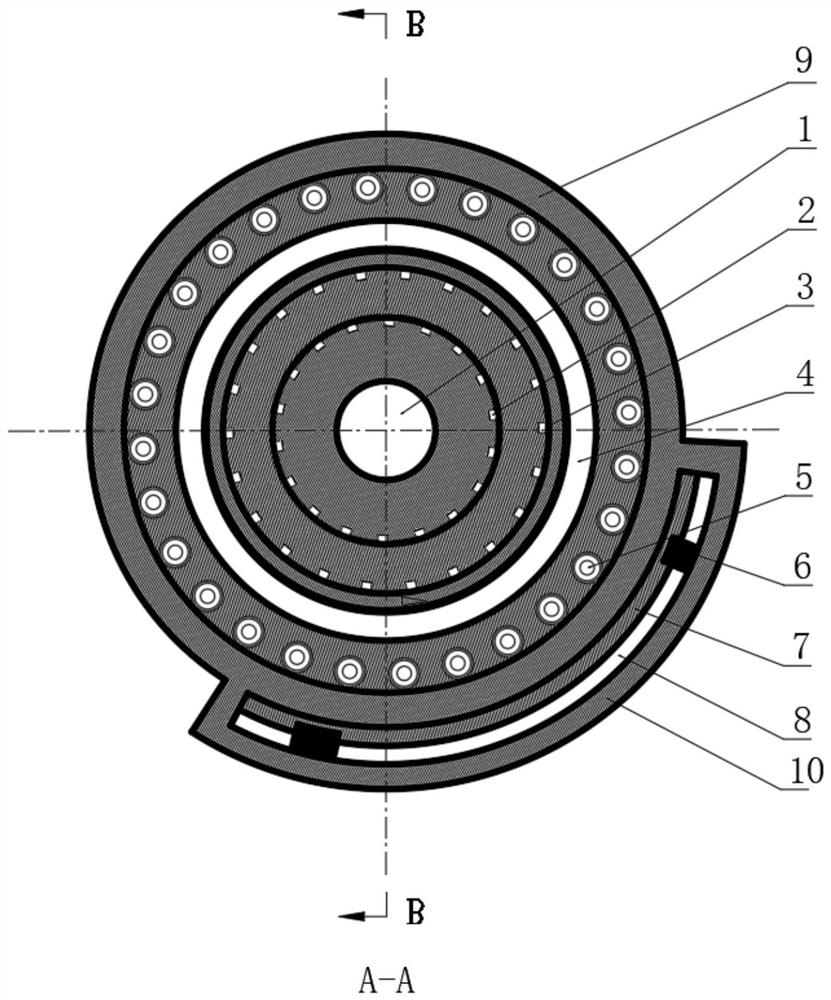

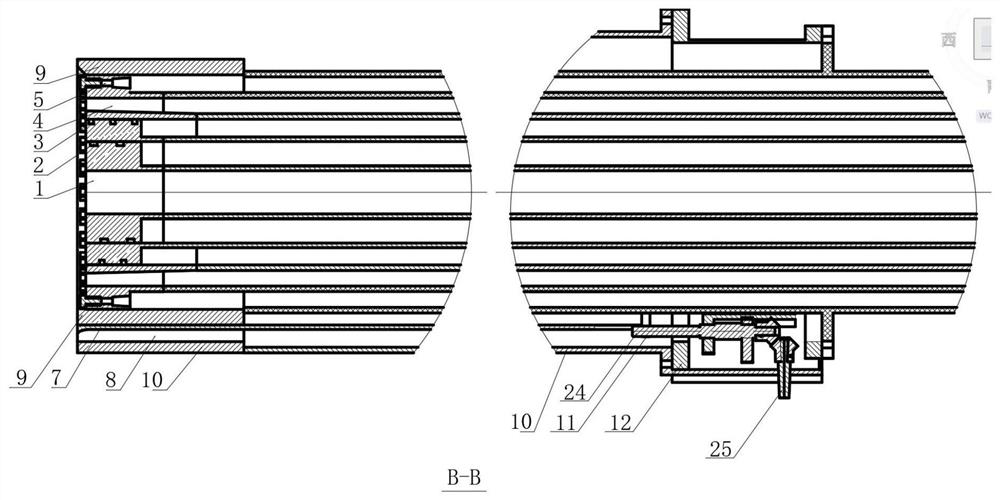

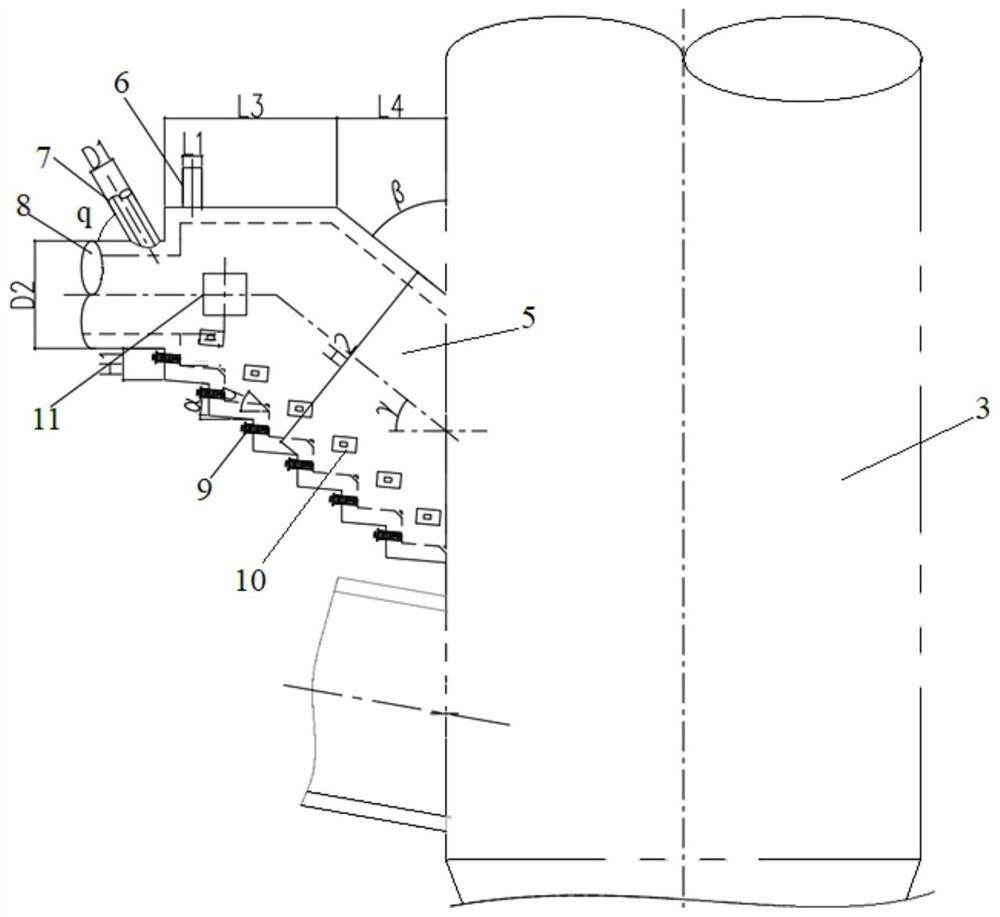

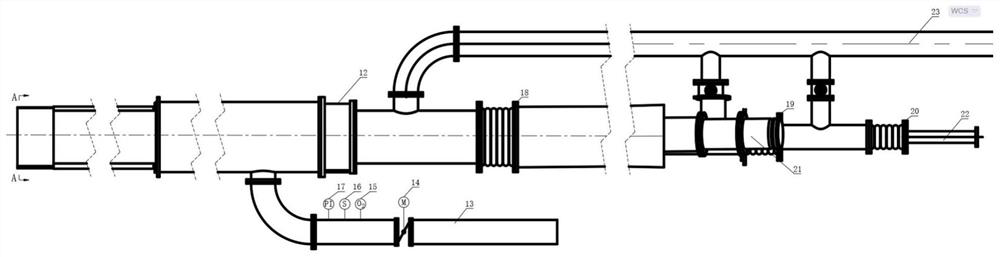

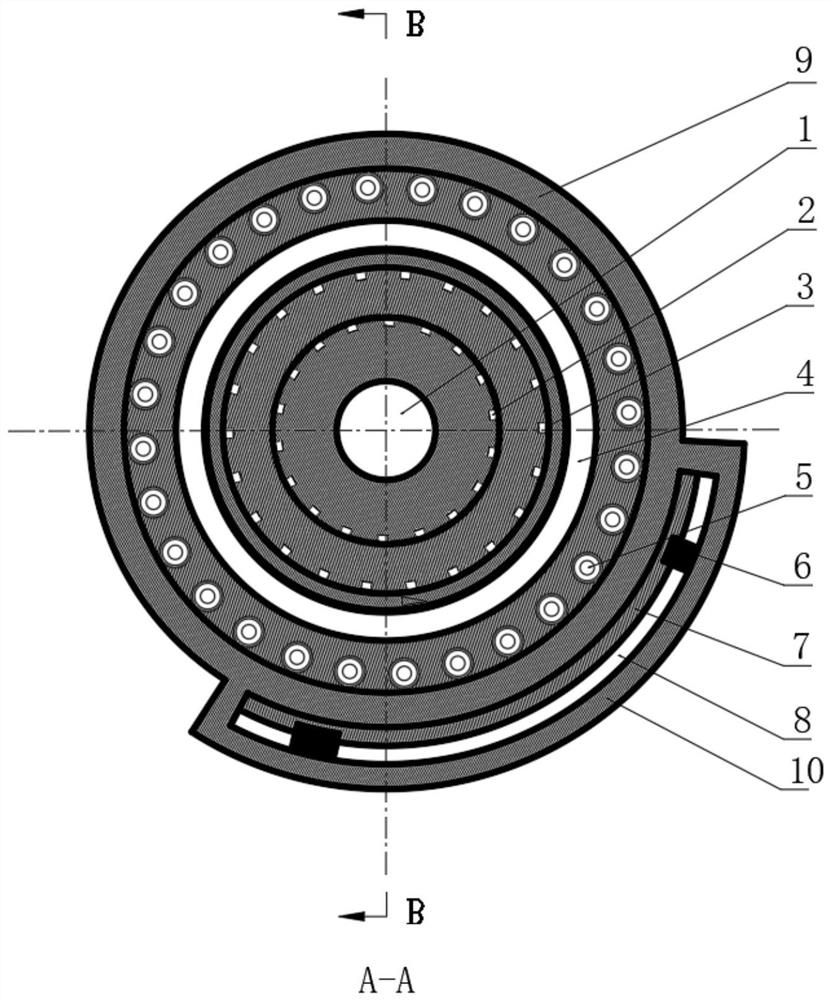

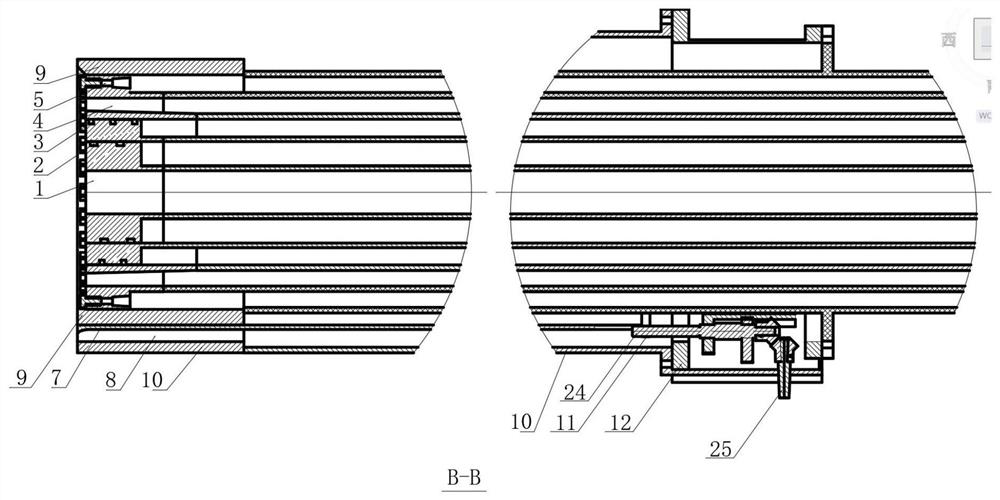

Multi-channel rotary kiln combustor with directional oxygen-enriched combustion supporting function

PendingCN113719835ARaise the combustion temperatureReduce power consumptionRotary drum furnacesPulverulent fuel combustion burnersThermodynamicsCombustor

The invention discloses a multi-channel rotary kiln combustor with a directional oxygen-enriched combustion supporting function. The multi-channel rotary kiln combustor comprises a multi-channel combustor body, an oxygen-enriched air sleeve is arranged on the outer side of the multi-channel combustor body, an arc-shaped flow guide assembly and an arc-shaped sealing assembly are arranged in the oxygen-enriched air sleeve in the circumferential direction, the sum of the radian of the arc-shaped flow guide assembly and the radian of the arc-shaped sealing assembly is 360 degrees, an arc-shaped oxygen-enriched air channel is formed between the arc-shaped flow guide assembly and the oxygen-enriched air sleeve, and the multi-channel combustor body and the oxygen-enriched air channel are concentrically arranged. Arc-shaped and flat uniform oxygen-enriched air flow with a proper angle and a proper range can be formed at the bottom of the lower belly part of the outer axial flow air sleeve and is directionally and accurately injected into a specified area, so that directional oxygen-enriched air combustion supporting is realized, a better combustion-supporting effect is achieved, the combustion effect and the fuel burnout rate are favorably improved, the combustion temperature of the specified area is improved, and calcination effect is improved, coal consumption is reduced, and clinker quality is improved.

Owner:福建省世能科泰节能设备有限公司

Boiler-use coal combustion-supporting material formulation method

The invention discloses a boiler-use coal combustion-supporting material formulation method. The material is composed of the components of, by weight, 50-70% of manganese ore, 10-20% of potassium carbonate, 5-20% of ammonium nitrate, 10-20% of aluminum powder, 10-20% of potassium chlorate, and 10-30% of a clinker sintering aid, wherein the total amount of the components is 100% by weight, and manganese dioxide content in the manganese ore is no lower than 40%. The raw materials of the material provided by the invention can be easily purchased in market. With the formulation, coal can be saved by more than 18%, and sulfur dioxide emission can be reduced by more than 90%.

Owner:洛阳大泽节能环保科技有限公司

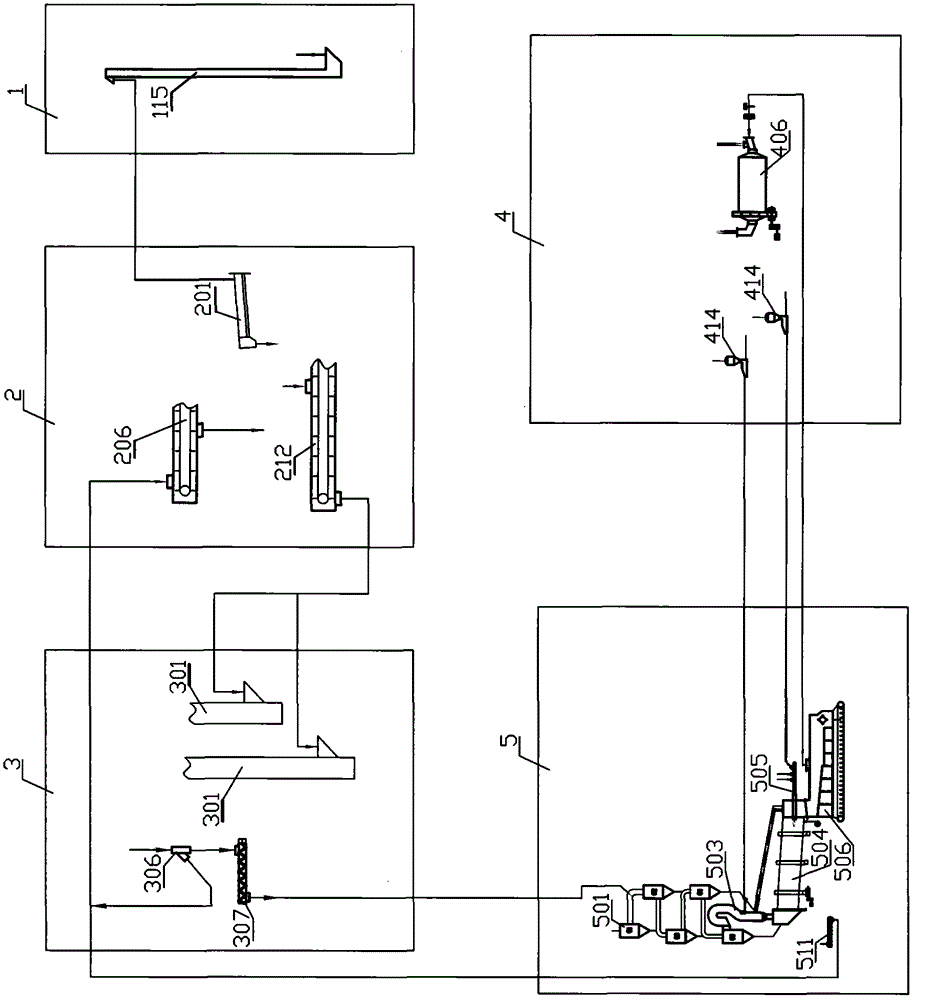

Process and processing system for co-processing shellfish waste with cement clinker production line

ActiveCN104003634AImprove waste heat utilizationReduce firing heat consumptionIncreasing energy efficiencyWaste heat treatmentExhaust gasCo-processing

The invention discloses a high-efficiency process for co-processing shellfish wastes with a cement clinker production line. The process comprises the steps: placing collected shells in a piling shed, rinsing cleanly with water, sending the air-dried shells to a dryer, introducing dedusted hot wind of a kiln tail of a rotary kiln in the cement clinker production line into the dryer, drying the shells, directly discharging emptily deodorization-treated tail gas discharged by the dryer, sending the dried shells into a crusher, crushing, sending the crushed shell broken material as a cement clinker raw material to the cement clinker production line for producing cement clinker or being directly used as a cement raw material. Not only is the shellfish waste utilized, but also energy sources are saved. The invention also discloses a system suitable for the process.

Owner:广东省建筑材料研究院有限公司

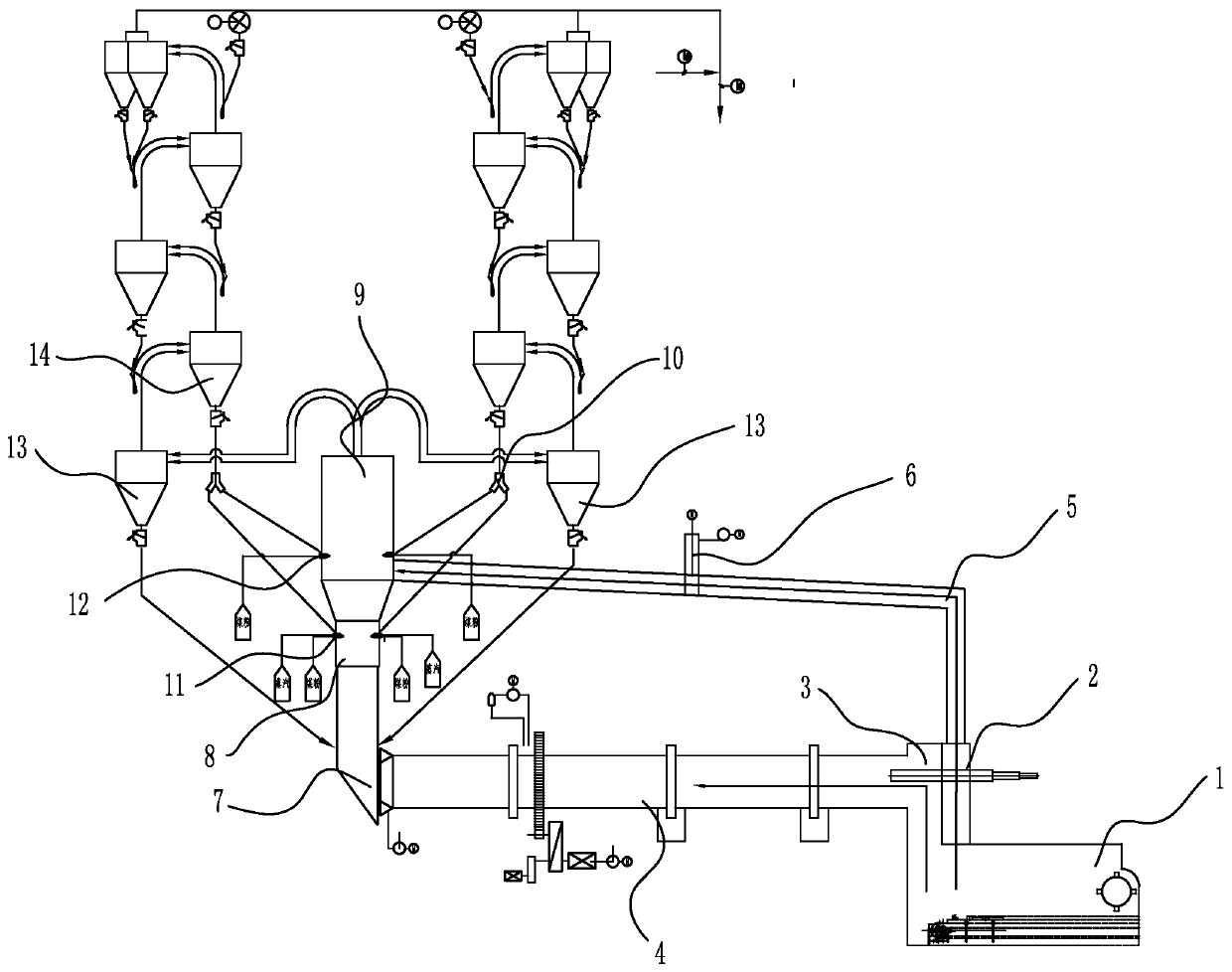

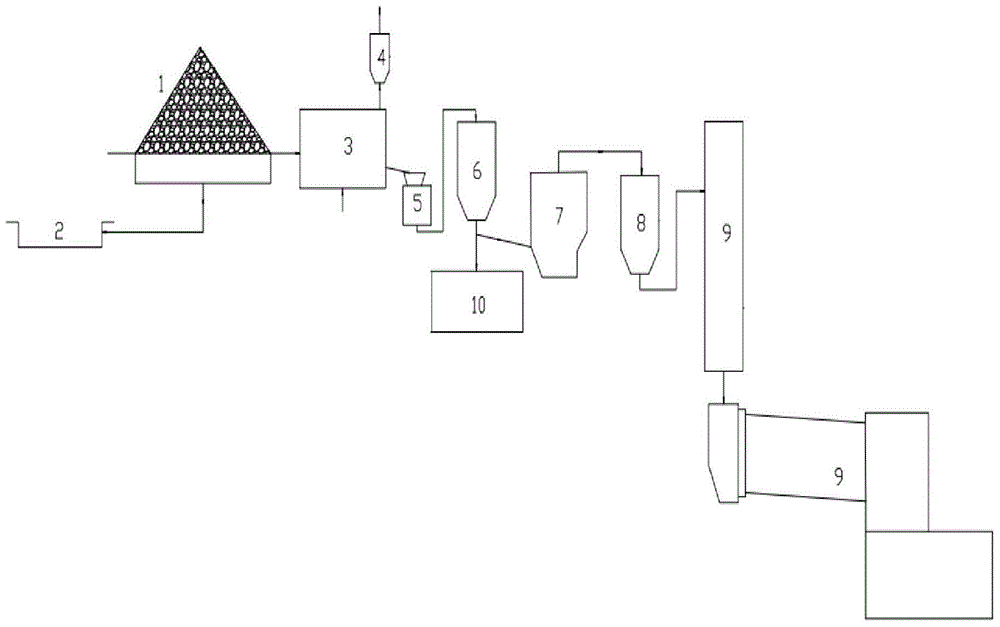

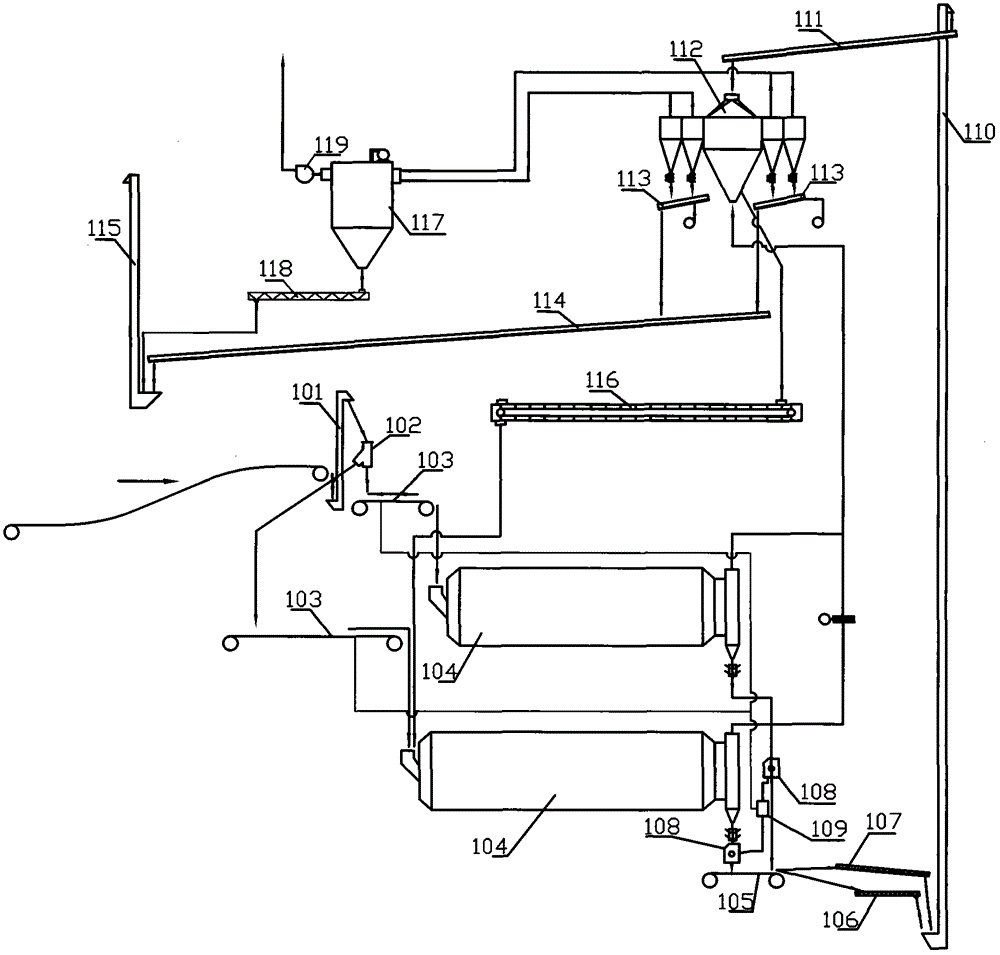

Preparation process and system for raw material used for dry-process sintering production of aluminum oxide clinker

ActiveCN105060325ANo grinding phenomenonReduce power consumptionAluminium oxides/hydroxidesNephelineBall mill

The present invention discloses a preparation process for raw material used for dry-process sintering production of aluminum oxide clinker. The preparation process comprises: after metering limestone in proportion, feeding the limestone to a vertical mill; after grinding and carrying out powder selecting by virtue of the vertical mill, feeding qualified limestone powder to a gas-solid separator I; and after the gas-solid separator I collects the qualified limestone powder, feeding the qualified limestone powder to a material-mixing device; after metering nepheline and albic powder in ratio, feeding the nepheline and albic powder into a ball mill; after grinding, feeding the nepheline and albic powder to a powder concentrator by virtue of wind to perform grading; after grading, feeding qualified nepheline and albic powder to a gas-solid separator II for collecting, feeding thenepheline and albic powder into the material-mixing device; and and after limestone powder materials are mixed with the nepheline and the albic powder material in the material-mixing device, taking the mixture as a raw material finished product and feeding the raw material finished product into a homogenizing silo. The present invention further discloses a raw material preparation system applying the process. According to the preparation process, grinding is performed on the limestone and the nepheline separately by use of different grinding systems and equipment, and qualified products are acquired after being mixed and homogenized, so that product particles are distributed reasonably, and the raw material grinding system is low in power consumption.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Energy saving and environmental protection cement clinker preparation system

ActiveCN103351106BStable and uniform qualityReduce the load rate of the internal circulation of the millClinker productionDecompositionBucket elevator

The invention discloses an energy-saving and environment-friendly cement clinker preparation system, which includes a raw material preparation system, a raw material homogenization system, a fed raw material conveying system, a cement and pulverized coal preparation system and a cement clinker calcination system, wherein a material outlet of a loading bucket elevator is connected with a material inlet of a raw material homogenization air conveying chute; a material outlet of an unloading chain conveyer is connected with material inlets of two unloading bucket elevators respectively; a material outlet of a raw material feeding spiral conveyer is connected with a material inlet of a preheater; a material outlet of a spiral pneumatic conveying pump is connected with a material inlet of a decomposition furnace; a material outlet of another spiral pneumatic conveying pump is connected with a material inlet of a four-passage pulverized coal combustion device; a hot air outlet of an air-beam type grate cooler is connected with an air inlet of an air-swept coal mill; one material outlet of an electric tee scraper-trough conveyer and a material outlet of a kiln tail dust collection spiral conveyer are both connected with a material inlet of a re-homogenization loading chain conveyer. The system has the advantages as follows: the yield of the clinker is increased, the energy consumption is lowered, the emission is reduced, the quality of the clinker is improved, and the quality of the cement is stable.

Owner:INNER MONGOLIA MENGXI CEMENT CO LTD

Raw meal preparation process and system for dry sintering to produce alumina clinker

ActiveCN105060325BNo grinding phenomenonReduce power consumptionAluminium oxides/hydroxidesNephelineBall mill

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Multi-channel rotary kiln combustor with directional oxygen-enriched combustion supporting function

ActiveCN113776045ARaise the combustion temperatureReduce power consumptionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

The invention discloses a multi-channel rotary kiln combustor with a directional oxygen-enriched combustion supporting function. The multi-channel rotary kiln combustor comprises a multi-channel combustor body, an externally-hung oxygen-enriched channel sleeve is arranged on the outer side of an outer axial flow air sleeve of the multi-channel combustor body in a welded mode through two surrounding plates, an arc-shaped flow guide assembly is arranged on one side, close to the outer axial flow air sleeve, of the externally-hung oxygen-enriched channel sleeve, an externally-hung oxygen-enriched air channel is formed between the arc-shaped flow guide assembly and the outer axial flow air sleeve, the radian of the externally-hung oxygen-enriched air channel ranges from 10 degrees to 180 degrees, the externally-hung oxygen-enriched air channel is arranged on the lower portion of the outer axial flow air sleeve of the multi-channel combustor body, and the multi-channel combustor body and the oxygen-enriched air channel are concentrically arranged. According to the multi-channel rotary kiln combustor, arc-shaped and flat uniform oxygen-enriched gas flow with a suitable angle and a suitable range can be formed at the bottom of the lower belly part of flame formed by the combustor, and is directionally and accurately injected into a specified area, so that directional oxygen-enriched air combustion-supporting is realized, and a better combustion-supporting effect is achieved.

Owner:SHENZHEN SINAEAN CO TECH ENERGY TECH CO LTD

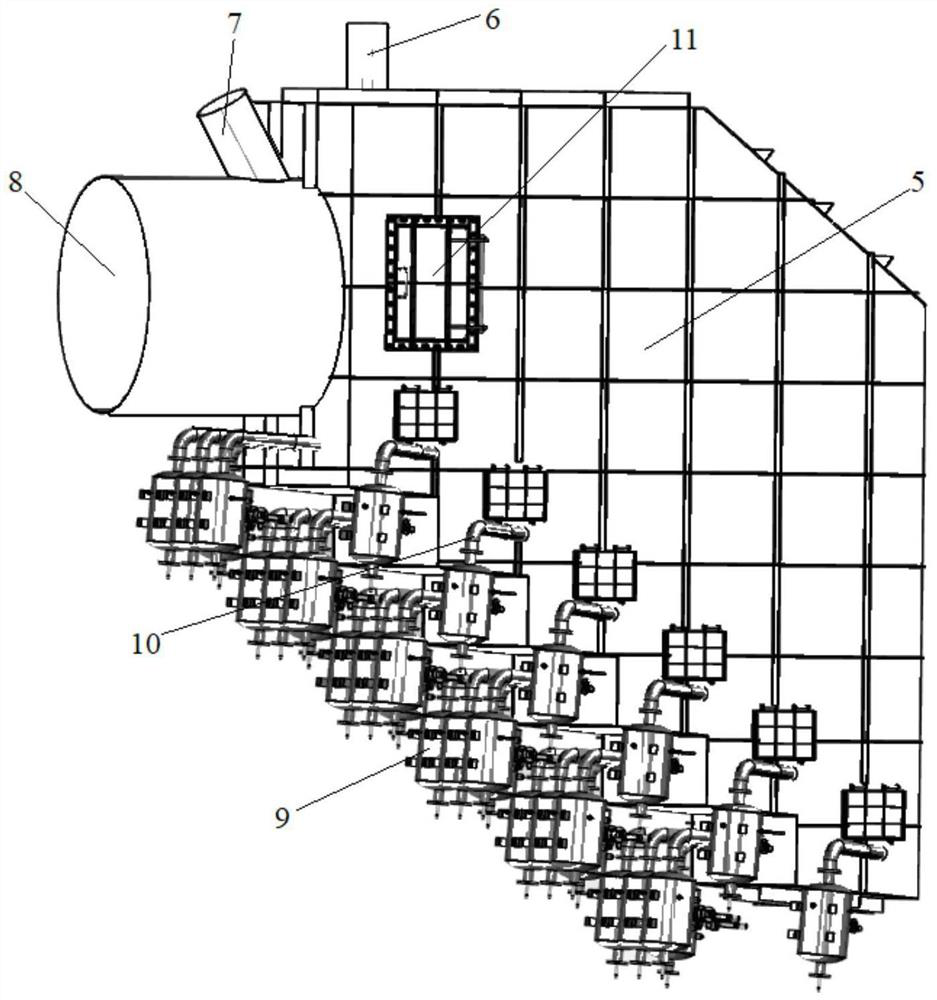

Solid waste treatment device of cement kiln

PendingCN113531541AImprove disposal capacityHarmlessIncinerator apparatusEnvironmental engineeringWaste treatment

The invention discloses a solid waste treatment device of a cement kiln, which structurally comprises a stepped furnace (5), wherein a solid waste and hazardous waste feed opening (6) is formed in the upper plane of the stepped furnace (5), a tertiary air distribution port (8) is formed in the front side surface of the stepped furnace (5), the rear side surface of the stepped furnace (5) is communicated with a kiln tail decomposing furnace (3), the lower surface of the stepped furnace (5) is in a stepped shape, and the inclined direction of the stepped shape is from the tertiary air distributing port (8) to the kiln tail decomposing furnace (3) and is from high to low. By the adoption of the technical scheme, the solid waste and hazardous waste treatment device is additionally arranged beside the kiln tail decomposing furnace, solid waste and hazardous waste are pre-disposed before entering a firing system, and the influence of the solid waste and hazardous waste on the firing system is reduced; and meanwhile, the disposal capacity of the solid waste and hazardous waste is improved, and recycling, harmless disposal and reduction disposal of the solid waste and hazardous waste are achieved.

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

A kind of production method of gypsum production cement co-production sulfuric acid

ActiveCN103496861BReduce dosageEliminate environmental problemsSulfur compoundsEnergy inputDecompositionFixed bed

Owner:龚家竹

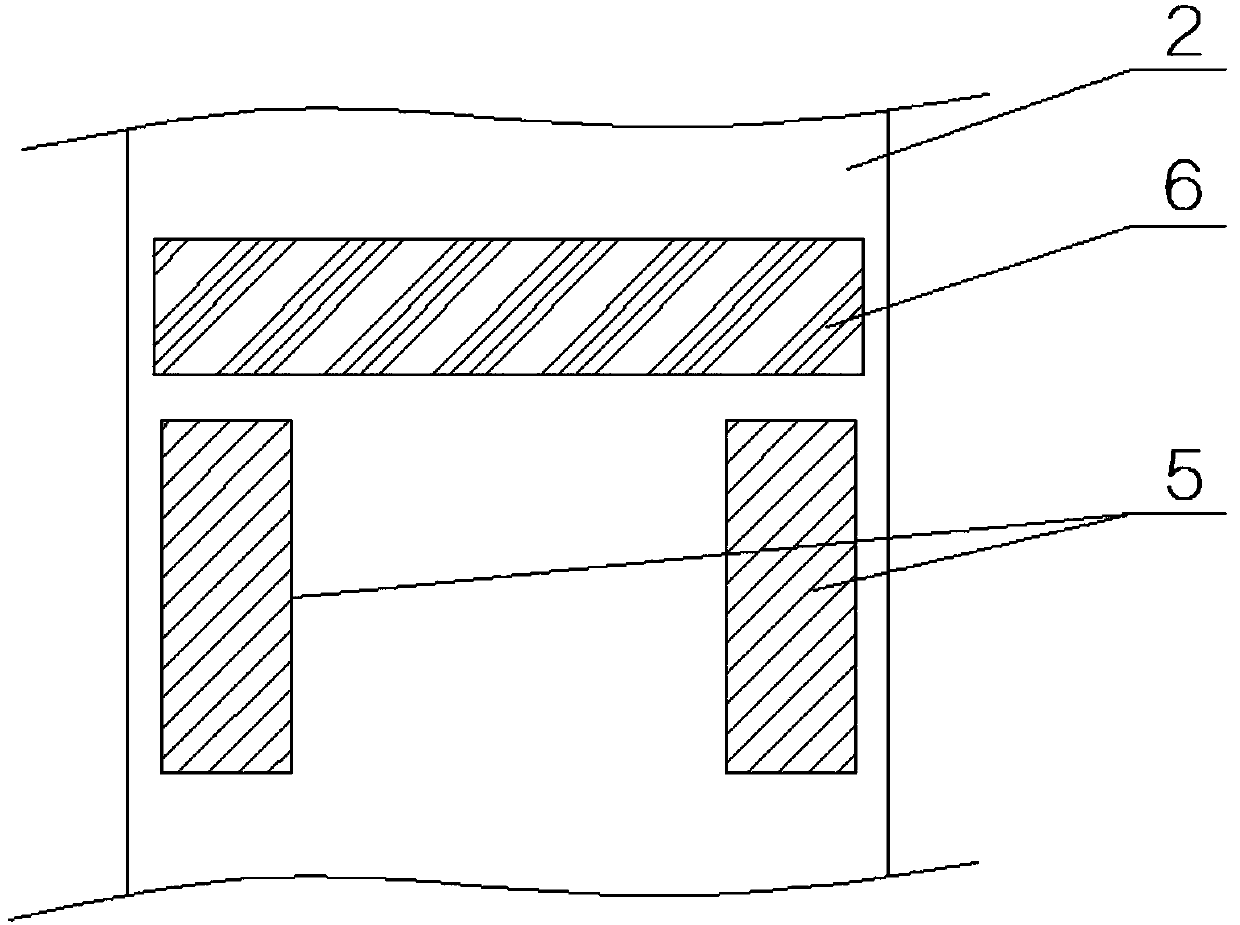

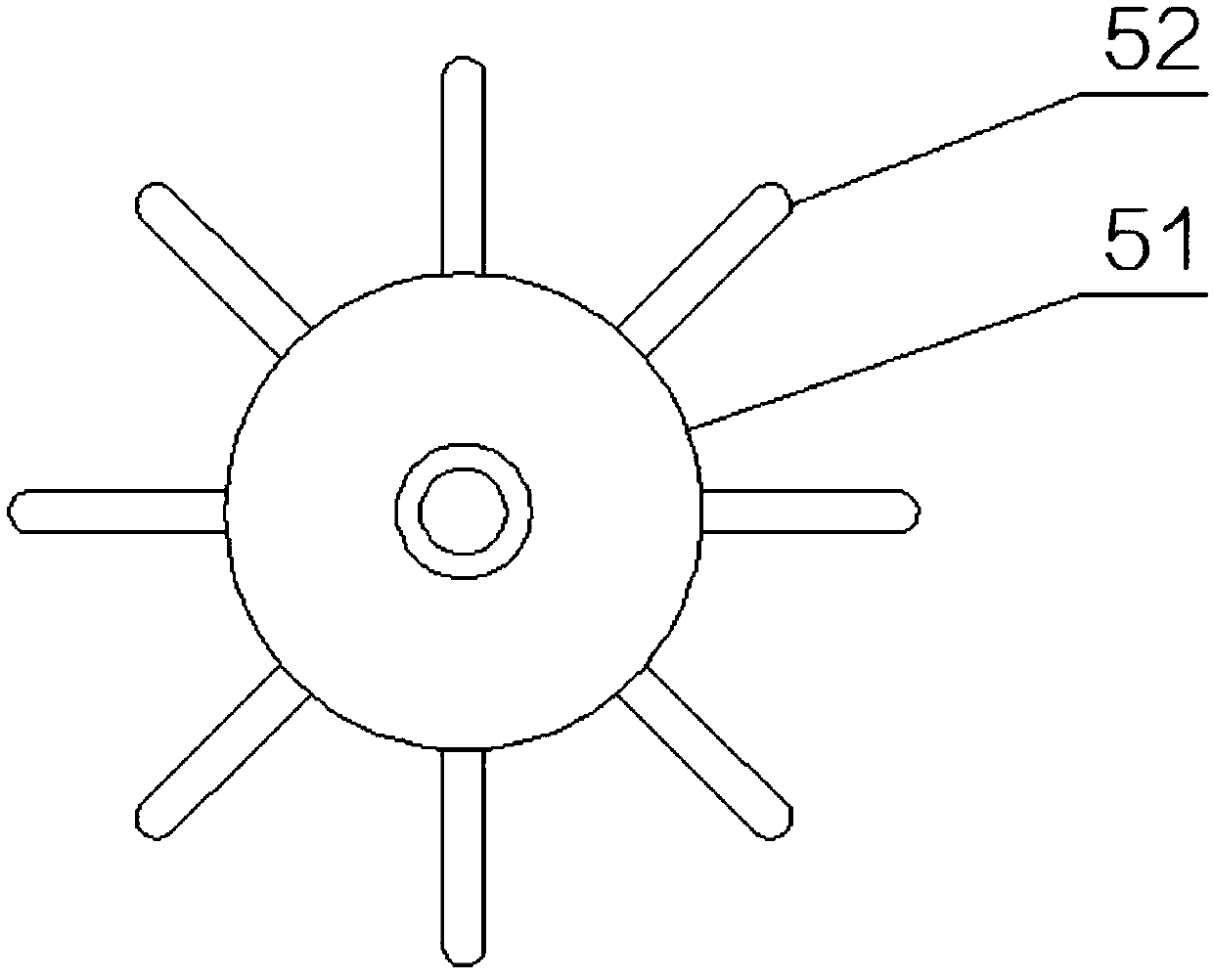

High-efficiency white cement clinker grate cooler

PendingCN108680033AEvenly distributedUniform cooling treatmentHandling discharged materialEngineeringWater supply

The invention discloses a high-efficiency white cement clinker grate cooler. The grate cooler comprises a first material turnover mechanism and a second material turnover mechanism. The first materialturnover mechanism and the second material turnover mechanism are both located in a waste heat recovery area and above a grate plate. The first material turnover mechanism comprises two first coolingrollers. Each first cooling roller is provided with turning blades. The second material turnover mechanism comprises a second cooling roller. The second cooling roller is provided with curved turningblocks. The first cooling rollers and the second cooling roller are all connected with corresponding to rotating driving devices and water supply devices. According to the high-efficiency white cement clinker grate cooler, the first cooling rollers of the first material turnover mechanism can turn over clinkers at the two ends of a grate bed and throw the clinkers to the middle; when the clinkersare continuously pushed to a cooled clinker outlet, so that coarse particles and fine particles in the clinkers are distributed more uniformly on the grate bed, and the Red River phenomenon is avoided; the second cooling roller of the second material turnover mechanism can turn over and stir the clinkers, so that all parts of the clinkers are cooled more uniformly.

Owner:江西银杉白水泥股份有限公司

Preparation method of magnesium calcium clinker

InactiveCN100369846CPromoting rational and efficient comprehensive utilizationHigh purityCarbonationCalcium magnesium

The present invention relates to a preparation method of calcium-magnesium clinker. Said method includes the following steps: using magnesite and limestone as raw material, soft burning at 800-100deg.C, cooling, hydration, ball-grinding and wet mixing, filtering, carbonating, drying, forming and calcining at 1600-1900deg.C so as to obtain the invented calcium-magnesium clinker.

Owner:NORTHEASTERN UNIV LIAONING

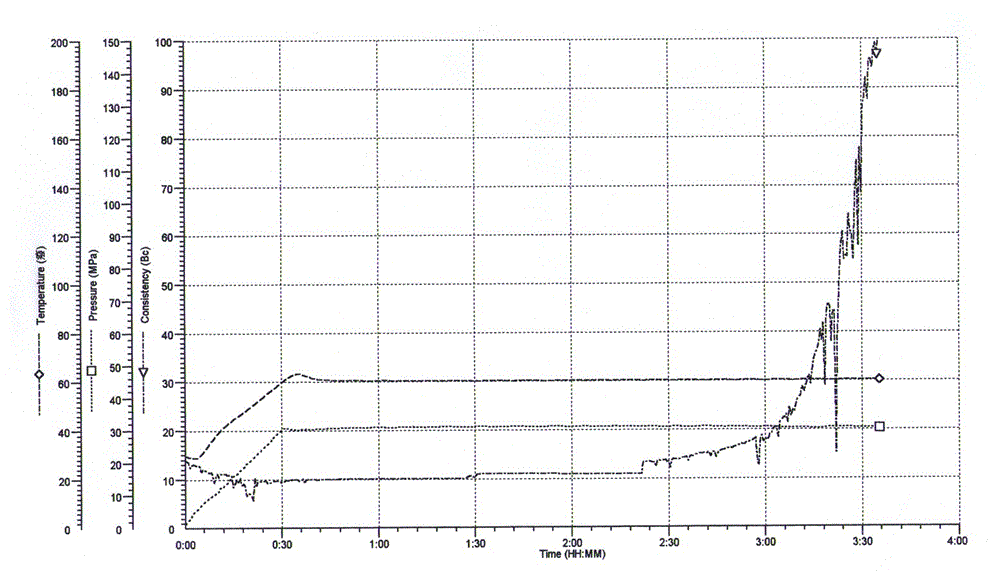

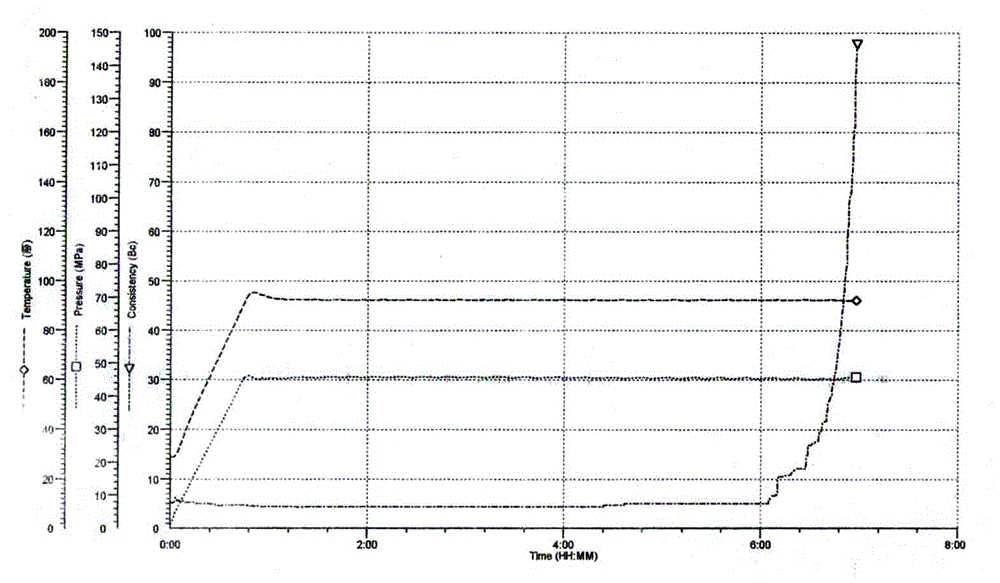

Oil well cement and production method thereof

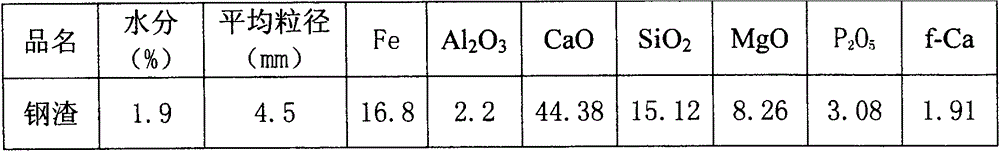

The invention discloses oil well cement and a production method thereof and belongs to the technical field of building materials. The cement contains oil well cement clinker and gypsum, wherein the weight ratio of the oil well cement clinker to the gypsum is (94:6):(96-4); and the oil well cement clinker is made by preparing raw batch from the following raw materials in percent by weight: 75-85% of limestone, 8-18% of sandstone and 5-12% of converter slag, grinding the raw batch, dehydrating slurry, drying and crushing filter cake and sintering to obtain the clinker. The oil well cement disclosed by the invention adopts a scientific clinker formula with high saturation ratio, high iron content and low aluminium ratio, the obtained cement has high strength, appropriate thickness and good mobility, can be used for effectively controlling the thickening time and free liquid and is applicable to oil well construction.

Owner:GUANGXI YUFENG CEMENT

Method and device for supplying primary air for kiln head of cement kiln

InactiveCN104110958AIncrease the lengthImprove coal saving effectRotary drum furnacesIndirect carbon-dioxide mitigationCombustorEngineering

The invention discloses a method and a device for supplying primary air for a kiln head of a cement kiln. A step of heating the primary air is additionally carried out in a process. The device comprises a Roots blower, a primary air pipe, a combustor and a heating pipeline. The primary air pipe is connected with an air outlet of the Roots blower and is connected with the heating pipeline, an air outlet of the heating pipeline is connected with an air inlet of a coal injection pipe of the combustor, the heating pipeline is arranged on the top of an intermediate-temperature section of a grate cooler, and the primary air in the heating pipeline is heated by afterheat air in clinker which is cooled by the grate cooler. The method and the device have the advantages that a scheme for supplying the primary air for the kiln head of the cement kiln is optimized and starts with regulating and controlling the temperature of the primary air, accordingly, energy consumption in production procedures can be reduced, benefits can be indirectly increased for enterprises, the quality of the clinker can be improved, and the clinker yield can be increased.

Owner:TIANRUI GROUP CEMENT

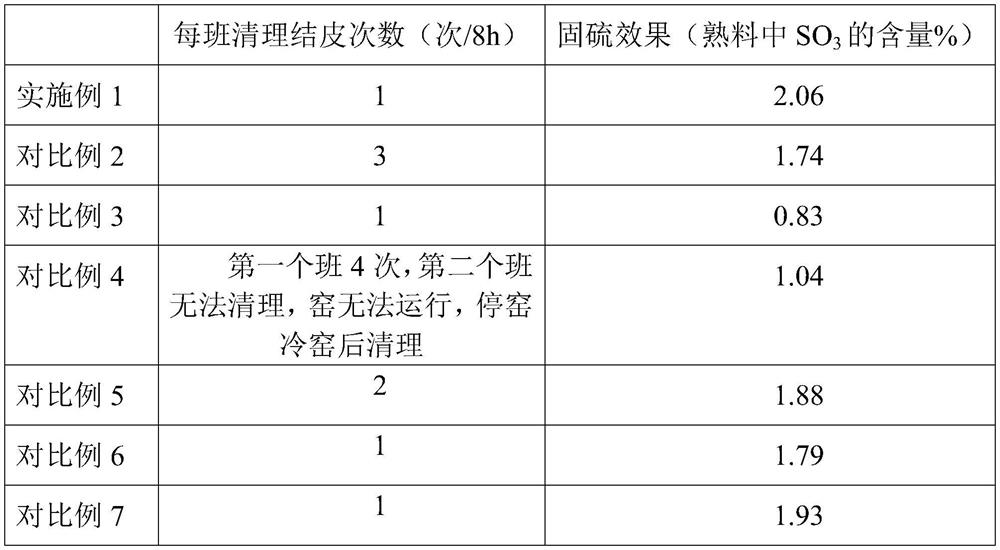

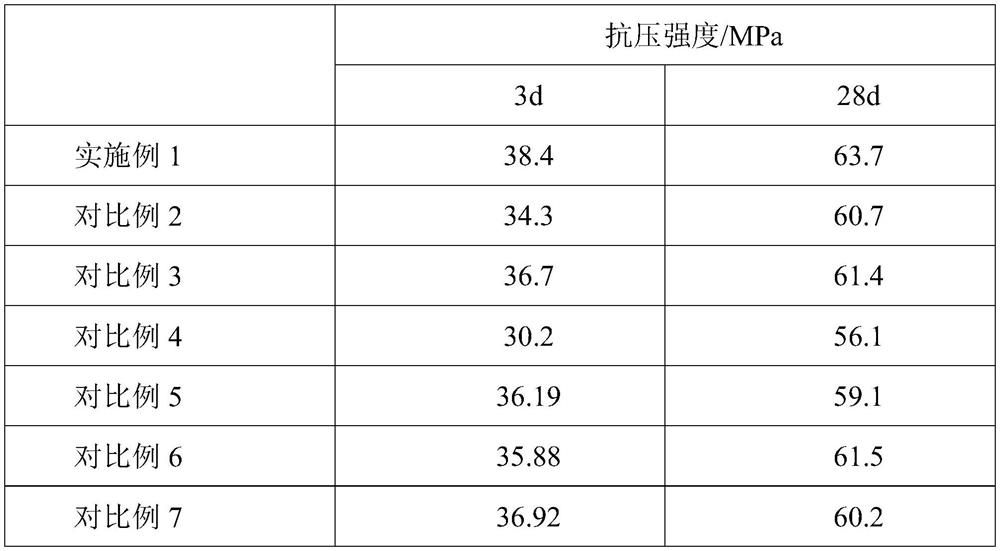

Method for calcining cement clinker by using high-sulfur coal as fuel

The invention relates to the technical field of cement production, in particular to a method for calcining cement clinker by using high-sulfur coal as fuel, by controlling the content of CaF2, ZnO and PbO in fluorite mine mining waste residues and lead-zinc residues and combining the use of raw materials, sulfur in the coal is fixed in the clinker in a calcium sulphoaluminate mineral form to reduce the circulating enrichment of sulfur and relieve the skinning and blockage of a kiln tail system, so that the production efficiency of the cement clinker is improved. The problem that high-sulfur coal (the total sulfur content is about 6%) cannot be used as a main fuel in cement clinker calcination at present is solved, and continuous and normal operation of the kiln system when the high-sulfur coal is used for calcining the clinker is effectively guaranteed. Meanwhile, clinker heat consumption is reduced; the cost pressure caused by purchasing a large number of commercially available sulfur-fixing agents is avoided, the clinker strength can be improved, and the clinker performance is improved.

Owner:贵州德隆水泥有限公司

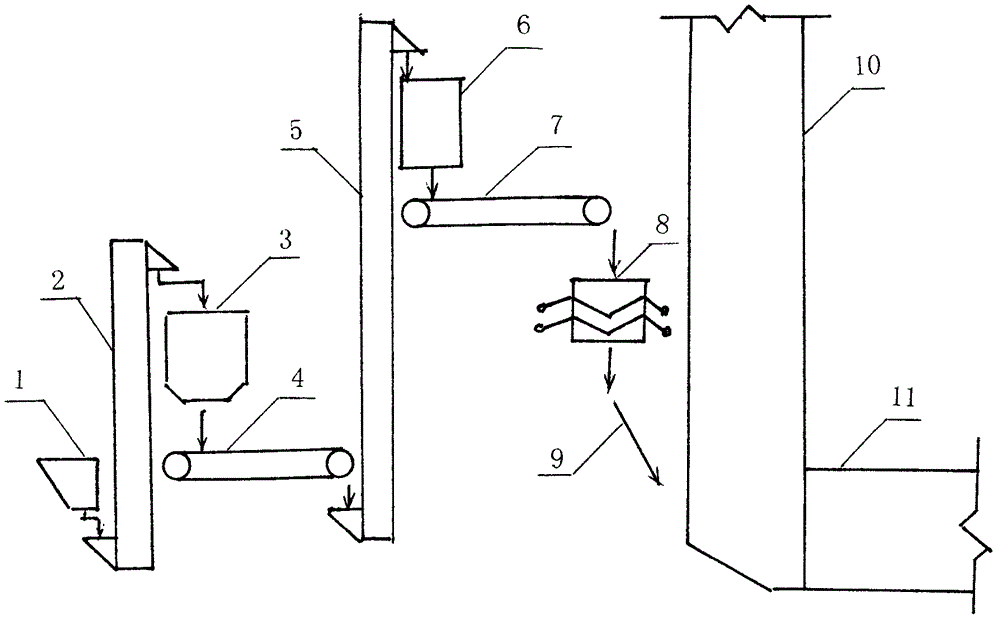

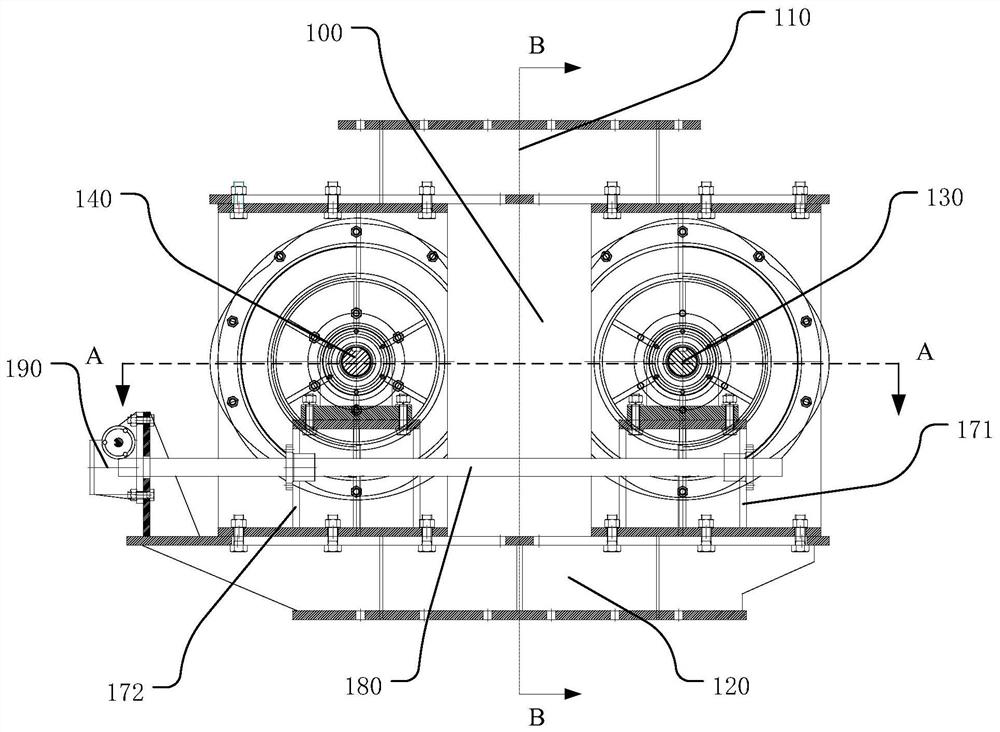

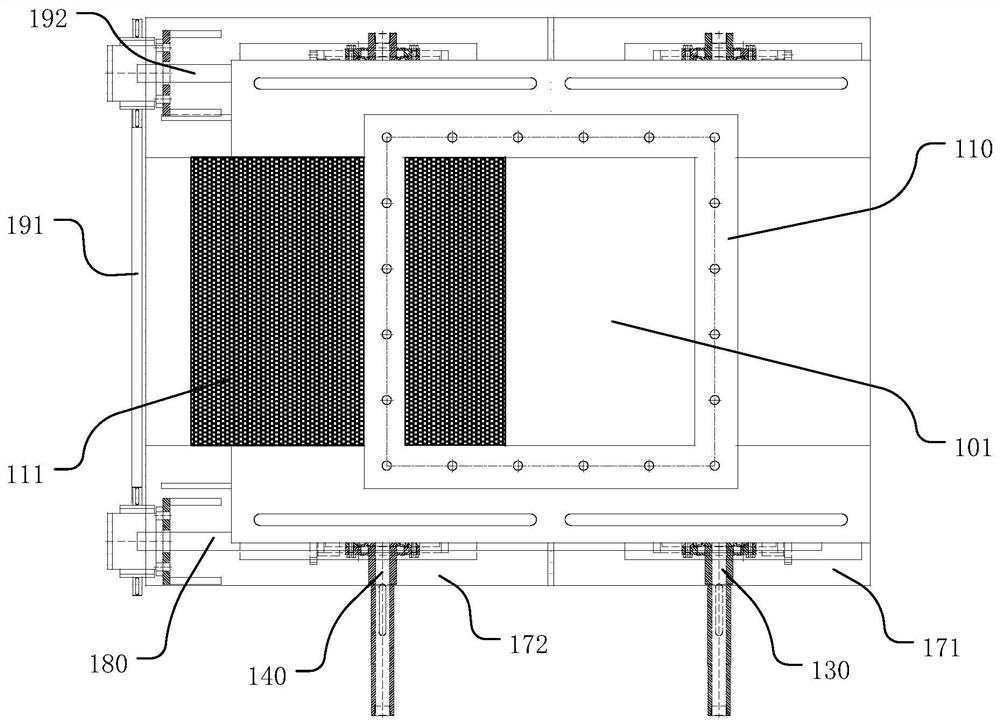

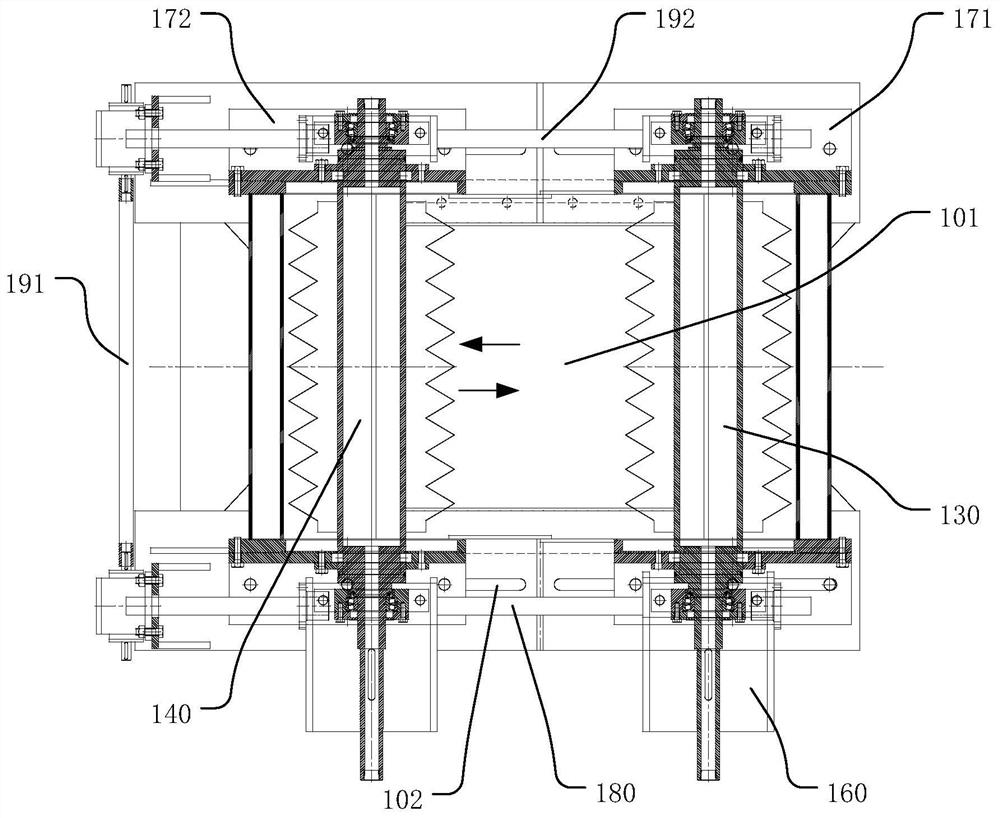

Sintering technology of cement clinker with directly doped steel slag in cement sintering system rotary kiln

InactiveCN106316170AReduce manufacturing costIncrease productionCement productionSlagElectric energy

The invention discloses a sintering technology of cement clinker with directly doped steel slag in a cement sintering system rotary kiln. Steel slag in a molten state in a steel plant is processed by a hot smothering method; steel slag is cooled and cracked into particles; after magnetic screening, most steel is removed; then the steel slag is transported to a cement plant; after going through a buffer chamber, steel slag flows into a feed weigh; according to a preset flow, the steel slag is weighed; then the steel slag is transported to a sintering feed-end chamber platform; the steel slag is fed into a feed-end chamber ramp through dual wind blockage valves; steel slag flows into a rotary kiln, is mixed with other components of raw materials, and moves forward; and the high temperature flame from the coal-injection duct of the kiln head participate in the sintering chemical reactions to generate cement clinker. The target cement clinker comprises the following components: 67.47% of CaO, 22.50% of SiO2, 4.80% of Al2O3, 3.25% of Fe2O3, 2.00% of MgO, 0.5% of SO3, and 1.2% of f-Ca. The production and quality control are performed according to three values (KH, SM, and LM). Through the provided technology, the steel slag can be used as a resource in the cement industry; the grinding medium and electric energy are saved, the output of cement clinker is increased, and the space occupied by the steel slag is reduced.

Owner:纵凌云 +1

Air-locking discharging device

PendingCN113023391AGood air lock effectImprove clinker qualityLoading/unloadingElectrical and Electronics engineeringSupport plane

Owner:广灵金隅水泥有限公司

A multi-channel rotary kiln burner with directional oxygen-enriched combustion

ActiveCN113776045BRaise the combustion temperatureReduce power consumptionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsCombustor

The invention discloses a multi-channel rotary kiln burner with directional oxygen-enriched combustion, comprising a multi-channel burner body. The outer side of the outer axial flow air sleeve of the multi-channel burner body is welded with an externally-mounted rich air casing through two surrounding plates. Oxygen channel casing, an arc-shaped diversion component is provided on the side of the external oxygen-enriched channel casing close to the outer axial flow wind casing, and an external oxygen-enriched oxygen-enriched casing is formed between the arc-shaped diversion component and the outer axial flow wind casing. The air channel, the arc of the external oxygen-enriched air channel is 10-180°, and is arranged at the lower part of the outer axial flow wind sleeve of the multi-channel burner body, and the multi-channel burner body and the oxygen-enriched air channel are concentric set up. The invention can form an arc-shaped, flat, uniform oxygen-enriched flow with a suitable angle and a suitable range at the bottom of the lower abdomen of the flame formed by the burner, and inject it into the designated area in a directional and precise manner, so as to realize the directional oxygen-enriched air to support combustion and achieve better combustion efficiency. combustion effect.

Owner:SHENZHEN SINAEAN CO TECH ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com